- Pipe bending tools

- bending plate

- Mandrel bending

- Profile bending application

- Bending with or without homemade equipment

- Auxiliary Methods for Pipe Bending

- What can be bent and what can't

- Choosing the right tool

- Classification of pipe benders

- Pipe bending technology

- Simple ways to bend pipes

- Bent by hand

- Using the hot method

- We use fillers - sand and water

- Heat Treatment Method

- Pipe bending radii

- Pipe bending radii

- How to work with a pipe bender at home

Pipe bending tools

The question of how to bend a pipe without a pipe bender will not cause difficulties if you use the simplest devices to perform this operation. You can perform cold bending of pipes using the following devices.

- In cases where it is necessary to bend a soft (aluminum) or steel pipe with a profile height of not more than 10 mm, a horizontal plate with holes is used, into which stops are inserted - metal pins. With the help of these pins, products are bent according to the required parameters. This method has two serious drawbacks: the low accuracy of bending, as well as the fact that when using it, it is necessary to apply significant physical effort.

- Products with a profile height of 25 mm are best bent using roller fixtures. The pipe is securely fixed in a vice, and a force is applied to that part of it that needs to be bent using a special roller. This device allows you to get a better bend, but also requires the application of physical effort.

Option, as they say, in haste. The long lever of this extremely simple device allows you to cope with rather thick pipes.

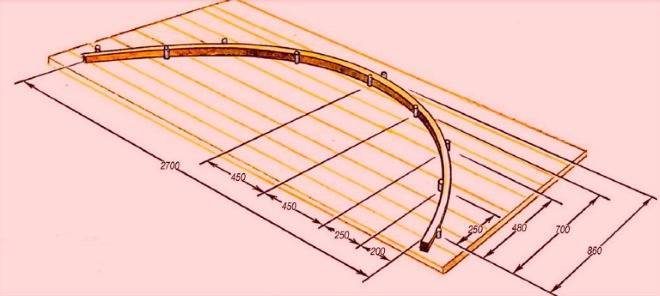

To form a bend with a large radius of curvature on steel or aluminum corrugated pipes, fixed rounded templates are used, on which special clamps are mounted to fix the product. On such a device, the pipe is also bent manually, with force laying it in the groove of the template, the shape of which exactly corresponds to the required bending radius.

Plywood and metal staples are all you need to make a bending template

bending plate

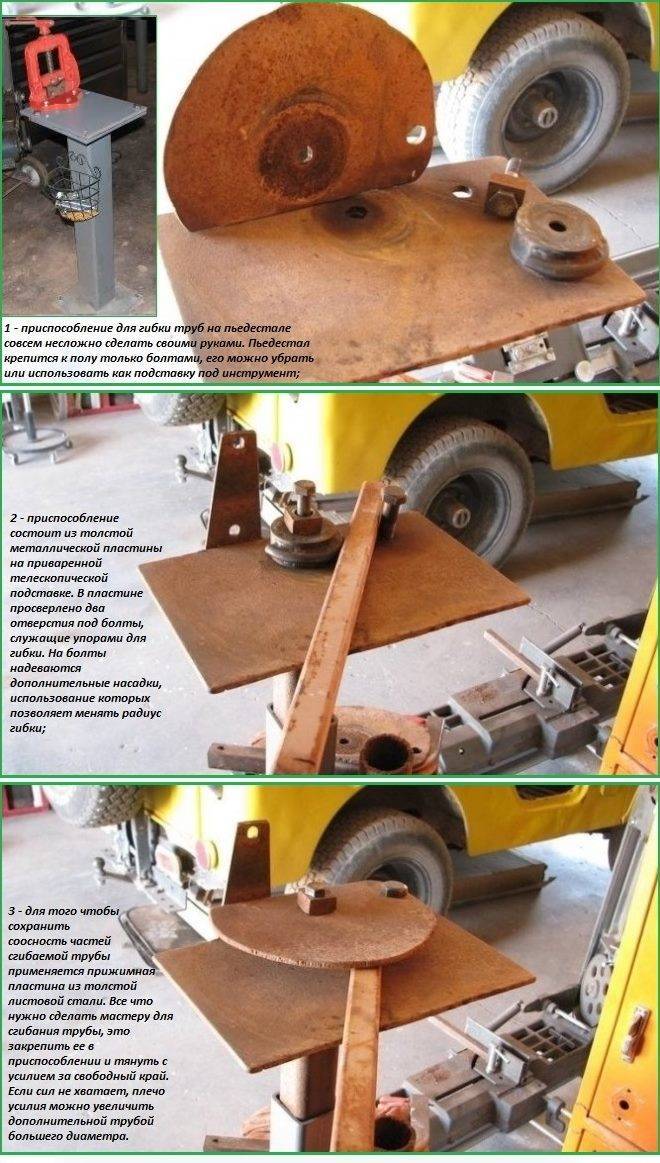

To effectively bend steel or aluminum pipes at home, you can make an upgraded bending plate using the following guidelines.

- The role of such a plate is played by a panel, which is cut out of sheet metal of great thickness.

- The panel, made in this way, is welded to the rack, which is installed on a special pedestal.

- Two holes are drilled in the panel, necessary for installing bolts that serve as stops for the profile pipe.

- A special nozzle is installed on one of the stop bolts, with the help of which the bending radius is adjusted.

- To ensure the alignment of the pipe sections adjacent to the bend, a metal plate is placed above the workpiece, fixed with bolts.

Mandrel bending

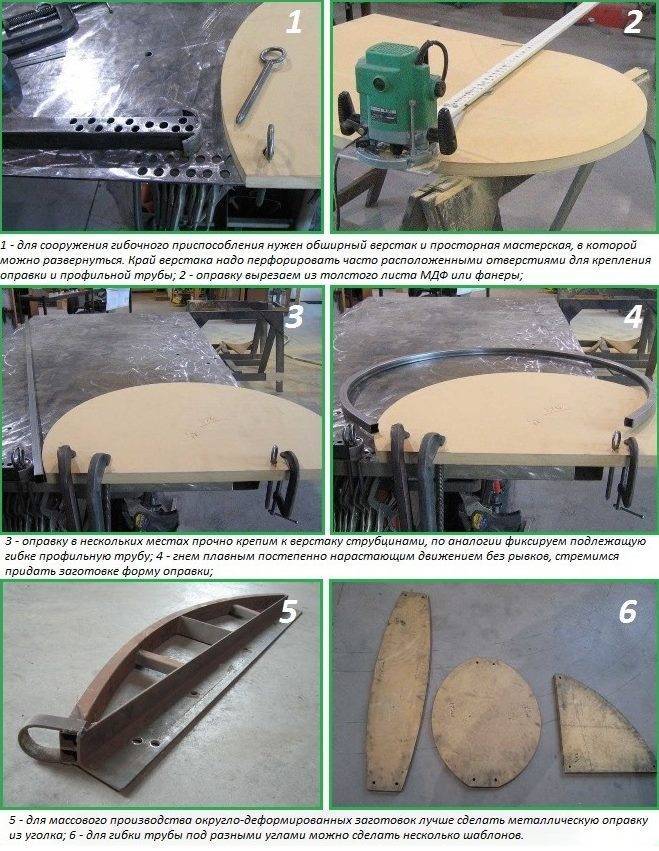

For bending profile pipe products at home, the wall height of which does not exceed 25 mm, a special mandrel can be made. For these purposes, it is better to use an overall workbench, on the surface of which there will be enough space for such a device. To select the optimal location of the element that fixes the bendable pipe, often located holes are made at one end of the workbench. A special template is responsible for ensuring the required bending radius of the corrugated pipe, which can be made from thick plywood or a metal corner if you are going to use it often.

Profile bending application

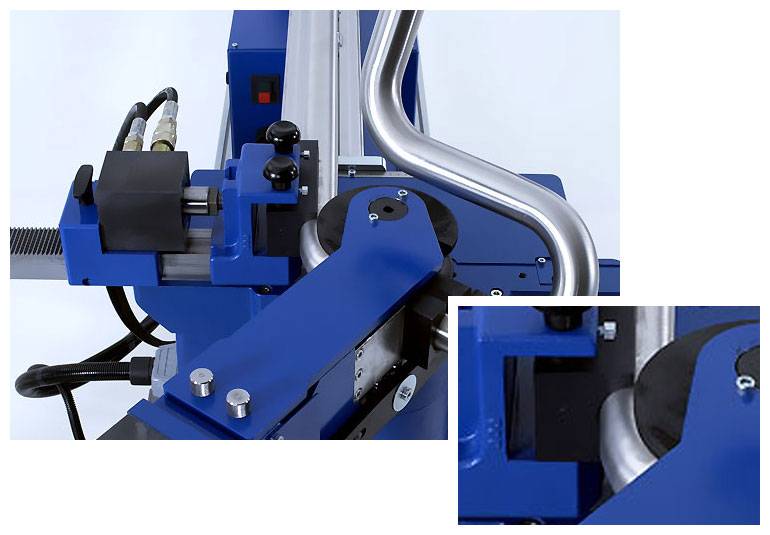

Of course, if you have a significant amount of work on bending profile pipes, it is better to make a special machine for this, the drawings of which are easy to find on the Internet. We will not analyze this issue here, since it is considered in more than detail in the articles on the links below.

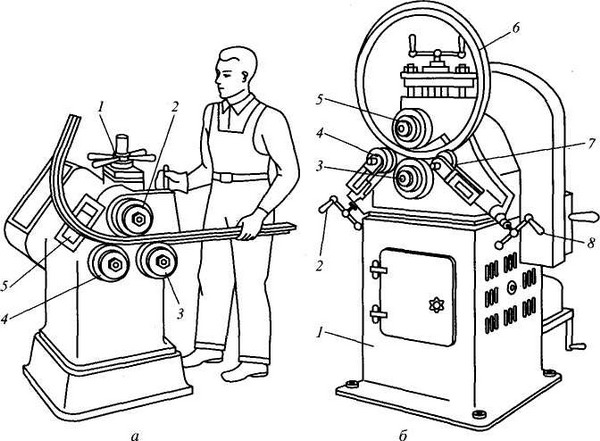

You can not do without such a machine even if you need to bend pipes with a large profile section. The main working bodies of such a machine, which is characterized by wide versatility, are three rolls, two of which are fixed motionless, and by changing the position of the third, the bending radius of the product is adjusted. As a drive for such a device, a chain drive and a handle that is rotated by the operator are used.

Curved pipes may be needed when installing heating appliances, plumbing, when installing pipelines in a house, etc. If you have not purchased the necessary pieces of pipes already bent, then you can bend them yourself at home.The only thing that can go wrong is the bending of the pipe inward and its rupture, since when bending the metal of the product, it experiences both compression and tension at once. And in order for this not to happen, you must adhere to the following tips.

Bending with or without homemade equipment

This option is common, as a jack is a very popular tool that most motorists have. It is perfect for bending rolled metal at home. According to the principle of operation, this method is similar to a crossbow pipe bender. The pipe is fixed at three points, two of which are stops, and the third is the jack rod.

Using an angle grinder (grinder) for bending profile pipes

This method works with a rectangular section profile. Several cuts are made along three walls, the fourth remains untouched. Due to the appearance of cuts, the pipe is easily bent, after which the cuts are welded and polished.

Homemade roller pipe bender

Excellent for obtaining a large diameter bend on a profile pipe. It is convenient for them to bend, for example, a pipe for greenhouses. A piece of metal is fixed on rollers, pressed, and rolled. Then it tightens again, and rolls again. The result is a large uniform bending radius.

Auxiliary Methods for Pipe Bending

Filling

A filler is placed in the pipe to fill the internal space. In this case, the ends are tightly sealed, for this you can use welding. The use of filler allows you to "fix" the internal volume. When bending, avoid the appearance of "waves", "corrugations" on the inside of the corner and make the bend smoother.Pure quartz sand is often chosen as a filler.

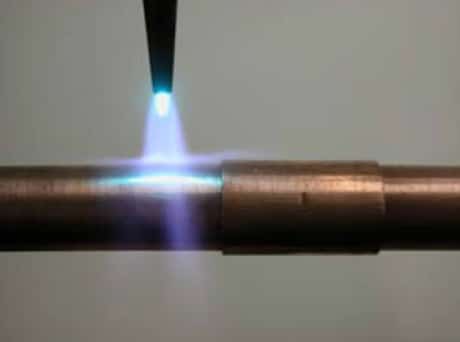

Heat. Increase in metal ductility during bending

The heated metal becomes softer, the higher its temperature. Pipe metal is heated using gas burners, induction heating, as well as any other available method. The heating temperature depends on the metal. Low-alloy and ordinary standard steel is heated up to ~500 degrees Celsius.

Using these methods, you can bend a metal pipe with your own hands at home without the use of specialized equipment and get good results.

What can be bent and what can't

Many compatriots are wondering whether it is possible to bend polypropylene pipes and how to do it correctly ().

Consider which materials are subject to mechanical deformation without prejudice to subsequent operation, and which are not.

It is possible to bend almost all metal products, including aluminum, copper and steel pipes of various diameters. It is more difficult to change the configuration of stainless steel and similar hard alloys.

For the correct deformation of all metals without exception, a special pipe bending machine is needed. The use of a special machine will not only ensure the optimal quality of the bend, but will also allow you to complete the task with minimal physical effort.

Some plumbers, in order to save fittings, heat polypropylene with an industrial hairdryer and bend it to the required shape. It is impractical to do this, because due to deformation in combination with heating, a curved plastic pipe will have an uneven wall thickness on the outer and inner radius.

As a result, the operation of the constructed water pipeline will be short-lived, since under the pressure of the liquid medium, cracks will appear in the thin wall over time.

Choosing the right tool

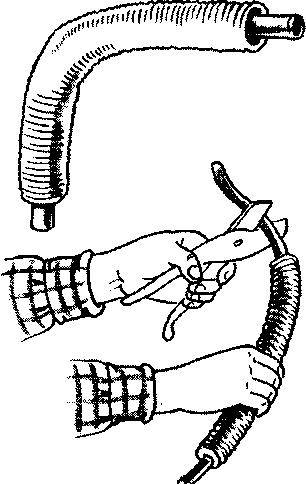

The spring is an effective tool for working with metal-plastic. Springs on the market are of two types: external and internal. Both types of tools are distinguished by an affordable price. The tool must be selected according to the outer or inner diameter of the pipe.

The device is made of polished steel. The smooth surface of the coils allows you to remove the spring from the bent pipe. The use of a spring makes it possible to ensure the same cross-sectional diameter throughout the bend.

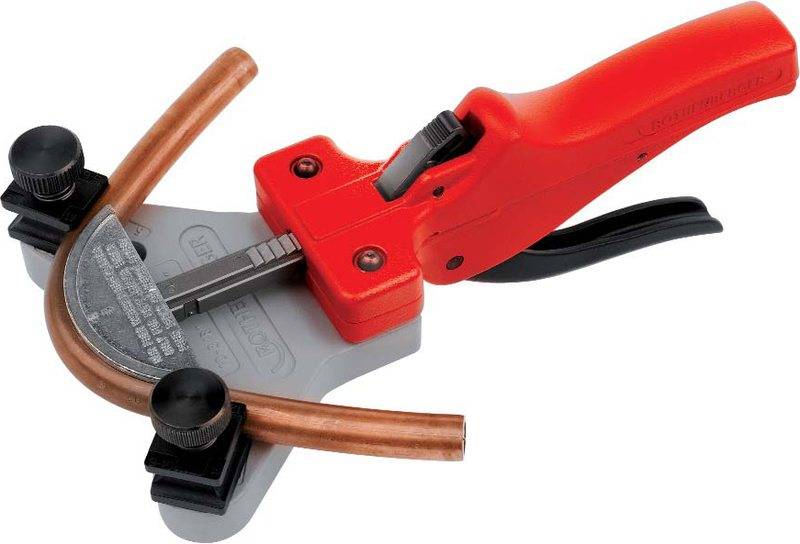

A pipe bender is a wide range of machines or devices designed to deform rolled metal, taking into account the required bending angle and radius. The devices are actively used in the construction of pipelines for various purposes of various configurations and sizes.

Classification of pipe benders

All modern pipe benders meet the following requirements:

- the possibility of bending at an angle of up to 180 degrees;

- the ability to work with pipes made of various materials, including aluminum, copper, steel and polymer compositions.

Such equipment, according to the type of drive used, is divided into the following categories:

- Manual modifications

, as a rule, are applied to work with pipes of small diameter. The device is driven by a collar, to which a significant muscular effort is applied. - Hydraulic Modifications

is the best choice for working with pipes whose diameter does not exceed 3 inches.The operation of hydraulic devices allows you to work with pipes without excessive physical effort. There are mobile and stationary hydraulic pipe benders on the market. - Electromechanical modifications

presented on the market with universal devices designed to perform high-precision bending. The main advantage of such pipe benders is the ability to work with thin-walled rolled metal without the threat of damage.

According to the bending method and working part configuration, the tool can be:

Crossbow

, where a replaceable metal guide mold is used as a deforming element, which is selected for a certain pipe diameter.

Segment

, where rolled metal is pulled by a special segment that wraps the pipe around itself.

In the photo - a mandrel machine

Dornov

, where work with rolled metal is carried out both from the outside and from the inside of the pipe. This feature allows the device to be used to change the configuration of thin-walled pipes without the threat of metal rupture or wrinkling along the inner diameter.

Pipe bending technology

The instruction for changing the configuration of pipes by means of an external spring is as follows:

- The spring is put on metal-plastic;

- Then the pipe is grasped with both hands at a distance of 20 cm from the spring and bent until the desired angle is obtained;

- After the desired angle is obtained, the spring rotates around its axis and is removed.

The use of an internal spring is different in that the device is inserted from the edge of the pipe, where it can then be pulled out.

The bent end of the pipe can be obtained using a pipe bender. In this case, the device, in accordance with its modification, is configured to the required parameters. Then the pipe is inserted into the receiving gap and the device is driven by one or another drive.

Simple ways to bend pipes

Bent by hand

Do not despair if you have to install a complex structure using curved pipes, but there is no professional tool available. Even if it was not possible to purchase blanks with the desired bending angle in advance, you can make parts for the work yourself, at home and with a minimum of tools.

How to act? Grab the structure with your hands, hold it tightly and gradually bend it. Be careful not to damage the part. Smoothly, centimeter by centimeter, move along the length of the pipe. You need to repeat the manipulation in 5-6 approaches. Manual work is not suitable in all cases, since bending an aluminum pipe, for example, is much easier than doing the same with a metal product.

The tube can be bent without pipe bender - by hand

The manual method is effective when working with pipes with a diameter of 16-20 mm. With a larger cut, the process will stretch and be more laborious, but this is real.

Using the hot method

We figured out aluminum, but how to bend a metal pipe on your own so that the result does not disappoint? A gas burner will solve the problem.

Action algorithm:

- We fix the metal segment in a vice.

- We warm up the section of the future bend.

- When scale appears, proceed to bending.

How do you know when to start work? If the material is aluminum, hold a sheet of paper close to the surface of the pipe. The signal will be its ignition or the appearance of smoke.If other metal, the heated area will turn red.

Please note: the heating method is not suitable for working with galvanized parts - damage to the coating is guaranteed, the coating will become unusable

Heating is an effective way to safely bend pipes

We use fillers - sand and water

The use of fillers makes it possible to bend both the corrugated pipe and large-diameter aluminum pieces.

How to work with sand:

- we fill the sand inside the structure, put plugs on the ends of the pipe (watch for tightness);

- fix the part in a vice;

- we heat the place of the bend with a soldering iron or a gas burner;

- when the area heats up, bend the structure with a rubber mallet or a wooden mallet, gently tapping on the heated surface;

- upon completion of the manipulations, we remove the plugs, remove the sand from the cavities - everything is ready.

Sand protects the pipe from deformation and uneven bending.

Keep pipes tight when working with sand and water

The principle of working with water is almost identical - we pour water into the part, put plugs. Before bending a PVC pipe or a product made of another material, let the water freeze (expose it to frost or place it in a refrigerator). Upon freezing of the liquid, with translational movements we give the structure the desired bending radius.

According to this principle, you can both bend a sheet of metal into a pipe (only without the use of water and sand), and give a bend to the pipe itself.

Heat Treatment Method

As for the metal pipe, your assistant should be a gas burner. We act in stages.

- With the help of a vice, the metal section of the pipe is fixed.

- The intended section of the bend is heated with a gas burner.

- After the appearance of scale, we carry out a bend.

It is important to catch the moment of the beginning of the bend. If the pipe is aluminum, then it is necessary to bring a sheet of paper to it

If it lights up or smokes, then you can start. If the pipe is made of another metal, then the area reddened during the heating process will serve as a signal. The heat treatment method cannot be used when bending galvanized pipes. High temperatures will damage the coating and render the coating unusable. You need to know that if we are talking about bending a square pipe, then you cannot do without a powerful blowtorch or burner. And most importantly, at the very beginning of work, such a product is heated from all sides.

Pipe bending radii

Pipe bending radii

Pipe bending is a technological process, as a result of which, under the influence of external loads, the slope of the geometric axis of the pipe changes. In this case, elastic and elastic-plastic deformations occur in the metal of the pipe walls. Tensile stresses occur on the outer part of the camber, and compressive stresses occur on the inner part. As a result of these stresses, the outer wall of the pipe with respect to the bending axis is stretched, and the inner wall is compressed. In the process of bending the pipe, a change in the shape of the cross section occurs - the initial annular profile of the pipe turns into an oval one. The greatest ovality of the section is observed in the central part of the camber and decreases towards the beginning and end of the camber. This is explained by the fact that the greatest tensile and compressive stresses during bending occur in the central part of the bend. The ovality of the section at the bend should not exceed: for pipes with a diameter of up to 19 mm - 15%, for pipes with a diameter of 20 mm or more - 12.5%. The ovality of the section Q in percent is determined by the formula:

where Dmax, Dmin, Dnom are the maximum, minimum and nominal outer diameters of the pipes at the bend.

In addition to the formation of ovality during bending, especially for thin-walled pipes, folds (corrugations) sometimes appear on the concave part of the bend. Ovality and wrinkling adversely affect the operation of the pipeline, as they reduce the flow area, increase the hydraulic resistance and are usually the site of clogging and increased corrosion of the pipeline.

In accordance with the requirements of Gosgortekhnadzor, the bending radii of steel pipes, bends, compensators and other bent elements of pipelines must be at least the following values:

when bending with pre-stuffing with sand and with heating - at least 3.5 DH.

when bending on pipe bending machines in a cold state without sanding - at least 4DH,

when bending with semi-corrugated folds (on one side) without sand stuffing, heated by gas burners or in special furnaces - at least 2.5 DH,

for curved bends made by hot drawing or stamping, at least one DH.

It is allowed to bend pipes with a bending radius less than those indicated in the first three paragraphs, if the bending method guarantees thinning of the wall by no more than 15% of the thickness required by the calculation.

The following main methods of pipe bending are used at pipe procurement depots and plants, as well as installation sites: cold bending on pipe bending machines and fixtures, hot bending on pipe bending machines with heating in furnaces or high-frequency currents, bending with folds, hot bending sand-filled condition.

The length of the pipe L, necessary to obtain a bent element, is determined by the formula:

L = 0.0175 Rα + l,

where R is the pipe bend radius, mm;

α—pipe bending angle, deg;

l - a straight section 100-300 mm long, necessary to grip the pipe during bending (depending on the design of the equipment).

1. Name the tolerances for the ovality of the pipe section.

2. How is ovality calculated as a percentage?

3. What bending radii are allowed by the requirements of Gosgortekhnadzor when bending pipes in various ways?

4. How to determine the length of the pipe to obtain a bent element?

All materials of the section "Pipe processing" :

● Pipe cleaning and straightening

● Flanging of pipe ends, fittings and holes

● Threading and thread rolling on pipes

● Pipe bending radii

● Cold pipe bending

● Hot pipe bending

● Cutting and processing of pipe ends

● Processing of non-ferrous pipes

● Plastic and glass pipe processing

● Preparation and revision of fittings

● Production of gaskets in pipe shops and workshops

● Safety regulations for pipe processing

How to work with a pipe bender at home

Pipe benders are called special mechanisms, which are characterized by a different principle of operation. With their help, manual and mechanical bending of profile and round pipes is realized in production or at home.

There are the following types of manual pipe benders suitable for bending plastic thin-walled aluminum products with a small diameter:

- Lever. This mechanism is also called the Volnov machine. For laying the workpiece, it provides a special form. The bending process itself does not require heating the pipe, and is carried out by leverage.The shape corresponds to a certain diameter.

- Crossbow. The structure in which the workpiece is fixed is equipped with a bending segment that pushes through the middle of the pipe from the side opposite from the ends.

- Spring. Before bending, the pipe is equipped with a spring, which is laid inside the product. Further, the workpiece can be heated, or a cold bending method can be used. At the end of the procedure, the spring must be removed.

With the help of machine bending, it is possible to solve the problem of how to bend and how to straighten an aluminum tube of various diameters and shapes. The risk of damage is reduced to almost zero.

These mechanisms can have an electromechanical or hydraulic principle of operation, which guarantees an accurate result of work, according to the requirements put forward.

![§ 29. Pipe bending [1980 Makienko N.I. - general plumbing course]](https://fix.housecope.com/wp-content/uploads/d/8/f/d8f00e83aca4da127ce2c77d06c2c08a.jpg)

![§ 29. Pipe bending [1980 Makienko N.I. - general plumbing course]](https://fix.housecope.com/wp-content/uploads/2/4/5/245c1ed6eda8cb674f45c7734f687d31.jpg)