- German hydrogen strategy

- The role of Russian companies in the new energy industry

- Is it possible to independently create a hydrogen generator?

- Prospects for hydrogen as a fuel for a heating boiler

- How does a hydrogen heating boiler work

- Advantages of hydrogen boilers

- Cons of hydrogen boilers

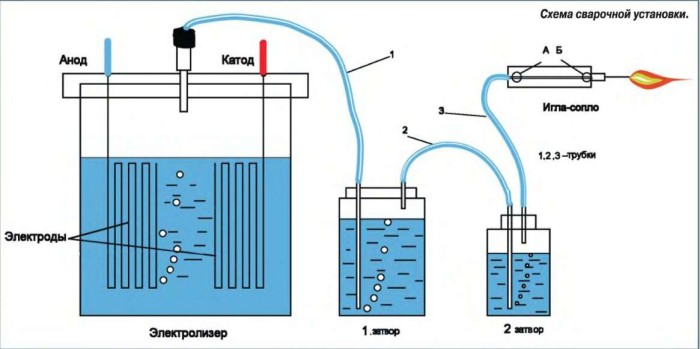

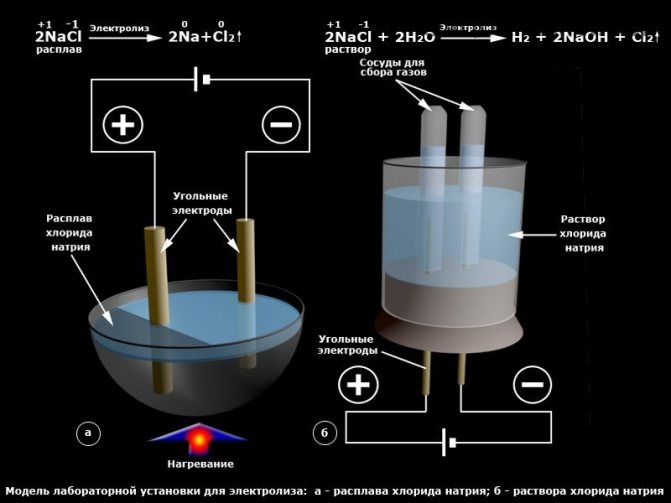

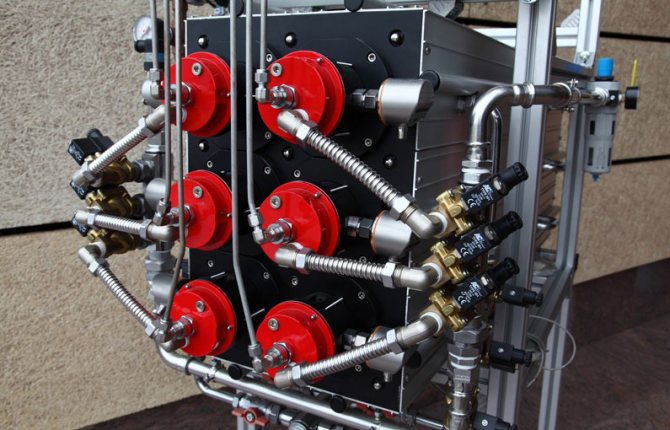

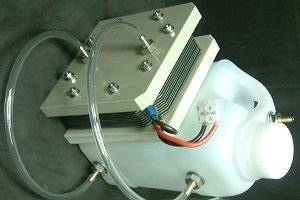

- Features of Electrolytic Hydrogen Generator

- Features of Electrolytic Hydrogen Generator

- Implementation into existing systems

- The myth that a hydrogen boiler is the most economical way to heat a house

- DIY manufacturing

- Main knots

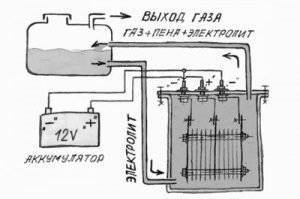

- How the device works

- How to make hydrogen heating with your own hands

- Making a generator on your own

- Tips for assembling and operating the generator

German hydrogen strategy

The course towards hydrogen energy was finally fixed by the National Strategy for the Development of Hydrogen Energy of Germany, published on June 10, 2020. The long-term goal of the country is to create a climate-neutral economy with a reduction in CO2 emissions2 95% of the 1990 level. And hydrogen, to which not only transport will be transferred, but also metallurgy with the petrochemical industry, will play a central role in this process.

Germany will allocate more than €10 billion for the development of hydrogen energy until 2023: €7 billion for “market launch” (that is, for creating framework conditions and stimulating domestic demand), €2 billion for international cooperation and another €1 billion for the needs of industry , which should introduce hydrogen technologies in order to become their number one exporter in the world in the future.

At the same time, the German government recognizes only “green hydrogen” as environmentally friendly, produced using electricity obtained from renewable sources - the sun and wind. To increase its volumes, Germany will need additional wind-generating capacities on the Northern and Baltic coasts. Over time, "green hydrogen" should replace "gray", "blue" and "turquoise", that is, obtained with the release of CO2 into the atmosphere from fossil sources such as natural gas or methane.

True, the strategy recognizes that Germany will not be able to meet its hydrogen needs on its own, and it will have to import either electricity for the production of "green hydrogen" or feedstock. And the €2 billion allocated for the development of international cooperation will go primarily to solar energy pilot projects for the production of "green hydrogen" in North Africa and Morocco, where the sun shines all year round.

The role of Russian companies in the new energy industry

However, it is not only North Africa that is suitable for pilot projects. As the hydrogen tram project launched in St. Petersburg in November 2019 shows, modern Russian cities are perfect as showrooms for hydrogen technology.Such vivid examples of innovation will have a positive image effect not only for the Russian economy, but also for long-term cooperation with the European Union.

The potential for this cooperation is partly reflected in the energy strategy of the Russian Federation, published to the same day with the German hydrogen strategy. In the document, hydrogen is designated as a fuel with high export potential. By 2024, Russian hydrogen exports should amount to 0.2 million tons, and by 2035 grow to 2 million tons. According to the plans of the Ministry of Energy, Russia should take up to 16% of the world hydrogen market.

In a paradigm where the level of development and prosperity of the country directly depend on the export of energy resources, the bet on hydrogen is completely justified. This technology can become an additional development driver in the overall balance of exports. But in order to realize these ambitious plans, Russian corporations need to develop hydrogen energy now and quickly review their business models, because the “energy transition”, which the Germans are aiming for, will inevitably lead to a decrease in demand for petroleum products and natural gas in the near future.

Is it possible to independently create a hydrogen generator?

It is better not to take risks, because such a process is associated not only with the need to know the intricacies of technology and chemistry, but also requires proper compliance with safety rules. But do-it-yourself installation of equipment is possible. To do this, it is enough to follow the instructions and not allow amateur performance.

The heating of any house should provide not only comfortable living for a person, but also the ecological cleanliness of the environment. This is achieved due to the fact that after the combustion of hydrogen, no harmful compounds are formed.

In Western countries, heating with hydrogen generators has gained wide acceptance and economic justification. If a similar method takes root in Russia, it will significantly increase the heating efficiency with minimal resource costs.

Prospects for hydrogen as a fuel for a heating boiler

- Hydrogen is the most common "fuel" in the universe and the tenth most common chemical element on Earth. Simply put - you will not have problems with fuel reserves.

- This gas cannot harm people, animals or plants - it is not toxic.

- The "exhaust" of a hydrogen boiler is absolutely harmless - the combustion product of this gas is ordinary water.

- The combustion temperature of hydrogen reaches 6000 degrees Celsius, which indicates the high heat capacity of this type of fuel.

- Hydrogen is 14 times lighter than air, that is, in the event of a leak, the “emission” of fuel will evaporate from the boiler house on its own, and in a very short time.

- The cost of one kilogram of hydrogen is 2-7 US dollars. In this case, the density of gaseous hydrogen is 0.008987 kg/m3.

- The calorific value of a cubic meter of hydrogen is 13,000 kJ. The energy intensity of natural gas is three times higher, but the cost of hydrogen as a fuel is ten times lower. As a result, alternative heating of a private house with hydrogen will cost no more than the practice of using natural gas. At the same time, the owner of a hydrogen boiler does not need to pay the appetites of the owners of gas companies and build an expensive gas pipeline, as well as go through an extremely bureaucratic procedure for coordinating all sorts of “projects” and “permits”.

In short, as a fuel, hydrogen has the brightest prospects, which have already been appreciated by the aerospace industry, which uses hydrogen to “refuel” rockets.

Modern development - hydrogen heating boiler

How does a hydrogen heating boiler work

In the same way as a conventional gas boiler:

- Fuel is supplied to the burner.

- The burner torch heats up the heat exchanger.

- The coolant poured into the heat exchanger is transported to the batteries.

Only instead of the main gas pipeline or tanks with liquefied fuel for the production of fuel, it is necessary to use special installations - hydrogen generators.

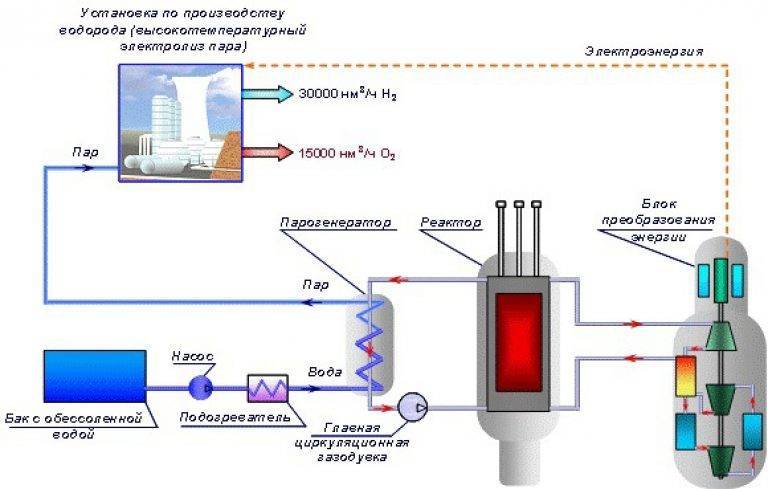

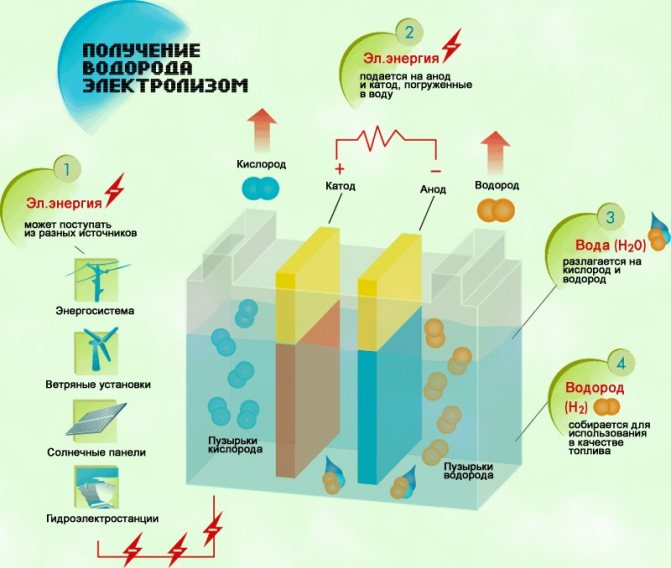

Moreover, the most common type of household generator is an electrolytic plant that splits water into hydrogen and oxygen. The cost of fuel produced by electric generators for heating with hydrogen reaches 6-7 dollars per kilogram. At the same time, water and 1.2 kW of electricity are needed to produce a cubic meter of combustible gas.

But in this case, you can save money on the removal of combustion products. After all, in the process of burning a mixture of oxygen and air, only water vapor is released. So such a boiler does not need a “real” chimney.

Advantages of hydrogen boilers

- Hydrogen can "fire" any boilers. That is, absolutely any - even the old "Soviet" units purchased in the 80s of the last century. To do this, you will need a new burner and granite or fireclay stone in the furnace, which increases thermal inertia and levels the effect of overheating of the boiler.

- Hydrogen boilers have increased heat output.A standard gas boiler for 10-12 kW on hydrogen will “give out” up to 30-40 kilowatts of thermal power.

- For heating with hydrogen, by and large, only a burner is needed. Therefore, even a solid fuel boiler can be converted “under hydrogen” by installing the burner in the furnace.

- The base for obtaining fuel - water - can be removed from the water tap. Although the ideal semi-finished product for the production of hydrogen is distilled water, which is mixed with sodium hydroxide.

Cons of hydrogen boilers

- A small range of hydrogen boilers and gas generators of industrial type. Most sellers offer "homemade" products with dubious certification.

- High price of industrial models.

- The explosive "character" of the fuel - in a mixture with oxygen (in a ratio of 2: 5), hydrogen turns into an explosive gas.

- High noise level of gas generating installations.

- High flame temperature - up to 3200 degrees Celsius, making it difficult to use hydrogen as a fuel for a kitchen stove (special dividers are needed). However, H2ydroGEM, a hydrogen heating boiler manufactured in Italy by giacomini, is equipped with a burner with a flame temperature of up to 300 degrees Celsius.

Features of Electrolytic Hydrogen Generator

A hydrogen generator based on the principle of electrolysis is most often produced in a container version. A prerequisite for the purchase of such a device for heating is the presence of the following documents: permission from Rostekhnadzor, certificates (compliance with GOSTR and hygienic).

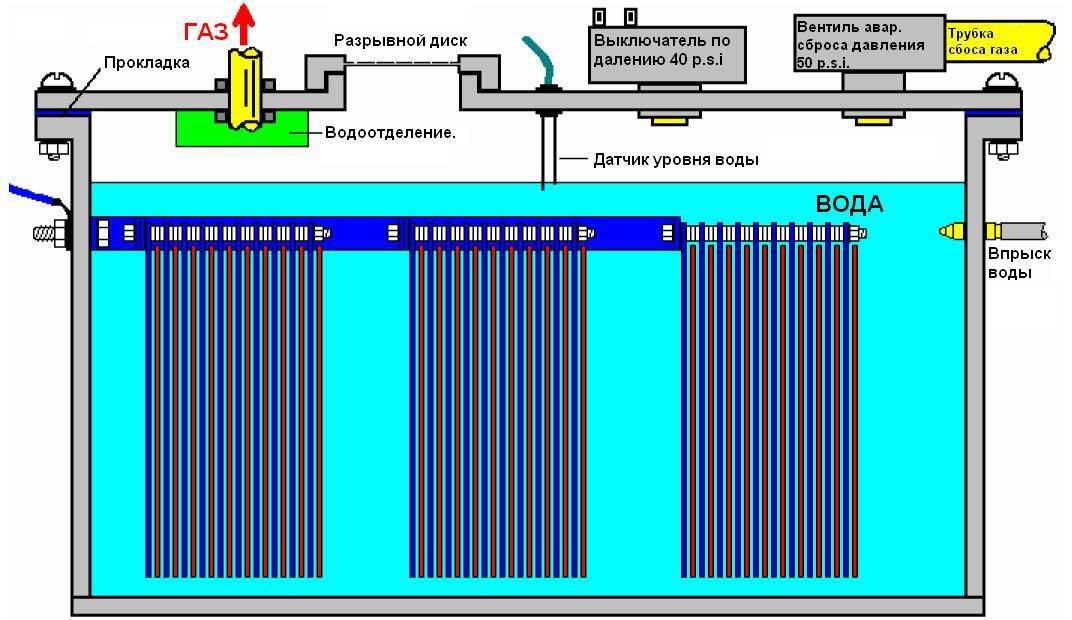

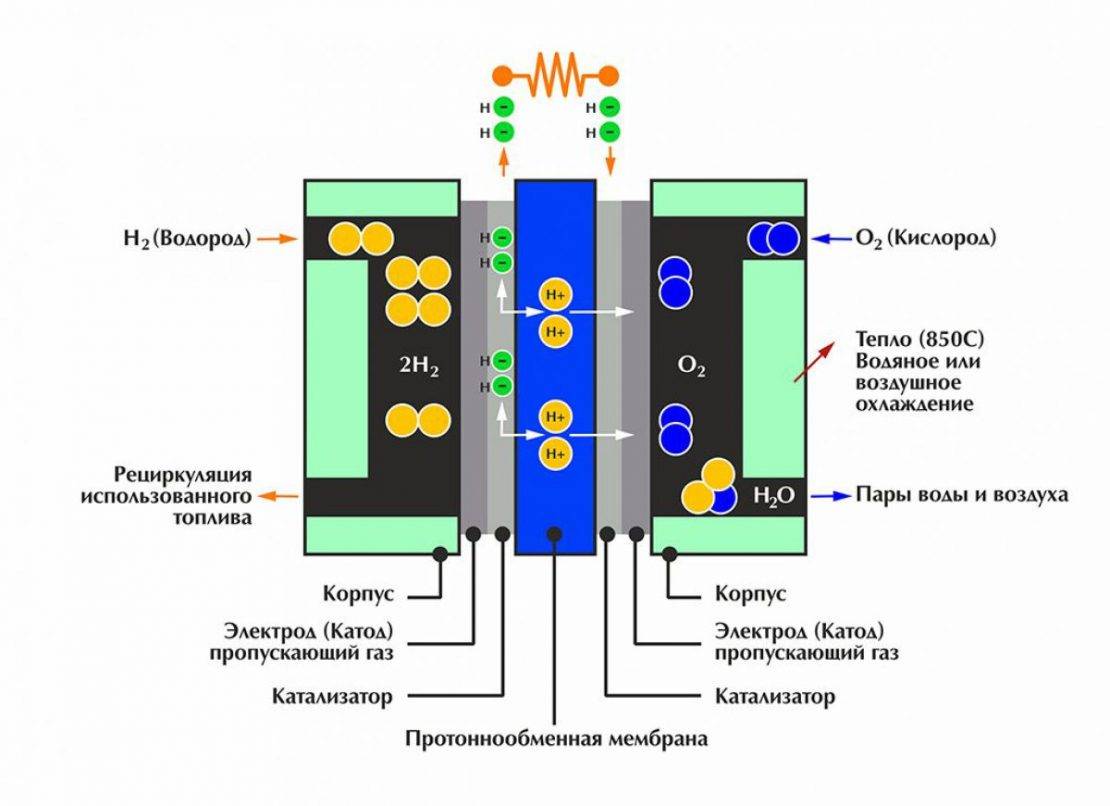

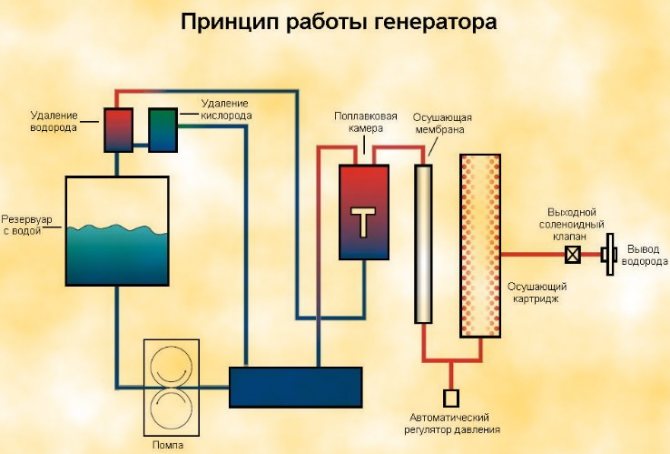

The electrolytic generator consists of the following elements:

- a block that includes a transformer, a rectifier, junction boxes and devices, a block for replenishing and demineralizing water;

- devices for separate production of hydrogen and oxygen - an electrolyzer;

- gas analysis systems;

- liquid cooling systems;

- a system aimed at detecting a possible hydrogen leak;

- control panels and automatic control systems.

To achieve the most efficient process of electrical conductivity, lye drops are used. The tank with it is replenished as needed, but most often this happens about 1 time per year.

Any electrolytic generators of industrial type are produced on the basis of European environmental and safety standards.

It has been experimentally proven that the purchase of a hydrogen electrolytic generator is much more profitable than the regular purchase of gas. So, for the production of 1 cubic meter of gas from hydrogen and oxygen, only about 3.5 kW of electrical energy is required, as well as half a liter of demineralized water.

Features of Electrolytic Hydrogen Generator

A hydrogen generator based on the principle of electrolysis is most often produced in a container version. A prerequisite for the purchase of such a device for heating is the presence of the following documents: permission from Rostekhnadzor, certificates (compliance with GOSTR and hygienic).

The electrolytic generator consists of the following elements:

- a block that includes a transformer, a rectifier, junction boxes and devices, a block for replenishing and demineralizing water;

- devices for separate production of hydrogen and oxygen - an electrolyzer;

- gas analysis systems;

- liquid cooling systems;

- a system aimed at detecting a possible hydrogen leak;

- control panels and automatic control systems.

To achieve the most efficient process of electrical conductivity, lye drops are used. The tank with it is replenished as needed, but most often this happens about 1 time per year. Any electrolytic generators of industrial type are produced on the basis of European environmental and safety standards.

It has been experimentally proven that the purchase of a hydrogen electrolytic generator is much more profitable than the regular purchase of gas. So, for the production of 1 cubic meter of gas from hydrogen and oxygen, only about 3.5 kW of electrical energy is required, as well as half a liter of demineralized water.

Implementation into existing systems

The construction of new heating systems is an expensive and time-consuming process. The purchase of hydrogen generators for small buildings has a long payback period, so often such devices are assembled independently.

Adding an existing heating circuit with a generator requires space expansion. It is necessary to take care of the installation site of the device in advance.

Old boilers can be adapted to work on hydrogen gas: new burners are placed in the furnace. The system is supplemented with the necessary instruments to control parameters and search for gas leaks.

Upgraded systems also require the use of a catalyst. Renovation of old systems is much cheaper than a complete replacement of equipment.

Modernization is advisable if the main unit - the boiler is suitable for adaptation to work with hydrogen generators.

The construction of a hydrogen generator on your own allows you to save a fairly large amount.

All home-made devices, as well as those purchased from the manufacturer, must be checked by specialists.Installation of faulty devices is not allowed.

The myth that a hydrogen boiler is the most economical way to heat a house

You can often hear that a hydrogen boiler is the most economical way to heat a private house. Usually, to justify this thesis, references are made to the high calorific value of hydrogen - more than 3 times higher than that of natural gas. A simple conclusion is drawn from this - it is more profitable to heat a house with hydrogen than with gas.

Sometimes, as an argument for the effectiveness of a hydrogen boiler, the so-called “Brown gas” or a mixture of hydrogen and oxygen atoms (HHO) is given, which releases even more heat during combustion, and on which “advanced boilers” operate. After this, the justifications for efficiency simply end, leaving the opportunity for the imagination of the layman to draw beautiful pictures under the general name "heating for almost nothing." Just think - hydrogen burns "warmer" and is obtained from practically free water, a real benefit!

Imagination is also fueled by the news of an ever-growing fleet of hydrogen-powered vehicles as an alternative to traditional ones. Say, if cars “drive” on hydrogen, then a hydrogen boiler is a really worthwhile thing.

But in reality, things are a little more complicated. If pure hydrogen were an element readily available in nature, everything would be so, or almost so, it would be. But the fact is that pure hydrogen does not occur on Earth - only in a bound form, for example, in the form of water. Therefore, in practice, hydrogen must first be obtained from somewhere, moreover, with the help of energy-consuming chemical reactions.

DIY manufacturing

So, having decided to make a water-powered stove, the first thing to do is determine the main design of the future heater.

Using this method, any oven can be converted into an economical option.

Most often, such a heater is already available and it just needs to be modified. Here is the workflow diagram:

- Find a container for water and fix it.

- Make a steamer.

- They think over its fastening and the method of heating in order to get steam.

- Make a superheater. This is usually a thin-walled stainless steel tube with evenly sawn holes. It is wrapped with a stainless steel mesh - this device will serve as a noise suppressor.

- Think over the scheme of connection and fastening of all parts. The superheater must be located on the grate of the furnace in order to have good access to oxygen. Many come up with additional devices so that it does not clog with ash and oxygen access is constant.

- Check the device for efficiency and fire safety. The absence of smoke from the chimney when the stove is hot indicates proper operation. All rubber, wooden and plastic parts of the device must be at a fireproof distance from fire and hot parts of the structure.

More details about the stove on the water in this video:

Installing this design can save a lot of money. In addition, as a fuel, water in the furnace reduces air pollution from combustion waste. Even the simplest way to modify the stove can lead to a wonderful result.

For example, some summer residents use a water blower. That is, they insert a metal container with water under the firebox.As a result of evaporation and heating, such a simple method turns an ordinary stove into a water stove and improves its performance many times over.

Main knots

- Boiler. It is selected based on the type of building, the area and the required efficiency of the installation.

- Pipe system. The most rational for home heating is the use of pipes with a diameter of 1.25 inches. It is necessary to follow the rule - each subsequent branch must have a smaller diameter than the previous one. Therefore, calculations of material requirements and installation efficiency should begin with the minimum allowable pipe diameter.

- The output of waste products - water vapor, without impurities.

- Burner. To burn hydrogen, a temperature of more than 3000 degrees is required.

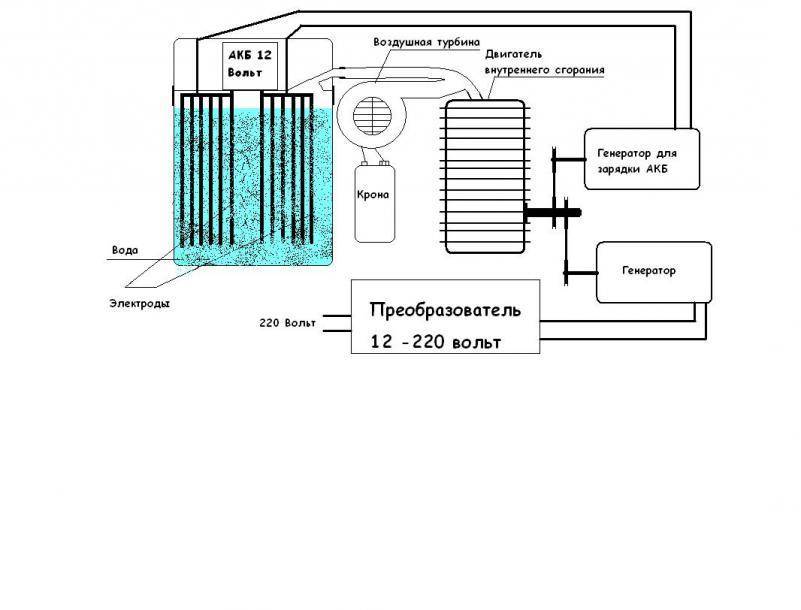

The internal structure of the hydrogen generator

Self powered generator

To increase efficiency, modular units with several burners should be purchased - this is an increase in the speed of electrolysis. The type and power of the burner is also selected taking into account the needs of the premises for heat supply (area, wall material, climatic region, etc.) and the optimal power of the generator.

For a residential building, the highest power rating of a hydrogen generator is 6 kW.

Hydrogen generator for home

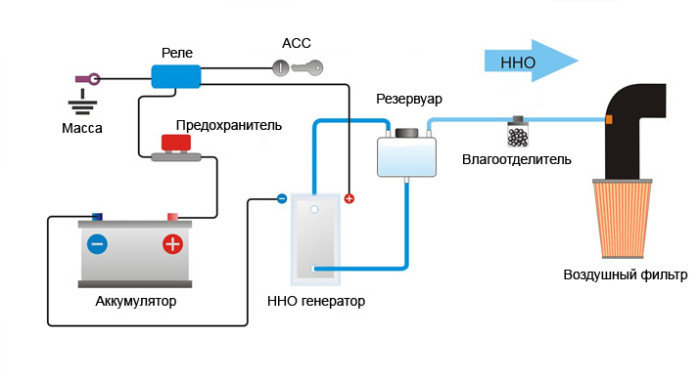

How the device works

The case itself has terminals to connect the power source and there is a sleeve through which gas is discharged.

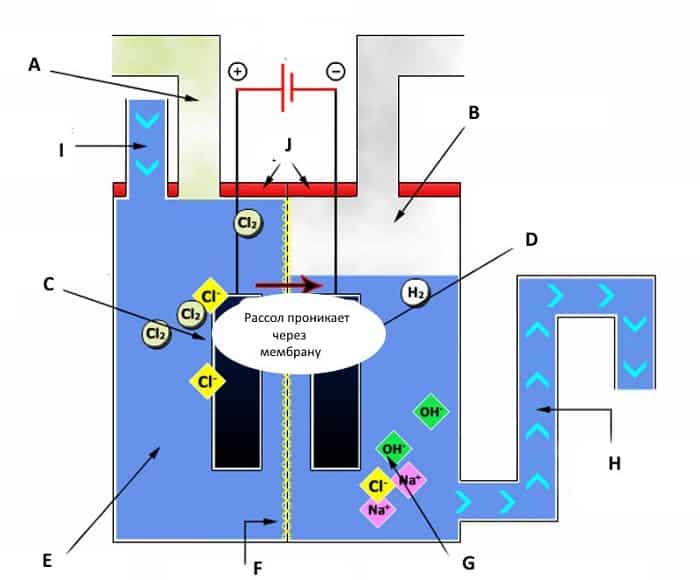

The operation of the device can be described as follows: an electric current is passed through distilled water between plates with different fields (one has an anode, the other has a cathode), splits it into oxygen and hydrogen.

Depending on the area of the plates, the electric current has its strength, if the area is large, then a lot of current passes through the water and more gas is released.The plate connection scheme is alternate, first plus, then minus, and so on.

Electrodes are recommended to be made of stainless steel, which does not react with water during electrolysis. The main thing is to find high quality stainless steel. It is better to make the distance between the electrodes small, but so that the gas bubbles move easily between them. Fasteners are best made from the appropriate metal as the electrodes.

Take into account:

due to the fact that the manufacturing technology is associated with gas, in order to avoid the formation of a spark, it is necessary to make a snug fit of all parts. In the considered embodiment, the device includes 16 plates, they are located from each other within 1 mm

Due to the fact that the plates have a fairly large surface area and thickness, it will be possible to pass high currents through such a device, but the metal will not heat up. If you measure the capacitance of the electrodes in air, then it will be 1nF, this kit uses up to 25A in plain water from the tap.

To collect a hydrogen generator with your own hands, you can use a food container, since its plastic is heat-resistant. Then you need to lower the gas collection electrodes into the container with hermetically insulated connectors, a lid and other connections.

If you use a metal container, then in order to avoid a short circuit, the electrodes are attached to the plastic. On both sides of the copper and brass fittings, two connectors are installed (fitting - mount, assemble) to extract the gas. Contact connectors and fittings must be firmly fixed using silicone sealant.

How to make hydrogen heating with your own hands

Any master who has the ability to work with metal can make heating on hydrogen with his own hands.

To form the device, you will need the following set of materials:

- stainless steel sheet with parameters 50x50 cm;

- bolts 6x150, equipped with washers and nuts;

- flow-through filter element - useful from an old washing machine;

- a transparent hollow tube 10 m long, for example, from the water level;

- a regular 1.5 liter plastic food container with a strong airtight lid;

- a set of herringbone fittings with a hole diameter of 8 mm;

- grinder for cutting;

- drill;

- silicone sealant.

To make a hydrogen furnace, steel 03X16H1 is suitable, and instead of water, you can take an alkaline solution, which will create an aggressive environment for the passage of current, while extending the life of the steel sheets.

How to make home heating with hydrogen yourself:

- Lay the metal sheet on a flat table, cut into 16 equal parts. Rectangles are obtained for the future burner. Now cut off one corner of all 16 rectangles - this is necessary for the subsequent connection of the parts.

- On the reverse side of each element, drill a hole for the bolt. Of all 16 sheets, 8 will be anodes and 8 will be cathodes. Anodes and cathodes are needed for the passage of electric current through parts with different polarity, this ensures the decomposition of alkali or distillate into hydrogen and oxygen.

- Now put the plates in a plastic container, taking into account the polarity, alternating plus and minus. A transparent tube will serve as an insulator for the plates, which must be cut into rings, and then into strips 1 mm thick.

- The metal plates are fixed to each other with washers in this way - first the washer is put on the bolt leg, then the plate is put on. After the plate, you need to put 3 washers on the bolt, then the plate again. In this way, 8 plates are hung on the anode and 8 plates on the cathode.

Now you need to figure out the stop point for the bolt in the food container, drill a hole in this place. If the bolts are not included in the container, then the bolt leg is cut to the desired length. After that, thread the bolts into the holes, put washers on the legs and clamp the structure with nuts for tightness. Equip the container lid with a hole for the fitting, insert the element into the hole and, for tightness, coat the joint area with sealant. Now blow out the fitting. And if air escapes through the lid, then you will have to seal the lid around the entire perimeter.

The generator is tested by connecting any current source with filling the container with water. A hose is put on the fitting, the second end of which is immersed in a container. If air bubbles form in the liquid, then the circuit is working, if not, you need to check the current supply power. It happens that air bubbles do not form in the water, but they certainly appear in the electrolyzer.

To provide the required amount of thermal energy, it is necessary to increase the production and output of gas by increasing the voltage in the electrolyte. Pour alkali into the water, for example, sodium hydroxide, which is in the Krot pipe cleaner. Reconnect the power supply and check the capacity of the electrolyzer.

The very last stage is the connection of the burner to the pipeline of the heating main. It can be a warm floor, plinth wiring. The joints should be sealed with silicone and the equipment can be put into operation.

Making a generator on your own

On the Internet you can find a lot of instructions on how to make a hydrogen generator. It should be noted that it is quite possible to assemble such an installation for a house with your own hands - the design is quite simple.

Do-it-yourself hydrogen generator components for heating in a private house

But what will you do with the resulting hydrogen? Once again, pay attention to the combustion temperature of this fuel in air. It is 2800-3000°С

Considering that metals and other solid materials are cut with burning hydrogen, it becomes clear that installing a burner in a conventional gas, liquid fuel or solid fuel boiler with a water jacket will not work - it will simply burn out.

Craftsmen on the forums advise laying out the firebox from the inside with fireclay bricks. But the melting temperature of even the best materials of this type does not exceed 1600 ° C, such a furnace will not last long. The second option is to use a special burner, which is able to lower the flame temperature to acceptable values. Thus, until you find such a burner, you should not start mounting a homemade hydrogen generator.

Tips for assembling and operating the generator

Having solved the issue with the boiler, select the appropriate scheme and instructions on how to make a hydrogen generator for heating a private house.

A homemade device will be effective only if:

- sufficient surface area of plate electrodes;

- correct choice of material for the manufacture of electrodes;

- high quality electrolysis fluid.

What size should be the unit that generates hydrogen in sufficient quantities to heat the house, you will have to determine "by eye" (based on someone else's experience), or by assembling a small installation to begin with. The second option is more practical - it will allow you to understand whether it is worth spending money and time on installing a full-fledged generator.

Rare metals are ideally used as electrodes, but this is too expensive for a home unit. It is recommended to choose stainless steel plates, preferably ferromagnetic.

Hydrogen generator design

There are certain requirements for water quality. It should not contain mechanical impurities and heavy metals. The generator works as efficiently as possible on distilled water, but to reduce the cost of construction, you can limit yourself to filters to purify water from unnecessary impurities. In order for the electrical reaction to proceed more intensively, sodium hydroxide is added to the water in the ratio of 1 tablespoon per 10 liters of water.