- The device and principle of operation of the hydrogen generator

- How it works

- electrolysis method

- Stanley Meyer fuel cell

- Benefits of Brown's gas as an energy source

- Hub models, which are the best according to the editors Tehno.guru

- "ARMED 7F-3L" - an oxygen concentrator with good functionality

- "OXYbar Auto" is a product from the very famous brand "Atmung"

- "BITMOS OXY-6000" - a device with fairly good performance

- How it works

- Why is water still not heated

- Is there a "water" car

- Law of conservation of energy ↑

- Application area

- Compliance with security measures

- Selected points of use

- Rules for the selection of a heating hydrogen boiler

- How to install a hydrogen boiler?

- Features of the hydrogen generator

- ESSENCE OF HYDROGEN HEATING SYSTEM

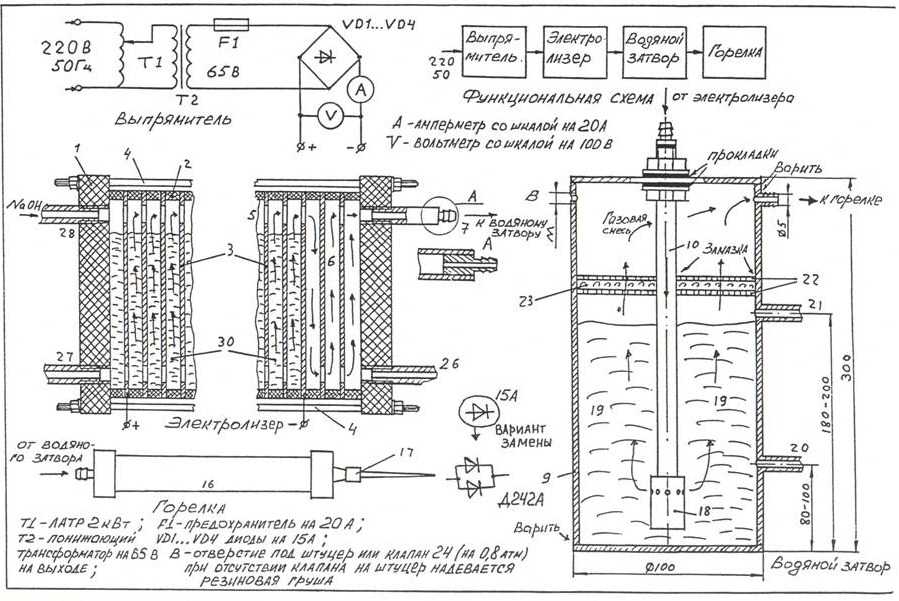

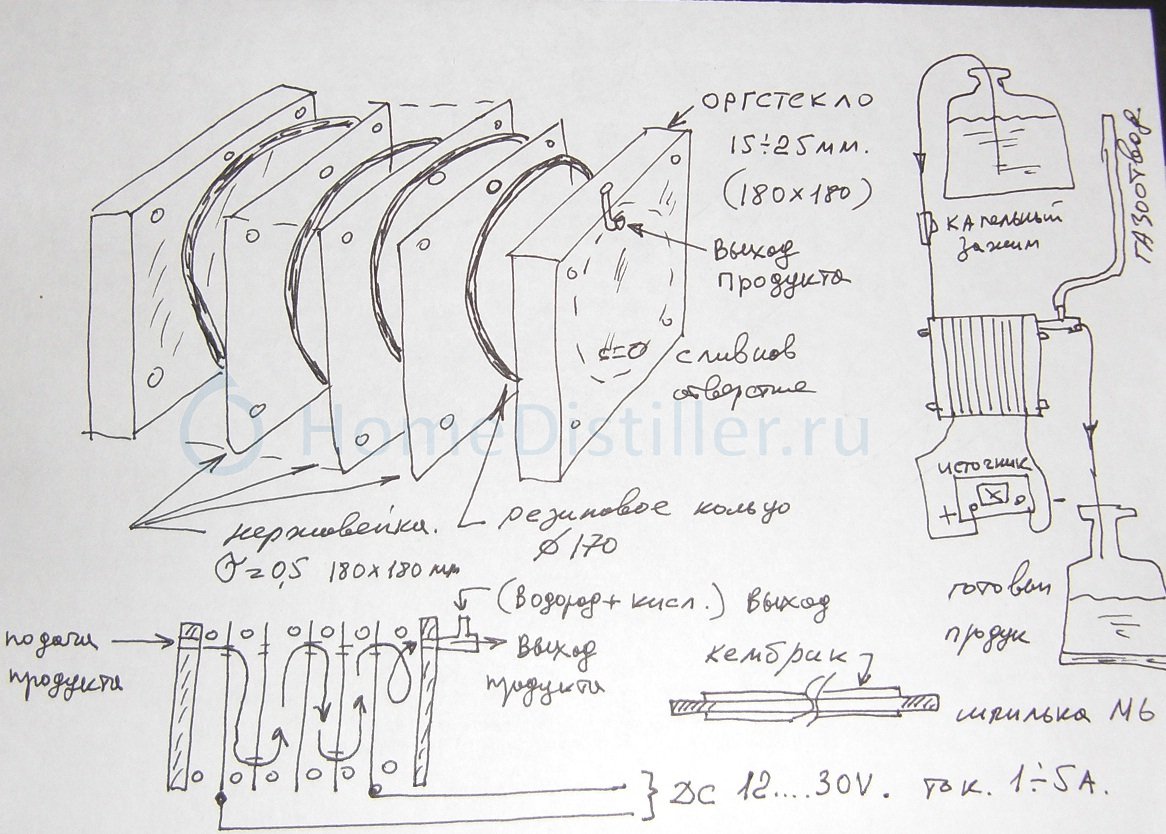

- DIY hydrogen generator

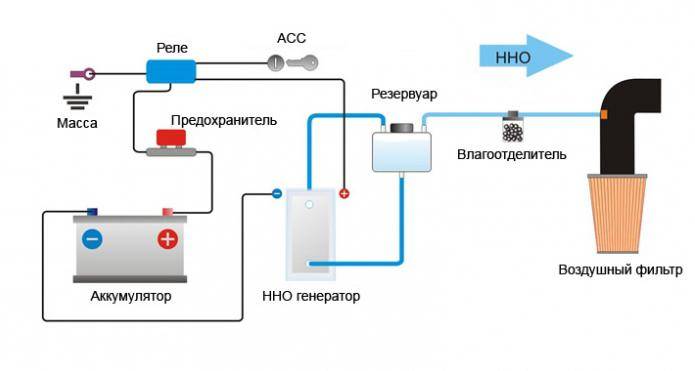

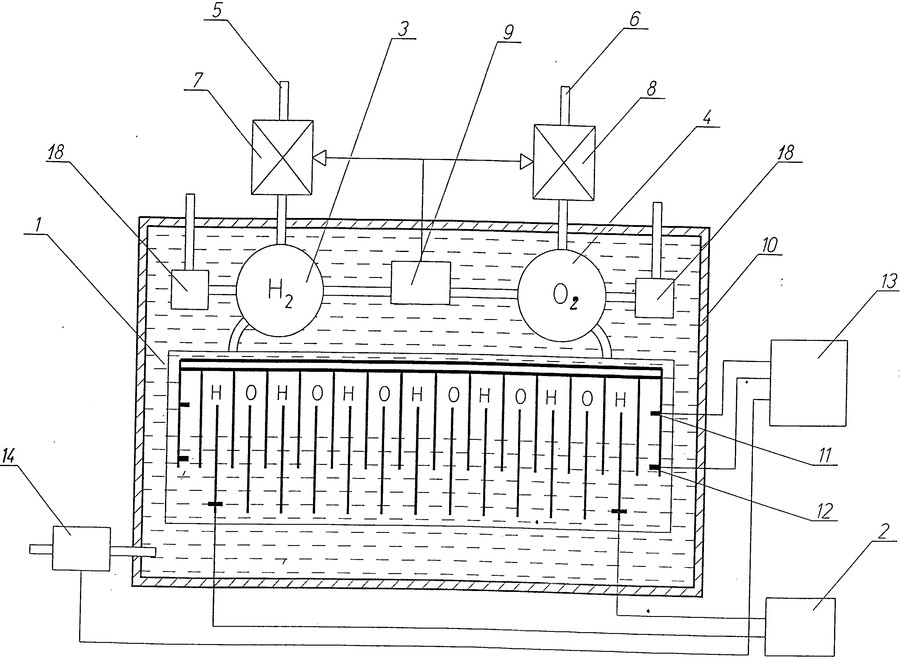

The device and principle of operation of the hydrogen generator

How it works

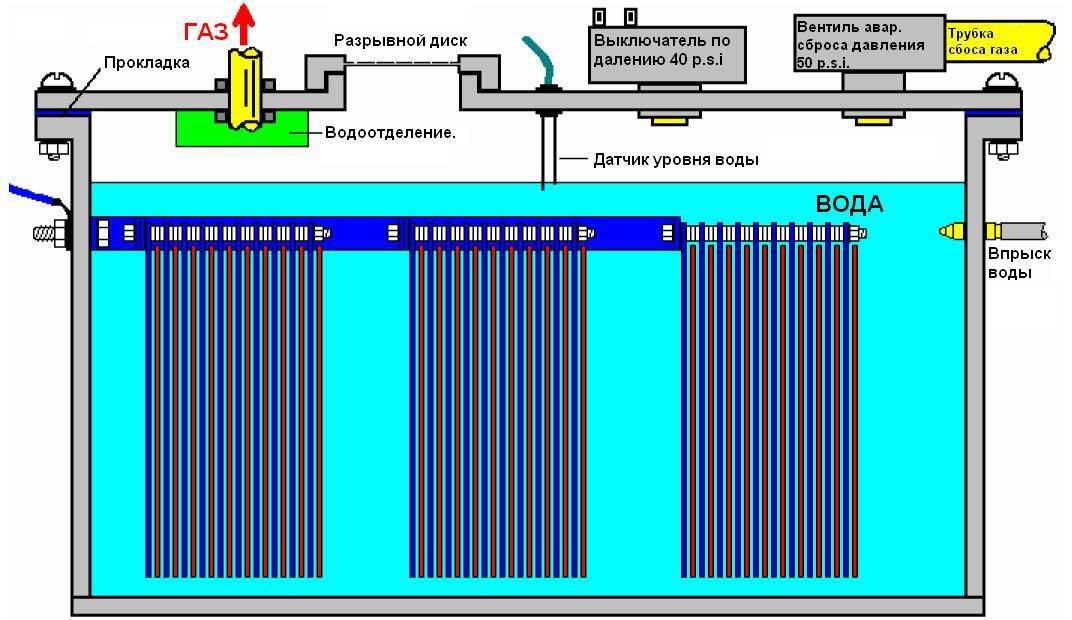

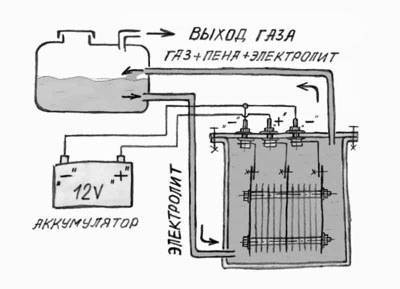

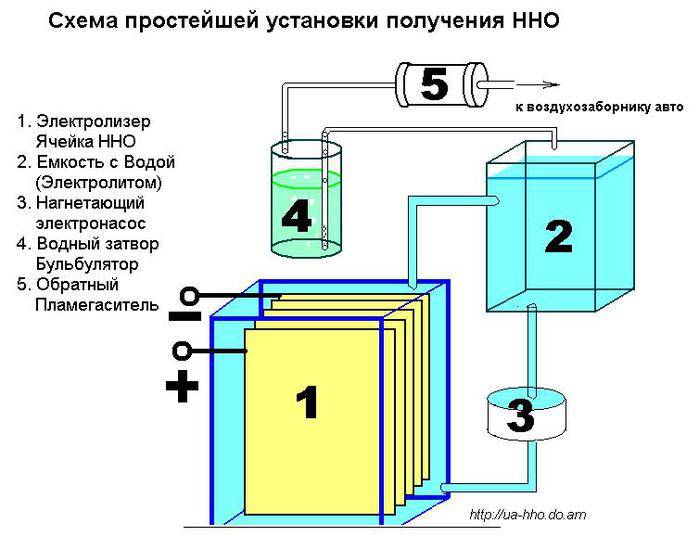

The classic apparatus for generating hydrogen includes a tube of small diameter, often with a circular cross section. Under it are special cells with electrolyte. The aluminum particles themselves are located in the lower vessel. The electrolyte in this case is suitable only for the alkaline type. A tank is installed above the feed pump, where condensate is collected. Some models use 2 pumps.The temperature is controlled directly in the cells.

The generator gets gas from the water. Its quality directly affects the amount of impurities in the finished product. So, if water with a high concentration of foreign ions enters the generator, then it will first have to pass through a deionization filter.

Here is how the process of obtaining gas occurs:

- The distillate is split into oxygen (O) and hydrogen (H) during the electrolysis process.

- O2 enters the feed tank and then escapes to the atmosphere as a by-product.

- H2 is supplied to the separator, separated from the water, which then returns to the supply tank.

- Hydrogen is re-passed through a separating membrane, which extracts the remaining oxygen from it, and then enters the chromatographic equipment.

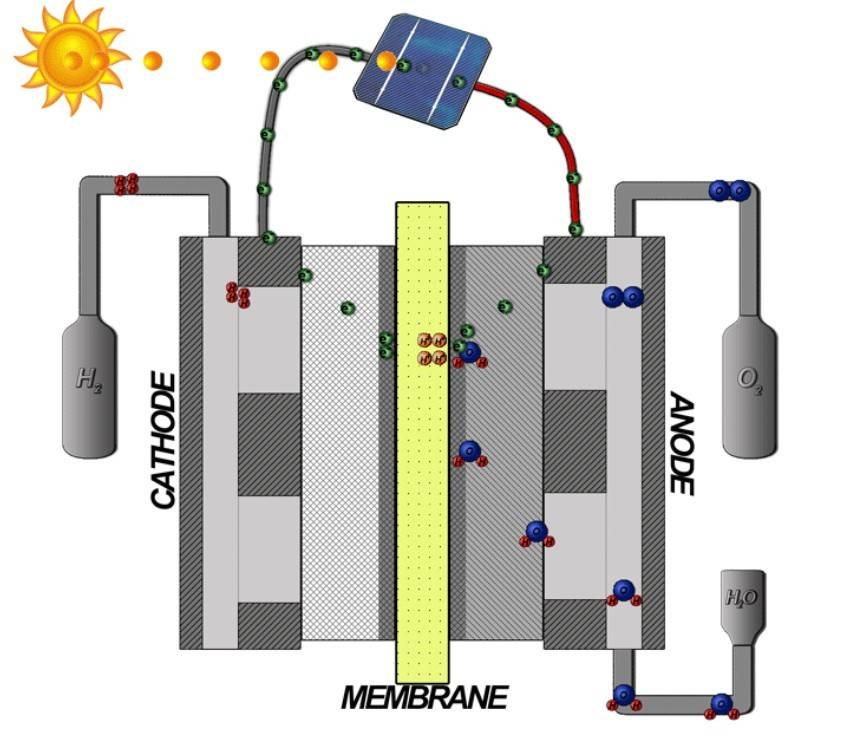

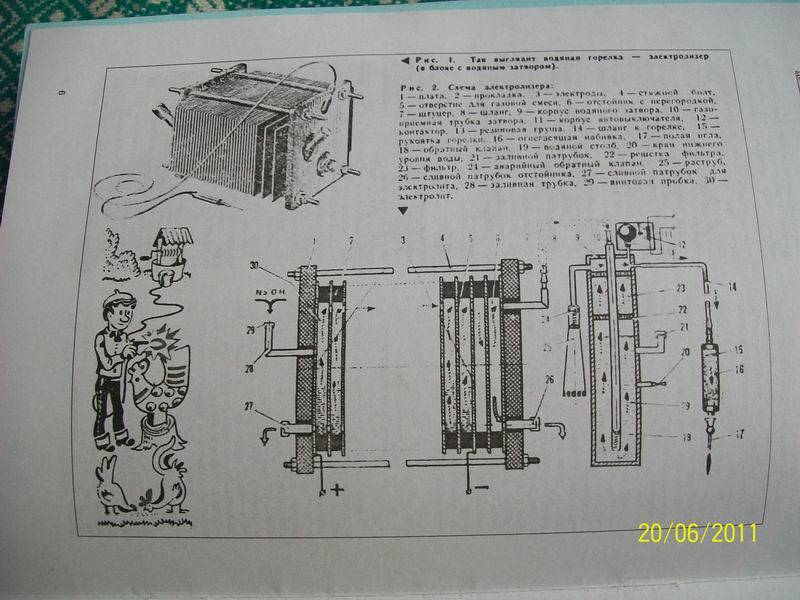

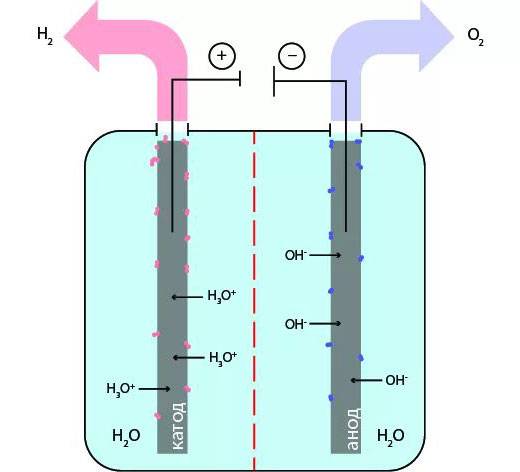

electrolysis method

As mentioned above, there are practically no such inexhaustible energy sources in the world as hydrogen. It should not be forgotten that 2/3 of the World Ocean consists of this element, and in the entire Universe, H2, together with helium, occupies the largest volume. But to get pure hydrogen, you need to split water into particles, and this is not very easy to do.

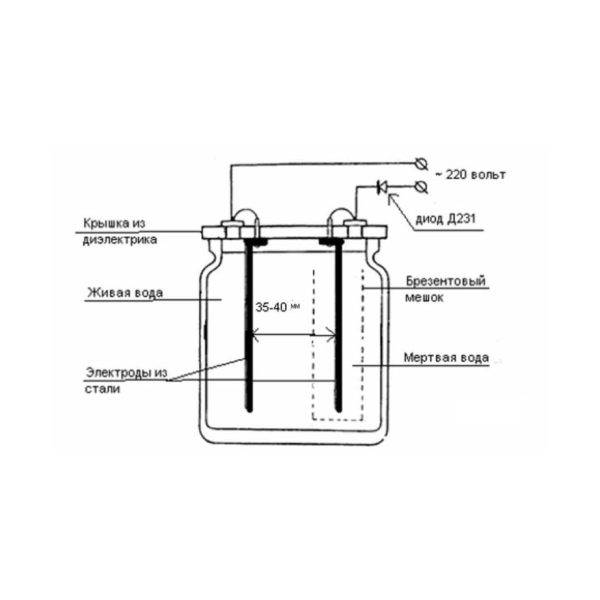

Scientists after many years of tricks invented the method of electrolysis. This method is based on placing two metal plates close to each other in water, which are connected to a high voltage source. Next, power is applied - and a large electrical potential actually breaks the water molecule into components, as a result of which 2 hydrogen atoms (HH) and 1 oxygen (O) are released.

This gas (HHO) was named after Australian scientist Yull Brown, who in 1974 patented the creation of an electrolyzer.

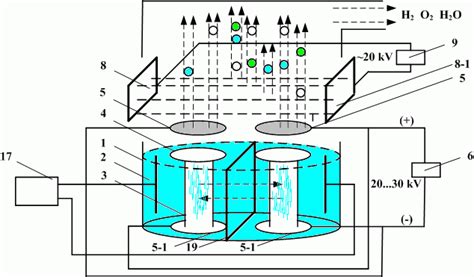

Stanley Meyer fuel cell

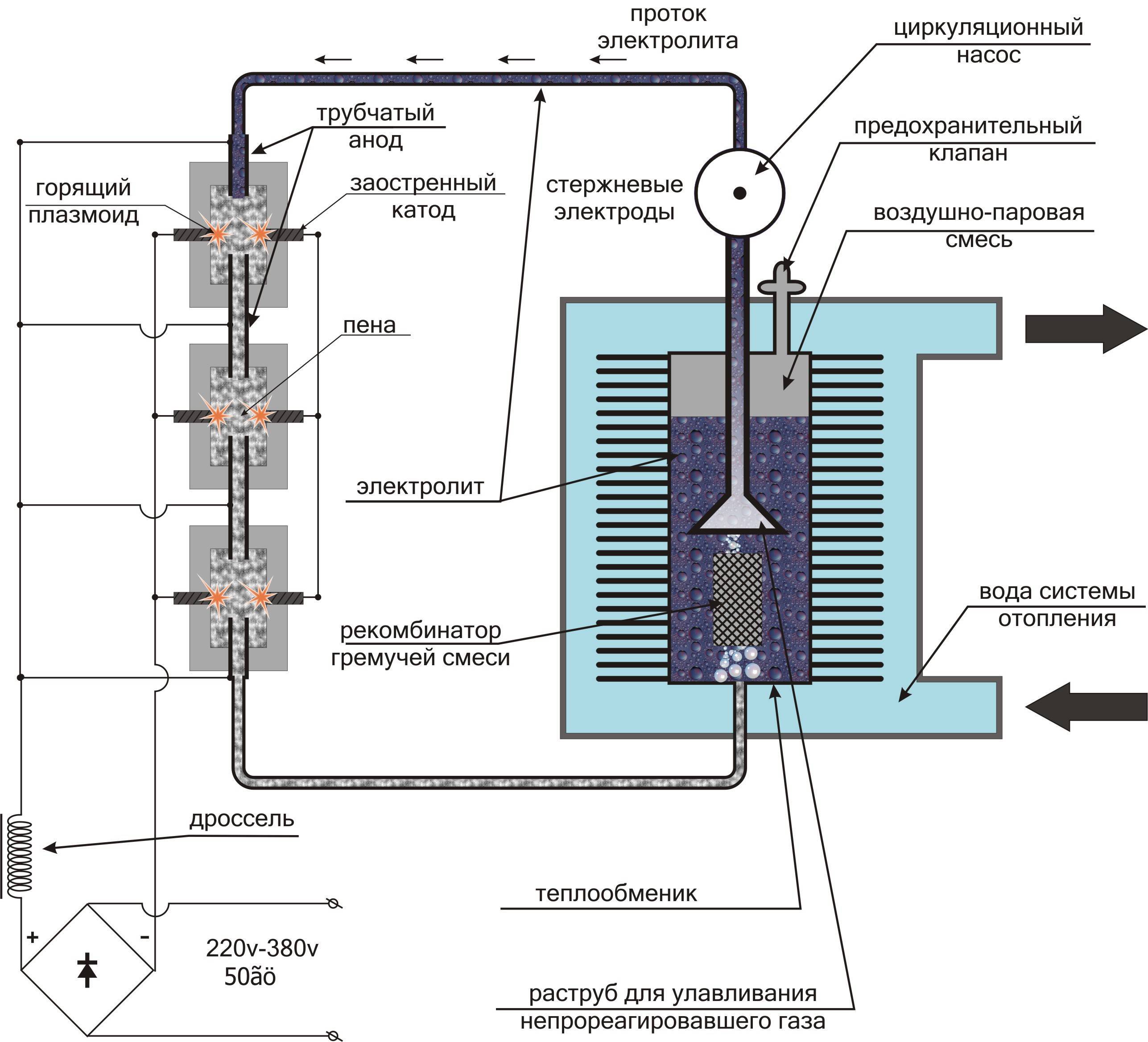

The US scientist Stanley Meyer invented such an installation that did not use a strong electrical potential, but currents of a certain frequency. The water molecule oscillates in time with the changing electrical impulses and enters into resonance. Gradually, it gains power, which is enough to separate the molecule into components. For such an impact, currents are ten times smaller than for the operation of a standard electrolysis unit.

Benefits of Brown's gas as an energy source

- The water from which HHO is obtained is present on our planet in huge quantities. Accordingly, the sources of hydrogen are practically inexhaustible.

- The combustion of Brown's gas produces water vapor. It can be re-condensed into a liquid and used as a raw material again.

- The combustion of HHO does not release any harmful substances into the atmosphere and does not form by-products other than water. We can say that Brown's gas is the most environmentally friendly fuel in the world.

- When using a hydrogen generator, water vapor is released. Its quantity is enough to maintain a comfortable humidity in the room for a long time.

Hub models, which are the best according to the editors Tehno.guru

After reading a lot of reviews on the Web, having considered the technical characteristics of many models, the Tehno.guru editorial team has chosen some of the best models. This should help our dear reader to make the right choice without unnecessary hassle and many hours of shoveling the Internet in search of a good device.

"ARMED 7F-3L" - an oxygen concentrator with good functionality

This is how one of the best devices looks like - "ARMED 7F-3L" "ARMED 7F-3L" is recommended not only for home use, but also for use in a kindergarten, school, fitness center. The productivity of the device is up to 3 l / min at an oxygen concentration of 93%. The dimensions of the device are 480 × 280 × 560 mm, weight - 26.5 kg. Suitable for preparing oxygen cocktails. Here are some of its characteristics.

| brand, model | Oxygen productivity, l/min | Noise level, dB | Power consumption, W |

| ARMED 7F-3L | 0-3 | 49 | 350 |

A little noisy, but overall a pretty decent unit. Here's what netizens are saying about him.

ARMED 7F-3L

"OXYbar Auto" is a product from the very famous brand "Atmung"

OXYbar Auto is one of the quietest and most compact devices Very quiet, light and compact device

The kit includes an adapter for connecting in the car, which is very important for many on long trips. Weight only 5.2 kg

To date, there are no such light devices on the Russian market. The manufacturer claims that the device can work around the clock. The maximum capacity of the unit is 6 l / min, however, the oxygen concentration will be only 30%, which cannot please. With performance settings of 1l/min, the concentration is acceptable - 90%. Consider the characteristics of the device.

| brand, model | Oxygen productivity, l/min | Noise level, dB | Power consumption, W |

| Atmung OXYbar Auto | 0,2-6 | 40 | 115 |

Thus, the device can be called not only the smallest, but also one of the quietest.

Atmung OXYbar Auto

"BITMOS OXY-6000" - a device with fairly good performance

"BITMOS OXY-6000" has good characteristics

| brand, model | Oxygen productivity, l/min | Noise level, dB | Power consumption, W |

| BITMOS OXY-6000 | 1-6 | 35 | 360 |

"BITMOS OXY-6000" is the brainchild of German manufacturers. And, like any German technique, it is made very high quality. It has a very convenient shape - it is a "suitcase" on wheels, which is very convenient with a weight of 19.8 kg. The dimensions of the device are 520 × 203 × 535mm. There is a function for preparing oxygen phytococktails. In case of temperature increase, flow rate drop, oxygen concentration drop, network disconnection and microprocessor errors, the device beeps. With a capacity of 1-4 l / min, the oxygen concentration reaches 95%. And what about the characteristics?

BITMOS OXY-6000

USEFUL INFORMATION!

The cost of such devices is quite high and not everyone can afford. That is why today you can find many companies offering an oxygen concentrator for home use for rent at quite reasonable prices.

How it works

The development of a promising method of heating was carried out in Italy. During the operation of a hydrogen boiler, toxic substances are not released into the atmosphere, for this reason its use is the safest for heating houses and apartments. The reactions carried out during the conversion process are not accompanied by noise, so the sound vibrations from the operating boiler are minimal.

Floor structure in a container

Floor structure in a container

The usefulness of the technology is that scientists and designers have managed to achieve a relatively low temperature of hydrogen gas combustion. The indicator reaches approximately three hundred degrees Celsius. This feature allows significant savings on materials for boilers, since protection against melting can be neglected.

The principles of the ongoing reaction inside the generator have been known since school days. When an oxygen and a hydrogen atom interact, a water molecule is formed. Reaction catalysts are required to start the transformation process. During the formation of bonds, the liquid circulating through the pipeline is heated to approximately 40 degrees. This is enough to heat the floors to a sufficient level.

Hydrogen heating

Hydrogen heating

In order to achieve higher temperatures in the house, the operation of boiler equipment is regulated, especially its power. The need to change the parameters is required to fit the heating system to different dimensions of the room. Boilers designed for hydrogen conversion reactions are modular.

This means that they can include several channels that, independently of one another, are connected to a single unit. For each duct, a separate container with a catalyst is connected, so liquid enters the exchange part, with a temperature of about 40 degrees.

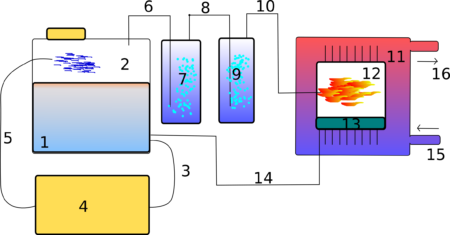

The principle of operation of the device is as follows:

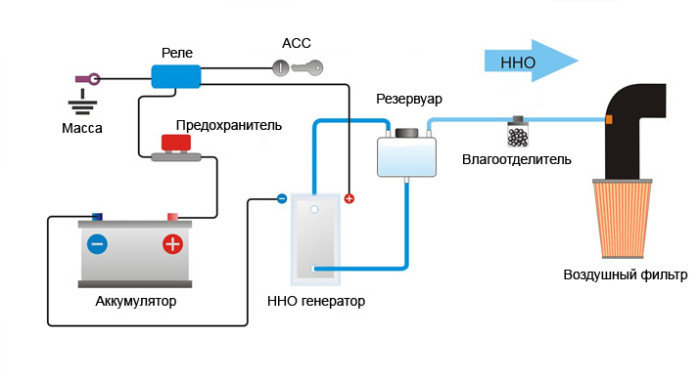

- The finished equipment includes a device with a pair of interconnected plates with different levels of charge (cathode and anode), which are immersed in water and a positive and negative signal is applied to them. For this, it is desirable to use an exclusively regulated current source. System performance is improved by using an electrolyte instead of a normal liquid, for example, an alkaline or acidic environment with a large amount of free ions.

- When reactions proceed from the cathode, hydrogen will begin to be released from the liquid, and oxygen near the anode.

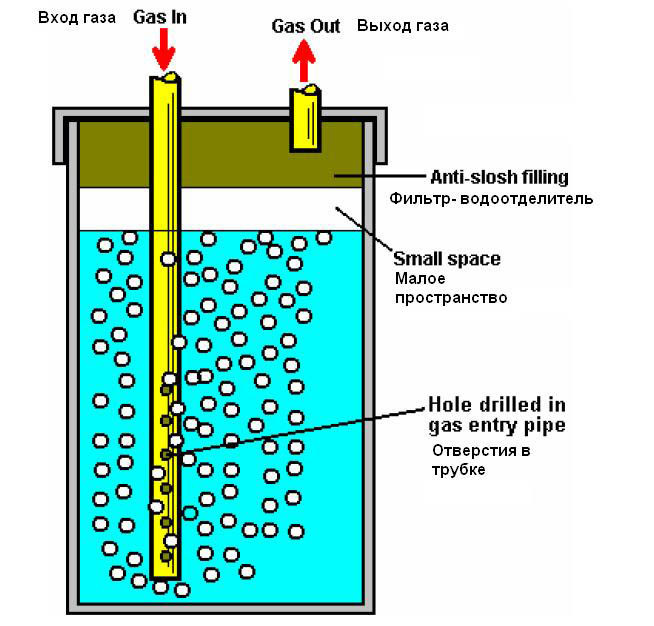

- Both gases are transferred through a tube to a water seal, which separates the steam and prevents an explosion in the reactor.

- After that, hydrogen gas enters the burner, where it must burn. The result is water.

Operating principle

Operating principle

Why is water still not heated

Intermolecular bonds of water arise and break much more easily than intramolecular ones. Therefore, it was they who decided to use them in heat transfer processes. Chemists experimentally found that the energy of intermolecular bonds of water is in the range from 0.26 to 0.5 eV (electronvolt).

The problem is that in order to obtain fuel from water, it must be decomposed into its components. In simple terms, it needs to be decomposed into oxygen and hydrogen, then burn the hydrogen and get water again. Splitting is achieved by passing an electric current through the liquid.

When boiling, water does not break into separate molecules, but only evaporates. Heating from ordinary combustion does not cause any other reactions in the liquid. Moreover, this process requires a lot of energy, which could be used with benefit. For example:

- burning 1 kg of dry firewood with a moisture content of not more than 20% gives about 3.9 kW;

- if the wood moisture level rises to 50%, then only 2.2 kW is released from 1 kg.

Decomposing water to produce real combustion requires a significant amount of energy. It needs much more than will be released when using the recovered elements again as fuel. An approximate ratio can be given:

- 100% energy - for splitting;

- 75% of the energy is from the combustion of recovered components.

It is the fact that less energy is released during the reverse reaction of the released hydrogen and oxygen, which is the reason why water as a fuel for cars and not only is still not used. Economically, this method turned out to be unprofitable. It is more realistic to make fuel from garbage. It can be liquid, gaseous and solid.

Is there a "water" car

In 2008, in Japan, a "water" car was presented by Genepax at an exhibition in Osaka. It was possible to use a glass of tap water or from the river as fuel, and even ordinary soda.

The device split the liquid into hydrogen and oxygen molecules, which began to burn and give the car energy to drive. Today it is known that Genepax went bankrupt and closed a year later.

Law of conservation of energy ↑

Everything in nature is interconnected. If something has arrived somewhere, it means that it has departed from somewhere. This folk wisdom, in a simplified but generally correct way, describes the law of conservation of energy. Hydrogen, when burned, releases heat energy. But in order to get gas by electrolysis, you will have to spend a certain amount of electricity. Which, in turn, is mostly obtained by generating heat from the combustion of other fuels. And if we take the pure thermal energy necessary to generate electricity and the energy that hydrogen will give during combustion, even the most advanced installations result in a double loss. We literally throw away half of the money. And these are only operating costs, but you should also take into account the cost of very expensive equipment.

The project of the wind-hydrogen airship Aeromodeller II.The Belgian engineers drew a beautiful picture, it remains to back it up with specific economically viable technologies

According to the INEEL research laboratory, on industrial hydrogen generators in the United States, the cost of one kilogram of hydrogen was:

- Electrolysis from an industrial power grid - 6.5 usd.

- Electrolysis from wind turbines - 9 usd.

- Photoelectrolysis from solar devices - 20 usd.

- Production from biomass - 5.5 usd.

- Conversion of natural gas and coal - 2.5 usd.

- High-temperature electrolysis at nuclear power plants - 2.3 usd. This is the least expensive way and the farthest from home conditions.

Moreover, even the best hydrogen generator at home will be noticeably inferior to the industrial one in efficiency. With such prices, there is no reason to talk about any serious competition for hydrogen fuel compared not only with cheap natural gas, but also with expensive electric heating, diesel fuel, and even heat pumps.

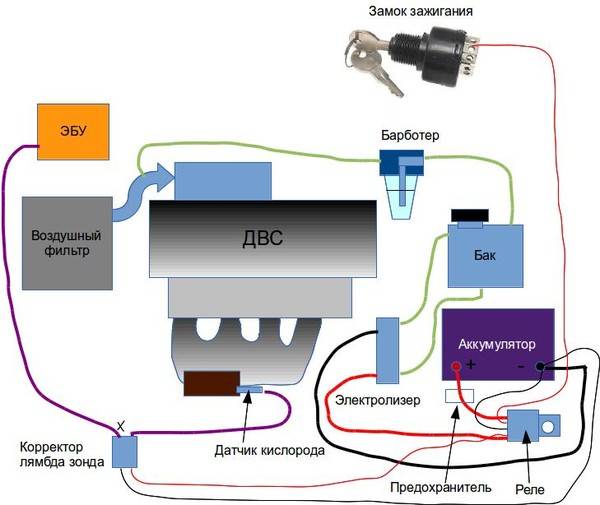

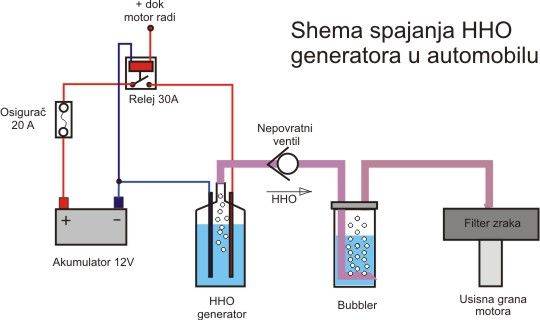

Application area

Today, the electrolyser is as familiar a device as an acetylene generator or a plasma cutter. Initially, hydrogen generators were used by welders, since carrying a unit weighing only a few kilograms was much easier than moving huge oxygen and acetylene cylinders. At the same time, the high energy intensity of the units was not of decisive importance - everything was determined by convenience and practicality. In recent years, the use of Brown's gas has gone beyond the usual concepts of hydrogen as a fuel for gas welding machines. In the future, the possibilities of the technology are very wide, since the use of HHO has a lot of advantages.

- Reducing fuel consumption in vehicles. Existing automotive hydrogen generators allow HHO to be used as an additive to traditional gasoline, diesel or gas. Due to more complete combustion of the fuel mixture, a 20–25% reduction in hydrocarbon consumption can be achieved.

- Fuel economy at thermal power plants using gas, coal or fuel oil.

- Reducing toxicity and increasing the efficiency of old boiler houses.

- Multiple reduction in the cost of heating residential buildings due to the complete or partial replacement of traditional fuels with Brown's gas.

- Use of portable HHO plants for household needs - cooking, getting warm water, etc.

- Development of fundamentally new, powerful and environmentally friendly power plants.

A hydrogen generator built using the “Water Fuel Cell Technology” by S. Meyer (namely, that was the name of his treatise) can be bought - many companies in the USA, China, Bulgaria and other countries are engaged in their manufacture. We offer to make a hydrogen generator yourself.

Compliance with security measures

The electrolyser is a device of very high danger.

Due to this, during its manufacture, installation and operation, first of all, it is necessary to comply with both general and specialized safety measures.

Specialized measures include the following items:

- the concentration of the mixture of hydrogen and oxygen should be controlled in order to prevent an explosion;

- if the liquid level is not visible in the viewing window of the hydrogen generator, then it cannot be used;

- during the repair, it must be ensured that at the end point of the system, as such, there is no hydrogen;

- the use of open flames, electrical appliances with a heating function and portable lamps with a voltage of more than 12 volts near the electrolyzer is contraindicated;

- during the working period with electrolyte, you should protect yourself by using protective equipment (special protective clothing, gloves and goggles).

Selected points of use

First of all, I would like to note that the traditional method burning natural gas or propane is not suitable in our case, since the combustion temperature of HHO exceeds that of hydrocarbons by more than three times. As you understand, structural steel will not withstand such a temperature for a long time. Stanley Meyer himself recommended using a burner of an unusual design, the diagram of which we present below.

Scheme of a hydrogen burner designed by S. Meyer

The whole trick of this device lies in the fact that HHO (indicated by the number 72 in the diagram) passes into the combustion chamber through valve 35. The burning hydrogen mixture rises through channel 63 and simultaneously carries out the ejection process, entraining outside air through adjustable openings 13 and 70. Under the cap 40, a certain amount of combustion products (water vapor) is retained, which enters the combustion column through channel 45 and mixes with the burning gas. This allows you to reduce the combustion temperature several times.

The second point that I would like to draw your attention to is the liquid that should be poured into the installation. It is best to use prepared water that does not contain salts of heavy metals. The ideal option is distillate, which can be purchased at any auto shop or pharmacy.

For the successful operation of the electrolyser, potassium hydroxide KOH is added to the water, at the rate of about one tablespoon of the powder per bucket of water.

And the third thing we put special emphasis on is safety. Remember that the mixture of hydrogen and oxygen is not accidentally called explosive. HHO is a hazardous chemical compound which, if handled carelessly, can cause an explosion. Follow safety rules and be especially careful when experimenting with hydrogen. Only in this case, the “brick” that our Universe consists of will bring warmth and comfort to your home.

We hope the article has become a source of inspiration for you, and you, having rolled up your sleeves, start manufacturing a hydrogen fuel cell. Of course, all our calculations are not the ultimate truth, however, they can be used to create a working model of a hydrogen generator. If you want to completely switch to this type of heating, then the issue will have to be studied in more detail. Perhaps it is your installation that will become the cornerstone, thanks to which the redistribution of energy markets will end, and cheap and environmentally friendly warmth will enter every home.

Rules for the selection of a heating hydrogen boiler

The first thing you need to require when buying is a certificate of conformity for the device protection unit.

Then check the details for compliance, determine a number of basic parameters:

- Power. Choose depending on the network available in the house and according to the volume of the area of \u200b\u200bthe building. For 10 m2, 1 kW of heat is needed.

- Heating system parameters. For example, if the boiler heats water from +90 C, and the network works with a coolant not higher than +80 C, the boiler power must be reduced.

- The volume of the combustion chamber.The indicator should correspond to the number of heat exchangers for warming up the house.

- The number of circuits and the technical possibility of installing an additional one. For example, for the distribution of hot water to different floors.

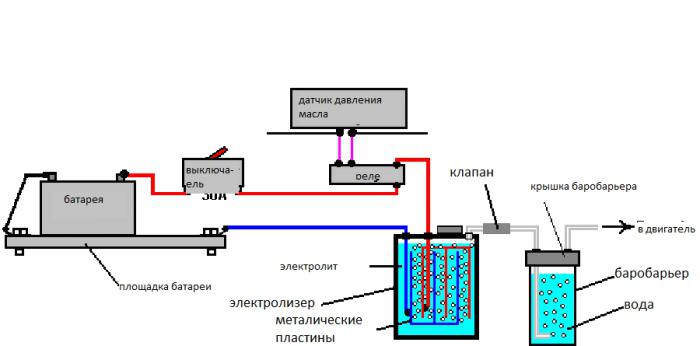

How to install a hydrogen boiler?

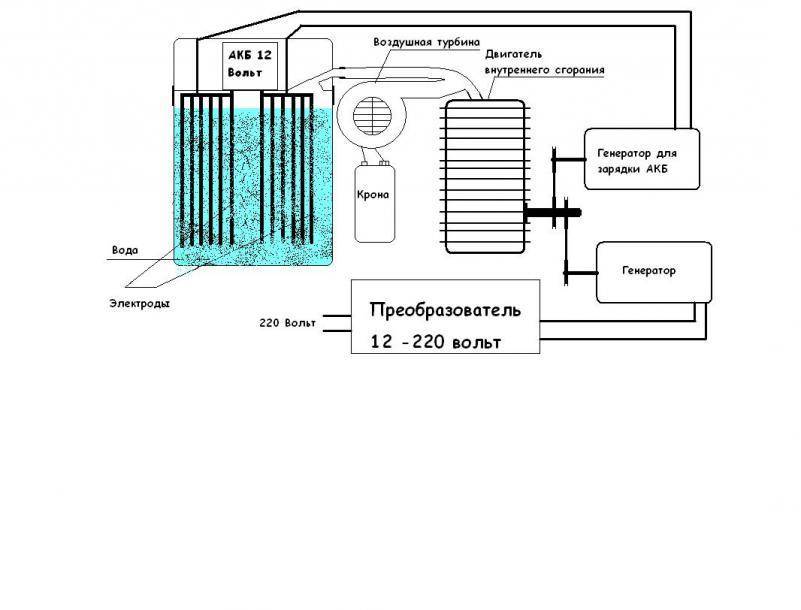

At the moment, many people prefer to independently produce hydrogen generators for their heating systems. And this is not surprising, because the "shop" analogues are not only very expensive, but also do not have a very high efficiency. But if this device is made by hand, then its efficiency will be an order of magnitude higher.

There are several options for how to assemble a generator that runs on hydrogen. But in any case, for its manufacture at home, the following consumables will be required.

12 volt power supply.

Several tubes made of stainless steel and having different diameters.

The tank in which the structure will be located.

PWM controller

It is important that its power is at least 30 amperes. These are the main components that homemade hydrogen generators usually consist of. In addition, do not forget about the distilled water tank - it is also a must.

Water must be supplied to a sealed structure with a dialectic inside. In the same design there will be a set made of stainless steel plates adjacent to one another by means of an insulating material. It is important that the 12-volt voltage is applied to these plates. If everything is done correctly, then when voltage is applied, the water will decompose into 2 gaseous elements

In addition, do not forget about the tank for distilled water - its presence is also required. Water must be supplied to a sealed structure with a dialectic inside. In the same design there will be a set made of stainless steel plates adjacent to one another by means of an insulating material.

It is important that the 12-volt voltage is applied to these plates. If everything is done correctly, then when voltage is applied, the water will decompose into 2 gaseous elements

These are the main components that homemade hydrogen generators usually consist of. In addition, do not forget about the tank for distilled water - its presence is also required. Water must be supplied to a sealed structure with a dialectic inside. In the same design there will be a set made of stainless steel plates adjacent to one another by means of an insulating material.

It is important that the 12-volt voltage is applied to these plates. If everything is done correctly, then when voltage is applied, the water will decompose into 2 gaseous elements

Note! More efficient in this regard is the use of direct current (it must have a specific frequency) produced by a PWM type generator. In this case, the pulsed current (or alternating) will be replaced by a constant one. As a result, the efficiency of the equipment will increase significantly.

As a result, the efficiency of the equipment will increase significantly.

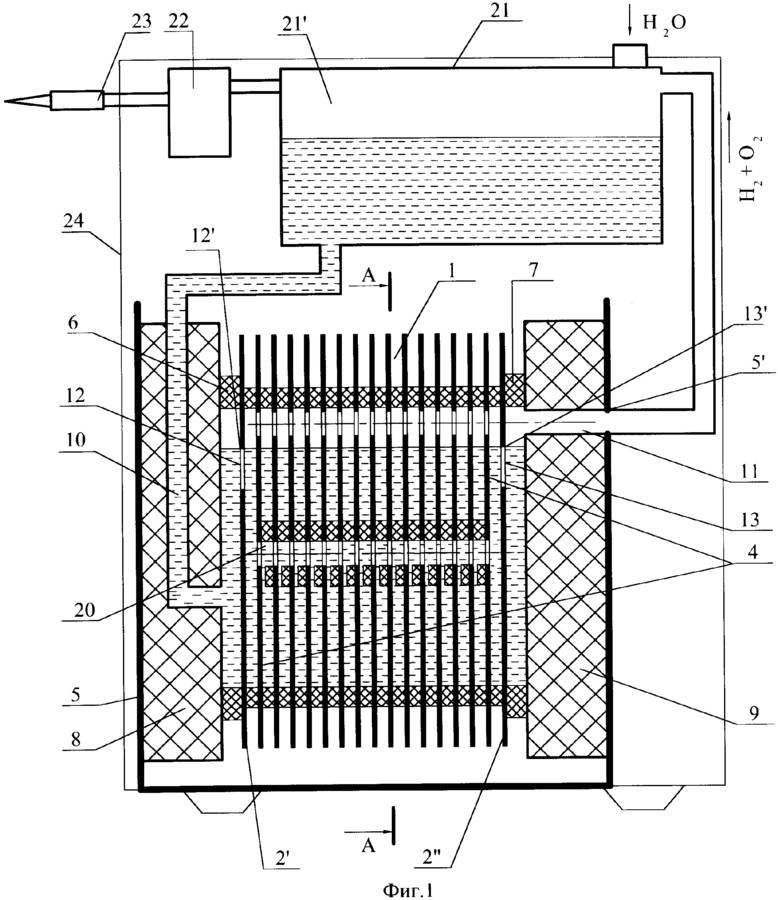

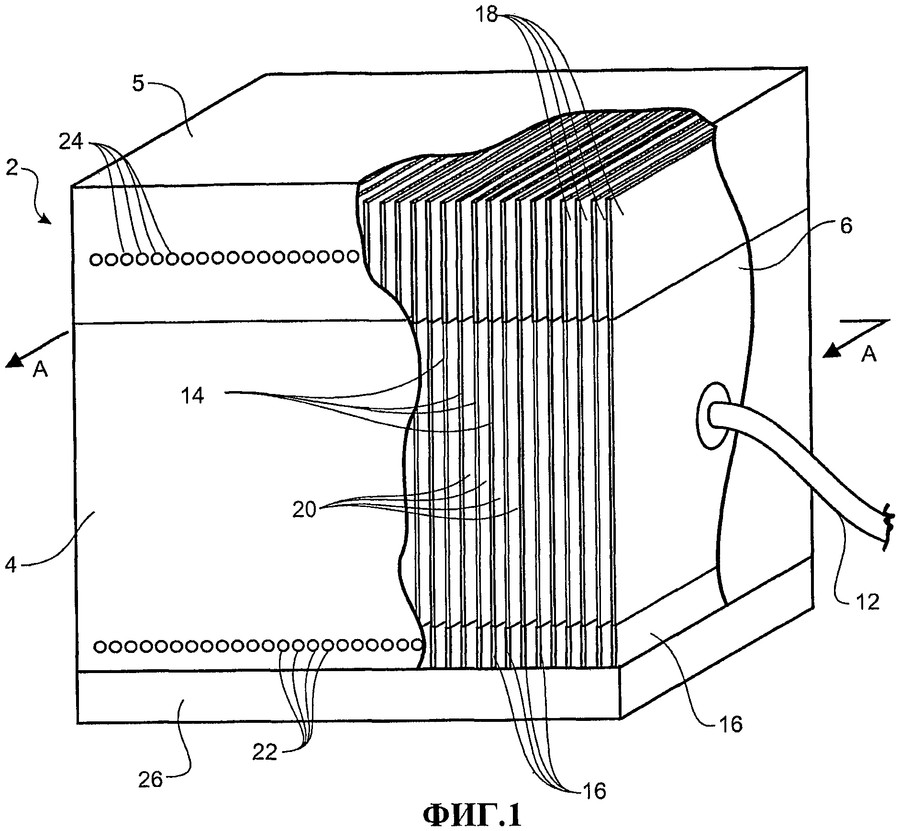

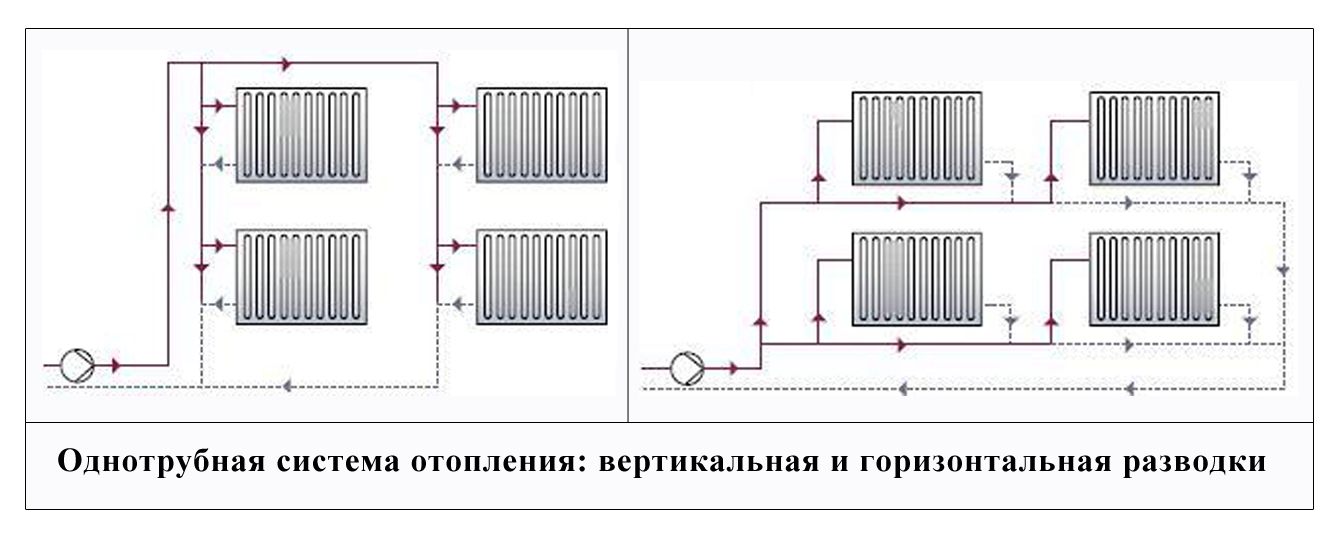

Features of the hydrogen generator

Pure hydrogen is released in a variety of chemical reactions, but this method of obtaining it is quite difficult, and often too expensive.

The exception is technological processes in which gas is formed as a by-product, but such production has so far scanty volumes.

It is much easier to extract hydrogen from water by passing an electric current through it - this process is called electrolysis. First, the H2O molecule decomposes into the hydrogen atom H and the hydroxo group OH, then the final separation of oxygen and hydrogen occurs.

It is obvious that the productivity of the installation will increase with an increase in the area of contact between water and electrodes. For this reason, the latter are made in the form of plates. They are assembled in structures resembling steel ribbed heating radiators.

In order to increase productivity today, cylindrical electrodes are used, as well as having a more complex shape.

The rate of hydrogen evolution also depends on the material of the electrodes.

Instead of copper or stainless steel, modern "advanced" generators use special alloys that are quite expensive.

Another condition is that the water must pass current. Note that in the distilled form, it is a dielectric. Ions make this liquid a conductor of electricity, into which substances dissolved in it, primarily salts, break down. The steeper the solution, the better it will conduct current.

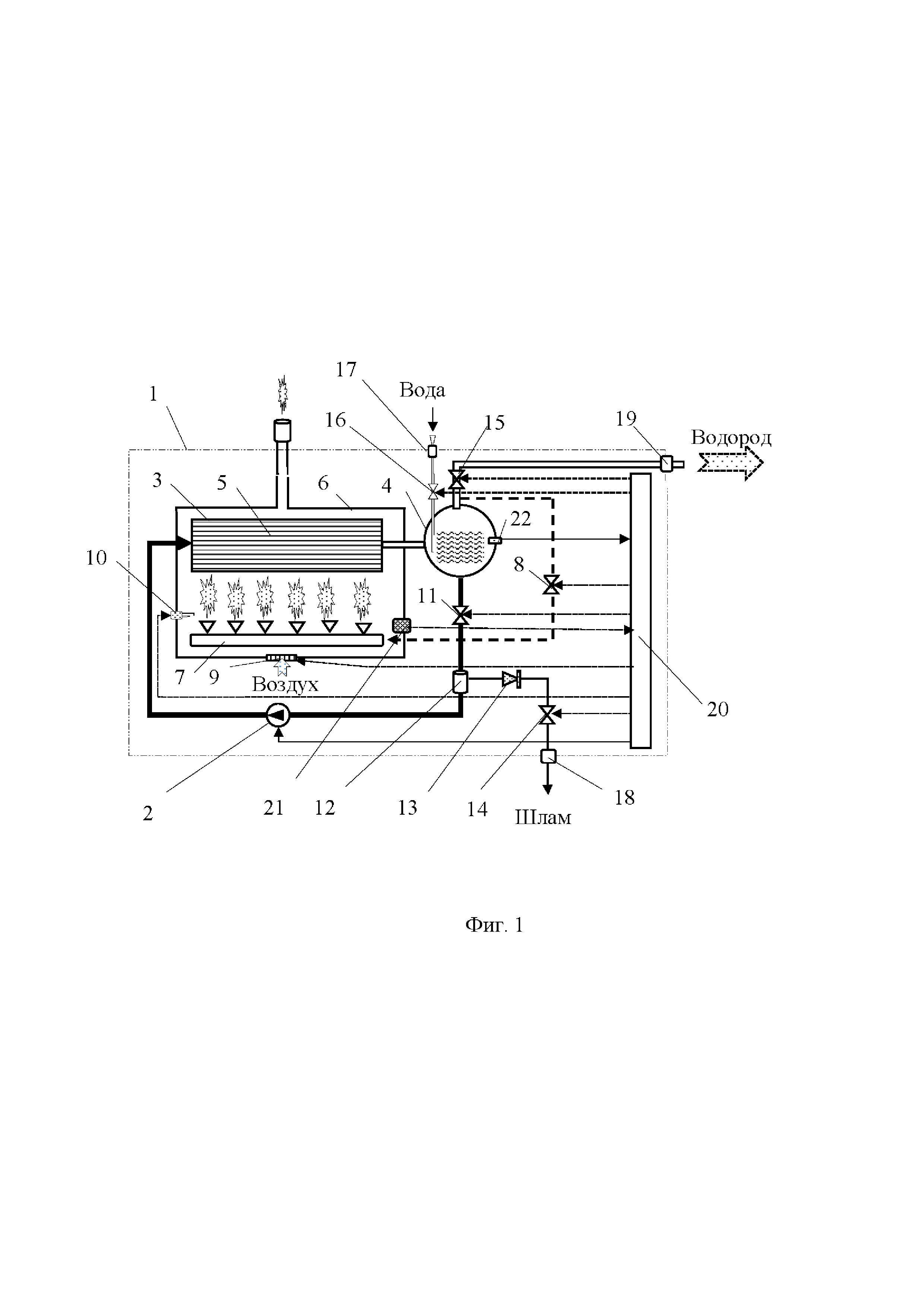

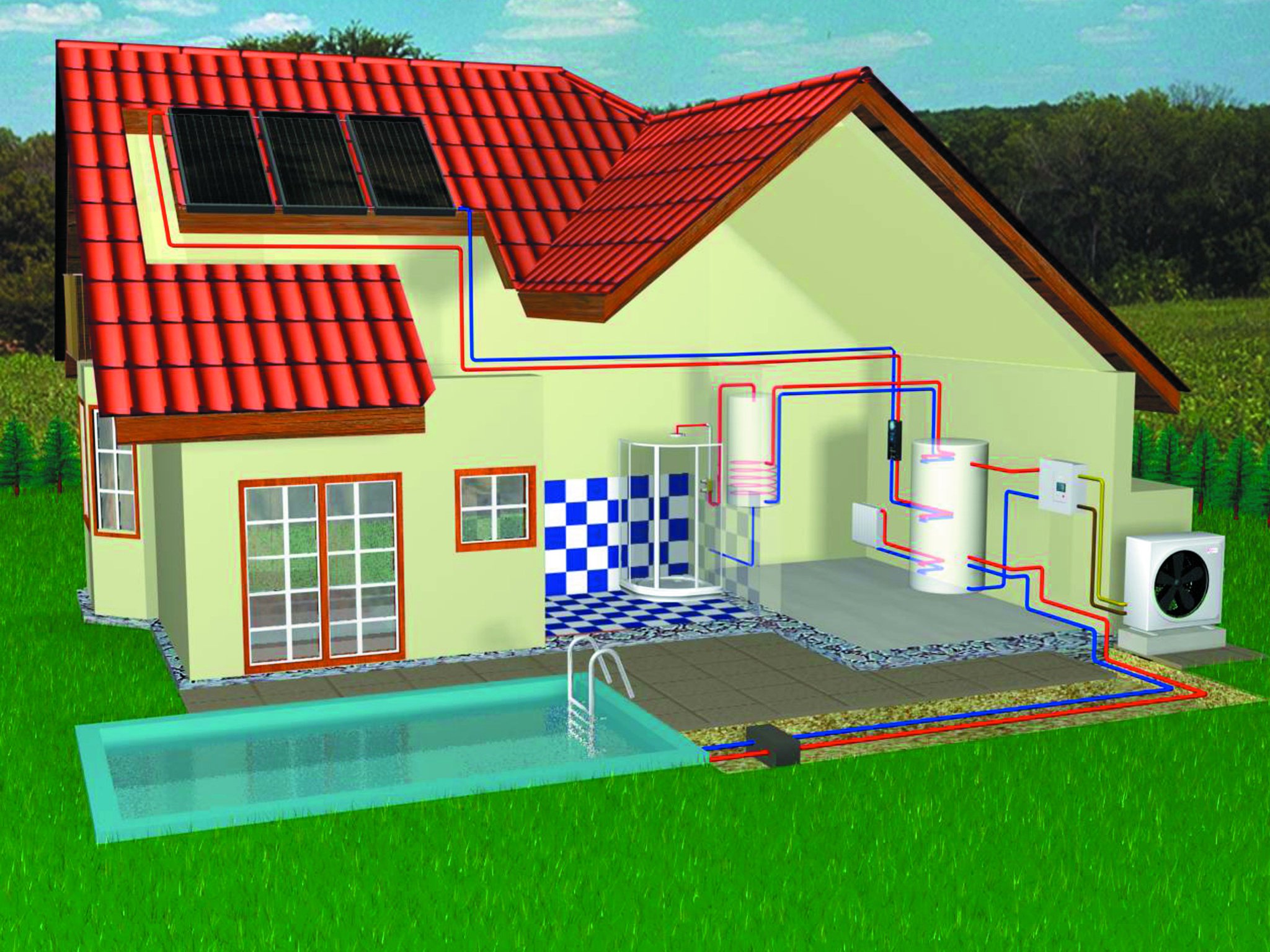

ESSENCE OF HYDROGEN HEATING SYSTEM

Hydrogen space heating is an excellent replacement for natural gas and solid fuels. The average combustion temperature of fuel can reach 3 thousand degrees. For the technological process, you will need a special burner, which is adapted for such temperature conditions.

The set of hydrogen equipment includes:

- Hydrogen generator (electrolyzer), which is responsible for the reaction between hydrogen and oxygen. Catalysts are used to optimize the process.

- A burner that creates a flame. The burner is located in the combustion chamber and provides heating of the heat carrier in the heating system.

- A boiler that performs the function of a heat exchanger.

Hydrogen boilers are often created on the basis of solid fuel or gas devices according to the above principle. In terms of savings, this is much cheaper than buying factory equipment. However, no one will guarantee that a home-made boiler will meet safety requirements.

DIY hydrogen generator

Factory-made models differ little from home-made counterparts and are more expensive. The total price of a finished generator ranges from 20 to 60 thousand rubles, so many craftsmen are trying to create hydrogen-powered heating devices on their own. But before starting work, it is necessary to weigh even the slightest doubts. If they are present, then it is better to refuse work. But if desires and opportunities give the green light, then the entire production process can be divided into the following steps:

drawing and search for materials. This step includes a thorough reading of all the nodes of the structure, the calculation of the required power and the general view of the generator;

the electrolyzer is a high quality stainless steel case;

electrolyzer plates

To create this important part, you will need a steel sheet, which must be cut into 18 equal strips. Next, you need to drill a hole for mounting and dividing plates on cathodes and anodes

It remains only to connect the current to the structure;

Gas Generator

- the burner should ideally be purchased, because it can be problematic to assemble this part without errors. In addition, in special stores, the choice of such elements is sufficient;

- the separator is connected to the structure to extract only the hydrogen component from the gas mixture;

- pipes are connected according to the area of the building.

In order for the system to work fully, it is necessary to have great knowledge and skills, otherwise you can build a dangerous structure. Also, self-made generators require an investment of material resources and a lot of time. The high risk of failure and the total waste of time leads to the fact that it is better to choose the purchase of a hydrogen heating system in the factory version.

How to make hydrogen heating at home?