- Power Generator Rating

- Electric boiler device

- Part required for boilers with electric ignition

- What is a gas burner

- Design features

- Connecting a gasoline generator

- Method number 3 - Homemade stations

- Installation Features

- Minimum power values

- The most worthy models of gasoline current generators by nominations: editorial version Tehno.guru

- The best frame gasoline electric generator for summer cottages according to Tehno.guru

- The smallest of the compact gasoline generators - "Kipor IG2000"

- The quietest gasoline generator: one of the best models - "Caiman Tristar 8510MTXL27"

- Most Popular Models

- The device and manufacture of the gas generator

- Conclusion

- Which generator is better

- Frequently asked Questions

- How is a gas generator for a gas boiler arranged?

- Making an electrode boiler with your own hands

Power Generator Rating

The presence of an electric generator instantly solves the problem of de-energization. Such products are in steadily growing demand, so there are more and more offers on the market. The Expert's Choice project team compiled a list of determining factors for which the top rating was compiled:

- Type of fuel consumed;

- Fuel tank capacity;

- Power in the minimum and maximum rate;

- The quality of the generated current;

- Purpose for use;

- Time of autonomous operation;

- Two- or three-phase view;

- Additional options;

- Size, weight;

- Unpretentiousness in service;

- Reliability of a design and service life;

- Permissible temperature conditions for uninterrupted operation;

- Profitability of consumed current consumption;

- Noise in the active state;

- Protection against moisture, dust, interruptions, overheating.

The expert review included those models that demonstrate the best specified parameters, while their price corresponds to the build quality and functionality. The opinions of experts in this field, positive customer reviews, and test results took part in the collection of information.

The best heat pumps

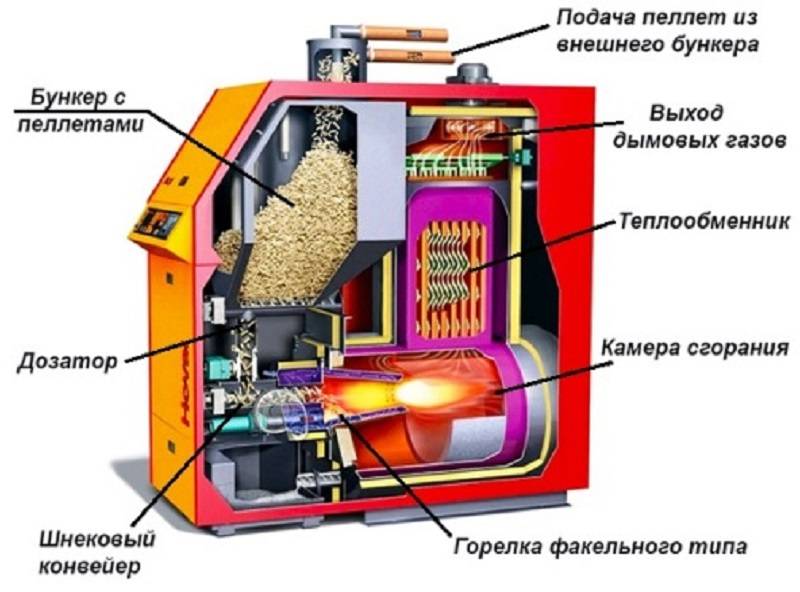

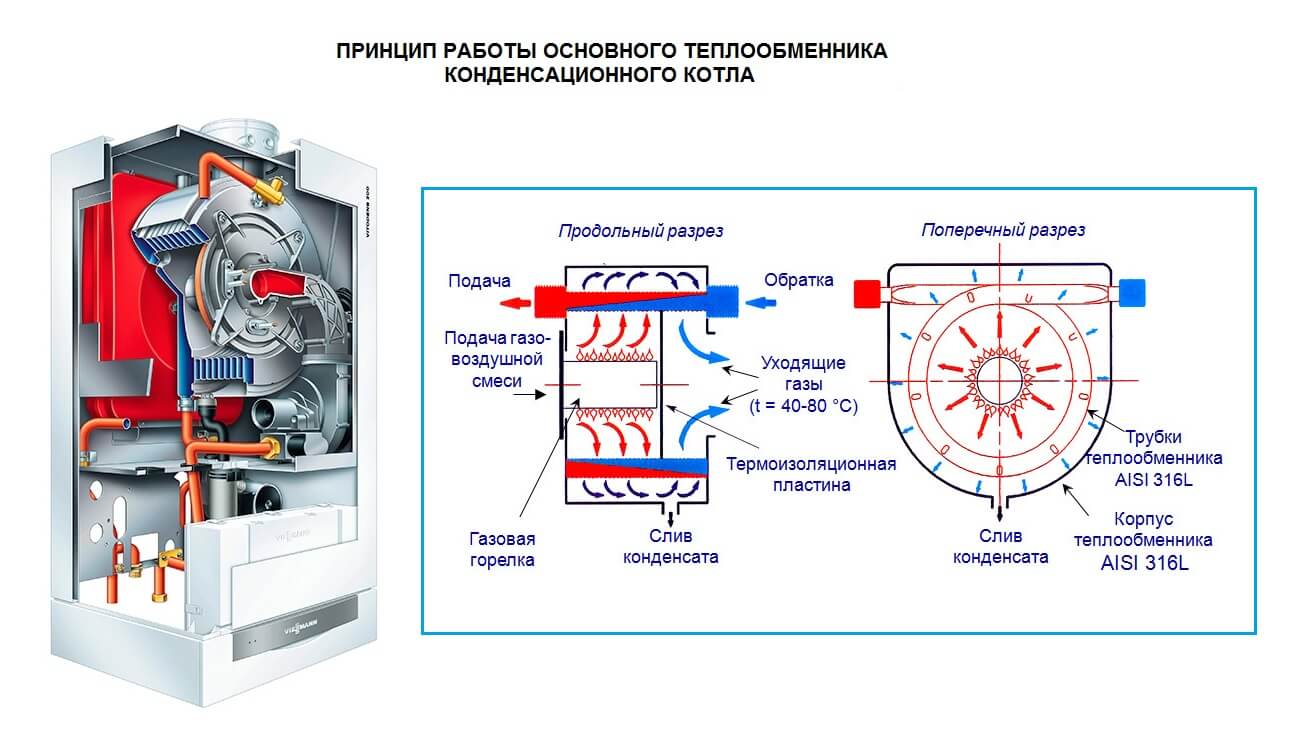

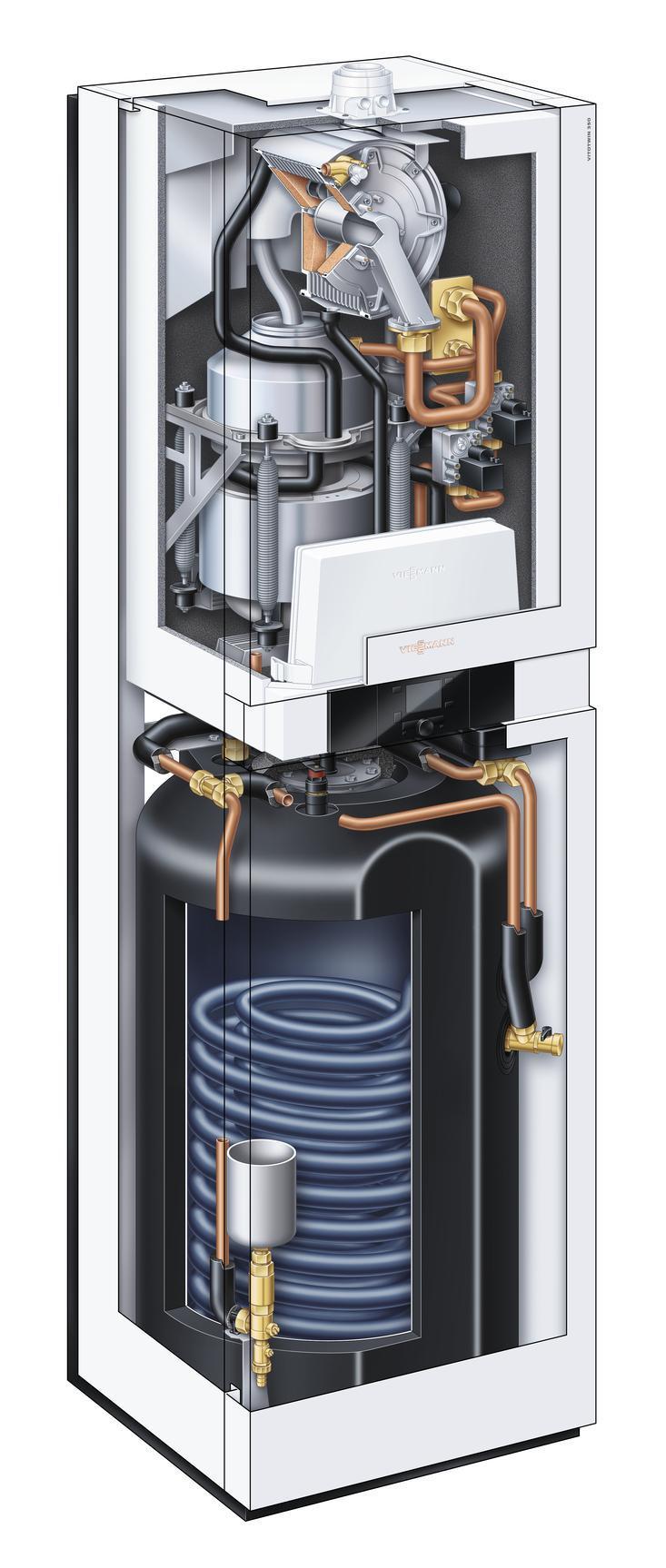

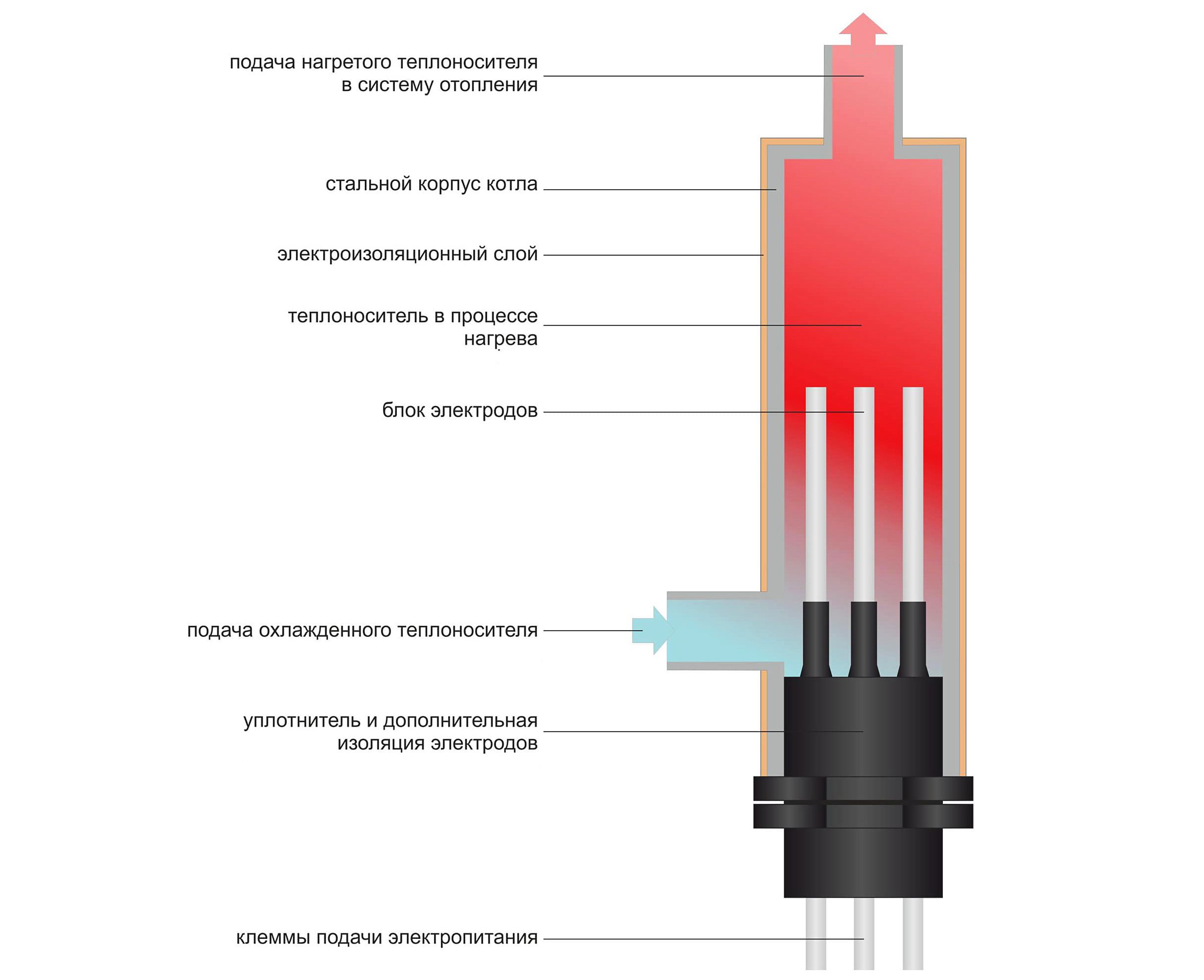

Electric boiler device

In the most general case, the electric boiler device looks like this. There is a steel container with branch pipes for connecting the supply and return pipelines of the heating system. Devices of various designs for heating boiler water are built into it - induction coils, electrodes or heating elements.

Source

They determine the cost of the boiler unit (in descending order). In some cases, thermal insulation of parts of the equipment in contact with heated water, a built-in circulation pump for it, and more are provided. There are necessarily elements of automation (air vents, thermistors, pressure gauges, etc.), protections (against overheating, current leakage) and thermal power control.

Part required for boilers with electric ignition

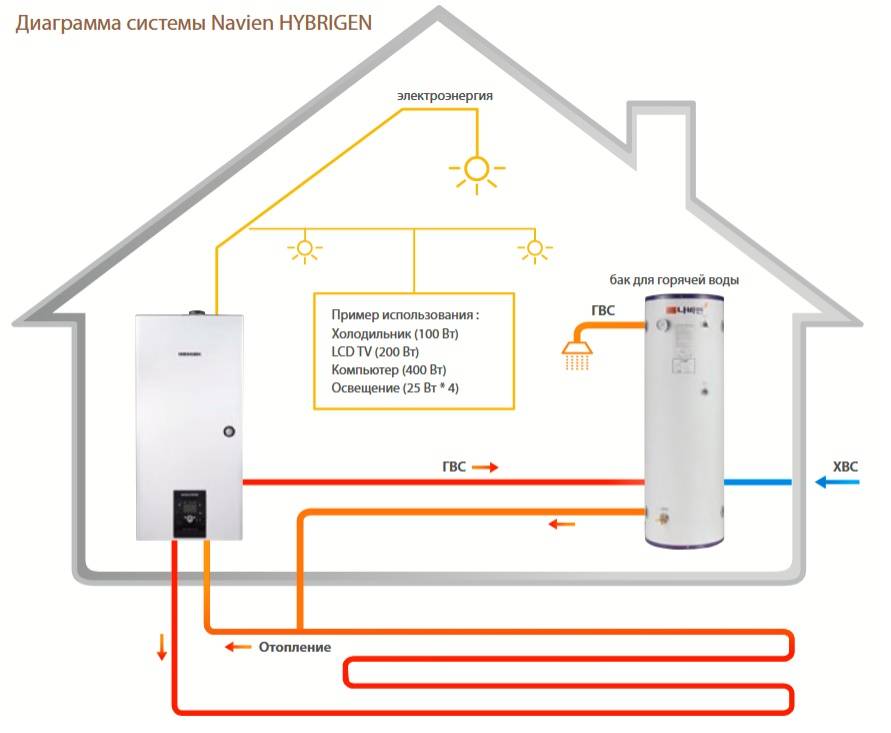

The generator is not mentioned by chance. If we talk about the complete independence of the house from external networks, then this device is one of the elements of its provision.Especially when it comes to country houses located in areas where, for some reason, power outages are possible. In this case, a gas generator will be needed.

The fact is that all boilers according to the connection method are divided into:

- systems with piezo ignition;

- with electronic ignition.

In the first, the flame is kindled manually. But the second, to start work, you need electricity. What to do if it is missing? Naturally, in such cases, the generator saves. It allows you to turn on light bulbs, maintains "life" in the refrigerator, makes it possible to watch TV. He will also start the gas boiler, thereby preventing people from freezing.

The only question is which gas generator will be ideal for a particular heating system. There is a serious problem here, due to the fact that many gasoline generators, no matter what manufacturer they are, are not able to provide high-quality electric current at the output. As you know, automation suffers greatly from voltage drops.

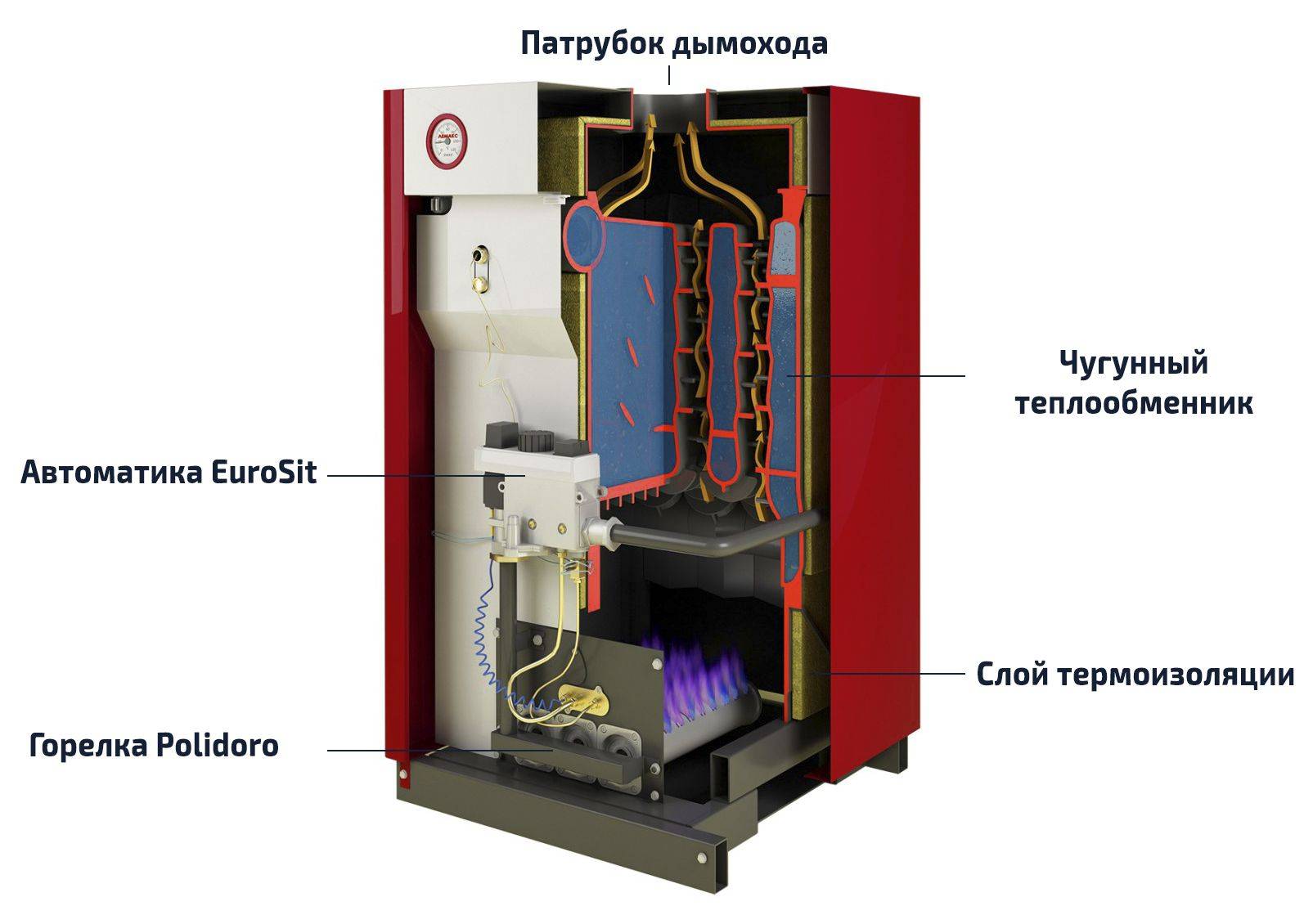

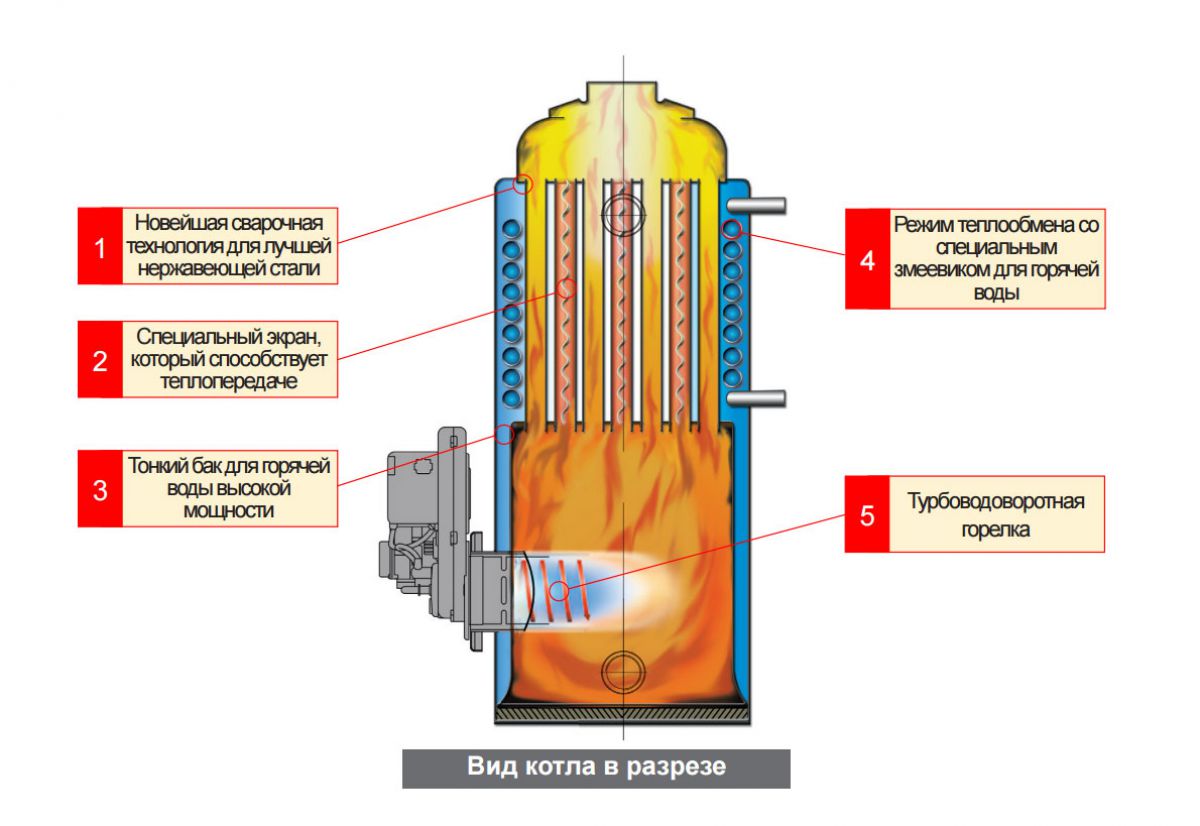

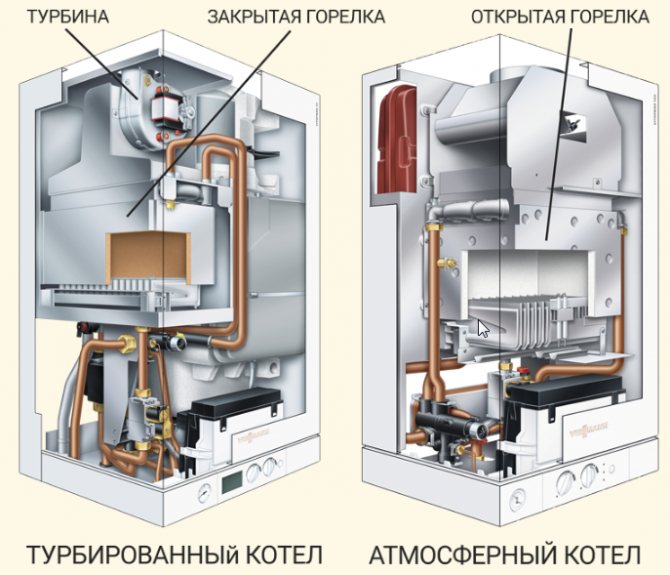

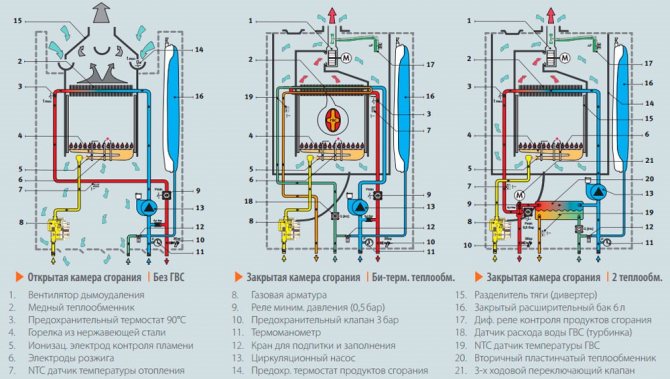

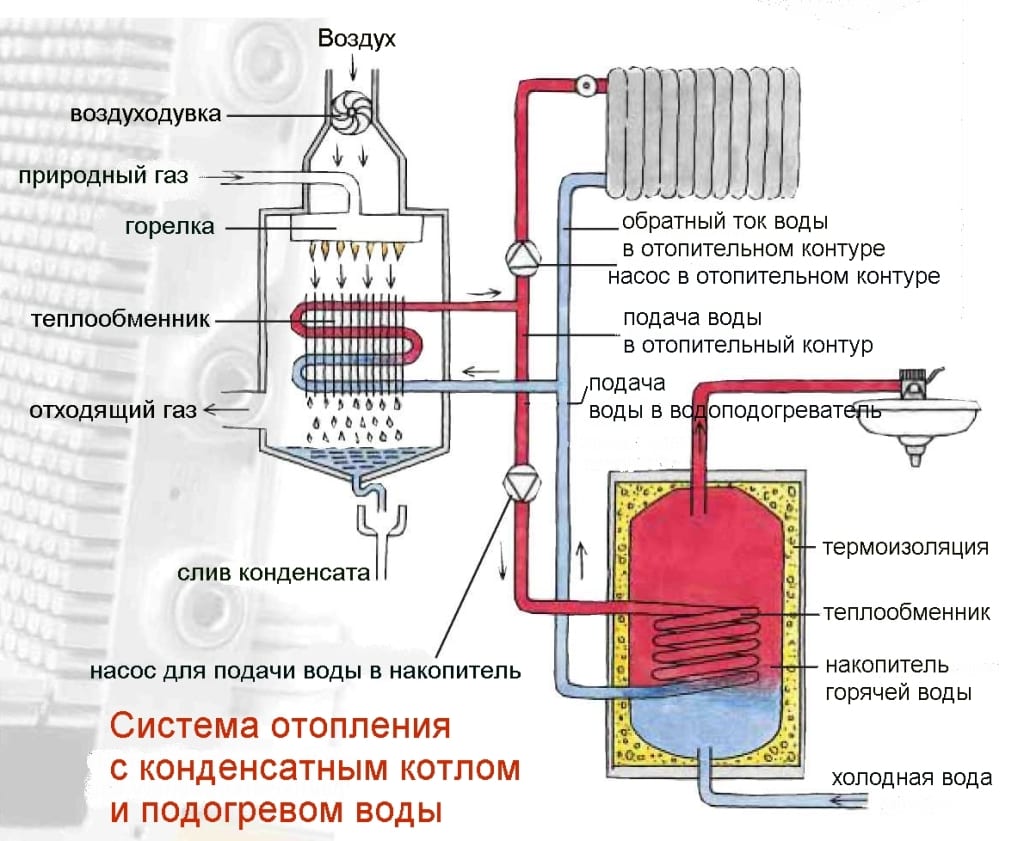

What is a gas burner

A gas burner is one of the most important components of any boiler. She is responsible for creating a sustainable flame. This is where the fuel is burned. The received heat rises up to the heat exchanger, where it almost completely passes into the coolant. Combustion products, together with the remaining heat, are somehow removed into the atmosphere.

The device of a gas burner for a boiler is extremely simple - it includes several main components:

The low emission of nitrogen oxides and carbon monoxide during combustion makes the boiler almost ecologically perfect.

- Nozzle - gas is ejected from here;

- Ignition system - provides gas ignition;

- Automation system - controls the temperature;

- Flame sensor - monitors the presence of fire.

Simply put, this is exactly what it looks like. And how these or those types of gas burners differ from each other in various models of boilers, you will find out a little later.

A modern gas burner for a heating boiler is a device that has certain requirements. First of all, quiet operation is important. I immediately recall some models of Soviet instantaneous water heaters, where the flame was noisy with the force of a hurricane

Modern samples burn relatively quietly (attention is also paid to quiet ignition, without pops and explosions). An additional influence on the noise level is exerted by the design of the combustion chambers. Long service life - if you remember the old gas units, they served for quite a long time (in those days everything was done for centuries)

Today, such technologies no longer exist, so burners in boilers often break. There is only one way out - to buy units from trusted brands, which use components of normal quality. As for any Chinese junk from obscure manufacturers, everything is obvious here - you should not take

Long service life - if you remember the old gas units, they served for quite a long time (in those days everything was done for centuries). Today, such technologies no longer exist, so burners in boilers often break. There is only one way out - to buy units from trusted brands, which use components of normal quality. As for any Chinese junk from obscure manufacturers, everything is obvious here - you should not take it.

The same applies to cheap Russian-made boilers - short-lived burners are often installed in them.

Complete combustion of the gas is another important requirement. The burner for a gas boiler must burn the fuel completely, with a minimum release of carbon monoxide and other related components. However, everything depends not only on it - the quality of combustion is also influenced by other nodes.

We must not forget about proper gas removal, for which you need to have a clean chimney with good draft at your disposal.

As for the principle of operation of a gas burner, it is simple:

However, everything depends not only on it - the quality of combustion is also influenced by other nodes. We must not forget about proper gas removal, for which you need to have a clean chimney with good draft at your disposal.

As for the principle of operation of a gas burner, it is simple:

In the burner, the combusted gas is combined with air. At high temperatures, a chemical reaction occurs with the formation of carbon dioxide and water.

- The boiler fixes the discrepancy between the temperature in the heating circuit and the parameters set by the users;

- The gas valve opens, gas begins to flow into the burner;

- At the same time, the ignition system is activated;

- The gas is ignited and a flame is formed.

At the same time, the control of the presence of a flame begins to work - if the fire suddenly goes out, the automation will cut off the supply of blue fuel. As soon as the temperature in the heating system reaches the set limit, the gas supply will be shut off.

The implementation of flame control is implemented in gas burners in different ways. Somewhere there is a simple thermoelement, and advanced boilers with electronics-based automation are endowed with ionization control systems.

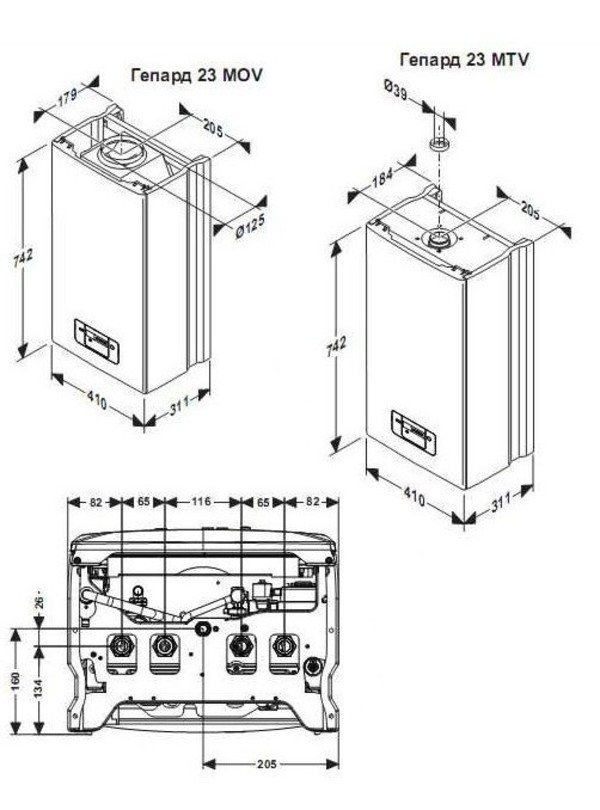

Design features

A double-circuit type heating boiler is distinguished by a simple device, although it performs the function of a mini-boiler room. Both of its circuits can work both separately and in pairs, heating the house and providing hot water at the same time. The considered equipment consists of the following components:

- heat exchanger;

- boiler;

- heating elements;

- expansion tank;

- circulation pump;

- air vent;

- safety valve;

- automation;

- control unit.

Electric double-circuit differ from single-circuit models by the presence of a built-in boiler in the design.

In appearance and the main design features of the model of electric boilers can be:

- wall-mounted - compact and relatively light;

- floor - massive, with a high power index (more than 60 kW).

As the name implies, the heating equipment of the first group is mounted on walls or on specially installed metal frames. The second group of boilers is placed directly on the floor in a specially designated place. It should be noted that modern electric boilers are quite aesthetic and in no way can spoil the interior of the room.

According to the method of heating can be divided into three groups:

- TENovye - highly reliable, having one or more heating elements inside the tank in the form of a metal tube;

- electrode (or ion) - warming up the coolant in the process of passing through the liquid medium of alternating current. They have the ability to self-shutdown in case of a short circuit, a maximum increase in temperature and a decrease in the volume of water to a critical level;

- induction - functioning thanks to inductors. They are energy saving devices.

The first option refers to indirect heating of the coolant, and the second is considered as direct heating.

By power, electric boilers intended for heating needs can be:

- single-phase (up to 12 kW);

- three-phase (more than 12 kW).

It is recommended to select power with the help of specialists, since only they are able to make a competent calculation. The method of choosing a boiler according to the area of \u200b\u200bthe house is incorrect, since in addition to this parameter, a number of others are taken into account (wall thickness, number of openings, orientation to the cardinal points, etc.).

As a rule, household heating units operate from a 220V network.

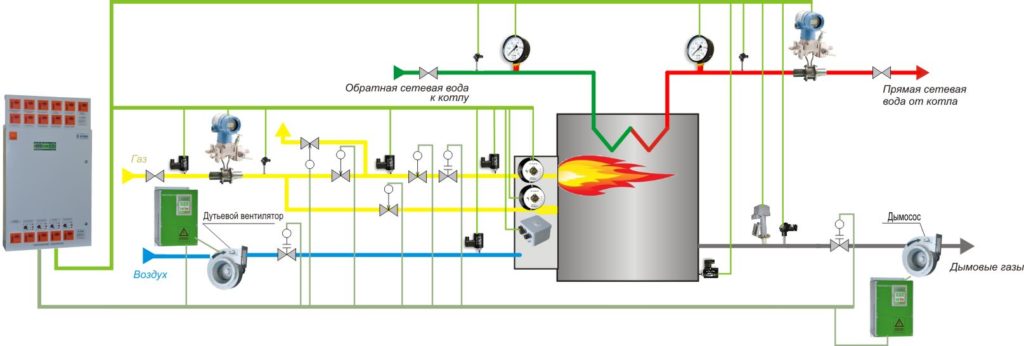

Connecting a gasoline generator

In this process, first of all, it must be taken into account that the device runs on fuel. And after burning it should come out. For this, an extract is created.

There should be free space around the device itself: 1-2 m. This is to provide access to the device for various purposes: refueling, manual start or repair.

Before connecting the unit to the boiler, read the instructions. To connect to the network, a switchboard is used, in which an automatic fuse is arranged.

Both devices must be grounded. You can act according to the standard scheme:

So you guarantee safety and the appearance of zero. These are mandatory conditions, without which the system will not be able to identify the flame, and the boiler will not start.

If the generator is installed for the whole house, then a common network is used to ground it.

In order for both units to function correctly, the output must have a sinusoid of 50 Hz. With other indicators, the boiler will start problematic.IBS can correct the situation.

In general, the algorithm for connecting the generator to the boiler has the following steps:

- Search for the necessary contacts in both devices (the diagram in the instructions helps with this).

- Connecting and insulating wires.

- Grounding of devices.

These operations look simple, well, it is better to trust them to professionals.

Method number 3 - Homemade stations

Also, many craftsmen create home-made stations (usually based on a gas generator), which they then sell.

All this indicates that it is possible to independently make a power plant from improvised means and use it for your own purposes.

Next, consider how you can make the device yourself.

We recommend: Cooling towers of open and closed types: their design, operating modes, photo

Based on thermoelectric generator.

The first option is a power plant based on a Peltier plate. We note right away that a home-made device is only suitable for charging a phone, a flashlight, or for lighting using LED lamps.

For manufacturing you will need:

- A metal case that will play the role of a furnace;

- Peltier plate (sold separately);

- Voltage regulator with installed USB output;

- A heat exchanger or just a fan to provide cooling (you can take a computer cooler).

Making a power plant is very simple:

- We make an oven. We take a metal box (for example, a computer case), unfold it so that the oven does not have a bottom. We make holes in the walls below for air supply. At the top, you can install a grate on which you can place a kettle, etc.

- We mount the plate on the back wall;

- We mount the cooler on top of the plate;

- We connect a voltage regulator to the outputs from the plate, from which we power the cooler, and also draw conclusions for connecting consumers.

POPULAR WITH READERS: What are smart sockets, their types, device and principle of operation

Everything works simply: we kindle firewood, as the plate heats up, electricity will be generated at its terminals, which will be supplied to the voltage regulator. The cooler will also start to work from it, providing cooling of the plate.

It remains only to connect consumers and monitor the combustion process in the stove (toss firewood in a timely manner).

Based on a gas generator.

The second way to make a power plant is to make a gas generator. Such a device is much more difficult to manufacture, but the power output is much greater.

To make it you will need:

- Cylindrical container (for example, a disassembled gas cylinder). It will play the role of a stove, so hatches should be provided for loading fuel and cleaning solid combustion products, as well as an air supply (a fan will be required for forced supply to ensure a better combustion process) and a gas outlet;

- Cooling radiator (can be made in the form of a coil), in which the gas will be cooled;

- Capacity for creating a filter of the "Cyclone" type;

- Capacity for creating a fine gas filter;

- Gasoline generator set (but you can just take any gasoline engine, as well as a conventional 220 V asynchronous electric motor).

After that, everything must be connected into a single structure. From the boiler, gas must flow to the cooling radiator, and then to the Cyclone and the fine filter. And only after that the resulting gas is supplied to the engine.

This is a schematic diagram of the manufacture of a gas generator. Execution can be very different.

For example, it is possible to install a mechanism for the forced supply of solid fuel from a bunker, which, by the way, will also be powered by a generator, as well as various control devices.

Creating a power plant based on the Peltier effect, there will be no special problems, since the circuit is simple. The only thing is that some safety measures should be taken, since the fire in such a stove is practically open.

But when creating a gas generator, many nuances should be taken into account, among them is ensuring tightness at all connections of the system through which the gas passes.

In order for the internal combustion engine to work normally, you should take care of high-quality gas purification (the presence of impurities in it is unacceptable).

The gas generator is a bulky design, so it is necessary to choose the right place for it, as well as ensure normal ventilation if it is installed indoors.

Since such power plants are not new, and they have been manufactured by amateurs for a relatively long time, a lot of reviews have accumulated about them.

Basically, they are all positive. Even a home-made stove with a Peltier element is noted to fully cope with the task. As for gas generators, the installation of such devices even on modern cars can be a good example here, which indicates their effectiveness.

Installation Features

The liquefied gas generator is connected to the cylinder through a special gearbox - this task is not difficult and is carried out by the owners regularly.It is more difficult to connect a stationary unit to the network - only professionals have the right to do this and only according to the results of officially obtained permits. In addition to the presence of a gas pipe, several more important requirements are put forward for the room chosen for the installation of an electric generator.

- Mandatory and good flow ventilation. Promotes better combustion and helps replenish the loss of oxygen in the atmosphere of the home.

- The generator should not be located close to the walls. The room should be large enough so that the device can be walked around from different sides and examined for damage. The owner should be able to get close to the unit from any side - this is a matter of operational safety.

- The room with the gas generator must be equipped with fire extinguishing equipment. With an instant reaction and a successful combination of circumstances, they will help to quickly avoid huge problems.

The following video provides a detailed overview of the Gazlux CC 5000 D gas generator.

Minimum power values

This is the second criterion that deserves close attention (after choosing a standard or inverter version) when you need to buy a generator.

Determining its power is easy. For this, the starting and functional power of all connected devices is added up. A reserve of 20-30% is added to the result.

The minimum power for the operation of the boiler is reflected in its documents. There are also indicators of electricity consumption and power consumption. As a rule, these are parameters in the range of 120-180 watts.Approximately 150 W is required for the circulation pump and the turbine, if it is installed in the boiler.

Calculation example:

One boiler is connected to the generator. Then, for full-fledged work, a minimum of 0.5 - 0.62 watts is required. This is the result of such arithmetic: 120-180 + 150 + 150 + 20-30%. It turns out 504-624 watts.

Today, buyers have the opportunity to purchase devices with parameters of 0.6 - 7 kW. In 90% of situations, this is enough for devices that produce 0.8 - 1 kW. In other cases, the total power of all equipment connected to the generator is calculated.

The most worthy models of gasoline current generators by nominations: editorial version Tehno.guru

It is clear that one generator cannot be the best in everything, so we will take one of the best in the following categories: “best frame gasoline generator”, “quietest gasoline generator”, “smallest gasoline generator”. Consider in passing the opinion of the owners of the models we have chosen. Let's start the analysis of our small rating of gasoline generators presented on Russian shelves.

The best frame gasoline electric generator for summer cottages according to Tehno.guru

"CHAMPION GG6500" is a good model with a rated power of 5 kW (maximum - 5.5 kW). Four-stroke internal combustion engine, 390 cm³ air-cooled. Tank volume - 25 l. A voltmeter, 2 sockets for 220 V and one for 12 V are installed on the case. There is overload protection.

The weight of the device is 85 kg. Users note ease of use and reliability (with proper care and observance of the operating rules established by the manufacturer). Here is one of the reviews about "CHAMPION GG6500".

CHAMPION GG6500

The smallest of the compact gasoline generators - "Kipor IG2000"

A very worthy device, despite the small size and weight. The power, of course, is small, only 1.6kW, but for such a kid it's decent. This is quite enough to illuminate a small country house and watch TV. Of course, he will not pull the electric stove, but this is not required of him if the generator is used only for emergency purposes.

The noise background from a working device is quite low - only 61 dB. And this despite the fact that according to the norms inside the apartment, 40 dB is allowed! This inverter model consumes only 0.6 l / h at a load of 75%. Weight - 22 kg, dimensions - 515 × 300 × 430 mm. We offer you to get acquainted with the opinion of one of the owners about this model.

Gasoline generator Kipor IG1000

The quietest gasoline generator: one of the best models - "Caiman Tristar 8510MTXL27"

No matter how surprising it may sound, the three-phase generator is becoming the quietest model today. current power 6 kW. Such a device is quite enough to provide a two-story cottage and a home workshop with electricity continuously for 13 hours in sufficient quantities. At the same time, the noise level during operation of the device will be only 45 dB. This means that even if the device is placed under the window, the noise of the motor will not disturb the neighbors.

The weight of the generator is 99 kg, which is quite a lot. The engine "Robin Subaru EH 41 DH" with a volume of 404 cm3 and a flow rate of 2.1 l / h was installed. Tank volume - 27 l. In addition to standard overload protection, two sockets (220V and 380V), you can optionally add a transport trolley, an electric starter, and a voltage regulator.

Caiman Tristar 8510MTXL27

Most Popular Models

An efficient outdoor unit is a non-volatile boiler Protherm Volk 16 KSO, which belongs to the category of budget equipment. The power is 16 kW. That is, in the presence of high-quality insulation and energy-efficient windows, the device provides heating for a house up to 150 m². At the same time, it has a high efficiency at the level of 92.5% - boilers with a large indicator are rare.

The gas flow rate is 1.9 m³/h, which is considered acceptable for this type of equipment. The model is equipped with a traction stabilizer. It operates almost silently, is distinguished by ease of installation and control, despite the fact that the simplest standard mechanical elements are installed.

The device has a high efficiency of 88%, while it consumes little fuel and works with the maximum level of safety. The unit is equipped with modern automation that protects against overheating and gas leakage. The durable and strong pig-iron heat exchanger is characteristic.

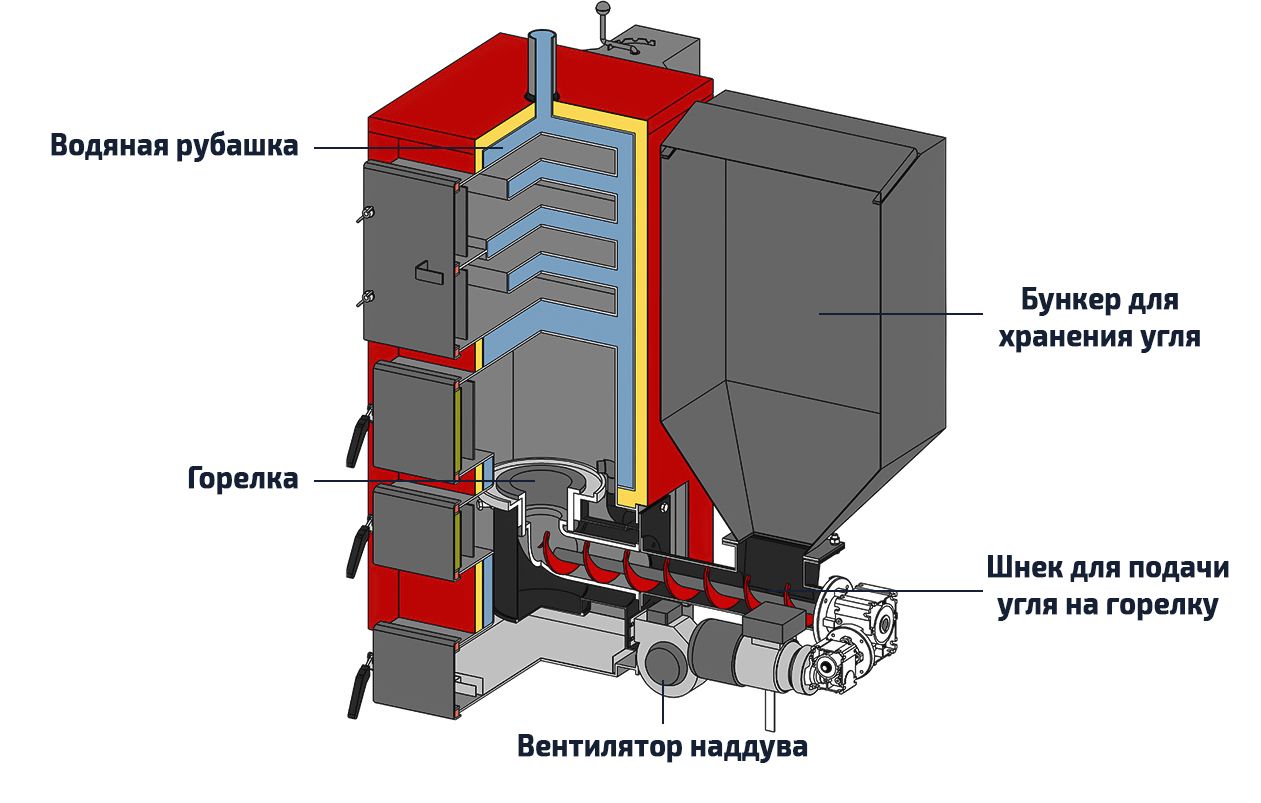

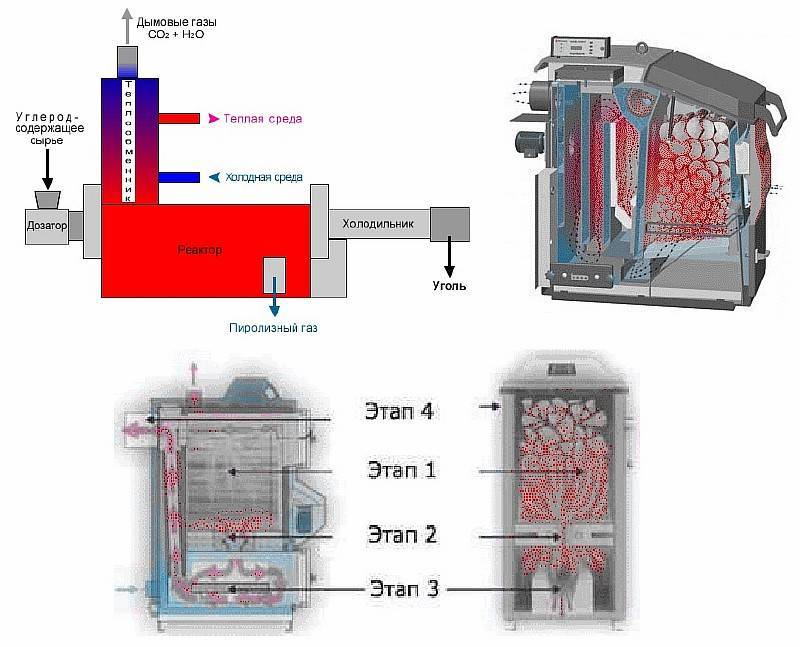

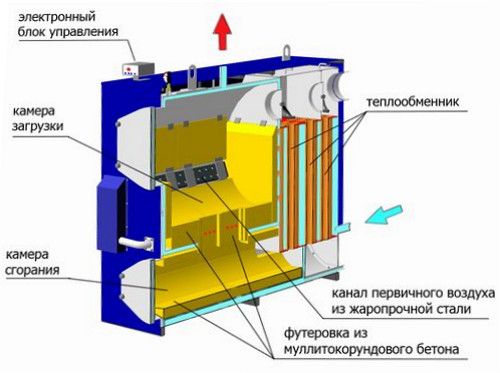

The device and manufacture of the gas generator

Let us consider in more detail the device of the gas generator. In addition to the case, inside which is located the main part of the elements, the design includes:

- bunker (chamber for loading fuel);

- combustion chamber (this is where the process of smoldering of wood takes place at high temperatures and with a minimum air supply);

- the neck of the combustion chamber (here cracking of resins occurs);

- air distribution box equipped with a check valve;

- lances (calibration holes, due to which the junction box communicates with the middle part of the combustion chamber);

- grate (serves as a support for smoldering fuel);

- loading hatches equipped with sealed covers (the hatches in the upper part are required for loading fuel, in the lower part - for cleaning the unit from accumulated ash);

- outlet pipe (flammable gas exits through it and enters the welded pipe of the gas pipeline);

- air cooler (in the form of a coil);

- filters for cleaning the mixture of gases from unnecessary impurities.

The gas generator circuit may include a fuel drying system. For pyrolysis to be effective, the firewood must be dry. If a part of the gas pipeline runs along the ring around the fuel loading chamber (between the walls of this chamber and the housing), damp firewood will have time to dry before it enters the combustion chamber. This will significantly increase the efficiency of the installation.

The body of the gas generator is made of a metal barrel, on top of which a pipe is attached to the seal with corners and bolts, and a propane cylinder is attached to the bolts from the inside

Before you make a gas generator, you need to find information about a suitable device model and detailed drawings indicating the dimensions of all elements.

Particular attention is paid to the choice of materials for each of the structural elements. The gas generator can have a rectangular or cylindrical shape - the body is usually welded from sheet metal or a metal barrel is used

The bottom and cover must be made of steel sheet with a thickness of 5 mm.

The hopper, which is bolted inside the hull, shall be made of mild steel. The combustion chamber is made of heat-resistant steel, you can use an empty bottle of liquefied propane.

The gas cylinder is installed inside the barrel and bolted to its top.

The lid of the bunker should be equipped with a reliable seal made of heat-resistant material (asbestos cord with graphite lubricant).Between combustion chamber neck and the body is laid with a refractory insulator (asbestos cord or material of similar properties). It is more convenient to make the metal grate of the grates removable, from reinforcing bars, so that it is more convenient to clean the combustion chamber.

A pipe is attached to the bolts on top of the barrel

The air distribution box with a non-return valve at the outlet is installed outside the housing, in front of it you can mount a fan that blows air to increase the efficiency of the unit when working on freshly cut wood.

Blower fan to help improve efficiency

As an air cooling coil, some craftsmen fit a steel or bimetallic radiator. The mixer, passing through which the purified combustible gas is mixed with air, is equipped with a fan.

When choosing materials for a fixed installation designed to generate electricity for domestic use, the emphasis is on reliability and affordability. If you want to make a gas generator for a car, preference should be given to stainless steel - this will make the unit lighter and more compact. But the use of stainless steel significantly increases the cost of construction.

Conclusion

The compact wood-fired gas generator is suitable for installation on a truck or car. The unit for a local power plant can be installed in the basement of a house, in an outbuilding, or, if necessary, installed on the street or under a canopy (when it is necessary to provide electricity to any stationary electrical equipment).

The fundamental issue is the correct operation of the gas generator.In order for the unit to function with high efficiency, it is necessary to carefully adjust the level of air supply (taking into account the moisture content of the fuel), the intensity of the exhaust gases, etc. It is desirable to manufacture a gas generator according to professional drawings, in compliance with all sizes and proportions.

Related video:

Which generator is better

Each nominee presented in the review demonstrates high build quality, decent technical characteristics, and performance. But in order to decide which electric generator to buy for the home, they rely on personal requests, conditions for further operation, and financial capabilities. Comparative analysis of parameters, test results, owner reviews showed:

- Hyundai HHY 7020FE ATS (5000 W) - long continuous operation, high reliability;

- Denzel GE8900 (7000 W) - the best ratio of compactness to performance;

- Bison ZIG-3500 (3000 W) - the best price, compatibility with gas boilers;

- Patriot GP 1000i (700 W) - ultra compact, quiet model with minimal weight;

- Hyundai DHY-6000 SE (5000 W) - a professional device with a total control system;

- Daewoo Power Products DDAE 10000SE (7200 W) - the highest performance;

- Generac 6520 (5000 W) is an original station with an informative display and light indication.

In addition to functional, high-quality characteristics, the portal advises not to forget about the need for regular maintenance. We are talking about changing the oil, cleaning the air filter, regular replenishment of fuel. If you carelessly treat such requirements, any device will shorten its service life.

Frequently asked Questions

Some manufacturers have generator power in kVA, others in kW.What does this mean and how to correctly compare these characteristics when choosing a generator?

Kilovolt-amperes (kVA) refers to the apparent power of the generator. Apparent power consists of active power (kilowatts - kW) and reactive power (kilovolt-amps reactive-kvar). For the consumer, active power matters. The power ratio depends on the load. For domestic calculations, we can assume that the active power of the generator is 0.8 of the total power. Can be taken as a rule for translation: “kW=0.8*kVA”

And yet, do not forget that the generator power should exceed 20-30% of the total power of consumers. Firstly, it will increase the service life of the generator. Secondly, you will be able to avoid turning off the generator when consumers are turned on, with a power commensurate with the generator.

What to look for when choosing a low-power gas generator?

Make sure that the engine is at least 40% more powerful than the alternator. A 3 kVA alternator requires a motor with a nameplate rating of at least 4.5 kW (6.2 hp). Otherwise, already at the rated load on the network, the engine will work for wear; in this case, large starting currents (grinder without soft start) and sudden load cuts (electric kettle) will have an even stronger effect.

I do not overload the generator, I do not violate the terms of maintenance. What else can be done to keep the generator running as long as possible?

It is extremely important to compare the power of the generator with the power of the load to be disconnected. Example: abruptly disconnecting a 2 kW stove from the network fed by a 3 kVA generator, you provoke a power surge

Which will affect both the gadgets charged along the way, and the "stuffing" of the alternator.

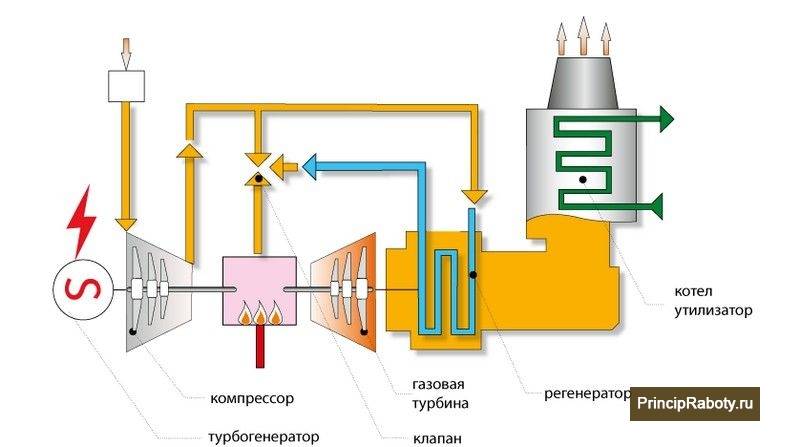

How is a gas generator for a gas boiler arranged?

In the event of a power failure, the boiler automation switches off the burner. The design of the gas valve is designed in such a way that due to the current passing through the coil, it is squeezed out. If there is no current, the valve closes.

In our country, power outages are not uncommon, so even if there is gas in the mains, the owners of gas boilers have to sit in a cold house. A gas generator will help solve the problem, which transforms thermal energy into electricity.

The indisputable advantage of a gas generator is its economical fuel consumption, due to which it is much more often chosen as a backup energy source for autonomous heating circuits.

The indisputable advantage of a gas generator is its economical fuel consumption, due to which it is much more often chosen as a backup energy source for autonomous heating circuits.

The equipment runs on liquid fuel (gasoline). The generator supports the uninterrupted operation of electrical appliances, in particular the electronics of a gas boiler. Its power is enough to provide electricity to a small one-story house.

The unit can be equipped with an automatic start system. Since a domestic gas boiler consumes a small amount of electricity, there is no need to purchase a powerful generator.

Such equipment is small and weighs up to 50 kg. Depending on the design, in emergency situations, the device is able to generate energy for up to 4-8 hours.

Making an electrode boiler with your own hands

To assemble an ion boiler with your own hands, you need: a pipe, an electrode, hot metal.

If you have become familiar with the principle of operation of ion boilers, as well as the features of their operation, and still want to make it yourself, then you will need:

- welding machine and skills to work with it;

- steel pipe of the required dimensions;

- an electrode or group of electrodes;

- neutral wire and ground terminals;

- insulators for terminals and electrodes;

- coupling and metal tee

- desire and perseverance in achieving the ultimate goal.

Before you start assembling the boiler with your own hands, you should pay attention to several important points. First, the boiler must be grounded. Secondly, the neutral wire from the socket is fed exclusively to the outer pipe

And thirdly, the phase must be supplied exclusively to the electrode

Secondly, the neutral wire from the outlet is fed exclusively to the outer pipe. And thirdly, the phase must be supplied exclusively to the electrode.

The do-it-yourself boiler assembly technology is quite simple. Inside a steel pipe with a length of about 250 mm and a diameter of 50-100 mm, an electrode or an electrode block is inserted from one side by means of a tee. Through the tee, the coolant will enter or exit. The other side of the pipe is equipped with a coupling for connecting the heating pipe.

An insulator is placed between the tee and the electrode, which will also ensure the tightness of the boiler. The insulator is made of any suitable heat-resistant plastic. Since it is necessary to ensure tightness and at the same time the possibility of a threaded connection with a tee and an electrode, it is better to order an insulator in a turning workshop in order to withstand all design dimensions.

A bolt is welded onto the boiler body, to which the neutral wire terminal and grounding are attached. It is possible to secure with one more bolt. The entire structure can be hidden under a decorative coating, which will also serve as an additional guarantee of the absence of electric shocks. Restricting access to the boiler is the first and most important task to comply with safety regulations.