- Types of sealants and methods of their application

- Silicone based sealants

- Tapes for sealing pipe joints

- Types of materials for waterproofing sewer pipes

- Sealing materials

- Tapes for sealing

- silicone sealants

- Sealing sewer pipes with other sealants

- Ways to fix leaks

- We close the joints with tape

- Use sealants to fix leaks

- The main types of sealing materials (characteristic)

- Sealing tapes

- Polymer sealants

- Mastics based on petroleum products

- Epoxy resin

- Portland cement

- Advantages and disadvantages

- Manufacturers

- Technical sulfur

- How to ensure the tightness of the junction of cast iron and plastic pipes

- What is better for sewerage

- For cast iron

- For PVC

- For joining cast iron and plastic

- Ceramics

- Cast iron and ceramics

- How to properly process a pipe

- Peculiarities

- The main types of hermetic materials

- Scotch tape

- Silicone sealants

- Technical sulfur

- Linen or jute cords

- Mastic and bitumen

- Portland cement mortar

- Epoxy adhesive

- Using glue for sewer pipes

- How to choose a sealant for sewer pipes

- Ways to solve the problem

Types of sealants and methods of their application

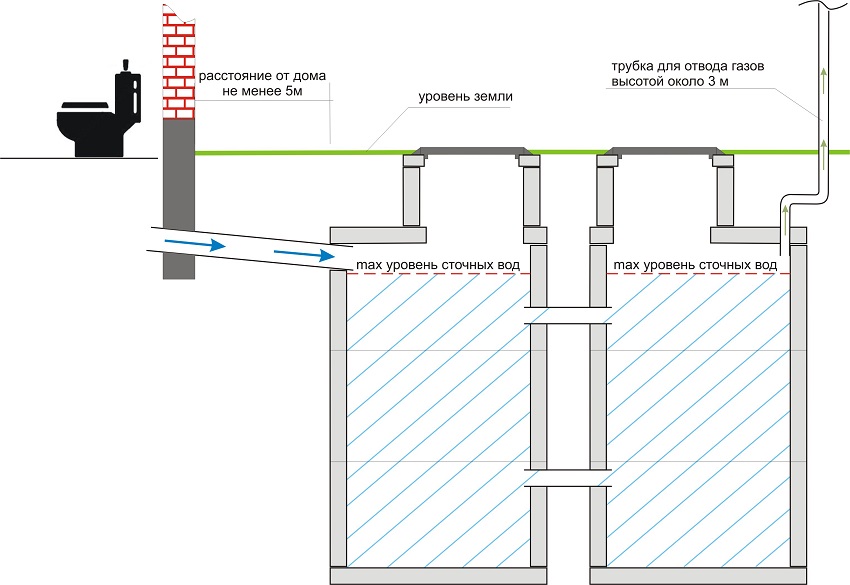

Especially responsibly, the sealing procedure must be approached when installing external sewer pipes buried in the ground, since correcting defects associated with pipeline leaks will be as difficult as laying pipes from scratch.

It should be borne in mind that leakage is not allowed not only from the cavity of the sewer pipes, but also inside them (in the case of high-passing groundwater), since this may affect the durability and normal operation of the external drainage system.

Silicone based sealants

Sealing sewer pipes with this type of sealant is currently more common than others.

These materials have the following features:

The main component of sealants is silicone rubber, supplemented by a whole composition of various kinds of substances and additives that provide them with excellent sealing properties.

Working with silicone sealant

Working with silicone sealant

- Manufacturers offer two types of silicone sealants - acidic and neutral - the first of which is cheaper, but not suitable for surfaces capable of interacting with acids; the latter are more universal and suitable for all cases.

- With silicone-based sealants, the joints of both plastic pipes and metal products can be sealed. During the vulcanization process, silicone paste turns into a substance similar in properties to rubber. The vulcanization process proceeds with the participation of moisture in the air.

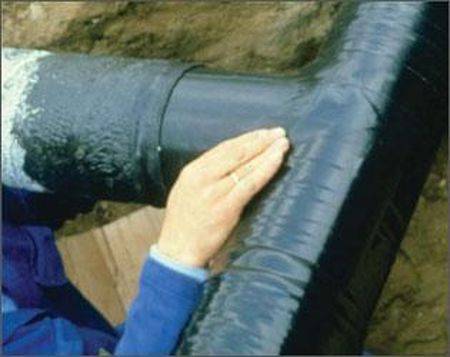

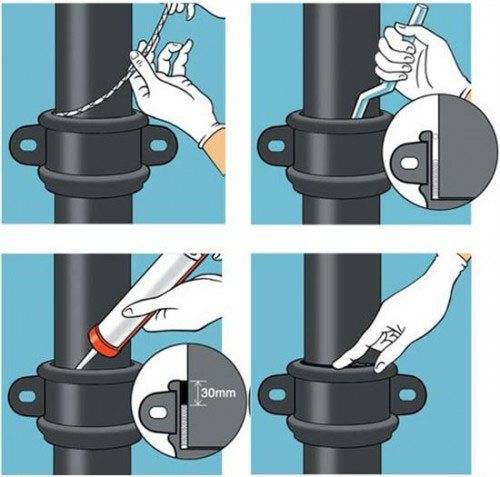

Tapes for sealing pipe joints

Anti-corrosion self-adhesive tapes are an innovative tool designed specifically for sealing pipe joints.They are distinguished by high efficiency combined with ease of use.

In addition to sealing, tapes can also serve as a means of complex protection of pipes, including dielectric and anticorrosion ones.

With the help of tapes, it is possible not only Tape for sealing pipe joints, but also tie-ins, plugs, turning corners, bends and many other elements of the pipeline.

Sealing with tape is done as follows:

- Carry out preparation for applying the tape to the surface by cleaning and drying the latter.

- When winding, keep the tape in constant tension to avoid the appearance of folds and wrinkles.

- The tape is applied in a spiral, providing an overlap of 50%, as a result of which the insulated surface of the pipe must be covered with two layers of insulating film.

It should be noted that sealing films are generally vulnerable to direct UV exposure. For this reason, when processing an open outer section of a sewer pipeline, it is necessary to cover the pipe wrapped with tape with any additional protective material.

Types of materials for waterproofing sewer pipes

To protect the joints of sewer pipes from internal and external influences, today the construction market provides a large selection of materials, including:

- self-adhesive tapes;

- silicone sealants;

- Portland cement;

- technical sulfur;

- epoxy resins;

- bituminous mastics;

- jute rope.

In everyday life, sealant tapes and building silicone are most widely used, which is caused by the availability of the material and its ease of use.However, other options also deserve attention, as they allow you to achieve sealing of sewer pipes at the same or higher level.

The result of poor-quality sealing of the pipeline

Sealing materials

Tapes for sealing

Both regular tapes and foil tapes are produced.

Self-adhesive tapes, which have anti-corrosion properties and are specially designed for sealing pipe joints, are one of the latest modern sealing products. They have many positive properties:

- Self-adhesive anti-corrosion tapes are highly effective and easy to use.

- Sealing films, thanks to their high-strength polyethylene backing, are characterized by good service properties.

- They are used to ensure the protection of various types of pipelines in the complex, as they have dielectric and anti-corrosion properties. In addition, sealing films are used for sealing linear elements of sewer pipes.

- Sealing using tape is possible not only when sealing the joints of sewer pipes, but also when sealing plugs, tie-ins, turning corners, bends, etc.

Before sealing a sewer pipe using sealing tapes, remember that they are sealed in the following sequence:

- surface preparation is necessary for applying the tape: it must be dry, dust-free and clean;

- it is necessary to ensure a constant tension of the tape, which is wrapped around the pipe, and also to exclude the appearance of folds and wrinkles;

- the tape must be applied with a 50% overlap in a spiral, as a result of which the entire surface to be insulated will necessarily be under two layers of film.

Sealing sequence (some tapes require primer treatment)

Pro tip:

Such films do not tolerate exposure to UV radiation. That is why, when pipes for sewerage are located in an area that is open to the sun, an additional protective layer must be provided over the film.

silicone sealants

Silicone is the most well known sealing material.

Silicone rubber forms the basis of silicone sealants. Silicone sealants in general are a composition of different substances that provide high sealing qualities. Silicone sealants have good adhesion to surfaces, while not requiring that they be pre-treated with primers.

According to the type of hardener in its composition, silicone sewer pipe sealant is divided into:

- Acid. Acid silicone sealants are quite inexpensive, although they do not accept application to some surfaces that can interact with acids.

- Neutral. In this regard, neutral silicone sealants are considered more versatile.

With the help of silicone sealants, it is possible to seal the joints of sewer pipes:

- from metal;

- from plastic.

After vulcanization silicone paste turns into a substance that is similar in its properties to rubber. Moisture in the air is involved in the curing process of silicone sealant.

Pro tip:

Squeezing out the sealant is quite simple - using a mounting gun.In its absence, you can use an ordinary hammer by inserting its handle into the tube and pressing like a piston.

How to squeeze out silicone sealant without a mounting gun

Sealing sewer pipes with other sealants

In addition to the above means, sealing pipes for sewerage is also carried out using other means:

- Epoxy resin - at home, it serves, as well as glue based on it, the most common tool that is used when connecting sewer pipes.

- Portland cement is a fairly common component of most sealing mixtures - it is used in the preparation of mixtures from asbestos cement and when caulking the connection of the socket of pipes for sewerage from cast iron.

- Oil bitumen and asphalt mastic - will be required for the preparation of the fill, which is designed to seal joints and fill the sockets of ceramic pipelines.

- Hemp or jute rope, resin strand - are used when sealing pipe sockets for sewage from cast iron and ceramics. The use of a combination of rope and resin impregnation would be preferred.

- Technical sulfur - used to ensure tightness, mainly, the joints of the sockets of pipes for sewerage made of cast iron. Before pouring into the joint slot, it should be crushed, and then heated until melting.

Technical sulfur can also be purchased in crushed form.

With such an abundance of materials, the question is unlikely to arise: “How to cover up the sewer pipe?”.

Ways to fix leaks

Residents must be warned not to use the sewer before work is carried out. Then you should turn off all appliances that use water, such as a washing machine. After blocking the leaking area, dry the leak thoroughly with a hair dryer.

Before starting work, it is worth understanding the material from which the sewer system is made. Today it is metal (steel, cast iron) or polymeric materials - polyvinyl chloride or polyethylene. How to cover up the joint of the sewer pipe depends on the material.

The leaking joint must be thoroughly cleaned from the remnants of the cementing mixture. Then treat with an aqueous solution of cement and PVA glue. Be sure to use gloves when doing this. The solution will dry for about a day. Accordingly, it is impossible to use the sewer at this time.

To perform work, it is desirable to use a repair clutch.

We close the joints with tape

Self-adhesive tape is a modern and reliable waterproofing material that allows you to quickly and efficiently seal sewer joints. The strength of the tape is given by a base made of polyethylene. Additionally, the product provides corrosion protection and good dielectric properties. The tape can be used to seal various parts of the plumbing system, such as bends, tie-ins and plugs.

Toilet plumbing involves the use of various sealants, and self-adhesive tape is the first way to wrap a leaking joint (but far from the only one).

Use sealants to fix leaks

Sealants based on silicone or rubber are an excellent option for waterproofing sewer structures.The high level of adhesion to the surface of the elements is due to excellent adhesion. Moreover, the sealing of pipes can be carried out without pre-treatment with primers and primers.

The type of hardener used in sealants imposes restrictions on use in different conditions. The cheapest, acid ones, cannot be used everywhere because of the possible chemical reaction with acids. Neutral sealants are universal.

We can safely recommend the use of such a sealant for most types of pipes. For reliability, after work it will be necessary to cover with silicone all the joints and places of possible leaks.

The main types of sealing materials (characteristic)

Previously, oil paint and sanitary flax were used as sealing materials. But modern technologies offer a much wider choice of different sealing materials.

Sealing tapes

These are self-adhesive tapes, somewhat similar to a skein of white tape. They are available in various widths and are mainly used for plastic pipes inside residential areas. Such tapes not only protect against water leakage, but also help to strengthen various related elements such as plugs, joints, and so on.

Of the main advantages of this sealant, the following can be distinguished: lack of electrical conductivity, reduced risk of corrosion of sewer pipes, ease of use and at the same time a high level of reliability of the material.

Sealing tape example

It is important to remember that under the influence of ultraviolet rays such tapes quickly deteriorate, therefore it is recommended to use them only inside residential premises.However, if there is still a need to use it in the sun, then the tape is covered from it, for example, with a special protective film

In order for this material to have the intended effect, the pipes must be cleaned of dust and dirt, and then thoroughly wiped or dried. A primer is applied immediately before gluing the tape. After that, the tape is wrapped around the pipe in a spiral, tightly, without folds with a half overlap.

Polymer sealants

Otherwise, they are also known as silicone rubber, since the main material in this case is silicone rubber. They are considered one of the most popular sealing agents, also because, if desired, you can choose such material in any color, including the same as that of the sewer pipe. They are mainly used to strengthen joints and seal fistulas. They can have both neutral and acidic compositions. Acid options are cheaper, but some pipes are not resistant to acids, and in general, such compounds are not recommended for fragile elements. Neutral options are used in all cases where acidic ones cannot be used.

Among the advantages of this type of product, the following can be distinguished: when using mold and rot, it does not appear, even over time, when it hardens, the composition becomes like rubber and perfectly protects sewer pipes from leaks. In addition, silicone sealants adhere well to pipe material, they are durable, resistant to moisture and temperature extremes, and also serve for quite a long time.

Polymer sealant for sewer pipes

extruded sealant with a special gun for installation, however, if there is none at hand, then you can use an ordinary hammer.

Mastics based on petroleum products

Also good for sealing sewer pipes, especially for filling sockets. There are several main varieties: bitumen-polymer, bitumen-talc, bitumen-rubber, bitumen-asbestos polymer. Mastics are both cold and hot method of application. Those with a cold method are a little more expensive, but they are simple and safe to use. Before using such products, it is advisable to turn off the water supply, and the pipes themselves must be cleaned, degreased and dried.

Epoxy resin

This variety is often used at home. In essence, resin is a universal adhesive. Before use, it is mixed with a special hardener. The required mixing ratios are indicated on the packaging by the epoxy resin manufacturer. By the way, it is impossible to deviate from the indicated proportions, this can lead to unexpected and unpleasant consequences. From suddenly boiling mixture, to the lack of effectiveness of the resin as a sealant for sewer pipes.

Portland cement

It is a dry mixture of gypsum, clinker and calcium silicates with special additives to increase the reliability of sealing. Before use, the composition is diluted with water to a thick solution. It is necessary to apply the resulting slurry immediately, since it hardens rather quickly (from 5 to 10 minutes) and turns into a monolithic structure with frost resistance, high strength, and the ability to repel water.

Advantages and disadvantages

To The advantages include the following qualities:

- Moisture and frost resistance, which allows the mixture to be used, including for external pipes;

- High strength and reliability of the solidified solution;

Portland cement - one of the sealants for sewer pipes

And as a drawback, it is worth noting the fact that it is necessary to work with a diluted mixture very quickly, otherwise it will harden and be useless.

Manufacturers

Among the most popular sealant companies, it is worth highlighting four main ones.

- Ceresit. German products that have European quality, standards and practicality in their arsenal. Sealants of this brand are known for their best adhesion to the treated surface, excellent waterproofing properties and the presence of special additives that protect the room from mold and germs.

- "Moment". The brand, founded by a German chemical company in Russia, has a large number of necessary construction assistants. Among them is the very popular Moment-Germent. A large number of varieties of sealants of this company allows you to choose your tool for any master. Among the unique products there are frost-resistant, high-temperature and restoration options.

- Ciki Fix. The Turkish manufacturer is also among the top four leaders in the Russian construction market. A characteristic feature of the sealants of this company lies in its extraordinary ability to fasten surfaces of different textures together. The seams are waterproof and elastic, but do not protect against fungus and mold.

- Makroflex. Another high-quality brand comes from Germany, but with Russian production.This is a modern and timely solution to any construction and finishing tasks. The company produces a variety of sealants that cope with both internal and external applications.

Technical sulfur

Sealing an old cast-iron sewer can be very difficult. Technical sulfur was often used to repair cast iron pipes. But for its application, it was necessary to heat the composition to a plastic state. A special vessel was used (a bath for heating sulfur). In addition to the high temperature and fire hazard, there was another risk factor in such work - toxic gas was released during combustion. Therefore, I had to work in a respirator. Now it is possible to seal the pipe in safer ways, so technical sulfur is practically not used.

How to ensure the tightness of the junction of cast iron and plastic pipes

For the manufacture of modern sewerage systems, polyvinyl chloride is used. Often there is a need to join PVC pipes with old cast iron pipes. Such a connection can be made in several ways, which depend on the state of the socket of the cast iron product.

If the old system is in good condition, the bell is cleaned of dirt and rust. A new pipe is mounted through a rubber adapter, having previously covered all the mating surfaces with silicone sealant. You can apply the method of sealing with tow or a tourniquet, followed by pouring with special mixtures.

If there is no socket, the connection is made through a plastic adapter and rubber seals. To do this, the edge of the cast-iron pipe is leveled and cleaned. A sealing ring is put on the socket adapter. This is followed by a rubber cuff and another ring. The whole structure is inserted.At each stage of the connection, silicone is applied to the surface. It remains only to apply a layer of sealant to the end of the PVC pipe and push it firmly into the constructed socket.

When docking, you can use a press fitting - an adapter with a thread on one side and a socket on the other. The edge of the cast-iron pipe is leveled with a grinder, cleaned, lubricated with grease or oil, and a thread is made. Tow or fum-tape is wound onto the formed furrows. Lubricate the joint with silicone and wind the adapter.

It is possible to combine means of sealing sewer pipes, thereby increasing the quality of the connection.

What is better for sewerage

The main question remains what to look for when choosing and how to seal the sewer pipe. The choice of sealant will largely depend on the material from which it is made.

In order to make the right choice, let's look at the main types of pipes that are used in sewer systems, and which sealing method is suitable for them.

For cast iron

For cast iron pipes, Portland cement sealant and technical sulfur are often used. This use is due to the low cost of the material and its reliability. The use of a polymer version would also be appropriate, but the cost of sealing would be much higher.

For PVC

It is recommended to use a sealant based on rubber or silicone to seal the plastic PVC pipeline. Such material is perfect for plastic and will last a long time. It sticks to plastic like glue. Such a sealant is also perfect for a metal-plastic pipe. Another common sealant for such a pipe is epoxy.

For joining cast iron and plastic

To seal the joint of pipes made of cast iron and plastic, it is required to use special adapters made of rubber or polymer. Before making a joint, it is required to clean the pipe socket from dirt and rust and degrease the surface.

For sealing, it is better to use silicone sealant, it must be applied to the inside and outside. After drying, the joint will be securely sealed. To perform the pipe transition process correctly, we recommend watching the video clip.

Ceramics

For ceramic pipes, silicone sealant must be used. On an industrial scale, petroleum bitumen and asphalt mastic are widely used.

Cast iron and ceramics

For joints of cast-iron and ceramic pipes, jute and hemp rope are perfect. A polymer sealant would also be a good option. Before buying the latter, be sure to tell the seller for what purposes it is needed. You will be helped to choose the most suitable composition.

How to properly process a pipe

The key to quality sealing is the correct preparation process. Depending on the type of sealant, you will need to use a special tool, it can be: a mounting gun, a clerical knife, etc.

Before applying the material, it is important to properly process the pipe:

- Clean the pipe of contaminants.

- Degrease the joint with gasoline or thinner.

- Allow time for the surface to dry.

- Apply sealant.

- Make the connection of the sockets.

- After drying, remove excess sealant residue.

If you follow these simple steps, the joint will be securely sealed and will last a long time.

Peculiarities

Sealant is used to ensure the smooth operation of sewer and water pipes. So that the tubes of plumbing accessories do not leak and do not spoil the mood of their owners with constant dripping. But this is only a small fraction of what this material is capable of.

Miracle tool is made on the basis of silicon. Since it is a hard stone, at least 4 more ingredients are added to it, which bring the sealant into a paste-like form. The plumbing option also incorporates fungicides - components that protect against bacteria and mold, which are a good antiseptic. Organic additives in the composition of the sealant are responsible for reducing the viscosity, and mechanical additives improve the adhesion of the product to the treated surface.

Today, one of the most fashionable trends is keeping the renovation of the premises in the same style, color, design. The sealant has an extensive range of colors, which is achieved by adding special dyes to the original composition.

Another nice thing about using this putty is that it can be stored for a long time when opened. To prevent it from drying out prematurely in the tube, it is necessary to close the hole with something.

What the sealant does not want to interact with under any circumstances is:

- polypropylene and polyethylene;

- PVC;

- polycarbonate;

- acrylic.

That is, not a single smooth surface in combination with a sealant will give the very powerful adhesion that is necessary to prevent moisture from entering where it is not needed. And the use of silicone with copper, zinc or lead can lead to intoxication of the body. Since this explosive mixture emits toxic fumes.

To understand which sealant is better to purchase for a particular situation, let's try to determine their main types.

The main types of hermetic materials

A variety of materials can be used to seal butt joints:

- self-adhesive sealing tapes;

- sealants based on modified silicone;

- technical sulfur;

- linen or jute rope;

- asphalt bitumen;

- Portland cement solution;

- epoxy resin.

Each of these materials has its own tasks, features and scope.

Scotch tape

The adhesive tape is made on an acrylic or bitumen-rubber base, it contains a copper or aluminum layer and a protective film that is removed during installation. This is a simple and effective tool with a long service life (over 10 years).

It provides high bond strength, protects pipes from corrosion and is a good dielectric. The scope of application is the sealing of tie-ins, functional plugs, pipeline rotation angles, bends.

Silicone sealants

The composition of such sealants includes rubber, so they are distinguished by increased elasticity and good adhesion to the surface. There are one and two-component compositions.

The first, depending on the components, are of two types:

- Acid. The polymerization process is accompanied by the release of acetic acid, but after solidification, the smell disappears. The elasticity of the material is maintained at temperature fluctuations from -50 to +200 °C. They are not used to seal metal elements, as they strongly oxidize the metal and can cause corrosion.

- Neutral.Suitable for all types of connections.

In two-component formulations, along with the base, there is a catalyst that accelerates polymerization, and the curing process does not depend on the layer thickness. But the cost of such sealants is higher.

Technical sulfur

Most often, technical sulfur is used to seal cast iron pipes. The trading network sells lumpy sulfur or a substance in the form of a powder.

Before use, the material must be crushed and heated to a melting temperature (130°C), after which it is filled into the joint surface.

We recommend that you read: Sealing the chimney with a heat-resistant sealant

After 10-15 minutes, a dense waterproof surface is obtained.

Low elasticity is the main disadvantage of such a sealant. To increase it, add white clay (10-15%).

Linen or jute cords

This type of material is distinguished by low cost and ease of use, but their technical and operational characteristics are inferior to modern types of sealants.

To create a strong connection, a 6-50 mm tourniquet is used, which is an ordinary twine or twine impregnated with bitumen or resin, which makes this material extremely durable and impermeable. Previously, before the advent of modern sealants, this was the most popular method for strengthening and sealing pipeline junctions.

Mastic and bitumen

To seal the joints of ceramic pipes and fill the sockets, compounds are used, the main components of which are asphalt mastic or petroleum bitumen. Rubber-bitumen, asbestos-polymer-bitumen, talc-bitumen mastics have shown themselves well.

According to the type of application, the mixtures are divided into cold and hot.The former are easier and safer to work with, they contain 50-70% bitumen and are more expensive.

When using hot applied mastics, they are heated to the required temperature, at which the solution becomes plastic. The result is a fast-setting seamless surface. When hardened, it does not shrink and is cheaper than cold-applied mastic.

Portland cement mortar

Portland cement consists of gypsum, clinker and calcium silicate. The working solution is obtained by mixing the dry mixture with water. It sets quickly and forms a durable water-repellent surface. To increase elasticity, special additives are used. The material is resistant to sudden changes in temperature and can be used for outdoor work.

Epoxy adhesive

To get a sealing composition universal adhesive mixes up with a hardener in the ratio depending on a brand of material of the pipeline.

All standards are available in the instructions for the epoxy resin, they must be observed, violation of the proportions will lead to a decrease in the performance of the finished coating and will affect the curing time.

Using glue for sewer pipes

Sewer equipment, significantly worn out, with numerous damages, is repaired using epoxy resin. The material is necessary to eliminate leaks when performing pipe repairs.

Through cracks found after inspection of the equipment are sealed with a two-component adhesive composition. The mixture is prepared immediately before use, following the manufacturer's recommendations.

A detailed inspection shows that it is quite easy to eliminate the leak if epoxy is used for sealing.The composition is used in combination with a hardener, and the ratio of components for the formation of a working mixture is 1:2 or 1:1. The polymerization reaction proceeds much faster with an increase in temperature by 10˚ C. The sealing of the formed cracks is quite strong, since the epoxy composition has minimal shrinkage, high resistance to adverse factors, and stable physical and mechanical characteristics.

Epoxy adhesive is obtained by mixing resin and hardener in a ratio of 1:10, and distilled water is used to form a composition with a water-borne resin.

Thus, following the rules for connecting sewer pipes, it is possible to carry out quality work related to the repair and planned replacement of equipment.

How to choose a sealant for sewer pipes

It is necessary to build on the type and structure of the engineering communications themselves. Polymer sealants are perfect for processing joints in an apartment, office, cottage, because they:

- are inexpensive;

- available to a wide range of consumers;

- presented in a rich assortment;

- easy to use;

- do not require special training.

With a large amount of work, it is recommended to combine materials with each other. As an option: sealing tape + mastic / epoxy / sealant.

An important factor is the material of manufacture of pipes. You need to make sure that the chosen agent has a good adhesion with metal, cast iron, polypropylene and PVC products, as the quality of the seam and its durability depend on this.

In some cases, other means of sealing drain lines are also suitable:

- rope soaked in resin - for cast iron / ceramic drains;

- technical sulfur - for sealing small joints;

- sealing cuffs - made of rubber and suitable for pipelines of various types.

Ways to solve the problem

The method by which the breakdown will be eliminated is selected based on the cause of the problem. Therefore, it is necessary to establish exactly what caused the crack, and only then proceed with the repair. If there is a leak in the sewer cast-iron pipe, then it can be eliminated in the following ways:

- install the clamp with rubber gasket. To use this method, the pipe must be located at a distance of more than 50 mm from the wall, otherwise the installation of the clamp is not possible;

- installation of cement bandage. Gauze impregnated with cement is applied to the accident site, a standard and universal way to eliminate malfunctions and cracks;

- use of chemicals. It is necessary to mix copper oxide powder and phosphoric acid, put the resulting solution on the site of damage and wrap it with a dense cloth.

When choosing a method, you should pay attention to the conditions for installing the cast-iron pipe itself and the cause of the problem. If you use the wrong method, you can only worsen the situation, which will lead to the formation of new cracks.