- The choice of material for pool waterproofing

- Concrete or composite

- Trend - terraced public pools

- Description and features of waterproofing mixtures

- Liquid rubber

- Liquid glass

- PVC film

- The most popular indoor pool waterproofing materials

- Liquid rubber

- Liquid glass

- PVC film

- Internal and external waterproofing

- More about internal waterproofing

- Planning and design selection

- Waterproofing under pool tiles

- Waterproofing, cladding

- Internal waterproofing of the pool

- Applied materials and their features

- Roll materials

- penetrating compounds

- Bituminous and rubber mastics

- Waterproofing of pools is carried out in various ways

- Description and features of waterproofing mixtures

- Liquid rubber

- Liquid glass

- PVC film

The choice of material for pool waterproofing

- PVC film. Using a membrane for waterproofing is considered an economical way to refine the reservoir. Thus, already built pools are protected. The film covers the surface of any material. It is produced in three types: unreinforced - the cheapest option, used to cover prefabricated structures. Not particularly durable. Reinforced - consists of two panels, between which there is a grid.It is usually installed on concrete or coffered foundations. The material is able to withstand the high pressure of water poured into the pool. Anti-slip - cover the walls of children's containers. Films are produced with various additives that give the coating additional qualities. For example, the introduction of acrylic does not allow the appearance of vegetation. The advantages of this method include the possibility of waterproofing the pool with your own hands and the good tolerance of chemical additives that are added to the water.

- Liquid rubber. The most popular way to cover containers from the outside and from the inside. The product is sprayed using special devices. The material fills all the pores and capillaries layer by layer and hardens, forming a monolithic shell without seams, pleasant to the touch. The substance can be applied to a wet surface, in cold weather, while after polymerization it will not peel off. Often liquid rubber is used as a base for ceramic tiles, but it is allowed to leave it without a decorative coating. The method is easy to perform and inexpensive.

- Liquid glass. It is mainly used at the construction stage of the pool. The material is added to concrete or applied to the surface, thus gluing the structure together. The composition of the substance includes potassium and sodium, as well as cement. When the components hit the walls, crystals are formed that have waterproofing properties. The mixture fills all the pores and cracks, eliminating all ways of penetration of moisture into the wall. It has high adhesion to all building materials. The composition has proven itself to protect the base from groundwater. The coating prevents the appearance of fungus on the walls of the container.However, without special equipment it is impossible to perform such an operation.

- Polyurethane mastics. The product is made on a cement basis with the addition of modified polymers. After application, a strong elastic seamless shell with a thickness of 2-5 mm is formed on the surface. Adheres well to any material. Can be used without a decorative layer. Mastic is versatile and is often used for exterior and interior coatings. It is usually laid at the stage of bowl formation. Of the minuses, one can note the difficulty with attaching decorative tiles to it.

Concrete or composite

Along with the construction of private concrete pools, composites are actively used. This is the name of artificially created combinations that combine the advantages of two or more materials. For example, the same reinforced concrete. Reinforcement makes it more durable, concrete mass prevents corrosion. Thanks to reinforcement, it was possible to create many durable polymers.

At first glance, the advantages of composite materials are obvious. But in the case of monolithic pool structures, everything is not so simple. The composite is stronger and cheaper, but it cannot maintain the constancy of its dimensions. The material bends, which significantly complicates the mating process.

Another disadvantage of composite materials is that they are easily scratched during operation. In the future, it will be difficult to repair the damage. Will need a comprehensive overhaul. Under the influence of chemicals, composites age, and micropores allow fungus to pass through. The choice of colors is very limited. This is another argument in favor of choosing a concrete pool.

Trend - terraced public pools

The public pool is a significant point of attraction for any public leisure infrastructure. Usually this:

- urban space, parks, leisure areas, countryside space (open airs, themed concerts, exhibitions, campsites, hotels, hotels);

- sports events, marathons, active recreation centers;

- urban and suburban beaches (in places with a high concentration of the target audience).

As part of the latest trends in the field of pool construction, one can highlight the growing popularity of so-called terraced pools for social events. But what are they? A terraced pool is a type of framed pool around which a terrace has been erected; it can be installed:

- in a dug pit, while the terrace around the pool will be located at ground level;

- directly on the ground - in this option, a terraced plateau is built around the pool at water level.

The growing popularity of such pools in cities is primarily due to the low cost of construction (compared to concrete structures), as well as the fact that they are quite easy to assemble and dismantle. In addition, terraced pools look very presentable.

The construction of such objects from concrete or steel is impossible to imagine. It is difficult, expensive, not mobile (quick dismantling is not provided), and no one will let trucks and excavators into the metropolis park. Composite pools of this scale are not built due to inconvenience: it is difficult to transport a large one-piece bowl. Therefore, terraced (frame) pools are the best solution. They do not require special design and dismantling for the winter period due to frost resistance. Installation of such objects is reduced to:

- to the assembly of the pool (assemble the frame, pull the bag);

- to connect equipment and water;

- to the construction of a terrace around the pool (in budget options it is possible without a terrace);

- to the installation of infrastructure facilities (cloakrooms, toilets, cafes, etc.), which are built as needed, depending on the location or format of the event.

Terraced pools are a unique opportunity to organize a public bathing facility with little effort. Its deployment will cost an order of magnitude cheaper than a similar-sized concrete pool. And the possibility of prompt dismantling makes terraced pools indispensable in conditions when it is necessary to build a temporary facility or when the construction of a stationary facility has not yet been approved, and it is necessary to test the location (the place of future construction), or a business niche, or an event format to collect data on the payback of the project .

This is interesting: The device of interfloor ceilings: we describe from all sides

Description and features of waterproofing mixtures

Liquid rubber

Liquid rubber is a bitumen-polymer mastic that has almost perfect waterproofing properties and excellent adhesion. The only point that can cause difficulties for a non-professional is that you will need a special compressor to work with this material. A brush or roller will cause difficulty in application and increase the time of work.

Liquid rubber combines the advantages of PVC membrane properties and liquid waterproofing in its composition, which makes it possible to obtain an ideal, continuous coating that is reliably ingrained into the concrete surface and the complete absence of seams.

The material is pleasant during tactile contact, has a high density and maximum strength.It can be used as a top coat, or can be applied under a decorative layer, provided that you add some kind of coloring pigment. For example, blue.

If you decide to use liquid rubber, then the pool bowl should be as level and degreased as possible.

Liquid glass

A mixture of potassium or sodium silicates gives a solution that professionals call "liquid glass". Such a solution can only be used at the stage of pool construction, because the mixture is added directly to the concrete itself at the rate of one liter of glass per hundred liters of ready-made concrete mixture. After such manipulations, concrete becomes very durable and strong, as resistant as possible to mechanical stress and moisture.

It is possible, of course, to apply liquid glass and at the end of construction work immediately on the concrete surface. But the above option is preferable.

Liquid glass allows not only to achieve maximum waterproofing properties of concrete and extend the service life, but also protect against mold, fungus, ultraviolet radiation and temperature extremes.

Glass is quite budgetary and easy to do on your own.

PVC film

This is probably the most popular type of waterproofing. Very reliable and advanced option for protection against moisture ingress. That is why it is most often used in the construction of pools.

The amazing thing about PVC film is that with this material we practically kill two birds with one stone: we waterproof the pool and perform a decorative and finishing procedure, which saves money and time very significantly.

Retail offers a lot of various options for films, any colors, textures and patterns.

In addition to all the charms, PVC is also an excellent protector of concrete from mechanical damage and exposure to ultraviolet rays.

The algorithm for applying the film to the surface of the pool bowl, in principle, is not much different from other options.

It is also necessary to remove debris, prepare the pool bowl, fix the fastening tapes and corners, to which, subsequently, the film will be attached.

Experts advise laying PVC on special geotextiles, which will increase adhesion and extend the life of the film, preventing it from rubbing against concrete.

Separate parts of the film are fixed with a special welding tool, which will not raise questions even from an amateur.

Having familiarized yourself with the brief characteristics of the materials that are suitable for waterproofing the pool, you just have to make your choice and study the description of the work that we provide below.

The most popular indoor pool waterproofing materials

When building a pool, a variety of materials are used to waterproof the bowl. Since each has its own disadvantages and advantages, this issue must be approached reasonably and responsibly. To do this, you should study different types of insulating materials. Consider the most popular of them.

Liquid rubber

Compositions based on synthetic bitumen are considered the most popular, since they are well applied to concrete walls. One of them is liquid rubber. Pool waterproofing with liquid rubber is an emulsion of a polymer in an aqueous solution.

Such material is more often applied by spray, but some builders still use a roller or brush for this. To make liquid rubber harden faster, a solution of calcium chloride is added to the material.

After applying liquid rubber to the walls of the structure, moisture evaporates with the help of a water-absorbing component, resulting in an elastic and very dense precipitate that looks like rubber. When the mass hardens, the pool is washed and filled with water to release chloride salts from the waterproofing.

With the help of liquid rubber, the pool is isolated, both under the tile and without its use. The only drawback of this material is the instability to ultraviolet light. If the bottom and lower parts of the walls are well insulated from the sun with water, then the upper parts of the walls will gradually collapse from exposure to the rays.

Liquid glass

Liquid glass is a substance made on the basis of a solution of silicate and water. Such material has good viscosity, which provides waterproofing of the structure.

Small crystals, which are visible when the mixture is applied to the surface, increase and fill all the cracks. Liquid glass is waterproof and has an antiseptic effect.

Liquid glass is used as a hardener for the base of waterproofing. This material well strengthens the structure of the mixture on which it is applied. The technology of waterproofing with liquid glass is quite simple, since it has high adhesion and fits well.

Such a coating has no seams, joints, has high tightness and good waterproofing qualities.

Another advantage of the material is a fairly high water repellency.Liquid glass has a fairly low price, non-toxic, environmentally friendly. Liquid glass can be used in regions with high humidity.

However, in addition to the advantages, coatings also have disadvantages:

- fragility, will last no more than five years;

- such a coating requires additional protection, since it is fragile;

- you can not use liquid glass on brick surfaces;

- It dries very quickly, so it can be difficult to apply it to the surface.

PVC film

Of all the components for pool waterproofing, the most reliable is the PVC membrane coating, which not only insulates well, but is also often used to decorate the structure.

PVC coating is a soft, durable, elastic film of various colors, resistant to high temperatures. Such material has a high resistance to mechanical damage. Under the film, a geotextile is often laid, which is applied to eliminate irregularities.

However, no matter how strong this coating is, after the expiration of the period, the material will still begin to collapse. You can also make a hole in it, whether on purpose or by accident. Therefore, for capital structures, it is usually not PVC films that are used, but liquid glass, liquid rubber, and mastic.

Based on the foregoing, it should be noted that, having decided to build a pool, the builder needs to thoroughly study the technology for arranging waterproofing and the properties of materials. After all, waterproofing is the main stage of construction. It protects the structure from external irritants and ensures the durability of the pool.

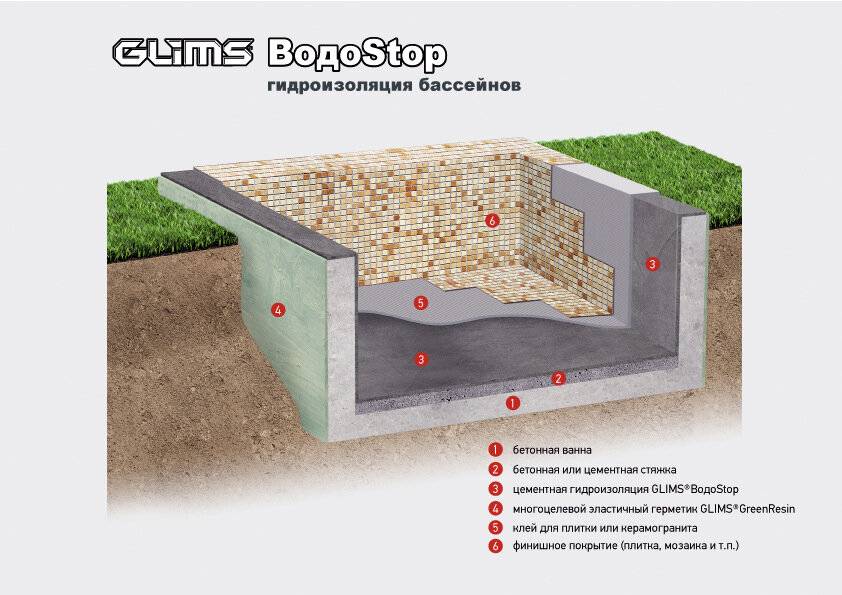

Internal and external waterproofing

A number of measures are taken to protect the outer surface of the base of the pool.In this case, we mean the laying of moisture-resistant materials from the side of the ground. The waterproofing of the pool is called external

It is equally important to protect the fine finish and all internal communications from exposure to the water contained in the bowl. Such waterproofing of the pool performs other functions and is called internal

The features of each of these layers should be studied in more detail. For example, external waterproofing significantly reduces the likelihood of groundwater impact on the structure base. At the construction stage, they are guided by the requirements that apply to foundations. However, the pool is subjected to more intense loads, since it is influenced not only by the heaving process and groundwater (from the soil), but also by dynamic loads, as well as shrinkage and possible changes in the geometry of the bowl, which occur due to thermal expansion and as a result of impact large volume of water.

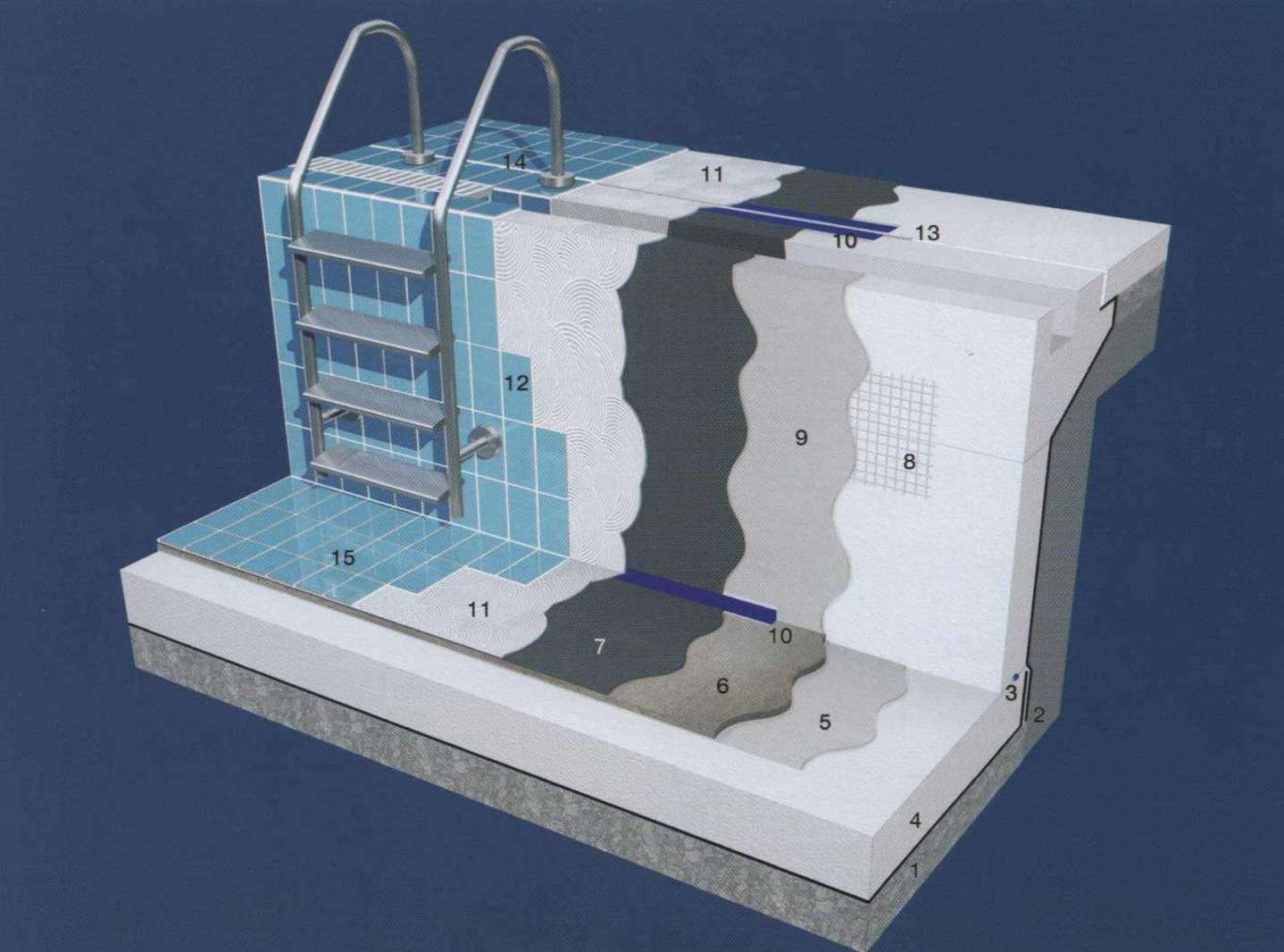

Waterproofing layers

External waterproofing of the pool is carried out using different materials. The main options that are suitable for this purpose are:

- roll;

- coating;

- penetrating;

- membrane.

However, roll materials are more often used. In this case, it is not necessary to carefully prepare the surface. Additionally, clay castles are made. This is a natural way to protect against groundwater penetration, which is due to the properties of clay. However, such measures are not effective in some cases. So, if groundwater lies closer to the soil surface, and there is a risk that the liquid will wash away the base of the pool, measures must be taken to divert it. For this purpose, a drainage system is equipped.

The most effective option is that which involves the use of different types of waterproofing materials to protect the base of the tank. For example, the walls on the outside are insulated, insulated, and then another moisture-proof layer is laid, but of a different structure. For reliability, a clay castle is equipped.

Internal waterproofing - installation

More about internal waterproofing

For the pool, it is important to protect the base (external walls) and the bowl itself. You should know that concrete is a hygroscopic material, due to its porous structure. Gradually, it absorbs moisture, which reaches the metal structure provided to strengthen the pool. The frame, made of reinforcement, rusts over time. This means that it will become less durable. As a result, the entire structure will suffer, and it will be impossible to operate the pool.

When frozen, the liquid in the pores of the concrete can cause irreversible changes. During the thawing process, the degree of stress increases significantly. Cracks appear, and they appear inside. In addition, it is necessary to take into account the constant impact of aggressive environments on the materials from which the bowl is made.

All these factors can be eliminated or smoothed out as much as possible if the inner surface of the pool is covered with a waterproofing material. For this purpose, various types of protection are used:

- roll coating;

- penetrating compounds;

- liquid and coating insulation.

When arranging the pool inside the building and in the open air, various technologies are used.The internal insulation of pools is a mandatory step in any of the cases, but the protection of the external surface of the structure from the soil is necessary only for outdoor structures. If internal waterproofing of pools is performed, it is recommended to use coating, liquid materials. This is due to the fact that such compositions are characterized by high adhesion to surfaces. However, in this case, you will have to carefully prepare the pool bowl.

outdoor swimming pool

Planning and design selection

You should start, of course, with the project. First you need to assess the condition of the site, decide on the place where the pool will be located, choose the size of the tank, the configuration of the bowl, etc.

An important point is the level of occurrence of the first groundwater horizon from the surface on the site. If this indicator is less than one meter, i.e. groundwater runs high; it is not recommended to build a stationary pool in a pit.

Alternatively, you can consider installing a portable frame or inflatable model.

When choosing a place to build your own pool, you should consider the following recommendations of experts:

- The pool should be located at a sufficient distance from a residential building and other buildings, since the close proximity of these structures can have a devastating effect on the integrity of the foundation of the building.

- It is undesirable to place the pool in the immediate vicinity of the trees or plant them afterwards, so that the root system, attracted by a large amount of moisture, does not grow and destroy the frame of the structure.

- The presence of a large number of trees near the pool also increases the intensity of pollution by foreign debris and stimulates the growth of algae.

- Clay soils are best suited for building a pool, which serve as an additional barrier to ground moisture, if there is a choice, just such a site should be allocated for the pool.

- Digging a large pit by hand is an extremely time-consuming task, it is better to choose a place to which construction equipment can be brought: an excavator, a concrete mixer, possibly a crane, etc.

When a place is chosen, you need to take a sheet of paper and draw a future building on it. You should choose the configuration of the bowl and its depth, as well as designate the location of all communications: the place of water supply, the ladder for descent, the installation location of the filter, overflow, lighting, external lighting, etc.

At the planning stage, it is necessary to consider the type of pumping and treatment of water. The diagram shows a skimmer-type pool. Polluted water is pumped out from the surface with a skimmer, and after cleaning with heating, it is supplied through nozzles located opposite (+)

In addition to the main place for draining, it is recommended to provide an emergency water discharge system. Electrical wires must be laid in the corrugation.

At this stage, it is necessary to take into account the predominant wind direction on the site. Debris that has fallen on the surface of the water will be blown away by the wind to a specific side of the pool.

The overflow type of artificial reservoirs involves the outflow of polluted water through the overflow gutter into the container of the same name. After cleaning and heating, it is delivered back to the pool through nozzles located in the bottom area.

In building stores, you can find pool equipment kits that include everything you need for installation.

This set may include:

- waterproofing materials;

- materials for the construction of the walls of the pool bowl;

- fittings;

- flanges and nozzles;

- filter, pump, skimmer;

- stairs;

- PVC film for decoration, etc.

The basic set can be supplemented with other elements, depending on the features of the project of the future pool.

The easiest way to arrange a pool for the summer season is to purchase a prefabricated version with the accessories and equipment included in the package.

When choosing the dimensions of the structure, it should be remembered that for one adult, a depth of 1.5 m is considered suitable for swimming, and the recommended length of the pool is about 5 m. or more.

The deeper the pool, the larger the volume of its bowl, the thicker the pool walls should be made, respectively, the more materials will be needed to complete the work.

Separately, it is worth discussing the configuration of the future pool. The following principle should be remembered here: the more complex the outlines of the bowl, the more effort will be required to implement the project and the subsequent maintenance of the pool.

The easiest way to build a pool with rectangular, round or oval bowl outlines. If all these points are taken into account in advance, and the project is drawn up correctly, there will be much less problems during construction.

For example, if there is no clear project, after pouring the bowl, you have to additionally drill concrete to make holes for communications.

When choosing a pool of the wrong configuration, it should be borne in mind that the complexity of its installation, as well as maintenance, can increase significantly.

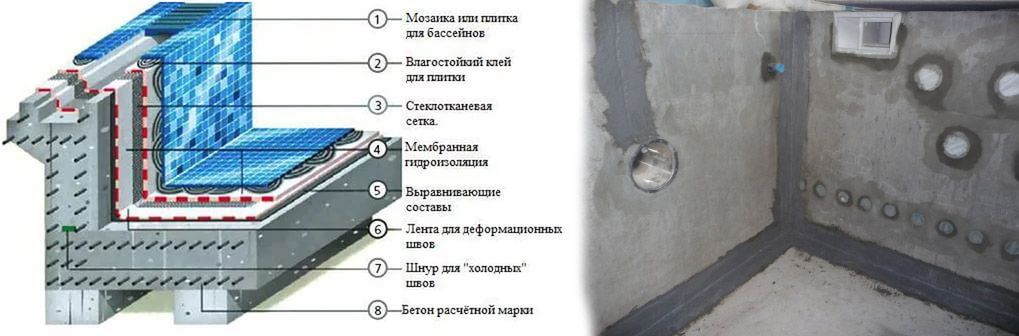

Waterproofing under pool tiles

It is also necessary to carry out waterproofing for tiled finishing of the structure. More precisely, the space that is located under the tiles or mosaics. The presence of water under the tile can cause the finishing material to gradually peel off. To fix this problem, use specially designed grouts for joints.

Grouts can be polymeric materials. A construction spatula is used to apply this insulating material. Polymer compositions must be pressed into the space that is found between the tiles. Waterproofing the pool under the tiles is carried out without problems.

Waterproofing, cladding

With a pool of concrete rings, everything is much easier

But when you make a monolithic tank, after removing the formwork, it is important to make good waterproofing and lining. The composition purchased in advance in the hardware store is applied with a roller

All joints of the foundation, irregularities are worked out with the utmost care. It is important that the composition is completely dry.

Waterproofing is very easy to check. It is enough to fill the pool with water, wait a week. Before pouring, level measurements are made. If the changes are significant, look for a leak, fix it.

Which cladding option to choose? It all depends on your budget and personal preference. Someone chooses mosaic or film, others prefer tiles

It is very important to use a high quality adhesive that is resistant to moisture. All seams are additionally treated with antifungal agents

So you will significantly extend the life of the lining, and it will be much easier to care for it.

Pool waterproofing

Internal waterproofing of the pool

Ensuring the tightness of the inside of the reservoir is the most important step. Therefore, it is better to use several methods at the same time.

Waterproofing technology:

when pouring a bowl of concrete, you can initially add a plasticizer that will increase the insulating capabilities of concrete. We leave the bowl to dry;

the resulting cracks are covered with sealant or resin;

we cover the base with a screed, with self-leveling properties;

apply plaster on a flat surface;

sandpaper make the surface slightly rough to ensure better grip;

cover with a primer and let dry;

apply waterproofing material in 2-3 layers

We pay special attention to places with cracks or other defects;

after drying, check the bowl for leaks;

we finish the work with facing the reservoir using tiles or other methods.

Using different materials will allow you to protect your pool from water for many years.

Applied materials and their features

Modern manufacturers offer a large number of different options for waterproofing materials that differ in composition and main active ingredients.

All composites have their advantages and disadvantages, so it is important to get acquainted with the features of each type of pool waterproofing. The most popular material options are:

- PVC films and membranes;

- bituminous composites;

- liquid rubber;

- penetrating compounds;

- polymer mastics.

Roll materials

The waterproofing of pools requires good adhesion of the material and the base, therefore only bituminous roll materials or PVC membranes are suitable for the internal processing of the bowl. Bitumen on a special frame made of polyester fibers perfectly penetrates into the surface layer of concrete when heated.

As a result, a layer of bituminous composition reinforced with thin fiber is formed on the surface of the base, which significantly increases the reliability of waterproofing. The disadvantage of this option is the inconvenience in work and the large weight of the material itself.

A very interesting type of waterproofing for the pool is a polymer membrane or film. It performs a dual function, because in addition to protecting against water penetration, such material is used as a decorative coating that does not require finishing. Polyvinyl chloride lends itself perfectly to coloring, so films based on it have an amazing palette.

The membrane gives the inner surface of the bowl softness, smoothes out all the irregularities and surface defects, which increases the comfort of the pool. The main disadvantage of polymer films is their sensitivity to damage.

penetrating compounds

Composites based on mineral binders provide additional compaction of the top layer of concrete, significantly increasing its water resistance. Most often, such materials are produced in the form of mastics or dry mixes that require prior mixing with water.

Waterproofing of swimming pools with such composites can be carried out when tiling.In this case, the adhesion of the finishing material to the base increases, and the protective properties of the penetrating composition are sufficient to prevent waterlogging of the concrete.

For reliability, the layer of the penetrating composition can be additionally covered with polymer or bituminous mastic. Such compositions are best used for repairs, and not for basic waterproofing.

Bituminous and rubber mastics

The most popular options for pool deck materials are liquid rubber and bituminous composites. Both coating options are perfect for tiles, as they have good adhesion to the base and finishing materials. The waterproofing device using liquid rubber or bituminous mastic is performed manually or mechanically.

In the first case, do-it-yourself waterproofing of the pool is carried out by carefully applying the composition with a brush, spatula or roller in two stages. The second layer of coating is applied in a perpendicular direction for better overlapping of the material a few hours after the start of work.

Particular attention is paid to the study of all corners and transitions.

The mechanized method involves spraying a liquid composition under low pressure. There are both professional installations for application, and household ones, which anyone can use. This method is most often used for liquid rubber.

As a result, the waterproofing layer has approximately the same thickness over the entire surface of the base and covers the concrete as densely as possible.

Waterproofing of pools is carried out in various ways

1. Films polymer-based: polypropylene, polyvinyl chloride, polyethylene, cellulose acetate, synthetic rubber, etc.Reinforced with polyester mesh, synthetic fibers or fiberglass. Differ in high mechanical durability (including to punctures), are insensitive to freezing and thawing. They are also resistant to preparations used for maintenance of swimming pools, UV rays and weather conditions.

2. Coating (penetrating) waterproofing of pools. Often used under ceramic tiles or mosaics. New materials that have appeared on the market have high adhesive (adhesion to the base) and physical and mechanical properties, due to which they create a reliable barrier to protect against groundwater penetration. A paste-like solution is applied to the inner surface of the bowl, penetrates into the pores of the concrete and clogs them. After contact with water, the material is activated and becomes waterproof.

3. Membrane waterproofing. A composition based on bitumen-latex compounds is sprayed on the floor and walls in 2 layers. It is used as a supplement to the coating, takes on the main load of the water column.

4. Hydrophilic profiles. They are used in places of installation of embedded parts to eliminate water leaks due to different thermal expansion of concrete and pipe materials. They are made on the basis of polyofelin rubber or bentonite clays.

Order Avancé pool waterproofing services today! Our experts will provide your artificial reservoir with reliable protection against water leaks.

The basin, like any other reservoir, is a rather complex hydraulic structure. Its main working part is a bowl - in fact, a container for water. Most often it is made of monolithic concrete, as this material can withstand high loads and is waterproof.

However, as the strength qualities of concrete are not high, over time the material wears out and undergoes cracking. To a large extent, this is facilitated by the water inside the pool and groundwater. Waterproofing protects the structure from its action.

Description and features of waterproofing mixtures

Liquid rubber

Liquid rubber is a bitumen-polymer mastic that has almost perfect waterproofing properties and excellent adhesion. The only point that can cause difficulties for a non-professional is that you will need a special compressor to work with this material. A brush or roller will cause difficulty in application and increase the time of work.

Liquid rubber combines the advantages of PVC membrane properties and liquid waterproofing in its composition, which makes it possible to obtain an ideal, continuous coating that is reliably ingrained into the concrete surface and the complete absence of seams.

The material is pleasant during tactile contact, has a high density and maximum strength. It can be used as a top coat, or can be applied under a decorative layer, provided that you add some kind of coloring pigment. For example, blue.

If you decide to use liquid rubber, then the pool bowl should be as level and degreased as possible.

Liquid glass

A mixture of potassium or sodium silicates gives a solution that professionals call "liquid glass". Such a solution can only be used at the stage of pool construction, because the mixture is added directly to the concrete itself at the rate of one liter of glass per hundred liters of ready-made concrete mixture. After such manipulations, concrete becomes very durable and strong, as resistant as possible to mechanical stress and moisture.

It is possible, of course, to apply liquid glass and at the end of construction work immediately on the concrete surface. But the above option is preferable.

Liquid glass allows not only to achieve maximum waterproofing properties of concrete and extend the service life, but also protect against mold, fungus, ultraviolet radiation and temperature extremes.

Glass is quite budgetary and easy to do on your own.

PVC film

This is probably the most popular type of waterproofing. Very reliable and advanced option for protection against moisture ingress. That is why it is most often used in the construction of pools.

The amazing thing about PVC film is that with this material we practically kill two birds with one stone: we waterproof the pool and perform a decorative and finishing procedure, which saves money and time very significantly.

Retail offers a lot of various options for films, any colors, textures and patterns.

In addition to all the charms, PVC is also an excellent protector of concrete from mechanical damage and exposure to ultraviolet rays.

The algorithm for applying the film to the surface of the pool bowl, in principle, is not much different from other options.

It is also necessary to remove debris, prepare the pool bowl, fix the fastening tapes and corners, to which, subsequently, the film will be attached.

Experts advise laying PVC on special geotextiles, which will increase adhesion and extend the life of the film, preventing it from rubbing against concrete.

Separate parts of the film are fixed with a special welding tool, which will not raise questions even from an amateur.

Having familiarized yourself with the brief characteristics of the materials that are suitable for waterproofing the pool, you just have to make your choice and study the description of the work that we provide below.