- How to make the right choice?

- How long does silicone sealant for the bathroom dry: the main factors

- 1 Ceresit CS 7

- In what forms is the sealant produced, types

- Instructions for use

- Devices for applying sealant. Sealant gun

- How to use a caulk gun

- Types of guns for sealant

- What is a sealant for?

- The Best Acrylic Bathroom Sealants

- Lacrysil

- Ceresit CS 11

- Remontix

- VGT

- Prevention

- Characteristics of sealants

- How to apply sealant to a bathtub?

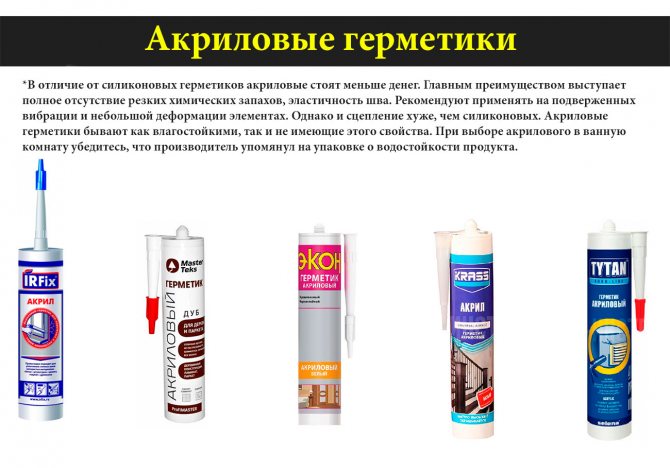

- Acrylic

- Application area

- Grades of acrylic sealants

- Tips and tricks for operation

How to make the right choice?

The type of work is the first thing you need to decide before choosing a specific product. For a bathroom, sealing is an excellent solution. It is known that the humid zone is a favorable place for the appearance of fungal bacteria. Thanks to the sealant, you can close all the cracks where water often flows. This will help to eliminate the microclimate favorable for the growth of unwanted microorganisms.

When choosing, the greatest attention should be paid to the following characteristics:

- How strongly the material and surface adhere to each other. In this case, it allows you to see after what time the substance will begin to exfoliate from the surface.

- Sealant suitability under different storage conditions. This takes into account the ability to maintain properties at any temperature.

- Pulling ability. This refers to the maximum length a substance can stretch before breaking.

- Drying of the sealant after complete drying. The material should not shrink too much.

Based on common features, the probability of choosing with the maximum benefit for oneself increases. However, for a clearer idea of each type, it is worth considering separately all the qualities in more detail.

How long does silicone sealant for the bathroom dry: the main factors

How long does sanitary sealant dry? The complete drying time of a silicone-based sealant is determined by the composition of the substance, the thickness of the layer, the place of application and external factors.

Acid silicone cures after 5 hours and neutral silicone after 24 hours. During this period, the ambient temperature must not drop below 5 °C. In this case, the sealant is applied in one layer, which can be quite thick, which is determined by the size of the filling gap. To harden such a seam, it will take 1.5-2 times more time. In the case of multi-layer application, there is a possibility of delamination of the seam.

Note! On the packaging of any adhesive composition, the drying period and the necessary conditions for its creation are indicated.

Depending on the type of silicone sealant, complete drying occurs within 5-24 hours. Drying of silicone sanitary sealant occurs gradually

First of all, the outer layer solidifies, which occurs after 10-20 minutes. After this time, the composition will not stick to your hands.

If the sealant is carelessly hooked before the end of the specified period, the integrity of its external texture will be violated or it may come off completely.

Drying of silicone sanitary sealant occurs gradually. First of all, the outer layer solidifies, which occurs after 10-20 minutes. After this time, the composition will not stick to your hands.

If the sealant is carelessly hooked before the end of the specified period, the integrity of its external texture will be violated or it may come off completely.

Sanitary silicone bathroom sealant should dry under normal environmental conditions. The room temperature should be between 5-40 °C. The second important requirement for good drying of the sealant is to ensure the movement of air masses in the room, which is extremely difficult to achieve in this room.

1 Ceresit CS 7

The best elasticity of the seams Country: Turkey Average price: 140 rubles. Rating (2019): 4.8

Sealant from Ceresit is a popular composition for sealing joints when installing plumbing and laying tiles. A feature of this product is the increased elasticity of the seams, which provides high-quality and durable insulation, despite the acrylic type. After drying, the sealant can be painted in the actual design color, which users especially like. The composition is characterized by good resistance to humidity in the bathroom, and a possible change in temperature conditions. Ceresit is one of the most famous brands, according to reviews, whose recognition has a positive effect on sales of this brand. To avoid cracking, it is not recommended to apply a large layer.

Advantages:

- popular brand;

- elasticity of seams;

- high-quality insulation;

- resistance to moisture and temperature extremes;

- the possibility of staining the sealant.

Flaws:

may crack when applied in large layers.

In what forms is the sealant produced, types

Depending on the material of the water pipe, different insulating pipe sealants are used:

Linen fibers - serve to seal the joints of the knees of metal parts. The tow is disassembled into fibers, while the layer can be folded of any thickness. If water seeps through the attachment area, the linen will absorb the liquid and swell, blocking the flow. But water will seep through the fibers and leak.

Flax is not used in pipelines with high water pressure. It can be used in combination with liquid sealants for better insulation.

Since linen contains natural fibers, they are prone to rot and mold if exposed to water. To slow down this process, the tow is impregnated with varnish.

Thread for plumbing work. It is a thin elastic tape impregnated with a solution that does not shrink or dry out. It is evenly wound on threaded pipe connections. The use of a plumbing thread allows you to tighten the thread not to the end, while the sealing will be maintained.

Thread for plumbing is not destroyed by water, does not rot, protects the surface from corrosion. The disadvantages of the sealant are the high cost and the processing of holes with a diameter of no more than 5–7 cm. With uneven winding, there may be gaps through which water can leak.

FUM (fluoroplastic) sealant. This is a smooth elastic strip that is wound around threads or elbows. Fluoroplastic sealant for water supply pipes is not subject to rotting, shrinkage.Withstands high pressure, temperatures up to +280˚С, protects against corrosion.

But the FUM pipe seal may not withstand prolonged vibration. If you disassemble the joints with fluoroplastic, then during further installation it must be applied again.

Liquid formulations are produced in cylinders or soft packs for refilling a gun. They are used for large diameter pipes. Or in bottles for minor repairs and installation of small connections. Depending on the composition, insulating solutions are:

Acid sealants contain acid as a solvent. They are cheaper than neutral ones, form an elastic waterproof seam.

Having an acidic environment, they prevent the development of mold and decay. Do not collapse under the influence of UV - rays, can withstand pressure and temperature drops from -40 to + 120˚С.

The disadvantages of acidic sealant include that they can damage the amalgam coating and non-ferrous metals. Also, acidic insulating compounds are not used in areas in contact with food.

Neutral are made on the basis of artificial rubber. It is a viscous dense mass that polymerizes upon contact with air. Neutral plumbing adhesive forms an impenetrable elastic joint, which retains its qualities during deformation, vibration loads.

Such compounds do not destroy plastic pipes and protect metal pipes from corrosion. Resistant to UV rays, not afraid of solvents, have a working temperature range from -40 to +280˚С.

Plumbing silicone sealants are transparent viscous substances.They create an elastic connection that does not collapse, does not crack under vibration or high water pressure. They have high adhesion to metal, plastic and alloys.

Resistant to the action of reagents, solvents.

Anaerobic solutions polymerize in the absence of oxygen. If some of the sealant is left outside, it is easily removed because the sealant remains in the air in a liquid state.

Anaerobic composition allows you to connect plastic and metal parts. Not afraid of chemicals, high water pressure.

This is interesting: Houses made of bricks and glued beams (video)

Instructions for use

Before using this tool, you should study the instructions and conduct preliminary preparation to learn how to use the tool correctly.

When working with a sealant, you should take care of special clothing, protective gloves

It is important that the product does not get on the skin.

The place of application of the product is wiped from dirt and degreased. Masking tape is glued to decorative surfaces so that silicone does not get on the surface.

For application use a mounting gun

The method of its use is indicated on the package.

The edge of the cartridge is cut along an oblique line so that the sealant can flow out evenly.

Apply the product at an angle of about 45 degrees. You should not make a thick strip so that the material can dry faster, both sides are connected, and excess is removed with a spatula.

When sealing a threaded connection in a heating system, gas and water supply, a sealant thread is used for threaded connections. The sealing thread is made of polyamide and fluoroplastic and is used to seal pipes made of metal and plastic.

Starting to wind the thread, hold the part with one hand, and the thread for sealing in the other hand. Winding should be from the beginning of the thread, make the layer thicker, then continue along the thread. The thread is wound clockwise, thereby a uniform distribution of the product will be achieved.

Henkel's products have repeatedly shown how much easier it has become to carry out construction work, installation, and other types of work. The brand is recognizable in many countries, the company's products have many advantages, the main of which are: reliability, quality and durability.

Next, see the review of the Moment sanitary sealant.

Devices for applying sealant. Sealant gun

You probably noticed that in almost all the drawings and photographs, the sealant is not poured out of the can (although it also happens in cans, only it is already called mastic), but is gently squeezed out of a plastic tube with a special gun, in which the sealant is located. So, I would like to say a few words about such a sealant gun, otherwise the article would not be completely complete if this device was not mentioned in it, without which it would not be possible to use the sealant normally.

The main purpose of such a gun is the ability to gently squeeze the sealant out of the tube and, maintaining a fixed pressing pressure, accurately and evenly apply the sealant. Using such a gun is not difficult at all and you can figure out its mechanism of action on your own, but for those who cannot, here is a short description of working with household sealant guns (skeletal, semi-body).

How to use a caulk gun

First you need to press the locking lever (on the back) of the gun to the handle and completely pull the piston out of the gun, then insert the tube with sealant into the “body” of the gun (first insert the tube nose) and press the piston to the bottom of the tube with sealant, pressing the “trigger”. That's all, the gun is "loaded" and ready to go. Just remember to cut off the tip of the sealant tube before applying.

To quickly stop the extrusion of sealant from the tube (if you need to temporarily interrupt work or move a little), it is necessary to release the pressure of the piston on the bottom of the tube by pressing the locking lever, which was already mentioned earlier. During a long break in work, do not forget to screw the protective cap onto the spout of the tube.

Types of guns for sealant

Now on sale there are several types of such pistols:

- skeleton pistol - the most common and affordable option (20-50 rubles), designed for short-term home use;

- semi-body gun with a smooth or toothed stem - a fairly popular version of the gun, the cost is slightly higher, and the only difference is the possibility of more accurate dosing of the sealant due to the design of the stem and the ability to protect the tube from damage by a semicircular reinforced body wall;

- a tubular metal gun for sealants of a closed type - an even more expensive option, designed for more professional use, when a significant amount of work is expected, the main difference of which is the ability to work with bulk sealants (not in standard tubes, but in film packaging);

- pneumatic gun for sealants - the most expensive option of the listed guns (from 3000 rubles), designed for professional and industrial use, when the expected amount of work is constantly very large, can be used to work with bulk sealants (not in standard tubes, but in film packaging) , has a pressure regulator and must be connected to the air supply line, the working pressure can reach up to 7 bar;

- electric (battery) sealant gun - has a high adjustable flow rate, allows you to work with different types of sealants and quickly switch between them, provides high accuracy of sealant application, has an easy feed, the ability to work with film packaging or cartridges. Due to the automatic return of the piston, the formation of drops and sealant leakage is eliminated.

|

Skeleton caulk gun |

|

Half body caulk gun |

|

Tubular metal caulk gun |

|

Pneumatic sealant gun |

|

Cordless Caulking Gun |

What is a sealant for?

TOP 8 Best ceiling paints: priority of reliability and durability. Overview of the most popular manufacturers

Insulating compounds are used to process seams and gaps between plumbing and the wall

Sealant is a viscous mass based on polymers of a heterogeneous structure, used in construction to firmly connect or seal materials. It happens single- and multi-component.

In the composition of the product:

- polymers (base)

- filler

- hardener

- dye

To reduce the cost or give additional properties, additives are added to the product, which make up no more than 10% of the volume.

Among the most common additives are:

- expanders (extenders)

- fillers (flour from quartz, chalk)

- fungicides

- mineral oils

Previously, cement-based grouts were used instead of polymer sealants in bathrooms.

Silicone plumbing sealant

Plumbing sealants are used for:

- protection of joints between the sides of the bathtub or shower cabin and tiles (tiles)

- processing of seams between the back surface of the sink and the wall

- closing gaps between the bottom of the toilet and the floor

Sealing is necessary to prevent water from leaking into the gap between the bathtub and the wall, the formation of fungus, mold at the joints.

The Best Acrylic Bathroom Sealants

Acrylic-based sealants are distinguished by their low price and the possibility of further painting. They are used mainly for mineral surfaces - concrete, brick, plaster.

Lacrysil

4.9

★★★★★

editorial score

95%

buyers recommend this product

Lacrysil is an acrylic sealant for wet areas. It contains a high-quality antiseptic that prevents the appearance of mold and fungus. The hardened seam is characterized by vapor permeability, high elasticity (up to 500%). The composition withstands deformations up to 35%.

The line contains only white color, but after hardening it is easily painted in any other. The manufacturer recommends applying the product to glass, wood, ceramic, metal and plastic surfaces.

Sealant is produced in cartridges of 280 ml for a construction gun and tubes of 150 ml for small jobs.

Pros:

- convenient release form;

- high elasticity of the seam;

- vapor permeable;

- can be painted;

- adhesion to various surfaces.

Minuses:

hard to find for sale.

Lacrysil is a quality inexpensive sealant. However, to buy it, you will have to go around several hardware stores. The manufacturer's products are not widely represented.

Ceresit CS 11

4.9

★★★★★

editorial score

94%

buyers recommend this product

Waterproof acrylic sealant with high adhesion to mineral substrates, wood and metals. The hardened seam is not afraid of water, however, the manufacturer does not recommend the use of CS 11 inside pools or other tanks.

Ceresit is produced in cartridges for a construction gun of 280 ml. The sealant is available in 5 colors: white, grey, brown, black and golden oak.

The composition does not contain flammable solvents, which makes the composition odorless and suitable for application in unventilated areas. The formula withstands temperature fluctuations from -30 to +80 °C. The film is formed after 20-30 minutes, but it takes about 10 days for a 5 mm wide joint to completely harden.

Pros:

- sold in most stores;

- no smell;

- adhesion to various surfaces;

- suitable for different temperature conditions;

- 5 colors.

Minuses:

- not suitable for seams under constant exposure to water;

- dries for a long time.

Freshly applied sealant can be removed with water. Dried residues are removed only mechanically.

Remontix

4.8

★★★★★

editorial score

89%

buyers recommend this product

Remontix is a white acrylic sealer used for mineral and porous surfaces, as well as for grouting tiles and applying to painted or varnished materials.

The sealant has no smell, it can be used indoors.The composition is produced in cartridges of 310 ml. It is convenient to apply it with a construction gun.

Buyers note that the sealant is reliable and durable. The seam does not change color over time, withstands temperature tests. The composition becomes moisture resistant within 5 hours after application. The hardened seam can be sanded, painted and varnished.

Pros:

- adhesion to different surfaces;

- water and heat resistant;

- presented in most stores;

- can be painted;

- has no smell.

Minuses:

not elastic.

Remontix is only suitable for tight joints, otherwise the sealant may crack.

VGT

4.7

★★★★★

editorial score

77%

buyers recommend this product

VGT Acrylic Sanitary Sealant has good adhesion to almost all surfaces.

Users note the high elasticity of the composition. The tensile strength is also high: with a uniform separation - at least 10 kg per cm2. The seam does not turn yellow and does not darken. Antiseptic additives prevent the appearance of fungi and mold.

After complete drying, the composition is not afraid of water and is suitable for sealing cracks in rooms with high humidity.

The sealant is available in packages ranging from 250 to 400 g. The range includes transparent and white options. In a frozen form, the composition can be additionally painted and varnished.

Pros:

- sold in all construction stores;

- convenient packaging;

- 2 colors, plus the possibility of staining;

- adheres to most materials;

- high elasticity of the seam;

- antifungal supplements;

- waterproof.

Minuses:

great shrinkage on drying.

The density of the transparent composition is somewhat lower - its dry residue is 50%. When sealing wide joints, it is most often necessary to apply the product in 2 layers.

Prevention

It is important not only to know which kitchen sealant is best, but also to understand what to do after cleaning the surface so that the process does not repeat itself. Prevention is the key to protecting the health of people living in the house

It is always easier to carry out preventive measures than to deal with mold that has appeared.

Good ventilation is created in the room, periodically it is necessary to ventilate the room. Otherwise, it will not be possible to get rid of high humidity in the bathroom and in the kitchen. Problems with plumbing, in the form of water leakage, need to be addressed on time.

If the ceiling and walls freeze through, then insulation is required, this is an ideal environment for the formation of moldy areas. In order to avoid the transition of mold from neighbors, those with cracks are also sealed, an antifungal sealant is suitable. These simple methods will help prevent the formation of mold again, protecting people.

Good ventilation is created in the room, periodically it is necessary to ventilate the room.

Good ventilation is created in the room, periodically it is necessary to ventilate the room.

Choosing the best sealant is necessary, taking into account the working conditions, the degree of the problem. There are many options for mold removal, everyone decides which one will be best for him.

It is important to find all areas with mold, otherwise the spread of the fungus will not stop. And in the future, they resort to preventive measures that will help avoid re-education.

Characteristics of sealants

To choose the right sealant for you, keep in mind that in terms of its composition it must be durable and resistant to any effects of chemicals, salts and acids, have good elasticity, must not corrode, be sufficiently sticky to the surface of materials.In addition, a good sealant can withstand any atmospheric influences for a long time. Its composition should be such that when it is used in work, it can compensate for any movement of the seams (if necessary). When filling such joints with sealant, in no case should it form voids and crack.

How to apply sealant to a bathtub?

To apply the sealant end-to-end on the bath, try to follow the following instructions:

- We clean the bath from dirt and dampness, then dry it and the walls around it.

- We degrease the joints that are to be sealed.

- We stick masking tape to define the boundaries of the seam and make it even.

- We cut off the tip of the cartridge or tube at a certain angle, on which the width of the seam will depend.

- By squeezing the pistol grip or pressing on the tube, we apply an even seam along the junction of the bathroom with the walls with uniform movements.

- To align the seam, dipping your finger into the soapy solution, run it along the docking joints.

In the event that the distance is large enough, up to 3 cm, it is sealed with ceramic skirting boards. There are three ways to do this:

- buy special ceramic borders and use them as skirting boards;

- if you still have the material that was used to cover the walls of the bathroom, then this will be the best option for ceramic tiles;

- the most time-consuming way is to cut the desired pattern from the tile with your own hands.

First, it is recommended, if the gap is large, to seal the joint with polyurethane foam. Then you can, having made a cement-sand mortar, lay the tiles, trying to maintain an angle of 45 degrees. It would be even better if you manage to lay out the junctions of the walls and floor in the bathroom in the same way.

Acrylic

These are the cheapest sealing compounds, which at the same time have good technical characteristics:

- Does not contain hazardous and toxic components.

- Chemically neutral.

- Good adhesion to most surfaces (concrete, brick, plastic, glass, metal, wood and its derivatives MDF, chipboard, plywood).

- Temperature range from -20°C to +80°C (available with a wider and narrower range).

- Withstands long-term vibration with a small amplitude (used in mechanics and mechanical engineering when installing devices).

- After polymerization, the seam is inelastic, destruction begins at a stretch of 10-12%.

- Fast drying.

-

The dried surface can be painted or varnished.

In general, good qualities, especially considering the low cost, as well as harmlessness. It is possible to work with acrylic sealants without protective agents, and the short time required for non-hardening speeds up the work. Their disadvantage is shrinkage during drying. Because of this, when in contact with water, the seam begins to leak, so this bathroom sealant is best used in places where water does not flow. Also, before application, for better adhesion, a primer of surfaces (under acrylic) is required. In this case, there is more chance of getting a non-leaking seam.

Application area

The main disadvantage of acrylic sealants is the rigidity of the resulting seam. Even with small expansions, it bursts. That is, it is not worth using it to protect the junction of a steel or acrylic bath (shower tray) with a wall. Under load, they change their dimensions and so that the seam does not collapse, it must be elastic.

Excellent for filling voids and cracks in various building materials (brick, concrete, etc.), connecting fixed or inactive joints (gaps between a jamb and a brick or concrete wall, sealing knocks in pipes, etc.). These compositions process the unprotected edges of the furniture that is installed in the bathroom, suitable for filling the junction of the sink with the wall.

Acrylic sealants are good for filling cracks

Another unpleasant moment: in a humid environment, fungi and bacteria multiply well on the surface of ordinary acrylic sealant. This disadvantage is eliminated by the presence of antiseptic additives, but it is better not to use acrylic sealants for areas that are constantly in contact with water.

And one more thing: in the bathroom, acrylic quickly changes color - it starts to turn yellow. Therefore, white should not be used. Better colored (there are some) or transparent. On them, color changes are not so visible.

When choosing, it is worth remembering that acrylic sealants may or may not be waterproof. Acrylic bathroom sealant must be waterproof. Even in those areas where water cannot directly contact it, but due to high humidity it can absorb moisture from the air.

Grades of acrylic sealants

There are many good brands. Only for the bathroom it is necessary to make sure that the composition is moisture resistant.

- Bison Acrylic. There are several different compositions: Super fast with drying in 15-30 minutes, Universal - can be used to seal wood.

- Bosny ACRYLIC SEALANT;

- boxer;

- Dap Alex Plus. This is an acrylic-latex composition with greater elasticity and anti-fungal additives.

- KIM TEC Silacryl 121. Polyacrylate moisture resistant and flexible sealant.Can be used in areas of prolonged contact with water.

- Penosil. For filling joints and cracks that are not in direct contact with water.

There are many other brands and manufacturers out there. Many acrylic sealants have special additives that change their properties. If you are satisfied with their harmlessness, you can find a composition even for direct contact with water.

Tips and tricks for operation

A few professional recommendations will ensure a presentable appearance and preservation of the technical characteristics of the sealant throughout the entire service life:

- After finishing work on sealing the seams, you need to carefully remove the masking tape. This is done at a time when the sealant has not dried up completely, but has already seized. If the seam is deformed at the same time, it must be slightly wetted, then leveled.

- If the seal turns yellow, wipe it with purified gasoline.

- If the surface is covered with mold, it should be removed and a new one applied.

After replacing the silicone sealant due to the appearance of mold, a composition with antiseptic additives based on polyurethane or polymers is often used.