- Compositions based on epoxy resins and other polymers (Elakor, Technoplast, KrasKO)

- Sealing and injection of concrete

- Cracks in concrete on paths, blind areas and in decorative products made of artificial stone

- Ready-made hydraulic seal for wells: how to use it

- What are concrete damages and causes

- Repair technology

- Preparatory work

- Solution preparation

- Elimination of a large defect with formwork

- Repair with composite compounds

- Elimination of cracks, liquid composition, filling and injection

- Thixotropic Torqueting Method

- Sealing cracks in concrete on horizontal and vertical surfaces, concrete repair mortar

- Large cracks in concrete

- Tool for sealing cracks in concrete

- Types of cracks and other defects in concrete

- injection

- Sealing

- Classification of concrete damage

- Types of cracks and the reasons for their formation

- vertical

- Horizontal

- through

- Shrink

- Leveling damage

- More about the main reasons

- Long-term repair of defects

- The best epoxy compounds

- How to cover the seams in the well between the rings

Compositions based on epoxy resins and other polymers (Elakor, Technoplast, KrasKO)

Such materials are used for various types of concrete repair, for injection work to protect concrete from various kinds of influences (polyurethane, acrylate, epoxy). Rigid, semi-rigid, elastic solutions are taken into work.

Polymer materials require preparation and priming. The application is carried out with a smooth spatula or polyamide rollers, or with special injection equipment.

Repair acrylate compositions are used to seal cracks, chips, increase strength, waterproofness of the base. To enhance the positive properties, you can fill it with quartz sand.

Two-component epoxy compounds are used in cases where it is necessary to restore the bearing capacity of concrete, create an adhesive layer, and repair cracks. Two-, three-component polyurethane are effective in localizing leaks, blocking the flow of water.

Scope of application: repair of concrete floors for industrial and civil purposes, warehouses, garages, workshops, hangars, etc.

Advantages:

Advantages:

- high rates of chemical and mechanical resistance;

- high wear resistance;

- fire safety;

- good adhesion to the base;

- waterproofing, waterproofing.

Flaws:

low viability.

Specifications

| Viability | 30 minutes |

| Curing time | 24 hours |

| Adhesion to concrete | Over 1.5 MPa |

| Consumption | 200-300 g/sq.m. |

Sealing and injection of concrete

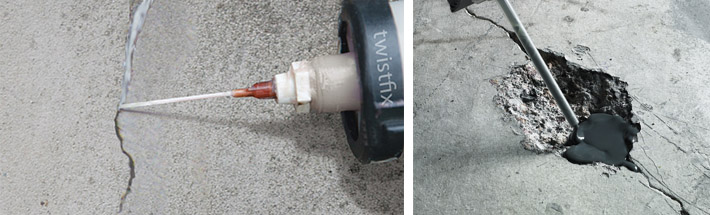

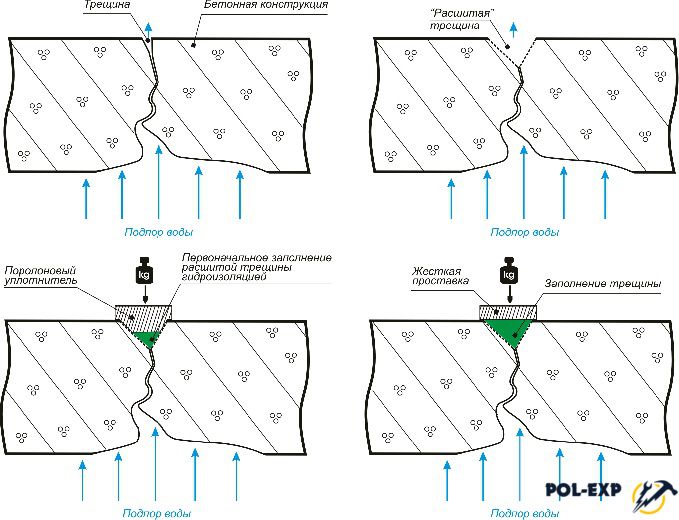

One of the methods most often used to eliminate defects is called sealing, the second is injection. He is considered the most professional and has the best effect. But to use it, you need to have certain working skills.This method is more expensive, but the results are impressive. The procedure is carried out as follows: special compounds of polymers or cement mixtures with additives are pumped into the formed seams, voids, cracks in concrete under pressure. They are able to quickly fill the space, after which they harden.

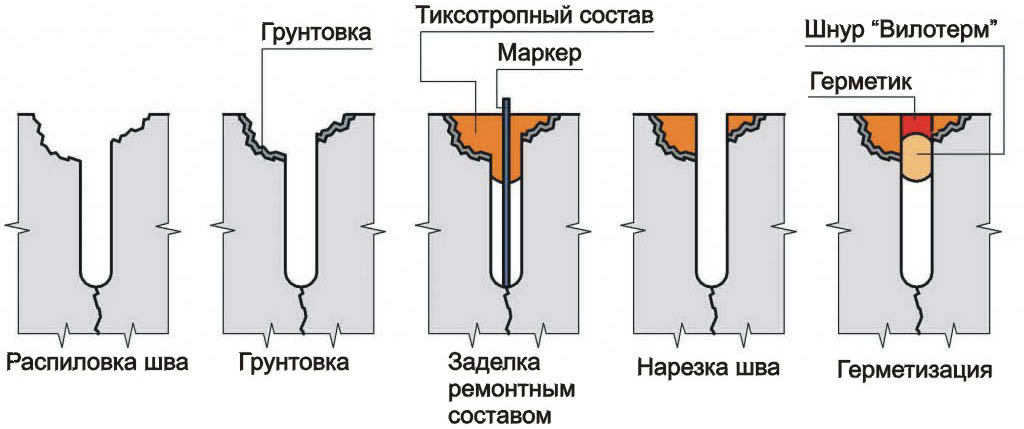

Another method is called crack sealing. First, the cavity should be cleaned of crumbling concrete particles. Then the space is tapped with a chisel. The excess layer of concrete must be removed 300 mm up from the crack and the same - down. After processing, crumbs and dust are completely removed from the site and the prepared repair composition is applied. It's cooked from a solution of sand and cementadding polymeric components there. Epoxy resin can be used in this composition. The treated surface the last stage is covered with a polyurethane sealant.

Cracks in concrete on paths, blind areas and in decorative products made of artificial stone

Most often, cracks in concrete on garden paths, playgrounds and blind areas near the house occur in the event of insufficient thickness of the concrete coating, the absence of the necessary technological gaps or their incorrect location, poor-quality base, and the wrong ratio of the ingredients of the cement mixture.

Once again, it must be recalled that in the calculations, first of all, it is necessary to take into account the characteristics of the soil on the site (for slabs and foundations), climatic factors and requirements for surface decoration (for small architectural forms).

For the former, the main reason for the formation of cracks is the uneven shrinkage of the substrate of the concrete slab or block.Since ordinary concrete does not work well in bending, when deformation occurs, the concrete structure cracks.

For the latter, an important factor is the exact dosage and precise execution of technological operations.

In decorative products, cracks in concrete occur much less frequently. This is because a stronger composition is used due to special additives. Such a stone is more elastic.

However, they can occur with improper storage in the winter. So, if you do not cover the flowerpots (for example, with plastic wrap), when the positive and negative temperatures drop, the water accumulated in the flowerpot, freezing, expands and can destroy the concrete wall. This is clearly seen in the following example.

But if they appeared, then refurbishment is required. Otherwise, it often threatens partial or complete destruction of the product.

In the latter case, this is not the repair of a crack, but the gluing of the product in parts.

If it was made of concrete, then epoxy or cement glue will also work fine for this job.

If the product is made of ceramics, then it is advisable to use a special glue for this type of stone.

Ready-made hydraulic seal for wells: how to use it

Leak-sealing solution make dry mixstrictly adhering to the instructions. As a rule, 150 ml of water 18-20 degrees is needed for 1 kg of dry mix. If necessary, you can knead small volumes of waterproofing composition, based on the proportion of 1 part of water - 5 parts of dry cement.

The solution is mixed for half a minute, after which it is immediately applied to the area with a leak.

What mixtures for waterproofing are better:

- Waterplug. Diluted with slightly warm water.It hardens within 120 seconds, it is applied at temperatures from +5 to +35 degrees.

- Peneplag. In addition to concrete, it can be used to fix leaks in brick and stone wells. Freezing time - 40 sec.

- Puder ex. One of the fastest fillings, hardens in 10 seconds. Not applicable at temperatures below 5 degrees.

During the preparation of the solution, as well as subsequent work with it, certain rules should be followed. Always wear a respirator and protective gloves when working. Do not use any liquids to mix the solution - only ordinary water, and the container must be metal.

What are concrete damages and causes

To understand the causes of damage, you need to know the properties and composition of concrete. It is prepared from cement, sand and water. I use crushed stone as a filler, and to improve performance - special additives, for example, a plasticizer, fiberglass. For strength, the concrete structure is reinforced with reinforcement.

When the solution hardens, it shrinks, in other words, it shrinks. The resulting artificial stone is strong in compression, but not resistant to stretching. When such forces act on it during operation, defects are formed.

Damage is of the following types:

- Loosening the overall structure. Defects may not be visually visible, but minor damage reduces the strength of the concrete structure.

- Surface destruction. The defect appears on the upper layers of concrete in the form of chips, potholes.

- Destruction of deep layers. The defect is manifested by cracks that form in loose areas of the concrete structure.

In general terms, there are two reasons for the occurrence of the destructive process of concrete: a violation of the technology of its manufacture and from old age. There are no questions about the first factor. If the mortar is not made correctly, then the concrete structure will be of the same quality.

As for old age, the following factors influence the acceleration of the process:

- excessive mechanical loads;

- exposure to chemicals;

- increase in physical processes caused by thermal expansion;

- reinforcement corrosion.

If the initial stage of damage is detected, it is urgent to carry out old concrete repair prevent it from further destruction.

Repair technology

In general terms, the repair technology is based on the following steps:

- preparation of the foundation for restoration;

- installation of formwork and moistening of the base (if necessary);

- solution preparation;

- applying the concrete repair mix to the repaired base.

The next step is to take care of the restored area.

Preparatory work

The concrete structure for restoration is prepared in the following ways:

- Mechanical preparation involves the use of a chisel, hammer, puncher, other tool to help remove unreliable areas of concrete.

- Thermal preparation is based on heating the surface of the concrete base with a burner to a temperature of 90 ° C. Roasting removes contaminants from the artificial stone. Thermal preparation is followed by mechanical or hydraulic preparation.

- Chemical preparation involves the treatment of the base with reagents, it is used where the mechanical method cannot be used.

- Hydraulic preparation is based on the use of equipment that creates high pressure up to 120 MPa. The method is used wherever it is safe to increase the humidity of the air.

The purpose of the preparation is to remove the broken sections of concrete. Optimal layer sampling up to 20 mm deep, minimum width 100-150 mm.

Solution preparation

The dry composition of the concrete repair mix is diluted with water. It is optimal to use a concrete mixer for large quantities, for a small batch - a drill with a nozzle. The amount of water added is indicated in the instructions, but usually 0.13 liters of liquid are added per 1 kg of powder.

The preparation of composite, sealing and injection formulations involves mixing the components in a clean container. The proportions are similarly indicated in the instructions.

Any solution is prepared in the right amount, taking into account the period of its viability.

Elimination of a large defect with formwork

Action is necessary when large defects made by builders are being repaired. The formwork is equipped with boards, plywood, long sections are reinforced with supports to prevent deflections.

The resulting extra protrusions are cleaned off, technological voids are sealed by injection.

Repair with composite compounds

The technology is used, if necessary, to strengthen the structure without its weighting and changing the geometry. First, the base is sandblasted or sanded, an epoxy primer is applied, left to dry for up to 12 hours.

The liquid mixture is applied with a roller, brush. If sand is present in the composition, it is leveled with a rule or trowel.After hardening, the restored surface is ground, epoxy resin is applied with a roller to seal the pores.

Elimination of cracks, liquid composition, filling and injection

Repair of cracks is carried out after elimination of their causes formation, restoration of waterproofing, complete drying of the base.

The method depends on the depth of the defect:

- Small spider-like cracks are eliminated by applying liquid compositions that form a protective coating.

- Deep cracks on both sides are expanded to approximately 150-200 mm, deepened to 50-70 mm. Dust is blown out of the grooves with a compressor, a polymer composition is injected by injection or a seal is placed, filling the voids with fiber-reinforced concrete.

The composition of the mixture for injection, the technology of its supply depends on the size of the crack. Small grooves are filled with a pneumatic injector that creates a pressure of 0.2-0.3 MPa. In cracks with a depth of 450 mm or more, the composition is injected using a hand pump, packers.

The working pressure is maintained at 20 bar, but in the process it can be increased to 40 bar. The mixture is supplied until it exits the neighboring packer installed in the fracture.

Areas with large cracks are stitched together with anchors, after the injection of channels, a layer of mortar with a thickness of about 20 mm is applied over the entire area of \u200b\u200bthe base.

Thixotropic Torqueting Method

In order for thixotropic mixtures to adhere firmly to the base, after preparation it must have a rough texture. The concrete surface is abundantly impregnated with water and treated with soil when wet.

In small areas, thixotropic concrete repair is carried out manually. The mixture is applied with a spatula, trowel or trowel. In large areas, the torteting method is used. The thixotropic mixture is supplied using compressed air or a pneumoconcrete pump.

One cycle provides for the application of a layer up to 30 mm thick. The mixture is leveled on a recoverable base. The number of layers, as well as their thickness, is determined by the project.

Sealing cracks in concrete on horizontal and vertical surfaces, concrete repair mortar

On the walls, cracks can have different directions, but most often they are vertical.

The appearance of thin cracks with a width of less than 1 mm indicates that during construction in the structure or in the base of the foundation there are shortcomings in work, errors in technology, or incorrectly selected materials.

It is necessary to analyze and perform corrective actions for backfilling, waterproofing, additional strengthening of stone structures.

Fine cracks in concrete can be sealed with epoxy or liquid cement. The ratio of cement and the finest sand is 1:1. Sand can be replaced with stone flour, for example, dolomite.

If using epoxy, then the crack must be thoroughly blown and dried before sealing. If you use a cement mortar, then first the crack must be treated deep penetration primer or at least moisten with water, removing dust and crumbs.

Usually thin cracks putty. With the end of the tool or another thin metal plate, you should try to “push” the solution as deep as possible deep into the crack. After that, the surface is leveled with a spatula.

Large cracks in concrete

If the gap is large (several mm or more), in order to save money, the same amount of quartz sand with a fraction of up to 1 mm can be added to the epoxy resin.

If you use a cement mixture, you can purchase ready-made cement glue for gluing heavy slabs or prepare the composition yourself, as was done during the construction of an artificial rock and in the article about concrete tiles (how to glue concrete tiles).

In this case, in addition to sand and cement, cellulose ethers and redispersible powder (RPP) are added to the mixture, which have already been repeatedly described in the articles on the pages.

Cellulose ethers accumulate and retain water in the solution for a long time and give it the opportunity to carry out all the necessary reactions to obtain the necessary strength of the artificial stone.

RPP allows you to increase the stickiness of the adhesive solution and improve the connection with the stone. RPP is actually a dry form of latex, which is found in many varnishes and paints, as well as various impregnations. Therefore, they are sometimes added to the cement mixture, but this, as you understand, is much less effective and more costly than using pure RPP.

Therefore, the masters solve this issue in very different ways: what kind of repair mix for concrete to use.

Tool for sealing cracks in concrete

Now a few words about the tools that will help and facilitate the repair of concrete.

If you use epoxy resin, then the tool becomes disposable. Therefore, as a spatula, you can use scraps of plastic and thin plywood. You can use a syringe, but it will most likely have to be thrown away after work.

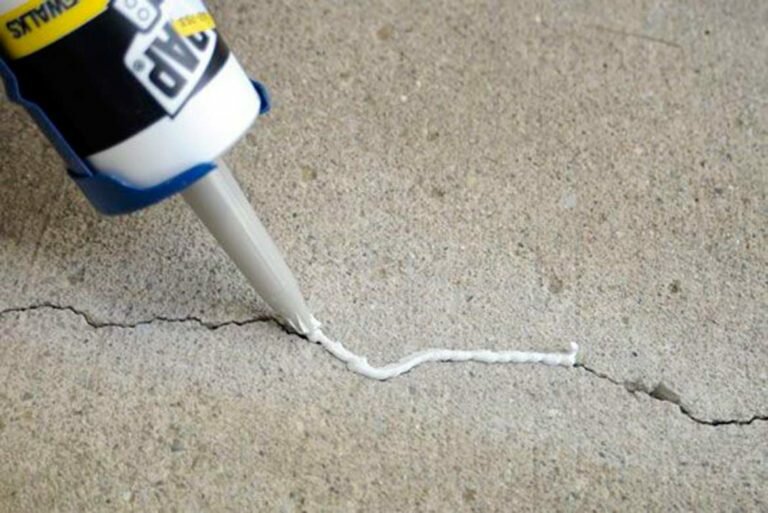

It is quite another matter if cement glue is used as a repair mixture for concrete. It is easy to wash any dishes from it for further use.In this case, there are two options for using a syringe to seal a crack.

First option: use a syringe for filling machine oil or a large medical syringe, which can be bought at a pharmacy.

Second option: use a used and cleaned tube of silicone glue. The remnants of the old silicone are easily removed, as they do not stick to the plastic of the tube. The piston is also easily squeezed out with a metal rod or a long screwdriver.

Filling the tube with cement glue and installing it in the glue gun, we get an excellent reusable free tool.

Using such a tool, it is easy to inject the repair cement mixture to a great depth into the cavity of a crack in concrete.

Such a tool can also be used for decorative purposes: filling the joints between tiles on paths and playgrounds or applying a color pattern on concrete surface.

Sometimes cracks in stone walls are sealed with mounting foam, using its properties of significant expansion and high-quality filling of the cavity. From the outside, the foam is painted with paint in the color of the wall. It also protects it from ultraviolet solar radiation.

Types of cracks and other defects in concrete

When it is necessary to restore a concrete pavement with the guarantee of a long service life without further deterioration, resin-based compositions are considered. They are characterized by good adhesion, increased strength, do not allow cracks to increase in size. In addition, such mixtures are versatile. Another advantage of sealing cracks in concrete floors and walls using this method is the quick drying of the composition.

Prepare tools and materials:

- containers for preparing the solution;

- spatulas;

- grinder, diamond-coated discs;

- a vacuum cleaner;

- primer;

- resin composition;

- fine grained sand.

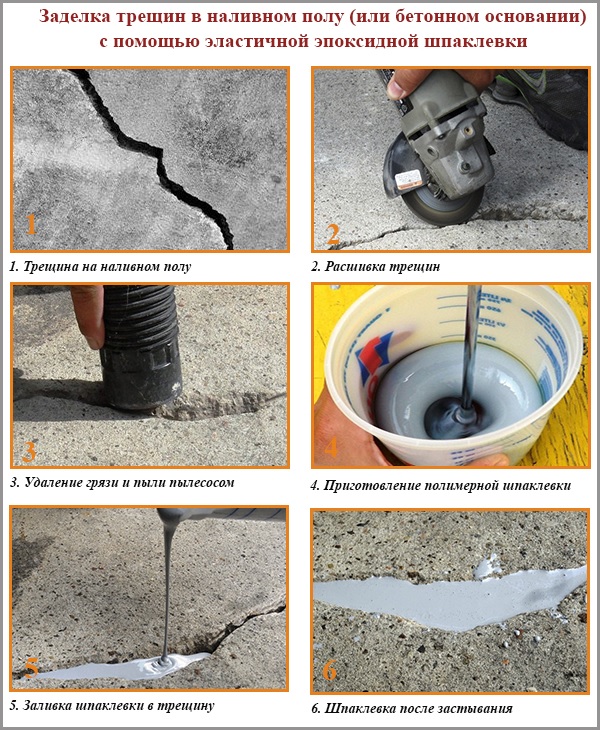

The sequence of actions for the repair of concrete pavement:

- The crack is being patched. At this stage, using a chisel and a hammer, the deformed sections of the coating along the gap are removed. The recommended leak width is 5 mm or more.

- To harden the coating in this area, transverse grooves are created using a grinder and a diamond disc. They should be located with a step of no more than 400 mm. The length of each groove is up to 150 mm. Their width corresponds to the thickness of the diamond disk.

- By means of a vacuum cleaner, dirt, building dust are removed.

- The grooves are fixed with special brackets.

- The side surfaces of the crack are treated with a primer. Without this material, sufficient strength of the coupling will not be ensured.

- Given that the epoxy-based mixture hardens quickly, it is necessary to prepare it immediately before use. The composition should contain sand and a hardener, in addition to resin. The ratio of components is indicated in the manufacturer's instructions for the mixture.

- The crack is filled with epoxy. Freezing time - 10 minutes.

- When the gap is filled, sand is sprinkled on top of the mixture. It is removed before finishing work.

Epoxy resins for sealing cracks in concrete. If it is necessary to fill cracks in concrete, materials of increased strength should be considered. These include:

- epoxy resin ED-16 and ED-20, the kit does not include a hardener, so it is purchased separately (price up to 500 rubles), the cost of the main material is 2000 rubles. for 3 kg of resin;

- Epoxy 520 (manufacturer Spolchemie), price 3500 rubles. for 5 kg;

- UZIN KR 416 is more expensive than analogues (2700 rubles for 0.75 kg), but it is distinguished by increased reliability, it is made in Germany.

Cracks appear on large and small construction sites subjected to heavy loads or collapsing under their own weight, located in moderate or extreme climatic conditions. Defects are classified according to several criteria:

- Through and superficial, which can be deep and shallow.

- In width - cracks in concrete can be hairy (up to 1 mm), medium (1-10 mm), wide massive (over 10 mm).

- In relation to reinforcement - with its partial or complete exposure or without exposure of reinforcing bars. The latter option is possible if the defects are located along the edges of the structure or between the reinforcing elements.

- By location - local, over the entire surface, at the edges and corners.

- According to the time of occurrence - primary cracks formed during hydration or during shrinkage processes in concrete, and secondary ones that occurred during operation.

- According to the impact on the integrity of the object - no effect, reducing strength (5-50%), destructive (the drop in the strength level of the structure exceeds 50%).

injection

Injection is based on the supply of special compounds under pressure into the openings that have appeared, which completely fill the voids formed and harden. The injection of the filling mixture is carried out by pneumatic, electric or mechanical pumps. Their design capabilities are designed for a clear dosage of injection components, maintaining the required pressure level.The injection material is polymer-cement materials, epoxy resin. To carry out such a procedure, holes are drilled in concrete along the crack on both sides and packers are installed through which the injection composition is supplied (Fig. 1).

Sealing

Sealing - filling the formed cracks with a special compound that ensures tightness. To carry out this procedure, the damaged area is tapped with a hammer to determine the level of corrosion. On each side of the crack, damaged material is removed by about 30 cm. The prepared area is free from dust. A repair-sealing mixture for concrete is laid on it with a spatula or trowel. Such a mixture may consist of:

- cement-sand mortar with plasticizers;

- epoxy resin;

- polyurethane based sealant.

Classification of concrete damage

As a result of various internal and external influences (see table 1), concrete may crack. This applies to large and small objects stressed by external loads or under tension from their own weight. To understand why concrete cracks after pouring, you first need to know the classification of cracks.

Chipping and cracks in concrete vary:

-

by nature - through and superficial (deep and shallow). To determine the depth, probes of various types, ultrasonic devices are used;

-

in width - microscopic (hairy), medium (over 1 mm), wide, massive (more than 10 mm). To determine the width of cracks, measuring instruments of different accuracy and nature are used;

- by exposure of reinforcing elements - contributing to corrosion (to the reinforcement, with its full or partial exposure) and passing between the reinforcement elements (at the edges, in between);

-

by the time of formation - primary (in the process of hydration, shrinkage of the concrete mixture) and secondary (during operation structures);

- by location - at the corners and edges of a concrete object, over the entire surface, throughout the volume, local (for example, in the area of applied stress or periodic mechanical impacts);

- according to the degree of impact on the structure - reducing strength (5 ... 50%), destructive (reduction in strength over 50%).

Important: if the expected conditions of concreting and operation are violated, the occurrence of cracks is inevitable, therefore, a margin of 10 ... 30% is included in the design conditions.

Types of cracks and the reasons for their formation

If the damage in the cross section has a width of 1-2 mm, then this is considered an acceptable and safe phenomenon. When the parameter exceeds 5 mm, then it is worth contacting specialists for an examination. It includes an analysis of the current state of the structure, the identification of threats and the issuance of recommendations on how to close a crack in a brick house wall outside, inside, winter or summer.

vertical

The appearance of such crevices is preceded by miscalculations of designers and mistakes of builders. The reasons include non-compliance with expansion joints, excess load on lintels and partitions, poor quality of concrete and masonry mixture. Manifestations of violations occur more often in winter.

Vertical split type

Horizontal

This kind of cracks appear more often in masonry mortar.The reason for this is shrinkage. This may concern the foundation due to pressure from the building or groundwater, loaded structures. Often in this situation, the house is pulled around the perimeter. If the split in width is less than 5 mm, then such a decision is erroneous.

through

Such defects are considered the most dangerous, therefore, in this case, the building is often transferred to emergency status. Through holes appear due to deformation of the foundation. In this case, it is not shrinkage that becomes the cause, but a natural element or a falling tree, an explosion.

Through damage to brick structures

Shrink

This type of damage is otherwise called hair damage. Here there is a deformation of the foundation and the main part of the building, including the roof. Prevention of crack formation is a competent approach to the choice of concrete mortar, compliance with construction technologies.

Leveling damage

It is not uncommon for occupants to experience damage on leveled structures. In this case, also before repairing cracks in the plaster on the wall, it is necessary to determine reasons for their appearance. They come down to a violation of the technological process of plastering. In particular: heterogeneous composition, excess thickness of a single layer application, lack of reinforcement.

Cracking of plaster from shrinkage of the building

More about the main reasons

A number of reasons that lead to destruction are identical for brick walls, foam blocks, panels, concrete and plastered structures. In new buildings, problems appear relatively faster than in the old fund due to non-compliance with construction deadlines. On the shrinkage of the skeleton today, a rare customer or developer will suspend work for a whole season.As a result, the installation of windows and finishing works are carried out in a still moving building.

Cracks on a brick facade in a new building

The second common reason is the quality of geodetic surveys. The choice of a constructive solution, building materials, additional measures to ensure the durability of the planned facility depends on the results of research and examinations. More often, problems arise due to neglect of unstable soil and groundwater.

The list of common causes also includes the wrong approach to plastering walls. Work is often carried out on a damp base, when the floors and ceilings have not yet dried out, due to time savings. To reduce the cost estimate, low-quality reinforcing materials, primers, and leveling mixtures are used. In order not to expect a long time for the complete drying of the applied layer, additional ventilation with heating is created, the coating is formed in one run in excess of the recommended limits.

Plastering walls without reinforcing mesh

Long-term repair of defects

When deciding how to repair cracks in concrete for a long time, you should pay attention to this method of processing defects. Resin and mixtures for sealing based on it are suitable for the restoration of screeds, blind areas and various concreted areas or horizontal surfaces

Repairing cracks in concrete using such compounds has several advantages. First of all, this is the cheapness of the mixtures, as well as their quick drying. On the other hand, the resin allows you to securely fix the seams and keep them from further increase.

So, to eliminate defects, you will need to prepare:

- angle grinder and diamond-coated discs;

- a vacuum cleaner;

- spatulas and a trough for diluting the composition;

- primer for concrete;

- Epoxy (base A and hardener B);

- Fine-grained sifted sand.

Before you close the crack, you need to clean it from dust and dirt. After that, we perform the termination in the following sequence:

- We make crack jointing. In this case, the width of the resulting recess must be at least 5 mm.

- With the help of a grinder, we cut transverse seams in concrete with a step of 400 mm (the length of the grooves is about 100-150 mm).

- We remove the loose layer of concrete and dedust the surface with a vacuum cleaner.

- We treat the surface of the defect with a primer, and fix the transverse grooves with repair brackets.

- We prepare a solution of resin (base), hardener and sand according to the instructions on the package with the composition.

- We close the defect with the resulting mixture and quickly level the surface, since the setting time of the resin is only 10 minutes.

After that, it is recommended to cover the surface with sand, which will need to be removed with a vacuum cleaner before filling the base or covering it with a finishing material.

The best epoxy compounds

If we talk about the best materials for repairing cracks in concrete walls and other surfaces, then the most effective today are:

- Epoxy resin of domestic production ED-16 and ED-20 costing about 2,000 per 3 kg. The hardener will have to be bought separately (it costs about 300-500 rubles).

- Epoxy 520 resin from the Czech manufacturer Spolchemie worth 3,500 rubles per 5 kg.

- German composition UZIN KR 416, which will cost 2,700 rubles for 0.75 kg.

Also, compositions from the Italian manufacturer Sika are very popular.

However, it should be borne in mind that this method of correcting defects is not suitable for processing holes that form in concrete bases that are under strong pressure from water. In this case, it is worth using a sealant.

How to cover the seams in the well between the rings

Do not use foam or epoxy for sealing joints.

You should also be careful with various sealants. Such sealing materials may not bring the desired effect, and also spoil drinking water.

For sealing seams between rings you can use ordinary cement with sand. This will be the cheapest way, but not the most durable. Under the influence of moisture and cold, such seams collapse very quickly.

For additional strength, liquid glass can be added to the solution. It should be borne in mind that with the addition of liquid glass, the solution quickly hardens.

If water oozes from the seams, then the cement mortar is not suitable at all. Such a mixture simply does not have time to harden and will be washed by the pressure of water. In this case, you will need a hydraulic seal. This is a specially designed solution that is not afraid of temperature changes, does not let water through at all and expands when dried.

If the seams, after cleaning from dirt, debris and chipped concrete, turned out to be too deep and wide, they are plugged with jute, hemp or linen rope, impregnated with a special compound suitable for waterproofing.

It is most convenient to caulk or, in other words, hammer a rope into a slot with a wooden spatula and a hammer. Then the remaining space is sealed with a hydraulic seal. Sealing dry seams are carried out with cement mortar. This approach will save money and reliably cover up cracks and seams.