- About method

- Other models of drilling rigs

- Drilling rig with "cartridge"

- Simple screw installation

- Drilling and installing casing pipes - a guide for beginners

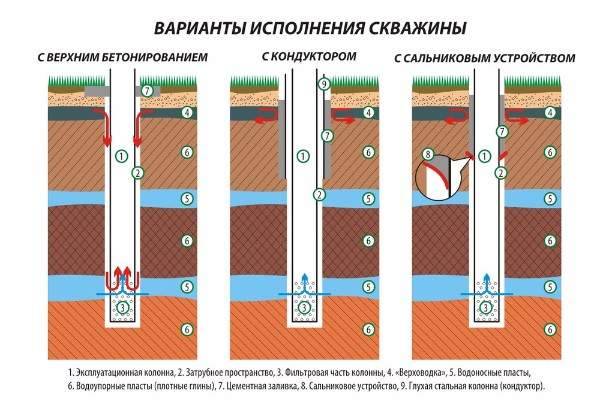

- What type of water wells are

- Features of the installation of casing pipes

- Peculiarities

- Step by step work plan

- Determination of the occurrence of aquifers

- Preparation of the drilling site

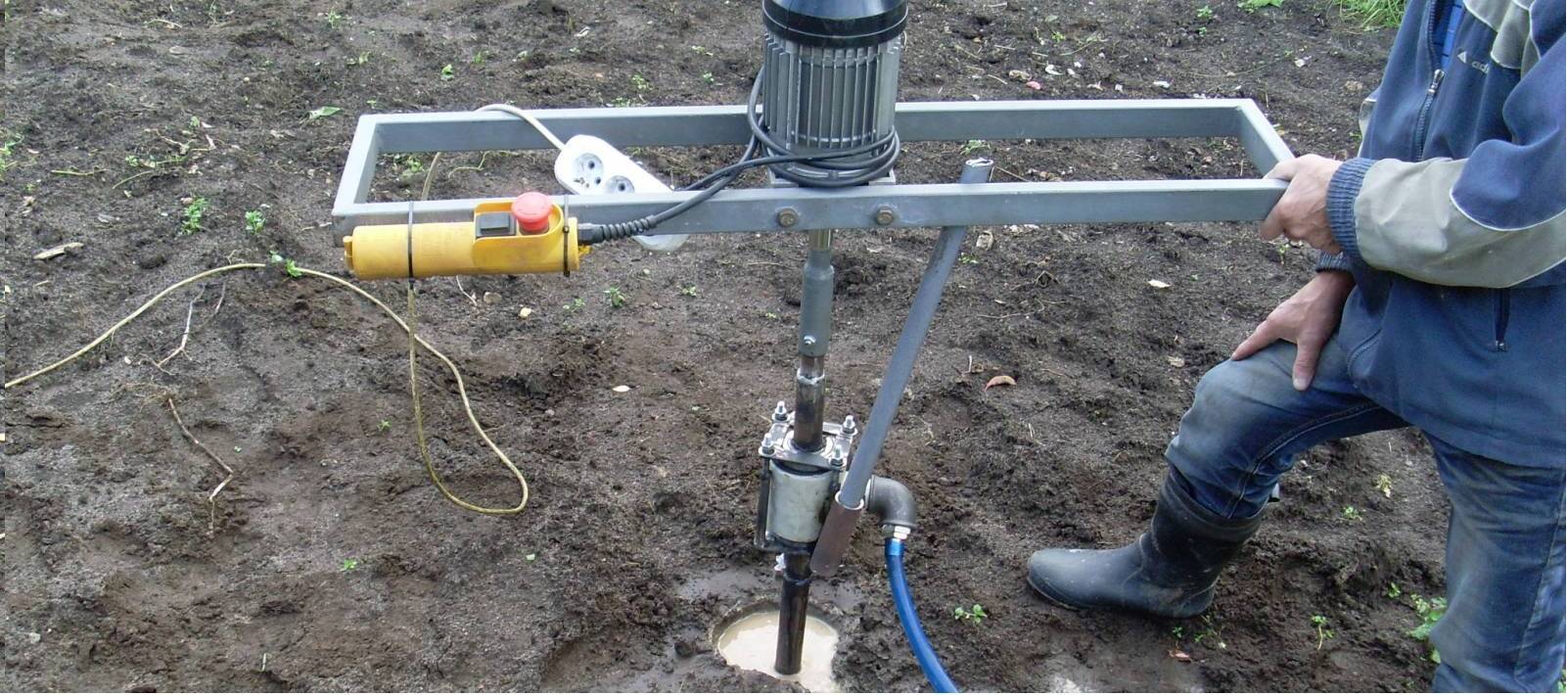

- Well drilling MBU

- Filter installation and well construction

- Casing installation

- What do you need to prepare for work?

- Conclusions and useful video on the topic

About method

This method is suitable for different types of soil:

- Sandy;

- sandy loam;

- loamy;

- Clayey.

This method is not suitable for rocky soil, since its principle is to soften the rock with water pumped into the drilling zone using a pump, which greatly facilitates the process. Waste water enters the pit next to the installation, and from there it returns to the well through hoses. Thus, the whirlpool has a closed system and a lot of liquid is not required.

Hydro-drilling of wells is carried out by a small-sized drilling rig (MBU), which is a collapsible mobile structure of compact size and light weight. It consists of a bed, which is equipped with:

- A reversible motor with a gearbox (2.2 kW) that creates torque and transmits it to the drilling tool.

- Drill rods and drills.

- A manual winch that raises and lowers the equipment when building up the working string with rods.

- Motor pump (not included).

- Swivel - one of the contour elements with a sliding type of fastening.

- Hoses for water supply.

- A petal or exploration drill in the shape of a cone, which is used to penetrate compacted soils and center the equipment.

- Control unit with frequency converter.

The presence of rods and drills of different diameters allows drilling wells of different depths and diameters. The maximum depth that can be passed with the MBU is 50 meters.

Water well drilling technology consists of several stages. A frame is mounted on the site, an engine, a swivel and a winch are attached to it. Then the first elbow of the rod is assembled with a head in the lower end, pulled up to the swivel with a winch and fixed in this knot. The elements of the drill rod are mounted on a conical or trapezoidal lock. Drilling tip - petals or chisel.

Now we need to prepare the drilling fluid. Near the installation, a pit is made for water or drilling fluid in the form of a thick suspension, for which clay is added to the water. Such a solution is poorly absorbed by the soil.

The intake hose of the motor pump is also lowered here, and the pressure hose is connected to the swivel. Thus, a constant flow of water into the shaft is ensured, which cools the drill head, grinds the walls of the well and softens the rock in the drilling zone. Sometimes an abrasive (such as quartz sand) is added to the solution for greater efficiency.

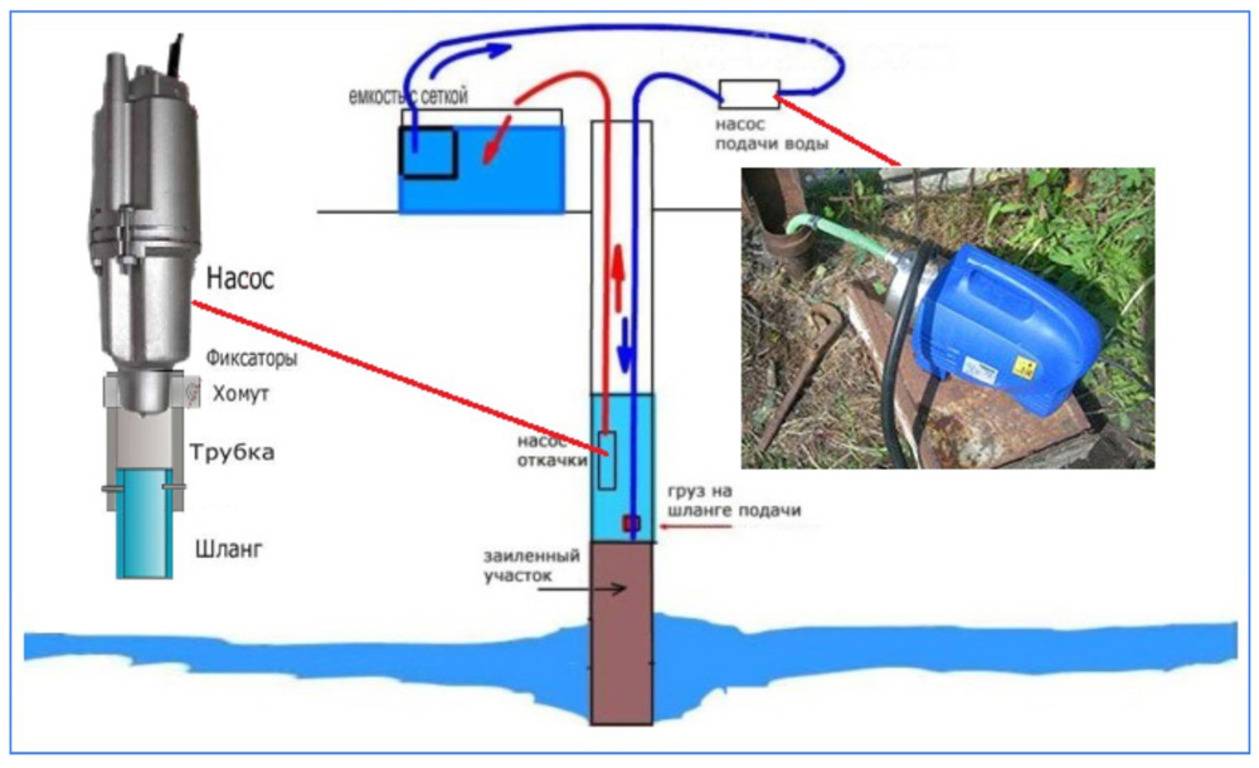

The torque of the drill rod is transmitted by a motor, below which the swivel is located. Drilling fluid is supplied to it and poured into the rod. The loosened rock is washed to the surface. Waste water is reused many times as it flows back into the pit. The technical fluid will also prevent water release from the pressure horizon, as back pressure will be created in the well.

As the well passes, additional rods are set until the aquifer is opened. After drilling is completed, a filter with casing pipes is inserted into the well, which are threaded and extended until the filter enters the aquifer. Then a cable with a submersible pump with a hose and an electric drive is lowered. Water is pumped until transparent. The adapter connects the source to the water supply.

This is interesting: Purification of water from a well - we learn from all sides

Other models of drilling rigs

In general, the assembly process of most of the existing varieties of drilling rigs remains the same. The frame and other elements of the structure under consideration are prepared in a similar way. Only the main working tool of the mechanism can change.

Read the information on the manufacture of various types of installations, make a suitable working tool, and then attach it to the support frame and connect it to other required elements using the recommendations from the instructions discussed above.

Drilling rig with "cartridge"

Drilling rig with "cartridge"

The main working element of such a unit is a cartridge (glass). You can independently make such a cartridge from a thick-walled pipe with a diameter of 100-120 mm.The optimal length of the working tool is 100-200 cm. Otherwise, be guided by the situation. When choosing the dimensions of the support frame, you will have to take into account the dimensions of the cartridge. Think over everything so that in the future it will be convenient for you to use the finished drilling rig.

The working tool should have as much weight as possible. From the bottom of the pipe section, make triangular points. Thanks to them, the soil will loosen more intensively and quickly.

Do-it-yourself drilling rig

If you wish, you can leave the bottom of the workpiece even, but it will need to be sharpened.

Poke some holes in the top of the glass for attaching the rope.

Attach the chuck to the support frame using a strong cable. Choose the length of the cable so that in the future the cartridge can freely rise and fall down. When doing this, be sure to take into account the planned depth of the source.

To increase the efficiency of excavation, you can connect the assembled unit to an electric motor. The cable with the cartridge in such a situation will be wound on the gearbox drum.

It is possible to ensure the cleaning of the bottom from the soil by including a bailer in the structure.

Using such an installation is very simple: you first manually create a recess in the drilling site with a diameter greater than the diameter of the working cartridge, and then begin to alternately raise and lower the cartridge into the hole until the required depth is reached.

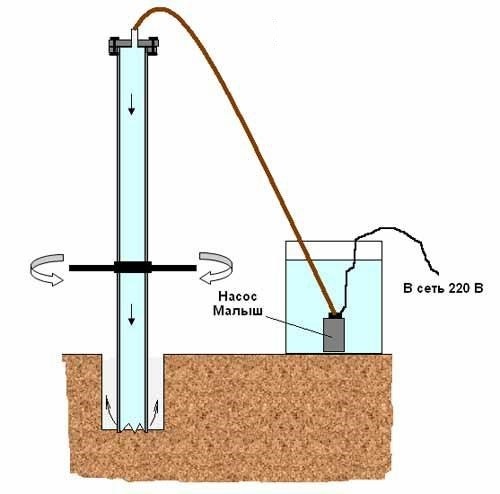

Simple screw installation

Homemade auger

The main working element of such a mechanism is the drill.

Drilling auger drawing

Diagram of an interturn screw ring

Make a drill from a metal pipe with a diameter of 100 mm.Make a screw thread on the top of the workpiece, and equip an auger drill on the opposite side of the pipe. The optimal drill diameter for a homemade unit is about 200 mm. A couple of turns is enough.

Drill disc separation scheme

Attach a pair of metal knives to the ends of the workpiece by welding. You must fix them in such a way that at the time of the vertical placement of the installation, the knives are located at a certain angle to the soil.

Auger drill

To work with such an installation was most convenient, connect a piece of metal pipe 1.5 m long to the tee. Fix it by welding.

Inside the tee must be equipped with a screw thread. Screw the tee itself onto a piece of a collapsible one and a half meter rod.

It is most convenient to use such an installation together - each worker will be able to take on a one and a half meter pipe.

Drilling is performed in the following order:

- the working tool goes deep into the ground;

- 3 turns are made with a drill;

- loosened soil is removed and removed.

Drilling method wells for water with auger

Repeat the cycle until you reach about a meter deepening. After the bar will have to be lengthened with an additional piece of metal pipe. A coupling is used to fasten pipes.

If it is planned to build a well deeper than 800 cm, fix the structure on a tripod. At the top of such a tower there should be a hole large enough for the unhindered movement of the rod.

In the process of drilling, the rod will need to be periodically increased.With an increase in the length of the tool, the mass of the structure will also increase significantly, it will become very difficult to manage it manually. For convenient lifting of the mechanism, use a winch made of metal or durable wood.

Now you know in what order simple drilling rigs are assembled and how to use such units. The knowledge gained will help you significantly save on the services of third-party drillers.

Successful work!

Drilling and installing casing pipes - a guide for beginners

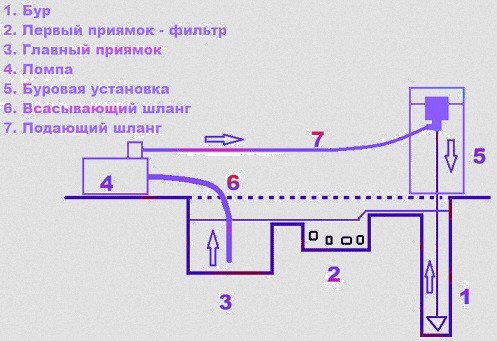

The manual drilling procedure is simple. Its scheme is as follows:

- Pour water into the pit and knead the clay in it to the consistency of kefir. The operation is performed by a mixer. Such a solution during drilling will form a kind of container with smooth walls in the well.

- Start the pump. It pumps flushing fluid into the hoses, which flows to the drilling rig through the rod. Then the water goes into the first pit. In it, the liquid from the well, saturated with soil particles, is filtered out (suspensions settle to the bottom). The drilling fluid becomes clean and passes to the next sump. It can be reused for drilling.

- In cases where the length of the drill string is not enough to reach the water layer, install additional rods.

- Having reached the coveted aquifer, you supply a large volume of clean liquid into the well to thoroughly rinse it.

- Remove rods and install pipes (casing).

Typically, tubular products are used with a cross section of 11.6–12.5 cm with walls having a thickness of about 6 mm. It is allowed to install any casing pipes - plastic, made of asbestos cement, steel.

It is desirable to provide casing pipes with filters.Then the water from the well will have a higher quality. You can purchase ready-made filtering devices. But there is a more economical option - to make the simplest filters with your own hands.

Casing pipes with filters

Drill many small holes in the bottom of the casing with a drill. Wrap the product with geofabric, fixing it with suitable clamps. The filter is ready! Believe me, such a simple design will make the water from the well much cleaner.

Also, after installing the casing, it is recommended to fill it with a little gravel (about half a regular bucket). This building material in this case will serve as an additional filter.

After the casing is installed, the well is flushed again. The procedure makes it possible to wash out the aquifer, which, in the course of drilling operations, was saturated with flushing fluid. Such an operation is done as follows:

- install the head for the well on the tubular product;

- carefully fasten the hose coming from the motor pump;

- supply clean water into the well.

All work has been completed. Lower the pump into the well and enjoy clean water.

What type of water wells are

With all its diversity, experts distinguish only a few types of water wells.

The first one is so-called well-needle. Wherein drilling rod, well casing and drilling tool are a single whole. The drill remains in the ground throughout the drilling process. The process itself is carried out by the shock method.

The rate of deepening with this method is on average about 2 meters per hour. The maximum possible depth in this case is up to 45 meters.A well-needle, as a rule, is equipped for the so-called Abyssinian wells in the country. They are in demand in the summer, as in winter they can show unstable water intake. A distinctive feature of such a well is that it can last for several decades. However, it cannot be repaired. As soon as the well stops producing water, it is clogged and a new one is started.

The diameter of the drill rod is up to 12 cm without the use of a pile driver - this corresponds to a submersible pump of 86 mm.

Types of arrangement of water wells.

The second is an imperfect well. Such a well seemed to hang inside the reservoir. It is easy to arrange and does not require special skill from the performer. However, the fence from it is not very high quality. In order to maximize the quality of water taken from an imperfect well, it is recommended to equip the bottom of the well with a plug.

In order for an imperfect well to be drilled on its own, a fairly powerful aquifer will be required.

The third type of well is perfect. In this case, its casing rests on the roof of the water-resistant layer. The passage of such a well will require accurate knowledge of local geology, as well as certain skills and abilities of the driller.

The quality of water in such a well is the best, and the service life is maximum.

The fourth type is the so-called bottom hole. In turn, it can be both perfect and imperfect. Thanks to the bottomhole, it will be possible to service such a well and, if necessary, repair it. However, only the most experienced craftsmen who are well acquainted with the local geology can drill it.

Features of the installation of casing pipes

After flushing the well, the drill rods are carefully removed. It should be borne in mind that if the parts are difficult to lift, then the flushing was insufficient. Now you can install the casing pipes. They can be metal, asbestos-cement or plastic. The latter option is the most widespread, since it is very durable, does not corrode and deform. Most often, pipes with a diameter of 125 mm are installed; for shallow wells, the 116 mm option is suitable. Sufficient wall thickness of parts - 5-7 mm.

For the best quality of the supplied water and additional purification of it from dirt, filters are used: sprayed, slotted or home-made. In the latter case, the simplest option can be considered as follows: with the help of a grinder, cracks are made across the entire casing across. To make a filter of higher purification, many holes are drilled in the pipe, then the part is wrapped with a special mesh or geofabric for better filtration, everything is fixed with clamps. A casing pipe with a filter at the end is lowered into the well.

A well filter of this type can easily be made independently. To do this, in the casing holes are drilled, which are best covered with a layer of geotextile or special mesh on top

If the installation is difficult due to the presence of a strong water carrier, which quickly “washes out” the wells, you can try the following. Slots are cut or holes are drilled in the tip screwed onto the filter. A head is put on the pipe, to which the pressure hose from the pump is attached. Then the most powerful water pressure is turned on.After these manipulations, the casing should easily enter the water carrier. After installing the casing, half a bucket of gravel can be poured into the column as an additional filter.

The next step is another flushing of the well. This is necessary to wash out the water carrier, which was saturated with drilling fluid during drilling. The operation is performed as follows. A head is put on the pipe, a hose from the motor pump is fixed, and clean water is supplied into the well. After washing, the column is evenly and densely covered with gravel. Now the pump can be lowered on the cable and use the well. A small nuance: the mechanism cannot be lowered to the very bottom, otherwise it will fail very quickly. The optimum depth is just below the water column.

The process of hydrodrilling a well for water is quite simple and quite affordable for independent implementation. However, before starting work, you need to carefully study the instructions, and best of all, take part in drilling under the guidance of specialists. Despite the apparent simplicity, there are many nuances known only to professionals. If there is no experience or desire, you can invite specialists who will punch a well quickly and at an affordable cost and equip it. The owner will only have to rejoice at the appearance of an autonomous water supply system in his house.

Peculiarities

The key difference between hydrodrilling wells for water is the presence of two drilling processes. First of all, when choosing this method, the rock is destroyed with the help of special devices. Next, pieces of earth are extracted with water under pressure. In other words, hydrodrilling involves washing out the soil with a powerful jet of water.

The peculiarity of the method is that the stages are carried out simultaneously, which allows you to get a high-quality result as soon as possible. To destroy the rock, special drilling equipment is immersed in the ground, and the cleaning is carried out by equipment that pumps water into the ground and delivers it to the body of the well being built in the process.

Another feature of hydraulic drilling is that the fluid from the equipment is used not only to wash out the rock destroyed by the drilling equipment. Additional functions of the supplied fluid:

- the possibility of carrying out the destroyed rock to the surface;

- cooling of tools that are used for drilling;

- grinding the well from the inside, preventing its collapse in the future.

There are quite a few advantages of hydrodrilling wells in suburban areas.

- Reducing financial costs. Work on drilling wells with the help of a hydraulic drilling rig can be done by hand without inviting specialists and special skills.

- The ability to install compact small equipment to work in small areas. For the arrangement of the well, small-sized equipment is used.

- convenience of the method. For drilling, you do not need to carry out any preliminary calculations, purchase a huge range of equipment and tools. The modern technique is simple and understandable to anyone who decides to try this method.

- Fast drilling and well completion time. Work can be completed in a maximum of a week.

It is also worth noting the environmental safety of the method and the minimal impact on the landscape. It is possible to carry out work on drilling wells even in landscaped areas. However, this method is not always suitable.

Step by step work plan

The specifics of hydraulic drilling provides for a strict sequence of work stages: a casing string is purchased, drilling equipment and a flushing solution are prepared. The well construction begins after the assembly of a small-sized drilling rig.

As the mine deepens, it becomes necessary to strengthen the walls by installing a casing pipe. It prevents the shedding of sand and the ingress of fragments of pebble rock into the wellbore.

The result is considered achieved when the water carrier passes: drilling is completed with the appearance of liquid in the mine.

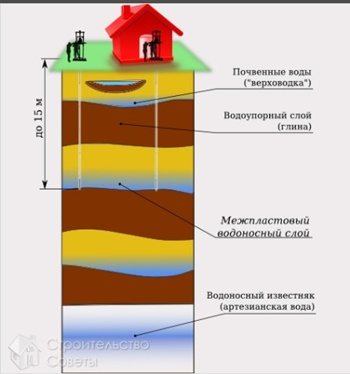

Determination of the occurrence of aquifers

The construction of an autonomous well is preceded by a search for an underground source. Aquifers are arranged in horizontal layers in clastic and clayey sedimentary rocks. A study of the water level in water mines in neighboring areas will help determine the approximate depth of the aquifer.

For exact information, it is recommended to contact the company that carried out drilling work near the site planned for development. Full information can be obtained after a geological assessment of the territory.

Features of the procedure allow the use of hydrodrilling technology for the construction of boreholes with a depth of 10-30 m. When determining the location of the aquifer, it is recommended to use a reconnaissance drill with a diameter of 100 mm.

Verkhovodka appears in the shaft after drilling the first 6 m of the mine well. High contamination does not allow the use liquid from the upper horizons for drinking, only its use for watering the garden, washing the car and other household needs is allowed.

An increase in the volume of the washing solution in the pit indicates the opening of the water carrier. To facilitate orientation, special beacons are installed on the sump to control changes in the amount of drilling fluid in the pit. An increase in the water level is considered a signal to terminate the procedure.

Preparation of the drilling site

The main condition for ensuring the effectiveness of the technique is the prevention of interruptions in the supply of the washing solution. For the required amount of water, it is necessary to prepare special containers with a capacity of more than 2 m³ or build a separate pit with a volume of more than 5 m³. The walls of this recess must be treated with a clay mixture.

For hydraulic drilling, 2 adjacent sumps are constructed, connected by an overflow trench. In the first pit, the liquid settles, the sand sinks to the bottom, and from the second (main) pit, water is supplied to the wellbore. The pits intended for holding the prepared flushing solution are located no further than 2 m from the drilling equipment.

It is recommended to start assembling the drilling rig after preparing the water tank. The installation procedure is simple and takes about 60 minutes.

Well drilling MBU

Drilling a well in sandy rocks requires a large reservoir of drilling fluid and a thick mud. Clay closes the pores in the trunk, preventing the seepage of liquid.

Casing pipes made of plastic.

Simultaneous lowering of the casing pipe and deepening of the rod with a hydraulic drill at the end prevents the collapse of sedimentary deposits into the mine. The best casing material is steel or plastic.

For reliable fixation of the string in the body of the well, it is recommended to use clamps.It is allowed to replace fasteners with a rope loop.

The principle of operation of the MBU is to cyclically repeat the following actions:

- the washing solution is supplied by a motor pump through hoses into the cavity of the rod;

- through the pipe, the working fluid is directed to the drilling tool, destroying the soil;

- leachable rock with washing solution fills the first sump-sump;

- after the suspension settles, the suspension flows into the main sump, from where it again enters the hose, the pump starts to repeat the cycle.

Filter installation and well construction

It is allowed to use a rod with a perforated upper section as a filter element. It is placed inside the casing string.

When lowering the filter to the bottom, the casing pipe is pulled out of the shaft until the perforation zone is exposed. The protruding part is cut off for the convenience of arranging the head. To strengthen the mouth and prevent groundwater seepage, the gap around the trunk is filled with crushed stone and poured with concrete. To operation wells start after pump installation.

Casing installation

When the drill reaches the aquifer, flushing is carried out. Then you should carefully remove the drill rods.

If the rods come out hard, repeat flushing!

To prevent collapse of the borehole wall immediately after the rods are retrieved, a casing should be installed. Three types of pipes are used: asbestos-cement, steel and plastic. The latter are the best choice. They are inexpensive, while high-strength and elastic, not afraid of corrosion.

Filtration is needed to improve water quality and create additional protection against dirt. Filters can be both homemade and industrial. The latter are slotted and "coated".

The simplest home-made filter is done like this: a grinder cuts transverse slots in the casing pipe. Better cleaning can be achieved by drilling holes in the pipe and wrapping it with geotextile or a special mesh. The design of such a do-it-yourself filter is fastened with clamps.

What do you need to prepare for work?

Hydrodrilling of wells is carried out using a small-sized installation or MBU. Those who are accustomed to associate the drilling process with bulky mechanisms will be surprised that this device is a device three meters high and a meter in diameter. This assembly includes:

- collapsible metal frame;

- drilling tool;

- winch;

- an engine that allows you to transfer force to the drill;

- swivel - part of the working circuit, providing a sliding fastening to the rest of the parts;

- a water pump that creates and maintains pressure in the system;

- a drill for passing the soil, can be exploratory or petal;

- drill rods forming a column;

- hoses supplying water from the motor pump to the swivel;

- unit control unit.

You will need a current converter, which is necessary for the uninterrupted supply of electricity to the equipment, a winch for lowering and raising stacking and casing pipes. The device can be built into the MBU, this point will need to be clarified. When choosing a gasoline motor pump for pumping drilling fluid, it is better to take a sufficiently powerful high-quality device, since the load on it will be large. You will need casing pipes, a filter and small tools, which include a pipe wrench, transfer fork, hand clamp, etc.

A standard drill is used to drill a well, but depending on the type of soil, special varieties may be required.

Conclusions and useful video on the topic

The video will show you the process drilling a well manually with a rig casing and filter in the casing pipe:

Each type of water well has its own advantages and disadvantages.

Now that you have got an idea about the type of wells, their design and construction methods, it will be easier for you to make a choice in favor of a particular design, based on the characteristics of your site and your own financial capabilities.

If you have ever drilled a well with your own hands, tell us about how difficult or simple the process was to perform. Please write in the box below. Ask questions, share your impressions, post pictures on the topic of the article.