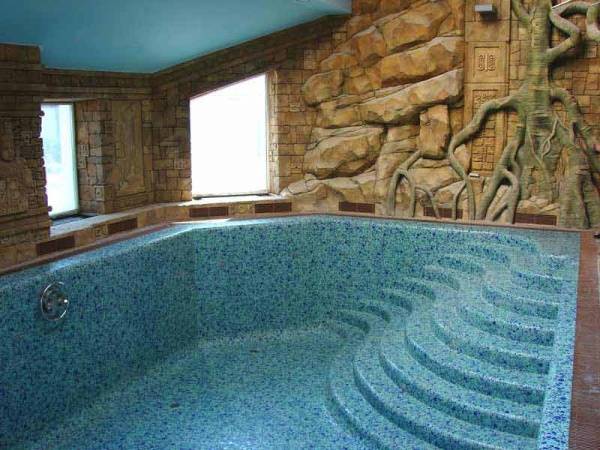

- Bowl waterproofing

- How to prepare a pool for waterproofing

- Pool waterproofing

- External waterproofing device

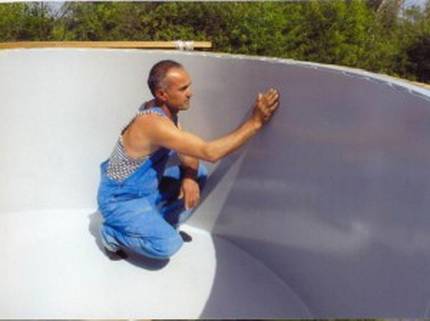

- Waterproofing the pool from the inside

- Types of pool waterproofing

- External moisture protection of the bowl

- Internal waterproofing of the pool

- The most popular indoor pool waterproofing materials

- Liquid rubber

- Liquid glass

- PVC film

- Used materials for pool waterproofing

- PVC films

- Waterproofing membranes

- Bentonite mat

- Liquid rubber

- Polymerizing impregnations or liquid glass

- Coating composition

- Bitumen

- Additional materials

- How to choose the right waterproofing material

- Advantages and disadvantages of pool waterproofing

- Internal waterproofing

Bowl waterproofing

Currently, two-component elastic mixtures, which are classified as coating type, are considered the best material for waterproofing. With their help, you can create a seamless waterproofing barrier and cover cracks up to 4 mm in size.

The advantages of such compositions include:

- Possibility of application on a wet basis.

- Can be used in constant contact with moisture.

- High adhesive performance.

- No shrinkage.

- Ease of application.

- Resistant to the negative effects of weather conditions, including frost.

- Environmental Safety.

Such a check of the waterproofing of the pool consists in monitoring the decrease in the volume of water in the filled bowl for about 10 days. If the water level drops too quickly, it means that there are leaks in the coating. All of them must be detected and eliminated before finishing work. If the quality of sealing has not caused any doubts, you can safely proceed to lining.

- Enter the parameters of your pool or just leave a request

- We will receive an estimate for your project from each of our contractors

- We will select the best offer and contact you

- You will get the pool at the best price

Your promo code: "Pool for you"! Tell it to our employee and the departure of the measurer will be free for you.

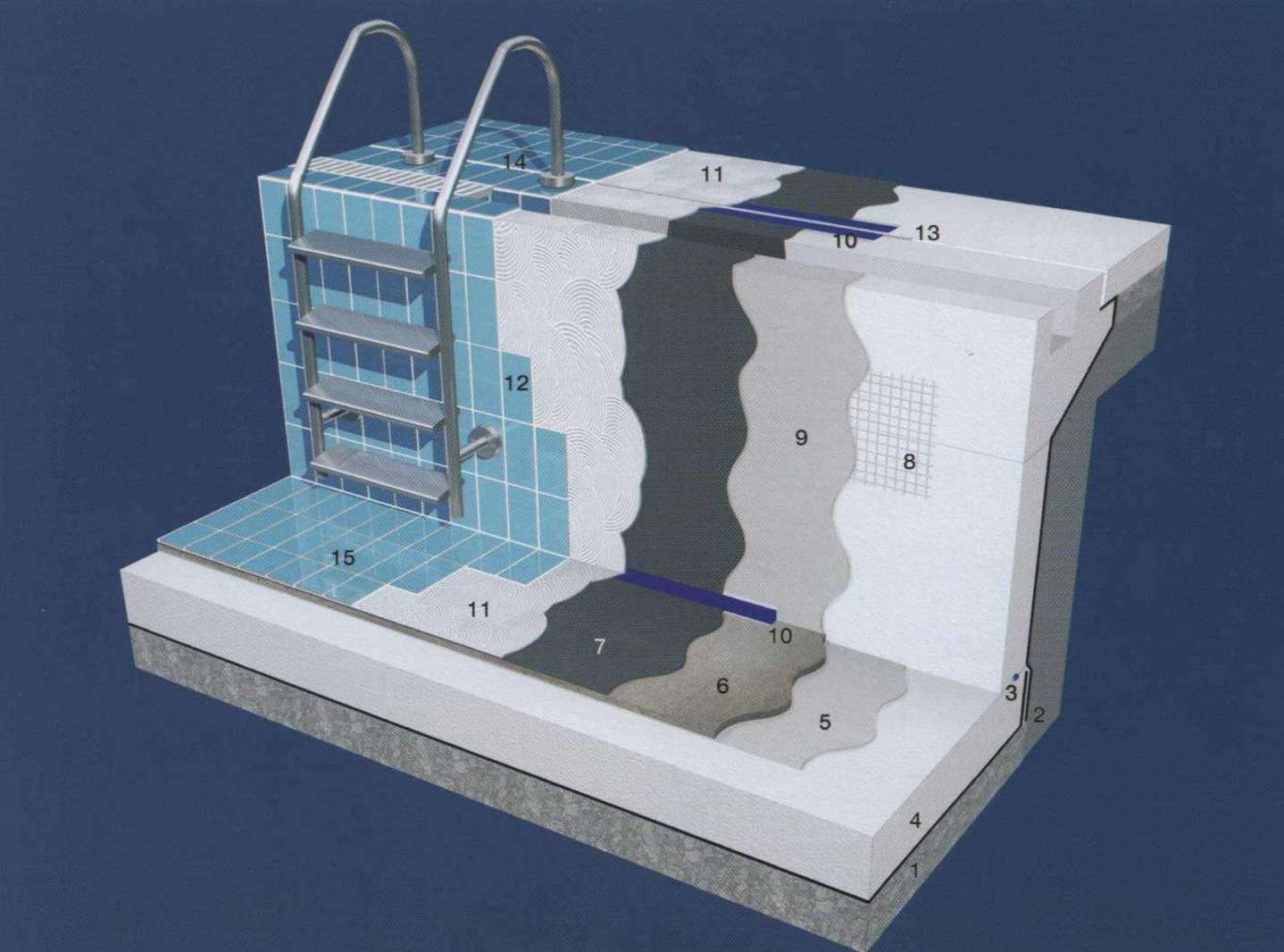

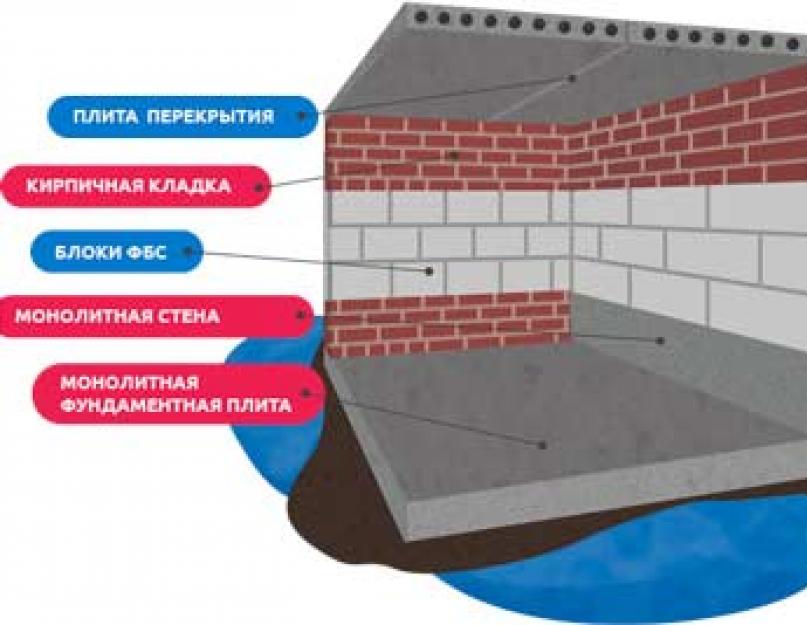

How to prepare a pool for waterproofing

When preparing a structure for treatment with moisture-proof materials, special attention should be paid to the condition of the concrete. Instructions for the effective implementation of waterproofing the pool assumes that the bowl will initially be endowed with the necessary margin of moisture resistance. This is ensured by compliance with the construction technology:

This is ensured by compliance with the construction technology:

Instructions for the effective implementation of waterproofing the pool assumes that the bowl will initially be endowed with the necessary margin of moisture resistance. This is ensured by compliance with the construction technology:

- Filling the bottom of the pit. The first contour of the moisture-proof base is sand and gravel bedding. After leveling the bottom of the pit, it is covered with a sand-gravel mixture with a layer of about 20 cm. The mixture is thoroughly moistened and rammed. Then reinforcing bars and beacons are laid on the base, which are used as guidelines when pouring the bottom.

- External waterproofing of the formwork. The formwork for the walls of the pool bowl is assembled from thick plywood or boards. Outside, the structure must be wrapped with a thick plastic film, which will prevent the concrete from leaking during pouring and facilitate further external processing.

- Pool bottom concrete. Concrete the bottom using a high-quality mortar with a high degree of frost resistance. The optimal layer thickness at the bottom is from 30 cm or more.

- Filling formwork with concrete. After the initial polymerization of concrete at the bottom, it is necessary to pour the formwork. In order for the walls to have sufficient moisture resistance, their thickness must be at least 20 cm. The mortar for pouring is prepared on the basis of cement not lower than M400 with the addition of sifted sand 1.5-2 mm and gravel with a fraction of up to 10-20 mm. The solution must be compacted with a deep vibrator or with a bayonet.

- Drying of the concrete pool. Dismantling of the formwork is carried out 10-14 days after pouring. Then you need to make a rough alignment of the surfaces, overwriting all the defects. Leave the structure to dry, preventing the concrete from drying out. For a full set of strength, a concrete solution without additives takes about 28 days.

- Aligning the walls to the grid. We level the internal surfaces of the pool with a moisture-resistant cement composition. Alkali-resistant fiberglass mesh must be used to ensure maximum grip. Before leveling, the walls of the pool can be additionally protected from moisture with a penetrating compound.

- Sealing the joints of the walls and floor. The junction of the walls to the floor most often suffers from leaks. To prevent leakage, the corners must be glued with a strip of plaster mesh and carefully sealed with mortar.If possible, use a special sealing tape that must be glued to the concrete under the layer of leveling mortar.

After that, the internal and external protection of the bowl from water is carried out with the selected materials.

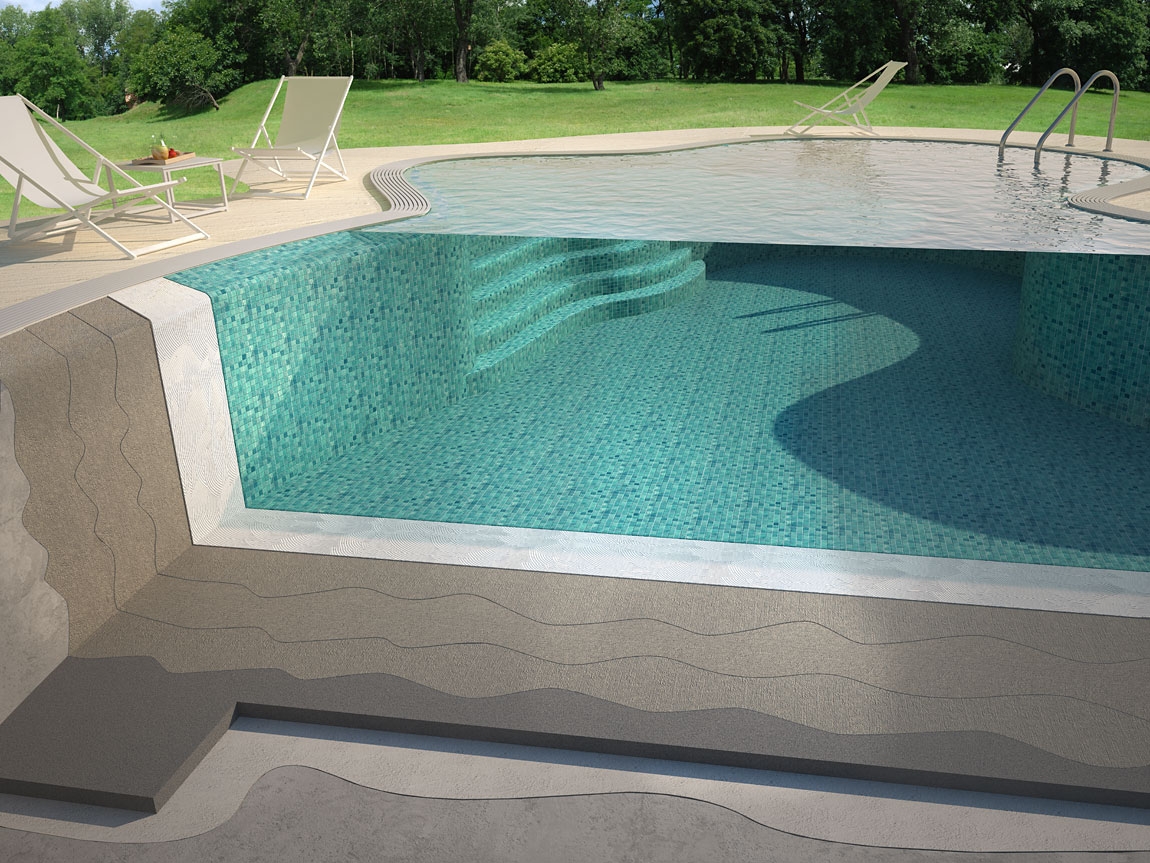

Pool waterproofing

Protection of the pool from water filtration is divided into external and internal. External is designed for protection against groundwater and is used only in open structures. The inner one protects concrete structures from the water itself filled in the pool.

External waterproofing device

Even at the construction stage, concrete is modified with special compounds (for example, Penetron Admix), which increase its water resistance and strength. Of course, when it comes to repair work, the introduction of additives (and waterproofing for pools in general) is done differently. If the groundwater level is or could potentially rise above the level of the bottom of the pool, a drainage system is installed.

Usually, complex waterproofing is performed, combining different types of materials and / or technologies. Consider one of the options for waterproofing the pool during repair work.

- The walls of the pool are exposed. Of course, this is not necessary at the construction stage - they are already open.

- The walls are inspected for integrity and the presence of defects or seams interrupting the concreting.

- Cracks or defects / seams are deepened and filled with Penekrit - a mixture of the Penetron system for waterproofing joints and cracks. If there is significant damage, an excellent solution would be to use the Scrape M500 restoring composition. It sets quickly and has high compressive strength.

- The walls of the bowl are cleaned, the surfaces are prepared and treated with Penetron, a penetrating mixture.The composition penetrates deep into the concrete, as a result of which the pores crystallize, preventing the movement of the liquid.

This is the simplest yet very effective way to waterproof the outside of your pool. Of course, the outer part is protected from moisture only in cases with open structures.

Waterproofing the pool from the inside

External insulation is important, but it is also important to make an internal hydro-barrier. Stages of work:

- The walls and floor of the pool are cleaned.

- Existing cracks are embroidered and sealed with Penekrit, you already know about its purpose.

- Then the entire concrete surface of the walls and floor is covered with Penetron material.

- A hydraulic barrier is being installed. Internal waterproofing for swimming pools is usually a penetrating and coating mixture. First, they work with penetrating - Penetron, which clogs the pores of concrete. Then the base is coated with the appropriate mixture - there are many variations on the market, as a rule, it is also a tile adhesive, say for mosaics / tiles.

There is an intermediate stage between penetrating and coating. At this stage, the base must be moistened for several days. After that, a technological pause is expected up to 28 days from the completion of the application of the penetrating composition, then the strength of the applied layer is checked, and in case of its peeling, it is mechanically removed. And only after that, the coating waterproofing for pools is applied in two layers, each of which is about 2 mm thick. Usually pools are tiled. In such cases, the described steps are sufficient. We only note that under the ceramics the base is leveled very carefully.However, if the tile is not provided for by the project, a third, polymeric, is applied over the second, coating, layer. Certain pigments must be added to it. Sometimes multi-colored mastics are mixed to form a characteristic pattern.

Pigmentation is combined with hardening of the finish layer. The application of the last layer is similar to working with self-leveling floors.

If Penetron and/or Penekrit is used, after finishing the insulation work, the base is moistened:

- outside for about 3 days;

- inside about 14 days.

After the waterproofing for the pools is arranged, a check is made by filling the bowl with water. If there is no leakage, you can proceed with the cladding. If there are, problem areas are waterproofed.

It is only necessary to waterproof the pool yourself if you are completely confident in your abilities. They don’t joke with water, so we recommend contacting the BAZIS-Pro company. Call us and they will help you to decide on the choice of materials, and if necessary, they will perform the whole range of works to ensure the protection of the pool from destruction by water. Extensive experience and dozens of ready-made objects are a guarantee of the quality of waterproofing your pool.

Types of pool waterproofing

The structure is protected from water from the outside and inside, and therefore the waterproofing materials used are divided into two groups.

External moisture protection of the bowl

External waterproofing is used to protect the structure from flood and groundwater. It is relevant for street structures deepened into the ground. The requirements for external waterproofing are similar to those for moisture protection of foundations.

The main difference lies in the shrinkage rates and changes in the geometry of the bowl design, which occur under the influence of a significant mass of water on it. Before building a bowl, it is necessary to carefully study the soil structures in the selected area, find out the level of soil freezing, as well as the depth of groundwater.

It is very important that the level of the bottom plate of the bowl is not lowered below the depth of groundwater. If so, waterproofing alone will not be enough.

In this case, groundwater must be diverted from the structure using a drainage system.

The internal waterproofing of the bowl protects the structure not only from moisture, but also from the damaging effects of chemicals, so it must be resistant to them

The most proven and affordable method of arranging external waterproofing is considered to be a clay castle, which is mounted directly during the construction period. After the soil is taken out of the pit prepared for the pool, clay is poured into it and it is carefully compacted.

This is the clay castle. The best result is achieved when it is used in combination with other insulating materials: adhesives, coatings or penetrating materials.

It is necessary to choose the option of an external hydrobarrier for the bowl at the design stage. After the construction of the pool, it is more expensive and more difficult to eliminate imperfections and apply material to the walls. And it will be impossible to protect the bottom at all.

Internal waterproofing of the pool

Inner bowl insulation is a must for any type of pool. The insulating layer protects the material from which the structure is made from the damaging effects of moisture and chemical compounds.

Most often, the composition includes protection against disinfectants, which will necessarily be present in the water. The latter are relatively safe for humans, but they are an aggressive environment for building materials.

Waterproofing not only protects the pool from moisture, but also from possible leakage and corrosion. Internal insulation will be considered of high quality if it is resistant to opening holes and cracks up to 3 mm wide.

It is desirable that the waterproofing layer be low, but at the same time elastic. The material must have good adhesion to the substrate and maximum water resistance.

In addition, the insulating coating must resist hydrostatic and dynamic loads and fully comply with environmental standards. It would be nice if the waterproofing suppressed the activity of microorganisms. Another important nuance is full compliance with the type of finish chosen, otherwise it will be impossible to carry out a full lining of the bowl.

The internal waterproofing of the bowl is applied at the final stages of pool construction. You can choose the material for it even after all the work on the construction of the bowl has been completed, but always before the cladding.

The most popular indoor pool waterproofing materials

When building a pool, a variety of materials are used to waterproof the bowl. Since each has its own disadvantages and advantages, this issue must be approached reasonably and responsibly. To do this, you should study different types of insulating materials. Consider the most popular of them.

Liquid rubber

Compositions based on synthetic bitumen are considered the most popular, since they are well applied to concrete walls.One of them is liquid rubber. Pool waterproofing with liquid rubber is an emulsion of a polymer in an aqueous solution.

Such material is more often applied by spray, but some builders still use a roller or brush for this. To make liquid rubber harden faster, a solution of calcium chloride is added to the material.

After applying liquid rubber to the walls of the structure, moisture evaporates with the help of a water-absorbing component, resulting in an elastic and very dense precipitate that looks like rubber. When the mass hardens, the pool is washed and filled with water to release chloride salts from the waterproofing.

With the help of liquid rubber, the pool is isolated, both under the tile and without its use. The only drawback of this material is the instability to ultraviolet light. If the bottom and lower parts of the walls are well insulated from the sun with water, then the upper parts of the walls will gradually collapse from exposure to the rays.

Liquid glass

Liquid glass is a substance made on the basis of a solution of silicate and water. Such material has good viscosity, which provides waterproofing of the structure.

Small crystals, which are visible when the mixture is applied to the surface, increase and fill all the cracks. Liquid glass is waterproof and has an antiseptic effect.

Liquid glass is used as a hardener for the base of waterproofing. This material well strengthens the structure of the mixture on which it is applied. The technology of waterproofing with liquid glass is quite simple, since it has high adhesion and fits well.

Such a coating has no seams, joints, has high tightness and good waterproofing qualities.

Another advantage of the material is a fairly high water repellency. Liquid glass has a fairly low price, non-toxic, environmentally friendly. Liquid glass can be used in regions with high humidity.

However, in addition to the advantages, coatings also have disadvantages:

- fragility, will last no more than five years;

- such a coating requires additional protection, since it is fragile;

- you can not use liquid glass on brick surfaces;

- It dries very quickly, so it can be difficult to apply it to the surface.

PVC film

Of all the components for pool waterproofing, the most reliable is the PVC membrane coating, which not only insulates well, but is also often used to decorate the structure.

PVC coating is a soft, durable, elastic film of various colors, resistant to high temperatures. Such material has a high resistance to mechanical damage. Under the film, a geotextile is often laid, which is applied to eliminate irregularities.

However, no matter how strong this coating is, after the expiration of the period, the material will still begin to collapse. You can also make a hole in it, whether on purpose or by accident. Therefore, for capital structures, it is usually not PVC films that are used, but liquid glass, liquid rubber, and mastic.

Based on the foregoing, it should be noted that, having decided to build a pool, the builder needs to thoroughly study the technology for arranging waterproofing and the properties of materials. After all, waterproofing is the main stage of construction.It protects the structure from external irritants and ensures the durability of the pool.

Used materials for pool waterproofing

Various materials are used for waterproofing pools. Materials for waterproofing for swimming pools - a lot. Each individual material has its own individual characteristics and features. Consider - pool waterproofing materials.

PVC films

Polyethylene films are the cheapest in hardware stores, and everyone can afford it. However, PVC films have a significant disadvantage - if some defect (hole) appears on the film, then the material will have to be completely replaced. To isolate the pool with your own hands from the film, use a durable product.

Waterproofing membranes

The strength of this tool has long been tested. But in order to install the material, the intervention of professionals is necessary. For self-waterproofing, the use of other materials is required. The main disadvantage is that you will have to spend a lot of money, since the waterproofing membrane costs a lot of money, as well as installation this material is expensive.

Also, the waterproofing membrane must be stored from various kinds of damage. Main advantages:

- the membrane has a huge operational life (fifty years);

- the material is completely environmentally friendly material;

- you can carry out self-repair of a damaged membrane.

Bentonite mat

This material is based on a natural sodium mat. A distinctive feature of the bentonite mat is that it can self-repair.A gel-like state is formed when a certain amount of moisture enters the material. The resulting gel-like state closes all defects (cracks, crevices, and so on).

The main advantage of bentonite mat is its high level of resistance to various mechanical damages. Also, bentonite mat has some disadvantages:

Might be interesting

Waterproofing

Clean water is a guarantee of health, waterproofing of concrete…

Waterproofing

The choice of materials work methodology for waterproofing...

Waterproofing

Types of pasting waterproofing

Waterproofing

Optimum indoor air humidity

- bentonite mat cannot withstand high water pressure;

- A certain load (200 kg/sq.m.) is required to install the bentonite mat.

Liquid rubber

This material is great for any pool configuration. Liquid rubber does not have any seams. Liquid rubber is an environmentally friendly material, and it will not bring any harm to human health. Waterproofing the pool with liquid rubber is not often done.

Polymerizing impregnations or liquid glass

Liquid glass for pool waterproofing is an emulsion of polymer resins. This emulsion penetrates the concrete of the structure. After a certain period of time passes, the material becomes plastic. Liquid glass is best suited for the top of the structure. After applying the polymerizable impregnation, a layer of plaster can be applied. Waterproofing the pool with liquid glass is an easy process of work.

Coating composition

The coating composition is intended for internal waterproofing of the structure. The coating composition is a waterproof solution.It becomes waterproof after it dries. This method of isolation from water has significant efficiency and reliability.

Bitumen

Although bitumen has a low cost in the construction market, it has many disadvantages:

- short service life;

- poor adhesion to any surface (adhesion);

- the surface on which bitumen is to be applied must be perfectly flat;

- if the base is uneven, then the material deteriorates in a short period of time.

The use of bitumen is not recommended.

Additional materials

Sold materials that are intended for auxiliary purposes. For example, sealing cords are such material. Sealing cords are used to seal joints and cracks. They are also suitable for seams.

Tapes, which are also intended for sealing joints, are installed at the place where the wall joins the wall or where the wall joins the bottom.

In order to seal process waters, use "Penebar". "Penebar" is a tourniquet that has a rectangular section. At the base of this material is a polymer substance. As soon as "Penebar" is in contact with water, it begins to swell, thereby closing cracks and crevices. "Penebar" are also used to seal work seams.

How to choose the right waterproofing material

The waterproofing of the bowl of the future pool will fully meet its functional purpose only if the material for it is selected competently and professionally.When choosing a waterproofing material, factors such as:

- type of pool, its shape, design and size;

- material for the manufacture of the pool bowl;

- requirements for the aesthetic component of the waterproofing material;

- the location of the pool, its purpose and attendance.

An important criterion when choosing a waterproofing material is its cost, the specialists of our company will help you choose the best material in terms of price / quality / reliability ratio.

Advantages and disadvantages of pool waterproofing

No one wants their pool to leak water, it is for this reason that a number of works are carried out related to the protection of the structure from the flow of water. At the same time, many people are faced not only with the advantages of waterproofing, but also with its disadvantages.

Advantages:

- some materials are able to tightly seal cracks and chips;

- long service life;

- materials do not deteriorate under the influence of water.

Flaws:

- some materials do not differ in durability and reliability;

- waterproofing can deteriorate if there is an uneven surface;

- chipping and cracking may occur.

Internal waterproofing

The pool bowl is a monolithic reinforced concrete structure, and the penetration of moisture into the micropores of concrete will inevitably lead to corrosion of the reinforcing cage and a decrease in the strength of the entire bowl. Moisture that has entered the micropores under the influence of negative temperatures will begin to expand and form cracks. The mass of water in the pool bowl constantly exerts static and periodically dynamic pressure on the structure, accelerating the negative processes in the bowl material. Internal waterproofing must resist this.

For the device of internal waterproofing, the concrete bowl is cleaned of dust and debris, checked for cracks and seams, which are treated with materials to seal the seams. Sealing tapes are used to seal joints.

The surface of the bowl is leveled by plastering the walls with waterproof compounds for pools, a self-leveling mixture is used to level the bottom. All surfaces are primed with a primer (Gruntofol, AquaDyur).

Next, the type of waterproofing is selected, based on the capabilities of the customer:

- For gluing, materials based on polymerized bitumen (Stekloizol, Stekloelast, Rubitex) are used. They are placed hot.

- For coating, mastics such as Cemizol 2EP, Idrosilex Pronto, Ceresit, Penetron are used. According to their composition, these are polymer-cement mastics that create an elastic layer on the surface of the bowl.

- The waterproofing of the pool can be done with bitumen-polymer mastic, which is called liquid rubber. Spray liquid rubber with a compressor (for large volumes of work) or apply with a roller or brush. This mastic has increased adhesion (adhesion) to the surface of the pool bowl and creates a durable, elastic layer with excellent waterproofing properties. Liquid rubber combines the qualities of liquid waterproofing and PVC membranes. On the resulting layer, you can lay a mosaic or tile. Now manufacturers have mastered the production of liquid rubber in different colors, which allows you not to lay the finish layer and do without decoration. To the touch, liquid rubber is as pleasant as membrane materials. If the work on applying this bitumen-polymer mastic is performed by a team of specialists (usually of 3 people), then they can process up to 1000 m² per shift.

- The use of membranes allows you to combine waterproofing and decorative functions. Membranes imitating marble, mosaic and other finishing materials are produced. The disadvantages of this material include a fairly high cost and the complexity of the application process. First, the corners and junction lines of the bowl surfaces are treated with a special liquid, then a reinforcing fabric is glued to these places, and the liquid is applied again. After drying, the liquid is applied with a roller to the entire internal area of the pool. A reinforced canvas is laid on the liquid, carefully distributed along the bottom and walls, and again covered with a special liquid. After drying, all layers form a single continuous membrane with excellent waterproofing properties. Membranes require strict adherence to the laying technology and control over the safety of the material.

- The most affordable material for pool waterproofing is PVC film. Typically, such films are used on inexpensive pools. After the film is spread out, the seams are welded with a building hair dryer. The laying speed of this material is high. The disadvantages include a very small selection of material shades and the inability to spread the film without seams, which will be clearly visible in the pool.

In the work on the waterproofing device, sealing cords are necessarily used to seal joints and seams, for example, the Penebar polymer tow. The polymer, upon contact with water, swells and seals the gap or seam. After sealing the seams with cords, they are treated with a penetrating waterproofing compound.

After performing waterproofing work, mosaics or tiles are laid on the walls and bottom.In order for water, having got through the inter-tile seams, not to lead to the peeling of the tiles, special insulating grouts are used. Insulating grouts are polymer or epoxy compounds. Using a rubber spatula, they are pressed into the space between the tiles. Immediately after application, the tile must be wiped off so that the remains of the composition do not dry out on the surface.

Before starting work on the waterproofing of the pool, it is recommended to evaluate your capabilities and strengths. A very important stage is to be carried out, and non-compliance with technology, inaccuracy, inattention can be very expensive in the future. Choose the type of waterproofing that you can handle on your own, while doing all the work with high quality.