- Calculation of the number of ventilation grilles

- Air heaters and heat exchangers

- Features of the use of gas air heat generators

- Air heaters with water heat exchanger

- Types of air coolers

- Types of heat guns

- What you need to know to make the right choice

- Overview of popular models

- Conclusion

- Types of gas heat generators

- The device of gas heat generators

- Calculation and selection of a gas generator

- Features of industrial heating

- Types of heat generators for air heating

- About company

- Varieties of heat generators for air heating systems

- Calculation and selection of equipment for heating a house with a total area of 100 sq.m

- Heat exchanger size

- Security requirements

- Choice of gas heat generator

- Heat exchanger size

- Power calculation

- Security requirements

- Advantages and disadvantages of diesel equipment

Calculation of the number of ventilation grilles

The number of ventilation grilles and the air velocity in the duct are calculated:

1) Set the number of gratings and select their sizes from the catalog

2) Knowing their number and air flow, we calculate the amount of air for 1 grate

3) We calculate the speed of air outlet from the air distributor using the formula V = q / S, where q is the amount of air per grate, and S is the area of the air distributor.It is imperative to get acquainted with the standard outflow rate, and only after the calculated speed is less than the standard one, it can be considered that the number of gratings is selected correctly.

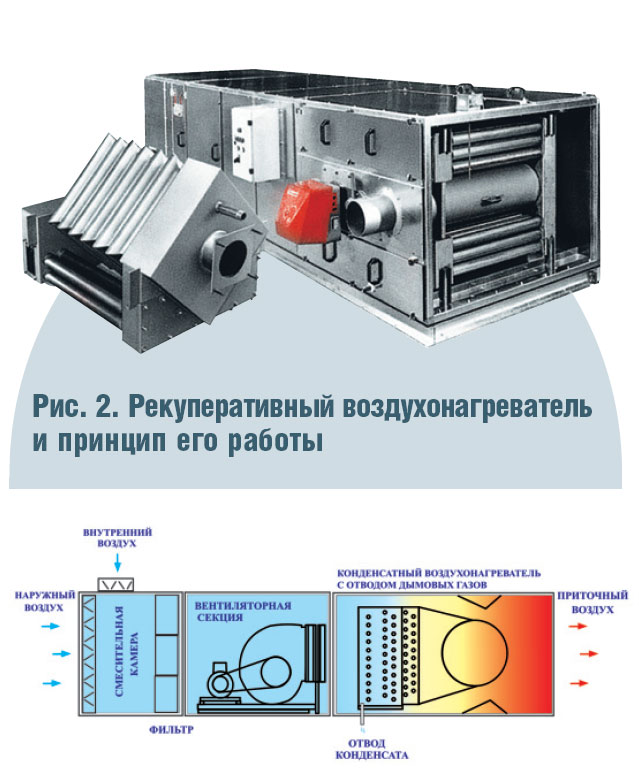

Air heaters and heat exchangers

It is not always advisable to heat and cool large rooms with traditional radiators or fans. That is why industrial air heaters and air coolers, presented on the modern market in a fairly wide range, are especially popular when establishing air conditioning systems.

For a competent selection of the optimal equipment, you should understand the main types and design features of such devices.

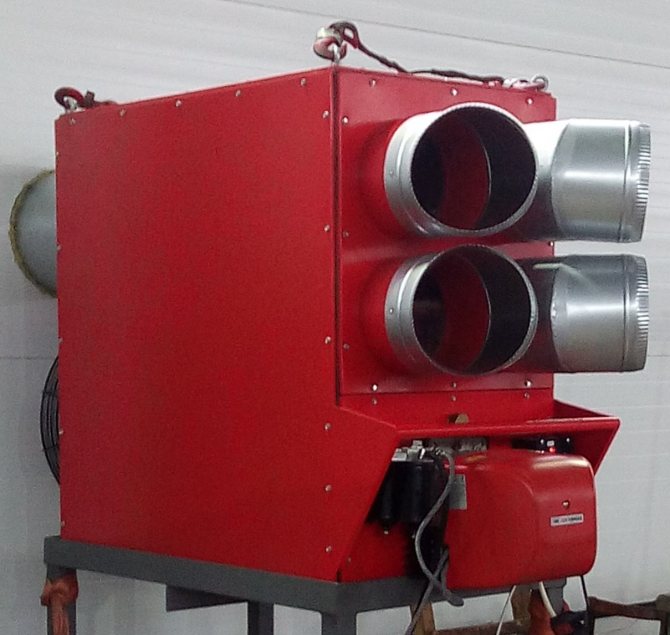

Features of the use of gas air heat generators

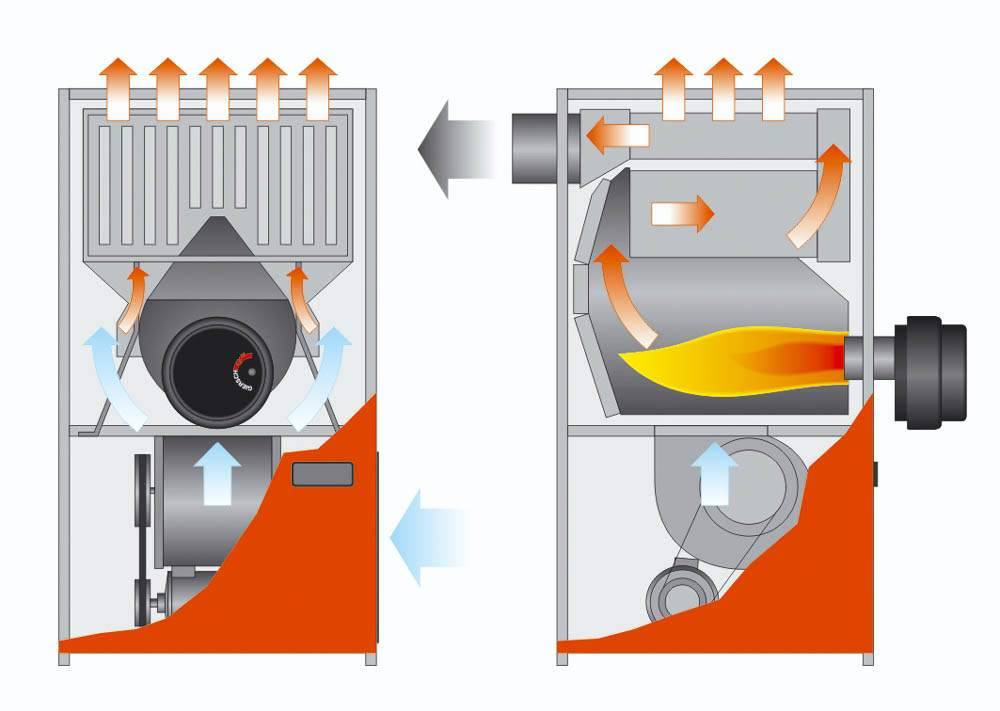

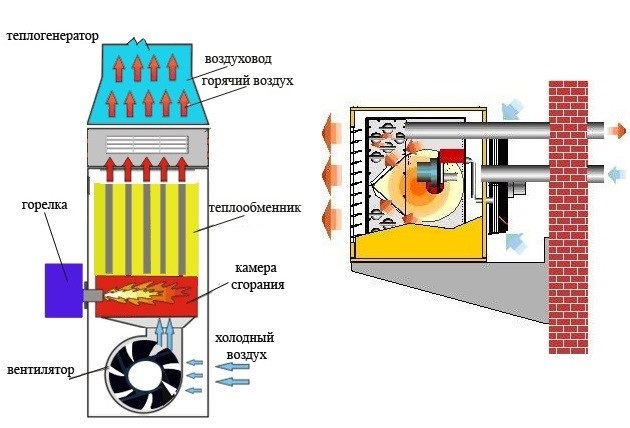

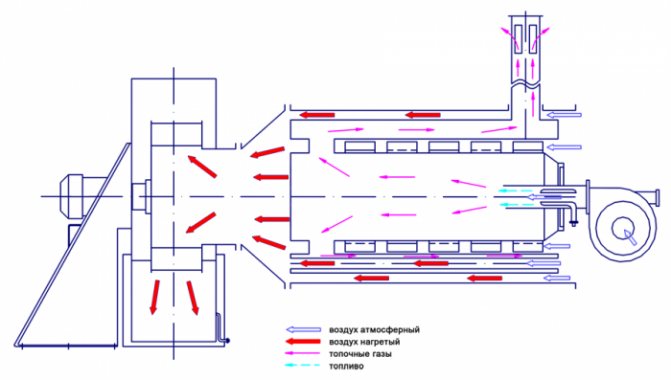

In a heat-resistant case (usually steel) of such devices, a fan, a burner and a combustion chamber are placed.

The process of operation of gas air heat generators is very simple: cold air enters the combustion chamber through a fan, where it is heated by gas and a burner. After that, the already heated air enters the heat exchanger and then is distributed in the duct system, and then enters the room that needs heating.

Modern models of gas air heat generators operate from a network of 380 and 220 volts.

Depending on the design features, such air heaters can be mobile and stationary (suspended, which are also called heaters, and floor - vertical or horizontal).

But stationary air heaters are in high demand, because they are easy to use and highly efficient.

Air heaters with water heat exchanger

In this equipment, the source of thermal energy is superheated water (maximum up to +180°C). Heat exchange is carried out by constant heating of the aluminum fins with a coolant on the tubular contour, as well as by washing the fins with a supply air flow. Both centrifugal and axial fans can be used together with water heaters to move air.

Air heaters with a water heat exchanger (water heaters) are used, as a rule, for heating industrial premises: workshops, warehouses, workshops. However, subject to the technical feasibility of connecting to a system with a coolant (for example, centralized heating), they can also be used in private households - for example, for heating a garage and a number of utility rooms.

In addition, air heaters with a water heat exchanger can be used as part of specific technological systems: for example, complete with an axial fan for drying lumber.

In general, water air heaters as a heat carrier ensure the efficiency and reliability of engineering heating systems.

Types of air coolers

- Dry (surface). In such heat exchangers, heated air masses are cooled by contact with a heat exchanger, through the pipes of which cold water or freon passes. This type of air cooler is the most common.

It has only one drawback: to defrost ice on the heat exchanger, it is necessary to periodically use heat sources, for example, heating elements.

- Wet (contact). In these heat exchangers, direct heat exchange is carried out between the water cooled in the evaporator and air.

By means of a fan, an air stream is driven through a nozzle cooled in water. The design of these heat exchangers also provides for the use of nozzles that spray water. The disadvantages of contact air coolers include an increased risk of corrosion of the metal parts of the devices due to the enrichment of water with oxygen.

- Combined (mixed) air coolers. In them, the water is cooled by spraying the freon evaporator, and then cools the air mixture passing through it, created by a fan.

A wide range of quality air heaters and air coolers from well-known brands Polar Bear (Sweden) and Arktos (Russia). All sold products are provided with an official guarantee.

Types of heat guns

Equipment for air heating is conventionally divided into two classes:

- mobile;

- Stationary.

But the units belonging to the first type do not always have compact dimensions. Some mobile models have quite impressive dimensions. Such devices are usually equipped with special carts necessary for moving the equipment.

They got the name mobile only because they are designed to work from gas cylinders and do not require connection to the central highway. They can be installed anywhere and are designed for heating industrial premises. But cavitation heat generators of heating systems require an effective ventilation system at the facility, because the heated air is removed along with the exhaust gases.

Stationary devices are designed for connection to the gas pipeline. They differ in the installation method and, depending on this, the criteria are:

- suspended;

- floor.

The first are small in size, which means they take up little space. They are designed for heating private households. Suspended heat generators are easy to use and install, quickly warm up the room, have clear instructions for use.

Floor units are more bulky devices. They are used for heating large areas. Many models of such equipment can be connected to an air duct system, which allows you to evenly distribute heat throughout all rooms.

What you need to know to make the right choice

It is possible to ensure efficient gas-air heating only when installing equipment that meets the parameters of the room. Important features to choose from are:

- heater type;

- Power.

In addition, for reliable operation of the device, it is necessary to ensure the flow of air into the room. For this, a ventilation system is most often used. It is able not only to supply oxygen to the room, but also to remove exhaust gases to the outside.

Overview of popular models

The leader among heat guns, of course, remains the products of foreign companies and, in particular, US manufacturers. The device under the brand name Master BLP 73 M is popular with owners of private houses and industrial facilities. It can be used not only as heating equipment, but also as a building hair dryer.

Watch a video about the Master BLP 73 model:

An American-made heat gun consumes no more than 4 kg of liquefied gas per hour, while generating up to 70 kW of energy. Its power is enough to heat a room up to 700 m² with a capacity of about 2.3 thousand cubic meters of warm air per hour. The cost of such a device is no more than 650 dollars.

But there are domestic models on the market that meet all regulatory requirements. One of them is the Patriot GS53 heat gun. It is capable of generating up to 50 kW of thermal power at consumption up to 415 kg of gas in hour. This is enough to heat a room of no more than 500 m². The cost of the unit does not exceed 400 dollars.

Of the models consuming main gas, the heat generator AKOG-3-SP can be noted. This is a small device, the power of which is enough to heat a room with an area of 30 m², while consuming 0.3 m³ of natural gas.

The thermal convector of this brand is designed for wall mounting and will be able to heat one functional area in a suburban household. The cost of this device is one of the lowest and is less than $ 250.

Conclusion

The use of such equipment in heating systems is considered one of the most effective and economical solutions. It is easy to use, safe and therefore can be used not only in industrial facilities, but also in residential premises.

Types of gas heat generators

Gas heaters for heating are divided into mobile and stationary. The latter, in turn, are divided into suspended and floor. At the same time, mobile units are less common, because gas cylinders are used for their operation, which is not always convenient and possible to provide. That is why such devices are used only in extreme cases, for example, when the main heating in the room is turned off, and it is urgent to heat it up with a sharp drop in temperature outside.Also, such units are used as the main heating in regions with a short winter season.

The stationary type of heaters is used in various fields. Mounted heat generators are hung on the walls inside and outside the premises. Floor type devices, depending on the features of the assembly, are horizontal and vertical. The former are more often used in low rooms, while the latter are suitable for installation in a private house or on the street. It is convenient to use floor devices for heating small rooms by installing them at the entrance and exit to the heated area.

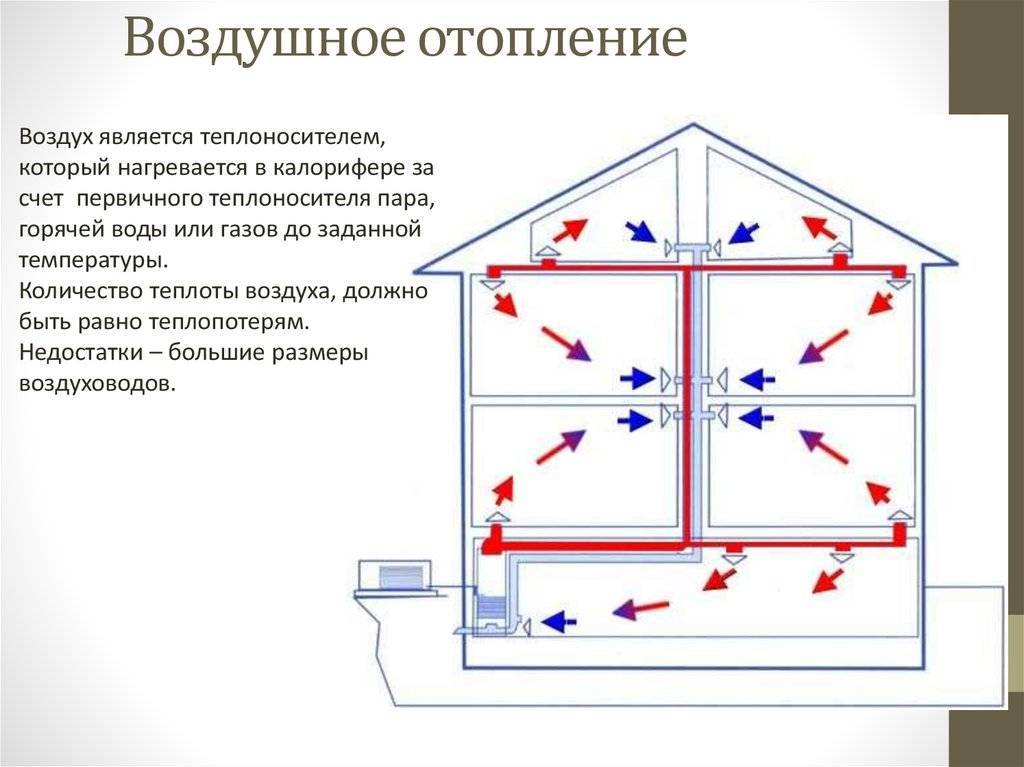

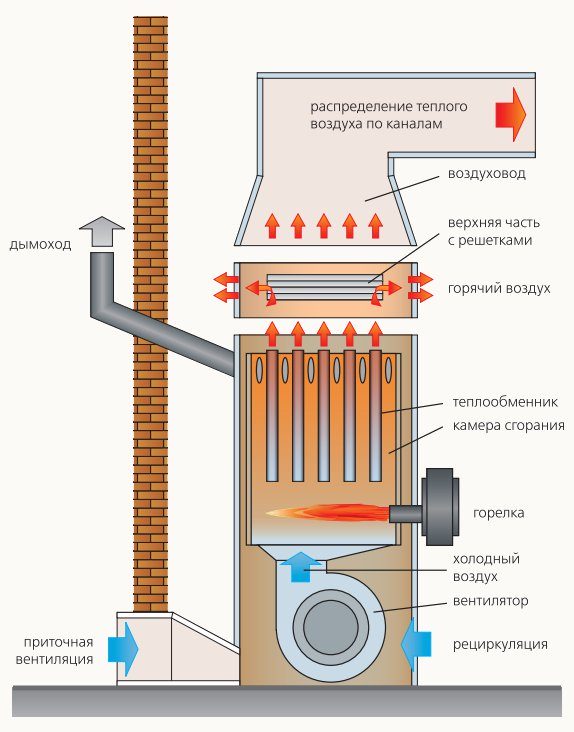

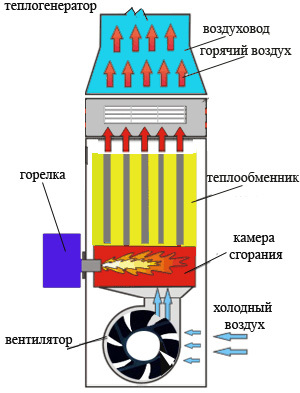

The device of gas heat generators

A gas heat generator is a heater that heats the coolant (air) to the required temperature.

His device is as follows:

- The air fan is designed for uninterrupted supply of air masses and removal of exhaust air from the system. The exhaust air is discharged upwards.

- By means of a gas burner, fuel is burned and the coolant is heated.

- Complete combustion of the heat source occurs in the combustion chamber. If the fuel burns completely without residue, then the amount of carbon dioxide emitted by the system is small.

- The purpose of the heat exchanger is to ensure normal heat exchange between the room and the heat generator. In addition, the heat exchanger protects the heating equipment from overheating.

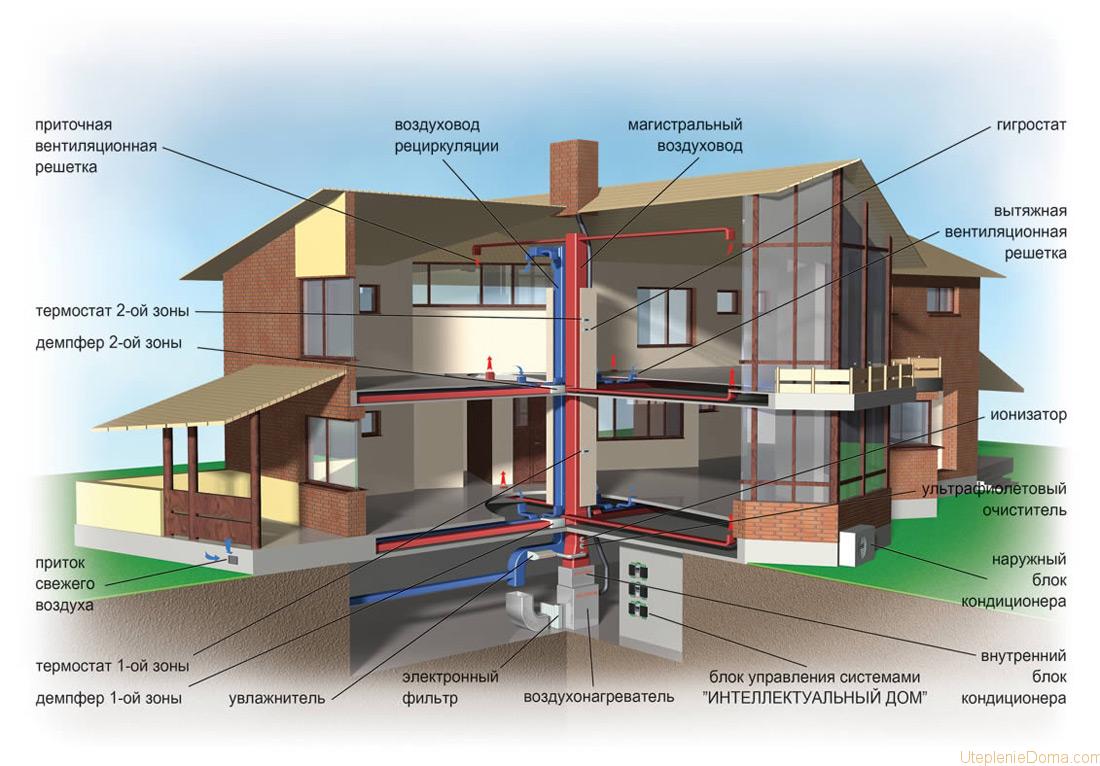

- Air ducts are used to remove heated air into the room.

The principle of operation of such heating equipment is as follows: the fan draws cold air into the device, it heats up in the process of fuel combustion to the required temperature and is discharged through the air ducts into the room.

The process of operation of a gas heater can be divided into the following stages:

- cold air from the street or premises is drawn by the fan into the device and enters the heating element;

- since gas is constantly burned in the combustion chamber, thermal energy is released, which heats the air;

- after that, the fan supplies heated air to the heat exchanger;

- air ceilings are distributed through the duct system through the use of air valves;

- heated air is fed into the room through the grilles and gradually heats it up.

Calculation and selection of a gas generator

In order for the efficiency of the system to be sufficient, the gas air heater for air heating must be correctly selected

To do this, first of all, you need to pay attention to the size of the heat exchanger. The dimensions of the heat holder must be 1/5 part larger than the dimensions of the burner

To choose the right gas generator, you need to calculate its power. To do this, use the formula - P \u003d VxΔTxk / 860, where:

- V in m3 indicates the heated area of \u200b\u200bthe building;

- ΔT in °C is the temperature difference between inside and outside the house;

- K is an indicator of the thermal insulation of the house (the number can be selected from the directory);

- 860 - this number is a coefficient that allows you to convert kilocalories to kW.

The power of the device is selected in accordance with the value obtained. As a rule, the operating power of the equipment is indicated in its technical characteristics.

For uninterrupted operation of heating equipment for air heating, it is necessary to ensure a continuous supply of air to the device. To this end, the ventilation system of the structure must be properly equipped.If there are problems with ventilation, then it is better to use a hanging type device that takes air from the street.

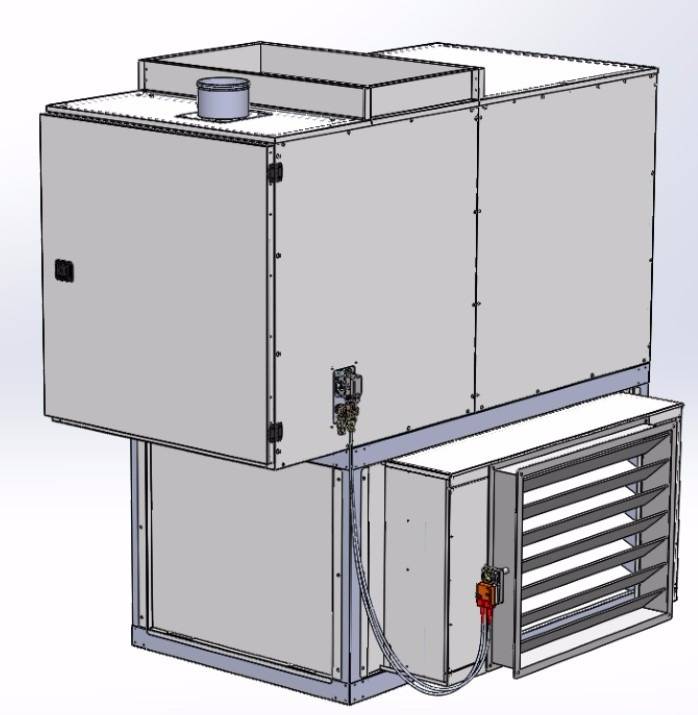

Features of industrial heating

- Firstly, most often we are talking about work on energy-intensive Objects of a fairly large area, and there is a requirement for the maximum possible energy saving for heating systems (as well as for all other auxiliary systems). It is this factor that is at the forefront.

- In addition, often in heated rooms there are non-standard conditions for temperature, humidity, dustiness. Therefore, the thermal equipment and materials used must be resistant to such adverse effects.

- Flammable and explosive substances may be used at a number of Sites, and, based on this, the installed system must comply with stringent explosion and fire safety requirements.

- Another important difference between the systems under consideration is, as a rule, their large total power. It can reach hundreds of megawatts. Therefore, boilers used for heating houses are often not suitable for the scale in question. The use of cascades from domestic boilers is simply becoming economically impractical

- In addition, the heating of industrial buildings is often designed and installed in a single complex with climate systems. This makes it possible to implement heating of industrial premises with large areas and at the same time save resources and the space occupied by the mains. First of all, this method is used in the organization of air heating.

- The next feature that industrial heating of a building has is its “unconventional”.There are certain standard solutions on the basis of which the heating of a country house is carried out. These solutions can be applied with small nuances almost everywhere and always. Technical solutions for large-scale Objects are much more diverse. Engineering art in this segment is the selection of the optimal technical solution. Before the start of the project stage, the most important stage will be the competent preparation of the Terms of Reference. And when the installation of heating of industrial facilities takes place, the Terms of Reference drawn up by qualified designers and engineers will help optimize the process of installation work. Designers carry out various engineering calculations. Based on an individually selected engineering solution, the most efficient way of heating the Object in question is determined

- Often, if we are talking about production, then technological equipment is located at the Facility - machines, conveyors, production lines. Also, perhaps, the people who work on it. This needs to be taken into account

- As a rule, uniform distribution of heat is necessary, unless the project involves the creation of zones with a special temperature regime. By the way, the presence of such zones is also a feature that must be taken into account when organizing the heating of industrial buildings.

- As already mentioned, the traditional method for heating the housing stock (in particular, cottages) using a domestic boiler and radiators in the conditions under consideration is, as a rule, inefficient. For this reason, industrial heating systems are built according to other principles. Recently, these are most often autonomous systems of the scale of the Object, and sometimes of its individual parts.Autonomous heating is easier to manage than centralized (through CHP) due to the ability to control and regulate the consumption of fuel resources

- There are some features and at the stage of operation. In the residential sector, often the level of service of the heating system is sometimes not professional enough. If heating is installed in an industrial building, then, as a rule, you can be sure that the maintenance service will be carried out by a qualified team (most often, this is the chief power engineer’s service or a staff unit of the enterprise similar in function). On the one hand, this somewhat facilitates the responsibility of the installation organization. Most likely, after the commissioning of the facility, no one will apply "on trifles". On the other hand, the requirements for the composition and level of writing as-built documentation are increasing. Employees of the operation service, being professionals, are well aware of what exactly it should include and how to compose it. All necessary licenses, certificates, permits, passports for equipment, acts of work performed must be provided without fail. Only after that the system will be put into operation.

Types of heat generators for air heating

A heat generator is an air heating unit that produces heat energy by burning one of the fuels. Power, efficiency, installation method, operation features are largely determined by the type of fuel. For heating residential premises, social facilities, the following types of units are mainly used:

- pyrolysis boilers. They work on solid fuels of plant origin (firewood, woodworking industry waste, pellets, briquettes, peat).

- Gas boilers. Burn natural gas.

On a note! Before installing an air heating and air conditioning system that involves a long service life, it is necessary to correctly calculate the fuel resources. Switching to another type of fuel requires an almost complete replacement of the system.

Pyrolysis or gas boilers, as well as diesel and universal heat generators can be used for space heating.

Pyrolysis or gas boilers, as well as diesel and universal heat generators can be used for space heating.

For air heating of large production areas, the following types of generators can also be used:

- Diesel. They work on diesel fuel. They are refueled once a day (this is an average, there are models that may not be refueled for 2-3 days).

- Universal heat generators. Diesel is also used as fuel for them, as well as oil waste, vegetable fats to be disposed of.

These types of fuel are cheap, which significantly reduces the economic costs of enterprises for heating production facilities.

About company

If you need to purchase first-class gas air heaters, but you have no idea where they could be ordered online, then we are ready to help you. For more than 18 years, our main activity has been the sale, installation and maintenance of high-quality gas heating equipment that meets all modern standards. On this page you will find a detailed description of gas heat guns.This will help you make the right choice and purchase the exact model that best suits your specifications.

Varieties of heat generators for air heating systems

A heat generator is a unit that transmits a coolant heated to certain temperatures. The carrier is heated during the combustion of energy carriers of various types. The heat generator is an alternative to conventional heating appliances for domestic and industrial applications.

Devices differ according to the type of energy carrier:

- Universal. These are modules that run on diesel fuel, waste oil, animal or vegetable fats. The peculiarity of the use is the presence of fuel in a sufficient amount, therefore, furnaces are most often used in industrial conditions. The power of the devices is slightly less than other devices, also in the process of burning fuel, a lot of combustion products and slag are released - you will have to regularly clean the ash pan. To maintain the continuity of work in universal units, two combustion chambers are installed - while one is undergoing a cleaning process, the other is being operated.

- Solid fuel. The generator combines the functions of a conventional furnace and a diesel or gas unit. The device is supplemented with a combustion chamber with a door and grates. Fuel - firewood, pellets, peat, coal. Efficiency up to 85%. The large size of the devices and the need to regularly clean out slags are a minus.

- The gas heat generator runs on liquefied gas, therefore it is considered the most popular type of equipment. Natural gas supplied via the mains is inexpensive, you do not have to store fuel and allocate space for storage.A small amount of harmful emissions during combustion, high efficiency (up to 91%), a variety of models in terms of power are pluses.

- Diesel. Kerosene or diesel fuel is used as an energy carrier. Devices differ according to the type of nozzle - drip or spray supply. With atomizing supply, the fuel is distributed more evenly throughout the combustion chamber and the combustion process is faster.

- Vortex. These heat generators run on antifreeze or water, converting electrical energy into heat.

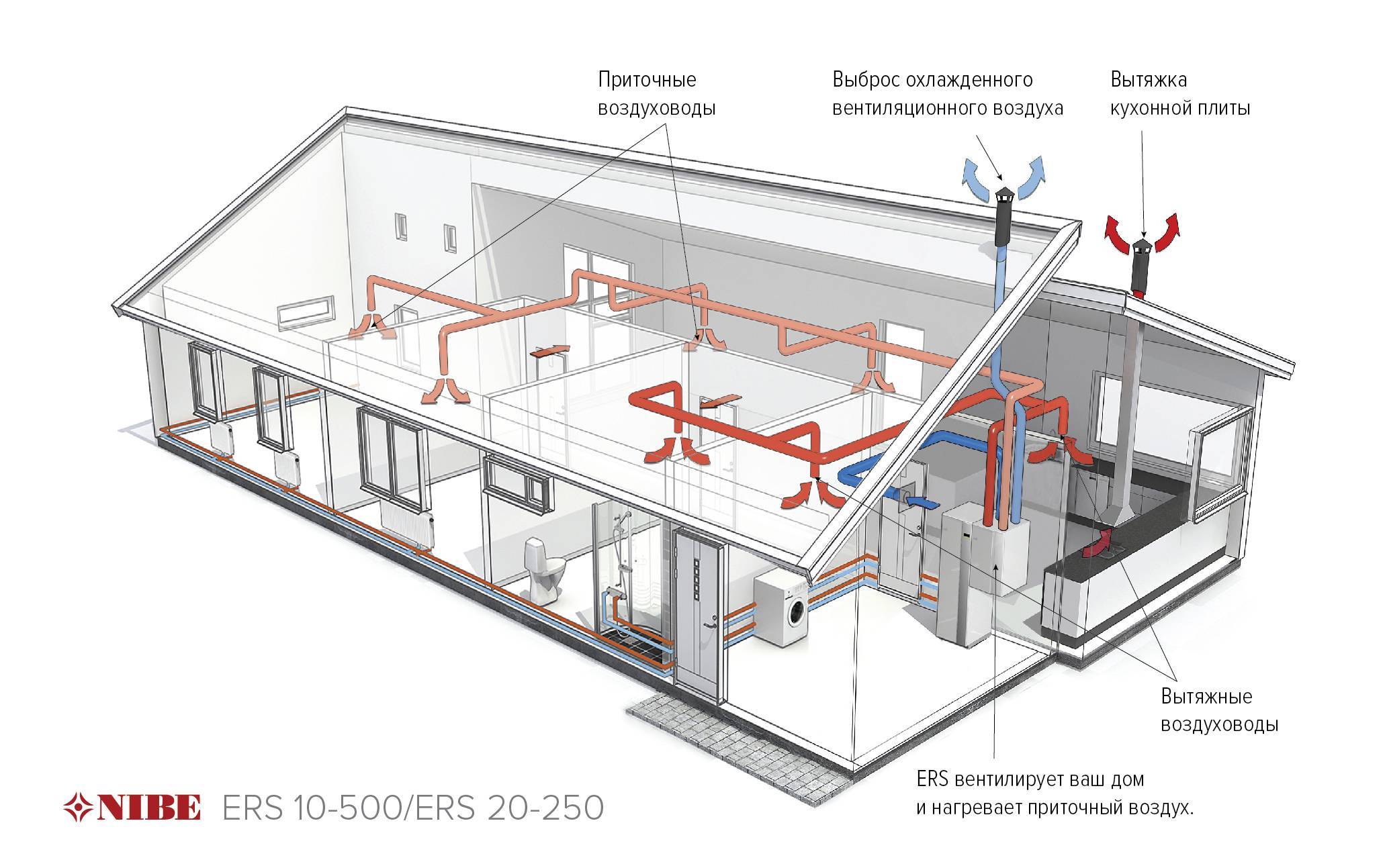

Calculation and selection of equipment for heating a house with a total area of 100 sq.m

In order to choose the right heater, you need to calculate the smallest possible power required to fully warm up the heated building.

Then gas-air equipment is selected by quantity and power.

The basic formula for calculating the heat capacity of a room is as follows:

P \u003d Vx? Txk / 860

Where:

- V, m3 - the total volume of the heated building (length, width and height).

- ?T, °C is the difference (in degrees) between the temperature inside the object and the temperature outside.

- k is the insulation coefficient of the room, which has different values and is taken from the directory.

- 860 is a special coefficient for quickly converting power from kilocalories to kilowatts (1 kilowatt = 860 kilocalories per hour).

Example: let's calculate how much power you need to spend to warm up a building (house) with an area of 100 square meters. m, with a ceiling height of about 3m, up to an average temperature of 20 °C, with a winter ambient temperature of -20 °C.

Let's take a building of conventional design (built from a single layer of simple brick).

For such a building, the value of k=2.3.

Let's calculate the power:

P \u003d 100x3x40x2.3 / 860 \u003d 32.09 kW.

Now, according to the calculated minimum possible power, we select the required number and type of heat generators.

For this there is a manual for the equipment.

For the smooth operation of heating equipment, a constant supply of fresh air is necessary.

In this case, ventilation performs several functions:

- pumps oxygen (for combustion)

- helps eliminate excess carbon dioxide

- removes by-products (life-threatening) combustion products such as carbon monoxide (CO)

To do this, it is recommended that the percentage of oxygen in the ventilated air be more than 17%.

For safety and sanitary conditions, 30 m3 of forced air is required for 1 kilowatt of heater power

To ensure air flow, you can punch a hole of 0.003 m2 per 1 kW of the heater with your own hands. If there is no ventilation system, then the required area of open vents or windows must be at least 1 m2 for every 10 kW of power.

Insulation factor value:

- 3.0 - 4.0 - room made of wood or profiled sheet

- 2.0 - 2.9 - conventional construction - one layer of brick

- 1.0 -1.9 - ordinary houses, double brick layer - medium insulation

- 0.6 - 09 - perfectly insulated buildings - double brick

The use of a heat generator in a small workshop

Heat exchanger size

And, perhaps, the first thing to be based on when choosing equipment for a private house is the size of the heat holder, it should be one fifth larger than the burner.

Security requirements

Also, there are special safety requirements, the meaning of which is that 0.003 m2 of ventilation hole must be allocated per 1 kW. If there is no such possibility of organizing the room, then you will have to ventilate the space with your own hands, opening windows and vents for ventilation. At the same time, it should be borne in mind that in this case, the area of \u200b\u200binfluence of ventilation increases and a little more than 10 meters squared is already needed for 10 kW.

Examples of coefficients for calculating the heating power and thermal insulation:

- 2-2.9 - an ordinary brick structure, if one layer of brick is visible;

- 3-4 - houses from a wooden panel or profiled sheet;

- 1-1.9 - double insulated brick layer;

- 0.6-0.9 - houses of modern construction with new walls and windows.

Choice of gas heat generator

Partly because this possibility is fairly new, partly because hunting is the best option, when buying a gas heater there are questions that can not always be answered competently. Therefore, buying a gas heat generator can lead to disappointment due to the incorrect operation of the system.

Heat exchanger size

And, perhaps, the first thing to be based on when choosing equipment for a private house is the size of the heat holder, it should be one fifth larger than the burner.

Power calculation

For the most competent selection of a heater, you need to calculate what kind of power of the heat generator is acceptable for the minimum heating of rooms, for this you need to use an example of the formula: P \u003d Vx & # 916; Txk / 860, where V (m3) is the final area of the heated space, & # 916; T (°C) is the difference between indoor and outdoor temperatures, k is an indicator focused on thermal insulation in the selected building, and 860 is a factor that converts kilocalories to kilowatts. Regarding the mark (k), if there are difficulties with this information about the room, then you can use a specialized directory.

In order to more clearly demonstrate how exactly the power of the heat generator device is calculated, consider an example:

- Given: area - 100 m2, height - 3m, inside temperature +20, outside temperature -20, k - 2.3 (a brick building in one layer).

- The calculation is carried out according to the example: Р=VхΔ Tхk/860

- Result: P \u003d 100x3x40x2.3 / 860 \u003d 32.09 kW

It is with these indicators in mind that it is necessary to select a gas heat generator for air heating a house. The power parameters of the mechanism and its coincidence with the required ones, you need to look in the product description.

An equally important point: for the smooth operation of the mechanism, it is necessary to provide it with a constant supply of fresh outdoor air. For this, a ventilation system is always used in the premises, as soon as cold air can be taken from there, which is able to support combustion. In the event that there are problems with ventilation in the house itself, then it is better to purchase a suspended heat generator with an outlet to the street.

Air heating ventilation system

In addition, if the gas heater in the air heating system has a supply to street ventilation, this will allow warm air to be as breathable as possible, excess hot air will not be blown into the room, and therefore the possibility of a lack of dry air and additional mechanisms for humidifying the space will be preserved. .

Security requirements

Also, there are special safety requirements, the meaning of which is that 0.003 m2 of ventilation hole must be allocated per 1 kW. If there is no such possibility of organizing the room, then you will have to ventilate the space with your own hands, opening windows and vents for ventilation. At the same time, it should be borne in mind that in this case, the area of \u200b\u200binfluence of ventilation increases and a little more than 10 meters squared is already needed for 10 kW.

Examples of coefficients for calculating the heating power and thermal insulation:

- 2-2.9 - an ordinary brick structure, if one layer of brick is visible;

- 3-4 - houses from a wooden panel or profiled sheet;

- 1-1.9 - double insulated brick layer;

- 0.6-0.9 - houses of modern construction with new walls and windows.

Advantages and disadvantages of diesel equipment

Although the modern market offers a fairly wide selection of heating appliances, diesel guns do not lose popularity among consumers.

Indeed, despite the fact that the cost of similar gas and electric units is significantly lower, the operation of diesel devices is much cheaper due to the affordable price of a diesel engine.

In many guns, you can use not only diesel fuel, but also other fuels, for example, diesel fuel, kerosene or filtered oil recovery, but this point needs to be clarified when buying

The advantages of a diesel heat generator include:

- High efficiency index - even taking into account ventilation and forced ventilation, the device quickly warms up the air and distributes it throughout the entire volume of the room.

- Ease of operation - to start the system, just point the "muzzle" of the gun at the center of the room or a building element and press the power button.

- Safety - modern devices are equipped with various sensors and thermostats, thanks to which the device itself does not overheat. Also, accidental attenuation of the flame is excluded, and when the air is heated to a predetermined temperature, the gun temporarily stops working.

- Low cost of fuel - even devices that are demanding on the quality of diesel fuel will be much more profitable to operate than electric or gas appliances.

- Ease of transportation - the heat generator is compact and light enough (a simple device with a power of 10-22 kW weighs about 11-13 kg), so it will not be a problem to bring it to the site or move it from one room to another.

- Profitability - a small amount of fuel is required to heat the room, and the device can work for a long time without refueling. For example, a direct heating unit of 22 kW and a tank volume of 20 liters consumes an average of about 2.5 liters per hour of operation.

- Long service life is ensured by wear-resistant materials, standard replaceable components and the simplicity of the design itself.

Of course, it was not without drawbacks.In addition to harmful fumes from diesel fuel, the problem with which can be solved with the help of a chimney or a well-functioning ventilation system, the disadvantages of the device include the need to connect to the power grid, noise during fan operation and fuel level control.

In addition, the cost of the gun itself and its repair will be higher than that of similar devices powered by gas or electricity.