- Repair mortars for concrete

- Major Damage Repair

- Dry mixes for concrete repair

- Thixotropic mixtures

- Epoxy and polymer compounds

- Peculiarities

- Where should waterproofing be done?

- Waterproofing outside

- Ways to increase the moisture resistance of concrete rings

- Waterproofing penetrating or capillary

- Specificity of additional processing

- drinking spring

- Wastewater

- Renovation of the insulation layer

- Why waterproof a sewer well?

- Types of materials for waterproofing

- Two-component formulations

- Roll materials

- Mastics on a bitumen-polymer basis

- Coating mixtures

- Membrane materials

- Mixtures on a binder mineral basis

- Video description

- Waterproofing works

- Outdoor waterproofing

- Manufacturing materials

- Polymer

- Plastic

- Reinforced concrete

Repair mortars for concrete

In order for the restoration of the artificial stone to be successful, before choosing a repair composition, a thorough inspection of the destroyed structure is carried out, an analysis is made. The mixture is selected taking into account the following factors:

- the degree of loading of the structure, its bearing capacity;

- depth of damage;

- operating conditions of concrete (humid environment, temperature regime, degree of exposure to aggressive environment);

- accessibility to the damaged area;

- estimated scope of work.

If repairing a concrete surface in a visible place, it is important to take into account aesthetic requirements.

Major Damage Repair

A large damaged area is filled with new concrete mortar. First, the surface of the structure is cleaned of loose pieces, dust. A clean, solid base of good-quality concrete should remain.

Filling is carried out with a cement composition with complex additives that improve its performance. Fast-hardening polymer mortar or fiber-reinforced concrete gives good results.

In order for the repair of concrete with cement mortar to be successful, it is important to create conditions for its reliable adhesion to the restored base. Usually two methods are practiced:

- Continuous pouring of the entire area of the structure is carried out with a solution with a thickness of more than 100 mm. If partial restoration is carried out, the concreting site is deepened.

- The best adhesion of old and new layers occurs when the steel mesh is attached with dowels to the restored base.

Before pouring the solution, the surface of the structure to be repaired is treated with epoxy, acrylic or other adhesives that provide better adhesion.

Dry mixes for concrete repair

All concrete repair dry mixes contain cement to ensure optimal compatibility with the concrete structure to be repaired. There are many compositions from different companies on the construction market.

The repair composition is applied in a layer 5-50 mm thick on horizontal and vertical bases. To restore the ceiling, it is optimal to maintain a mixture thickness of 30 mm. The best adhesion is provided by pre-treatment of concrete with a primer or primer.

OSNOVIT concrete repair mortar

According to the type of application, dry mixes are divided into the following types:

- for work at temperatures above + 5 ° C;

- at negative temperatures;

- for waterproofing and providing protective properties;

- for repairs that do not change the geometry and bearing capacity of the concrete structure.

The scope of dry mixes is wherever you need to perform quick repairs, eliminate defects.

Pros:

- good adhesion with the old base;

- high mechanical strength of the hardened composition;

- due to additives, the mixture does not shrink;

- the ability to eliminate defects up to 100 mm deep.

The downside is the high cost, short shelf life.

Thixotropic mixtures

In fact, these are analogues of conventional dry mixes, but with improved characteristics. Popular manufacturers are: MAPEI, BASF, Sika. At the heart of the thixotropic composition for the repair of concrete is cement, sand, complex additives. The most effective are mixtures with polymer fiber.

Sika concrete repair mortar

The optimal layer thickness is from 10 to 30 mm. The mixture is used in the repair of monolithic and prefabricated concrete structures, for sealing joints, restoring protective layers.

Pros:

- resistance to mechanical stress, abrasion;

- good adhesion to the base;

- resistance of the frozen composition to moisture, low temperatures.

The downside is the high cost, the inability to use at sub-zero temperatures.

Epoxy and polymer compounds

The main purpose of the compositions is the repair of self-leveling floors, injection work, the organization of the protection of the concrete structure from the effects of destructive factors. Popular, Technoplast, KrasKO.

polymer composition for concrete repair Elakor

Sometimes the composition is applied to improve the adhesion of the base with a new repair layer. Polyurethane mixtures eliminate leaks, prevent water inflow.

Pros:

- resistance to mechanical and chemical stress;

- good wear resistance;

- high adhesion with the base;

- good waterproofing properties.

The downside is the short shelf life.

Peculiarities

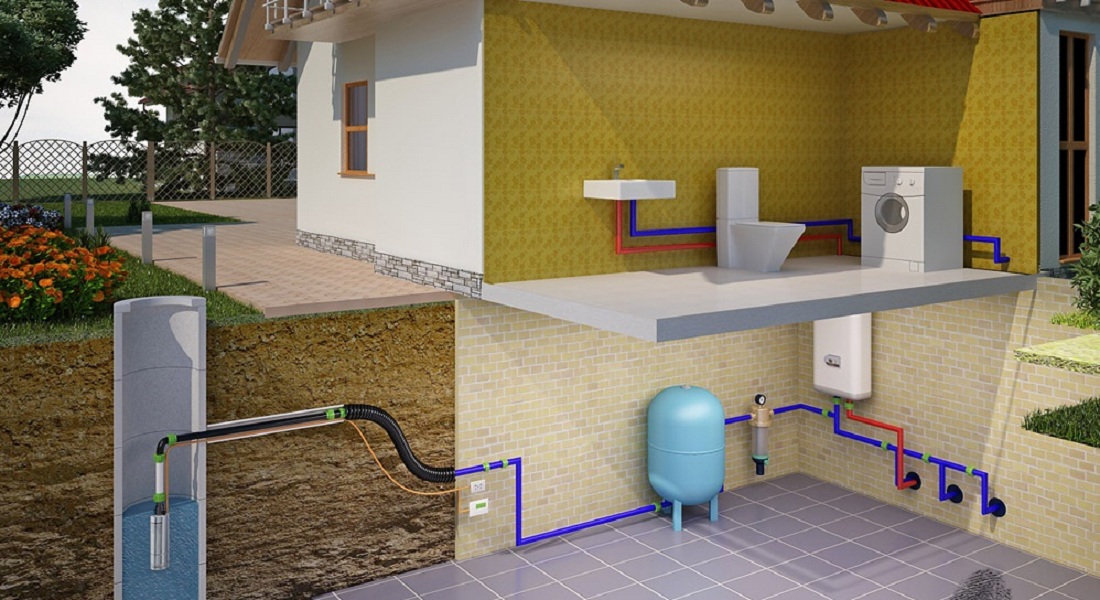

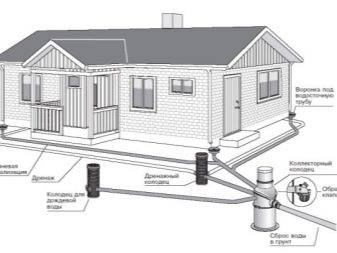

Any drainage system must have a sewer well or chamber. Such equipment should be located at the entrance to the septic tank, which is located on a suburban area. Also, sewer facilities have a different name - a wet or drainage well.

Sewerage of an autonomous type is a complex standard design of an engineering system, the installation of which will require plumbing and construction knowledge. A key component of every autonomous sewer is a special well.

The system should have several wells:

- lookout;

- turning;

- well for household waste;

- well for rain water.

The owner of a country estate should understand the features and differences of each type of structure.

Features of the creation of sewer wells are described in the sanitary and technical standards of SNiP. The documents describe the location of the wells, the implementation of markings and the need for preliminary preparation.

Features of arrangement according to SNiP are as follows:

- before work, you need to decide where the well will be located;

- on the ground, markup will be required;

- trees with shrubs that interfere with construction work must be uprooted;

- to the construction site it is necessary to ensure easy passage of equipment;

- a detailed scheme will be required, which is agreed with the water utility and neighbors.

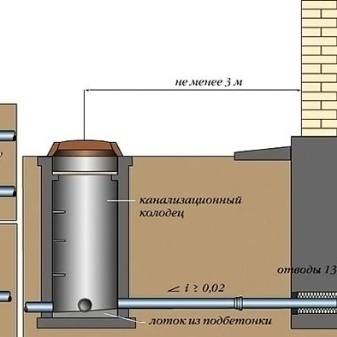

The following technical requirements are imposed on sewer wells:

- observation structures should be located in increments of 30-40 m if the diameter of the hatch is 15 cm, or 50 m - with a diameter of 20 cm;

- on each pipeline bend, as well as in the places where the branch pipe branches, there must be rotary-type wells;

- in places where the diameter of the pipes changes or there is a sharp slope, an overflow well will be required;

- there must be a minimum distance of 3 m between the storage well and the dwelling;

- the diameter of a modern sewage well can be 40-70 cm, auxiliary pipes are allowed for the outlet.

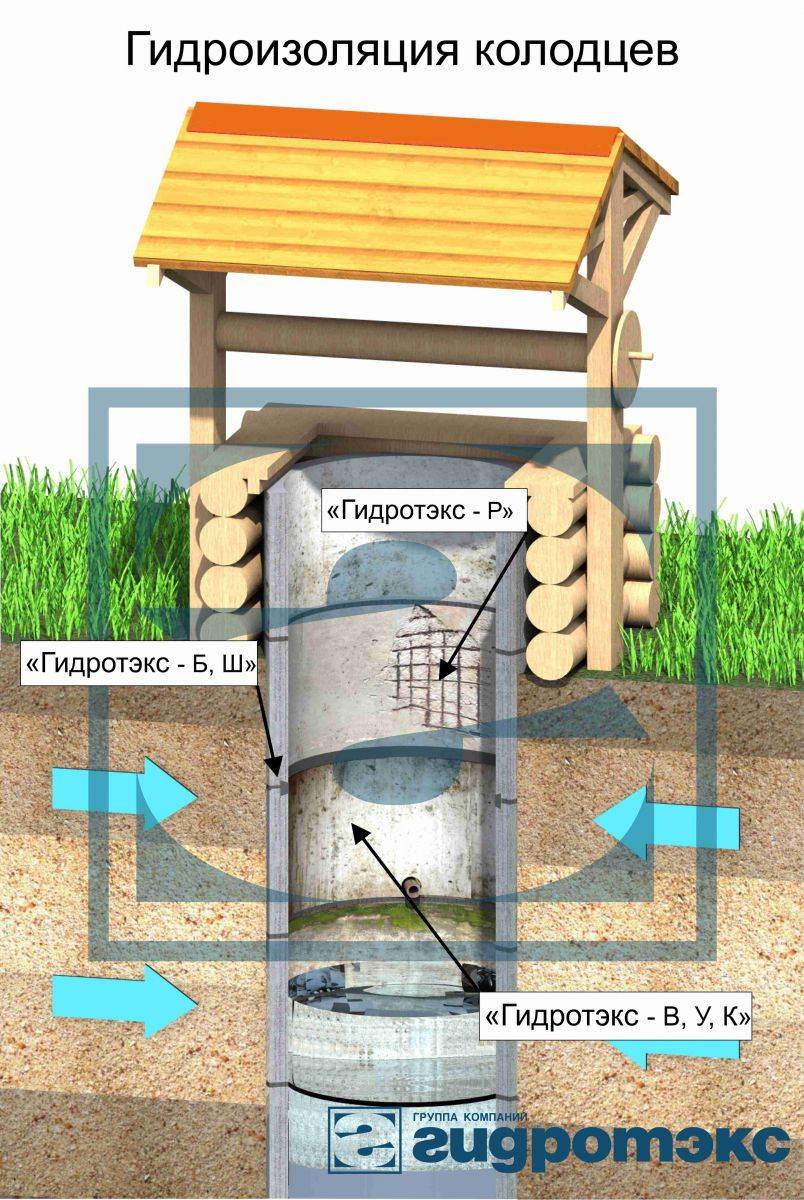

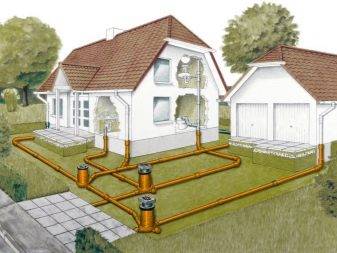

Where should waterproofing be done?

Waterproofing work should be carried out both outside and inside the well.

Waterproofing outside

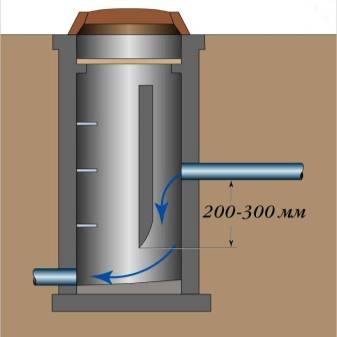

In addition, when building a concrete well (most often constructed from rings), it is important to achieve complete tightness of the walls.

Pay attention to two points. Waterproofing work should be carried out both outside and inside the well.

Waterproofing work should be carried out both outside and inside the well.

-

A potential place for water leakage from a well, ingress of atmospheric or groundwater, soil particles from the outside.

-

Under the constant influence of moisture and temperature changes, concrete loses its strength and collapses. Concrete has capillaries into which moisture penetrates. At low temperatures, moisture freezes, which leads to cracks.

Ways to increase the moisture resistance of concrete rings

There are the following methods of waterproofing concrete wells:

- Constructive. Treatment of concrete rings with hydrophobic impregnations directly at the factory, after the products have hardened.

- Technological. The use of special techniques for compacting concrete poured into molds is envisaged. We are talking about centrifugation, vibrocompression and removal of moisture by the vacuum method.

- Improving the water resistance of cement. It is possible to increase the resistance of concrete rings to moisture through the introduction of special water repellents into the composition of the solution. The specificity of the action of these substances lies in their swelling and blockage of pores and microcracks as the concrete hardens.

The use of these methods increases the cost of reinforced concrete rings. A cheaper option is the sealing of the walls and butt sections between the individual elements of the well shaft.

Sometimes it’s easier and cheaper to just put hydraulic seals (cover up internal joints), but no one can guarantee how effective and durable it will be.

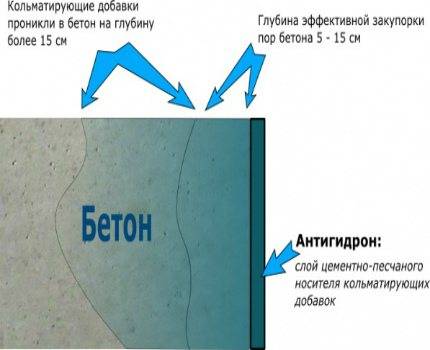

Waterproofing penetrating or capillary

This type of waterproofing is the most reliable. Materials, after being applied to a concrete surface, penetrate into the pores, crystallize, fill all the voids. Filamentous crystals are introduced into the structure of concrete, clog microcracks and become one with its body. They do not impair the air permeability of the surface, but, sealing its structure, do not allow water to pass through.

Penetrating insulation improves the quality of concrete, makes it strong and moisture resistant

Crystalline hydrates do not decompose and are not washed out of concrete, so this septic tank protection lasts a long time.The layer on the surface of the rings only fixes, and for some time retains the active chemical components that play the main role in creating high-quality waterproofing of the structure.

Some manufacturers claim that once all chemical processes are completed, the layer can be removed.

The duration of crystallization and the depth of penetration of the insulating material into the thickness of the concrete is affected by the degree of porosity, moisture content of the septic tank rings. With high humidity parameters, crystals form faster, and with a decrease in this indicator, the process slows down. In concrete surfaces treated in this way, microcracks are tightened by themselves.

The use of penetrating waterproofing in increasing the strength of concrete rings and resistance to aggressive media is the most affordable, reliable and easy-to-implement method.

The application of penetrating waterproofing is preceded by careful surface treatment. It is completely cleaned using special chemical solutions or a mechanical method.

When the result is a flat surface, it is saturated with moisture, pouring water from a hose under high pressure. The active components of the waterproofing compound will penetrate to the same depth as water.

Processing begins with seams. It is better to do this during the installation of the rings. They are laid on a layer of cement mortar, then treated with a penetrating mixture. Next, apply the mixture to the entire surface, strictly following the manufacturer's instructions, otherwise the waterproofing layer will not meet the stated requirements.

The mixture is prepared in small batches. To mix it with water, an electric drill is used, operating at low speeds and equipped with a spiral nozzle.The composition is applied to the surface of the rings using a sprayer, roller or paint brush. You need at least 2 layers with an application interval of 1.5 to 3.5 hours.

The second treatment is started when the first layer has not yet had time to dry completely. A coating with a total thickness of 1.5-2 mm should be obtained. It takes a lot of material - about 1 kg per 1 sq. m.

For penetrating waterproofing, the following compositions are used:

- "Lakhta". Inexpensive dry mix based on cement.

- "Kalmatron". The composition includes Portland cement, sand, patented active reagents.

- "Hydro S". Waterproofing coating based on mineral raw materials.

- "Penetron". A penetrating mixture that creates a barrier that prevents capillary suction of liquid.

If you process the septic tank from the outside and inside, then in the end you will have a durable sealed structure with a homogeneous structure.

Specificity of additional processing

The construction of a well from prefabricated concrete elements is in demand when arranging an intake point for technical or drinking water or a sewer system. In the first two cases, groundwater leakage into the reservoir is especially dangerous, since the quality of the water in it deteriorates sharply.

drinking spring

Surface waters are less suitable for use, because they are more polluted with small particles of soil and sand, as well as various microorganisms. If even a small amount of such water enters the drinking water supply system, the human body can be seriously harmed.

Wastewater

In the case of sewer systems, waterproofing helps to protect the environment from the ingress of untreated sewage.In addition to a large amount of organic matter, such waters are a source of pathogenic bacteria, which negatively affects human health and plant life.

Renovation of the insulation layer

The main processing of concrete rings is carried out at the stage of well construction, because concrete itself is a moisture-permeable material. Signs for renewal of coverage may include:

- rapid and excessive filling of the sewer tank;

- noticeable displacement of elements relative to each other;

- the presence of suspension in the water taken from the well.

If such phenomena occur, an immediate update of the waterproofing and sealing of the joints is required.

Why waterproof a sewer well?

A serious mistake is made by those who believe that it is possible to neglect the work associated with sealing the sewer well.

In the best case, there will be severe pollution of groundwater, and in the worst case, the septic tank made of concrete rings will collapse in a few years.

Image gallery

Photo from

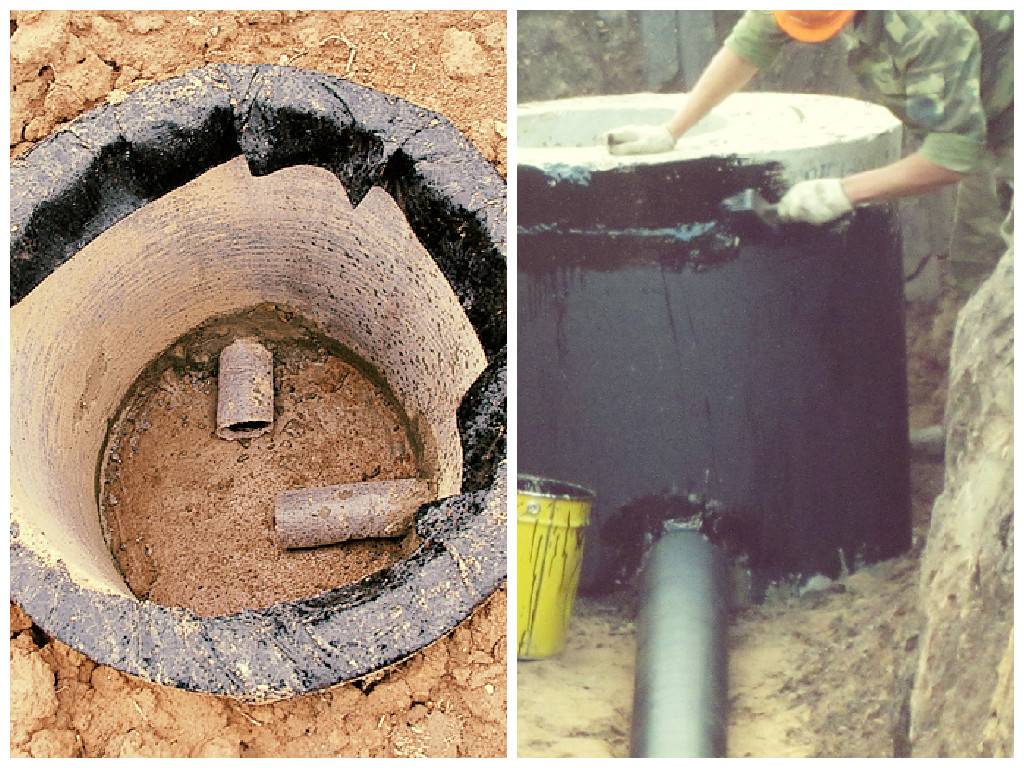

Waterproofing is applied to the outside of concrete sewer wells to protect structures from groundwater

Part of the well, located above the depth of seasonal freezing of soils, waterproofing will protect against destruction of the concrete structure

The pores of artificial concrete stone, closed from water penetration, will not let water into its thickness, which, when frozen, increases in volume and breaks the structural bonds of concrete

Processing a well shaft below the level of seasonal freezing of soils is an optional measure. However, it is necessary at high GWL

The device for waterproofing protection of sewer wells uses spraying technologies and products suitable for treating all types of underground structures

Most often, bitumen and bitumen-polymer coating compositions are used to protect sewer wells.

Cement mortars with liquid glass introduced into the product are actively used.

If a part of the well located at a great depth is to be treated with waterproofing, it is better to install already processed rings into the pit

The purpose of waterproofing wells

Features of protection of the upper part of the structure

The insulating layer closes the pores of the material

Application of waterproofing below freezing depth

Spray method for applying a protective agent

The most common option

The use of coating agents with liquid glass

The period of application of the waterproofing composition

There are several reasons why you should not neglect the waterproofing of a well, these are:

- Corrosion of the reinforcing component of reinforced concrete rings. As a result of the formation of rust pockets on the reinforcement elements, the bearing capacity of the well shaft, which is constantly subjected to pressure from the surrounding soil, is significantly reduced.

- Weakening of the concrete walls of the mine. Waste and groundwater contain chemically aggressive substances that adversely affect the structure of concrete. Over time, under their action, shells and cracks form, leading to the destruction of concrete.

- Potential for sewage infiltration. The walls of a concrete shaft with cavities and cracks will not be able to prevent sewage infiltration into the surrounding soil. As a result, it will lead to a critical change in the ecological balance.

- Depressurization of joints.Concrete that has absorbed water during the frosty period will slightly increase in size. Visually imperceptible "movements" of concrete rings will become a serious threat to the joints of the mine assembled from them.

- Destruction of concrete. Freezing out of the binding component of concrete stone at sub-zero temperatures, especially in the zone of seasonal freezing of the soil, leads to a rapid breakdown of bonds in a monolithic massif. For this reason, the well will last two to three times less than the prescribed period.

If everything is clear with the protective properties of waterproofing, then there is another important reason for sealing the sewer well. We are talking about floods and groundwater, the level of which becomes significantly higher during the period of active snowmelt and heavy rains.

Flood and ground water can cause premature filling of the well, because. concrete without waterproofing is able to pass water. As a result, it will be necessary to pump out with the use of special equipment.

Properly executed external waterproofing will reliably protect the sewer well from the aggressive action of groundwater and protect concrete from erosion

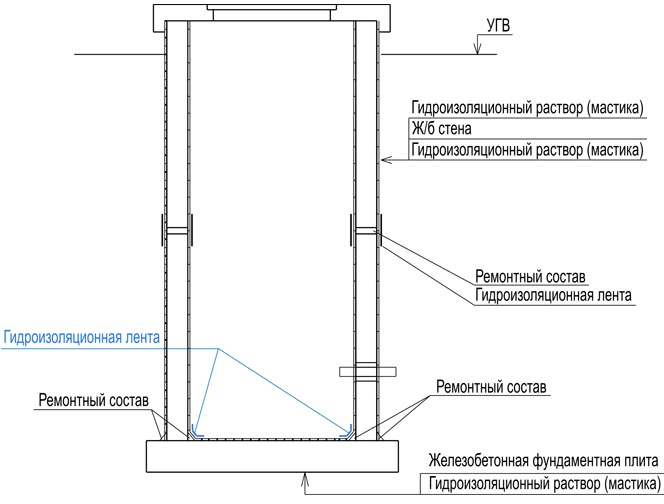

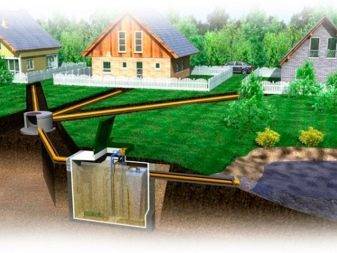

Work on the insulation of sewer wells can be divided into two main types:

- Internal waterproofing;

- External waterproofing.

It is recommended to simultaneously perform internal and external waterproofing, which will maximize the protection of the walls of the well from erosion, and the soil and groundwater from pollution.

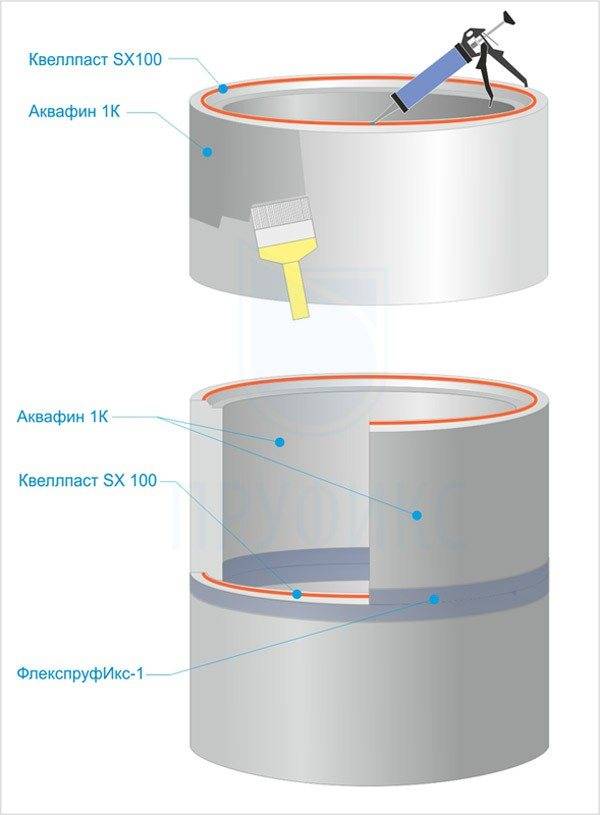

Types of materials for waterproofing

For external and internal waterproofing of hydraulic structures, special protective materials are used.

Waterproofing the well from the inside and outside is carried out:

- two-component compositions;

- roll materials;

- bitumen-polymer mastics;

- coating mixtures;

- membrane materials;

- mixtures on a binder mineral basis

Two-component formulations

The sealing of the seams in the well with two-component waterproofing is carried out only from the outside of the structure. The material is presented in the form of a spray, which is applied to the seam using a special sprayer. The two-component composition provides effective treatment of the entire surface of the rings, even in the most inaccessible places.

Such materials are non-toxic, practical, durable and easy to use.

Roll materials

Reliable waterproofing of wells in wet soils is possible using rolled materials of high strength. They are intended for outdoor work. Gluing waterproofing of this type is able to provide high-quality protection to the external walls of the structure from the penetration of groundwater.

This category includes: hydroisol, isol, PVC films, roofing felt, foil bitep. The service life of waterproofing is 40 years.

Roll pasting waterproofing consists of a canvas, a moisture-repellent layer of petroleum products, a protective foil and an impregnating agent. Repair using roll materials provides full access to concrete rings from all sides of the structure.

Mastics on a bitumen-polymer basis

Wear-resistant mastics are successfully used to isolate hydraulic structures of any complexity. Mastics, which include polymers and bitumen, have high performance characteristics.

Bituminous adhesive waterproofing is resistant to temperature extremes and high moisture, withstands the ultimate load of groundwater.Sealing the seams between the rings of the well with bitumen-polymer mastics will reliably protect the structure from the negative effects of external factors.

Coating mixtures

This category includes products that are designed to protect drinking and sewer wells from concrete rings from high moisture. In order to qualitatively seal the joints in the rings with your own hands, you need to properly prepare the coating mixture. The calculation of the required amount of material is carried out according to the instructions from the manufacturer. The finished mixture is applied with a spatula to the seams and damaged areas in a thin layer.

The main advantages of the material: low cost, ease of application, fast curing, creation of a durable protective layer.

Waterproofing a drinking well involves the use of such products without prior surface preparation.

Membrane materials

Modern polymer-based membrane materials with limited water resistance are becoming increasingly popular. Waterproofing of sewage wells and other structures with membranes is effective only in combination with polymer-bitumen mastics.

The only disadvantage of polymer membranes is their susceptibility to mechanical damage to the film base, which leads to a decrease in the effectiveness of waterproofing protection as a whole.

Mixtures on a binder mineral basis

How to seal the seams in the well with your own hands in the presence of small cracks and minor damage? For these purposes, you can use special mixtures, which include an astringent mineral component.It reliably fills existing voids in concrete and between individual structural elements, thereby providing high protection against moisture penetration.

Mixtures are applied to the treated surface with special equipment under high pressure. A similar method of insulation can be used on the inside and outside of the well.

If it is required to close up a leak inside the structure, how to cover up the seams in the well in this case? To do this, it is recommended to treat the shaft with a polymer membrane or water-repellent paint.

Video description

You can clearly see the work on the repair and waterproofing of wells from reinforced concrete rings in the video: To achieve durability of the protection of the seams from moisture, do the following:

- Perform centering. The cause of the leak at the joints may be a misalignment of the rings. To avoid this, a ridge plate is laid at the bottom of the well, which ensures the alignment of the prefabricated shaft.

- Lay the connecting sections between the individual rings with a laying cord. The sealants "Gidroizol M" and "Barrier" have proven themselves well in this regard.

- Carry out internal and external coating of seams. For interior work, it is recommended to use special compounds, such as AQUAMAT-ELASTIC (manufacturer - ISOMAT). From the outside, joints are allowed to be sealed with coating materials based on bitumen and rubber.

Fully waterproofed wells on the outside will last longer

Waterproofing works

Hydraulic seals on a well made of concrete rings, if it is already ready, can be placed from the inside or outside. To achieve an enhanced protective effect, it is recommended to use two methods at once.

Outdoor waterproofing

The main purpose of this procedure is to eliminate the impact of groundwater on the outer walls of the well. It is most convenient to implement it at the stage of laying the rings, otherwise you will have to dig out the finished barrel manually. Sewer and manholes must be completely exposed, and drinking wells - 50 cm from the water level mark. The air temperature during work should not be lower than +5 degrees.

Waterproofing a well from concrete rings from the outside is carried out in the following sequence:

Foundation preparation. In order for the seals to hold well, they are applied to a dry base. This means that the existing well will have to be drained first. Next, a careful inspection of the outer walls is carried out: they must be cleaned of dirt, salt accumulations and loose concrete. All protruding parts of the metal reinforcement of the rings are treated with an anti-corrosion compound. The joints must be expanded and deepened for further laying of the sealant. This also applies to detected cracks with a length of 20 mm or more.

Hydraulic seals must be installed on all joints and cracks

- Primer. The cleaned and dried outer walls are impregnated with a primer. The brand of composition used depends on the type of well. Drinking facilities are treated with safe ready-made impregnations. For inspection and sewer shafts, a bitumen-gasoline solution is suitable. The priming of the seams is carried out more carefully: they are pre-glued with a special tape sealant. Thanks to this, additional tightness of the joints is achieved.

- Alignment of the outer surface of the rings. To seal cracks, drops and chips, a repair sand-cement mixture reinforced with PVA glue is used.

- Installing a hydraulic seal.The most popular material for outdoor protection are bituminous rolls. In this case, tar mastic acts as an adhesive: the surface treated with it is tightly wrapped several times with waterproofing strips. The joints between the individual sections of the winding are additionally treated with mastic.

- Sealing of external seams. For these purposes, special penetrating compounds are often used, before applying which the primer can be omitted (it is replaced with plain water).

One of the options for external waterproofing can be mastic.

Completion of the procedure. After waiting for the finished walls of the well to dry, they are covered with earth. As the recommended protection against atmospheric precipitation, a clay castle and a concrete pavement are used.

Manufacturing materials

Such materials are used in production.

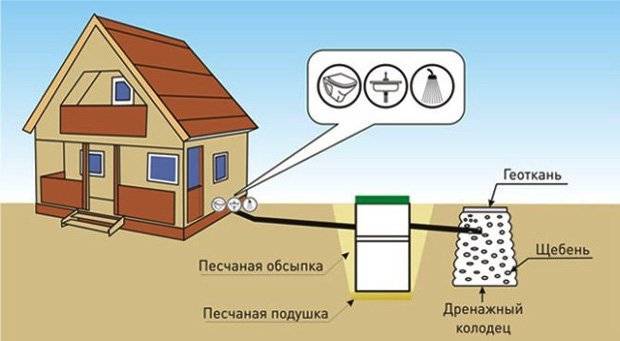

Polymer

Polymer wells are the most common variations of such devices. Some users use non-traditional methods for their production, which consist in the use of automotive rubber. This method is considered the simplest and least expensive. However, this solution does not differ in tightness and long service life.

Plastic

Plastic is the simplest and most durable raw material for arranging wells. On sale there are ready-made models of polymers, you can also create such a structure with your own hands. This will require the use of a corrugated pipe and a plastic plate. Construction requires little expense along with certain skills.

Advantages of plastic:

- small mass;

- high level of reliability and durability;

- replaceability of the lower tray;

- all elements are sealed;

- can be ordered in any size.

Flaws:

- high price;

- specified placement depth;

- often plastic is a non-separable product.

Collapsible models are endowed with versatility, since the depth can increase or decrease. Most often, plastic wells are used as turning or viewing structures. However, due to tightness, such structures can be used instead of a water collector. Liquid is pumped out using a pumping station.

Reinforced concrete

Reinforced concrete is a classic material for arranging sewers. Construction is made of concrete rings with further processing of all joints with sealant. Such cesspools are highly functional.

Benefits include the following criteria:

- universal characteristics;

- long service life, which exceeds 50 years;

- fast installation;

- high strength indicators;

- reliability of the material;

- affordable price range.

Flaws:

- large mass;

- installation will require the use of a winch and other special equipment.

Such reservoirs are often used as viewing structures with a significant depth of the pipeline. Due to high-quality sealing, concrete products can play the role of water collectors.