- How to properly adjust the relay and calculate the pressure

- The number of standby units in pumping stations for different categories:

- The principle of operation of the ejector

- Reliability category, temperature, lighting, display of fire extinguishing pumping stations:

- Choosing a place to install

- How is the pumping station set up?

- Design features of the pumping unit

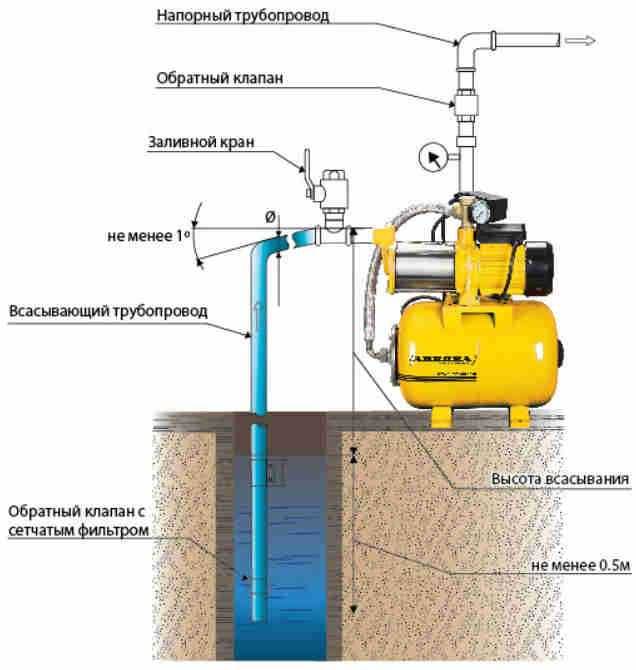

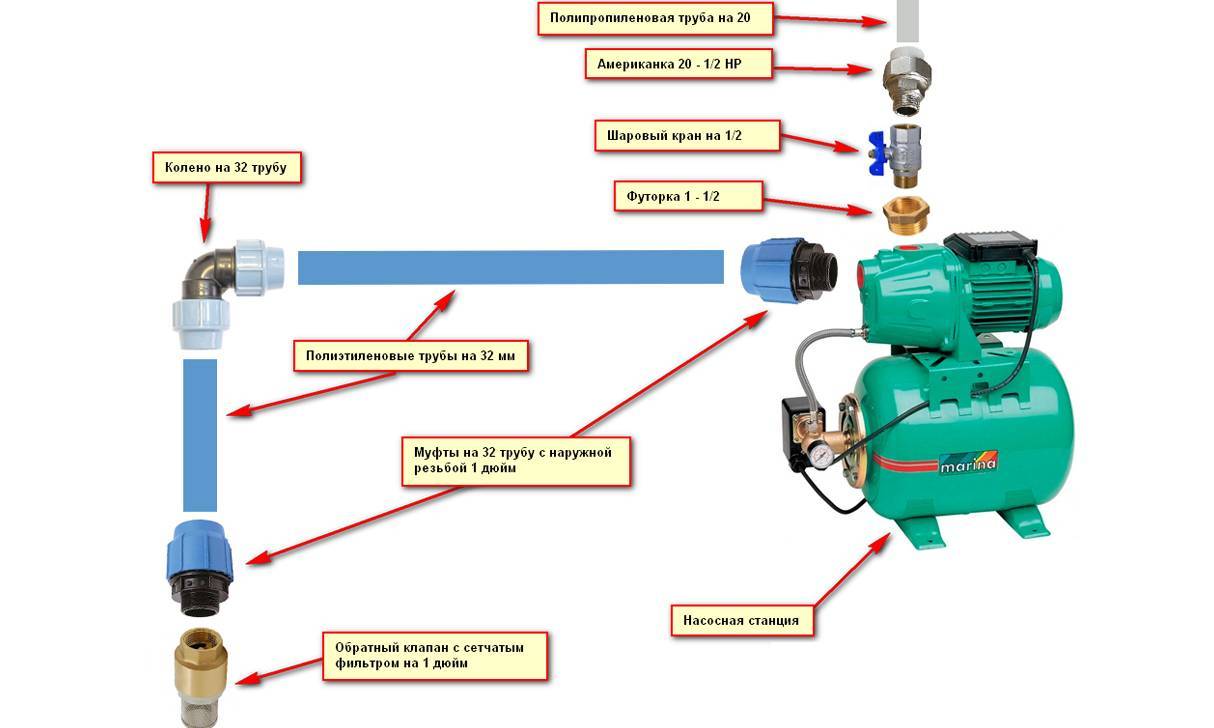

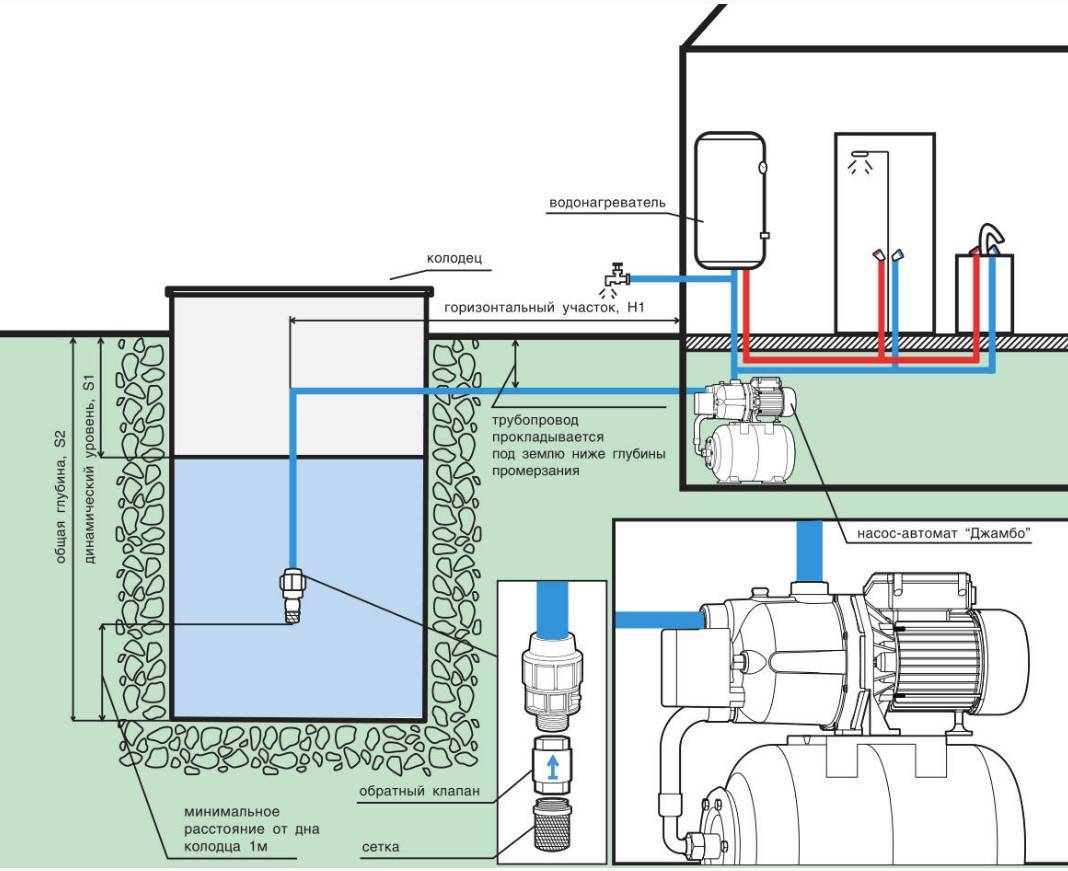

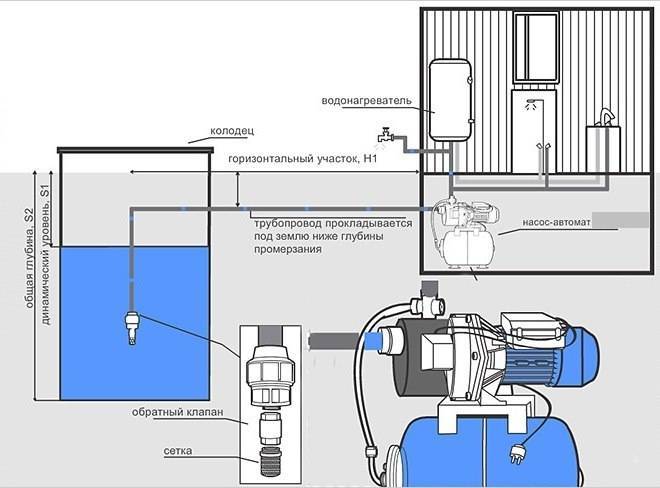

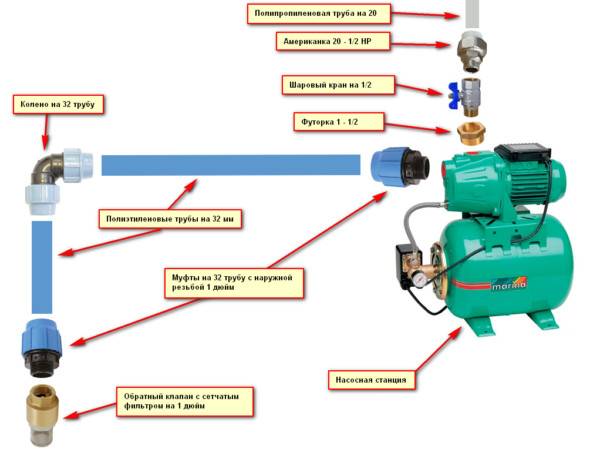

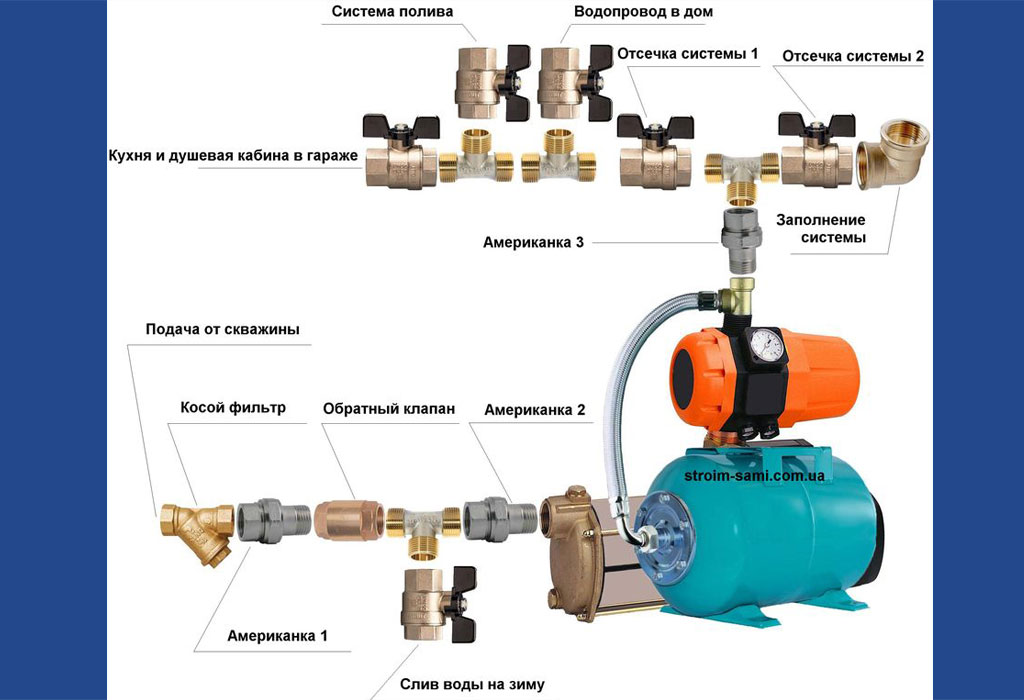

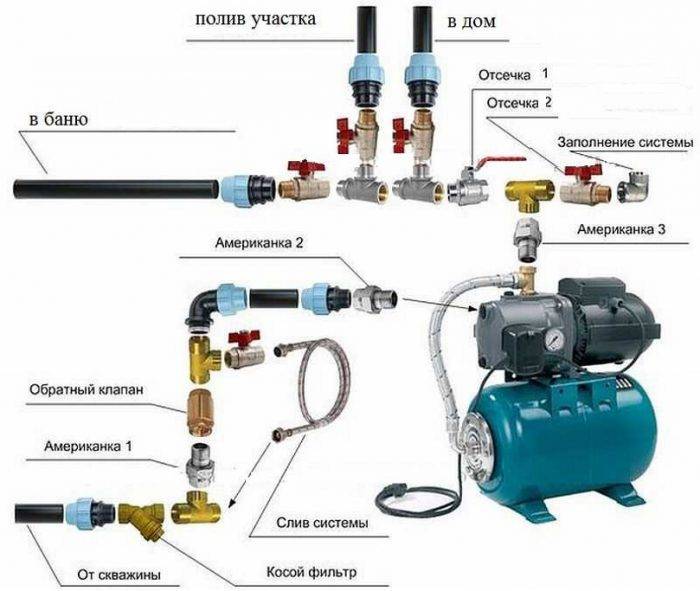

- Scheme of connecting a pumping station to a well in the country

- How to calculate the volume of a hydraulic accumulator?

- Water purification

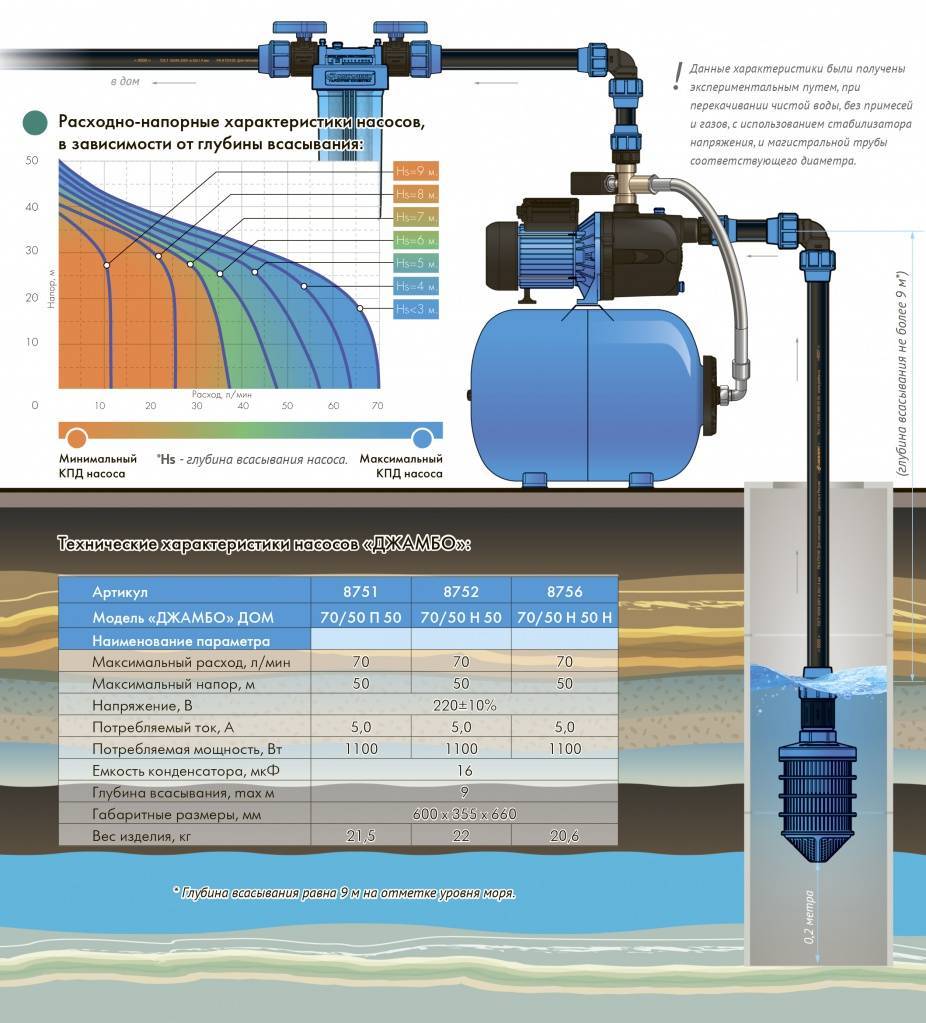

- Models

- Interaction of the pump with the accumulator

- Operation features

- Correction of errors in work

- Violation of the rules of operation

- Engine malfunctions

- Problems with water pressure in the system

How to properly adjust the relay and calculate the pressure

All devices leave the production line with certain settings, but after purchase, additional verification must be performed. When buying, you need to find out from the seller what values the manufacturer recommends using when adjusting the depth pressure. In other words, the pressure at which the contacts close and open.

If the station fails due to improper adjustment of the pressure switch of the jumbo pumping station, then it will not be possible to use the manufacturer's warranty.

When calculating the cut-in pressure values, the following parameters are taken into account:

- Required pressure at the highest draw-off point.

- Difference in height between the top draw point and the pump.

- Loss of water pressure in the pipeline.

The value of the switching pressure is equal to the sum of these indicators.

The calculation of the turn-off pressure to solve the question of how to set up the pressure switch is performed as follows: the turn-on pressure is calculated, one bar is added to the value obtained, then one and a half bar is subtracted from the amount. The result should not exceed the value of the maximum allowable pressure that occurs at the outlet of the pipe from the pump.

The number of standby units in pumping stations for different categories:

Number of working units of one group | The number of standby units in the pumping station for the category | ||

| I | II | III | |

| Until 6 | 2 | 1 | 1 |

| More than 6 | 2 | 1+1 in stock | — |

| 1 The number of working units includes fire pumps. 2 The number of working units of one group, except for fire engines, must be at least two. In pumping stations of category II and III, upon justification, it is allowed to install one working unit. 3 When installed in the same group of pumps with different characteristics, the number of standby units should be taken for pumps of higher capacity according to this table, and the standby pump of lower capacity should be stored in a warehouse. 4 In pumping stations of water pipelines of settlements with a population of up to 5 thousand people. with one power supply, a backup fire pump with an internal combustion engine and automatic start (from batteries) should be installed. |

The principle of operation of the ejector

The deeper the water is, the more difficult it is to raise it to the surface.In practice, if the depth of the well is more than seven meters, the surface pump can hardly cope with its tasks.

Of course, for very deep wells, it is more appropriate to purchase a high-performance submersible pump. But with the help of an ejector, it is possible to improve the performance of a surface pump to an acceptable level and at a much lower cost.

The ejector is a small device, but very effective. This knot has a relatively simple design, it can even be made independently from improvised materials. The principle of operation is based on giving the flow of water an additional acceleration, which will increase the amount of water coming from the source per unit of time.

This solution is especially convenient for those who are going to install or have already installed a pumping station with a surface pump. The ejector will increase the depth of water intake up to 20-40 meters.

It should also be noted that the purchase of more powerful pumping equipment will lead to a noticeable increase in electricity consumption. In this sense, the ejector will bring noticeable benefits.

The ejector for a surface pump consists of the following elements:

- suction chamber;

- mixing unit;

- diffuser;

- narrowed nozzle.

The operation of the device is based on the Bernoulli principle. It says that if the speed of the flow increases, an area with low pressure is created around it. In this way, a dilution effect is achieved. Water enters through a nozzle, the diameter of which is smaller than the dimensions of the rest of the structure.

This diagram allows you to get an idea of the device and the principle of operation of the ejector for a pumping station. The accelerated reverse flow creates an area of low pressure and transfers kinetic energy to the main water flow

A slight constriction gives a noticeable acceleration to the flow of water. Water enters the mixer chamber, creating an area with reduced pressure inside it. Under the influence of this process, a stream of water at a higher pressure enters the mixer through the suction chamber.

Water in the ejector does not come from a well, but from a pump. Those. the ejector must be installed in such a way that part of the water raised by the pump returns to the ejector through the nozzle. The kinetic energy of this accelerated flow will be constantly transferred to the mass of water that is sucked from the source.

To create a rarefied pressure area inside the ejector, a special fitting is used, the diameter of which is smaller than the parameters of the suction pipe.

Thus, a constant acceleration of the flow will be ensured. Pumping equipment will need less energy to transport water to the surface. As a result, its efficiency will increase, as will the depth from which water can be taken.

Part of the water extracted in this way is sent back to the ejector through the recirculation pipe, and the rest enters the house's plumbing system. The presence of an ejector has another "plus". It sucks water on its own, which additionally insures the pump from idle work, i.e. from the “dry running” situation, which is dangerous for all surface pumps.

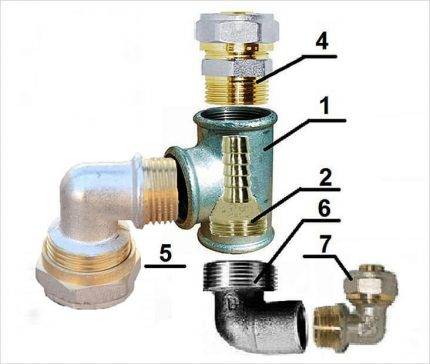

The diagram shows the device of an external ejector: 1- tee; 2 - fitting; 3 - adapter for a water pipe; 4, 5, 6 - corners

The diagram shows the device of an external ejector: 1- tee; 2 - fitting; 3 - adapter for a water pipe; 4, 5, 6 - corners

To regulate the operation of the ejector, use a conventional valve. It is installed on the recirculation pipe, through which water from the pump is directed to the ejector nozzle.Using a tap, the amount of water entering the ejector can be reduced or increased, thereby reducing or increasing the reverse flow rate.

Reliability category, temperature, lighting, display of fire extinguishing pumping stations:

According to the degree of availability of water supply, the fire extinguishing pumping station of the automatic fire extinguishing installation belongs to the 1st category, according to the reliability of the power supply they correspond to the 1st category according to the PUE. If, according to local conditions, it is impossible to supply the category I pumping units from two independent power supply sources, it is allowed to supply them from one source, provided that they are connected to different lines with a voltage of each 0.4 kV and to different transformers of a two-transformer substation or transformers of the two nearest single-transformer substations (with an automatic backup device). switch).

If it is impossible to ensure the necessary reliability of power supply to fire pumping units, it is allowed to install standby fire pumps driven by internal combustion engines. However, they are not allowed to be placed in the basement. The time to enter the operating mode of a fire pump driven by internal combustion engines should not exceed 10 minutes.

The air temperature in the room of the pumping station should be from 5 to 35°C, the relative humidity of the air should not exceed 80% at 25°C.

Working and emergency lighting is adopted in accordance with SNiP 23-05-95 - 75 lux and 10 lux, respectively.

At the entrance to the pumping station there is a light panel "Pumping station" connected to the main emergency lighting.

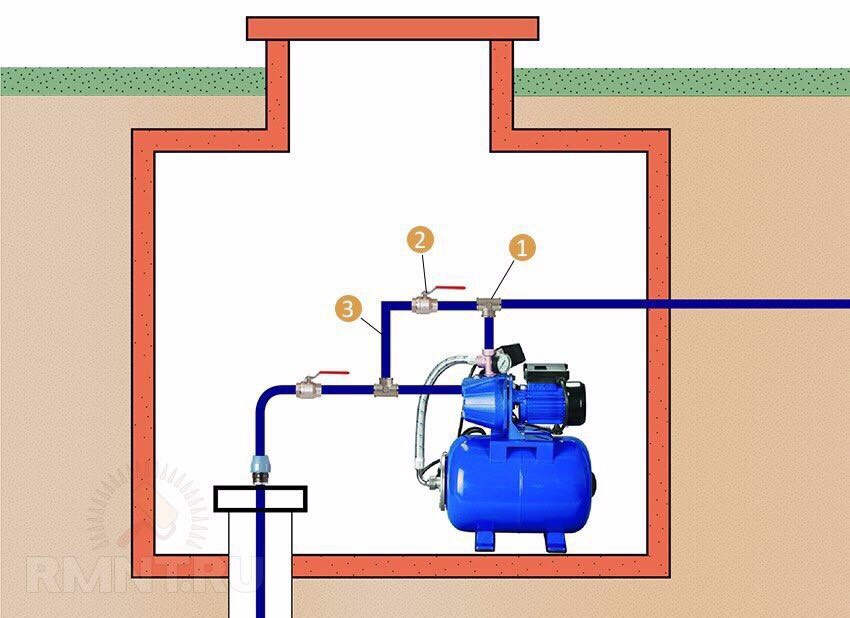

Choosing a place to install

It is not difficult to make a pumping unit for a private house or cottage with your own hands. However, at the same time, it is necessary to solve the question of how and where to install the pumping station correctly. The place for installing a pumping station, on the correct choice and arrangement of which the efficiency of the equipment will depend, must meet certain requirements.

- If drilling a well or arranging a well on a personal plot has already been completed, then the pumping station is mounted as close as possible to the source of water supply.

- In order to protect pumping equipment from water freezing during the cold season, the installation site must be characterized by comfortable temperature conditions.

- Since pumping units require regular maintenance, free access must be provided to their installation site.

Based on the above requirements, a caisson or a separate and specially equipped room is used as a place to install a pumping station in a country house or in a private house.

Ideally, a place for a pumping station should be provided at the stage of building a house, allocating a separate room for this

Sometimes they install pumping units in buildings that already exist on the territory of the infield. Each of these options has its pros and cons, which should be discussed in more detail.

Placing a pumping station in a separate room in a building with a well drilled under the house

The scheme for installing a pumping station in the basement of a house is an almost ideal option for locating such equipment.With this installation scheme, easy access to the equipment is provided, and the issue of reducing the noise level generated during the operation of the station is also easily solved. This option will be most successful if the pump room is heated.

Placing a pumping station in a warm equipped basement

If the pumping unit is located in an outbuilding, quick access to it is somewhat difficult. But with such a scheme for connecting a pumping station, the problem with noise from the operation of the equipment is radically solved.

The station can be installed on a bracket in a sufficiently wide and deep well

Installing the station in a caisson will provide frost protection and complete sound insulation

Quite often, pumping stations are mounted in a caisson - a special tank that is installed above the head of the well, directly into the pit. A caisson can be either a plastic or metal container buried in the ground below its freezing level, or a permanent underground structure, the walls and base of which are made of concrete or finished with brickwork. It should be borne in mind that when installing a pumping station in a caisson, access to equipment is rather limited. In addition, if a connection scheme of this type is used for a pumping station, then the pipeline section between the pumping equipment and the building it serves must be carefully insulated or placed in the ground at a depth below the freezing level.

How is the pumping station set up?

The level of comfort in a country house is largely determined by the presence of a professionally debugged water supply system, the main component of which is a pumping station.

The structure of the devices involved in the organization of water supply must be known in any case. It will come in handy if you lay the plumbing yourself or entrust the installation work to professionals.

Knowing the principle of operation of individual elements of the system, in the event of an accident or failure of one of the devices, you can independently, and most importantly, quickly repair the pumping station or replace it.

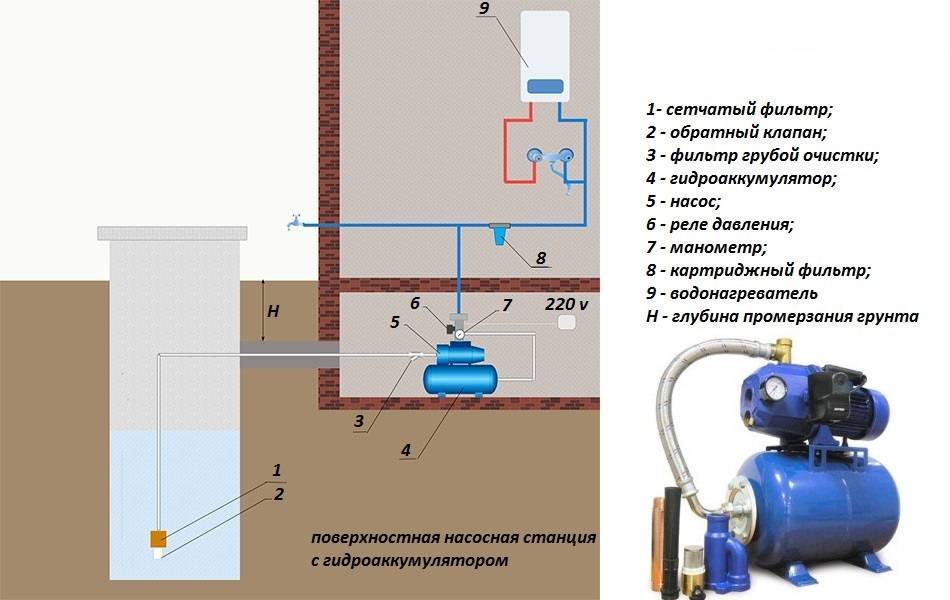

So, the most important components of the water supply scheme using a pumping station are the following:

- device for water intake with a filter;

- non-return valve that prevents the movement of water in the opposite direction;

- suction line - a pipe leading to the pump;

- pressure switch for adjusting the water supply;

- pressure gauge showing the exact parameters;

- hydraulic accumulator - automatic storage;

- electric motor.

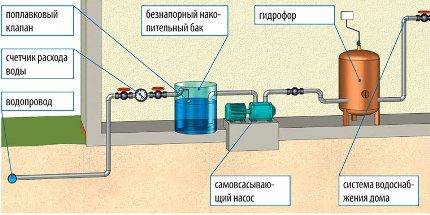

Instead of a hydraulic accumulator, a more modern and practical device, a storage tank is sometimes used, which has several disadvantages (weak pressure, inconvenient installation, etc.).

The diagram shows one of the ways to install a non-pressure storage tank and a hydrophore that can regulate the pressure and water level in the system

However, now that many modern inexpensive models with a hydraulic accumulator have appeared in stores, there is no point in self-assembly of a system with a storage tank.

If you still decide to purchase a container for collecting water, try to consider the following nuances:

- The reserve tank is installed in the highest possible area (for example, in the attic) in order to create the necessary pressure.

- The volume of the tank should be such that there is a reserve for 2-3 days in case of failure of the pumping equipment (but not more than 250 liters, otherwise sediment may accumulate).

- The base for mounting the tank must be reinforced with beams, slabs, additional ceilings.

The reserve storage tank, as well as membrane equipment (hydraulic accumulator), should be equipped with a filter. In addition, it is mandatory to install a safety pipe to drain excess water. The hose connected to the branch pipe is led out into the drainage system or lowered into containers designed to store irrigation water.

Standard diagram of a pumping station with the designation of the main elements: check valve, pressure switch, pressure gauge, pressure pipeline; red arrow points to accumulator

The principle of operation of the pumping station is cyclical. As soon as the supply of water in the system decreases, the pump turns on and begins to pump water, filling the system.

When the pressure reaches the required level, the pressure switch is activated and turns off the pump. The relay settings must be set before starting the equipment operation - they depend on the volume of the tank and the characteristics of the pump.

Design features of the pumping unit

A pumping unit (station) is a whole complex of technical devices, each of which plays a role in ensuring the efficient operation of the entire system as a whole. A typical structural diagram of a pumping unit includes a number of elements.

The main parts of the pumping station

Pump

In this capacity, as a rule, surface devices of a self-priming or centrifugal type are used. They are installed together with the rest of the equipment that is part of the station on the surface of the earth, and a suction hose is lowered into the well or well, through which the liquid medium is pumped out from the underground source.

Mechanical filter

The filter is installed on the end of the hose lowered into the pumped liquid medium. The task of such a device is to prevent solid inclusions contained in the composition of water pumped out from an underground source from entering the inside of the pump.

Screen filters for wells

check valve

This element prevents the water pumped out of the well or well from moving in the opposite direction.

Hydraulic accumulator (hydraulic tank)

The hydraulic tank is a metal container, the inner part of which is divided by an elastic partition made of rubber - a membrane. Air is contained in one part of such a tank, and water is pumped into the other, raised by a pump from an underground source. The water entering the accumulator stretches the membrane, and when the pump is turned off, it begins to shrink, acting on the liquid in the other half of the tank and pushing it through the pressure pipe into the pipeline under a certain pressure.

The device of the hydraulic accumulator of the pumping station

Working according to the principle described above, the hydraulic accumulator of the pumping station provides a constant pressure of the fluid flow in the pipeline. In addition, the pumping station, the installation of which does not take much effort and money, eliminates the occurrence of hydraulic shocks that are dangerous for the water supply system.

Automation block

It controls the operation of the pumping unit. The main element of the pumping automation unit is a relay that reacts to the level of water pressure, which is filled with a hydraulic accumulator tank.In the event that the water pressure in the accumulator drops to a critical level, the relay automatically turns on the electric pump, and water begins to flow into the tank, stretching the membrane. When the pressure of the liquid medium rises to the required level, the pump turns off.

Automation units allow you to automate the operation of the electric pump

Pumping units are also equipped with pressure gauges and pipes, which are used to tie and connect to the main circuit of the water supply system.

It should be borne in mind that a typical pumping unit, which is made on the basis of a surface pump, can be used to pump water from wells and wells, the depth of which does not exceed 10 meters. In order to raise water from deeper underground sources, you can additionally equip the pumping unit with an ejector or assemble a pumping station with a submersible pump, but such a design scheme is used quite rarely.

Installation diagram of a pump with a remote ejector

The modern market offers many pumping stations of various models and brands, the prices of which vary quite a lot. Meanwhile, you can save on the purchase of serial equipment if you buy the necessary components and assemble the pumping station with your own hands.

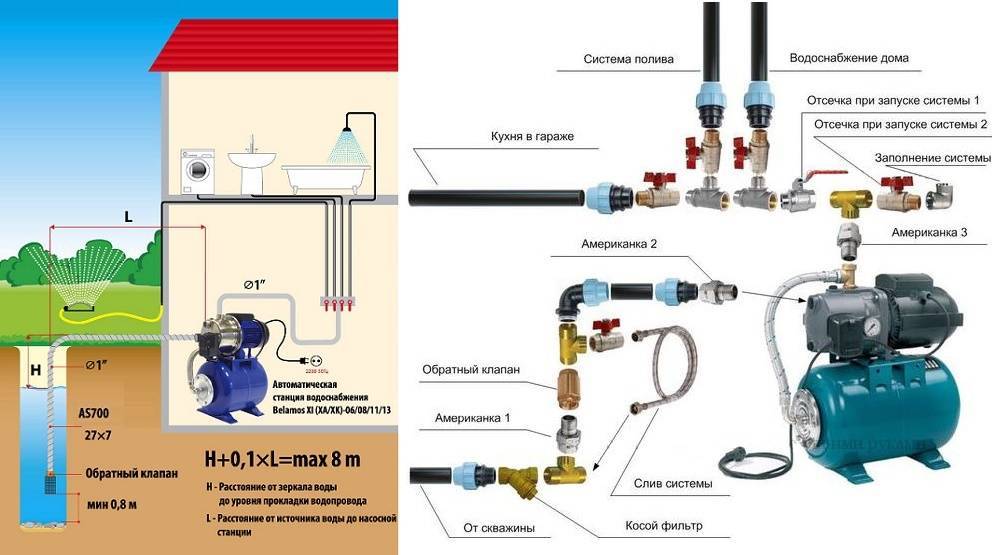

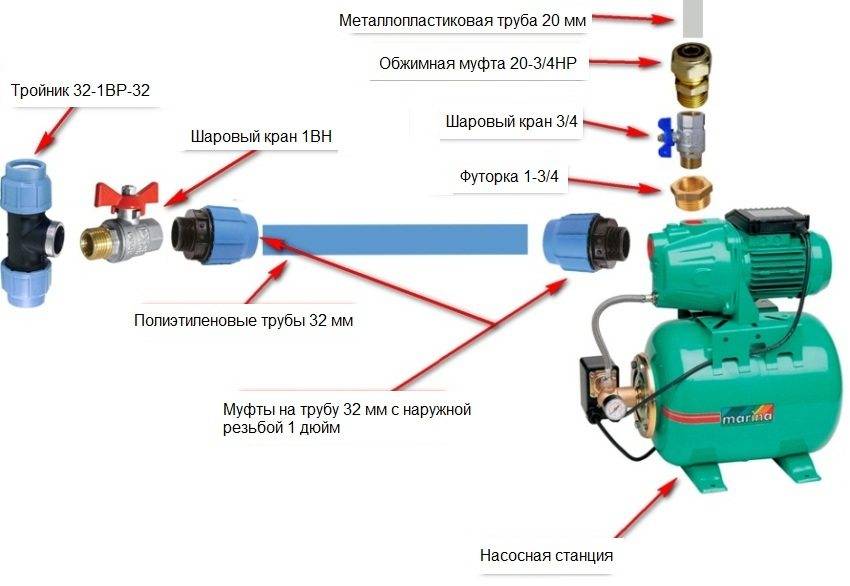

Scheme of connecting a pumping station to a well in the country

The pumping station can be placed inside the well, if there is a place for this, in addition, utility rooms are often allocated for it in the house itself or in the room

Pay attention to the depth at which the pipeline will be.The pipe must not only be insulated, but also placed below the freezing depth of the soil, so that during the cold season the water in it does not freeze

In order for the system to work correctly, you need to choose not only the type of pump, but also the depth at which it will work. The deeper the water source and the farther it is from the building, the more powerful the pump itself must be. There should be a filter at the end of the pipe, it is located between the pipe and the pump, protecting the latter from debris entering the mechanism.

Devices usually write at what depth they are designed, but it is worth taking a more powerful one, since the calculation is carried out only from the bottom of the well to its surface, not taking into account the distance to the building. It is easy to calculate: 1 meter of the vertical location of the pipe is 10 meters of its horizontal location, since it is easier to supply water in this plane.

Depending on the type and power of the pump, the pressure may be stronger or weaker. It can also be calculated. On average, the pump provides 1.5 atmospheres, but this is not enough pressure for the normal operation of the same washing machine or hydromassage, the water heater may require a higher temperature.

In order to control the pressure, the equipment is equipped with a barometer. Depending on the pressure parameter, the size of the storage tank is also calculated. Station performance also plays an important role. This parameter indicates how many cubic meters per minute the pump is capable of delivering. You need to calculate based on peak water consumption, that is, when all the taps in the house are open or several consumer electrical appliances are working. In order to calculate which pumping station is suitable for giving in a well, you need to know the performance.To do this, add up the number of water supply points.

From the point of view of power supply, it is more convenient to use those systems that are powered by a 22-volt network. Some stations operate 380 V phases, but such motors are not always convenient, because a three-phase connection is not available in every home. The power of a household station may vary, on average it is 500-2000 watts. Based on this parameter, RCDs and other devices are selected that will work in conjunction with the station. In order to prevent the design from overheating, many manufacturers install automation that will turn off the pumps in the event of an emergency load. The protection also works if there is no water in the source when power surges occur.

How to calculate the volume of a hydraulic accumulator?

The size of the tank determines how often the pump motor will turn on. The larger it is, the less often the installation works, which allows you to save on electricity, increase the resource of the system. Too large a hydraulic accumulator takes up a lot of space, so a medium-sized one is usually used. It holds 24 liters. This is enough for a small house in which a family of three lives.

Trailer work accumulator expansion tank

If up to 5 people live in the house, then it is better to install the tank at 50 liters, respectively, if more than 6, it should be at least 100 liters. It is worth noting that the standard tanks of many stations hold 2 liters, such a hydraulic tank can only cope with water hammer and maintain the required pressure, it is better not to save money and immediately replace it with a large one. It is the number of water users in the house that will determine which pumping station to choose for a summer residence.

Water purification

Do not forget that the water from the well, even if it is suitable for drinking, may have impurities, for example, sand, small stones, various debris can get into it, which can be disposed of using a special system for water purification. The most commonly used filters. They are placed outside so that it is convenient to change them. They can have different fractions and purify water to varying degrees. At the outlet, deep fine filters are used.

Models

- Gilex.

- Vortex.

- Ergus.

- Bison.

- gardena.

- Wilo SE.

- Karcher.

- Pedrollo.

- grundfos.

- Wilo.

- Poplar.

- Unipump.

- Aquario.

- Aquarius.

- Biral.

- S.F.A.

- Vortex.

- waterstry.

- Zota.

- Belamos.

- Pedrollo.

Before choosing a pumping station for a summer residence with a well, it will not be superfluous to find out how things are with the maintenance of the products of the selected manufacturer, are there any nearest dealers who can provide spare parts.

Interaction of the pump with the accumulator

The capacity of the membrane tank is selected taking into account the volume of water consumption. For a couple, a 25–40 liter option is quite enough, and for a family of several people, you will have to select a device from 100 liters.

Tanks less than 15 liters and it is generally recommended to buy only for seasonal use in the country. Due to the constant pumping of water, the membrane in them wears out quickly.

In the initial state, air is pumped into the hydraulic tank through a nipple (air valve), creating a pressure of 1.5 atm. During operation, water is pumped into the membrane under pressure, compressing the air “reserve”. When the faucet is open, the compressed air pushes the water out.

According to the rules, the hydraulic tank is selected on the basis of calculations, based on the values \u200b\u200bof the on and off pressure specified by the manufacturer, the actual water flow when the water intake points are turned on at the same time.

The fluid reserve in a hydraulic tank is usually about a third of the total volume of the tank. All the remaining space is given over to compressed air, which is needed to maintain a constant pressure of water in the pipes.

If a hydraulic accumulator is built into the water supply system to minimize the risks associated with hydraulic shocks, then the tank can be selected in a small size. In this case, it is not the volume of the container that is important, but the presence of a membrane and air behind it. It is they who, in which case, will take the blow, smoothing out its consequences.

The performance of the pump should correspond to the volume of the membrane tank (for a capacity of 20–25 liters, it is recommended to take a hydraulic pump for 1.5 m3 / h, for 50 liters - 2.5 m3 / h, and for a tank of 100 liters - at least 5 m3 / h).

The automatic pumping station operates in two cycles:

- First, water is pumped into the accumulator from the water intake, creating excess air pressure in it.

- When the tap is opened in the house, the membrane tank is emptied, after which the automation restarts the pumping equipment.

The device of a hydraulic accumulator for a water supply pumping station is extremely simple. It consists of a metal case and a sealed membrane that divides the entire space inside into two parts. In the first of them there is air, and in the second water is pumped.

The pump pumps liquid into the membrane tank only when the pressure in the system drops to values in the region of 1.5 atm, when the predetermined maximum high pressure value is reached, the station turns off (+)

After filling the accumulator, the relay turns off the pump. Opening the faucet in the washbasin leads to the fact that the water squeezed out by air pressure on the membrane begins to gradually flow into the water supply system. At some point, the tank is emptied to such an extent that the pressure weakens. After that, the pump is turned on again, starting the cycle of operation of the pumping station according to a new one.

When the tank is empty, the membrane partition is crushed and pressed against the flange of the inlet pipe. After turning on the hydraulic pump, the membrane is expanded by water pressure, compressing the air part and increasing the air pressure in it. It is this interaction of gas-liquid through a changing barrier that underlies the principle of operation of the membrane tank of a pumping station.

Operation features

The operation of pumping equipment should be carried out in accordance with the instructions. Subject to all the rules, the equipment will last a long time, and the number of breakdowns will be minimal. The main thing is to eliminate any malfunctions in time.

From time to time, the pumping station should be serviced

Station operation features:

- Once every 30 days or after a break in work, the pressure in the accumulator should be checked.

- The filter will need to be cleaned. If this rule is not followed, water will begin to flow jerkily, pump performance will decrease significantly, and a dirty filter will lead to dry operation of the system, which will cause breakdowns.The frequency of cleaning depends on the amount of impurities in the water that comes from the well or well.

- The installation site of the station should be dry and warm.

- The system piping must be protected from freezing during the cold season. To do this, during installation, observe the desired depth. You can also insulate the pipeline or use an electrical cable that is mounted in trenches.

- If the station is not operated in winter, then the water from the pipes should be drained.

In the presence of automation, the operation of the station will not be difficult. The main thing is to change the filters in time and monitor the pressure in the system. Other nuances are taken into account at the installation stage.

It doesn’t matter if the Gilex pumping station or any other, the instructions to start the system will be unchanged. The hydrophore has no difficulty when starting, the receiver is used to adjust the pressure

It is important to know how to operate the water station in winter and whether it is necessary to distill the liquid during work breaks.

Correction of errors in work

Before embarking on a more serious intervention in the operation of the equipment, it is necessary to take the simplest measures - clean the filters, eliminate leaks. If they do not produce results, then proceed to further steps, trying to identify the root cause.

The next thing to do is to adjust the pressure in the accumulator tank and adjust the pressure switch.

The following are the most common malfunctions in the domestic pumping station, which the user can try to solve on his own. For more serious problems, contact the service center.

Violation of the rules of operation

If the station runs continuously without shutting down, the likely cause is incorrect relay adjustment - a high shutdown pressure is set. It also happens that the engine is running, but the station does not pump water.

The reason may lie in the following:

- When first started, the pump was not filled with water. It is necessary to correct the situation by pouring water through a special funnel.

- The integrity of the pipeline is broken or an air lock has formed in the pipe or in the suction valve. To find a specific cause, it is necessary to make sure that: the foot valve and all connections are tight, there are no bends, narrowings, hydraulic locks along the entire length of the suction pipe. All malfunctions are eliminated, if necessary, replace damaged areas.

- The equipment works without access to water (dry). It is necessary to check why it is not there or to identify and eliminate other causes.

- The pipeline is clogged - it is necessary to clear the system of contaminants.

It happens that the station very often works and turns off. Most likely this is due to a damaged membrane (then it is necessary to replace it), or the system does not have the pressure required for operation. In the latter case, it is necessary to measure the presence of air, check the tank for cracks and damage.

Before each start, it is necessary to pour water into the pumping station through a special funnel. She must not work without water. If there is a possibility of the pump running without water, you should purchase automatic pumps equipped with a flow controller

Less likely, but it can happen that the check valve is open and blocked due to debris or a foreign object.In such a situation, it will be necessary to disassemble the pipeline in the area of \u200b\u200bpossible blockage and eliminate the problem.

Engine malfunctions

The household station engine does not run and does not make noise, possibly for the following reasons:

- The equipment is disconnected from the power supply or there is no mains voltage. You need to check the wiring diagram.

- The fuse has blown. In this case, you need to replace the element.

- If you cannot turn the fan impeller, then it is jammed. You need to find out why.

- Relay damaged. You need to try to adjust it or, if it fails, replace it with a new one.

Engine malfunctions most often force the user to use the services of a service center.

Problems with water pressure in the system

Insufficient water pressure in the system can be explained by several reasons:

- The pressure of water or air in the system is set to an unacceptably low value. Then you need to configure the relay operation in accordance with the recommended parameters.

- Piping or pump impeller blocked. Cleaning the elements of the pumping station from contamination may help solve the problem.

- Air enters the pipeline. Checking the elements of the pipeline and their connections for tightness will be able to confirm or refute this version.

Poor water supply can also be caused by air being drawn in due to leaky water pipe connections or the water level has dropped so much that air is being pumped into the system when it is taken.

Poor water pressure can create significant discomfort when using the plumbing system