- Rules for operation and repair

- Volume calculation

- Balloon or membrane

- Operating recommendations

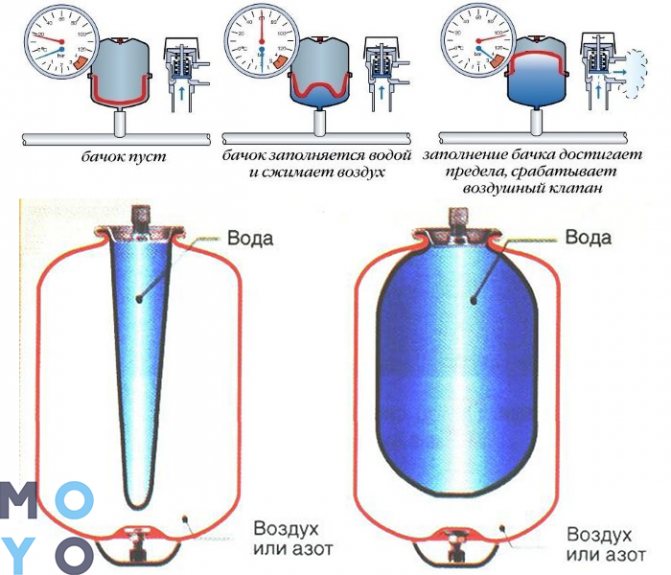

- Principle of operation

- 2

- Device and principle of operation

- Hydraulic tank connection

- With surface pump

- With submersible pump

- Hydraulic accumulator device

- The principle of operation of the system without a hydraulic tank

- Tank volume is the main selection criterion

- According to the characteristics of the pump

- According to the minimum recommended volume formula

- How is it different from an expansion tank

Rules for operation and repair

Connecting and setting up the accumulator correctly is only half the battle. In order for the device to work for a long time, it must be correctly operated, periodically perform preventive inspection and maintenance.

The instructions prescribe a medical examination twice a year, but practice shows that this is not enough. The condition of the accumulator should be checked every three months. With the same frequency, it is advisable to monitor the settings of the pressure switch in order to correct them if necessary.

Incorrect operation of the relay creates additional loads on the entire system, which can also affect the condition of the accumulator.

If dents or signs of corrosion are found on the body of the device during the inspection, these damages must be repaired.It is best to do this as early as possible, otherwise corrosion processes will develop, which can lead to a violation of the integrity of the accumulator housing.

An important preventive measure is to check the pressure in the hydraulic tank itself using a pressure gauge. If necessary, the required amount of air should be pumped into the device or its excess should be bled off.

If this does not help and the new pressure gauge readings do not correspond to the expected ones, then either the integrity of the accumulator housing is broken or its membrane is damaged.

If the membrane installed in the accumulator is worn out, you can try to replace it with a new one. To do this, the device will have to be dismantled and disassembled.

Some craftsmen manage to detect and repair damage to the hull, but such repairs are far from always durable and reliable. The rubber liner or membrane is the weak point of the accumulator. Over time, it wears out.

You can also replace the membrane with a new element at home, but for this you will have to completely disassemble and reassemble the accumulator.

When choosing a suitable place to install the accumulator, it should be remembered that it must be spacious enough to carry out maintenance of the device.

If a home craftsman doubts his abilities in this area or does not have enough experience, he can cause even more damage to the device than the previous breakdown. In such a situation, it is better to contact the service center.

Volume calculation

How to choose a hydraulic accumulator for water supply systems? You can get an answer by calculating the key parameters, first of all, the volume.

To perform calculations of the optimal volume of a hydraulic tank, you must first determine for what purpose it will be used, which devices can be installed for use for various purposes. Often their installation is carried out in order to prevent frequent switching on of the pump.

- Accumulators are also used to maintain system pressure when the pump is off.

- These devices are often mounted to provide a reserve of water.

- Some owners install them to compensate for peak water consumption.

If you decide to use a hydraulic accumulator together with your water supply system, then you should know that the closer the pumping equipment is located to this device, the higher its efficiency will be.

For example, if the pump is located in the basement, there is one hydraulic accumulator next to it, and the second one is in the attic, then you can see that the volume of water will be less on the hydraulic tank located in the upper part of the house, since the system water pressure will be less. When a hydraulic accumulator is located in the basement or on the first floor, the filling level will be the same.

When choosing a hydraulic accumulator in order to exclude frequent switching on of pumping equipment, several factors must be taken into account. Experts do not recommend turning on the pump more than once a minute

Domestic water supply systems are most often equipped with equipment that has a capacity of 30 liters per minute. Taking into account the fact that in the device, 50% of the total volume is water, and the rest is air, a battery with a capacity of 70 liters can easily cope with this task.

Experts do not recommend turning on the pump more than once a minute. Domestic water supply systems are most often equipped with equipment that has a capacity of 30 liters per minute

Taking into account the fact that in the device, 50% of the total volume is water, and the rest is air, a battery with a capacity of 70 liters can easily cope with this task.

When a hydraulic accumulator is installed to compensate for peak values in water consumption, it is necessary to take into account the flow characteristics that the water consumption points in the house have

- The toilet consumes an average of 1.3 liters per minute.

- Per shower, the consumption rate is from 8 to 10 liters per minute.

- Kitchen sinks require about 8.4 liters of water per minute.

When there are two toilets, then with the simultaneous operation of all sources, their total consumption is 20 liters

Now it is necessary to take into account the percentage of the actual filling of the tank with water and the fact that the pump is turned on no more than 30 times per hour. Having such results, we can assume that a hydraulic accumulator with a capacity of 80 liters is quite enough

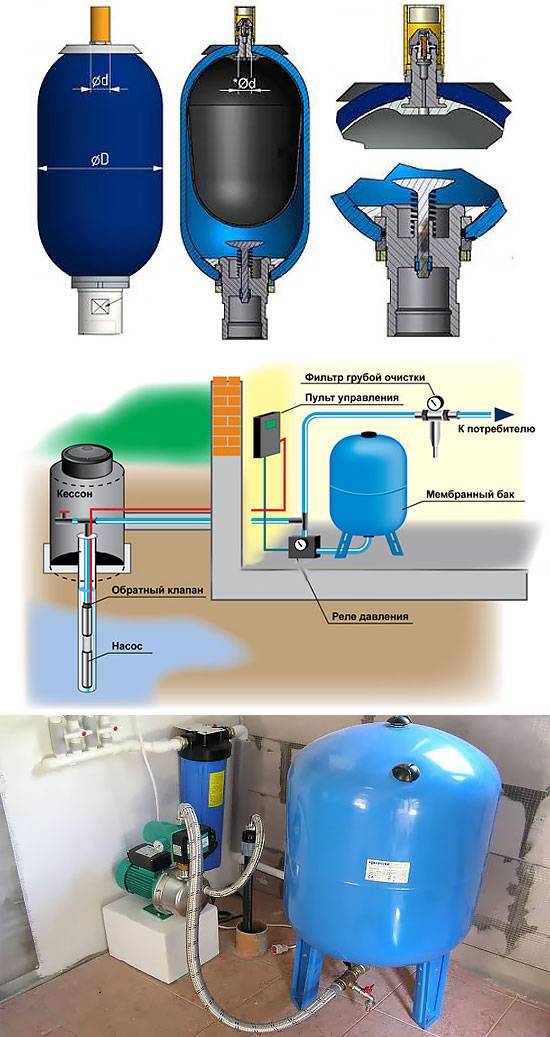

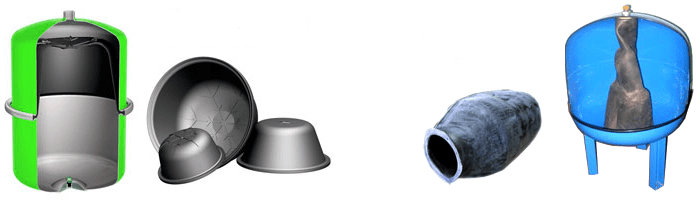

Balloon or membrane

Hydraulic accumulators are divided into two main types - membrane and balloon. The principle of operation of both types is similar - an elastic film of rubber expands or contracts under the influence of pressure from water and compressed air. The main difference is that in a membrane tank, the water coming from the well comes into contact with the metal walls of the tank, which can potentially lead to corrosion. In a tank with a rubber balloon, water comes into contact only with the balloon itself, without touching the metal walls.The absence of conditions for the development of corrosion prolongs the life of the balloon accumulator.

Additional convenience lies in the fact that the balloon, unlike the membrane, is a replaceable part. Carrying out the replacement will not cause any difficulties - even a non-specialist can do it. As a result, maintenance of a hydraulic accumulator with a cylinder will be cheaper. Taking into account the above factors of practicality and reliability, balloon accumulators are the best solution for individual water supply.

An important factor when choosing a hydraulic accumulator is the cost of spare parts.

Please note that some manufacturers may unreasonably inflate the price of components. For example, a rubber bladder can cost half or even more of the cost of the entire hydraulic accumulator.

Operating recommendations

After the accumulator is installed, it must be properly maintained. Approximately once a month, the pressure switch settings should be checked and adjusted if necessary. In addition, it is necessary to check the condition of the housing, the integrity of the membrane and the tightness of the connections.

The most common failure in hydraulic tanks is a rupture of the membrane. Constant cycles of tension - compression over time lead to damage to this element. Sharp drops in pressure gauge readings usually indicate that the membrane has torn, and water enters the “air” compartment of the accumulator.

To make sure there is a breakdown, you just need to bleed all the air from the device. If water flows out of the nipple after it, then the membrane definitely needs to be replaced.

Luckily, these repairs are relatively easy to make. For this you need:

- Disconnect the hydraulic tank from the water supply and power supply.

- Unscrew the bolts that hold the neck of the device.

- Remove damaged membrane.

- Install a new membrane.

- Assemble the device in reverse order.

- Install and connect the hydraulic tank.

At the end of the repair, the pressure settings in the tank and the pressure switch should be checked and adjusted. The connecting bolts must be tightened evenly to prevent warping of the new diaphragm and to prevent its edge from slipping into the tank housing.

Replacing the accumulator diaphragm is relatively easy, but care must be taken to ensure that the new diaphragm is the same as the old one.

To do this, the bolts are installed in the sockets, and then literally a couple of turns of the first bolt are alternately made, move on to the next one, etc. Then the membrane will be pressed against the body equally around the entire circumference. A common mistake newcomers make to repairing a hydraulic accumulator is the incorrect use of sealants.

The installation site of the membrane does not need to be treated with a sealant, on the contrary, the presence of such substances can damage it. The new membrane must be exactly the same as the old one in both volume and configuration. It is better to first disassemble the accumulator, and then, armed with a damaged membrane as a sample, go to the store for a new element.

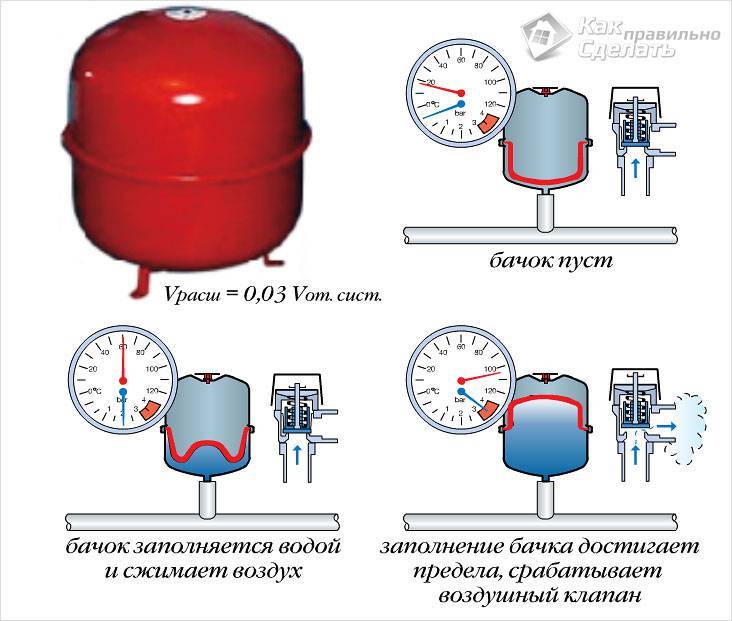

Principle of operation

- When water is supplied under pressure to the membrane, the pressure also increases.

- Upon reaching the desired pressure level, the relay turns off the pump.

Accordingly, the water supply is stopped.

- During the fall of the set pressure, the pump resumes operation, and water again enters the membrane.

Important! The efficiency of work depends on the size of the tank: the larger it is, the more effective the result. The frequency of the relay operation is adjustable. What is the pressure in the accumulator required to be, as well as the characteristics for achieving uninterrupted operation are indicated in the operating instructions

What is the pressure in the accumulator required to be, as well as the characteristics for achieving uninterrupted operation are indicated in the operating instructions

The frequency of the relay operation is adjustable. What the pressure in the accumulator is required to be, as well as the characteristics for achieving uninterrupted operation are indicated in the operating instructions.

2

According to the type of energy storage, the devices we are interested in come with mechanical and pneumatic storage. The first of these function due to the kinetics of a spring or load. Mechanical tanks are characterized by a large number of operational disadvantages (large geometric dimensions, high system inertia), so they are not used for domestic water supply systems. At the same time, it is worth noting that such devices do not need to be recharged and powered from external electrical sources.

Pneumatic storage units are more common. They function by compressing water under gas pressure (or vice versa) and are divided into the following types: piston; with a pear or with a balloon; membrane. Piston devices are recommended for cases when it is required to constantly have a sufficiently large supply of water (500–600 liters). Their cost is low, but in private dwellings such installations are operated extremely rarely.

Membrane tanks have small sizes. They are convenient to use. They are most often used for water supply systems of private housing construction.More simple balloon units are also actively used. Such devices are easy to install (you can install them yourself) and maintain (if necessary, any home master can easily replace a failed rubber bulb or a leaky tank). Although the need for repair of balloon accumulators is rare. They are truly durable and reliable.

Membrane tank for a private house

According to their purpose, storage tanks are divided into the following types:

- for heating systems;

- for hot water;

- for cold water.

And according to the method of installation, vertical and horizontal units are distinguished. Both the first and the second function in exactly the same way. Vertical hydraulic tanks with a volume of more than 100 liters usually have a special valve. It makes it possible to bleed air from the water supply network. Horizontal devices are supplied with a separate mount. An external pump is fixed to it.

Also, expansion tanks for differ in their volume. On sale there are also very small units, designed for 2-5 liters, and real giants for 500 liters or more. For private houses, it is recommended to purchase hydraulic accumulators for 100 or 80 liters.

Device and principle of operation

The device has the form of a box of various shapes with controls under the lid. It is attached to one of the outlets of the fitting (tee) of the container. The mechanism is equipped with small springs that are adjusted by turning the nuts.

Working principle in order:

- The springs are connected to a membrane that reacts to pressure surges. Increasing the rate compresses the spiral, decreasing leads to stretching.

- The contact group responds to the indicated actions by closing or opening the contacts, thereby transmitting a signal to the pump.The connection diagram necessarily takes into account the connection of its electrical cable to the device.

- The storage tank fills up - the pressure increases. The spring transmits the pressure force, the device operates according to the set values and turns off the pump, sending it a command to do so.

- The liquid is consumed - the onslaught weakens. This is fixed, the engine turns on.

The assembly consists of the following parts: a body (plastic or metal), a membrane with a cover, a brass piston, threaded studs, metal plates, cable glands, terminal blocks, a hinged platform, sensitive springs, a contact assembly.

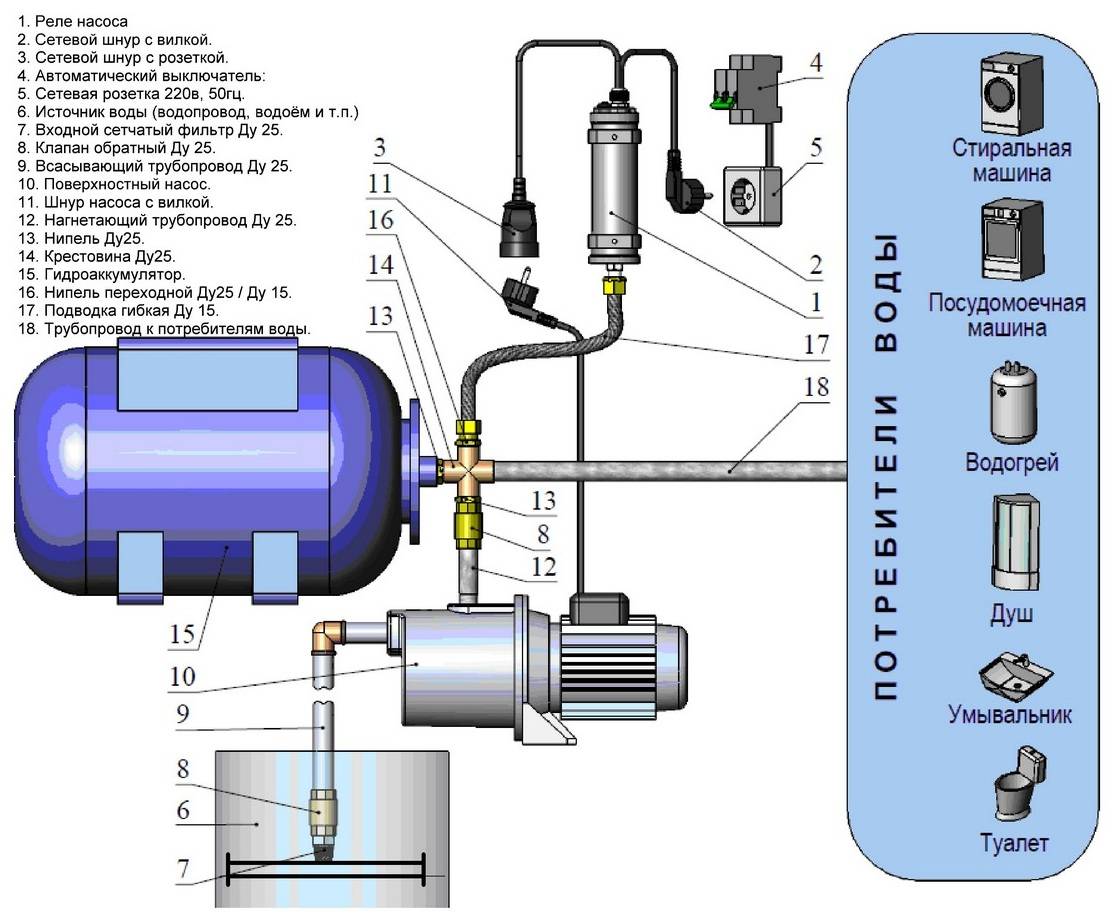

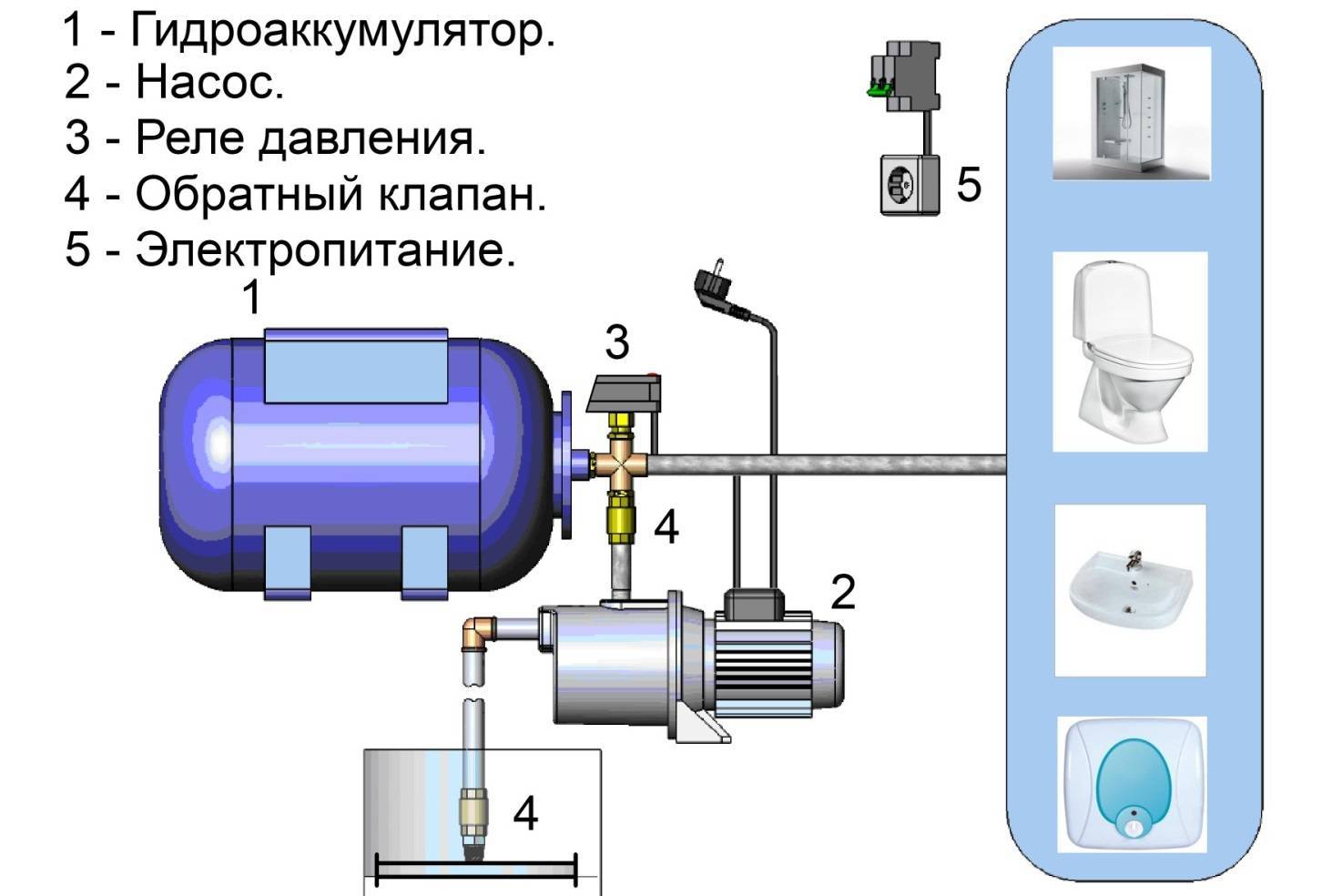

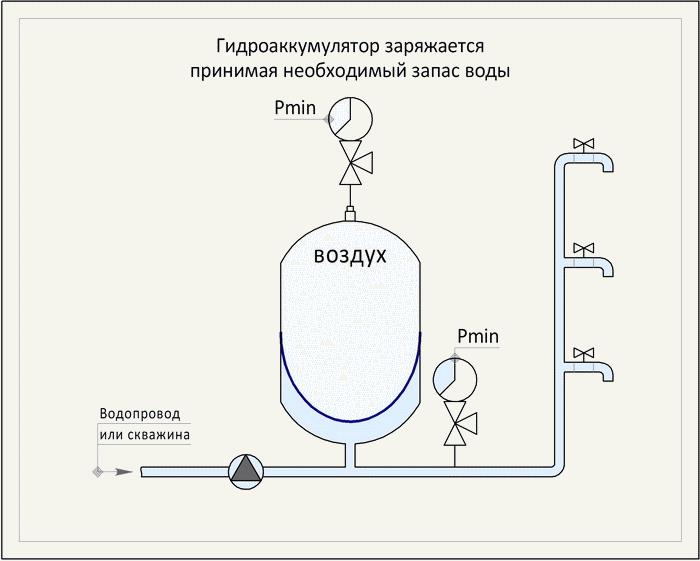

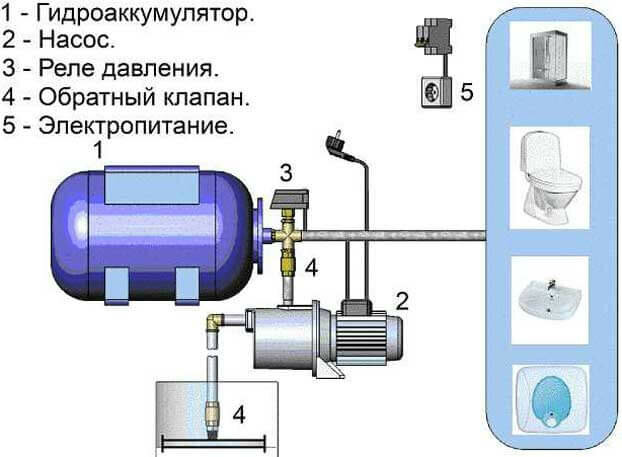

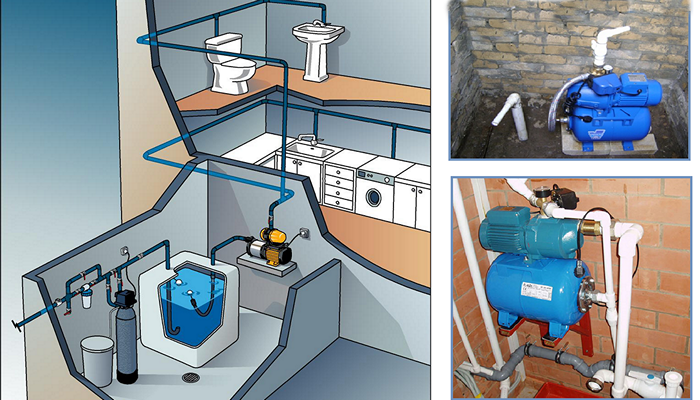

Hydraulic tank connection

A hydraulic tank is the second name for a hydraulic accumulator. It can be connected to the water supply system in various ways. The choice of a suitable connection scheme mainly depends on the capacity in which the device will be used, as well as what tasks it will perform. It is worth considering a few the most popular ways connections.

With surface pump

It is worth disassembling step by step how the hydraulic accumulator is connected to the system if there is a surface subtype of the pump.

- First you need to check the air pressure in the inside of the tank. It should be 0.2-1 bar less than the setting on the relay.

- Then you should prepare the equipment for connection. In this situation, technology means: a fitting, a pressure gauge, tow with a sealing compound, a relay responsible for pressure.

- You need to connect the fitting to the tank. The connection point can be a hose or a flange with a bypass valve.

- Then you should screw the other devices in turn.

To deal with the absence of leaks, it is necessary to start the equipment in a test order

When connecting the relay, which is responsible for regulating pressure, it is important to inspect all marks. Under the cover are contact connections - "network" and "pump"

Do not confuse wires. If there are no marks under the relay cover, then it is better to contact a professional for connection in order to prevent a serious mistake.

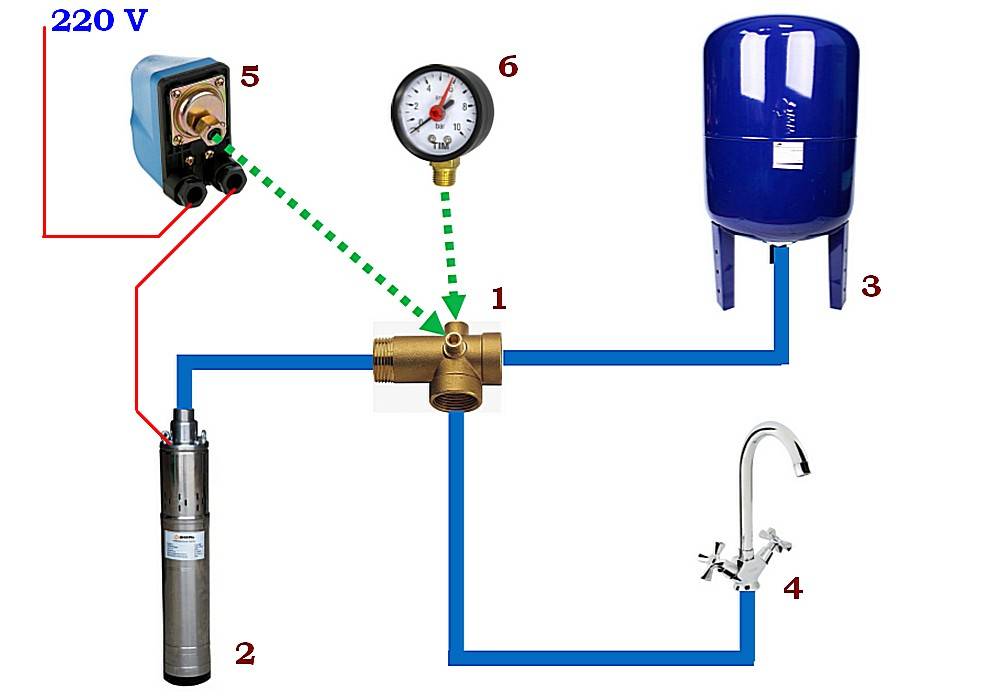

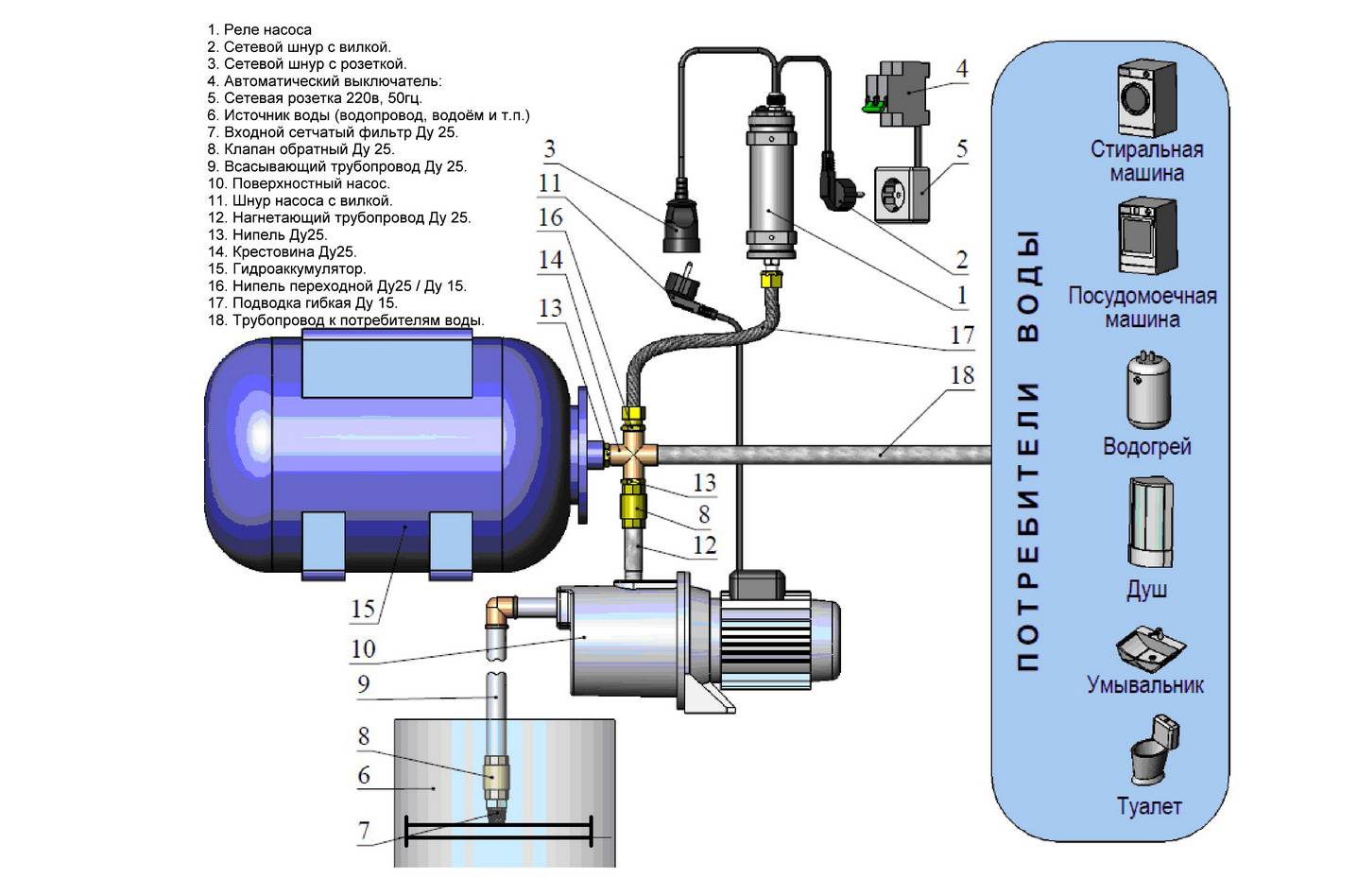

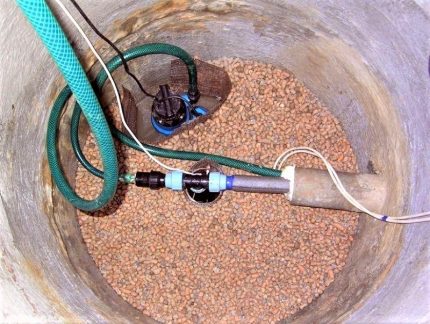

With submersible pump

The submersible or deep type of pump differs from the above option in that it is located in a well or dug well, in other words, in the area from which water is sent to the dwelling, and in the above situation - to the hydraulic accumulator. One detail is very important here - this is a check valve. This element is designed to protect the system from the penetration of liquid back into the well or well. This valve is fixed on the pump next to the pipe. For this purpose, a thread is cut in its cover.

First of all, a check-type valve is fixed, and then the hydraulic accumulator itself is connected to the system.

The schema is as follows:

in order to measure the parameter of the length of the pipe going from the deep-type pump to the extreme point of the well, they basically take a string with a weight;

the load is lowered to the bottom, and on the rope they make a mark on the edge of the well at the top;

after removing the rope, you can calculate the parameter of the length of the pipe from the lower plane to the top;

you need to subtract the length of the well, as well as the distance from the section of the pipe into the soil to the highest mark of the well;

in addition, it is very important to take into account the immediate location of the pump (pump) - it should be located 20–30 cm from the bottom.

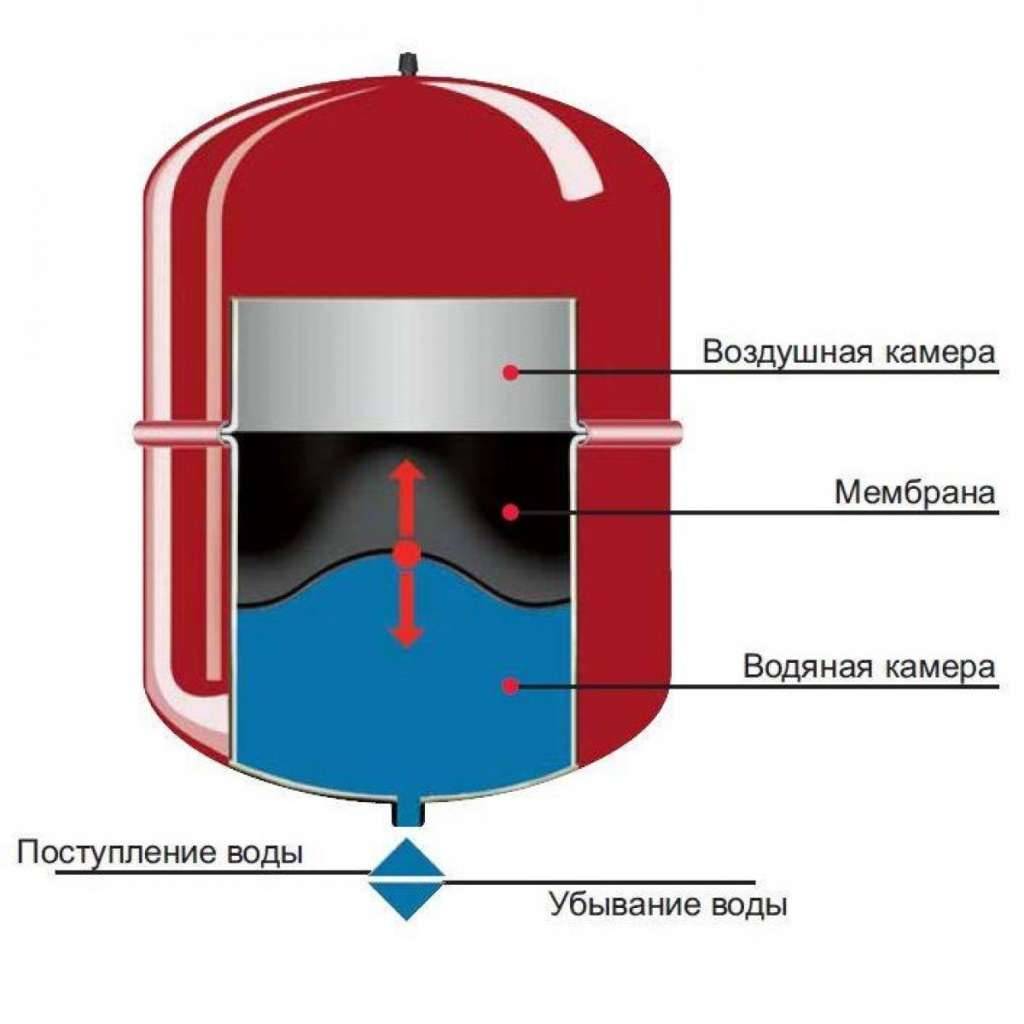

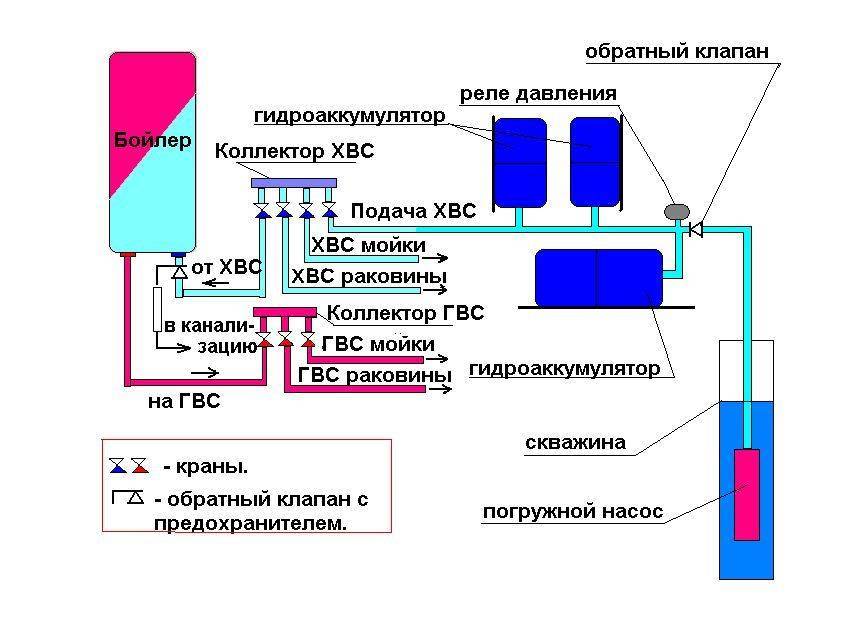

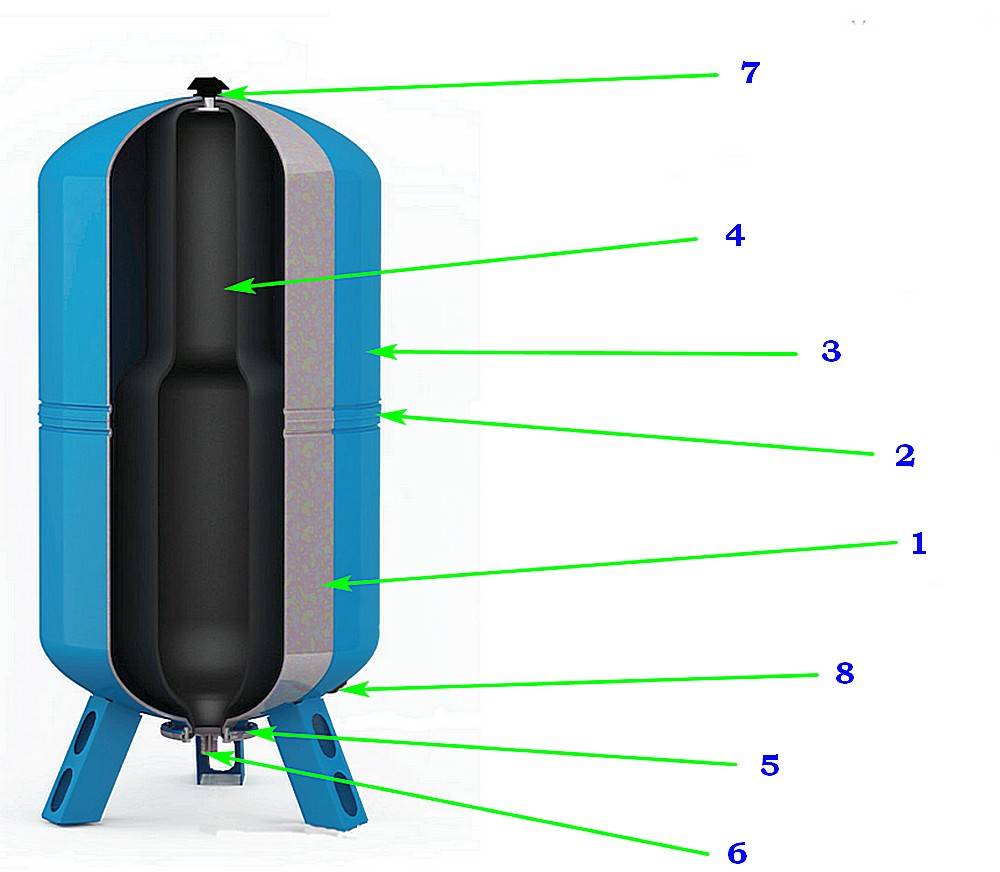

Hydraulic accumulator device

The device of a standard hydraulic accumulator with a replaceable membrane (the most common type) is quite simple. Inside the accumulator there is an elastic membrane of spherical or pear-shaped form.

In operating mode, there is water inside the membrane, and between the walls of the tank and the membrane there is pre-pressurized air or other gas (the pre-injection value is indicated on the label). Thus, water does not come into contact with the walls of the accumulator, but only with the membrane, which is made of a material suitable for contact with drinking water.

The neck of the membrane remains outside the body of the accumulator and is securely attracted to it by a removable steel flange using screws. Thus, the membrane is removable and can be replaced with a new one without much effort.

All hydraulic accumulators have a nipple in their design (as in a car wheel), which is directly connected to the air cavity of the tank. Through this nipple, you can regulate the air pressure inside the tank using a conventional air pump or compressor.

The nipple is located under a protective plastic cap, which is easily unscrewed by hand.

It is important to note that for many manufacturers, membranes in accumulators with a volume of 100 liters or more are attached not only from below (through the flange), but also from above. A special hollow rod passes through the hole in the upper part of the membrane (yes, in addition to the neck, the membrane will have one more hole in the upper part), with a sealing element at one end and a thread at the other

The threaded end is brought out of the tank and is attracted to the latter by a nut. In fact, the part brought out is a threaded fitting.This threaded fitting can simply be plugged or a pressure switch and/or pressure gauge fitted to it.

In this case, the accumulator (as well as the membrane to it) will be called a through passage.

Hydraulic accumulators come in vertical and horizontal versions. Vertical tanks are installed on legs, while horizontal tanks are on legs and have a platform for installing additional equipment. Equipment (pump, control cabinet, etc.). The fundamental point for choosing the layout is the specific installation location.

The principle of operation of the system without a hydraulic tank

The equipment that pumps water works the same way: it takes liquid from a source - a well, a well - and pumps it into the house, to the points of water intake. The pump can be both submersible and surface.

The role of connecting lines is performed by pipelines made of polypropylene pipes or flexible hoses. In the same way, water is supplied to the bathhouse, garage, summer kitchen, swimming pool.

So that water can be used in autumn or early spring, it is recommended to insulate the well, and bury the pipes to a depth of 70-80 cm - then the liquid will not freeze even during frosts

So that water can be used in autumn or early spring, it is recommended to insulate the well, and bury the pipes to a depth of 70-80 cm - then the liquid will not freeze even during frosts

The difference concerns the use of additional devices, such as a hydraulic accumulator, a pressure switch, etc. It is extremely dangerous to install pumping equipment without means of control and adjustment - primarily for the equipment itself.

The simplest example of equipment for providing summer cottage residents with water is the AL-KO garden pump. With it, you can water the plants, organize a shower, fill the pool with water

The simplest example of equipment for providing summer cottage residents with water is the AL-KO garden pump. With it, you can water the plants, organize a shower, fill the pool with water

If you need a large amount of water or a more stable supply, another important element is included in the circuit - a storage tank. First, water enters it, and only then - to consumers.

When using domestic pumps, the liquid volume is usually between 2 and 6 m³/h. This amount is usually enough if the station is connected to a well or well and serves a country house.

When choosing a unit, it should be borne in mind that the absence of a hydraulic tank accelerates the wear of parts, so the equipment must be durable - with a steel or cast iron body coated with anti-corrosion paint.

The pump functions are controlled by a pressure switch responsible for adjusting the pressure. For control, it is easiest to install a pressure gauge, which is usually equipped with automation of pumping stations.

In the absence of a hydraulic accumulator, the pressure switch is connected directly to the pumping station or integrated together with the dry-running switch into the pipeline

In the absence of a hydraulic accumulator, the pressure switch is connected directly to the pumping station or integrated together with the dry-running switch into the pipeline

In addition to equipment for pumping water, you will need an electrical cable, a mains connection point and ground terminals. If the ready-made solution does not meet the requirements, the station parts can be purchased separately, and then assembled at the installation site. The main condition is the correspondence of the elements of the system according to the characteristics.

Tank volume is the main selection criterion

The most important question is how to choose the volume of the accumulator for water supply systems. To answer it, you need to bring together a lot of data. These are the performance of the pump, and the equipment of the house with water-consuming equipment, and the number of people permanently living in the house, and much more.

But first of all, you need to decide whether you need this reservoir only to stabilize the operation of the system as a whole, or whether there is a need for a supply of water in case of a power outage.

Internal cylinders of different volumes

If the house is small and equipped only with a washbasin, toilet, shower and watering tap, and you do not live in it permanently, you can not make complex calculations. It is enough to buy a tank with a volume of 24-50 liters, it will be enough for the system to work normally and be protected from water hammer.

In the case of a country house for permanent residence of a family, equipped with everything necessary for a comfortable life, it is advisable to approach the issue more responsibly. Here are a few ways to help you determine the size of your accumulator.

According to the characteristics of the pump

The parameters that affect the choice of tank volume are the performance and power of the pump, as well as the recommended number of on / off cycles.

- The higher the power of the unit, the larger the volume of the hydraulic tank should be.

- The powerful pump pumps water quickly and turns off quickly if the tank volume is small.

- A sufficient volume will reduce the number of intermittent starts, thereby extending the life of the motor.

To calculate, you will need to determine the approximate water consumption per hour. To do this, a table is compiled that lists all the devices that consume water, their number and consumption rates. For example:

Table for determining the maximum water flow

Since it is almost impossible to use all devices at the same time, a correction factor of 0.5 is used to determine the real flow rate. As a result, we get that you spend an average of 75 liters of water per minute.

How to calculate the volume of a hydraulic accumulator for water supply, knowing this figure, pump performance and considering that it should turn on no more than 30 times per hour?

- Let's say the productivity is 80 l / min or 4800 l / h.

- And during peak hours you need 4500 l/h.

- With non-stop operation of the pump, its power is enough, but it is unlikely that it will work for a long time in such extreme conditions. And if it turns on more often than 20-30 times per hour, then its resource will run out even faster.

- Therefore, a hydraulic tank is needed, the volume of which will allow you to turn off the equipment and give it a break. At the indicated frequency of cycles, the water supply should be at least 70-80 liters. This will allow the pump to run for one minute out of every two, having pre-filled the reservoir.

According to the minimum recommended volume formula

To use this formula, you need to know the settings of the pressure switch that turns the pump on and off. The following picture will help you understand:

Changes in pressure in the accumulator when the pump is turned on and off

- 1 – initial pressure Pair (when the pump is off);

- 2 - water flow into the tank when the pump is turned on;

- 3 - reaching the maximum pressure Pmax and turning off the pump;

- 4 - water flow with the pump turned off. When the pressure reaches the minimum Pmin, the pump is switched on.

The formula looks like this:

- V = K x A x ((Pmax+1) x (Pmin +1)) / (Pmax - Pmin) x (Pair + 1), where

- A is the estimated water flow (l / min);

- K - correction factor from the table, determined depending on the pump power.

Table for determining the correction factor

The values of the minimum (starting) and maximum (switching off) pressure on the relay, you must set yourself, depending on what pressure you need in the system. It is determined by the farthest from the accumulator, and the highly located draw-off point.

Approximate ratios of pressure switch settings

To adjust the pressure switch, you need to know how to pump up the accumulator for water supply systems with air, or bleed the excess. This will require a car pump that connects to the tank through a spool.

Now we can calculate the volume. For example, let's take:

- A = 75 l/min;

- Pump power 1.5 kW, respectively K = 0.25;

- Pmax = 4.0 bar;

- Pmin = 2.5 bar;

- Pair = 2.3 bar.

We get V = 66.3 liters. The closest standard accumulators in terms of volume have a volume of 60 and 80 liters. We choose the one that is more.

It's interesting: How to choose a wood splitter (video)

How is it different from an expansion tank

Hydraulic accumulators are often confused with expansion tanks, despite the fundamentally different problems that these devices solve. An expansion tank is needed in heating and hot water supply systems, since the coolant, moving through the system, inevitably cools and its volume changes. The expansion tank is configured with a “cold” system, and when the coolant warms up, its excess, which is formed due to expansion, has somewhere to go.

As a result, the accumulator is installed in order to get rid of water hammer and extend the life of the system as a whole. In addition, the accumulator has other functions:

Creates a certain supply of water (useful if the power is turned off).

If there are frequent interruptions in water, then the accumulator can be combined with a storage tank

- Reduces pump start frequency. The tank is filled with a small amount of water. If the flow rate is small, for example, you need to wash your hands or wash your face, water starts to flow from the tank, while the pump remains off.It is activated after there is very little water left;

- Maintains stable pressure in the system. In order for this function to be performed properly, an element called a water pressure switch is provided, which is capable of maintaining a given pressure within strict limits.

All the advantages of hydraulic accumulators make this device an indispensable element of any autonomous water supply system in country houses.