- Installation rules

- Installation of water pipes

- Advantages and disadvantages of using hard liner

- Advantages and disadvantages of using a flexible water supply

- How to choose the diameter of a flexible eyeliner, taking into account its type

- How to choose?

- "Not China!"

- Instructions for use

- Kinds

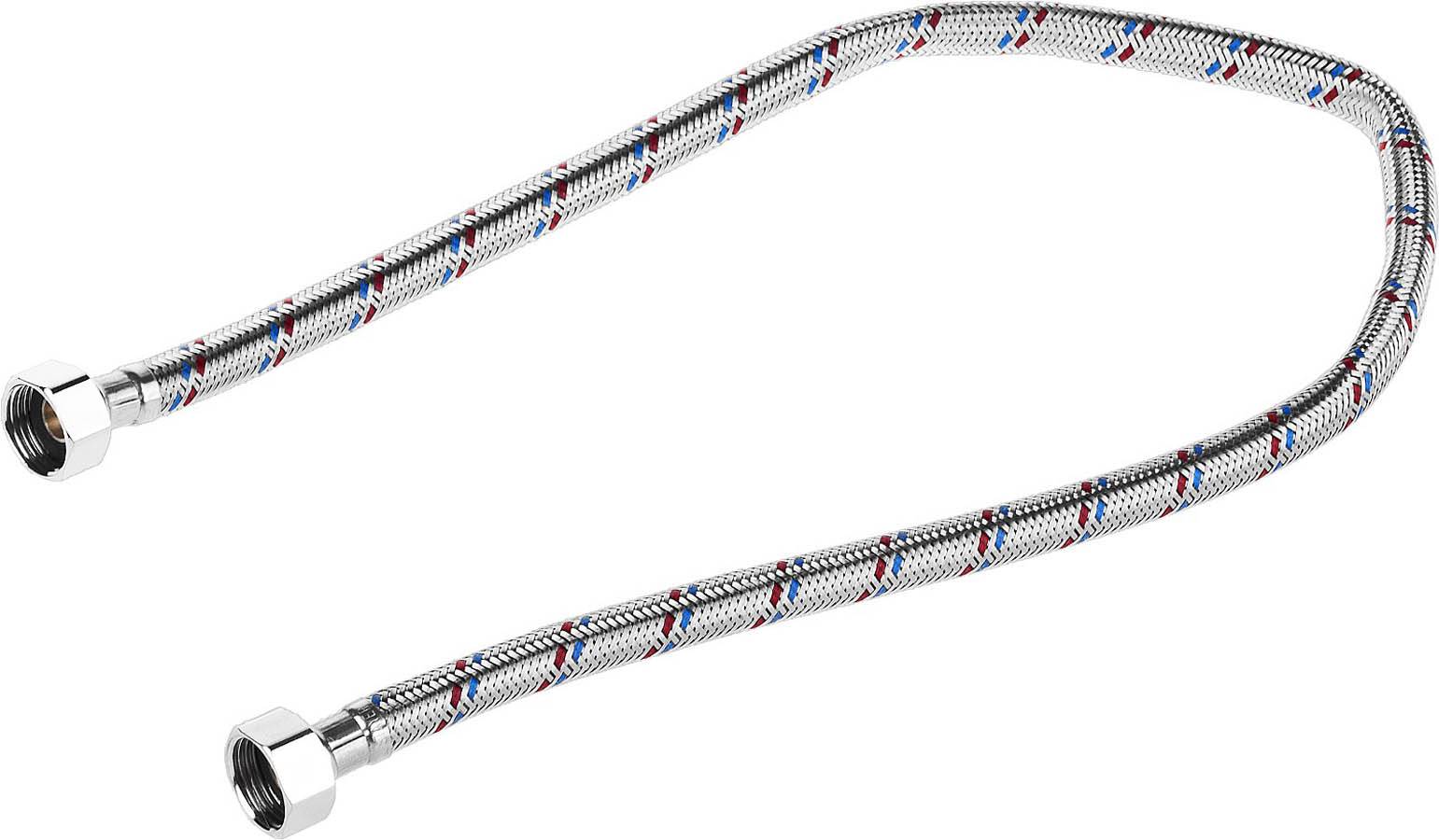

- Braided flexible hoses

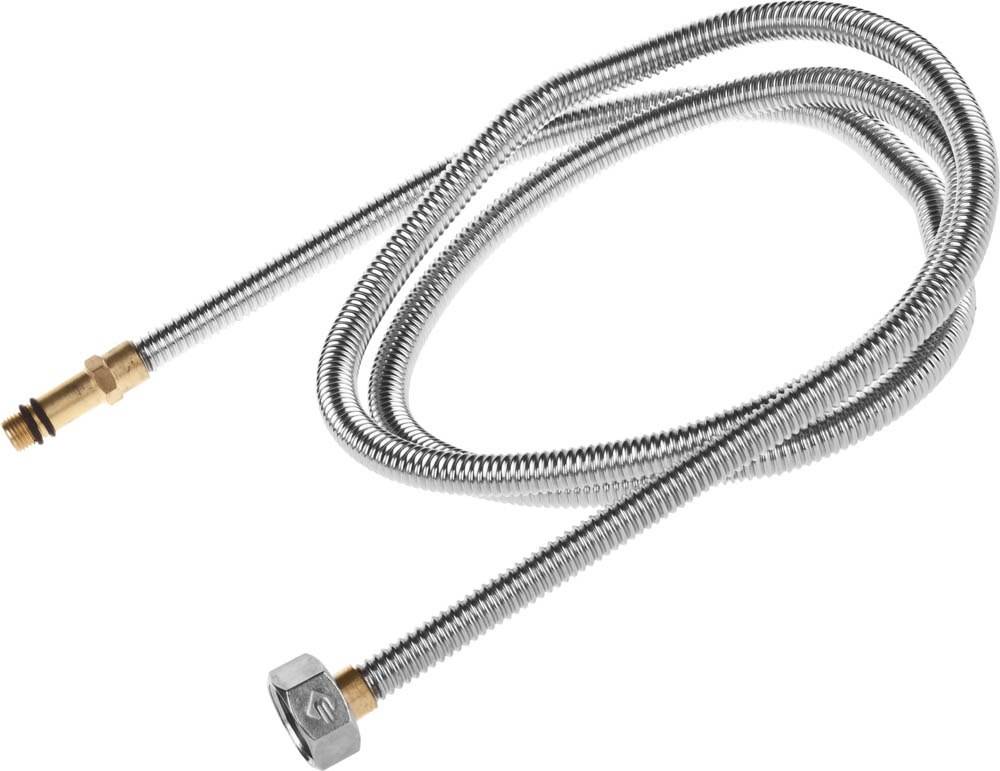

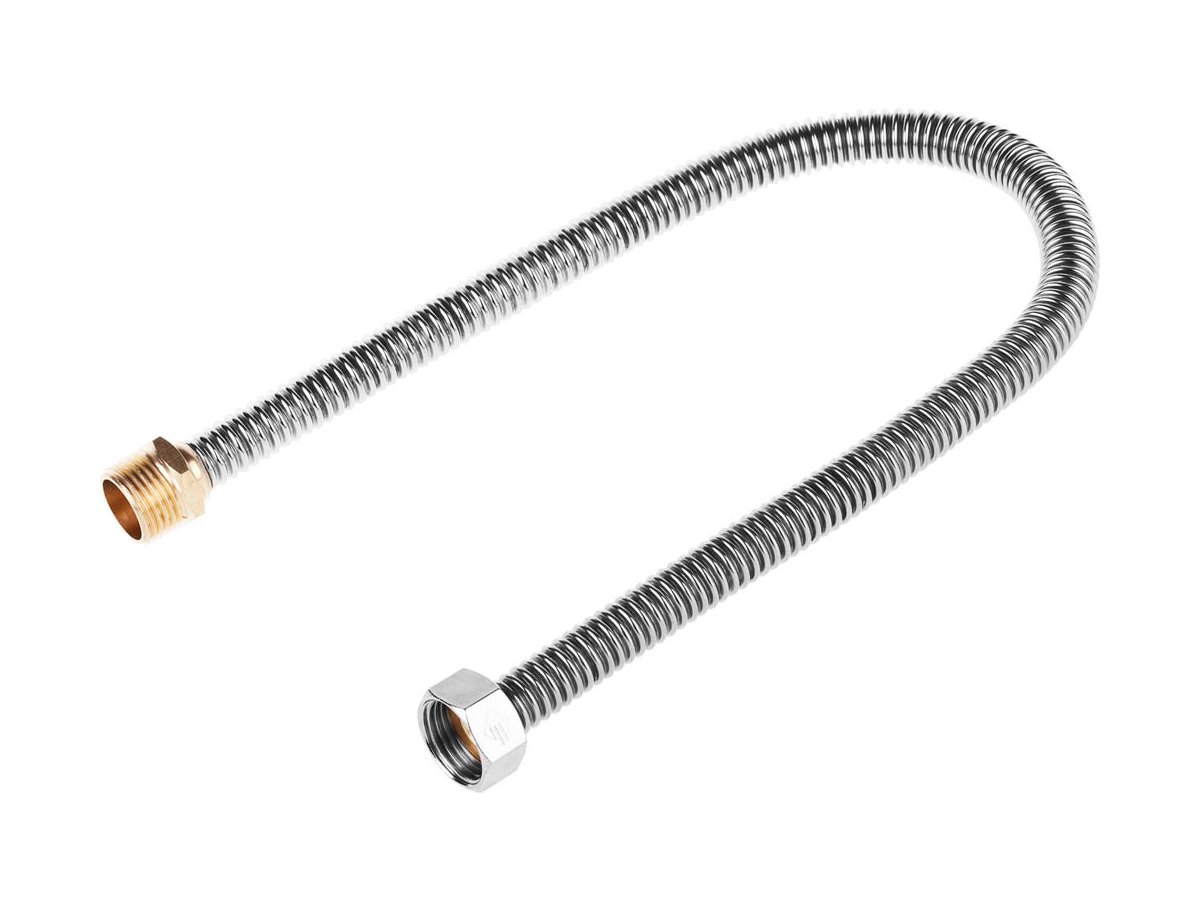

- Bellows connections

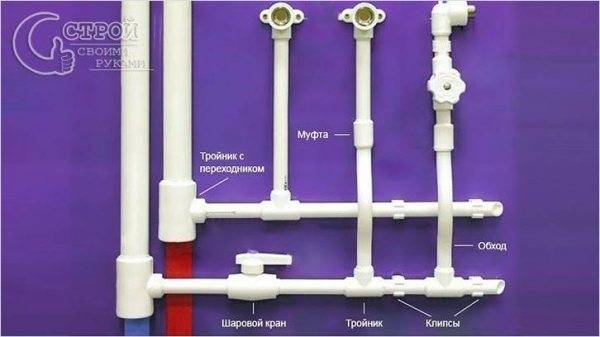

- Installation with metal-plastic pipes

- Types of eyeliner: characteristics and specifics of application

- Flexible hoses with reinforced braid

- Bellows tubes for water

- Polypropylene faucet

- What service life is guaranteed by various types of flexible piping

Installation rules

Despite the fact that the installation instructions for products are incredibly simple, when connecting them, you must follow certain rules:

- Before connecting, without fail, inspect the product for defects, braid breaks, the presence of sealing gaskets and rings;

- When choosing a hose, choose such a length so that it is not stretched, and the turning radius is at least 5-6 of its outer diameters;

- During installation, bends are unacceptable, instead of them it is better to make rings;

- It is not allowed to twist the tube along the longitudinal axis;

- The threaded connection of the nut and the fitting does not lack sealing with tow or FUM tape, rubber rings and gaskets play its role;

- The nut is screwed by hand until it stops, after which it is tightened with a wrench half a turn, a maximum of 270 degrees. Overtightening is fraught with cutting through the gasket, which leads to leaks.

Installation of water pipes

Although there are two different wiring schemes, in practice they usually use either a serial circuit or a combined one - series-collector. The simplest materials in terms of installing water distribution are considered to be polypropylene, metal-plastic, XLPE pipes and copper.

- The layout of water supply pipes starts from the entry point, i.e. source of water supply - a pumping station, a hydraulic accumulator, a pressure tank, the input of a central water supply pipe.

The common supply pipe, in order to have the least pressure loss, must be at least an inch in diameter.

It is mandatory to install a coarse water filter and a shut-off valve.

Next, the installation of pipe wiring begins according to the selected scheme, i.e. pipes are run to the bathroom, kitchen, laundry. If the piping begins in the basement and the heating boiler is located there, then a separate exit to the boiler is made.

With serial wiring, if it is not planned to hide it with decorative panels and a box, it is recommended to mount the pipes 15–30 cm above the plinth. Thus, the pipes will be hardly noticeable and in some places hidden by plumbing fixtures.

When laying through walls and ceilings, pipes must be protected from damage. To do this, a casing pipe or a special cuff is placed in the hole.

Pipes are fixed with the help of special clips, plastic and metal clamps.

Advantages and disadvantages of using hard liner

This type of eyeliner is characterized by rigidity. When connecting the mixer to the system using this design, the connection is fixed. Rigid eyeliner is presented in the form of a metal pipe with a chrome coating. The exception is copper products that do not have a protective layer, since harmful bacteria and mold do not multiply on their surface.

Rigid eyeliner has a long service life, which is about 20 years

Benefits of a hard faucet connection:

- Excellent decorative qualities and classic design.

- The ability to withstand exposure to high temperatures, as well as their differences.

- Resistant to aggressive chemicals.

- High margin of safety.

- Resistant to corrosion damage.

- Long service life (up to 20 years).

The disadvantages of rigid structures include a high price, as well as a rather complicated installation scheme. Since during the installation process all the elements are in a stationary position, the assembly of such a connection may be accompanied by certain difficulties.

Due to the smooth surface, keeping the eyeliner clean is not a problem

The length of the tubes must be chosen very carefully. If the direction of the water outlets is not vertical, you will have to change it. For these purposes, curved fittings are used. In addition, a fixed connection creates additional difficulties in the process of repair and maintenance of cranes. Therefore, customers prefer flexible connection options.

Advantages and disadvantages of using a flexible water supply

The installation of rigid steel pipes is a laborious process, which results in a bulky and heavy metal structure. Installation of flexible products does not require significant effort. At the same time, the reliability of the system and the quality of connections do not suffer at all.

Flexible hoses for kitchen faucets and other connection points have many beneficial advantages:

- Safety and convenient operation system.

- The tightness of the design, which is achieved through the use of high quality materials for the manufacture of these products.

- Installation and dismantling of the eyeliner does not require special skills, knowledge and professional equipment. Even an inexperienced person can cope with this work.

- Vibration resistant. Flexible connections are not afraid of hydraulic shocks.

- Under the condition of proper operation, the service life of products is quite long.

- Flexible hoses are able to function normally in a wide temperature range.

The technical characteristics of stainless steel make it possible to use a braid from it in almost all water intake units.

Unlike rigid structures, the position of flexible connections can be changed and moved relative to the mixer.

Disadvantages of flexible hoses for faucets:

- Flexible products are afraid of mechanical stress and are easily amenable to deformation changes, so they cannot be twisted, bent or stretched too much. Otherwise, the service life of the eyeliner will be significantly reduced.

- Do not install flexible hoses near open flames.

- If water is supplied to different rooms at the same time, the piping can make an unpleasant noise due to vibrations that occur in the pipes.

The main disadvantage of aluminum braids is their low corrosion resistance.

How to choose the diameter of a flexible eyeliner, taking into account its type

Flexible water supply consists of rubber hoses in a metal or nylon sheath and a bellows connection. The flexible water inlet has two ferrules (one for each end of the hose) that provide the ability to connect on a nipple-nipple, nut-nut and nipple-nut principle to pipes with a diameter of 1, 1/2, 3/4 and 3/8 inches. The inner diameter of the flexible hose affects the capacity of the hose.

A flexible hose in a metal or nylon braid is a hose made of ethylene-propylene rubber (non-toxic rubber) braided on the outside with stainless steel or nylon thread. This braid protects the hose from water hammer and increases its mechanical resistance.

The material used in the production of flexible hoses is safe for health (non-toxic), therefore it is often used in drinking water supply systems. This eyeliner is resistant to high temperatures up to +95 degrees Celsius. These characteristics allow it to be used in heating systems and in hot water supply.

The high mechanical resistance of the flexible hose allows it to withstand hydraulic shocks (working water pressure up to 20 atm). Depending on the required water flow, the diameter of the flexible piping (flow area) can be different. In water supply systems, an eyeliner with an internal diameter of 8 mm is most often used.The blue thread in the braid indicates the possibility of its use in cold water supply systems, and the red one - hot.

The stainless steel sleeve provides a secure connection between the metal-braided hose and the nickel-plated brass sleeve. For a more convenient installation of this type of connection, there are two types of fittings equipped with gaskets for a tight connection: a threaded fitting (for reliable connection with an internal thread on the connected equipment) or union nuts (for connecting to a pipe with an external thread). When installing a flexible hose in a metal winding, it is recommended to use hoses no longer than 2.5 m. The service life is no more than 5 years.

When purchasing a flexible eyeliner, you must carefully examine the products. The presence of dents, bulges and other flaws on the nut and winding is not allowed. Braid threads must be even, without protrusions, etc. The fitting elements must be aligned with the hose. The sealing gasket must not be wrinkled and detached. Defects on the decorative coating are also unacceptable. When choosing a product, ask for a product passport and specify the warranty period. If possible, purchase eyeliner only from authorized dealers.

Bellows eyeliner - a sleeve (hose) made of stainless steel in the form of a corrugation. For the production of this type of eyeliner, a stainless steel tape is twisted into a tube and welded with a laser beam along its entire length, and then compressed into a corrugation. Rolled sleeves are welded to the bushing. The service life of such an eyeliner is higher than that of a hose in a metal winding, and can be up to 25 years.Due to the corrugated structure, the bellows liner is able to withstand large pressure drops, water hammer and absorb thermal expansion (it is able to maintain its properties in the temperature range from -50 °C to + 250 °C).

During operation, microcracks form on the metal from variable pressure, which contributes to destruction. Under extreme conditions, a protected version is used - a bellows eyeliner in a metal braid. It is easy to install, has excellent flexibility and does not disturb the flow area (at least 11 bends per point).

In addition to the advantages, the bellows eyeliner also has disadvantages. With the simultaneous use of plumbing in the bathroom and in the kitchen, vibration and buzz of the corrugated hose are heard, which increase with increasing water pressure. For this reason, it is recommended to select a flexible liner with a larger diameter. For high water consumption, it is recommended to use a 3/4" flexible hose diameter. Another way to combat vibration and hum is to use a plastic-coated bellows, which also protects the bellows from damage.

Read the material on the topic: How to choose a flexible eyeliner

How to choose?

In order to choose the right flexible eyeliner suitable for each specific case, it is necessary to take into account many nuances:

- The braid should be selected depending on the room in which the installation and operation of the pipe will take place. A nylon pipe cannot be mounted near a fire, and a metal pipe in rooms with high humidity.

- The size should be such that the pipe does not stretch when connected, but you should not buy products that are too long.If the length of the hose is not correct, it will either not be securely attached or twisted with loose rings, which will quickly destroy the braid in the folds.

- The hose should not emit a strong rubber or chemical odor. It is strictly forbidden to use such an eyeliner for supplying drinking water, it is suitable only for technical needs.

- The product should not be too light - this is an indicator of the poor quality of the material. The highest quality is considered to be a product made of stainless steel or with brass fittings, and the lowest quality is made of silumin and zinc. There are hoses with plastic fittings - these are practically disposable products.

- The purpose of the liner must correspond to the operating temperature and pressure specified in the accompanying documentation. Do not connect the blue braided hose to a battery or gas stove - this can lead to both minor troubles and real emergencies.

- The hose should bend well, no defects should be visible on the body. Packaging must be selected whole and with the appropriate marking.

Italy is a manufacturer that has long established itself in the construction industry. Parigi products are considered one of the best Italian eyeliners. High prices are due to the reliability and durability of their eyeliners. All fittings are made of high strength nickel and will last at least 15 years.

No less popular foreign manufacturer is the company Mateu from Spain. Products of the middle price segment are found in almost every third apartment. Its distinguishing feature is the use of PEX hoses made of polyethylene.The same connections of this brand can be used both for supplying cold water and for installing a heating system.

Equation Bulgarian eyeliners are also quite common in the plumbing market. Despite the high quality and affordable price, reviews of real buyers vary greatly. This is most likely due to the fact that the more popular the product becomes, the more fakes for it appear on the market.

Domestic manufacturers are represented today by such companies as Aquatechnika, Monolith and Giant. Their products have a lower price, and the quality is often not inferior to foreign pipes. Buyers leave a lot of positive feedback on these models, however, they often point out some discrepancy between the technical specifications in the passport and the product itself. Despite this, the impression of Russian plumbing is generally positive.

"Not China!"

“The quality and durability of a flexible piping directly depends on who produces it,” explains Vitaly Dzyuba, plumbing equipment installation specialist. “Very often people buy Chinese faucets that come with low quality flexible piping. I immediately recommend changing them to high-quality, European-made ones. They are sometimes more expensive than the mixer itself, but they are reliable and one day you will not flood the neighbors from below.

Flexible eyeliner has many variations, but the structure of the material is similar for all models. The rubber hose is made of non-toxic material, and the braid is most often made of stainless steel, resistant to corrosion and chemical attack. Although there are options for braiding from other types of metal.The flexible cable can be from 30 cm to 5 m long. Both ends of the flexible cable are equipped with various connection options. These can be: nut - nut, fitting - nut and fitting - fitting.

When choosing a flexible eyeliner, the specialist advises to focus primarily on the name of the manufacturer, giving preference to European ones. You can press lightly on the braid - if it bends easily, then it is better to put the product aside.

Dziuba

If manufacturers use elastic non-toxic vulcanized rubber or EPDM in high-quality eyeliners, then manufacturers of cheap products use technical rubber with a pungent odor. So a low-quality hose can be identified even by smell. Such rubber in a short time "dubs" - loses elasticity and breaks. Accordingly, the service life of such hoses is minimal.

Dziuba

In their practice, plumbers also had to deal with a situation where the hose remained intact, but seemingly more reliable parts broke - fittings. They are made of aluminum, brass and nickel-plated brass. If fasteners from the last two materials serve for a long time, then made of aluminum quickly fails. Silumin elements behave even worse. If the fitting is made of plastic, then this is the worst possible option.

Pay attention to the quality of the crimping of the fittings, the material of the sleeves (only stainless steel is used in high-quality specimens) and the fit of the connectors. Weak compression of the braid indicates either a poor quality of the metal, or insufficient equipment settings from the manufacturer

Low-quality metal cannot provide sufficient wall thickness, which will lead to oxidation, corrosion, deformation and destruction.

A weak compression of the braid indicates either a poor quality of the metal, or an insufficient setting of the equipment from the manufacturer. Low-quality metal cannot provide sufficient wall thickness, which will lead to oxidation, corrosion, deformation and destruction.

Pay attention to the thickness of the union nuts. The thinner the walls of the metal nut, the more likely it is to deform

The weight of the product can also tell a lot about the quality of the nuts. The eyeliner you choose should not be too light. Very low weight indicates the use of aluminum in the braid, and the fittings are made of low quality metal. It will not take a long time to deform these elements.

If it is visually difficult to determine the material of manufacture of the nut, then it can be scratched a little. The color that appears on the scratch will tell you what material we are talking about: yellow is a sign that the nut is brass, and the absence of a color change or darkening of the nut indicates that you have silumin in front of you.

For what purposes this or that eyeliner serves, you will be prompted by the color of the tape integrated into the sheath: blue for cold water, red for hot water, and both colors are a sign of the versatility of this type of flexible eyeliner:

If you did not find any multi-colored ribbons on the braid of the flexible eyeliner, then you have a very cheap copy in front of you, which you should refuse to buy.

In high-quality flexible hose models, the nuts are already equipped with good gaskets and do not require additional sealing.

Instructions for use

Even if a good eyeliner has been purchased that meets the necessary requirements and is suitable for the operating conditions, it still needs to be connected correctly. Any product with an illiterate installation is unable to demonstrate high-quality and long-term operation - very soon the device will have to be removed and replaced with a new one.

Before proceeding with the installation of the hose, you need to inspect the liner

Attention must be paid to defects in sleeves and threads. If there is any doubt about the condition of these elements, it is better to replace the worn components or repair them.

Flexible piping does not handle kinks very well, so installation must be done with care. The possible bending radius should not exceed 6 times the diameter of the hose, otherwise the extension will be damaged and start to leak. Just a few minor cracks favor the rapid appearance of leaks.

If the fitting is screwed too tightly, the seal may be broken or the fitting may be damaged. Of course, it is necessary to tighten, but the main thing is not to overdo it. Even if there are already gaskets in the fittings, it is still necessary to rewind from linen tow.

The fittings are screwed into the holes of the mixer. Hoses should be routed through the openings of single wash basins. Fittings are used to attach the faucet to the bottom of the sink. The connection of the eyeliner to the water pipes is carried out by means of American women.

Upon completion of the installation work, the system is tested for water tightness.

Within 20 minutes it is necessary to test the connections for leaks. If nothing is found, then the mixer for cold and hot water will function flawlessly.If a leak is detected, it will be necessary to unscrew the connectors, inspect the seals, rewind and install the system in place.

The eyeliner system can be hidden, open, bottom, corner. The hidden method is often performed for the bath. It is desirable to carry it out even at the repair stage, since you will have to make drywall boxes or ditch the walls.

Hidden eyeliner must be arranged with high quality, using proven and expensive materials, since it will be difficult to unscrew this or that part and carry out repairs. For an open connection, it is enough to screw fasteners into the wall and install according to the previously formed plan.

Kinds

Now there are two types of flexible piping, which is used when connected to faucets:

- Flexible rubber hoses encased in steel braid;

- Bellows eyeliners with better connections.

Braided flexible hoses

Rubber options are produced quite easily, which has a positive effect on the final cost of products. Therefore, they are widely distributed among our consumers. It is also worth noting that some manufacturers produce anti-vibration eyeliners. Their peculiarity lies in the larger diameter of the hose. Thus, it is possible to avoid unnecessary noise and vibrations that appear as a result of the operation of pumping systems inside household appliances or plumbing communications. Bellows eyeliners with better connections.

Bellows connections

The bellows connections are made in the form of a corrugated sleeve made of high quality metal. Their sleeves are rolled and welded to the bushings. Each element providing contact with water is made of stainless steel.Alas, we only have imported options available, because their cost is much higher. Read more about them in the article about bellows type eyeliners.

Installation with metal-plastic pipes

Such pipes carry out both open and hidden installation.

When open - you can use press fittings (not collapsible) and clamping (collapsible).

When hidden - only press fittings.

This is due to the fact that clamp fittings weaken over time, and twisting with a wrench is required.

Metal-plastic pipes are sold in coils of great length, therefore, when laying pipes under a screed or plaster, it is advisable to use a single pipe.

Metal-plastic pipes are sold in coils of great length, therefore, when laying pipes under a screed or plaster, it is advisable to use a single pipe.

Installation of connections using threaded fittings.

Pipes and press fittings.

Types of eyeliner: characteristics and specifics of application

Elastic hoses for mixers are divided into two categories: reinforced braided hoses and bellows tubes. We will deal with the features of each type of product in more detail.

Flexible hoses with reinforced braid

The first type of eyeliner is a soft hose with high elastic properties, reinforced with a special braid.

The ends of the tube are equipped with fittings, with which the structure is attached to the mixer: on one side there is a fitting, on the other - a union nut with a certain diameter of the external thread. Reinforced devices are distinguished by an affordable price, therefore they are most in demand among buyers.

Despite the simple production technology, the structure of the hoses is quite complex. The base consists of rubber, rubber or transversely reinforced cross-linked polyethylene (PEX).

Experts say that in systems in which drinking water is supplied, the use of rubber liners is undesirable. The entire length of the product is braided with wire thread. Various materials are used to make braids.

Stainless steel. The most common type of winding for reinforced hose. It is characterized by optimal operating parameters of the middle level: the device functions perfectly within 10 atm. pressure and +95°С of liquid passing through it. Stainless steel devices work stably for up to 10 years.

Galvanized wire is a budget option both in terms of price and technical characteristics. Eyeliners made of this material have good flexibility, but they are not strong enough and quickly fail.

Nylon. The material has improved performance characteristics. Liners with nylon braid are as functional as possible: they are able to withstand up to +110°C and up to 20 atm. pressure. Their service life considerably exceeds analogs and usually makes not less than 15 years.

Aluminum braid is suitable only for those systems where the water temperature does not exceed + 80 ° C, and the operating pressure is not more than 5 atm. Such material is susceptible to corrosion, so it is better to use it in rooms with low humidity. Flexible hoses reinforced with aluminum braid do not require replacement for about 5 years.

Bellows tubes for water

The second type of connection is represented by bellows hoses. The durability and reliability of these models is much higher than reinforced products. The devices are distinguished by an unusual design that gives them excellent flexibility.

It consists of stainless steel assembled into alternating rings of different diameters. At the initial stages of production, the hose blank is selectively crimped, resulting in a movable corrugation shape.

The bellows water inlet can be foldable or have a fixed length. The first option is stretched within the range set by the manufacturer: from 200 to 355 mm, from 140 to 250 mm, etc.

Caution must be exercised when handling collapsible hoses, as excessive stretching will shorten the service life. Fixed length eyeliner is not stretchable

It is produced in a specifically designated size: from 20 to 80 cm (in 10 cm increments).

Devices show high resistance to low and high temperature parameters. They work great in the range from -50 to +250 degrees. Service life of bellows tubes reaches 25 years

Bellows hoses are united by a common drawback - noise when water is supplied to several consumers at once. The problem is relevant when, for example, water is supplied to the boiler, toilet and faucet at the same time.

To exclude it, experts recommend choosing an eyeliner with an insulating plastic coating. In addition, there are special anti-vibration modifications that absorb sound.

Polypropylene faucet

Polypropylene pipes began to replace metal pipes in the field of heating and plumbing. They also do not do without locking mechanisms. There are two ways to mount the crane on such products:

Threaded. Includes the following method, but allows the use of any ball or valve valve.

Threaded faucet polypropylene

Threaded faucet polypropylene

soldering method. For this case, special tap fittings have been developed.When used, permanent connections are formed.

soldering method

soldering method

To implement the first method, you will need the following tools:

- soldering iron;

- pipe cutter

Of the fittings, you can use the following options: MRV, MRN, a plastic neck with a union nut, an American with a plastic pipe. Each of them will be useful in certain situations. The work will be carried out in the following way:

- The end of the pipe must be straight.

- A nozzle of the required diameter is installed on the soldering iron.

- The soldering iron is heated to the desired temperature.

- On the one hand, a pipe is brought to the nozzle, on the other, a fitting.

- The elements are heated for the required time until the wall part softens.

- They are joined together and pressed tightly. You can not turn after the connection.

- After cooling, the male thread of the faucet or fitting is packed as described for metal pipes and the locking mechanism is screwed into place.

The second method is carried out in exactly the same way, but the tap is soldered directly onto the pipe.

What service life is guaranteed by various types of flexible piping

Flexible eyeliners of various types are used in almost all bathrooms, due to their versatility and ease of installation. Often, when laying or replacing plumbing in a house, rigid plastic pipes are used. Manipulations with a rigid pipe at the junction with a water intake point are very difficult and are used only in extreme cases, since it is much easier and more convenient to use various types of flexible pipes to connect mixers.

Inside the metal braid of the flexible hose is a rubber hose. What types of rubber and what structure of the metal braid are used determines the different types of flexible piping.The service life of the eyeliner and its purpose depend on the quality of the materials used (it is not at all necessary to use the most expensive type of eyeliner at every opportunity).

In high-quality types of eyeliners, non-toxic, safe rubber is used. Cheaper versions use technical rubber with a characteristic unpleasant odor.

During the laying of a water supply system or its replacement, special attention should be paid to the choice of the type of flexible piping, its purpose and the reliability of the manufacturer. Such actions will pay off many times over during the operation of the bathrooms.

After all, cheap samples of flexible hoses not only pose a health hazard, but can also cause leaks, which will entail additional repair costs.

Therefore, it is so important to immediately install such types of flexible wiring that will meet the established standards and serve you for a long time.

What is the service life of different types of flexible piping? This largely depends on the environment of use and the intensity of use of flexible hoses.

The most popular flexible eyeliner is types with a reinforced stainless steel braid. It is used in most houses and apartments and has a service life of about 10 years. The indicator of working pressure in these types of braid is 10 atmospheres.

There are also reinforced types of flexible piping with a service life of up to 15 years, a working pressure of 20 atmospheres and can withstand temperatures up to +110 ° C.

In cheaper types of flexible eyeliner, aluminum or galvanized iron braid is used. Such a material is less resistant to oxidation, especially in conditions of insufficient ventilation, which significantly accelerates the destruction of the reinforcing mesh. As a result, such a hose may suddenly explode (unable to withstand pressure) and lovers of such savings will be forced to make unplanned repairs.

Before installing any type of flexible piping, you should definitely find out the nominal working pressure and water temperature in the plumbing system of your house or apartment. In the case when the pressure does not exceed 5 atmospheres, and the temperature is not higher than +85 ° C, there is no need to install reinforced types of piping

But even in standard flexible piping options, it is better to pay attention to trusted manufacturers. Knowing some basics will allow you to easily communicate with sellers without fear of being scammed.

Flexible water or gas connections, reinforced with aluminum, have a service life of no more than three years, withstand loads up to five atmospheres and temperatures up to +80 °C. Further (more than three years) use of these types of flexible eyeliner can lead to sad consequences, so it is worth replacing them in a timely manner or immediately purchasing more durable models (made of stainless braid).

The main disadvantage of aluminum braids is their low corrosion resistance. Long-term operation in a humid environment (and in the bathroom, shower or bath it is always like this) leads to the destruction of the metal sleeve and, as a result, the rupture of the rubber hose.

An eyeliner from stainless steel. Such models are the most popular and are able to withstand up to 10 years of operation at pressures up to 10 atmospheres and temperatures up to +95 ° C. The technical characteristics of stainless steel make it possible to use a braid made of it in almost all water intake units.

Reinforced flexible water line is made with a nylon braid.The expected service life of such liners is up to 15 years with pressure parameters up to 20 atmospheres and temperatures up to +110 °C. Such types of flexible connections for connecting mixers are used infrequently, only in conditions of fairly intensive use.

Bellows type piping. This is a fundamentally different type of flexible hose, in which an all-metal corrugated hose is used instead of a braid. It has very high strength characteristics, not inferior in flexibility. The service life of these types of flexible hoses is even longer than those discussed above.

Read material on the topic: Flexible water supply in bulk