- Boiler gas single-circuit floor

- Advantages and disadvantages of units

- Double-circuit or single-circuit boilers?

- TOP-10 rating

- Buderus Logamax U072-24K

- Federica Bugatti 24 Turbo

- Bosch Gaz 6000 W WBN 6000-24 C

- Leberg Flamme 24 ASD

- Lemax PRIME-V32

- Navien DELUXE 24K

- MORA-TOP Meteor PK24KT

- Lemax PRIME-V20

- Kentatsu Nobby Smart 24–2CS

- Oasis RT-20

- Rating TOP-5 wall-mounted double-circuit boilers

- Buderus Logamax U072-12K

- Navien DELUXE 13K

- Vaillant turboTEC pro VUW 242/5-3

- Bosch Gaz 6000W WBN 6000- 12C

- BAXI LUNA-3 COMFORT 240 i

- Wall mounted condensing boilers

- Protherm lynx 25/30 MKV

- Vaillant ecoTec plus VU INT IV 346/5-5

- BAXI LUNA Duo-tec 40

- Criteria for choosing a gas boiler

- Rating TOP-5 floor-standing single-circuit boilers

- Protherm Wolf 16 KSO

- Lemax Premium-20

- Lemax Premium-12.5

- Lemax Premium-25N

- MORA-TOP SA 60

- Criteria for choosing a gas boiler

- The most popular manufacturers and their brief description

- The device of single-circuit gas boilers

- Principle of operation

Boiler gas single-circuit floor

This type of heating units is one of the most popular.

Consider its advantages:

- Profitability. The cost of such a variant of equipment is much lower than analogues - no more than 20 thousand rubles. And if you still choose a Russian outdoor gas boiler, then the price will surprise you even more. In this case, the quality will be at the proper level.Don't forget about maintenance. Repair of a domestic unit will cost significantly less.

- Simple structure, easy to maintain. Easy to operate.

- Can heat large areas.

- Economical gas consumption.

The gas single-circuit floor boiler can be produced with a closed and open combustion chamber, with a steel or cast iron heat exchanger. There are automated models. The disadvantages include the fact that for the hot water system you will have to buy a separate water heating system.

So, we want to buy a floor gas boiler. Which to choose? Reviews recommend buying such a device in houses and apartments that have central hot water supply. Below we consider two-circuit systems.

Advantages and disadvantages of units

Boilers running on liquefied gas are cheaper than appliances using other types of resources.

Among the advantages of the equipment are parameters such as:

- Complete independence from centralized fuel supplies and regular price increases for utility services. The autonomy of the system ensures the absence of emergencies.

- High level of efficiency - an average of 92-95% and up to 97% for individual models.

- Silent burner - in comparison, the burner device of a diesel boiler produces a noise effect of 60-75 dB.

- Ease of maintenance. The equipment does not require time-consuming and expensive maintenance, replacement of the fuel filter and nozzle, reconfiguration of the burner and cleaning of the heat exchanger.

- The ability to work through the main gas - in the future, you can not buy a new boiler, but transfer the existing one to a centralized supply of blue fuel.

- Duration of operation - the service life of outdoor - up to 25 years, wall - 15-20 years, subject to qualified installation, compliance with operating rules and timely service.

- The safety of liquefied gas devices - the fuel does not ignite even when the container it contains is heated. Combustion occurs only at the moment of mixing the substance and oxygen, and this happens directly in the burner and only in it.

On sale there are completely non-volatile products that allow you to organize a full-fledged heating system in hard-to-reach conditions, for example, in remote forest areas or high in the mountains.

Of the minuses of the devices, the following positions are most significant:

the need for constant high-quality work to connect the boiler to 3-4 propane cylinders by means of a reducer and a ramp;

it is undesirable to place containers with liquefied gas near the boiler - it is better to place them in rooms in the neighborhood, equipped with a good ventilation system, or take them outside and mount them in a special box;

care and caution required when connecting the cylinder, since all operations are performed manually and require the use of physical force;

subsequent conversion of some models of boilers to conventional gas is expensive (burner replacement costs 30-40% of the total price of the boiler);

unit installation and connection to gas supply communications must be done by a licensed specialist with experience.

The ratio of pluses and minuses must be considered in each individual case and, based on the conclusions drawn, a decision should be made regarding the appropriateness of purchasing one or another type of equipment.

Double-circuit or single-circuit boilers?

This applies more to wall models.The recommendation here is simple. If you have a small house with one bathroom and a kitchen, then take a double-circuit boiler and use hot water from it.

If you have several bathrooms, then choose a single-circuit gas boiler and combine it with an indirect heating boiler.

The main problem of double-circuit boilers is their low productivity. At the same time, such a device can provide one point of hot water. If there are several of them, problems may arise. For example, with a suddenly cold shower. Everyone passed, everyone knows and does not want to repeat. Therefore, it is better to put a boiler.

TOP-10 rating

Consider the most popular models of double-circuit gas boilers, recognized by experts and ordinary users as the most successful in terms of design and operation:

Buderus Logamax U072-24K

Gas double-circuit boiler designed for wall mounting. Equipped with a closed-type combustion chamber and a separate heat exchanger - primary copper, secondary - stainless.

Heating area - 200-240 m2. It has several levels of protection.

Models with the index "K" perform heating of hot water in flow mode. It is possible to connect a room temperature controller.

Federica Bugatti 24 Turbo

Representative of Italian heat engineering, wall-mounted double-circuit gas boiler. Designed to work in a cottage or public space up to 240 m2.

Separate heat exchanger - copper primary and steel secondary. The manufacturer gives a 5-year warranty period, which indicates confidence in the quality and operational capabilities of the boiler.

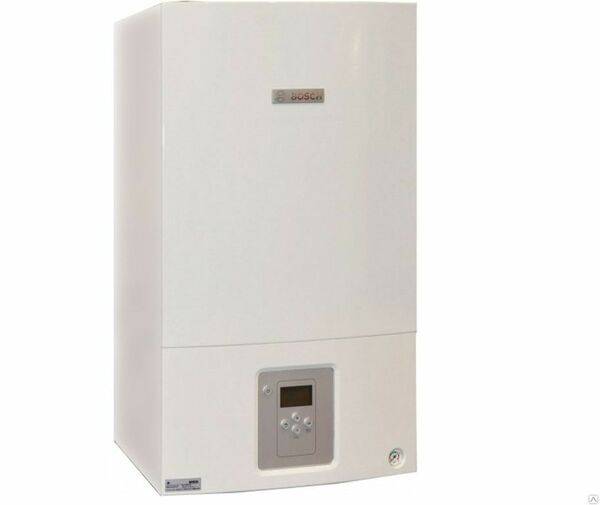

Bosch Gaz 6000 W WBN 6000-24 C

The German company Bosch is known all over the world, so it does not need additional introductions.The Gaz 6000 W series is represented by wall-mounted models designed for operation in private homes.

The 24 kW model is the most common, it is optimal for most residential and public buildings.

There is a multi-stage protection, the copper primary heat exchanger is designed for 15 years of service.

Leberg Flamme 24 ASD

Leberg boilers are usually referred to as budget models, although there is no noticeable difference in cost with the products of other companies.

The Flamme 24 ASD model has a power of 20 kW, which is optimal for houses of 200 m2. A feature of this boiler is its high efficiency - 96.1%, which is noticeably superior to alternative options.

Works on natural gas, but can be reconfigured to liquefied gas (replacement of burner nozzles is required).

Lemax PRIME-V32

Wall-mounted double-circuit boiler, the power of which allows you to heat 300 m2 of area. It is suitable for two-story cottages, shops, public or office spaces.

Produced in Taganrog, the basic technological principles of assembly were developed by German engineers. The boiler is equipped with a copper heat exchanger providing high heat transfer.

It is calculated on operation in difficult technical conditions.

Navien DELUXE 24K

Korean boiler, the brainchild of the famous company Navien. It belongs to the budget group of equipment, although it demonstrates high performance.

It is equipped with all necessary functions, has a self-diagnosis system and frost protection. The power of the boiler is designed to work in houses up to 240 m2 with a ceiling height of up to 2.7 m.

Mounting method - wall, there is a separate heat exchanger made of stainless steel.

MORA-TOP Meteor PK24KT

Czech double-circuit gas boiler, designed for hanging installation. Designed for heating 220 m2. It has several degrees of protection, blocking in the absence of liquid movement.

It is possible in addition to connect an external water heater, which greatly expands the possibilities of supplying hot water.

Adapted to unstable power supply voltage (permissible fluctuation range is 155-250 V).

Lemax PRIME-V20

Another representative of domestic heat engineering. Wall-mounted double-circuit gas boiler, designed to service 200 m2.

The modulating burner makes it possible to distribute fuel more economically by changing the gas combustion mode depending on the intensity of the coolant circulation. It has a separate stainless steel heat exchanger, can be connected to a room thermostat.

There is a possibility of remote control.

Kentatsu Nobby Smart 24–2CS

Japanese wall mounted gas boiler providing heating of 240 m2 and hot water supply. Model 2CS is equipped with a separate heat exchanger (primary copper, secondary stainless).

The main type of fuel is natural gas, but when changing jets, it can be converted to the use of liquefied gas. Most of the performance characteristics correspond to European boilers of similar power and functionality.

It is possible to use several design options for the chimney.

Oasis RT-20

Wall-mounted double-circuit gas boiler of Russian production. Designed to work in rooms of about 200 m2. Equipped with an efficient copper heat exchanger and a stainless secondary assembly.

The combustion chamber is of a turbocharged type, there is a built-in expansion tank and a condensate trap.

With an optimal set of functions and high build quality, the model has a relatively low price, which ensures its demand and popularity.

Rating TOP-5 wall-mounted double-circuit boilers

Of the huge number of double-circuit wall-mounted boilers, it is worth highlighting:

Buderus Logamax U072-12K

Wall-mounted double-circuit unit, designed specifically for operation in Russian conditions. Able to effectively heat a room with an area of 100-120 square meters. m., as well as provide hot water for a family of 3-4 people.

According to the manufacturer, the boiler can withstand voltage drops from 165 to 240 V, although practice does not confirm this. The unit is equipped with a pre-mix burner that can be adjusted to a specific heating mode.

Main characteristics:

- coolant temperature - 40-82 °;

- hot water temperature - 40-60 °;

- pressure in the heating circuit (max) - 3 bar;

- pressure in the DHW line (max) - 10 bar;

- dimensions - 400/299/700 mm;

- weight - 29 kg.

The boiler is easy to install and quickly set up, as it is sold already prepared for operation.

Navien DELUXE 13K

The Korean company Navien positions itself as a manufacturer of high-quality and inexpensive heat engineering.

The DELUXE 13K boiler with a power of 13 kW is capable of heating an area of up to 130 sq. m., which is suitable for a small house or apartment. The model has a low gas consumption, which is not typical for dual-circuit devices.

Characteristics:

- temperature in the heating circuit - 40-80 °;

- hot water temperature - 30-60 °;

- pressure in the heating circuit (max) - 3 bar;

- pressure in the DHW line (max) - 8 bar;

- dimensions - 440x695x265 mm;

- weight - 28 kg.

Korean boilers are criticized because of the high noise level, but the low price and reliability more than compensate for this shortcoming.

Vaillant turboTEC pro VUW 242/5-3

There is no need to represent Vaillant - one of the leading manufacturers of heat engineering is known to everyone. The Vaillant turboTEC pro VUW 242/5-3 boiler with a power of 24 kW is designed for private homes or medium-sized offices - up to 240 sq.m.

Its capabilities:

- temperature in the heating circuit - 30-85 °;

- hot water temperature - 35-65 °;

- pressure in the heating circuit (max) - 3 bar;

- pressure in the DHW line (max) - 10 bar;

- dimensions - 440x800x338 mm;

- weight - 40 kg.

Vaillant products are rightfully considered one of the benchmarks in terms of quality and durability. Specialists and ordinary users note the reliability and stability of these boilers.

Bosch Gaz 6000W WBN 6000- 12C

Double-circuit gas boiler of convection type. With a power of 12 kW, it is able to heat a room up to 120 sq.m., which is suitable for an apartment, office or small house.

Boiler parameters:

- temperature in the heating circuit - 40-82 °;

- hot water temperature - 35-60 °;

- pressure in the heating circuit (max) - 3 bar;

- pressure in the DHW line (max) - 10 bar;

- dimensions - 400x700x299 mm;

- weight - 32 kg.

Bosch is widely known throughout the world, but recently there has been a noticeable decline in the quality and reliability of its products.

This is due to the dispersion of production, the discrepancy between the parameters and quality of parts, and other organizational reasons.

BAXI LUNA-3 COMFORT 240 i

The brainchild of Italian engineers, the BAXI LUNA-3 COMFORT 240 i boiler has a power of 25 kW. This is suitable for heating rooms up to 250 sq.m.

The copper heat exchanger allows to receive the maximum efficiency of work. The efficiency of the boiler is 92.9%, which is a very high figure for double-circuit models.

Unit parameters:

- temperature in the heating circuit - 30-85 °;

- hot water temperature - 35-65 °;

- pressure in the heating circuit (max) - 3 bar;

- pressure in the DHW line (max) 8 bar;

- dimensions - 450x763x345 mm;

- weight - 38 kg.

The boilers of the Italian company demonstrate high performance and reliability. The only drawback is the low organization of service maintenance.

Wall mounted condensing boilers

The hinged condensing device is a worthy alternative to convection models. Thanks to the improved design, they spend less fuel on space heating, and their efficiency is higher. The only negative is the high price.

1

Protherm lynx 25/30 MKV

Double-circuit with a sufficiently high thermal performance

Characteristics:

- Price - 63 400 rubles

- Customer rating - 5.0

- Max. power - 25 kW

- Efficiency - 104%

- Fuel consumption - 3.2 cubic meters. m/h

It is used for heating houses and apartments with a large area. It is characterized by compact dimensions and low weight - 37 kg.

The device is equipped with an 8 l expansion tank and a modulating burner. Aluminum heat exchanger. The combustion chamber is closed type with the possibility of connection to the chimney. Controlled by touch panel.

Protherm lynx 25/30 MKV is protected from overheating and freezing

Advantages:

- high performance;

- compact dimensions;

- stylish case design;

- clear and convenient control.

Flaws:

price.

2

Vaillant ecoTec plus VU INT IV 346/5-5

Premium condensing unit.

Characteristics:

- Price - 108 320 rubles

- Customer rating - 5.0

- Max. power - 30 kW

- Efficiency - 107%

- Fuel consumption - 3.7 cubic meters. m/h

The model is intended for single-circuit heating of premises.Equipped with stainless steel heat exchanger and closed combustion chamber.

The device is characterized by increased efficiency. With it, you can heat not only residential, but also industrial premises. This is also facilitated by a built-in 10 l expansion tank and a circulation pump.

Vaillant eco Tec plus has an automatic self-diagnosis and emergency shutdown function

Advantages:

- excellent performance;

- remote control;

- capacious expansion tank.

Flaws:

- price;

- the heat exchanger quickly burns;

- no LCD display

- single heating.

3

BAXI LUNA Duo-tec 40

Italian wall-mounted condensing boiler.

Characteristics:

- Price - 79 620 rubles

- Customer rating - 4.7

- Max. power - 32 kW

- Efficiency - 105%

- Fuel consumption - 3.3 cubic meters. m/h

Equipped with a closed combustion chamber and electronic control. It is used for double-circuit heating. The device is also used for floor heating.

The BAXI LUNA Duo-tec 40 model is equipped with a 10 l expansion tank. The device operates from a single-phase electrical network, which does not adversely affect productivity. The model is energy efficient and economical.

Weight BAXI LUNA Duo-tec 40 – 41 kg

Advantages:

- performance;

- energy saving;

- you can heat the floor;

- built-in water filter;

- electronic control panel;

- gas control function.

Flaws:

- price;

- great weight.

TOP 10 Best hoods for the kitchen: built-in kitchen furniture | Rating 2019 + Reviews

Criteria for choosing a gas boiler

As you can see, non-volatile models from different manufacturers are very similar in design and characteristics.Almost all are installed on a parapet or floor, are of the convection type, and have mechanical control.

Single-circuit models differ in that they heat the coolant for only one circuit - the heating one. To additionally connect DHW, you need to purchase a double-circuit boiler or additionally install a boiler

Single-circuit models differ in that they heat the coolant for only one circuit - the heating one. To additionally connect DHW, you need to purchase a double-circuit boiler or additionally install a boiler

There are two subgroups in the rating: with open (OKS) and closed (ZKS) combustion chamber. For residential buildings, models with ZKS are preferable, since the combustion process is carried out through a coaxial chimney, isolated from the air in the room.

For the installation of models with OKZ, a boiler room with a well-established ventilation system is required.

When choosing a model, it is also important to take into account the dependence of the boiler on a stable supply of electricity. Devices stuffed with electronics largely depend on the capabilities and quality of the power supply.

Due to power surges, control boards burn out, sensors often wear out and “fly out”. Therefore, to ensure stable operation, you will have to use a stabilizer. Boilers that operate without being connected to electricity are considered more reliable.

So before buying, you need to pay attention to such characteristics as:

- equipment power;

- gas consumption;

- heat exchanger material;

- boiler dimensions.

The design of modern gas equipment is simple, no frills: more often it is a rectangular design in white or light gray with a control unit in a prominent place.

When buying, we recommend checking how easily the covers are removed to access the main parts - this is necessary for cleaning and maintenance.

Rating TOP-5 floor-standing single-circuit boilers

Consider the most popular models of floor single-circuit boilers:

Protherm Wolf 16 KSO

Convection type gas boiler made in Slovakia. Its feature is energy independence, which allows operation in remote villages or in areas with frequent accidents on the line.

It is equipped with an open type burner, a steel heat exchanger. The power of the unit is suitable for heating a house of 160 square meters. m. and is 16 kW. O

steel specifications:

- Efficiency - 92.5%;

- coolant temperature (max) - 80 °;

- pressure to the heating circuit - 1 Bar;

- gas consumption - 1.9 m3/hour;

- dimensions - 390x745x460 mm;

- weight - 41 kg.

The design of the boiler contains a 2-way heat exchanger, which allows you to increase the amount of liquid that is heated.

This allows you to enhance the natural circulation necessary for the operation of non-volatile installations.

Lemax Premium-20

The concept of Russian manufacturers differs from the Western approach. There, the widest possible opportunities are put at the forefront, but for operation in Russia it is necessary to ensure the reliability and continuity of the process.

Therefore, our manufacturers create mainly non-volatile boilers. The power of this model is 20 kW, allowing you to heat 200 square meters. m. area.

Unit parameters:

- Efficiency - 90%;

- coolant temperature (max) - 90 °;

- pressure to the heating circuit - 3 bar;

- gas consumption - 2.4 m3/hour;

- dimensions - 556x961x470 mm;

- weight - 78 kg.

An additional bonus to the purchase of the boiler will be a long warranty period of 3 years.

Lemax Premium-12.5

Heating floor boiler, manufactured in Taganrog, Demonstrates a power of 12.5 kW. This will heat 125 sq. m. area. This is a non-volatile unit with an atmospheric combustion chamber.

Main characteristics:

- Efficiency - 90%;

- coolant temperature (max) - 90 °;

- pressure to the heating circuit - 3 bar;

- gas consumption - 1.5 m3 / hour;

- dimensions - 416x744x491 mm;

- weight - 55 kg.

All control and protection devices operate on a mechanical principle, which eliminates the possibility of burnout or shutdown.

Lemax Premium-25N

Another product of the plant from Taganrog, with a capacity of 25 kW. This makes it possible to serve a room of 250 sq. m.

Its parameters are:

- Efficiency - 90%;

- coolant temperature (max) - 90 °;

- pressure to the heating circuit - 3 bar;

- gas consumption - 3 m3/hour;

- dimensions - 470x961x556 mm;

- weight - 83 kg.

The characteristics of all Lemax boilers differ little from each other, only in terms of power level and size of units.

MORA-TOP SA 60

Czech floor gas boiler, whose power is 49.9 kW. This is suitable for heating a large room - up to 500 square meters. m.

- Efficiency - 92%;

- coolant temperature (max) - 85 °;

- pressure to the heating circuit - 3 bar;

- gas consumption - 5.8 m3/hour;

- dimensions — 700x845x525 mm

- weight - 208 kg.

This boiler is equipped with a massive cast iron heat exchanger, which gives high efficiency and uniformity of heat transfer.

IMPORTANT!

All models can be used in conjunction with external drives, for which there are appropriate nozzles or a gap connection is used.

Criteria for choosing a gas boiler

One of the most important characteristics of a gas boiler is thermal power. This value shows the maximum amount of heat that the device can give out during the combustion of blue fuel. Power is selected taking into account the heated area. It is generally accepted that for heating 10 sq. m requires 1 kW of thermal energy.However, this ratio is ideal, and since gas boilers have an efficiency of 90-95%, a more powerful unit should be chosen (by about 10-15% of the calculated value).

Floor gas boilers can be single- and double-circuit. If the house has a source of hot water or it is not required every day, then single-circuit models should be preferred. Otherwise, it is more profitable to take a dual-circuit device.

Many modern models must be connected not only to the gas main, but also to a single-phase electrical network. In those settlements where power outages often occur, it is better to install non-volatile models. The only inconvenience will be the manual ignition of the burner, and the connection is made to an open-type heating system with good natural circulation of the coolant.

The main part of the boiler, which experiences extreme loads during operation, is the heat exchanger. The most durable are products made of cast iron. Steel analogues are subject to corrosion, deformation and cracking of the walls often occur. But boilers with steel heat exchangers attract buyers with their affordability.

Some homeowners are interested in universal gas boilers that can run on both natural and liquefied blue fuel.

When buying a gas boiler, you should pay attention to gas consumption. Not always low-power models outperform more efficient competitors in efficiency

It should also be noted that the consumption of natural gas is indicated in cubic meters per hour, and liquefied gas - in kilograms per hour.

According to the control method, there are gas boilers with a mechanical or electronic unit.The mechanics are cheaper and easier to maintain, and the presence of automation allows you to set the desired air temperature in the rooms and no longer interfere with the operation of the boiler.

The most popular manufacturers and their brief description

The leading manufacturers of floor single-circuit boilers are European companies, although domestic designs are optimal for Russian conditions.

The most famous companies are:

- Viessmann. German company, one of the most famous and reliable companies producing heat engineering products;

- Protherm. A Slovak company producing a wide range of heating boilers. All series bear the names of animals of different species;

- Buderus. "Daughter" of the world famous concern Bosh, which fully characterizes the quality and reliability of products;

- Vaillant. Another German company whose boilers are considered the highest quality and most reliable;

- Lemax. Russian manufacturer of non-volatile floor gas boilers. When developing the project, all the features of working in difficult conditions were taken into account;

- Navien. Korean boilers, successfully combining high quality and affordable prices.

You can continue the list of manufacturers for a very long time. All current firms care about the quality and reliability of their products, trying to outperform competitors and cover the maximum number of users.

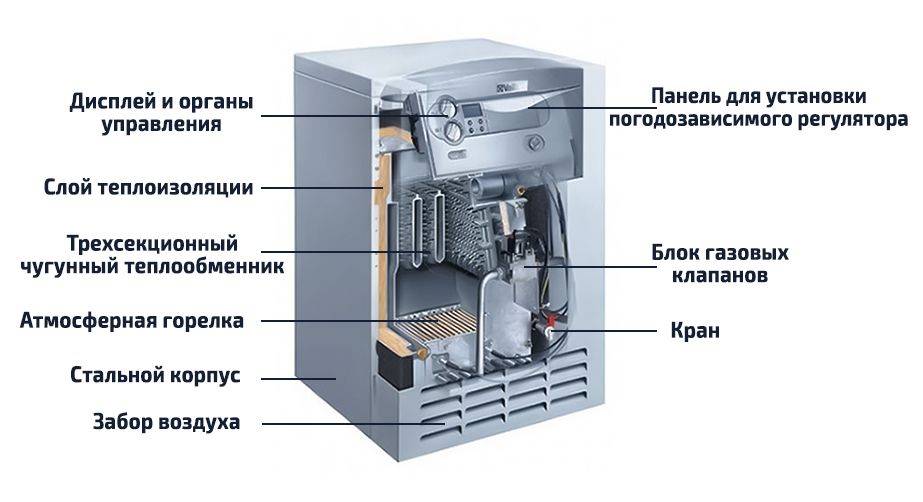

The device of single-circuit gas boilers

The fundamental structure of gas units is of the same type and rather conservative, since their main elements have remained unchanged for several decades:

- A firebox or combustion chamber in which, during combustion, the chemical conversion of gas into thermal energy occurs.

- The burner, usually rectangular in shape, performs the function of creating a gas-air mixture and igniting it, and also contributes to a uniform distribution of the flame throughout the combustion chamber.

- Heat exchanger - serves for the process of heat transfer from combustion products to the coolant.

- The flue system is responsible for removing the products of combustion of gas into the atmosphere.

Despite the fact that structurally single-circuit gas heating boilers are designed for heating, the latest modifications have special pipes for connecting an external indirect heating DHW boiler.

Principle of operation

The operation of a single-circuit boiler occurs when gas is supplied to the burner, where the igniter automatically ignites the gas-air mixture.

In the process of gas combustion, hot flue products of combustion are formed, which wash the heating surfaces of the heating heat exchanger. Heat due to convection and heat transfer is transferred to the heat carrier, which enters the boiler from the return cold heat supply circuit.

The heated network water enters the supply pipeline and is supplied by the circulation pump or by means of natural circulation to the heating devices installed in the room.

Due to convection, the heat from the hot water in the batteries is transferred to the internal air. The cooled coolant is returned through the return line to the boiler for the next heating cycle.

The igniter works constantly and heats the thermocouple of the boiler safety and control system, which controls the operation of the gas valve.Cold flue gases, after they have given up their maximum temperature in the boiler heat exchanger, enter through the gas outlet channels into the chimney and are then released into the atmosphere.

The movement of flue gases occurs naturally: in open-type furnaces - due to the temperature difference between hot and cold flows, or forcibly in closed furnaces, due to the creation of an aerodynamic pressure in the combustion chamber by an air fan.