- The best manual crossbow type pipe benders

- ZUBR Expert 23521-H6

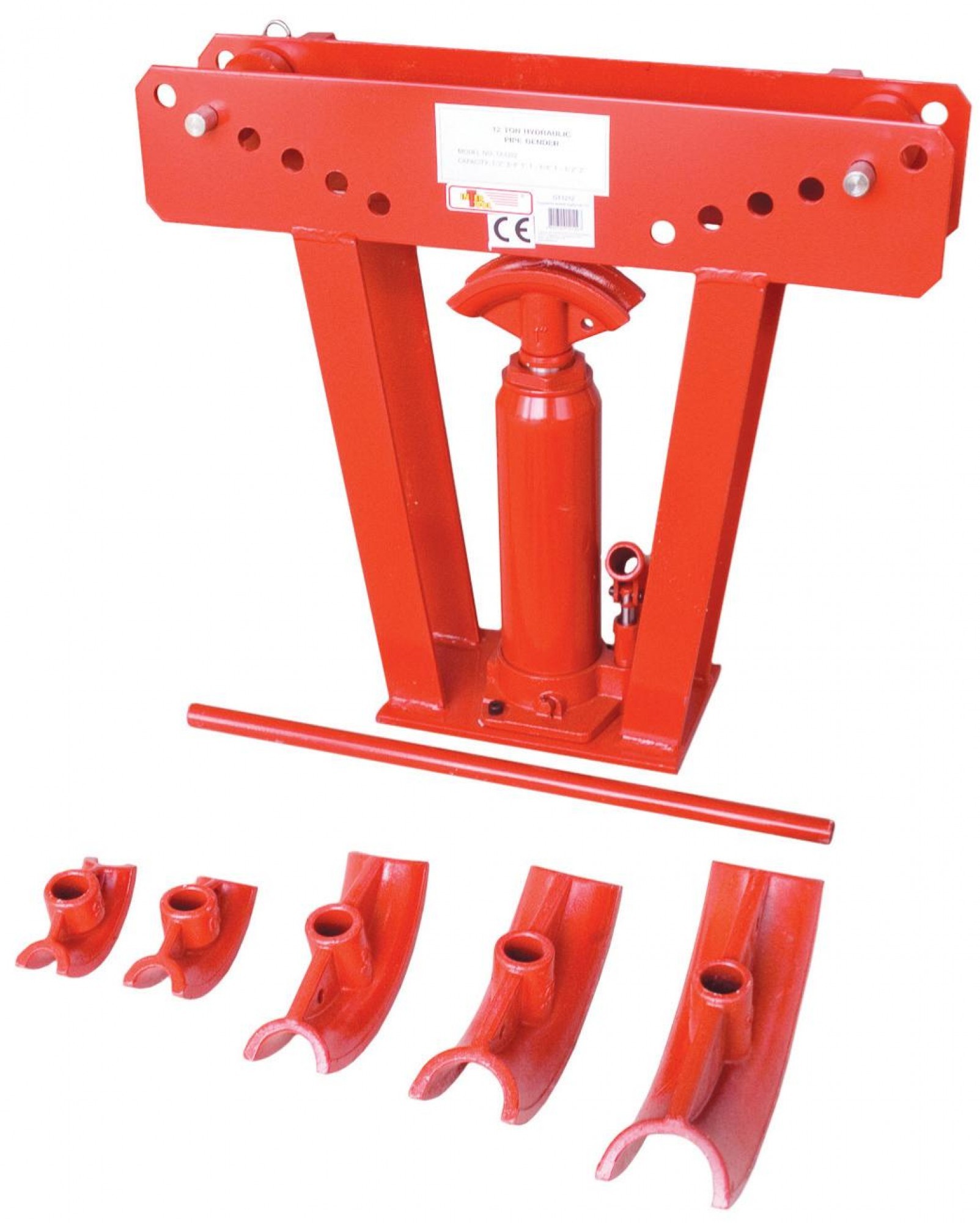

- Types of pipe benders with hydraulics

- Hydraulic pipe benders

- Pipe bender manufacturers

- With induction heating.

- Device and principle of operation

- The best electric pipe benders

- Ridgid 965 26-42

- Rothenberger Robend 4000

- Hydraulic pipe bender and its features

- 2 Stalex MHPB-1A HHW-1A

- How to make a snail pipe bender?

- Necessary materials and tools

- The assembly process of the snail pipe bender

- Structural design of pipe benders

- How to use?

- The best manual pipe benders

- Smart&Solid BendMax-300

- Rothenberger "Minibend", for pipes 1/4-5/16-3/8″

- "Yato", 6-10 mm

- Pipe bending by rolling

The best manual crossbow type pipe benders

ZUBR Expert 23521-H6 | 9.4 Rating Reviews Quite a normal pipe bender for this money, there are no problems in reliability so far, it’s definitely suitable for a copper. |

| 12 000 Doesn't it remind you of anything? Indeed, the “German type” is similar to the “Russian type” pipe bender, even with markings, not to mention the design. Only the coating differs (electroplating instead of paint, which is not particularly important) and the equipment: Kraftool has two additional “devices” that allow you to bend the pipe not “away from you” with a radius, but “towards you”. However, the need for this arises not to say that often, but in Kraftool stores it usually costs decently more than the Zubr with a similar set of punches. So, if you get a discount on some promotion, you can think about buying, otherwise the Zubr pipe bender definitely gets a higher rating: why pay more for the same thing? Main advantages: Possibility to reverse bending direction Minuses: Expensive two extra cast parts are obtained | 9.1 Rating Reviews I use it mainly with half-inch copper, while the effort is quite normal - if you have to do a lot of bends at a time, then your hands do not fall off. |

Types of pipe benders with hydraulics

All existing hydraulic pipe benders can be divided into two types:

- with a mechanical drive;

- with electric drive.

According to the dimensions and method of installation, they are divided into mobile and stationary.

Manual systems include a tool that forms the power traction of the actuator due to the user's muscular energy. Figuratively, this version of the tool looks simple: the design contains a hydraulic cylinder pump handle, which must be manually actuated.

Image gallery

Photo from

The main parts of a hydraulic pipe bender are an oil pump with a piston that presses on the bending frame. To fix the pipe, the tool is equipped with stops

The use of a hydraulic pipe bender allows the simplest way to bend the pipe without deformation of the section, applying a minimum of muscle effort

Even a small bending machine makes it possible to bend pipes for assembling communications on an industrial scale

Pipe benders are selected so that its design allows you to quickly and easily bend pipes from a certain type of material. The simplest and smallest tool is designed for manual deformation of copper and aluminum pipes.

Bending of steel water and gas pipes is carried out on stationary large-sized machines, the hydraulics and stability of which are designed for such operations.

Significantly facilitate and speed up the process of bending water and gas steel pipes allows equipping a hydraulic pipe bender with an electric drive

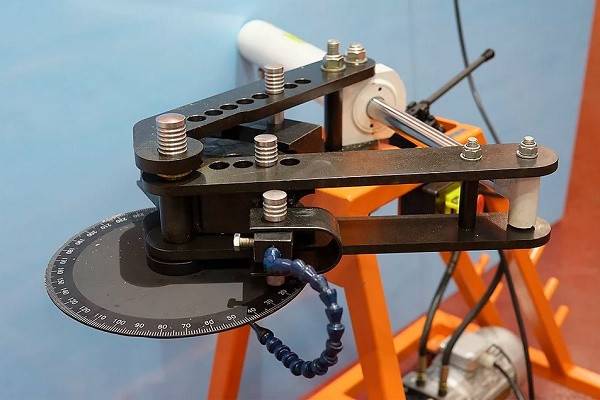

If high-precision bending of pipes is required, it is better to purchase a machine with a template stamp. The presence of a scale will ensure bending with a given radius

The mobile tool, which is used in repair work directly at the facility, is supplied with replaceable segments. They are changed depending on the required bending radius.

Structural parts of hydraulic pipe bender

Simplify and make work easier

Bending of water and gas pipes on an industrial scale

Pipe bender for copper and aluminum pipes

Stationary pipe bender

Equipping the pipe bender with an electric drive

Bending machine with template stamp

Portable Bending Tool Accessories

Automatic systems exclude the use of manual force, but they also do not show any special difficulties of mechanization. The pump handle on the hydraulic cylinder is simply replaced by an electric drive.

Standard design of a pipe bender equipped with a hydraulic cylinder. According to this principle, many models of manual action from different manufacturers are designed.

On such a pipe bender, the reciprocating movements of the pump rod are driven by an electric motor.

Modified manual model of pipe bending tool. Instead of a lever for manual action, a small-sized electric motor of low power is used here.

Mobile structures include both manual and automated tools. As a rule, these devices are lightweight, compact, convenient for transportation.

But the mobility and compactness of devices somewhat limits their technical characteristics.

The mobile tool is distinguished by small overall dimensions, relatively low weight, and the ability to connect to a household electrical outlet. However, there are technical limitations

Stationary pipe benders are also represented by manual (lever) structures or equipped with an electric drive (often three-phase). Here, quite a powerful overall technique is already noted, designed to perform a bend of strong, durable products.

Stationary structures are rigidly installed in one place without the possibility of their rapid transfer.

Stationary hydraulic pipe benders are powerful systems capable of bending large diameter pipes. They are usually used for industrial and production needs.

Hydraulic pipe benders

The principle of operation of a hydraulic pipe bender is similar to the mechanism of action of a hydraulic press or a jack. Due to the high pressure on the rod, it copes with products with a diameter of up to 8 cm. This allows the use of a hydraulic pipe bender on construction sites, in the construction of modular structures, laying pipelines and performing other installation operations.

Advantages of hydraulic pipe benders:

- High performance.

- Independence from power sources.

- Versatility due to the combination of the advantages of manual pipe benders and electric ones.

- Ease of use.

Pipe bender manufacturers

The fame of the manufacturer is an important aspect, given that you can quickly pick up a tool, skipping unreliable models. This rating contains products of the following companies:

- Stayer is a trademark of the German hand tool manufacturer Kraftool.The products are manufactured at advanced high-tech factories, which is why it is the standard of quality.

- Force is a company founded in the mid-80s. Actively produced professional tools for construction work. Within 10 years, it has become one of the leaders in the manufacture of reliable, high-quality pipe benders.

- TIM is a manufacturer of heating, plumbing, air conditioning and renewable energy systems for small and large businesses. The products are known for their high quality, which ensures their active service for many years.

- Zubr is a Russian manufacturer that has been actively manufacturing products since 2002. Manufactures power tools and gardening equipment. Products are widely distributed in the CIS countries and beyond.

- Kraftool is a German manufacturer with a worldwide reputation. Manufactures high quality tools at an affordable price. Gained fame due to the convenience of the manufactured equipment, noted by many builders.

- Ridgid is a manufacturer of maintenance products for the pipe industry. Provides a wide range of convenient, practical tools, popular in the Russian market.

- Rothenberger is a brand with half a century of history. During this European company has produced many models of equipment and building tools. They are characterized by convenience and reliability, valued among builders.

With induction heating.

There are also pipe benders with induction heating. Their drive can be electric and/or hydraulic. This equipment heats the workpiece at the place of deformation, after which bending is carried out. This prevents metal breakage.With the help of such machines, it is even possible to work with pipes made of spring steels, which usually break when stretched or squeezed. This equipment is the most expensive. When using it, you must strictly adhere to safety precautions. The workpiece is heated almost red-hot, so if you touch it, then the burn is guaranteed. In this regard, it is imperative to have personal protective equipment, in particular gloves. If the bending of an old pipe with rust on the surface is carried out, then there is a possibility that hot scale may fly off during deformation, so it is advisable to use a mask or glasses.

Pipe bender with induction heating

Device and principle of operation

The main distinguishing feature of such devices is the presence of a hydraulic cylinder. It is the part that affects the pipe during its bending. This allows you to process products without any effort. The pressure exerted by hydraulics on the pipe is 10–12 tons. In addition, each hydraulic device incorporates special supporting elements - shoes. Their size is selected according to the diameter of the bent products. The function of the support shoes is to securely fix the workpieces during the bending process.

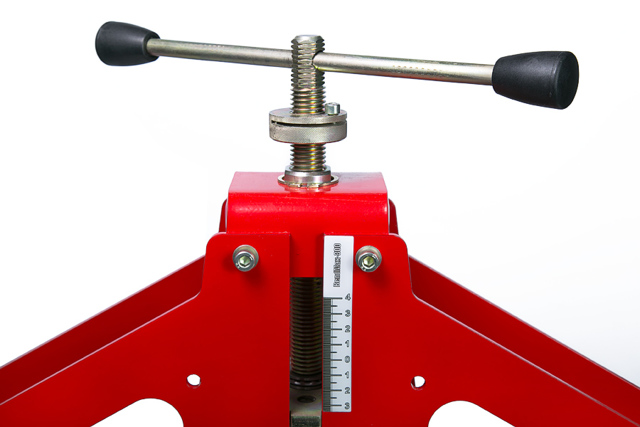

The bending itself goes like this: a hydraulic cylinder shifts the support shoes that fix the part, resulting in an even bend in its center. Hydraulic devices are often equipped with special marks with the designation of angles, which makes it much easier to navigate the workflow and make very precise pipe bends.

The best electric pipe benders

These models are powered by electricity.For bending in this case, no human force is required: the tool does everything on its own. Such tools are often used to perform a large amount of work, are used in the manufacturing sector.

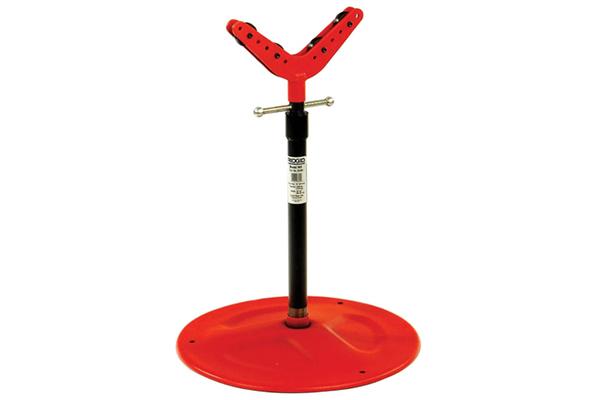

Ridgid 965 26-42

Adjustable roll groover support capable of cooperating with pipes up to 300mm in diameter. It is used together with threading machines used for threading, roll groovers, as well as electric pipe cutters and the like. The case can be adjusted in height (from 26 to 42 inches). It is made of durable metal alloys, which provides support for working with large loads (more than a ton).

Advantages

- Support for heavy structures;

- Interaction with other tools;

- Versatility;

- Flexible housing adjustment;

- Strength.

Flaws

Big weight.

It is a heavy but very efficient hydraulic pipe bender that can make any pipe structure much easier to work with.

Rothenberger Robend 4000

Portable electric model used in working with pipes with a diameter of 12 to 35 millimeters. The power of the built-in motor is 1010 V. It is used for installation of water supply, heating, air conditioning systems. It is convenient in working with refrigeration equipment, as well as in the production of pipe structures. Cold bending is carried out in automatic / manual modes. The maximum bend angle is 180 degrees. Works with pipes made of copper, thin-walled steel, black/galvanized steel with additional jackets.

Advantages

- Easy to carry;

- High power;

- Suitable for most pipes;

- Folds quickly and neatly.

Flaws

Ineffective when working in manual mode.

The tool is designed to work purely in automatic mode, although there is also a manual one. He is able to quickly make neat bends that do not affect the quality of operation of the structure. Easily interacts with the most dense materials. It has a convenient structure and simple functionality, which makes working with it as easy as possible.

Hydraulic pipe bender and its features

Connects to the network, so it is considered a high professional level tool. It allows you to perform a large amount of work. Among the positive qualities can be noted:

- when working with a hydraulic pipe bender, no specific knowledge is required; anyone can bend a pipe;

- with this tool, pipe bending is performed in a shorter time;

- The hydraulic machine can bend large diameter pipes.

Among the disadvantages of a pipe bender are:

- high price due to popularity and high performance;

- not to be used with low wall thickness pipes made from low cost materials that will break during bending.

2 Stalex MHPB-1A HHW-1A

At its core, a pipe bender is a very simple tool, and you can make it yourself. For example, this machine looks very handicraft, although it was produced in the factory. It has both its advantages and disadvantages. Let's start with the first: price. This is the cheapest hydraulic pipe bender, and if you look closely at its design, you will understand why this is so.The tool is made in the form of a small bed, in which a conventional car jack is installed. It is he who bends the pipe, laying it on a special roller, which already has the required angle of inclination. All you need to do is pump up the jack until the pipe rests completely on the base.

By the way, the profile pipe will not bend here. Firstly, there is no special roller for it, and secondly, such a bending method will simply flatten the walls and break the structure. The tool also comes with a set of rollers made of high-strength alloy steel. At least, this is what the manufacturer indicates, and judging by the reviews, the steel is not so strong. That is, for domestic use, this machine is perfect, but if you even have a small metalwork shop, it is better to choose a model that is more powerful and more reliable.

How to make a snail pipe bender?

Self-manufacturing a snail pipe bender may seem difficult. In fact, this device is no more difficult to assemble than a roller pipe bender. The process differs only in the parts used and assembly time.

The snail pipe bender allows you to bend the profile along the entire length at once, and not just in one place. For this property, he gained popularity among installers.

Necessary materials and tools

Since the described roller pipe bender does not have a specific working diameter and can be made from any available materials, the proposed materials will not contain specific sizes of parts. The thickness of all metal structural elements should be 4, and preferably 5 mm.

To make a pipe bender you will need:

- Channel - 1 meter.

- Sheet iron.

- Three shafts.

- Two stars.

- Metal chain.

- Six bearings.

- Metal 0.5-inch pipe for the manufacture of gates - 2 meters.

- Sleeve with internal thread.

- Clamp screw.

Particular attention is paid to the dimensions of sprockets, shafts and bearings, which must match each other. Asterisks can be taken from old bicycles, but they must be exactly the same size

Steel plates and profiles for the manufacture of a pipe bender should not be with deep rust, because they will have high loads during operation

Before choosing and purchasing all materials, you need to draw a drawing with a schematic representation of all structural elements so as not to buy them in the process of manufacturing a pipe bender.

The assembly process of the snail pipe bender

The assembly of any equipment begins with the drawing up of a drawing diagram.

After that, you can proceed to the main workflows, which are shown in the photo instructions:

- Weld the base of the tool from two parallel channels. If desired, you can use just a metal plate 5 mm thick or one wide channel.

- Put bearings on the shafts and weld two such structures to the base. It is desirable to limit the shafts with metal strips or place them in the inner cavity of the channels.

- Put on the sprockets and weld them, after stretching the chain between them.

- Cut and weld to the base the side guides of the clamping mechanism.

- Put the bearings on the pressure shaft and assemble the press structure with side stops from strips or channels.

- Make a base for the bushing and weld it to the plate. Screw in the clamping screw.

- Weld to the upper edge of the clamping screw and to the driving shaft of the pipe gate.

- Lubricate the bearings with engine oil.

Some useful tips:

After assembling the pipe bender and testing it, you can paint the structure with anti-corrosion paint to better preserve the welds. To increase the convenience of work, a spring is additionally attached to the guides to return the press to the upper position.

Structural design of pipe benders

Tools with hydraulic power traction according to their design are horizontal and vertical. The first designs are distinguished by the placement of the hydraulic cylinder in a horizontal plane. Accordingly, the direction of the force action is also carried out in the horizontal plane.

For the second designs, a distinctive feature is the vertical location of the hydraulic cylinder and the vertical force direction.

Model of a vertical pipe bender with a manually operated hydraulic drive. There are also universal designs that operate in both positions.

If in this case to judge the advantages and disadvantages, taking into account the choice of tool, the following should be taken as a basis:

- pipe processing conditions;

- overall dimensions of pipes;

- area of the working room;

- ease of use from the user's point of view.

And now in more detail about the characteristics.

How to use?

When working with a manual pipe bender, it is very important to follow the safety rules, as the device presents a certain risk of injury. To avoid damage, it is important to observe the following requirements

It is forbidden to approach the pipe from the edge from which the bend is formed.When the guide slides off, the metal blank begins to spring in the opposite direction, and the pipe can hit the stomach or chest, and the blow will be of a rather high force. This can lead to broken ribs and damage to internal organs. Ignoring this rule is fraught with the most dangerous consequences. There is also a high risk that the shaft where the roller is fixed will simply fly off under the influence of strong pressure.

If the workpiece is subjected to physical impact in order to deform, you should not hold it with your hands, you can touch the pipe only after the efforts have ceased. If a pipe bending machine is capable of operating on different speeds, it is not recommended to set the maximum. A high deformation rate often causes breakage of the workpiece, as a result, the pipe falls and presses the operator's legs, and if the pipe is quite long, it also captures the limbs of people standing nearby.

You can find out how to make a manual pipe bender yourself below.

The best manual pipe benders

With the help of the muscular strength of the operator, a manual pipe bender is actuated. Most often, such a device is used to work with soft "flowering" or thin-walled steel blanks. The device becomes an indispensable assistant for field installation work. The experts liked the following models.

Smart&Solid BendMax-300

Rating: 4.9

The main advantage of the Smart&Solid BendMax-300 manual pipe bender is the strength of the structure. For the manufacture of parts, the manufacturer used steel with a hardness of 42-48 HRC. The model is designed to work with square pipes with a cross section from 15x15 to 40x40 mm. The wall thickness can be 1.5-2.5 mm.The device allows you to bend profile pipes (50x30x2 mm), if you remove the fixing washers from the adjustable rings of the side mandrels. To protect the pipe bender from corrosion, the manufacturer applied a two-layer coating of zinc and powder paint. The device is equipped with a sealed bearing, so maintenance is greatly simplified.

Experts gave the first place to the model for reliability and ease of operation. Users appreciated the affordability and quality workmanship.

- quality manufacturing;

- durable construction;

- reliable protection against corrosion;

- affordable price.

not detected.

Rothenberger "Minibend", for pipes 1/4-5/16-3/8″

Rating: 4.8

A reliable assistant for plumbing installers, as well as specialists in the repair of hydraulics and refrigeration units, will be the Rothenberger Minibend manual pipe guide. The mobile device is lightweight (0.42 kg) and compact in size. The main purpose of the model is to bend round pipes at an angle of up to 180 degrees. It can be copper, brass, aluminum and steel blanks with a thin wall. Pipe diameter ranges from 6 to 10 mm (1/4-3/8″).

The pipe bender takes the second place in our rating, yielding to the winner in terms of strength and technical characteristics. Users are satisfied with the lightness and compactness of the device, ease of use. However, the narrow range of application is considered by many consumers as a disadvantage.

- lightness and compactness;

- you can work on weight;

- good bending accuracy;

- quality manufacturing.

narrow scope.

"Yato", 6-10 mm

Rating: 4.6

The Yato manual pipe bender boasts the most affordable price. With it, you can work with soft pipes with a diameter of 6-10 mm.Aluminum, brass, copper and steel blanks can be bent at an angle of up to 180 degrees. On the case, the Polish manufacturer has put a scale on which it is convenient to accurately determine the bending angle. Lightweight (0.45 kg) and compact device is easy to use, you can install or repair pipelines in the most inaccessible places. Experts appreciated the capabilities of the device, giving it the third prize in our rating.

Domestic users managed to test the Polish device. Of the advantages, they name low price, ease of use, good quality of the bend. The disadvantages of the product include a small play in the movable joint.

Pipe bending by rolling

For a manual pipe bender, working on the principle of running in, two rollers are used. One of them is static, the second one is running in the pipe. To do this, use a bending blank. A pipe is firmly attached to it, then the roller moves along it, creating the necessary bend. Due to the smooth movements of the movable roller, the bending radius is gradually reached. When working with such a pipe bend, the minimum possible bending radius is 4 pipe diameters. Smaller work is performed on equipment with mandrels.

According to the standards, the outer diameter of the pipe must correspond to the parameters of the bending blank stream. A very important indicator in running-in is the gap between the running-in roller and the pipe. If this distance is too large, then there will be defects at the bend in the cross section. If the gap is too small, more force is required to bend. The optimum distance between the roller and the pipe depends on the diameter of the pipe.