- How the hydraulic accumulator works simple and reliable design

- Operating rules

- Types of hydroaccumulator tanks

- Installation rules

- Hydraulic tank type

- Hydraulic accumulator functions

- What should be the pressure in the accumulator

- Pre-check and pressure correction

- What air pressure should be

- Device and principle of operation

- Recommendations for installation and operation

- Types of storage tanks

- Watch the video: Why is there a hydraulic accumulator in the water supply system

- How a hydraulic accumulator works

- Optimal Performance

- Role in the water supply system

- Types of structures and their device

- The principle of operation of the accumulator

- Application area

How the hydraulic accumulator works simple and reliable design

A stable functioning plumbing system of a private dwelling is the merit of its owner. People who have experienced the installation and operation of autonomous water supply networks realize how difficult it is to avoid failures in the supply of water in such complexes. Sometimes just one pressure surge is enough for expensive equipment connected to the water supply (for example, a water heater, a dishwashing machine) to fail. There is only one solution to this problem - the installation of a hydraulic accumulator. It maintains the set pressure in the system, creates a certain supply of water and eliminates the risk of damage to household electrical equipment. The need to install such a device is obvious.

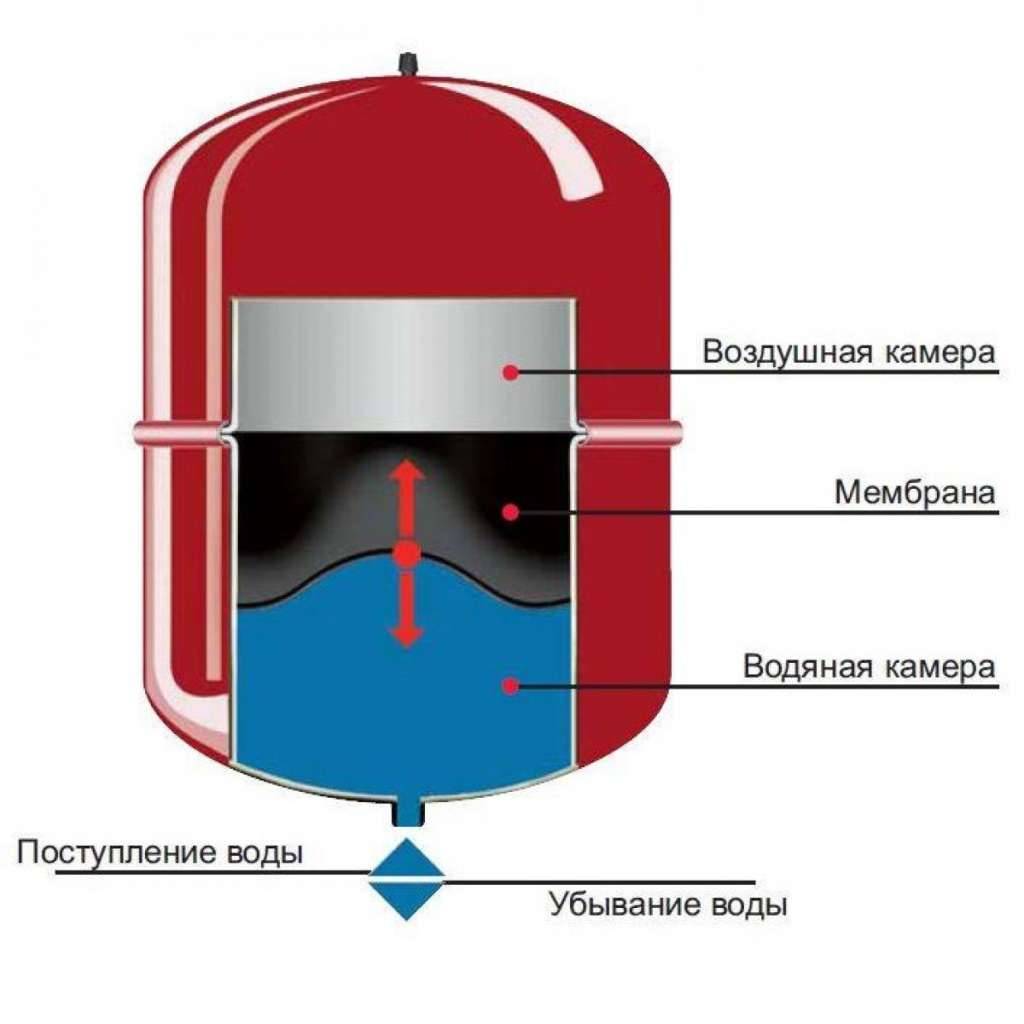

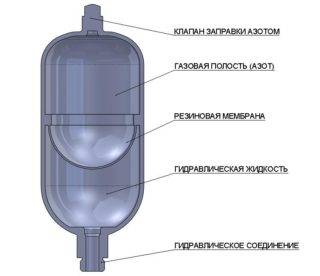

The device of the accumulator is quite simple. It is made in the form of a metal tank, inside which a rubber (rubber) membrane is installed. The latter is visually similar to a pear. The membrane is fixed on the body of the hydraulic tank by means of a special flange with a branch pipe. Water accumulates in the bulb under pressure. The space between the battery case and the membrane is filled with compressed air (if we are talking about household appliances) or an inert gas composition (industrial hydraulic tanks). The pressure in the system is maintained at the level of 1.5–3 bar. Air can be pumped into a hydraulic accumulator at home using a conventional car or even a bicycle pump.

The considered devices are usually divided into three types:

- 1.

For cold water supply systems. The device supplies water and accumulates it, protects pumping equipment from early wear due to frequent switching on and off of the system, protects electrical equipment in the house from water hammer. - 2.

For hot water. Such a hydraulic accumulator for water supply systems can work without problems in high-temperature environments. - 3.

Expansion tanks. They are designed for closed water heating systems.

The device and principle of operation of all these devices are identical. We will describe how such equipment works below.

Operating rules

Having installed the accumulator, you must follow three simple rules in the future:

- Use the ba only for its intended purpose, in accordance with the manufacturer's specifications. This applies above all to the fluid temperature and operating pressure range.

- Regularly monitor the settings of this device. This is done using tank piping pressure gauges and pressure monitoring devices on the pump and control relay. When fixing abnormal indicators, you need to stop the operation of the equipment (primarily the pump) and either find the cause of this failure yourself or contact a certified specialist.

- Annually perform not only visual, but also internal inspection of the device. If necessary (traces of wear), replace its parts with new ones. We are talking about the membrane (cylinder), nipple, spool and piping pressure gauges.

Types of hydroaccumulator tanks

Hydraulic accumulators differ in the type of installation: they are horizontal and vertical. Vertical accumulators are good because it is easier to find a suitable place for their installation.

Both vertical and horizontal varieties are equipped with a nipple. Together with water, a certain amount of air also enters the device. It gradually accumulates inside and “eats” part of the volume of the hydraulic tank. In order for the device to work properly, it is necessary to bleed this air from time to time through this same nipple.

According to the type of installation, vertical and horizontal hydraulic accumulators are distinguished. They have some differences in the maintenance process, but the choice is largely influenced by the size of the installation site.

In hydraulic accumulators that are installed vertically, a nipple is provided that is designed specifically for this purpose. Just press it and wait for the air to leave the device.With horizontal tanks, things are a little more complicated. In addition to the nipple for bleeding air from the tank, a stopcock is installed, as well as a drain to the sewer.

All this applies to models capable of accumulating a liquid volume of more than 50 liters. If the capacity of the model is less, then there are no special devices for removing air from the membrane cavity, regardless of the type of installation.

But the air from them still needs to be removed. To do this, water is periodically drained from the accumulator, and then the tank is refilled with water.

Before starting the procedure, turn off the power supply to the pressure switch and the pump, or the entire pumping station if the hydraulic tank is part of such a device. After that, you just need to open the nearest mixer.

The water is drained until the container is empty. Next, the valve is closed, the pressure switch and the pump are energized, the water will fill the tank of the accumulator in automatic mode.

Hydraulic accumulators with a blue body are used for cold water, and red ones for heating systems. You should not use these devices in other conditions, since they differ not only in color, but also in the material of the membrane, and the ability to tolerate a certain level of pressure.

Usually, tanks intended for autonomous engineering systems differ in color: blue and red. This is an extremely simple classification: if the hydraulic tank is blue, then it is intended for cold water supply systems, and if it is red, it is for installation in the heating circuit.

If the manufacturer has not designated its products with one of these colors, then the purpose of the device should be clarified in the technical data sheet of the product.In addition to color, these two types of accumulator differ mainly in the characteristics of the material used in the manufacture of the membrane.

In both cases, it is a high quality rubber designed for food contact. But in blue containers there are membranes designed for contact with cold water, and in red ones - with hot water.

Very often, a hydraulic accumulator is supplied as part of a pumping station, which is already equipped with a pressure switch, pressure gauge, surface pump and other elements.

Blue devices are capable of withstanding higher pressures than red containers. It is not recommended to use accumulators designed for domestic hot water systems for cold water and vice versa. Incorrect operating conditions will lead to rapid wear of the membrane, the hydraulic tank will have to be repaired or even completely replaced.

Installation rules

When installing a hydraulic accumulator, you must strictly adhere to certain rules.

When installing a hydraulic accumulator, you must strictly adhere to certain rules.

The first thing to do is to select a site in the heating network where the device will be mounted.

Experts strongly advise mounting the expansion tank in the return pipe through which chilled water circulates.

Important! The unit must be installed before the pumping equipment. In order to ensure maximum protection of the network from sudden pressure drops of the working fluid, a safety valve must be installed at the outlet of the heating device.

In order to ensure maximum protection of the network from sudden pressure drops of the working fluid, a safety valve must be installed at the outlet of the heating device.

The valve has the same purpose as the hydraulic accumulator, but it is able to withstand higher pressure drops.

The expansion tank normalizes the operation of the heating system with slight surges in water pressure.

Before proceeding with the installation, you need to select the installation location of the device. Do not forget that the device must be freely accessible, nothing should prevent you from getting to the air compartment control valve.

Shut-off and control valves cannot be installed between the expansion tank and the pump; they can significantly modify the hydraulic resistance.

In the room where the accumulator will be located, the air temperature must be at least 0 degrees. The surface of the device is not allowed to be exposed to mechanical loads.

The actuation of the reducer for removing air from the heating system of a private house must be carried out in accordance with the parameters of the heating system.

If you follow all the above recommendations, you will be able to install an expansion tank on your own, without outside help.

In the process of performing work, you should strictly adhere to the connection rules, accurately calculate the optimal volume of the tank and use products that are made of high quality materials.

Why do we need a hydraulic accumulator in heating systems, how to install and configure it - we suggest watching it in the video.

Hydraulic tank type

There are two types of such devices on the market:

- vertical;

- horizontal.

Horizontal tank

There are no fundamental differences in their work. The main difference is in the layout. Therefore, first of all, you need to focus on the convenience of placement in the room.After all, you need to take care not only of installation - in the future, the container will need to be serviced, which means that it should have easy access.

Another point is the release of accumulated air. In vertical type models, a special valve is provided located at the top of the tank. And for horizontal ones, you will have to mount an additional crane.

However, the main thing is to make sure that the chosen model generally has such an opportunity. After all, if the tank does not provide a special outlet for discharging air accumulated during the operation of the system, it will be possible to remove it only by completely draining all the water from the tank.

Hydraulic accumulator functions

A hydraulic accumulator, also called a membrane tank or hydraulic tank, performs a number of functions:

- Maintains the pressure in the plumbing system at a stable level.

- Protects the water supply from sudden changes in water pressure. In the event of drops, strong temperature fluctuations in the water occur if several taps are turned on at the same time, for example, in the kitchen and in the bathroom. The hydraulic accumulator is able to cope with such issues.

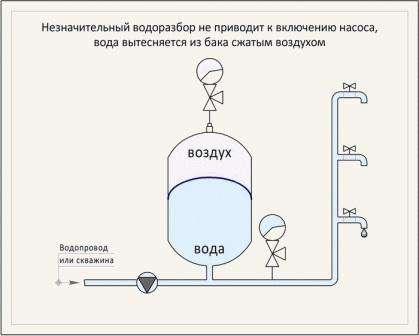

- Saves the pump from wear and tear due to frequent use. There is a certain volume of water in the hydraulic tank, so the pump does not start working for every opening of the tap, but only when the water is completely used up. Each pump has a standard indicator of the number of starts per hour. The use of a hydraulic tank allows you to increase the number of unclaimed pump connections, and this affects its service, increasing the operating period.

- Protects the plumbing system from probabilistic water hammer that occurs at the time of connecting the pump, which can seriously damage the pipeline.

- Allows you to create a certain amount of water in the system. Thanks to this, you will always have water, even during periods of power outage, and this is not uncommon in our world. This feature is especially useful for owners of country houses.

What should be the pressure in the accumulator

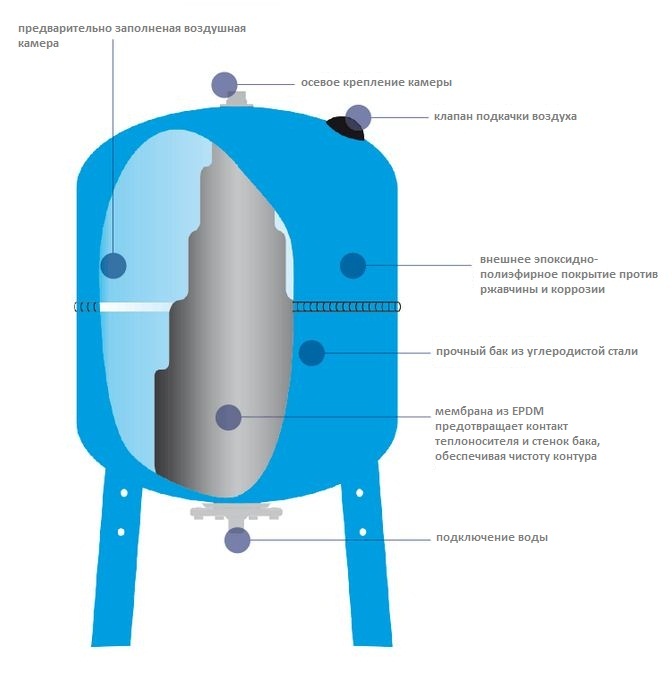

Compressed air is in one part of the accumulator, water is pumped into the second. The air in the tank is under pressure - factory settings - 1.5 atm. This pressure does not depend on volume - and on a tank with a capacity of 24 liters and 150 liters it is the same. More or less may be the maximum allowable maximum pressure, but it does not depend on the volume, but on the membrane and is indicated in the technical specifications.

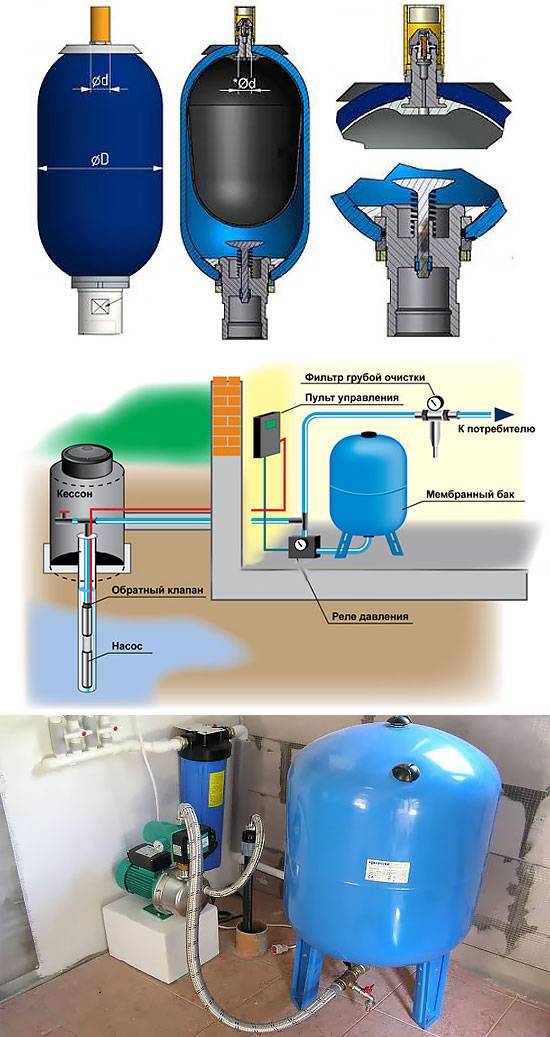

The design of the hydraulic accumulator (image of flanges)

Pre-check and pressure correction

Before connecting the accumulator to the system, it is advisable to check the pressure in it. The settings of the pressure switch depend on this indicator, and during transportation and storage the pressure could drop, so control is very desirable. You can control the pressure in the hydraulic tank using a pressure gauge connected to a special inlet in the upper part of the tank (capacity from 100 liters or more) or installed in its lower part as one of the piping parts. Temporarily, for control, you can connect a car pressure gauge. The error is usually small and it is convenient for them to work. If this is not the case, you can use the regular one for water pipes, but they usually do not differ in accuracy.

Connect pressure gauge to nipple

If necessary, the pressure in the accumulator can be increased or decreased. To do this, there is a nipple at the top of the tank.A car or bicycle pump is connected through the nipple and, if necessary, the pressure is increased. If it needs to be bled off, the nipple valve is bent with some thin object, releasing air.

What air pressure should be

So the pressure in the accumulator should be the same? For the normal operation of household appliances, a pressure of 1.4-2.8 atm is required. To prevent the tank membrane from tearing, the pressure in the system should be slightly higher than the tank pressure - by 0.1-0.2 atm. If the pressure in the tank is 1.5 atm, then the pressure in the system should not be lower than 1.6 atm. This value is set on the water pressure switch, which is paired with a hydraulic accumulator. These are the optimal settings for a small one-story house.

If the house is two-story, you will have to increase the pressure. There is a formula for calculating the pressure in a hydraulic tank:

Vatm.=(Hmax+6)/10

Where Hmax is the height of the highest draw point. Most often it is a shower. You measure (calculate) at what height relative to the accumulator its watering can is, substitute it into the formula, you get the pressure that should be in the tank.

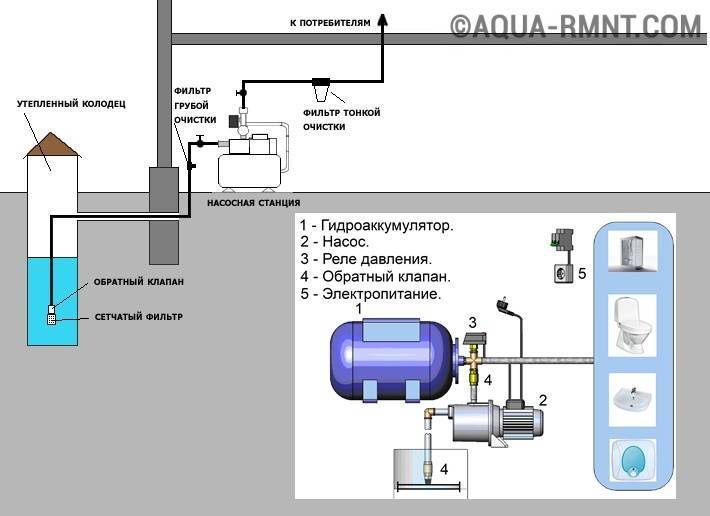

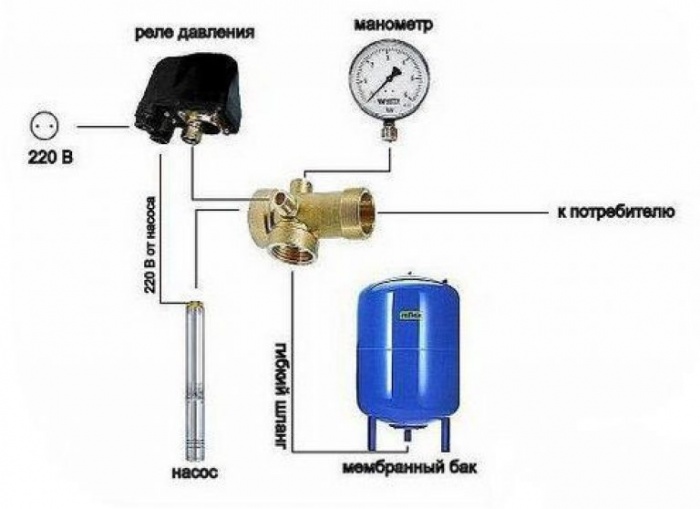

Connecting a hydraulic accumulator to a surface pump

If the house has a jacuzzi, everything is more complicated. You will have to select empirically - by changing the relay settings and observing the operation of water points and household appliances. But at the same time, the working pressure should not exceed the maximum allowable for other household appliances and plumbing fixtures (indicated in the technical specifications).

Device and principle of operation

Let's take a closer look at how this device works.

A hydraulic accumulator is a sealed container made of metal, inside of which there is an elastic membrane or cylinder.

Between these components and the walls of the skin, due to the compressed air pumped into the free space, pressure of a certain force is created.

Water has no points of contact with the surface of the body.

Because it is located in a special compartment called the camera-membrane.

It is made of rubber called butyl, which is not susceptible to the negative effects of pathogenic cocci.

In addition, this material complies with the sanitary and hygienic standards that apply to drinking water.

There is a pneumatic valve in the air compartment. Its purpose is to regulate pressure.

The liquid penetrates into the accumulator through a special connecting nozzle with a threaded connection.

The device must be mounted in such a way that, if repair or maintenance work is necessary, it can be quickly disassembled without draining the water from the system.

The cross-sections of the discharge pipe and the connecting pipeline must correspond exactly to each other.

Thus, it will be possible to insure against unforeseen hydraulic losses in the pipeline.

In the membranes of expansion tanks, the volume of which is 100 liters or more, a special spool is mounted, through which the air released from the water is bled (read about Mayevsky's automatic faucet in this article).

In hydroaccumulators of small displacement, such a valve is not provided.

Permissible pressure in the air valve of the device is 2 atmospheres.

Recommendations for installation and operation

It is not difficult to install a hydraulic tank, it is simply connected to the plumbing system after the pump. Before entering the device, it is necessary to put a good filter to purify the water from impurities. They can accumulate inside and damage the membrane.

A hydraulic accumulator designed for autonomous water supply is best used with a pressure switch that will control the operation of a submersible pump

You need to choose the right place for installation. The GA should stand where you can freely approach for inspection of the device and its maintenance. Over time, it may be necessary to repair the device, so it does not hurt to think in advance about the procedure for dismantling it and the difficulties that may arise at this time.

It is very important that the dimensions of the nozzle and the water pipe match. This will avoid hydraulic losses due to the narrowing of the route in some area.

The use of adapters is acceptable, but not recommended. During the inflow and outflow of water, the membrane tank may vibrate.

It is recommended to fix it to the base through shock-absorbing pads. Connection to the water supply is carried out with a flexible eyeliner. You should make sure that the device is correctly set horizontally and vertically, distortions are unacceptable.

It is necessary to take care in advance about the possibility of disconnecting the HA from the water supply in such a way that it is not necessary to completely drain the water from the system. This requirement is realized by installing a conventional shut-off valve. For small containers with a capacity of up to 10 liters, in which there is no nipple, it is also necessary to provide for the installation of a drain cock.

You can read more about how to connect a hydraulic accumulator to a water supply system in this material.

Maintenance of the hydraulic tank is reduced to a careful inspection of the body and control of the pressure in the air compartment. Sometimes you need to pump air or bleed it to restore the correct performance. Usually the pressure should be about two atmospheres or a little less. In addition, the air that has accumulated behind the membrane in the compartment where water is stored should be removed.

Sometimes you can even install an automatic air vent here. If there is no hole for this procedure, you need to disconnect the GA from the water supply and completely empty it through the drain tap. The air will come out of the tank along with the water. Then it remains just to turn on the pump again so that water begins to flow into the tank again.

Speaking about how a membrane accumulator works, it is worth noting that the most common breakdown in a GA is a membrane breakthrough. This elastic element is subjected to constant tension and compression, and therefore fails over time.

Here are signs that the membrane has ruptured:

- water comes out of the tap with sharp jerks;

- the pressure gauge needle “jumps”;

- after the contents of the “air” compartment are completely bled, water flows out of the nipple.

The last point allows you to find out exactly whether the problem is really with the membrane. If the water from the nipple does not flow out, and water enters the system weakly, most likely, the case is depressurized. It is necessary to carefully examine it, find and repair cracks.

The membrane may deteriorate due to wear or misuse. It needs to be completely replaced, it is useless to repair this element.

Replacing the membrane is not difficult, but you need to select exactly the same element as the damaged one, since it is designed specifically for this particular HA.

To carry out repairs, you need:

- Disconnect the device from the plumbing system.

- Drain water, bleed air.

- Loosen the fixing screws.

- Remove damaged membrane.

- Install the correct item.

- Fix it with screws.

- Install the GA in place and connect it to the system.

The most difficult part of this procedure is tightening the screws. It should be uniform, so it is recommended to twist them, making one turn alternately on each element. This tactic will allow you to properly fix the membrane on the case and prevent its edge from slipping inward.

Some inexperienced craftsmen, in an effort to improve the quality of the connection, apply a sealant to the edge of the membrane. This should not be done, as the composition can destroy the rubber and cause the opposite effect.

Types of storage tanks

Membrane accumulator

Membrane accumulator

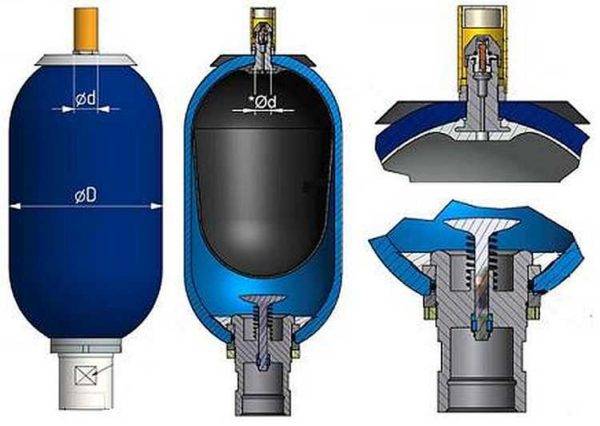

For domestic needs, two types of tanks are used:

- Membrane. Rubber is fixed in a retaining ring. In such a tank, the liquid comes into contact with the walls, but only in one half of the accumulator. The second half is occupied by an air mixture that can be bled or pumped in as needed.

- Balloon. The liquid enters the rubber pear, fixed to the neck at the entrance to the tank. Water does not come into contact with the walls and does not affect the metal. On the other hand, there is a possibility of a pear rupture and fluid leakage through the nipple. In this model, the membrane can be replaced.

There is also a variety without a membrane, but for use in a private house in a water supply system, such a hydraulic accumulator device is inconvenient. The air will mix in the tank and leave with the water, so it will have to be constantly monitored and pumped. You need to do this daily.Membraneless tanks are suitable for the accumulation of water for irrigation, outdoor showers.

Watch the video: Why is there a hydraulic accumulator in the water supply system

In a hydraulic accumulator designed for a water volume of more than 100 liters, a valve is provided that bleeds the air accumulated in the water. For a smaller hydraulic tank, without such a valve, devices are placed in the water supply system that allow air to be bled. It can be either a tee or a tap that shuts off the central water main.

In general, the accumulator should be mounted in such a way that it can be easily disassembled for repair or maintenance work, without draining all the water from the system.

How a hydraulic accumulator works

The operating principles are as follows:

- Water is supplied by a pump to the membrane of the hydraulic tank, thanks to the pressure that has been created;

- As soon as the pressure has reached the desired level, the pump turns off, which means that the water stops flowing;

- After the next water intake, the pressure gradually decreases, so the pump automatically turns on, starting to supply water to the membrane.

Scheme of operation of the hydraulic accumulator

Scheme of operation of the hydraulic accumulator

It has been established that the maximum efficiency of the hydraulic tank directly depends on its total volume. There is the possibility of regulating the operation of the pressure switch.

During operation, the air dissolved in the aquatic environment accumulates in the membrane of the device. This reduces the efficiency of the membrane tank. To correct the situation, it is necessary to carry out preventive work, during which air is bled.

The volume of the hydraulic tank, the frequency of its use affect the number of preventive maintenance carried out.On average, such work is carried out every three months, or even once a month.

Useful article: Sewerage pumps in a private house

The connection diagram of the accumulator directly depends on its purpose. The battery devices are not like a regular water tank, so special knowledge and skills are required to install them. Installation should be carried out by an experienced specialist, since the operation of the entire plumbing system directly depends on him.

Optimal Performance

In addition to the capacity, just as important is a suitable pressure indicator in an unfilled reservoir. This value is usually marked on the body of each individual model. It will not be difficult to calculate which parameter will be ideal in a particular case. It is detected based on hydrostatic pressure, because it depends on the height to which it is necessary to raise the liquid. For example, if the height of the pipes in the dwelling reaches 10 m, then the pressure parameter will be 1 bar

In addition, it is very important to consider that the working pressure of the hydraulic tank should not be more than the starting pressure of the pump.

For example, to ensure a stable supply of liquid in a house with two floors, you will need a high-quality hydraulic tank with an operating power level of 1.5 bar and a top power of up to 4.5 bar. In most cases, manufacturers form an air pressure in the accumulator of 1.5 bar. However, in certain cases, the values may be different. That is why, before starting to use the unit, you need to check these values using a pressure gauge. This part connects to the hydraulic accumulator nipple.

Role in the water supply system

Before dwelling on the pressure parameters in the accumulator, it is necessary to consider its main role in the water supply. The first purpose of this object is to support, as well as a gradual change in the pressure level of the fluid present in the system.

In addition, the accumulator performs such important functions as:

- provides reliable protection against water hammer (in this embodiment, a change in fluid pressure is meant, which was caused by a very rapid change in its speed);

- responsible for the presence of a minimum water reserve;

- limits the repeated-short-term start of the pump.

From the coverage of the listed functions, we can conclude that the hydraulic accumulator makes it possible to use a pressure switch, as well as automate the process of supplying fluid. If a hydraulic accumulator is not present in the system, then the relay will not be able to function correctly, since a rapid change in pressure in the system will provoke its frequent operation.

Types of structures and their device

Depending on the pump used and the location of the accumulator for the pumping station, horizontal and vertical installation devices are used in everyday life.

Such types of molding allow you to fit them into the space of any technical room. It is necessary to install the unit with the expectation of its convenient maintenance. It is necessary to provide access for repairs and, if necessary, draining water.

Vertical and horizontal accumulators fit into any room

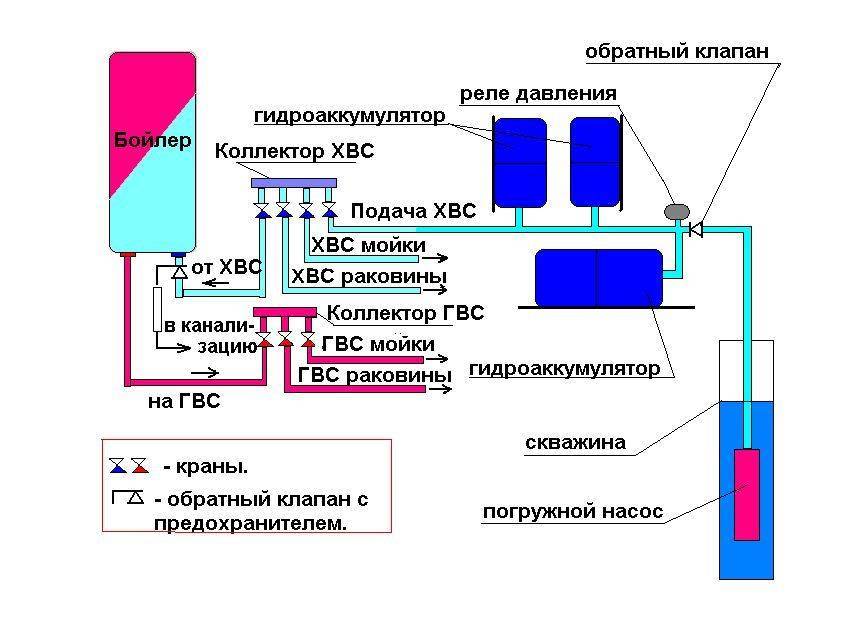

It is most rational to connect horizontal hydraulic tanks to external pumps, and vertical ones to submersible ones, but in any case, the final decision must be made on site, depending on the parameters of the entire system.

In designs with a vertically located cylinder, the opening with the valve is located in the upper part of the unit, because air collects at the top of the cylinder. In horizontal hydraulic tanks, there is usually no such device. Additional installation of the pipeline from the ball valve, drain pipe and nipple is required.

Water is drained by a standard tap at the inlet

The principle of operation of the accumulator

The rubber flat membrane plays the same role in some modifications. Pear-shaped cylinders are mounted near the neck. The diaphragm divides the tank into two parts. It is installed horizontally in the middle of the tank. One part of the volume is filled with water, the other with compressed air.

Hydraulic tanks are used in heating systems, as well as supplying cold and hot water. According to the principle of use, they differ in colors. Hot water and coolant - red tank. Cold water is blue. There are models that are a cylindrical tank mounted vertically. For convenience, modifications have been developed, horizontally oriented, which are mounted on supports.

The device assumes the presence of nipples. One of them is located behind, and is designed for pumping air. The other is for bleed. Initially, the pressure in the air chamber is required to be 1.5 bar. This will turn on the pumping station. Models differ according to what air pressure must be to turn it off. Usually it is 3.0 bar.

The scheme of work is as follows:

- Air is forced into the air chamber.

- Pressure squeezes water into the system, directing it to the consumer.

- As the liquid flows, the air pressure drops as the bulb expands and the diaphragm bulges.

- The relay is activated, the pump is turned on, the water supply is replenished, the air pressure is stabilized.

The cycles are repeated, and as a result, the homeowner can always use water without worrying that the pressure will become insufficient or too strong.

Application area

A hydraulic accumulator can be installed not only in a private house, but also in a high-rise building, so that during a water cut in the city, residents have a small supply. This allows you to maintain pressure and use household appliances - a washing machine or dishwasher.

A hydraulic accumulator with a membrane resistant to hot temperatures is used in the hot water supply system as an expansion tank, so when buying, you need to specify what function it will perform. The membrane for cold drinking water will not withstand boiling water. Rubber is also different - in the hot water supply it is technical, in the water supply - food. Hydraulic tanks are connected to the boiler and to the double-circuit boiler.

In addition to domestic use, HA is used in many industries, for example, in the engineering industry.