- When is the best time to drill a well in sand?

- You will be interested in:

- Drilling in winter conditions

- The difference between a well and a well

- What are wells?

- sand well

- Artesian well

- Abyssinian well

- Advantages and disadvantages

- Manual well drilling

- rotary method

- screw method

- Types of water intake workings and soils

- What criteria influence the choice of location for the well

- Seasonality and features

- Where to order water well drilling

- What type of water wells are

When is the best time to drill a well in sand?

The above cannot be attributed to a sand well, which is very close to wells. It is optimal to drill it in the summer, when there is a drought. You will immediately understand that if there is no water in the sands, it means that in any drought you will not have water. There will be no sense from such a well and it is optimal to continue drilling into limestone. Consider this in order not to get a dry well. Drilling a sandy well in the spring is definitely not worth it, at this time there is plenty of water everywhere and it will also be in the sands. But with the advent of summer, the situation can change dramatically. This is exactly what the majority does, and after 1-2 years, they start paying for the 2nd time, already for an artesian well.

You will be interested in:

Well drilling in winter

Choosing a drilling company

Sand well for water

Silting a well what to do

Choosing a location for a well

Well or central water supply

Drilling in winter conditions

Drilling wells in the cold season has many advantages and is always positively evaluated by professionals.

Drilling wells in the cold season has many advantages and is always positively evaluated by professionals.

A significant level of soil freezing during severe cold weather makes work difficult. But if it’s not worth the bitter cold, you can choose this option.

- It is easier to transport equipment and goods without damaging the surface layer of the soil.

- Due to the cold, the well shaft almost does not crumble, and its column is not clogged with mud, which helps to reduce the cleaning time.

- Errors in the calculation of the water horizon are minimal - a frozen top water does not interfere with determining the level of underground water and the installation point of the casing filter element.

If you decide to break through the water intake in the winter, by the spring you will have a ready-made well, which will significantly reduce the time for plumbing at a summer cottage or personal plot.

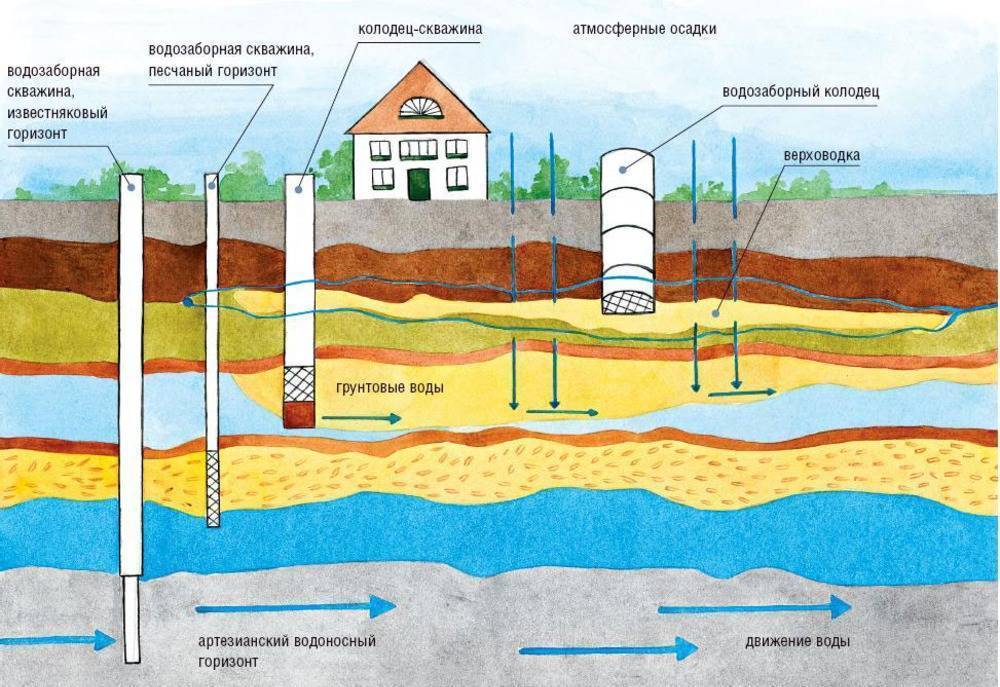

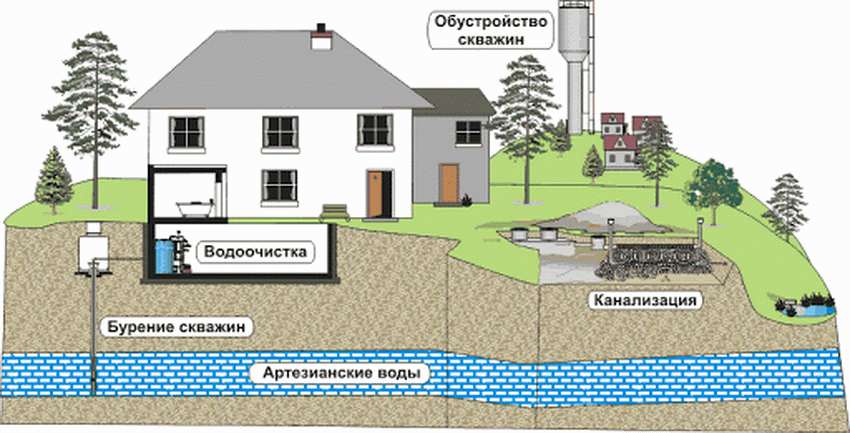

The difference between a well and a well

The shallow ones are sometimes called Abyssinian wells, but this definition is incorrect.

are different hydraulic structures

. Well - this is an open depression made in the rock by the digging method, protected from the collapse of the walls by concrete rings or brickwork.

Well device

Well device

The wells have a wide, from 70 cm to two meters in diameter and a small, from five to fifteen meters deep, they often use a hand drum or, at best, an electric pump to supply water from them.

Water in wells, especially shallow ones, is not of high quality and is suitable mainly for irrigation.

Well, in difference from a well, is not excavated, but is drilled with a special drilling device of small diameter, approximately 40-100 mm, to the first or second aquifer. Also, while the water in the well comes through the mine itself

Also, while the water in the well comes through the mine itself

, in the well, a casing pipe or otherwise a column is used to feed it up and at the same time protect the walls from destruction

- a plastic or steel pipe with a filter tip in its lower part.

The use of a casing pipe, as well as a cap that closes the wellhead, prevents water contamination with perched water and foreign biological materials from entering the well, and the quality of well water itself is usually higher than well water.

To lift water from a well, they are mainly used submersible type.

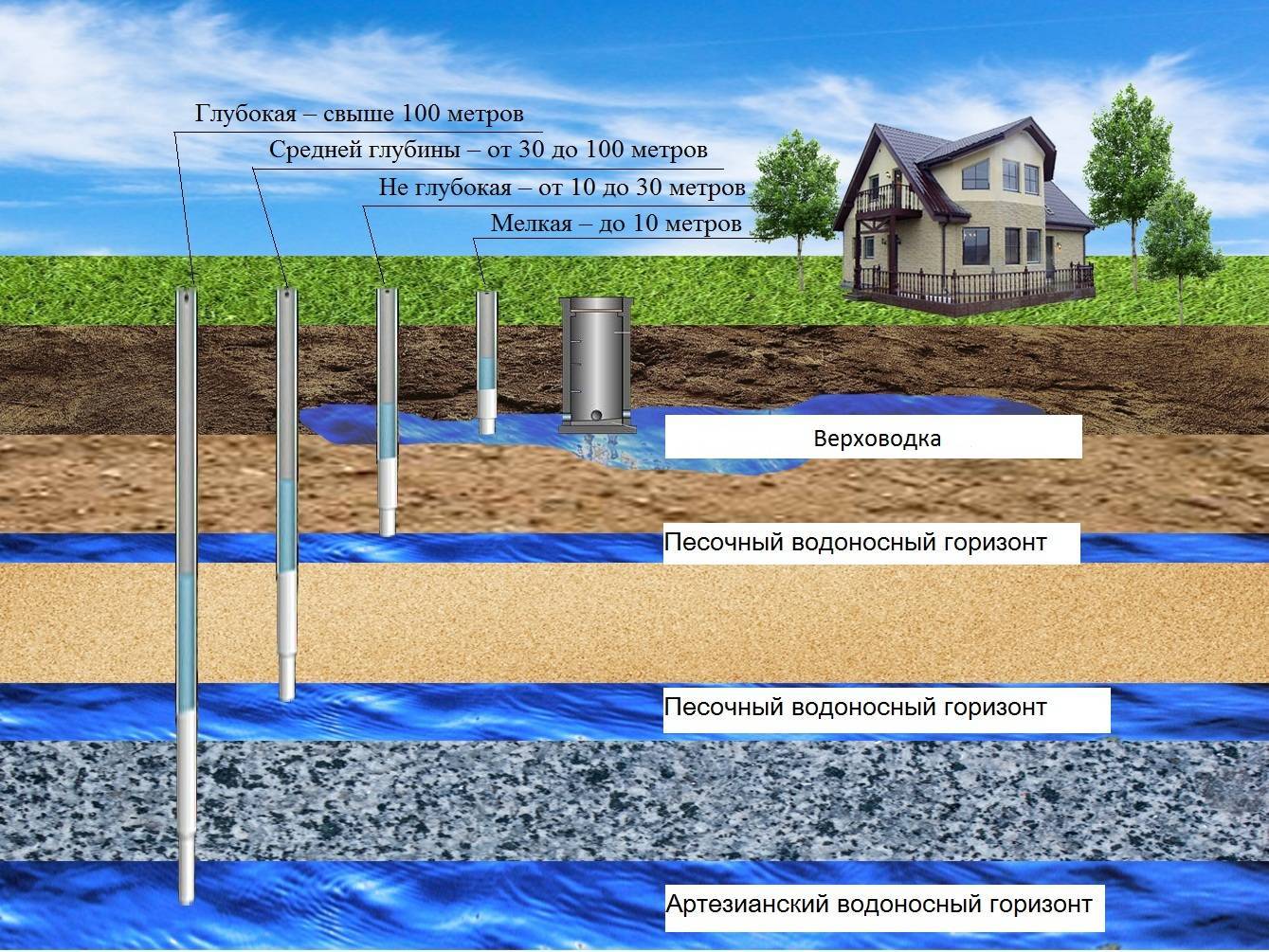

What are wells?

There are only two options here:

- sand;

- artesian.

And the water from them is completely different.

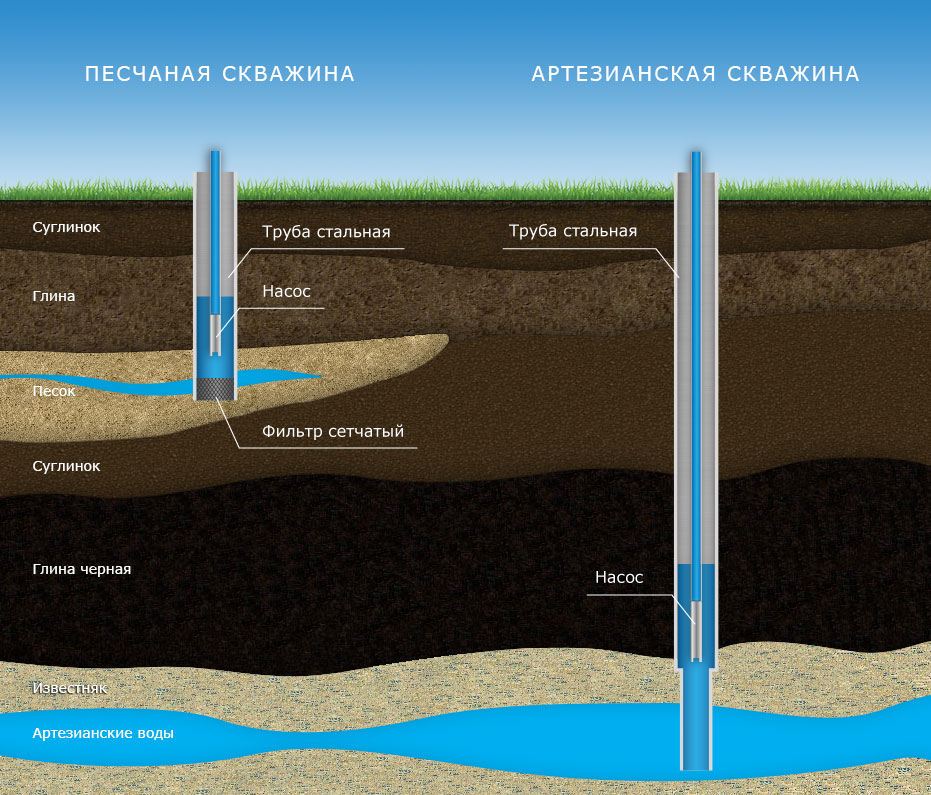

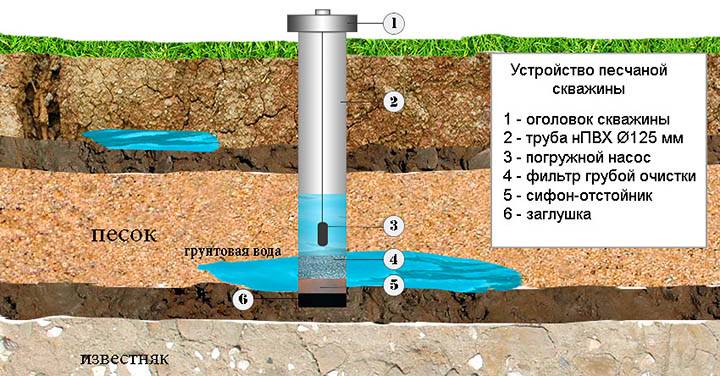

sand well

This is the option when you need to solve the issue of water supply at home quickly and inexpensively. The sand well has a relatively shallow depth (in the Moscow region - up to 30 meters). However, apart from the price, it actually has no advantages, and there are more than enough disadvantages:

- Low debit. You open all the taps - the pump starts to sip air. This is not good, even if it is self-priming. Plus seasonal fluctuations. It hasn't rained for a long time, and you need intensive watering? Just at this time, the water level will drop below the bottom (bottom) of the well (that is, it will leave the pump area);

- Filtration difficulties. Such water requires multi-stage purification from sand, clay, salts of natural and technogenic origin;

- Microorganisms. Water from such depths may contain waste products from the surface of the earth, including pathogenic microbes.The definition of "environmentally friendly" does not apply to it;

- Silting. Grains of sand and various particles are carried into the well, gradually filling it and "blocking" the water. To restore the flow rate, it is necessary to regularly flush. But in the end, after 5 - 10 years, you still have to call the drillers.

Thus, sand wells, as a rule, are not suitable for fully providing the house with high-quality water. They are suitable for technical needs or as a temporary solution with all the caveats.

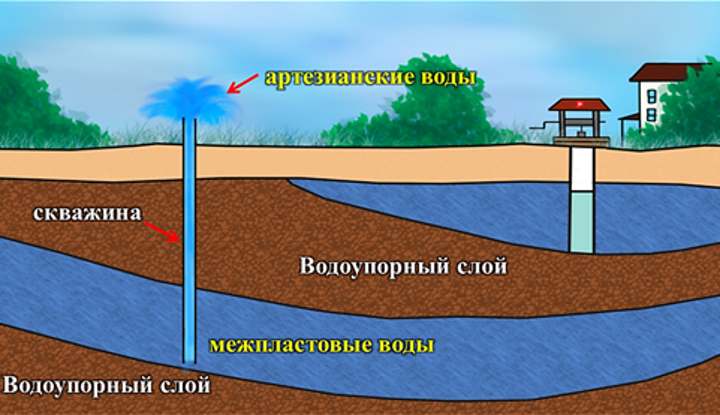

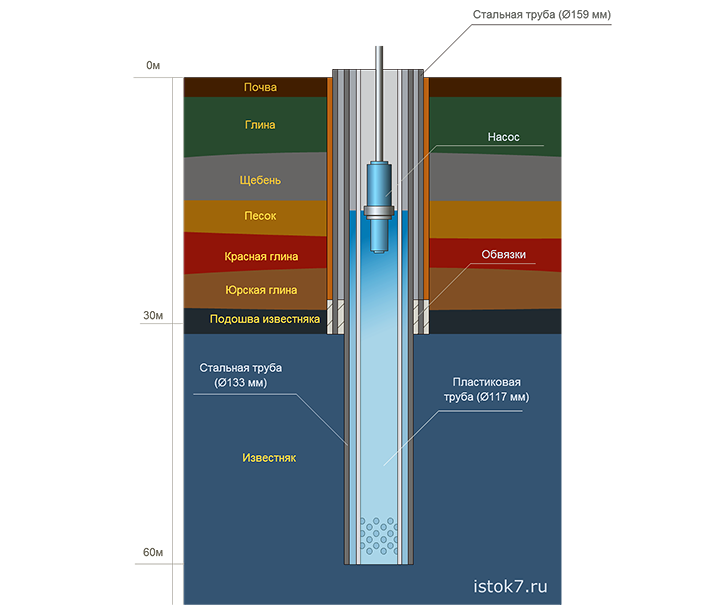

Artesian well

An artesian well (in the same suburbs) is much deeper than a sandy well and is drilled into aquiferous limestone. Due to long-term filtration through a multi-meter layer of water-resistant rocks, it does not contain substances of technogenic origin.

The advantages of artesian wells are stable productivity, high flow rate and service life for decades. This water can be safely used for drinking and cooking.

True, good natural filtration does not mean that artesian water does not need to be treated. It also contains dissolved salts. But filtering artesian water is much easier and cheaper than "sandy".

Abyssinian well

Abyssinian well for water.

The tubular well got its name from the territory in Africa, where the technology of extracting groundwater from the bowels of the earth was first used without the use of special equipment.

Self-drilling of wells is performed in this old way. Water intake is carried out from a depth of 8-13 m.

Sequence of work:

- A drill string is assembled from 1-2 m pieces of pipes Ø2 ″, it will also serve as a casing.The drill filter is made by flattening the downhole end of the first pipe or a nozzle on the cone rod for better penetration into the ground. Holes of 6-8 mm are drilled in the walls of the drill, so that water enters them, they are wrapped with a metal filter mesh.

- A shock headstock is made from a guide pipe Ø100 mm 1 m long, weighted with metal weighing 10 kg, handles are welded on both sides.

- The drill filter is driven entirely into the ground, after which the next section of the column is attached to it by welding or threaded connection. Having hammered the pipe after the drill, the operation is repeated until the filter penetrates into the aquifer.

- A manual or electric vacuum pump is connected.

Pumping of a tubular well is carried out until clean water appears. The quality of the liquid is checked in the laboratory of the sanitary and epidemiological station.

Advantages and disadvantages

The advantage of the Abyssinian water intake is the ability to build it yourself with minimal investment. The well-needle is completely isolated from the perched inflow. A tubular well can be hammered into the ground from the basement of your house.

There are few disadvantages:

- the impossibility of using a submersible pump due to the small diameter of the column;

- the need to clean the well from sand and silt;

- restrictions on soil properties: the method is used on soft rocks and coarse sands.

The service life of the water intake is ≥30 years. A prerequisite for longevity is the periodic extraction of silt and sand from the casing string. This is done with the help of a bailer - a cylindrical vessel with a valve lock.

Manual well drilling

Most often, summer residents are interested in how to drill a well with their own hands, and not just a well.You will need such equipment for drilling wells as a drill, a drilling rig, a winch, rods and casing pipes. The drilling tower is needed for digging a deep well, with its help, the drill with rods is immersed and lifted.

rotary method

The simplest method of arranging a well for water is rotary, carried out by rotating the drill.

Hydro-drilling of shallow wells for water can be carried out without a tower, and the drill string can be removed manually. Drill rods are made from pipes, connecting them together with dowels or threads.

The bar, which will be below all, is additionally equipped with a drill. The cutting nozzles are made of sheet 3 mm steel. When sharpening the cutting edges of the nozzle, it must be taken into account that at the moment of rotation of the drill mechanism, they must cut into the soil in a clockwise direction.

The tower is mounted above the drilling site, it must be higher than the drill rod in order to facilitate the extraction of the rod during lifting. After that, a guide hole is dug for the drill, about two spade bayonets deep.

The first turns of rotation of the drill can be done independently, but with a greater immersion of the pipe, additional forces will be required. If the drill cannot be pulled out the first time, you need to turn it counterclockwise and try to pull it out again.

The deeper the drill goes, the more difficult the movement of the pipes. To facilitate this task, the soil must be softened by watering. When moving the drill down every 50 cm, the drilling structure must be taken out to the surface and cleaned from the soil. The drilling cycle is repeated anew.At the moment the tool handle reaches the ground level, the structure is increased with an additional knee.

As the drill goes deeper, the rotation of the pipe becomes more difficult. Softening the soil with water will help facilitate the work. In the course of moving the drill down every half meter, the drilling structure should be brought to the surface and freed from the soil. The drilling cycle is repeated again. At the stage when the tool handle is level with the ground, the structure is extended with an additional knee.

Since lifting and cleaning the drill takes most of the time, you need to make the most of the design, capturing and lifting up as much of the soil as possible. This is the principle of operation of this installation.

Drilling continues until an aquifer is reached, which is easily determined by the condition of the excavated land. Having passed the aquifer, the drill should be immersed a little deeper until it reaches a layer that is located below the aquifer, waterproof. Reaching this layer will make it possible to ensure the maximum inflow of water into the well.

It is worth noting that manual drilling can only be used to dive to the nearest aquifer, usually it lies at a depth not exceeding 10-20 meters.

In order to pump out dirty liquid, you can use a hand pump or a submersible pump. After two or three buckets of dirty water are pumped out, the aquifer is usually cleared and clean water appears. If this does not happen, the well needs to be deepened by about another 1-2 meters.

screw method

For drilling, an auger rig is often used.The working part of this installation is very much like a garden drill, only much more powerful. It is made from a 100 mm pipe with a pair of screw turns welded onto it having a diameter of 200 mm. In order to make one such turn, you need a round sheet blank with a hole cut in its center, the diameter of which is slightly more than 100 mm.

Then, a cut is made at the workpiece along the radius, after which, at the place of the cut, the edges are parted in two different directions, which are perpendicular to the plane of the workpiece. As the drill sinks deep, the rod on which it is attached increases. The tool is rotated by hand with a long handle made of pipe.

The drill must be removed approximately every 50-70 cm, and due to the fact that the more it goes deep, it will become heavier, so you will need to install a tripod with a winch. Thus, it is possible to drill a well for water in a private house a little deeper than the above methods.

You can also use the manual drilling method, which is based on the use of a conventional drill and a hydraulic pump:

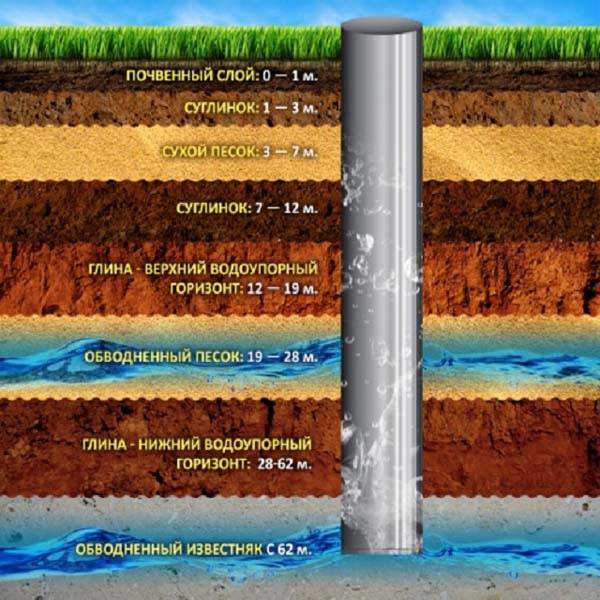

Types of water intake workings and soils

Before starting drilling, you should study the composition of the soil at the site in order to at least roughly imagine your future well.

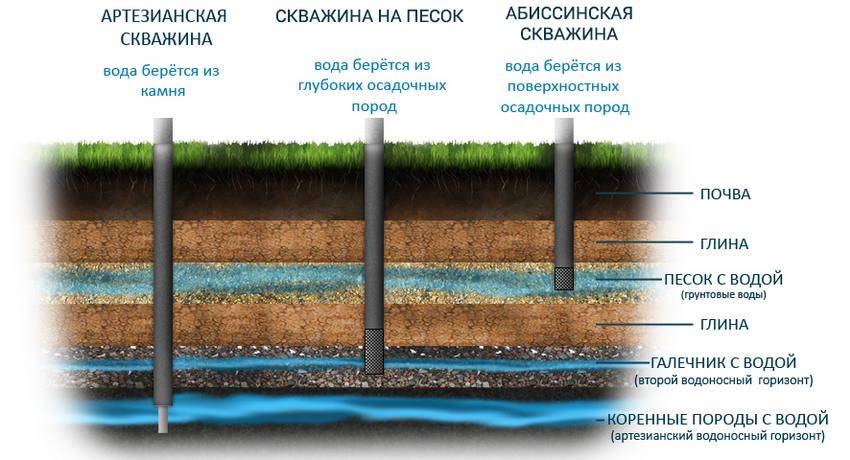

Depending on the characteristics of the aquifer, there are three types of wells:

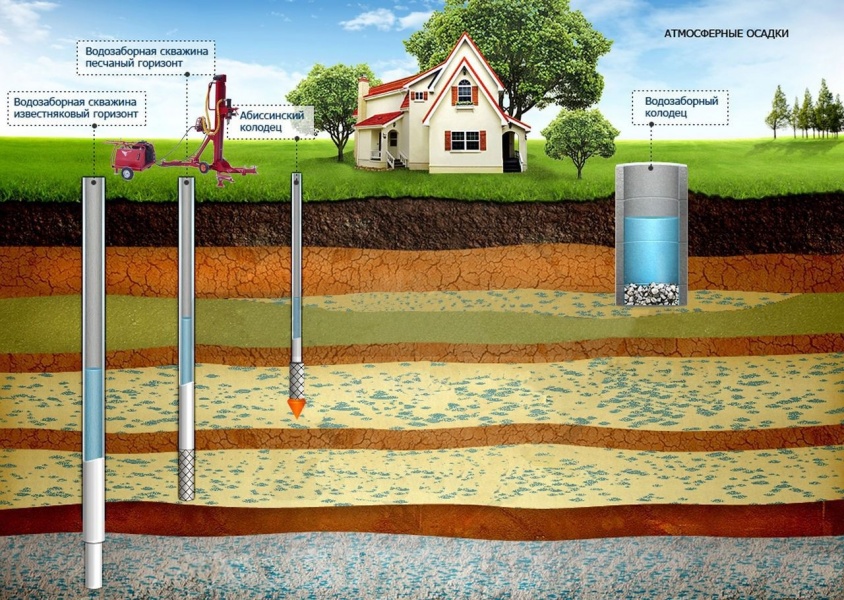

- Abyssinian well;

- filter well;

- artesian well.

The Abyssinian well (or well-needle) can be arranged almost everywhere. They punch it where the aquifer lies relatively close to the surface and is confined to the sands.

For its drilling, driving technology is used, which is not suitable for the construction of other types of wells. All work can usually be completed within one business day.

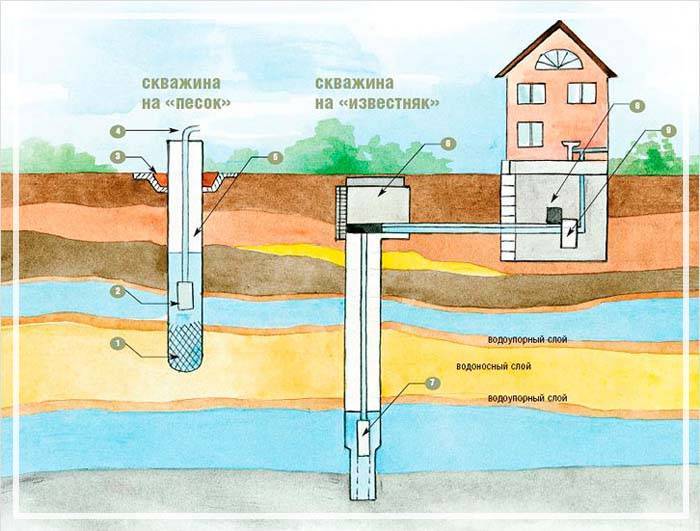

This scheme allows you to study the features of the device of various wells in order to better understand the technology of their drilling and choose the appropriate method (click to enlarge)

But the flow rate of such wells is small. To provide the house and the plot with enough water, it sometimes makes sense to make two such wells on the site. The compact dimensions of the equipment make it possible to arrange such a well right in the basement without any problems.

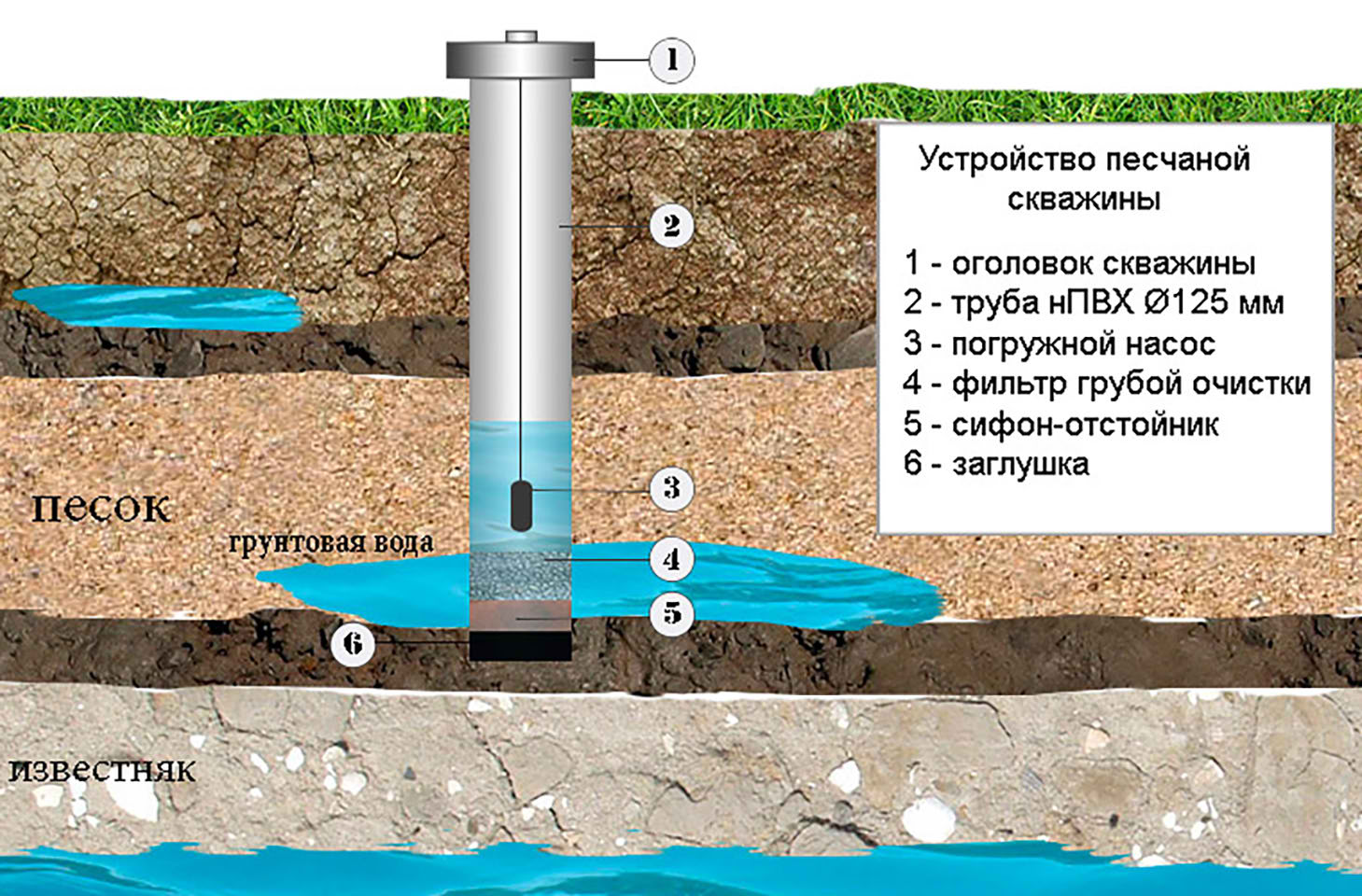

Filter wells, which are also called "sand" wells, are created on soils where the aquifer lies relatively shallow - up to 35 meters.

Usually these are sandy soils that lend themselves well to drilling. The depth of the filter well usually varies between 20-30 meters.

This diagram clearly shows the device of the filter well. A filter must be installed at the bottom of it to prevent sand and silt from entering the water.

Work in a good scenario will take two to three days. The filter well needs good maintenance, since the constant presence of sand and silt particles in the water can cause silting or sanding.

The typical life of such a well can be 10-20 years. The period may be longer or shorter, depending on the quality of the well drilling and its further maintenance.

Artesian wells, they are wells “for limestone”, are the most reliable, since the water carrier is confined to bedrock deposits. Water contains numerous cracks in the rock.

Silting of such a well usually does not threaten, and the flow rate can reach about 100 cubic meters per hour.But the depth to which drilling is to be carried out usually turns out to be more than solid - from 20 to 120 meters.

Of course, drilling such wells is more difficult, and it will take much more time and materials to complete the work. A professional team can cope with the work in 5-10 days. But if we drill a well on the site with our own hands, it may take several weeks, and even a month or two.

But the effort is worth it, because artesian wells can last half a century, or even more, without problems. Yes, and the flow rate of such a well allows you to supply water not only to one house, but also to a small village. Only manual drilling methods are not suitable for a device of such development.

The physical and mechanical properties of soils are also of great importance when choosing a drilling method.

In the course of work, it may be necessary to go through a variety of layers, for example:

- wet sand, which can be drilled in almost any way relatively easily;

- water-saturated sand, which can only be removed from the trunk with the help of a bailer;

- coarse-clastic rocks (gravel and pebble deposits with sandy and clay aggregates), which are drilled with a bailer or a glass, depending on the aggregate;

- quicksand, which is fine sand, supersaturated with water, it can only be scooped out with a bailer;

- loam, i.e. sand with abundant inclusions of clay, plastic, well amenable to drilling with an auger or core barrel;

- clay, a plastic rock that can be drilled with an auger or a glass.

How to find out what soils lie under the surface, and at what depth is the aquifer? Of course, you can order geological studies of the soil, but this procedure is not free.

Almost everyone chooses a simpler and cheaper option - a survey of neighbors who have already drilled a well or built a well. The water level in your future water source will be at about the same depth.

Drilling a new well a short distance from an existing facility may not follow exactly the same scenario, but it will most likely be very similar.

What criteria influence the choice of location for the well

If the well is located in the house, it will be almost impossible to repair it if the casing is damaged or contaminated.

If the well is located in the house, it will be almost impossible to repair it if the casing is damaged or contaminated.

When determining the source location area, the following points should be taken into account:

- Possibility of free access to the well at any time of the year. If, in order to drill a mine, the master drives the equipment through a neighboring, not yet built-up area, this is a temporary phenomenon. Someday they will buy it and definitely settle in. It is unlikely that future neighbors will allow vehicles to be driven through their yard.

- The need to preserve the source over time. It will be unrealistic to do this with a well located in a house (basement). The minimum prohibited option for the location of a hydraulic structure in a building is the construction of a greenhouse above it. In extreme cases, it can be quickly disassembled. In addition, the sources that it was decided to locate inside the house are not repairable. So, they are disposable designs.

Momentary short-sightedness when choosing a place for drilling often turns into big problems during the operation of a ready-made autonomous source.

Seasonality and features

Something in this matter depends on the depth of the future well. If its value is less than 25 m, the main factor influencing the choice of season can be considered the level of groundwater.

Something in this matter depends on the depth of the future well. If its value is less than 25 m, the main factor influencing the choice of season can be considered the level of groundwater.

If they stand high, it means that the earth is saturated with moisture and for all underground rivers located close to the surface, it is time for full water.

This applies mainly to free-flowing aquifers, on which the so-called “sand wells” are built - it is they that in most cases lie at such depths.

In such a situation, the probability of error increases sharply: you can build a well with an excellent debit, and with the advent of the dry season, when there is less water in the soil, it may become inefficient or dry out altogether.

When does the groundwater level reach its maximum? This usually happens twice a year:

- in early spring, when the snow begins to melt;

- late autumn when it rains heavily.

For wells with a depth of more than 25 m, the groundwater level does not play a special role. But even in this case, spring and late autumn are not very convenient for work. After all, heavy vehicles with drilling rigs will have to drive up to the place of work on the ground, and if it is limp from melted snow or heavy rains, ugly ruts will remain on the site.

Well drilling in summer

Based on the foregoing, it can be assumed that the most suitable time for well construction is the summer months. Indeed, the amount of ground moisture during this period becomes minimal, and the soil itself is quite strong. But here there is a nuance: the summer period seems ideal not to you alone. Firms and individual teams involved in drilling are literally besieged by customers at this time, which leads to two undesirable phenomena:

- rising prices;

- the appearance of haste in the performance of work, which inevitably affects the quality.

It is much more convenient to drill a well in early autumn, when the excitement subsides, and the weather is still dry. An additional advantage takes place if you have to drive up through garden beds - the crop has already been harvested.

But what about winter? We are accustomed to the fact that construction projects at this time fall into "hibernation". From the point of view of well construction, everything is quite different: it turns out that the winter period for the customer may turn out to be even more favorable than early autumn. This is explained as follows:

- In winter, due to a seasonal drop in demand, prices for services are significantly reduced, while drillers have the opportunity to do their work without haste, and therefore more carefully.

- The groundwater level, as in summer, becomes minimal.

- Precipitation falls in the form of snow, which, unlike rain, does not interfere with work.

- Frozen ground perfectly holds even the heaviest equipment.

- There is no need to take care of the disposal of the drilling fluid - the spring flood itself will wash everything away without a trace.

As you can see, winter with frost down to -20 degrees is not bad for ordering a well. It is only advisable to carry out preliminary drilling at the construction site in the fall with a garden drill to the depth of soil freezing - this will facilitate work in winter.

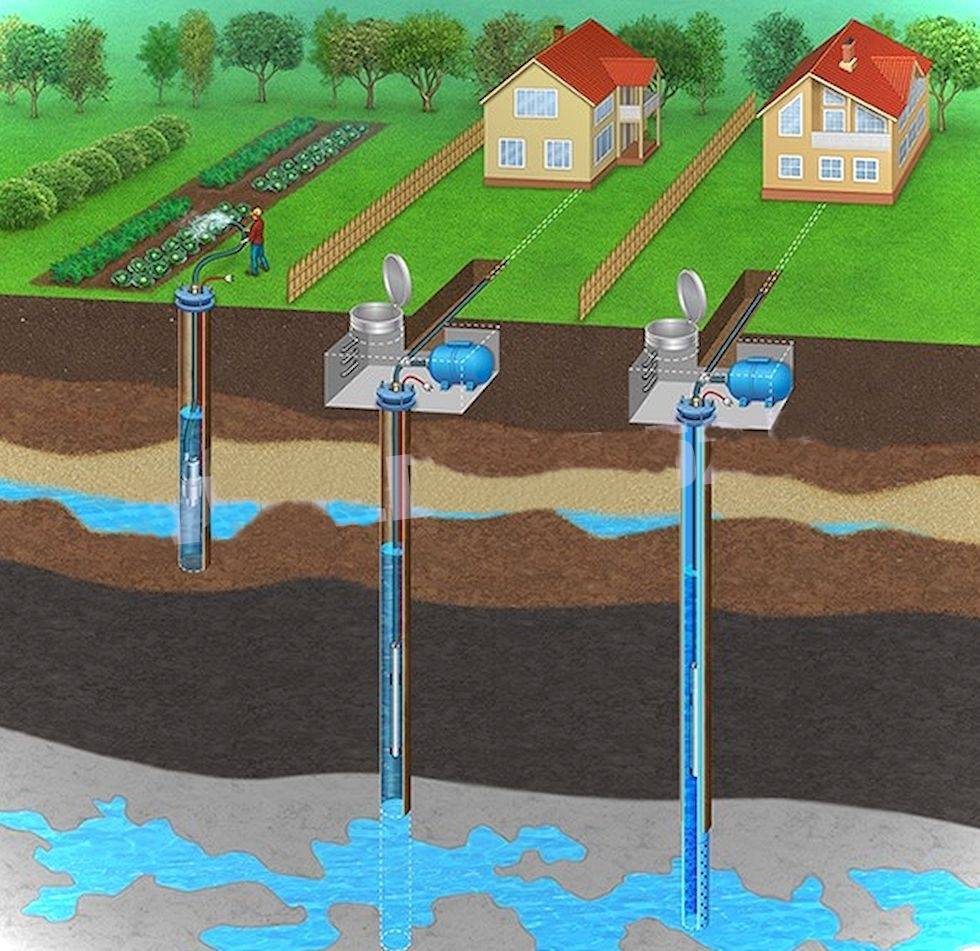

Where to order water well drilling

Often, a company is selected only at a low price, but you run the risk of running into newcomers, a one-day company (whose guarantee costs nothing), fraud, etc.

When choosing a drilling organization, it is important to pay attention not only to the price, but also what the company is like.Discard those who have their own production base, who “yesterday” came to the market, who are not members of the SRO or are not officially registered at all.

Here in this material we told in more detail what is worth looking at and what things do not play a role.

This will weed out the most risky options, but even more or less established drillers can go for a deception.

It is difficult to keep low prices when the cost of the metal is growing steadily, but you need to earn money. So there will be savings somewhere.

Where and on what drillers save and how it will affect your well, you will find out here

So, somewhere there will be savings. Where and on what drillers save and how it will affect your well, you will find out here.

What type of water wells are

With all its diversity, experts distinguish only a few types of water wells.

The first is the so-called well-needle. At the same time, the drilling rod, the well casing and the drilling tool are a single whole. The drill remains in the ground throughout the drilling process. The process itself is carried out by the shock method.

The rate of deepening with this method is on average about 2 meters per hour. The maximum possible depth in this case is up to 45 meters. A well-needle, as a rule, is equipped for the so-called Abyssinian wells in the country. They are in demand in the summer, as in winter they can show unstable water intake. A distinctive feature of such a well is that it can last for several decades. However, it cannot be repaired. As soon as the well stops producing water, it is clogged and a new one is started.

The diameter of the drill rod is up to 12 cm without the use of a pile driver - this corresponds to a submersible pump of 86 mm.

Types of arrangement of water wells.

The second is an imperfect well. Such a well seemed to hang inside the reservoir. It is easy to arrange and does not require special skill from the performer. However, the fence from it is not very high quality. In order to maximize the quality of water taken from an imperfect well, it is recommended to equip the bottom of the well with a plug.

In order for an imperfect well to be drilled on its own, a fairly powerful aquifer will be required.

The third type of well is perfect. In this case, its casing rests on the roof of the water-resistant layer. The passage of such a well will require accurate knowledge of local geology, as well as certain skills and abilities of the driller.

The quality of water in such a well is the best, and the service life is maximum.

The fourth type is the so-called bottom hole. In turn, it can be both perfect and imperfect. Thanks to the bottomhole, it will be possible to service such a well and, if necessary, repair it. However, only the most experienced craftsmen who are well acquainted with the local geology can drill it.