- Forced circulation system

- Design features

- Calculation of heat loss at home

- Calculation of the hydraulics of the water heating system

- Mounting order

- What does the calculation of hydraulics mean and why is it needed

- How hydraulic calculation calculations are carried out

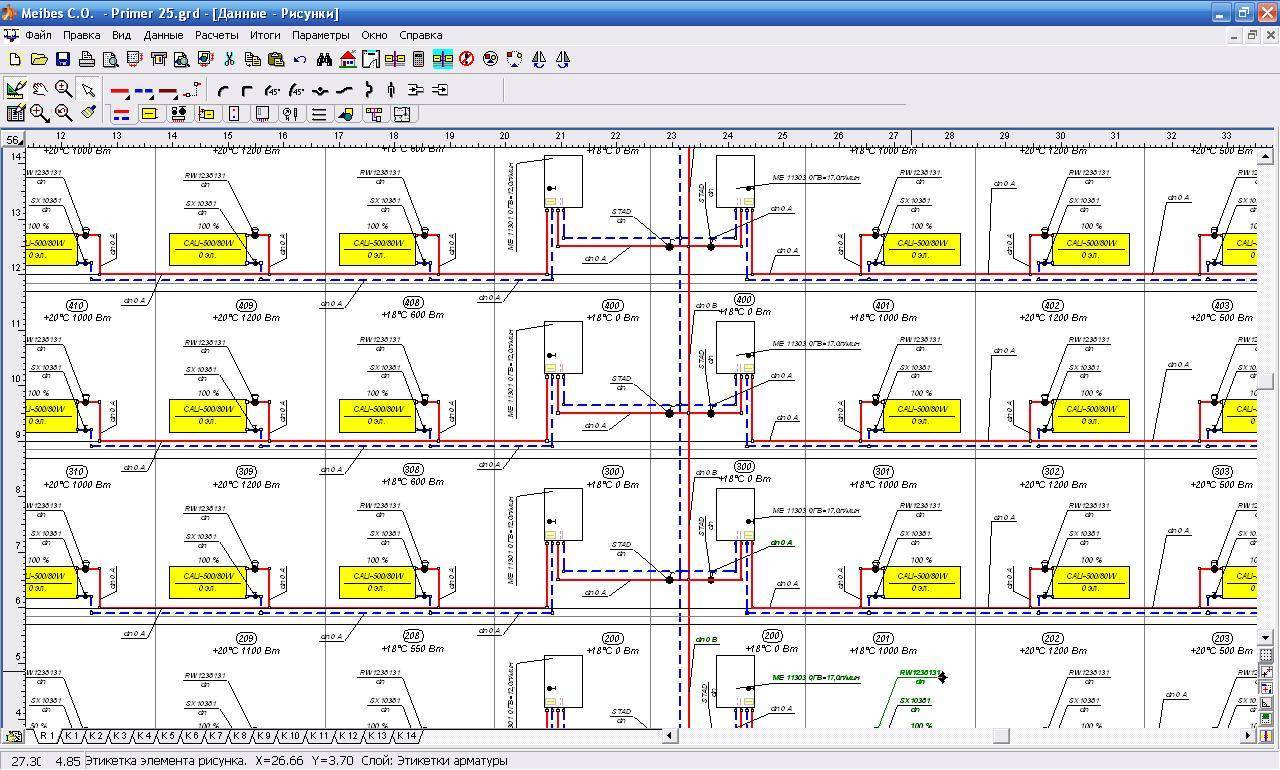

- What free programs exist for this?

- Two-pipe circuit in a high-rise apartment

- Data how to calculate the diameter of the pipe for heating

- Overview of programs for hydraulic calculations

- Oventrop CO

- HERZ C.O.

- Instal-Therm HCR

- Definition of resistance

- Calculation of coolant parameters

Forced circulation system

Equipment of this type for two-story cottages is considered more preferable. In this case, the circulation pump is responsible for the uninterrupted movement of coolants along the mains. In such systems, it is allowed to use pipes of smaller diameter and a boiler of not too high power. That is, in this case, a much more efficient single pipe heating system two-story house. The pump circuit has only one serious drawback - dependence on electrical networks. Therefore, where the current is turned off very often, it is worth installing the equipment according to the calculations made for a system with a natural coolant current.By supplementing this design with a circulation pump, you can achieve the most efficient heating of the house.

A gas boiler without electricity is a traditional model of a floor appliance that does not require additional energy sources to operate. It is advisable to install devices of this type if there are regular power outages. For example, this is true in rural areas or summer cottages. Manufacturing companies produce modern models of double-circuit boilers.

Many popular manufacturers produce different models non-volatile gas boilers, and they are quite effective and of high quality. Recently, wall-mounted models of such devices have appeared. The design of the heating system must be such that the coolant circulates according to the principle of convection.

This means that the heated water rises and enters the system through the pipe. In order for the circulation not to stop, it is necessary to place the pipes at an angle, and they must also be large in diameter.

And, of course, it is very important that the gas boiler itself is located at the lowest point of the heating system.

It is possible to separately connect a pump to such heating equipment, which is powered by the mains. By connecting it to the heating system, it will pump the coolant, thereby improving the operation of the boiler. And if you turn off the pump, then the coolant will again begin to circulate by gravity.

Design features

In order for the gravity system to work effectively, the following requirements must be met:

- any non-volatile heat generator with outlet pipes with a diameter of 40-50 mm acts as a heat source;

- at the outlet of the boiler or stove with a water circuit, an accelerating riser is immediately mounted - a vertical pipe through which the heated coolant rises;

- the riser ends with an open-type expansion tank installed in the attic or under the ceiling of the upper floor (depending on the type of wiring and design of a private house);

- tank capacity - 10% of the volume of the coolant;

- under gravity, it is desirable to choose heating devices with large dimensions of internal channels - cast iron, aluminum, bimetallic;

- for better heat transfer, heating radiators are connected according to a versatile scheme - lower or diagonal;

- on radiator connections, special full-bore valves with thermal heads (supply) and balancing valves (return) are installed;

- it is better to equip batteries with manual air vents - Mayevsky cranes;

- replenishment of the heating network is organized at the lowest point - near the boiler;

- all horizontal sections of pipes are laid with slopes, the minimum is 2 mm per linear meter, the average is 5 mm / 1 m.

On the left in the photo - the heat carrier supply riser from the floor-standing boiler with a pump on the bypass, on the right - the connection of the return line

Gravity heating systems are made open, operated at atmospheric pressure. But will gravity flow work in a closed circuit with a membrane tank? We answer: yes, natural circulation will continue, but the speed of the coolant will decrease, the efficiency will drop.

It is not difficult to substantiate the answer, it is enough to mention the change in the physical properties of liquids under excess pressure. With a pressure in the system of 1.5 bar, the boiling point of water will shift to 110 ° C, its density will also increase.The circulation will slow down due to the small difference in the masses of the hot and cooled stream.

Simplified gravity flow diagrams with an open and membrane expansion tank

Calculation of heat loss at home

These data will be needed to determine the required power of the heating system, i.e. the boiler, and the heat output of each radiator separately. To do this, you can use our online heat loss calculator. They need to be calculated for each room in the house that has an outer wall.

Examination. The calculated heat loss of each room is divided by its quadrature and we get the specific heat loss in W/sq.m. They usually range from 50 up to 150 W/kv. m. If your figures are very different from those given, then perhaps a mistake was made. The heat losses of the rooms of the upper floor are the largest, followed by the heat losses of the first floor and the least they are in the rooms of the middle floors.

Calculation of the hydraulics of the water heating system

The coolant circulates through the system under pressure, which is not a constant value. It decreases due to the presence of water friction forces on the pipe walls, resistance on pipe fittings and fittings. The homeowner also contributes by adjusting the distribution of heat to individual rooms.

The pressure increases if the temperature of the heating medium rises and vice versa - it falls when it decreases.

The pressure increases if the temperature of the heating medium rises and vice versa - it falls when it decreases.

To avoid unbalancing the heating system, it is necessary to create conditions under which each radiator receives so much coolantas long as necessary to maintain the set temperature and compensate for the inevitable heat losses.

The main purpose of the hydraulic calculation is to bring the calculated network costs into line with the actual or operating costs.

At this design stage, the following are determined:

- pipe diameter and capacity;

- local pressure losses in individual sections of the heating system;

- hydraulic balancing requirements;

- pressure losses throughout the system (general);

- optimum flow rate.

For the production of hydraulic calculation, it is necessary to do some preparation:

- Gather data and organize it.

- Select a calculation method.

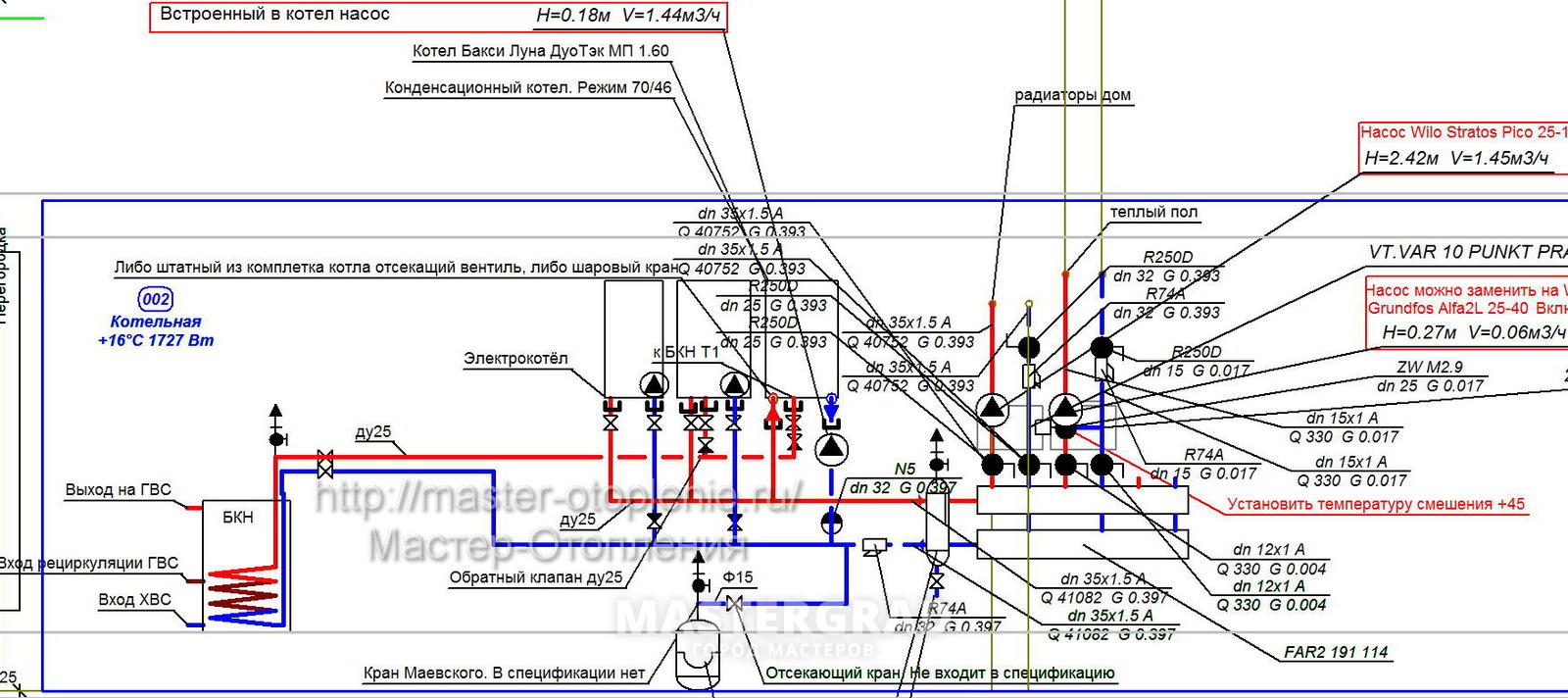

First of all, the designer studies the thermal parameters of the object and performs a thermal calculation. As a result, he has information about the amount of heat required for each room. After that, heating devices and a heat source are selected.

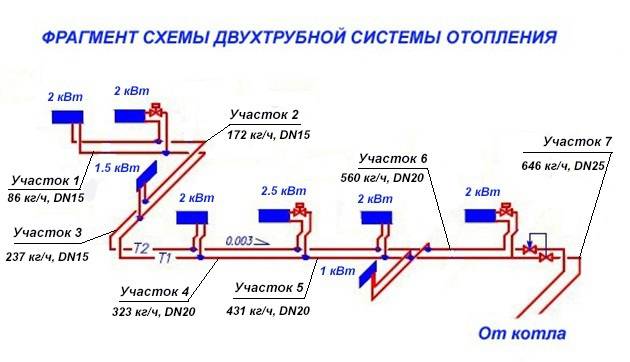

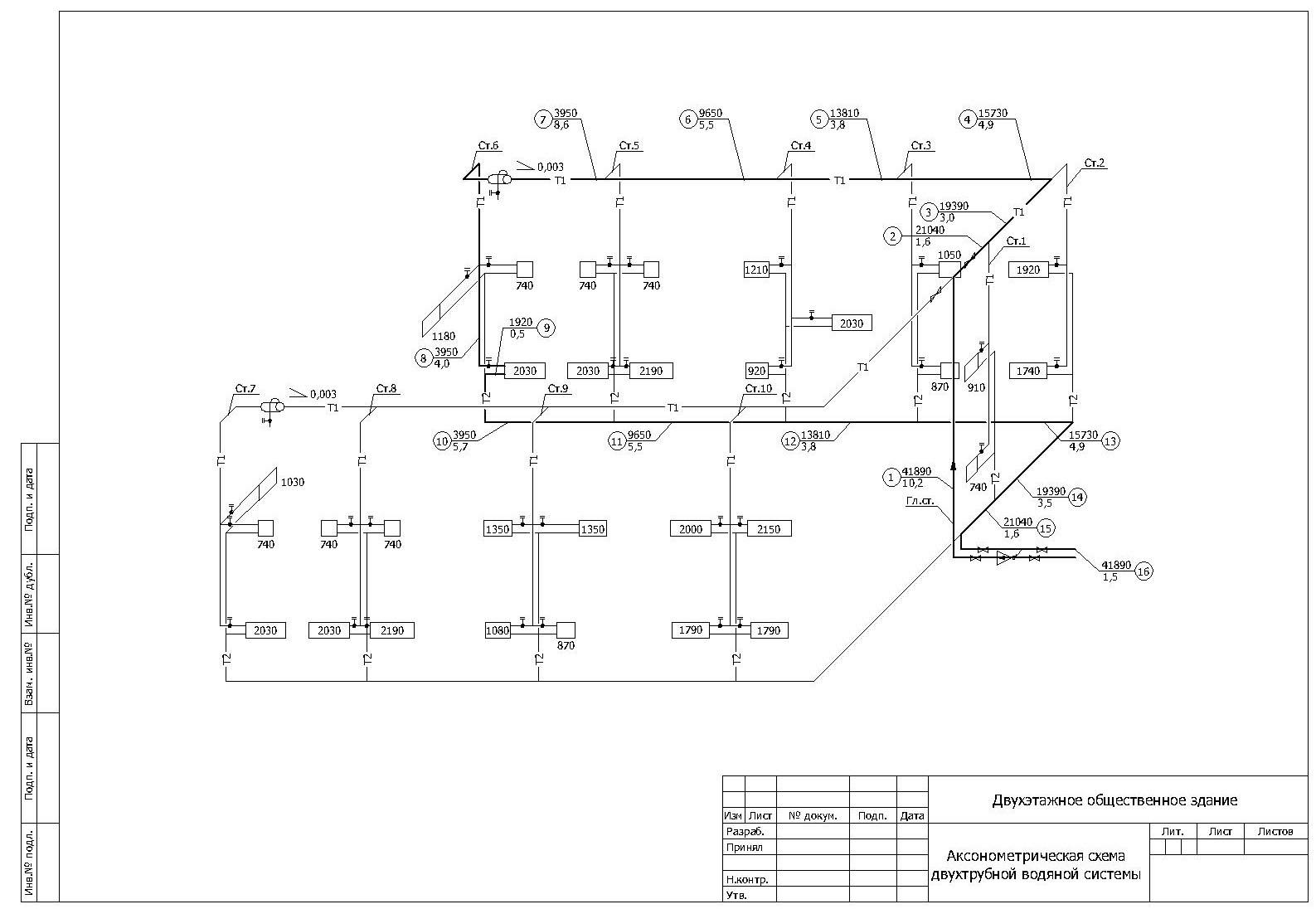

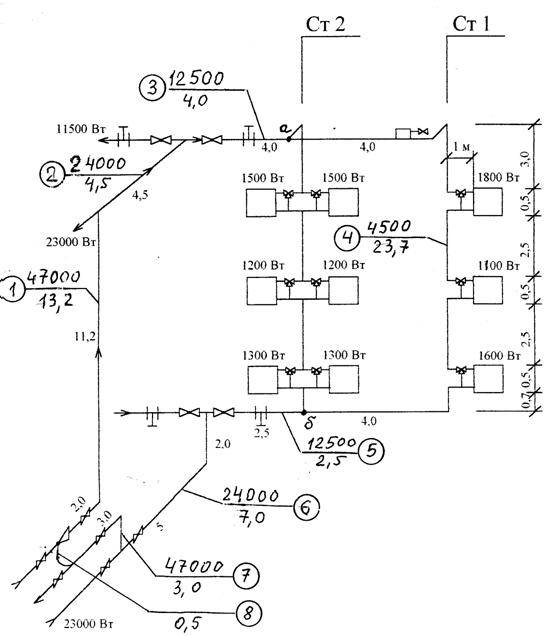

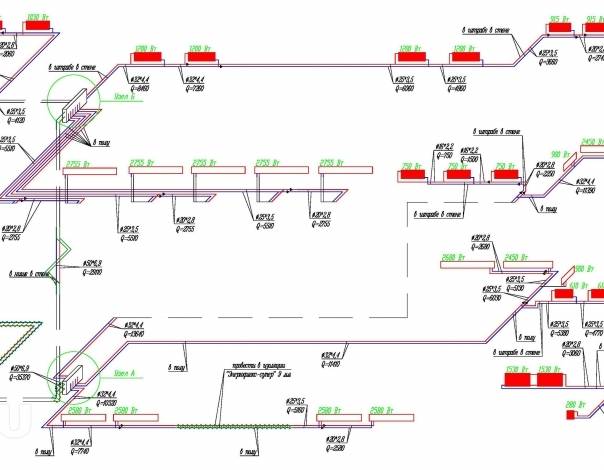

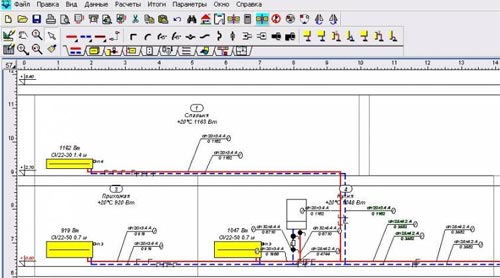

Schematic representation of the heating system in a private house

At the development stage, a decision is made on the type of heating system and the features of its balancing, pipes and fittings are selected. Upon completion, an axonometric wiring diagram is drawn up, floor plans are developed indicating:

- radiator power;

- coolant flow rate;

- arrangement of thermal equipment, etc.

All sections of the system, nodal points are marked, counted and applied to the drawing, the length of the rings.

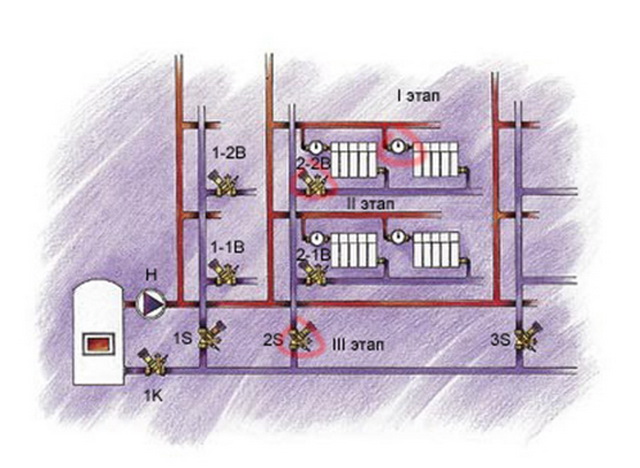

Mounting order

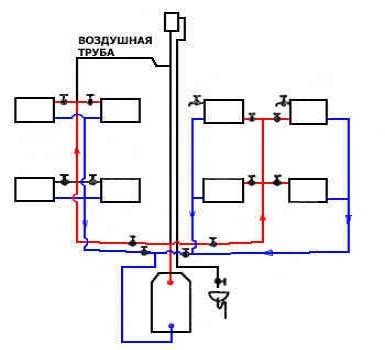

A single-pipe system is assembled as follows:

- In the utility room, the boiler is installed on the floor or hung on the wall. With the help of gas equipment, the most reliable and efficient one-pipe heating system of a two-story house can be arranged.The connection diagram in this case will be standard and will allow you to do all the work, if desired, even on your own.

- Heating radiators are hung on the walls.

- At the next stage, the “supply” and “reverse” risers are mounted to the second floor. They are located in the immediate vicinity of the boiler. At the bottom, the contour of the first floor joins the risers, at the top - the second.

- Next is the connection to the battery lines. A shut-off valve (on the inlet section of the bypass) and a Mayevsky valve should be installed on each radiator.

- In the immediate vicinity of the boiler, an expansion tank is mounted on the "return" pipe.

- Also on the "return" pipe near the boiler on the bypass with three taps, a circulation pump is connected. A special filter cuts in front of it on the bypass.

At the final stage, the system is pressure tested in order to identify equipment malfunctions and leaks.

As you can see, the single-pipe heating system of a two-story house, the scheme of which is as simple as possible, can be very convenient and practical equipment.

However, if you want to use such a simple design, at the first stage it is important to make all the necessary calculations with maximum accuracy.

Thinking about the installation of heating, it is initially determined what type of fuel will be used

But along with this, it is extremely important to decide how independent the planned heating will be. So, a heating system without a pump, which does not need electricity to work, will be truly autonomous. All you need is a heat source and a well-placed piping for efficient operation.

For efficient operation, you only need a heat source and properly located piping.

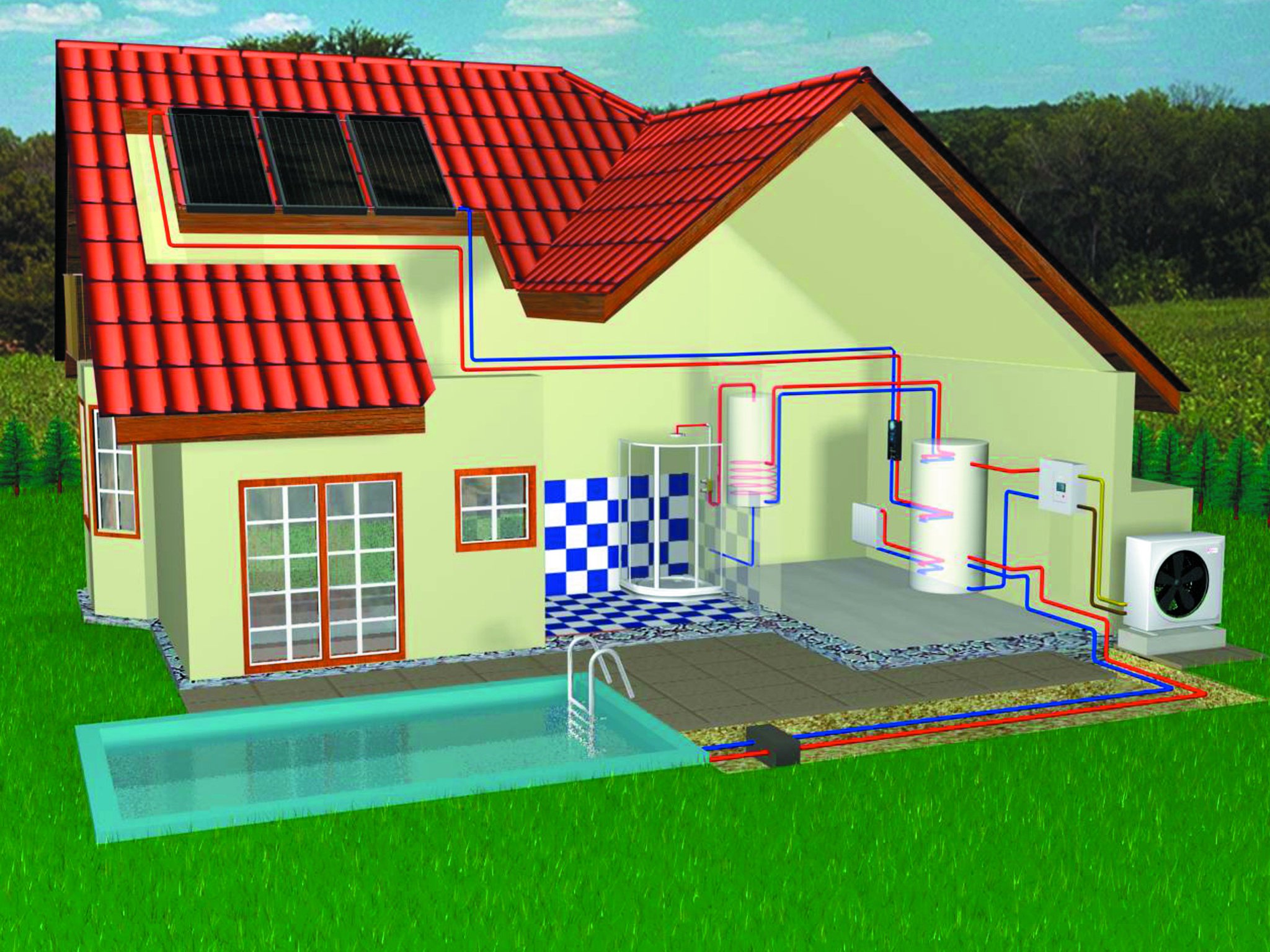

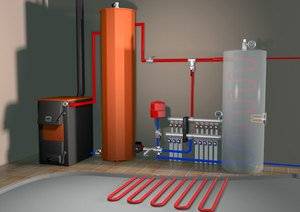

The heating circuit is a set of elements designed to heat the home by transferring heat to the air. The most common type of heating is a system that uses boilers or boilers connected to the water supply as a heating source. Water, passing through the heater, reaches a certain temperature, and then goes to the heating circuit.

In systems with a coolant, which is used as water, circulation can be organized in two ways:

Boilers (boilers) are used as a heat source for heating water. Their principle of operation is based on the transformation of the type of energy defined for them into heat, followed by its transfer to the coolant. According to the type of heating source, boiler equipment can be gas, solid fuel, electric or fuel oil.

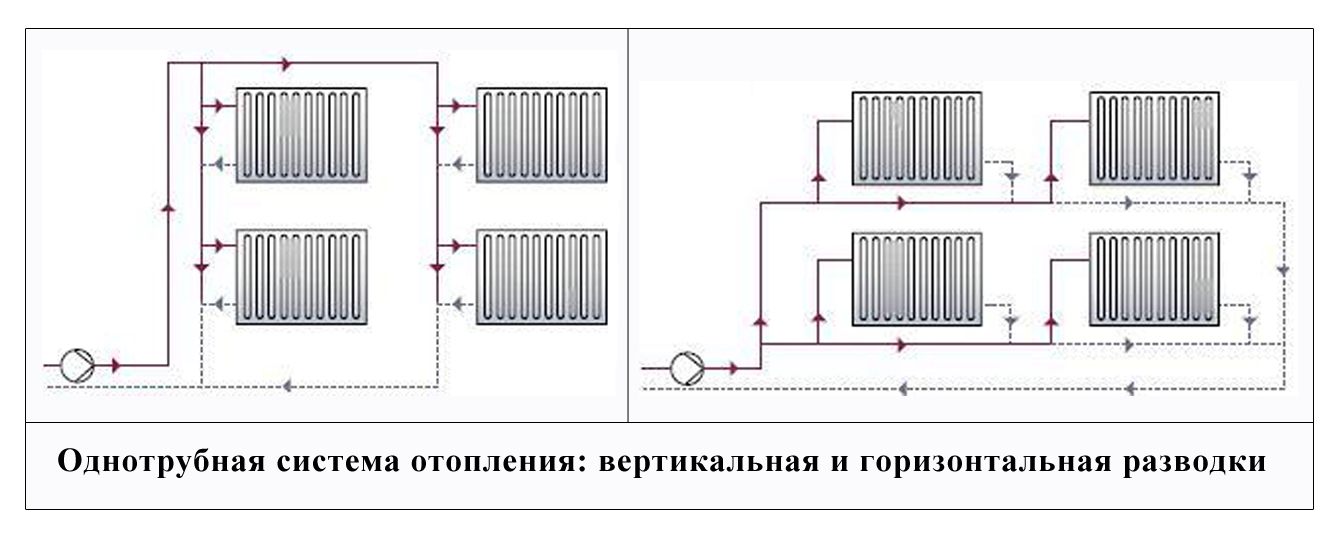

According to the type of connection of the circuit elements, the heating system can be one-pipe or two-pipe. If all circuit devices are connected in series relative to each other, that is, the coolant passes through all the elements in order and returns to the boiler, then such a system is called a single-pipe system. Its major drawback is uneven heating. This is due to the fact that each element loses some amount of heat, so the difference in boiler temperatures can be significant.

A two-pipe type system implies a parallel connection of radiators to a riser. The disadvantages of such a connection include a design complication and a doubled material consumption compared to a single-pipe system. But the construction of a heating circuit for large multi-storey premises is carried out only by such a connection.

A gravity circulation system is sensitive to errors made during heating installation.

What does the calculation of hydraulics mean and why is it needed

To make a hydraulic calculation of heating means to correctly select the parameters of certain sections of the network, taking into account the pressure, so that a certain coolant flow is carried out through them.

This calculation makes it possible to determine:

- Pressure losses in various parts of the network;

- throughput of the pipeline;

- Optimal fluid flow;

- Necessary indicators for hydraulic balancing.

Combining all the data obtained, you can select heating pumps.

The amount of heat source entering the radiators must be such that a heating balance is obtained inside the building, taking into account the street temperature and the temperature set by the user for each room separately.

If the heating is autonomous, you can use the following calculation methods:

- Using the characteristics of resistance and conductivity;

- According to unit costs;

- By comparing dynamic pressure;

- For different lengths, reduced to one indicator.

The calculation of hydraulics is one of the most important stages in the development of heating systems with a liquid heat carrier.

Before proceeding with its implementation, you must:

- Determine the balance of heat in the necessary premises;

- Select the type of heating devices and place them on the drawings of the building;

- Solve questions on the configuration of the heating system, as well as on the types of pipes and fittings used;

- Draw a diagram of the heating system, where the numbers, loads and lengths of the required sections will be visible;

- Determine the main circulation ring along which the coolant moves.

Typically, for buildings with a small number of floors, a two-pipe heating system is used, and for buildings with a large number of storeys, a single-pipe heating system is used.

How hydraulic calculation calculations are carried out

There are some tasks that need to be solved in order to make a hydraulic calculation of the heating system:

- Determine the diameter of the pipes in all sections of the system (do not forget to take into account the speed of movement of the heat carrier).

- Calculate the pressure loss.

- Solve hydraulic balancing.

- And, of course, the flow rate of the coolant.

What free programs exist for this?

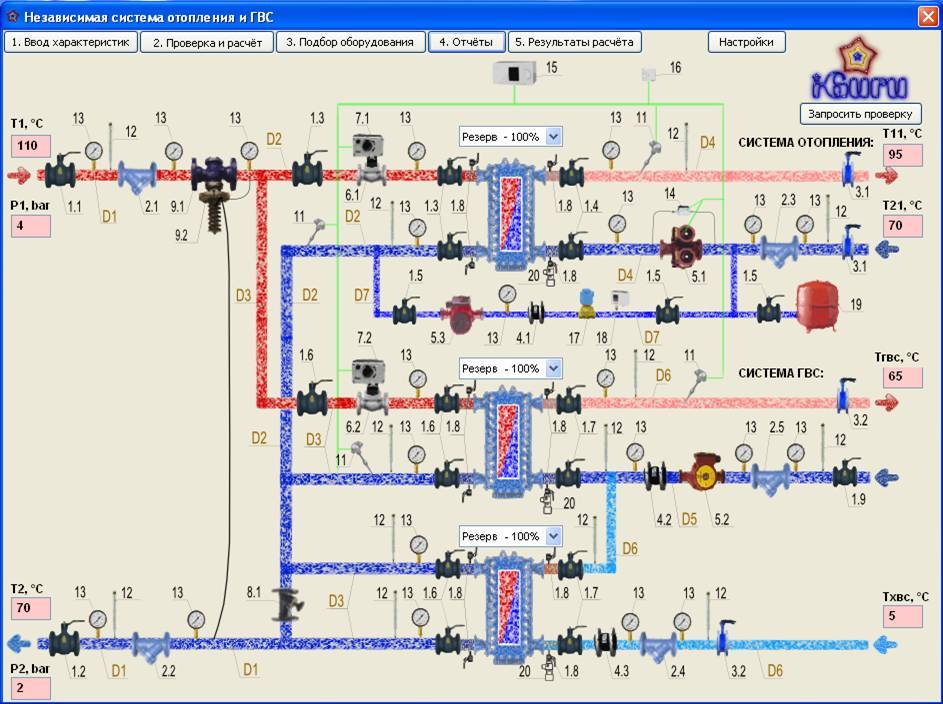

As you might guess, this program is designed to quickly perform the necessary calculations. First, you need to make all the appropriate settings and select the most suitable items of equipment. Thus, it is possible to create completely new schemes. Moreover, a ready-made scheme can be adjusted as necessary.

This software harmoniously combines both options, allowing you to create original designs and adjust old ones. The program has the widest possibilities regarding hydraulic calculations, from the flow rate of the coolant to the selection of pipes of the required diameter. All the results of your work can be imported into the operating system in any form.

This program is freely available. It allows you to calculate everything you need for systems, regardless of the number of pipes.The essential difference of "Hertz", which favorably distinguishes it from other analogues, is that you can create various projects, both in new buildings and in reconstructed buildings, in which the glycol mixture is the coolant. The program was certified by OOO TsSPS.

Data entry is very convenient, as it is carried out graphically. The results of calculations are visualized in the form of diagrams.

With it, you will calculate the surface or radiator. It consists of a special set of four similar programs. So, let's look at the possibilities of the program:

- Selection of the pipeline depending on the diameter.

- Selection of suitable radiators.

- It determines the height at which the pumps must be placed.

- Various kinds of calculations of heating surfaces.

- Determination of the most suitable temperature.

Unlike the previous options, you can download for free only a trial version of the program, which, of course, has some limitations. First of all, in the vast majority of options, you will not only be able to import an image into the operating system, but even print it. In addition, in each individual application there is a kind of limit: three completed projects per one. However, you can modify it an infinite number of times, this is not prohibited. And, finally, finished projects will be saved in a special format, no other version will be able to read such an extension.

As a result, I would like to note that the hydraulic calculation of the heating system is an integral part of the modern control system.In order to choose control valves without having an idea of what is happening on the market at the moment, you will have to make calculations over the entire area of \u200b\u200bthe structure, it is advisable to use the richest possible library. The operation of the entire system will depend on how correct your data will be.

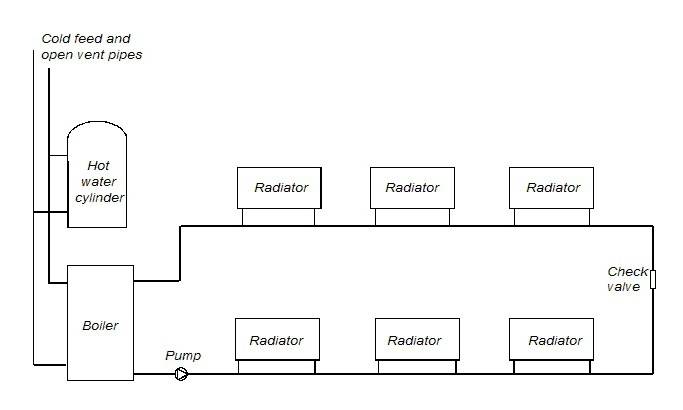

Two-pipe circuit in a high-rise apartment

To properly make heating in an apartment of a multi-storey building, you need to plan everything from the very beginning. One of the key points in planning is the calculation of the diameter of the pipe for heating.

The technical part of the case is called hydraulic calculation. At the same time, the following factors influence the choice of the diameter of pipes for heating:

- the length of the system;

- supply coolant temperature;

- return temperature;

- materials and accessories;

- area of the room;

- the degree of fatigue in the room.

In other words, before calculating the diameter of the pipe for heating, it is necessary to determine the hydraulic performance of the system. You can independently carry out only approximate calculations, which can also be used in practice.

The diameter of the pipes for a two-pipe heating system directly determines how quickly the heat from the boiler will reach the end point of the circuit. The smaller the conditional passage, the higher the coolant velocity.

After all, water over a longer amount of time will have time to give off a greater amount of heat.

The simplest solution to how to calculate the diameter of a pipe for heating is to adhere to the same conditional passage as in the branch pipe that goes into your apartment from the central riser.

This will save you time and nerves, because it was no coincidence that the developer installed a circuit with just such a section. Before the object began to build, all calculations were carried out, including hydraulic.

If you want to calculate everything according to the formula, then use the information from the next block.

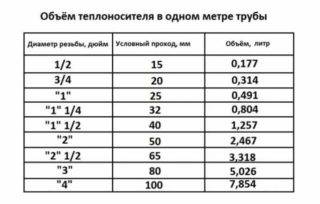

The optimal diameter of a pipe for heating in an apartment and in a private house up to 100 square meters is 25 mm. It refers to polypropylene products.

Data how to calculate the diameter of the pipe for heating

To calculate the diameter of the pipeline, you will need the following data: these are the total heat loss of the dwelling, the length of the pipeline, and the calculation of the power of the radiators of each room, as well as the wiring method. Divorce can be single-pipe, two-pipe, have forced or natural ventilation.

Unfortunately, it is impossible to accurately calculate the cross section of pipes. One way or another, you will have to choose from a couple of options. This point should be clarified: a certain amount of heat must be delivered to the radiators, while achieving uniform heating of the batteries. If we are talking about systems with forced ventilation, then this is done using pipes, a pump and the coolant itself. All that is needed is to drive the required amount of coolant for a certain time period.

It turns out that you can choose pipes of smaller diameter, and supply the coolant at a higher speed. You can also make a choice in favor of pipes of a larger cross section, but reduce the intensity of the coolant supply. The first option is preferred.

Overview of programs for hydraulic calculations

Sample program for heating calculation

In fact, any hydraulic calculation of water heating systems is a complex engineering task.To solve it, a number of software packages have been developed that simplify the implementation of this procedure.

You can try to make a hydraulic calculation of the heating system in the Excel shell, using ready-made formulas. However, the following problems may occur:

- Big error. In most cases, one-pipe or two-pipe schemes are taken as an example of a hydraulic calculation of a heating system. Finding such calculations for the collector is problematic;

- To correctly account for the hydraulic resistance of the pipeline, reference data is required, which are not available in the form. They need to be searched and entered additionally.

Given these factors, experts recommend using programs for calculation. Most of them are paid, but some have a demo version with limited features.

Oventrop CO

Program for hydraulic calculation

The simplest and most understandable program for the hydraulic calculation of the heat supply system. An intuitive interface and flexible settings will help you quickly deal with the nuances of data entry. Small problems may arise during the initial setup of the complex. It will be necessary to enter all the parameters of the system, starting from the pipe material and ending with the location of the heating elements.

HERZ C.O.

It is characterized by flexibility of settings, the ability to make a simplified hydraulic calculation of heating both for a new heat supply system and for upgrading an old one. Differs from analogues in a convenient graphical interface.

Instal-Therm HCR

The software package is designed for professional hydraulic resistance of the heat supply system. The free version has many limitations.Scope - design of heating in large public and industrial buildings.

Hydraulic Calculation Example heating systems:

Definition of resistance

Often, engineers are faced with calculations of heat supply systems for large facilities. Such systems require a large number of heating devices and hundreds of running meters of pipes. You can calculate the hydraulic resistance of the heating system using equations or special automated programs.

Often, engineers are faced with calculations of heat supply systems for large facilities. Such systems require a large number of heating devices and hundreds of running meters of pipes. You can calculate the hydraulic resistance of the heating system using equations or special automated programs.

To determine the relative heat loss due to adhesion in the line, the following approximate equation is used: R = 510 4 v 1.9 / d 1.32 (Pa / m). The application of this equation is justified for speeds not exceeding 1.25 m/s.

If the value of hot water consumption is known, then an approximate equation is used to find the cross section inside the pipe: d = 0.75 √G (mm). After receiving the result, you will need to refer to a special table to get the cross section of the conditional passage.

The principle of operation of an open heating system with a circulation pump

Calculation of coolant parameters

The calculation of the coolant is reduced to the determination of the following indicators:

- the speed of movement of water masses through the pipeline with the given parameters;

- their average temperature;

- carrier consumption associated with the performance requirements of heating equipment.

Known formulas for calculating the parameters of the coolant (taking into account hydraulics) are quite complex and inconvenient in practical application. Online calculators use a simplified approach that allows you to get a result with an error allowed for this method.

Nevertheless, before starting installation, it is important to take care to purchase a pump with indicators not lower than the calculated ones.Only in this case, there is confidence that the requirements for the system according to this criterion are fully met and that it is able to heat the room to comfortable temperatures.