- Introduction

- Sealing tape

- Characteristics

- Application features

- Silicone sealant

- Additional materials

- Table of advantages and disadvantages of different types of sealants

- Sulfur, cement, epoxy resin

- Cast iron pipes

- Asbestos cement pipes

- Ceramic pipes

- Pipes made of polymeric materials

- Metal-plastic pipes

- Sealing materials

- Tapes for sealing

- silicone sealants

- Sealing sewer pipes with other sealants

- Sealants for plastic pipes

- Bostik Sanitary Silicone A

- Kim Tec 101e / Kim-Tec 101E Silicon Acetat

- 100% universal silicone repair

- Useful tips for proper use

- How to ensure the tightness of the junction of cast iron and plastic pipes

- Ways to fix leaks

- We close the joints with tape

- Use sealants to fix leaks

- Best Sanitary Sealants

- Makroflex SX101

- TANGIT S 400

- Belinka Belsil Sanitary Acetate

- Bostik Sanitary Silicone A

Introduction

The tightness of the sewer system implies the absence of any leaks that may occur as a result of broken joints. It should also be said that for each type of material there is a certain type of sealant.In this article, we will consider not only how to seal the sewer pipe, but also the process itself.

The next point is the protection of the sewage pipeline itself from the ingress of various liquids into it, which can disrupt its stable operation. You must understand that if you do not seal or do it incorrectly, this can be the main reason for reworking the finished system.

sealant for sewer pipes ready to eat

Sealing tape

Pipe joints can be protected with special anti-corrosion sealing tapes.

In addition, they are used for such water supply elements as:

- coupling connections;

- bends;

- tie-ins.

Special tape for sealing pipes

Characteristics

- For its manufacture, a bitumen-rubber base is used.

- In addition, the composition contains a thin copper or aluminum layer and a protective film removed during installation.

- It does not cause any difficulties in work, as it is self-adhesive.

- Applies to any material.

- Possesses durability and high durability.

- All you need is a knife to do the job.

Application features

The sealing process begins with cleaning the pipe joint surfaces from deposits, dirt and dust. Then they should be degreased and primed with a primer.

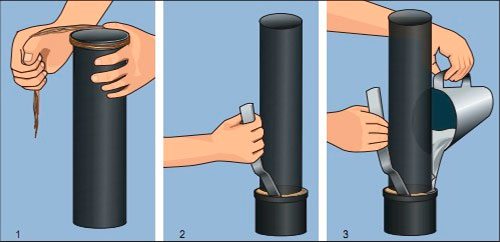

The tape is wound with their own hands at the junction in a spiral, not forgetting to overlap between the layers. As a result, the insulated surface will be covered with two layers. Docking should be carried out after winding is completed.

Chasing a cast-iron bell with cement

Silicone sealant

These compounds are made of silicone rubber and are acidic and neutral.The former are not used on surfaces that are not resistant to acid, the latter are used for any material, but their price is higher.

Applying silicone sealant to the socket

A special syringe is used to apply the material to the surface, but before that it should be cleaned of rust and debris in order to get the maximum effect. Otherwise, the material simply will not stick to the base.

After it hardens, you will get a rubber waterproof layer that will not allow any liquid to pass through the joint. Such connections are famous for their reliability and long service life.

Bituminous mastic for sealing sewer joints

Additional materials

In addition to those presented above - silicone and tape, other materials are also used, which can also ensure the reliability of the joints of the sewer system. Let's look at them in more detail below:

| melted bitumen | Working with it (also called bituminous mastic) is not difficult:

Among the shortcomings of the material, a specific smell should be noted, which can last for several days. Therefore, it is not recommended to use it for sewer systems in an apartment. |

| Cement based sealant | Let's consider two options:

To work, you will need an expanding waterproof cement, consisting of gypsum, aluminous cement and calcium hydroaluminate.It usually cures within 5-10 minutes depending on the ambient temperature, so the process must be carried out at a high pace. Connect the RVC with water in a ratio of 2.5:1. Use to seal cast iron joints |

| Asbestos cement mortar | The composition is prepared from asbestos and cement M400 (and higher) in a ratio of 1:2. After that, they fill the socket connections. |

Sealing sewer pipes in the traditional way

Finally, you can recall how you can still seal sewer pipes if the above materials are not at hand. Although the method is used quite rarely, it gives excellent results. It's about using paint.

The process instruction is simple:

- Clean the bell from dirt and dry it.

- Stuff it with pieces of cloth.

- Pour paint into it.

- Tamp the contents carefully with a curved wire or screwdriver.

- Wait until everything cools down.

Table of advantages and disadvantages of different types of sealants

| Types of sealants | Advantages | Flaws |

| Silicone | Waterproof | Little ability to stick (adhesion) to plastic |

| Resistant to high temperatures | Cannot be dyed | |

| Not afraid of UV rays | ||

| Resistance to temperature changes | ||

| Extensive color palette | ||

| Sanitary | Resistant to bacterial attack | The smell does not disappear for a long time |

| Extensive scope | High price | |

| Has little shrinkage | ||

| Good adhesion (adhesion) to the surface of any type of material | ||

| Can be used to repair old seams | ||

| Acrylic | Contains no toxic or harmful ingredients | Hardens for a long time during the day |

| Not afraid of temperature changes | The resulting seam is hard | |

| Good adhesion to various surfaces (metal, glass, concrete, wood) | Do not seal joints in places where deformation can occur | |

| Dries quickly and can be painted afterwards | ||

| Neutral from a chemical point of view | ||

| moisture resistance | ||

| Polyurethane | After shrinkage and drying, there is no deformation of the seam | dangerous to the health of the worker, it is necessary to use protective equipment |

| Has the ability to stick well | With erasers low stickiness | |

| When the seam is dry, you can apply paint | ||

| Sealing agent is strong and flexible | ||

| Waterproof |

The review includes the best sealants of each type, used in a room where humidity is above normal.

Sulfur, cement, epoxy resin

In addition to the most modern silicone and sealing products, other means are also used to isolate the pipeline connection.

Technical sulfur

The method is effective for ensuring the tightness of socket joints of cast-iron pipes - sulfur is first crushed, then heated until melting and poured into the joint slot. When the material hardens, it will turn into a dense, water-resistant mass. The disadvantage of the material is low elasticity.

Epoxy resin

Epoxy resin (epoxy-based glue) is one of the most affordable and simple means for creating an insulating layer in sewer pipe joints. For sealing, the resin is combined with a hardener (the proportions depend on the manufacturer of the material)

It is important to observe the recommended proportions when mixing, because

an increase in the amount of hardener leads to the boiling of the finished mixture, and this changes its solidification time and performance properties.

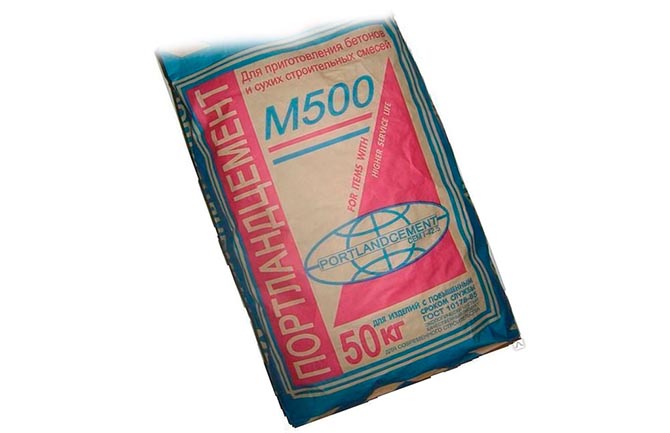

Portland cement

This substance is part of sealing (for example, asbestos-cement) mixtures, it successfully copes with the insulation of a cast-iron pipeline. Dry product to obtain a solution suitable for pipe insulation, stir in water 5-10 minutes before use. Portland cement is characterized by the ability to quickly harden, forming a strong frost-resistant and water-repellent layer at the joints.

Asphalt mastic

Asphalt (bitumen) mastic is a tool that is used to create fills that seal the joints of cast-iron and ceramic pipes. There is a choice of bitumen-rubber and bitumen-polymer products, each of them is resistant to chemical attack, elasticity and durability.

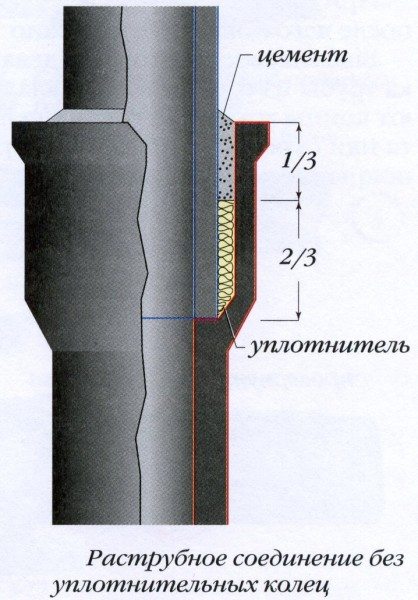

Resin strands of tow, hemp and jute ropes

Substances allow you to reliably seal the joints of ceramic and cast iron pipes, especially if they are used in combination with cement filling.

It is very simple to isolate pipe joints with resin bundles:

- Fill the socket of the pipe with tow or jute to 2/3 of the depth.

- Pour the remaining space with cement mortar (cement plus water in a ratio of 9:1).

- It is allowed to replace the cement mortar with an asbestos-cement mixture. Dry harvesting (asbestos fiber plus cement, proportion - 2: 1) is done in advance, and diluted with water right before sealing.

The easiest way to seal pipes is to use expandable waterproofing cement. This agent quickly hardens, expanding and self-compacting at the same time. Cement should be diluted with water in a ratio of 1: 2.5. Additional use of bundles of tow, hemp or jute is not required - the entire space of the socket joint is filled with the composition.

Cast iron pipes

Listing the types of metal pipes used for the installation of sewerage systems, one cannot fail to mention cast iron products. Since it was cast iron pipes for decades that were the main material for assembling sewer networks. The main advantages of this material are:

- Durability and long service life;

- Corrosion resistance.

The disadvantages of the material include:

- Large weight, which makes it difficult to transport the material and its installation.

- Relatively high brittleness. Pipes made of cast iron do not tolerate shock loads.

- The impossibility of using for laying an external pipeline in saline soils, since the soil brine quickly destroys the material.

- Rough inner surface, due to which the pipes become clogged faster.

Asbestos cement pipes

For the production of such pipes, a mixture of asbestos fiber with Portland cement is used. Advantages of these products:

- Resistance to corrosion processes.

- Ease of machining, which greatly facilitates installation.

- Long service life.

- Smoothness of the inner surface.

- Asbestos cement is a dielectric, so this material is not subject to electrochemical corrosion.

Asbestos-cement pipes have disadvantages, these are, first of all:

- Brittleness of the material. When working with pipes made of asbestos cement, you have to be extremely careful and accurate.

- Under the action of the soil, the outer surface of the pipes is quickly destroyed, so protective measures must be taken.

Ceramic pipes

Ceramic pipes in their properties resemble cast iron, however, they are lighter and one hundred percent resistant to corrosion.The undoubted advantage of ceramic pipes is their resistance to high temperatures and the effects of aggressive environments - acids and alkalis.

However, the material is quite fragile, so you need to carefully handle the pipes during loading, transportation and during installation. In addition, mechanical processing of pipes (cutting) is difficult; when trying to cut a pipe, it can simply split.

Pipes made of polymeric materials

Today, various types of plastic pipes for sewerage are widely used. For the manufacture of such products, three types of polymers are used:

- PVC.

- Polypropylene.

- Polyethylene.

PVC pipes are designed for gravity sewerage systems. The material is strong enough to withstand high loads. PVC pipes are widely used for the installation of outdoor systems, as they are inexpensive, able to withstand aggressive environments, and resistant to ultraviolet radiation. But the impact of temperatures above 70 degrees of the pipe does not tolerate, at very low temperatures PVC becomes brittle, so it is recommended to insulate them.

Various types of polypropylene pipes are widely used to assemble sewerage systems. These pipes have a long service life, they can be used for both gravity and pressure systems.

It is necessary to distinguish between types of propylene pipes intended for internal and external pipelines. The first type of pipes was created for use in the home, they are strong enough, but not able to withstand the effects of low temperatures and the load exerted by the soil.

For external pipelines, special types of pipes are produced - two-layer.Their inner layer is perfectly smooth, and the outer layer is corrugated, so the pipes are characterized by increased strength.

When assembling sewerage systems, different types of polyethylene pipes are increasingly being used. This material is mainly used for the installation of non-pressure systems. The great advantage of this material is its high elasticity, when the liquid in the pipe freezes, polyethylene does not collapse, but only deforms.

Metal-plastic pipes

For the assembly of various systems, including sewage systems, various types of metal-plastic pipes are widely used. These pipes have a plastic coating, so they are one hundred percent resistant to corrosion, chemically neutral and fairly easy to process.

At the same time, the presence of a metal core gives these products increased mechanical strength. The disadvantages of the material include their rather high cost.

Sealing materials

Tapes for sealing

Both regular tapes and foil tapes are produced.

Self-adhesive tapes, which have anti-corrosion properties and are specially designed for sealing pipe joints, are one of the latest modern sealing products. They have many positive properties:

- Self-adhesive anti-corrosion tapes are highly effective and easy to use.

- Sealing films, thanks to their high-strength polyethylene backing, are characterized by good service properties.

- They are used to ensure the protection of various types of pipelines in the complex, as they have dielectric and anti-corrosion properties. In addition, sealing films are used for sealing linear elements of sewer pipes.

- Sealing using tape is possible not only when sealing the joints of sewer pipes, but also when sealing plugs, tie-ins, turning corners, bends, etc.

Before sealing a sewer pipe using sealing tapes, remember that they are sealed in the following sequence:

- surface preparation is necessary for applying the tape: it must be dry, dust-free and clean;

- it is necessary to ensure a constant tension of the tape, which is wrapped around the pipe, and also to exclude the appearance of folds and wrinkles;

- the tape must be applied with a 50% overlap in a spiral, as a result of which the entire surface to be insulated will necessarily be under two layers of film.

Sealing sequence (some tapes require primer treatment)

Pro tip:

Such films do not tolerate exposure to UV radiation. That is why, when pipes for sewerage are located in an area that is open to the sun, an additional protective layer must be provided over the film.

silicone sealants

Silicone is the most well known sealing material.

Silicone rubber forms the basis of silicone sealants. Silicone sealants in general are a composition of different substances that provide high sealing qualities. Silicone sealants have good adhesion to surfaces, while not requiring that they be pre-treated with primers.

According to the type of hardener in its composition, silicone sewer pipe sealant is divided into:

- Acid.Acid silicone sealants are quite inexpensive, although they do not accept application to some surfaces that can interact with acids.

- Neutral. In this regard, neutral silicone sealants are considered more versatile.

With the help of silicone sealants, it is possible to seal the joints of sewer pipes:

- from metal;

- from plastic.

After vulcanization, the silicone paste turns into a substance that is similar in properties to rubber. Moisture in the air is involved in the curing process of silicone sealant.

Pro tip:

Squeezing out the sealant is quite simple - using a mounting gun. In its absence, you can use an ordinary hammer by inserting its handle into the tube and pressing like a piston.

How to squeeze out silicone sealant without a mounting gun

Sealing sewer pipes with other sealants

In addition to the above means, sealing pipes for sewerage is also carried out using other means:

- Epoxy resin - at home, it serves, as well as glue based on it, the most common tool that is used when connecting sewer pipes.

- Portland cement is a fairly common component of most sealing mixtures - it is used in the preparation of mixtures from asbestos cement and when caulking the connection of the socket of pipes for sewerage from cast iron.

- Oil bitumen and asphalt mastic - will be required for the preparation of the fill, which is designed to seal joints and fill the sockets of ceramic pipelines.

- Hemp or jute rope, resin strand - are used when sealing pipe sockets for sewage from cast iron and ceramics. The use of a combination of rope and resin impregnation would be preferred.

- Technical sulfur - used to ensure tightness, mainly, the joints of the sockets of pipes for sewerage made of cast iron. Before pouring into the joint slot, it should be crushed, and then heated until melting.

Technical sulfur can also be purchased in crushed form.

With such an abundance of materials, the question is unlikely to arise: “How to cover up the sewer pipe?”.

Sealants for plastic pipes

For plastic pipes, silicone sealants with acetoxy curing type are mainly used. Acid compounds form a durable and elastic bond and can be used both for sealing and for insulating individual surfaces. The editors tested 10 applicants. 3 winners got the highest score and a lot of positive feedback.

Bostik Sanitary Silicone A

The advantage of Bostik Sanitary Silicone A is its high resistance to moisture, mold and mildew. Thanks to these properties, the silicone product can be applied to joints in rooms with high humidity: showers and bathrooms, washing, laundries. It is used for sealing joints in the pool, toilet, washbasin and bath. It also works well with plastic products in which cold and hot water flows, as well as grouting ceramic tiles.

The acetoxy curing type sanitary product has high adhesive properties and excellent flexibility when working with ceramics, glass, PVC and plastics. It can be applied without a primer.The sealant does not break down at temperatures from -40 to +180°C and has good UV resistance. On average, the consumption of goods is 11 m.p. The film is formed within 15 minutes.

Advantages:

- Optimal volume (280 ml);

- Low price;

- Transparent color;

- Easy handling;

- Tensile strength - 1.3 MPa.

Flaws:

Not suitable for aquarium.

A tool should be used to clean the hardened substance, as it is insoluble.

Kim Tec 101e / Kim-Tec 101E Silicon Acetat

A one-component, silicone-based rubber with an acetate curing system. Due to the action of air and moisture, it forms an elastic seal that can be used as an adhesive. The sealant for plastic pipes is characterized by excellent adhesion to wood, glass, PVC, ceramics, plastic and various painted surfaces. It is used for application on window and door seams, as well as for processing plumbing fixtures.

Kim Tec 101e / Kim-Tec 101E Silicon Acetat is distinguished by the durability of the connection due to its resistance to ultraviolet radiation and temperature changes in the range from -50 to + 180 ° C. The composition includes inhibitory additives that help protect against bacteria and mold. Due to its thixotropic properties, transparent silicone can be applied to ceilings and vertical surfaces without fear of spreading. You can adjust the seam for 9 minutes until a film forms. Curing time is 1 day.

Advantages:

- Multifunctionality;

- Convenient capacity;

- Easy to apply;

- Warranty - 2 years;

- Optimal cost.

Flaws:

Strong smell.

100% universal silicone repair

Sealant has proven itself in everyday life, in repair and construction work on street and indoors. Acid type silicone product is suitable for sealing ceramic, glass, wood and plastic products.

Repair is 100% characterized by good resistance to temperature (-40 to +100°C) and UV exposure. Often it is used for processing drains, pipelines, air conditioning and ventilation systems. It is recommended to use it at temperatures from +5 to +40°C.

Advantages:

- Drying time - 25 minutes;

- budget cost;

- Maximum stretch - 200%;

- moisture resistance;

- Seam mobility - 20%.

Flaws:

Not detected.

The product is convenient to use due to the presence of a pistol for releasing from a cylinder.

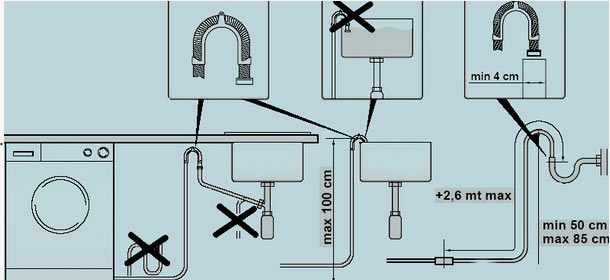

Useful tips for proper use

Experts make the following recommendations:

- Before applying plumbing sealant, you need to completely clean the surfaces of grease or residues of the previous solution. Otherwise, the composition may move away from the thread or begin to crumble if solid particles of dirt get into it.

- The amount of winding is determined empirically. It should not be too much so that the parts can fit into each other. But if the amount is insufficient, there may be water leaks.

- Brass and bronze pipes are very fragile, so be careful when twisting.

- Before putting the water supply into operation, the water pressure is started in test mode.

Recommended videos on the topic:

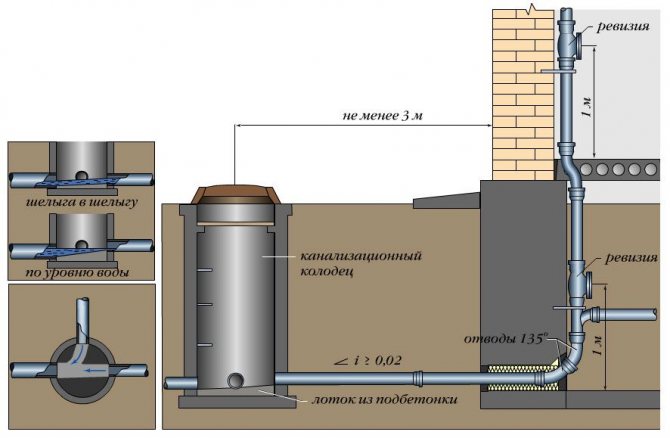

How to ensure the tightness of the junction of cast iron and plastic pipes

For the manufacture of modern sewerage systems, polyvinyl chloride is used. Often there is a need to join PVC pipes with old cast iron pipes.Such a connection can be made in several ways, which depend on the state of the socket of the cast iron product.

If the old system is in good condition, the bell is cleaned of dirt and rust. A new pipe is mounted through a rubber adapter, having previously covered all the mating surfaces with silicone sealant. You can apply the method of sealing with tow or a tourniquet, followed by pouring with special mixtures.

If there is no socket, the connection is made through a plastic adapter and rubber seals. To do this, the edge of the cast-iron pipe is leveled and cleaned. A sealing ring is put on the socket adapter. This is followed by a rubber cuff and another ring. The whole structure is inserted. At each stage of the connection, silicone is applied to the surface. It remains only to apply a layer of sealant to the end of the PVC pipe and push it firmly into the constructed socket.

When docking, you can use a press fitting - an adapter with a thread on one side and a socket on the other. The edge of the cast-iron pipe is leveled with a grinder, cleaned, lubricated with grease or oil, and a thread is made. Tow or fum-tape is wound onto the formed furrows. Lubricate the joint with silicone and wind the adapter.

It is possible to combine means of sealing sewer pipes, thereby increasing the quality of the connection.

Ways to fix leaks

Residents must be warned not to use the sewer before work is carried out. Then you should turn off all appliances that use water, such as a washing machine. After blocking the leaking area, dry the leak thoroughly with a hair dryer.

Before starting work, it is worth understanding the material from which the sewer system is made.Today it is metal (steel, cast iron) or polymeric materials - polyvinyl chloride or polyethylene. How to cover up the joint of the sewer pipe depends on the material.

The leaking joint must be thoroughly cleaned from the remnants of the cementing mixture. Then treat with an aqueous solution of cement and PVA glue. Be sure to use gloves when doing this. The solution will dry for about a day. Accordingly, it is impossible to use the sewer at this time.

To perform work, it is desirable to use a repair clutch.

We close the joints with tape

Self-adhesive tape is a modern and reliable waterproofing material that allows you to quickly and efficiently seal sewer joints. The strength of the tape is given by a base made of polyethylene. Additionally, the product provides corrosion protection and good dielectric properties. The tape can be used to seal various parts of the plumbing system, such as bends, tie-ins and plugs.

Toilet plumbing involves the use of various sealants, and self-adhesive tape is the first way to wrap a leaking joint (but far from the only one).

Use sealants to fix leaks

Sealants based on silicone or rubber are an excellent option for waterproofing sewer structures. The high level of adhesion to the surface of the elements is due to excellent adhesion. Moreover, the sealing of pipes can be carried out without pre-treatment with primers and primers.

The type of hardener used in sealants imposes restrictions on use in different conditions. The cheapest, acid ones, cannot be used everywhere because of the possible chemical reaction with acids. Neutral sealants are universal.

We can safely recommend the use of such a sealant for most types of pipes. For reliability, after work it will be necessary to cover with silicone all the joints and places of possible leaks.

Best Sanitary Sealants

Makroflex SX101

Silicone-based Macroflex sanitary sealant was developed by specialists for sealing gaps in rooms where the humidity is above the norm (bathroom, bathhouse). The composition contains fungicidal additives that prevent the growth of fungal deposits and mold fungi. The tool has frost resistance and heat resistance.

| Volume, ml | 290 |

| Color | white, black, beige, brown, transparent |

| Manufacturer | Estonia |

| Type of | silicone |

| Advantages | Flaws |

| Moisture resistant | Bad smell |

| Resistant to biodestruction | |

| Good adhesion (sticking) |

Review of Makroflex SX101

TANGIT S 400

Engineering sealant "Tangit" with a pasty density has an acetate composition, is famous for its excellent adhesion (sticking) and indestructibility to fungal formations and mold fungi. According to consumer reviews, a feature of this tool is the ability to order any color.

| Volume, ml | 280 |

| Color | transparent |

| Manufacturer | Belgium |

| Type of | silicone |

| Advantages | Flaws |

| Sealing durability | Rarely found on the Russian market |

| The composition contains fungicides | |

| Good adhesion (sticking) |

Belinka Belsil Sanitary Acetate

Due to the consistency of the sealant in the form of a paste, it is possible to fill gaps and cracks of any size in the best possible way. Finishers note that this is one of the best sealants used for laying ceramic tiles. The dried seam does not shrink, in addition, due to the viscosity, the sealant is washed out with water.

| Volume, ml | 280 |

| Color | white, transparent |

| Manufacturer | Slovenia |

| Type of | silicone |

| Advantages | Flaws |

| Antifungal Properties | Long drying time |

| Good adhesion to tiles | Strong vinegar smell |

| Uniform application |

Review of Belinka Belsil Sanitary Acetate

Bostik Sanitary Silicone A

In our country, this sealant is little known, although it is among the world's top five in terms of production. The sanitary silicone product has excellent adhesion (stickiness) and high strength of the applied seam. The surface on which the product is applied must be flat, free of dust and grease. Sealant can replace grout when laying ceramic tiles.

| Volume, ml | 280 |

| Color | 11 colors, including: white, transparent, jasmine, parchment |

| Manufacturer | USA |

| Type of | silicone |

| Advantages | Flaws |

| Strength, elasticity | Can't be dyed |

| Good stickiness (adhesion) | Acetic smell |

| Water resistant |

Review of Bostik Sanitary Silicone A