- Scale buildup inside the heat exchanger

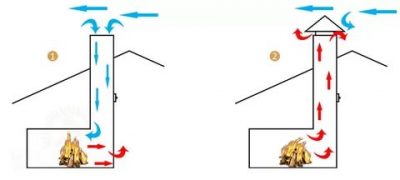

- Chimney (atmospheric) boiler

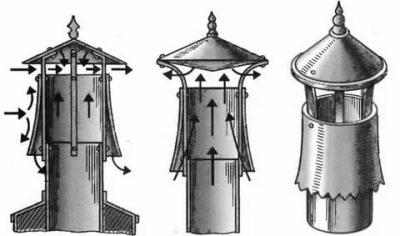

- Installation of "fungus"

- "Break Traction"

- Large chimney diameter

- Chimney diameter reduction

- How to repair the system

- What to do if a gas boiler with a traditional vertical chimney blows out. How to reduce draft in a chimney

- Extension of the height of the outer part of the chimney

- Installing the deflector

- Truncated cone for breaking thrust

- Chimney defects

- Why does back draft occur in the furnace or chimney

- Material selection

- Fight back thrust

- Why the gas boiler blows out: all the reasons

- Installation of a special deflector

- If smoke comes into the room from a gas boiler

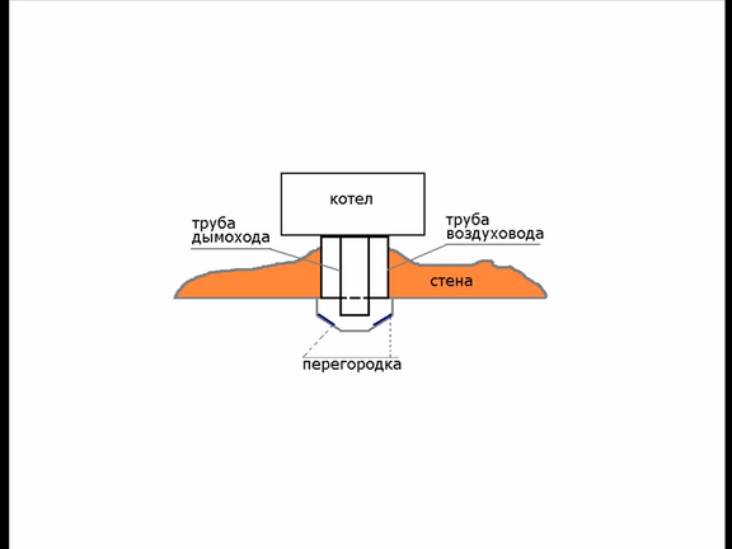

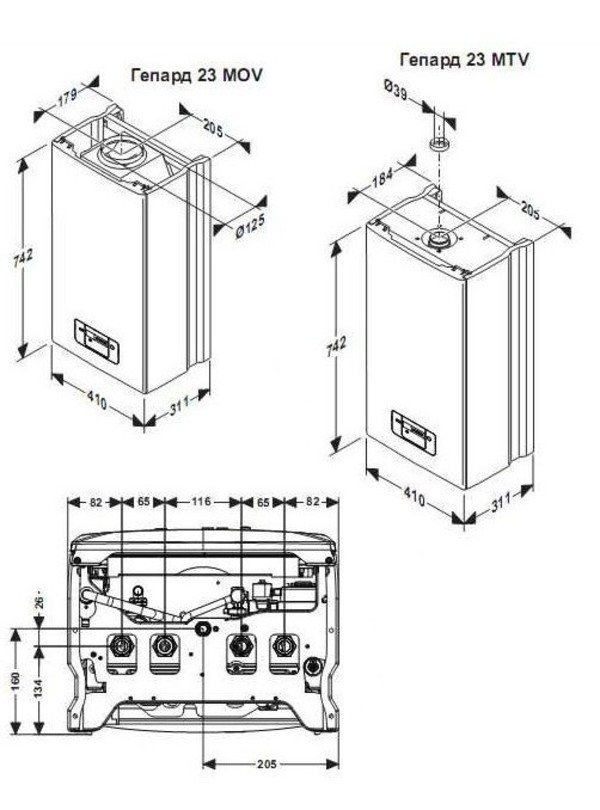

- Closed type turbocharged problems

- Blows the boiler through the chimney: what to do and how to prevent

- Blowing out the flame due to incorrect chimney parameters

- Other causes of blowing out the chimney

- One story building or top floor

- We make sure that the burner goes out precisely from the wind

Scale buildup inside the heat exchanger

The heat exchanger can be clogged not only with combustion products, but also with scale, limescale, which is formed with each portion of water entering the boiler. Scale builds up when hard water is heated.

Inside the heat exchanger, solid salt deposits turn into a kind of insulator that reduces heat transfer from heating.The larger the scale layer in the heat exchanger, the worse the heat transfer from fire to water will be, because. heat will not be able to break through a thick layer of hard deposits. This greatly affects the decrease in the energy efficiency of the entire system and the boiler stops gaining the desired temperature.

To eliminate scale, the heat exchanger must be removed and descaled using a special acid. As a preventive measure, it is recommended to maintain the operating temperature in the boiler.

Among the folk methods of descaling is the use of ordinary table vinegar (3-10% acetic acid solution). Table vinegar is poured in equal proportions with water, the solution is left to interact with scale all night. Also used methods of cationization and reverse osmosis.

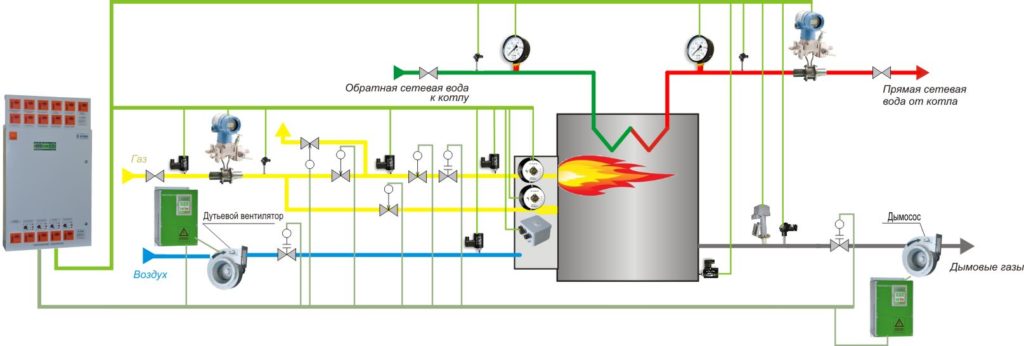

Chimney (atmospheric) boiler

This heating unit runs on natural draft, so the wind can have a significant impact on the combustion process. In the event that there is no draft or the air begins to move in the opposite direction, automatics are activated that stop the gas supply.

If the owners notice that their gas boiler regularly blows out, then they need to establish the cause of this problem. To do this, you must contact the controlling organization, whose specialists will check the operation of the chimney.

Depending on what conclusion the experts come to, it will be possible to start taking measures. Consider what needs to be done so that the boiler stops blowing with the wind.

At the first stage, you need to make sure that the chimney is functioning normally, that there are no blockages in it, as well as ice plugs. If this problem does not exist, then other causes of poor traction must be ruled out.

Installation of "fungus"

Sometimes, in order to solve the problem, such a simple measure as installing a "fungus" on the end of the pipe is enough. This simple device reduces the chance of backdraft. Fungi are of several types:

- in the form of a cone;

- in the form of a ring, larger than the chimney, diameter;

- combined, consisting of a ring and a cone.

Functions of the "fungus":

- dispersion of directed air flow;

- creating turbulences due to which reverse thrust does not develop.

Another solution to the problem may be to increase the height of the chimney to increase the draft force. Sometimes this has to be done after several years of normal operation of the boiler due to an obstacle that has appeared. For example, if a taller building or other high-rise object is built next to the house.

"Break Traction"

In that case, if you increase the height of the chimney impossible, it is worth trying to organize the so-called "traction gap". To do this, a special device is inserted into the pipe, which prevents the formation of reverse thrust.

The simplest version of the device has the shape of a truncated cone, it is installed with the wide end to the boiler. The point of installing such a device is that the air flow that has entered the pipe loses its strength and forms turbulences, since it cannot freely pass through the narrow part of the cone.

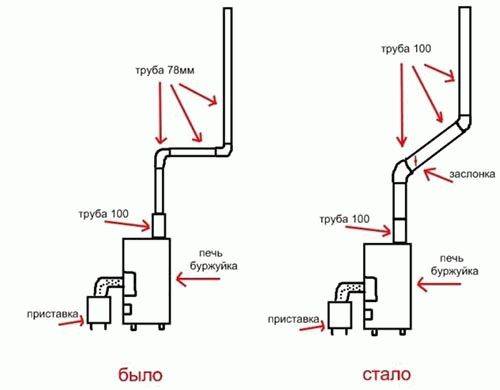

Large chimney diameter

Many believe that the larger the diameter of the chimney, the better the natural draft. But this is a wrong opinion, moreover, too large a diameter of the chimney can cause the burner to be blown out by the wind. Why is this happening? The fact is that in order to create enough traction, three conditions must be met:

- the supply of a sufficient amount of air to the furnace to ensure combustion processes;

- achieving a high temperature in the current for the most complete combustion of the flue gas;

- heating the inner walls of the chimney pipe.

In order to fulfill the latter condition, the inside of the chimney must be assembled from materials with low thermal conductivity. It is clear that the larger the inner diameter of the chimney, the longer it will take to heat them up.

That is, the cause of the poor operation of the boiler can be not only the ingress of air flows into the pipe and the creation of reverse thrust, but also the insufficient forward thrust force, due to the fact that the inner walls of the chimney do not have time to warm up.

To solve this problem, you do not need to disassemble the old chimney, just insert a smaller diameter pipe into it. In this case, the heating of the inner walls will occur much faster, this will increase the forward thrust force.

Chimney diameter reduction

Not in all cases, a large pipe diameter is good for the system. To ensure proper traction, the following conditions must be met:

- the required amount of oxygen in the place where combustion occurs;

- increasing the temperature regime to a level of 600 degrees, necessary for the complete combustion of the gas mixture;

- increase in temperature on the walls of the chimney.

The last point is the most important and is present in systems made of a material with a low level of thermal conductivity, such as brick.

In the case of a large diameter chimney pipe, whatever the material used to build the chimney, it is necessary to heat large volumes of air in order for the walls to begin to heat up.

In addition, a wide pipe allows hot air to mix with its cold stream coming from outside. This slows down the process of heating the walls and the desired level of thrust is not achieved.

The easiest way to make the diameter of the chimney hole smaller is to mount a pipe of the desired diameter inside the existing one. Due to this, heat loss will decrease, and the rate of heating of the walls will increase. As a result, when the device is ignited, the thrust begins to rise very quickly.

It is also worth checking the ventilation system, which can cause a lack of oxygen for combustion consumed by the boiler from the boiler room. To improve ventilation, a slot in the bottom of the door will help.

How to repair the system

Initially, to determine the malfunction of the pump, it is necessary to check the operation of the rotor, for this it is necessary to unscrew the plug nut at the end of the pump. When unrolled, a small amount of water will flow out. Next, you need to insert a screwdriver inside and turn the pump shaft. If there is an accumulation of air in the pump, open the air outlet and bleed it. The air outlet looks like a cap that rises up and rotates around the axis. At the moment of descent, a certain hiss will be heard, as if you deflated a balloon. If all these manipulations did not help, you will have to replace the faulty part with a new one. Since the repair is quite difficult, and the service is not cheap.

What to do if a gas boiler with a traditional vertical chimney blows out. How to reduce draft in a chimney

In older models of gas boilers, such as Don or Aton, and wood-burning stoves, the draft in the chimney could be adjusted using a damper and blower. But in modern models, such devices are not available.

To reduce draft in the chimney of a gas boiler, you need to understand how it works and what affects its operation.

- Chimney height. The more, the stronger the pull. If you reduce the height, then there will be a decrease in traction.

- Section of the chimney pipe. The smaller it is, the less thrust.

- Installing the gate (view). True, the gate is mainly installed on wood-burning stoves.

Modern options with AOGV and AKGV in the floor version are significantly different from older models. When replacing the boiler, changes to the heating system may be required.

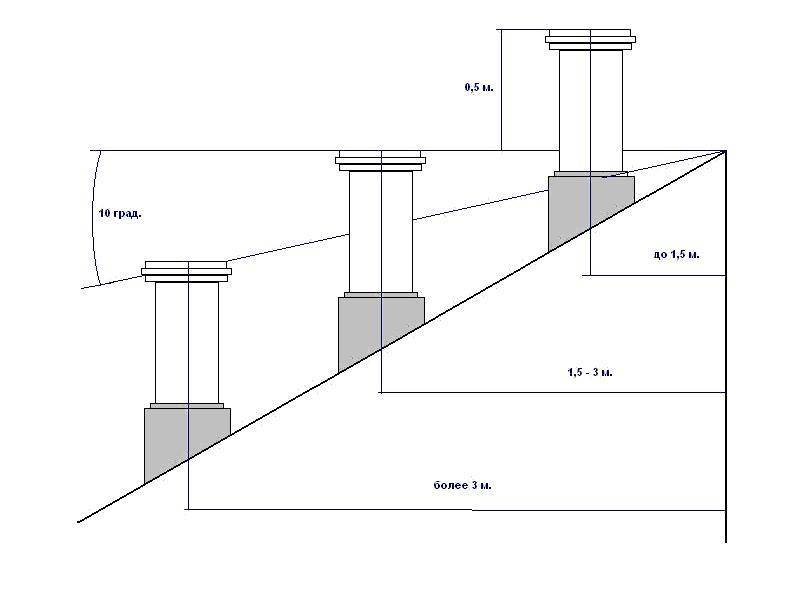

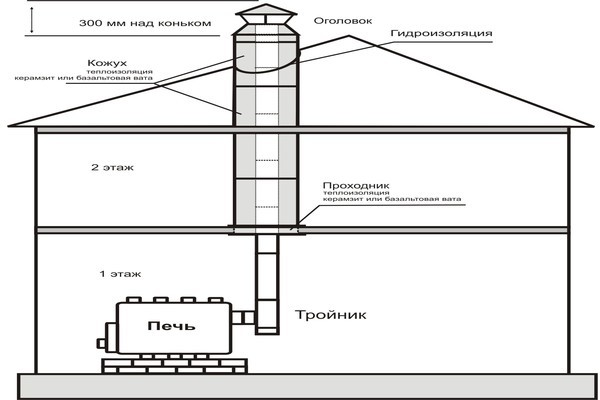

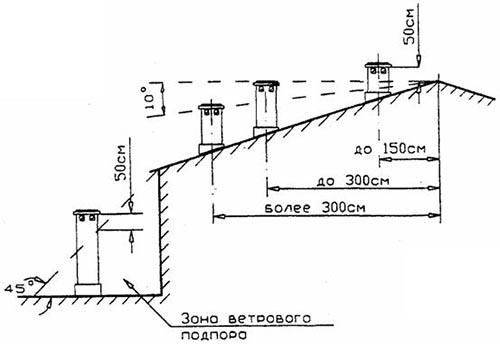

Extension of the height of the outer part of the chimney

This method can be considered the simplest, and at the same time the most effective option. For elimination blowing out a gas boiler in a house, one or more pipes are put on the chimney, which increase the height.

During the construction of a private or country house, the cross section of the chimney and its height are calculated in accordance with SNiP 41-01-2003. The optimal height of the chimney should be 5-6 meters from the level of the grate in the boiler.

But there are additional rules that must be observed for the efficient operation of the boiler:

- If the house has a flat roof, then the chimney must be at least 50 cm above the surface.

- In the case when there is a ridge on the roof and the distance from the ridge to the chimney is less than one and a half meters horizontally, then the chimney should be 50 cm higher.

- If the chimney is located at a distance of one and a half to three meters, then the chimney can be flush with the ridge.

- If the pipe is located more than three meters, its height may be 10 degrees horizontally below the ridge.

Pay attention to nearby buildings and trees. Their location can contribute to turbulence, which will lead to the damping of the gas boiler in strong winds.

You should not approach the increase in the chimney according to the principle: the higher the better. In this case it doesn't work. Too high a chimney can lead to condensation or contribute to excessive draft. Under such conditions, heat will be drawn out and the equipment will have to work in an enhanced mode.

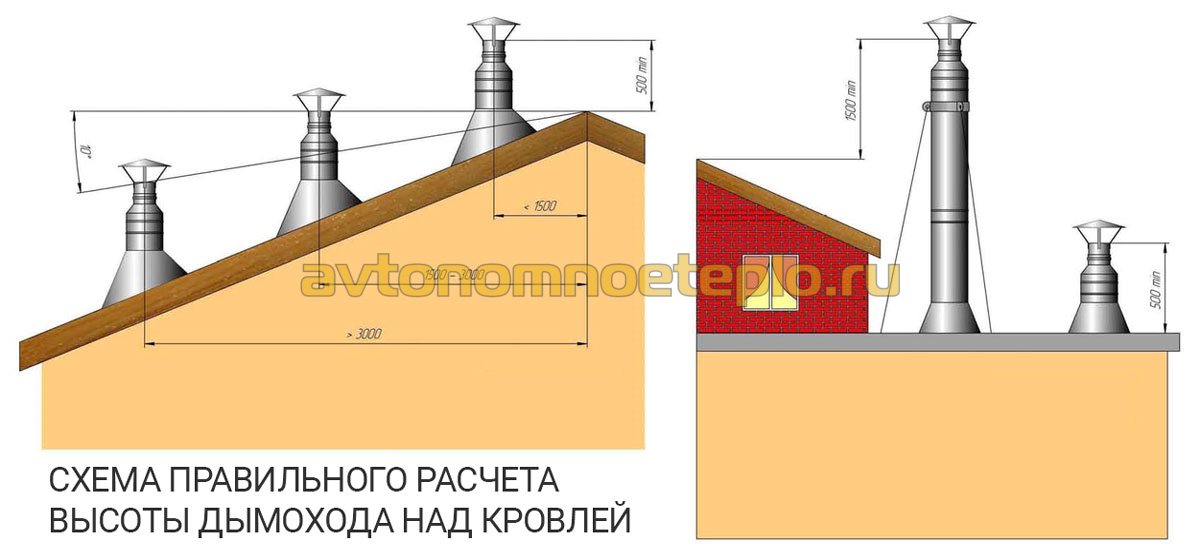

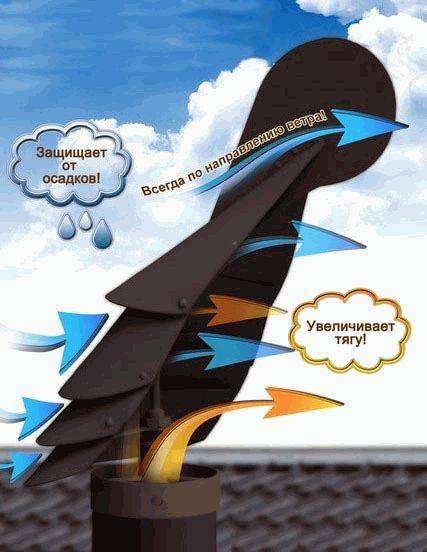

Installing the deflector

A deflector is a special nozzle for a pipe made of stainless steel or galvanized metal. Designed to protect against wind and prevent rain and debris from entering. Additionally, the deflector enhances the draft in the chimney.

There are several types of deflectors, among which the following options can be mentioned:

- Deflector Volpert Grigorovich.

- Tsaga.

- Dynamic turbo deflector.

- Dynamic vane deflector.

Each model is different in appearance and has features. Before choosing a deflector, we recommend that you familiarize yourself with the parameters and study the information about the operation of the product. Creating excess draft can reduce the performance of the boiler, or cause it to work under extreme conditions. Choose a deflector carefully. If there is not enough knowledge or information, it is better to consult a knowledgeable person.

Truncated cone for breaking thrust

The principle of operation of the cone is quite simple. When modernizing the chimney, a truncated cone is inserted inside, which can prevent the occurrence of excessive back draft.The air flow that tries to enter the combustion chamber meets an obstruction and cannot continue to move and affect combustion.

In order not to blow out the gas boiler, you can make and install a truncated cone on your own. But for its manufacture and installation, you must have the appropriate experience. If you do not have it, then it is better to entrust the work to specialists. If installed incorrectly, there is a risk of carbon monoxide build-up. To prevent such a situation, we also recommend checking the installation of the ventilation system.

Chimney defects

Sometimes you can meet errors in the construction of the chimney. Construction rules, requirements and standards are detailed in SNiP 41-01-2003. But even taking into account the existence of standards, many builders violate the following requirements:

- The number of knees is not more than three pieces.

- The length of the branch horizontally is not more than one meter.

- Structural deflection.

If errors are found, we recommend that you talk to representatives of the gas service and, if possible, eliminate the error.

Why does back draft occur in the furnace or chimney

Among the main reasons are the following:

- Incorrect design or installation of the chimney (height, pipe cross-section, the presence of horizontal sections).

- The presence of a standing tall object (tree or building).

- Violation of ventilation.

- Excessive soot emission and clogging of the chimney.

All the reasons for its appearance are conditionally divided into two groups:

- Simple - when it is only a temporary problem. The stove has been inoperative for a long time or the weather has been cold outside.

- Complex - complex, permanent, global, to get rid of which you need to take important steps.These include errors in design or ventilation, high objects near a residential building, clogging of the chimney.

Let's consider each of them with the obligatory mention of the degree of its severity.

The case when mistakes were made at the design stage and affect the operation of the equipped heating system. Major misses include:

- Incorrect calculation of the diameter (cross-section) of the pipe, due to which the channel for the exit of combustion products is too narrow.

- A large number of horizontal (or inclined, but at a low angle) sections in the sleeve, due to which the gas escapes too slowly.

- Insufficient volume of the combustion chamber, due to which harmful combustion products do not have time to completely leave the room. Height.

This is a problem from the category of complex ones, which can only be solved through refinement and restructuring.

From time to time, a situation arises when the design documentation is drawn up correctly, and those who installed the equipment made mistakes. Do-it-yourself assembly is fraught with the following errors:

- Pipes of different sections are used.

- Not all joints are covered.

- There are gaps left.

- The boiler is bad.

Failure to comply with the basic standards during the installation of the chimney leads to the occurrence of reverse thrust.

The work often becomes an explanation of why there is a reverse draft in the chimney, and a simple conclusion can be drawn. Only experienced professionals should be involved in the arrangement of the heating system of a private house, so that later you do not have to redo it, spend money, and risk your health.

Material selection

This point is also key, because if the inner surface of the pipe is rough, the steam particles will linger and go back.If you give preference to metal with low corrosion resistance, it will rust, which will also worsen the circulation of air masses.

We are not talking about the fact that ceramics, bricks, stainless steel differ from each other in terms of thermal conductivity and sealing, which means that there will be different pressure in the channel made from each of them. This is a moment that must be taken into account when designing, so that later you do not have to make difficult decisions and change or redo part of the heating system.

Fight back thrust

Its owner must install it in the place where the chimney pipe breaks. Its narrow end is directed along the movement of hot air. The advantage of this design is the isolation of the flow, due to which its power is significantly reduced.

Before starting the installation of the device, it is necessary to consult a specialist in order to avoid adverse consequences.

Drawing conclusions, we can say that not every serviceability can be solved independently. In some situations, it is best to turn to professionals who can accurately diagnose the problem and provide assistance. Otherwise, with illiterate handling of the device, you will have to buy new equipment.

Why the gas boiler blows out: all the reasons

For private houses, the reason why the boiler goes out is the wind. Which will never happen to residents of high-rise buildings, thanks to the specific design of the duct with insulated internal piping. A gust of wind will not get in to blow out the burner. In a private house, due to the specific ventilation device, this is more common.

There is no way to fix the problem on your own, you will have to contact specialists who, most likely, will offer a complete or partial alteration of them. Because of this, the external flow of air mass exerts pressure on the check valve with great force. It closes and blocks the flow of gas into the furnace. To exclude this, ventilation is reconstructed or the upper rows of the chimney are completed, which is especially important with a low chimney height.

Strengthen the draft, you can periodically clean the ventilation ducts. Intensive combustion may be due to poor saturation of the boiler with oxygen. When a gas boiler blows out, and the reason is not immediately known, and what to do in this case, first of all, it is worth inspecting the heating system.

The boiler itself may be technically defective, although due to its simple design and the increased build quality of modern boilers, it is rarely the cause. Pressure surges during gas supply are rare, and a small decrease in pressure does not contribute to the complete attenuation of the burner. A common reason why a gas boiler blows out if the gas burner blows out periodically is errors in the construction of the chimney.

Installation of a special deflector

To achieve the maximum result when solving the problem of what to do if the boiler goes out in the wind, a deflector of a special design allows - an aerodynamic device installed on the chimney.

In a simple deflector, the main function is performed by the outer part, which is affected by the air flow. At the point of contact of the air flow with the surface, a rarefaction zone is created, which increases the draft in the chimney channel.As a result of using a simple deflector, traction can be increased by 15-20 percent. Therefore, devices with a more complex design will be much more effective.

Complex structures are installed in the case when the use of a conventional deflector does not help solve the problem of blowing the boiler with gusts of wind. From a large number of deflectors of complex design, several types are distinguished, which are most often found in the consumer market:

- Deflector "Smoke tooth".

- Grigorovich deflector.

- Deflector "Voller"

- Deflectors are spherical and rotating.

The leader among the listed options is the Grigorovich deflector, so a little attention can be paid to its device.

This device has a special design, in which every contour and element is directly related to aerodynamics. If a simple deflector installed on a pipe of a private house is made in the form of an umbrella, then the Grigorovich deflector is distinguished by the presence of a direct and reverse cone. Due to their interaction, the necessary movement of air flows is created, as a result of which a zone of low pressure is created around the chimney. The different temperature of the hot and cold air flows greatly increases the draft in the chimney and prevents the penetration of air from outside into the pipe.

Deflectors, which have a complex design, make strong gusts of wind work to increase draft in the chimney. In any case, air masses fall under the lower cone of the deflector and suck in the flow coming from the boiler into the chimney.

The correct location and arrangement of the chimney, combined with a deflector of complex design, allows you to solve the problem of reverse draft.Due to this, gusts of wind of any strength do not blow out the flame of the heating boiler burner, but only increase the draft in the chimney channel, allowing the equipment to work more efficiently.

Particular attention should be paid to the situation when the gas boiler goes out during the wind, and the start of the heating system does not give a positive result. In this case, the cause is an insufficiently heated chimney.

Country houses and cottages are rarely visited, so the heating system does not function for a long time. As a result, the first start-up of the heating boiler does not lead to anything, the burner flame dies out after a short period of time. Many owners are wondering what is the reason for this behavior of gas heating equipment. The fact is that the spent combustion products with great difficulty rise up the cold chimney, and a gust of wind of any intensity does not allow the channel to warm up.

To solve a problem of this type, it is necessary to turn on the boiler at minimum power and warm up the chimney channel. In this case, the power of the device gradually increases to certain values. As a result, the hot stream with the combustion products of the fuel rises naturally.

Of great importance in creating an efficient heating system in a private house are well-executed calculations in the preparation of the project

However, the ventilation system in this case is no less important. Correctly chosen design and high-quality installation of ventilation will ensure uninterrupted operation of heating equipment.

Saving on exhaust and ventilation when deciding what to do so that the boiler does not blow out can give a negative result during operation

Therefore, special attention should be paid to the ventilation system when planning the house, otherwise the aesthetic appearance may turn into discomfort in the winter. There will be a need to re-equip the chimney channel and climb the roof in any frost.

If smoke comes into the room from a gas boiler

A wall-mounted or floor-standing boiler and AOGV can smoke for two main reasons: chimney malfunctions or poor gas quality.

First of all, it is necessary to inspect the chimney and carry out the following work:

Check for traction. This can be done either with a special measuring device, or by bringing a lit match. The flame should noticeably deviate towards the boiler. If this does not happen, then for some reason the chimney does not pull smoke out.

View the pipe with a mirror and a flashlight. If necessary, remove snow and foreign objects. If you can't do it yourself, call a chimney sweep.

If you are heating with raw wood, you need to clean the accumulated tar from time to time.

Replace the chimney with a suitable type and diameter for this model. For example, the Lemax Premium device requires a chimney with a diameter of 200 mm. Increase the length of the pipe; in your house, its end should end above the roof ridge. Outside, insulate it with glass wool.

Check the chimney for cracks

Pay special attention to the connecting seams. Remove right angles when cornering and make transitions smooth.

In the room where the gas boiler is located, a window must be open for air to enter. This is especially true in the cold season in high-rise buildings, where a layer of cold air can prevent combustion products from escaping.

If you are heating with a gas boiler and using cylinders rather than a centralized gas pipeline, it is important to purchase high-quality liquefied gas from trusted manufacturers. This allows you to make the Ross Lux model

Closed type turbocharged problems

Sometimes it happens when installing a new chimneyless apparatus, periodic attenuation of the flame. In this case, you need to check the components and parts. The problem is identified by the following factors:

ignition of the igniter is accompanied by periodic attenuation - this indicates the failure of the thermocouple, which affects the actuation of the valve. It is made in the form of a copper tube with a bimetallic piece at the end. When different metals come into contact, the voltage rises to 20-45 watts. This problem keeps the gas valve open. The thermocouple must be replaced with a new one; it cannot be repaired;

- failure or clogging of the thrust sensor - a flat part is combined with the fuel valve. When the leading contacts close and the burner ignites, ignition occurs - this indicates the need to replace the sensor. Oxidized contact areas can be cleaned with sandpaper with fine abrasives;

- in the event of a malfunction of the circulation pump, it is necessary to carry out a complete diagnosis of the unit and its replacement;

- yellow flame is due to the fact that the jet is clogged. You can clean it if you have experience with gas appliances.

Most of the causes can be eliminated with your own hands, however, this will require some knowledge and a lot of time.

Blows the boiler through the chimney: what to do and how to prevent

Self-construction of a chimney is available to anyone who is at least a little versed in construction and the use of appropriate materials. However, at the same time, mistakes can be made during construction, which will make themselves felt only during operation. So, it can start blowing the boiler through the chimney. What to do in this situation, you can find out by finding out the reasons for this phenomenon.

Blowing out the flame due to incorrect chimney parameters

If the structure is too small or not high enough above the roof, the boiler may blow through the chimney. What to do to prevent such a situation or if the chimney has already been built:

- On a flat roof, provide a pipe height of at least 0.5-1 m.

- With a sloping roof - at least 0.5 m above the level of the ridge.

The chimney pipe must be located at a distance of one and a half meters from the skate

- If there is a parapet, the chimney should not be lower than its level and a couple of meters away from it.

- If the chimney is more than 3 m away from the ridge: visually draw a line at an angle of 10 degrees from the ridge and make sure that the chimney is not below this line.

Drawing of "safe" zones for the chimney. With this arrangement, there will be no blowing

If it was found that the height of the chimney is not up to standard, you can build up the pipe and move the head.

The installed weather vane-deflector will increase traction and eliminate the cause of blowing

Other causes of blowing out the chimney

There are several more problems that could arise with incorrectly selected parameters and contributed to blowing through the chimney:

The pipe section is too narrow or too wide.In the first case, the gases will not escape completely, and in the second, the walls of the structure will not warm up, and the wind will turn into turbulences and will move in the opposite direction.

TIP: To reduce the likelihood of smoke coming through the chimney, you need to carefully insulate the pipes.

The sloping sections of the chimney were inclined more than 30 degrees or were more than 1 meter long. For an open firebox, it is better to create direct-flow vertical chimneys. If it is impossible to comply with such a rule, it is necessary to follow the specified parameters.

Vertical chimneys are more fireproof and easier to operate, as well as reduce the risk of blowing.

- There is not enough air in the structure, from which combustion occurs in the wrong way. This can happen if there is not enough additional supply channel in the chimney.

- If the ridge develops air turbulence at any time and the chimney is on a lee slope, this can cause the chimney to blow out. In this case, installing a deflector will help. It will not only eliminate the problem, but also, due to its design, will contribute to increased traction.

- Blowing the boiler through the chimney may occur after a long period of inactivity. In this case, it is necessary to heat the chimney over a small fire for several hours, and then use the structure to its full potential.

We advise you to study the calculation of the parameters of the chimney in more detail in order to reduce the risk of blowing through the chimney.

How not to make a chimney and how it is recommended

As you can see, some of the problems that contribute to blowing out the boiler can be eliminated without any problems after an incorrectly completed construction, and the other part can be corrected only by foreseeing all the important points when drawing up the drawings.

One story building or top floor

In this case, the easiest way for the wind to get into your boiler. In order to avoid attenuation of the wick in a gas boiler with such a chimney device, it is necessary to protect the chimney head, that is, put special protective devices - washers.

Please note that visors in the form of umbrellas, which can be found on certain houses, are strictly prohibited according to the safety rules of gas supply. This is due to the fact that in the process of melting snow, the resulting water immediately begins to gradually drain and form icicles on a burning chimney.

Thus, the chimney can be completely clogged. Therefore, they put the pucks. They seem to stand around the head of the chimney and thus protect it from the wind.

Another way to protect against attenuation and blowing out of a gas boiler with such a problem is to increase the number of turns of the chimney. If your chimney comes out of the boiler and immediately into the wall, respectively, to get there the wind, it is enough to overcome only one turn. That is, the place of docking of your chimney and boiler.

If you increase the number of turns in your boiler, then it will be much more difficult for the wind to get to your gas boiler and there will be less chance of blowing.

We make sure that the burner goes out precisely from the wind

In order not to waste efforts in vain, which sometimes happens according to practice, it is worthwhile to accurately determine the causes of the burner attenuation, since this can be an automation error, low gas pressure, and difficulties with the removal of combustion products. The characteristic signs of wind blowing are:

- visual change in the shape and direction of the flame caused by the wind;

- the characteristic sound of a vortex in the combustion chamber;

- the burner does not turn off for no reason in calm weather, this item must be checked!

A common cause of damping is low gas pressure in the line or incorrect flame height. At low gas pressure, the flame decreases and drops critically low to the burner. To prevent it from burning out, the automation turns off the burner and the boiler goes out. Values of 2-4 cm are considered normal flame heights. If the height of the burner flame is smaller, it is necessary to adjust it, but we do not recommend doing it yourself, for this it is better to call the gas service.