- Materials and tools

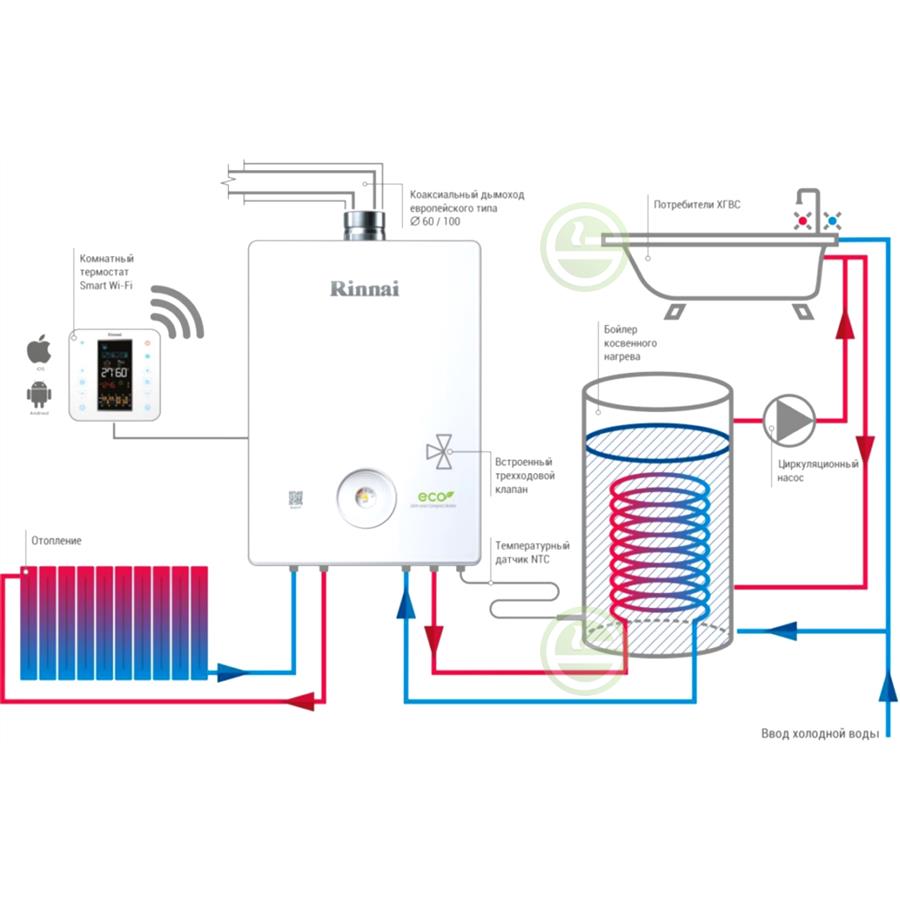

- Installation process: how to connect

- Startup and verification

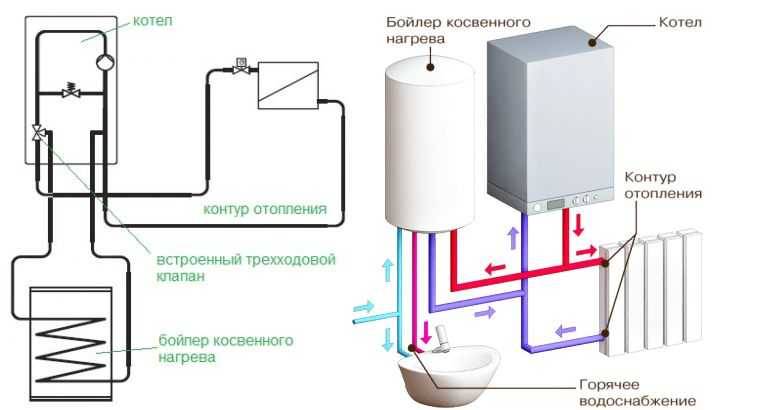

- Two in one. Gas boiler with boiler

- Possibility to connect a boiler

- Heater power

- Features of layer-by-layer heating of a liquid

- Types

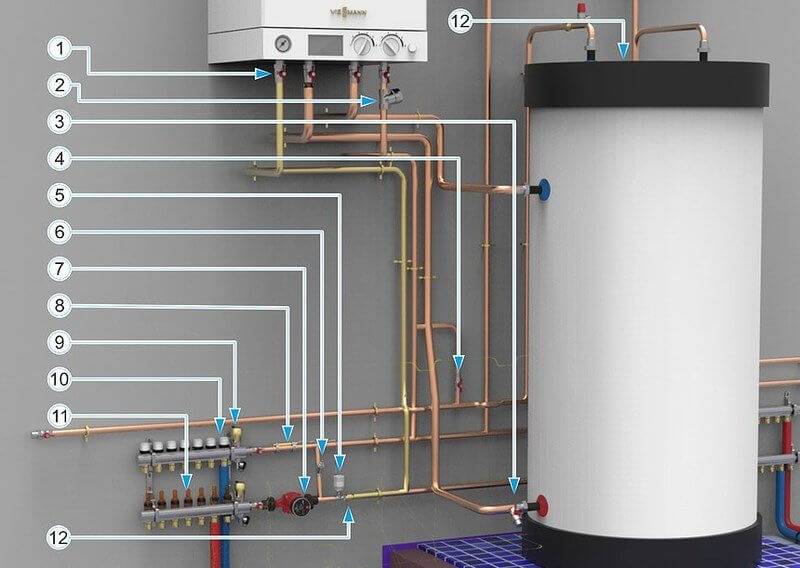

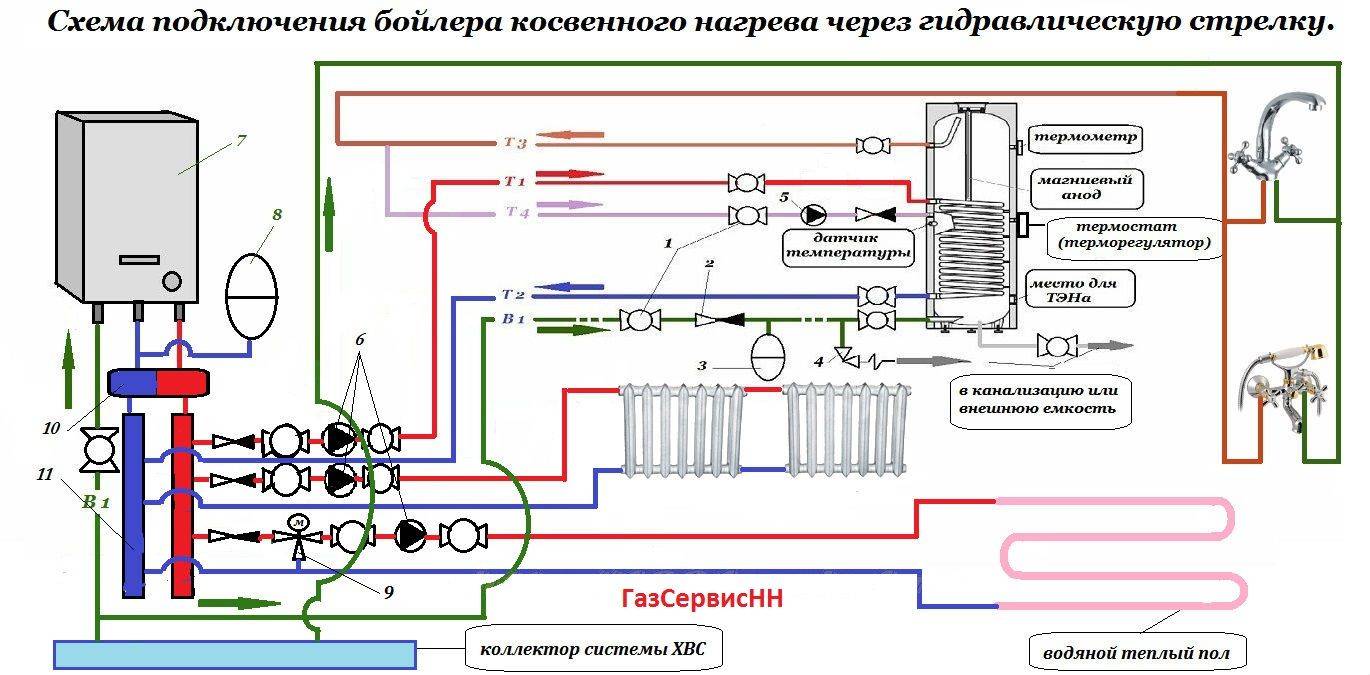

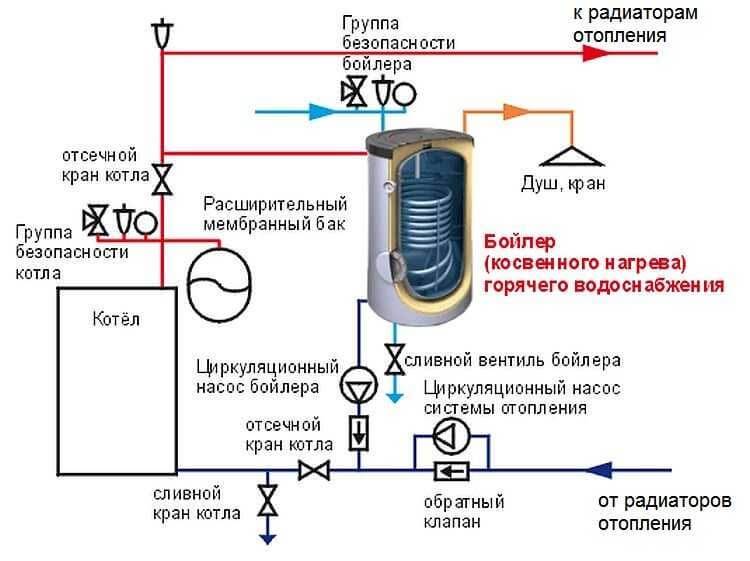

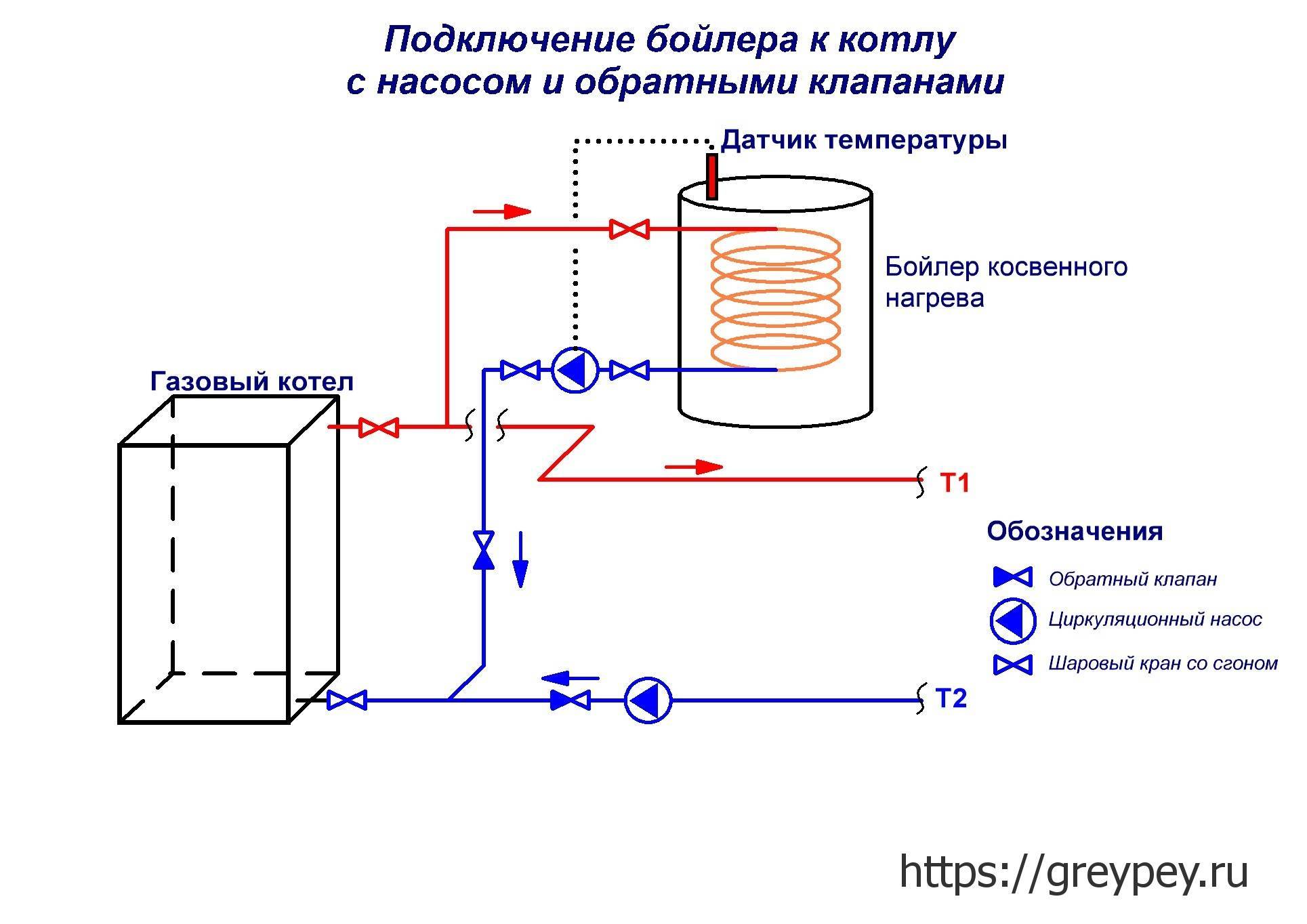

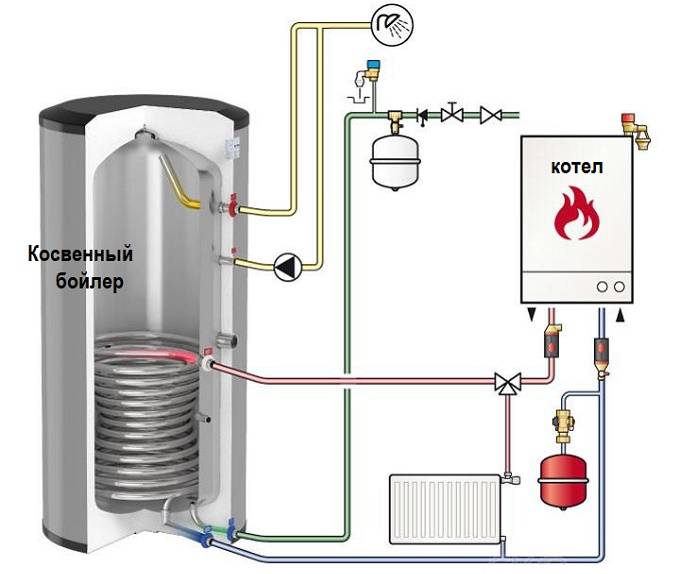

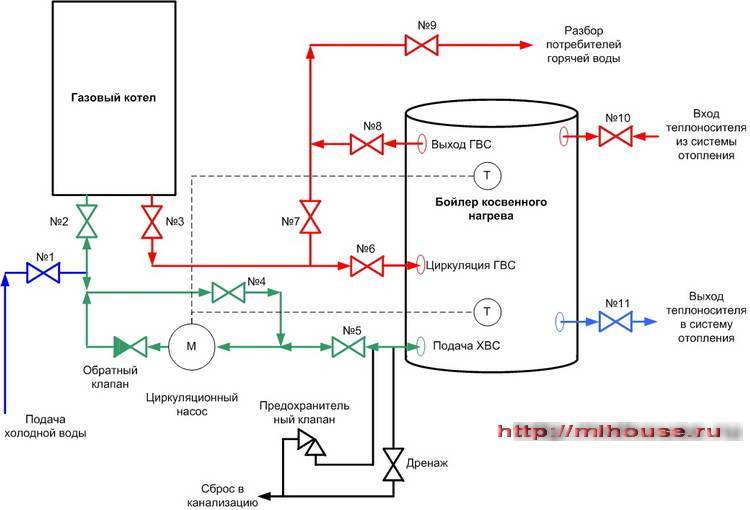

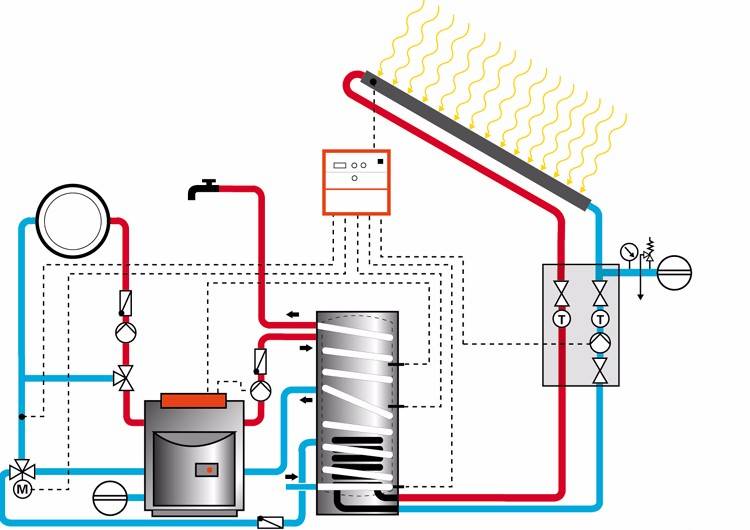

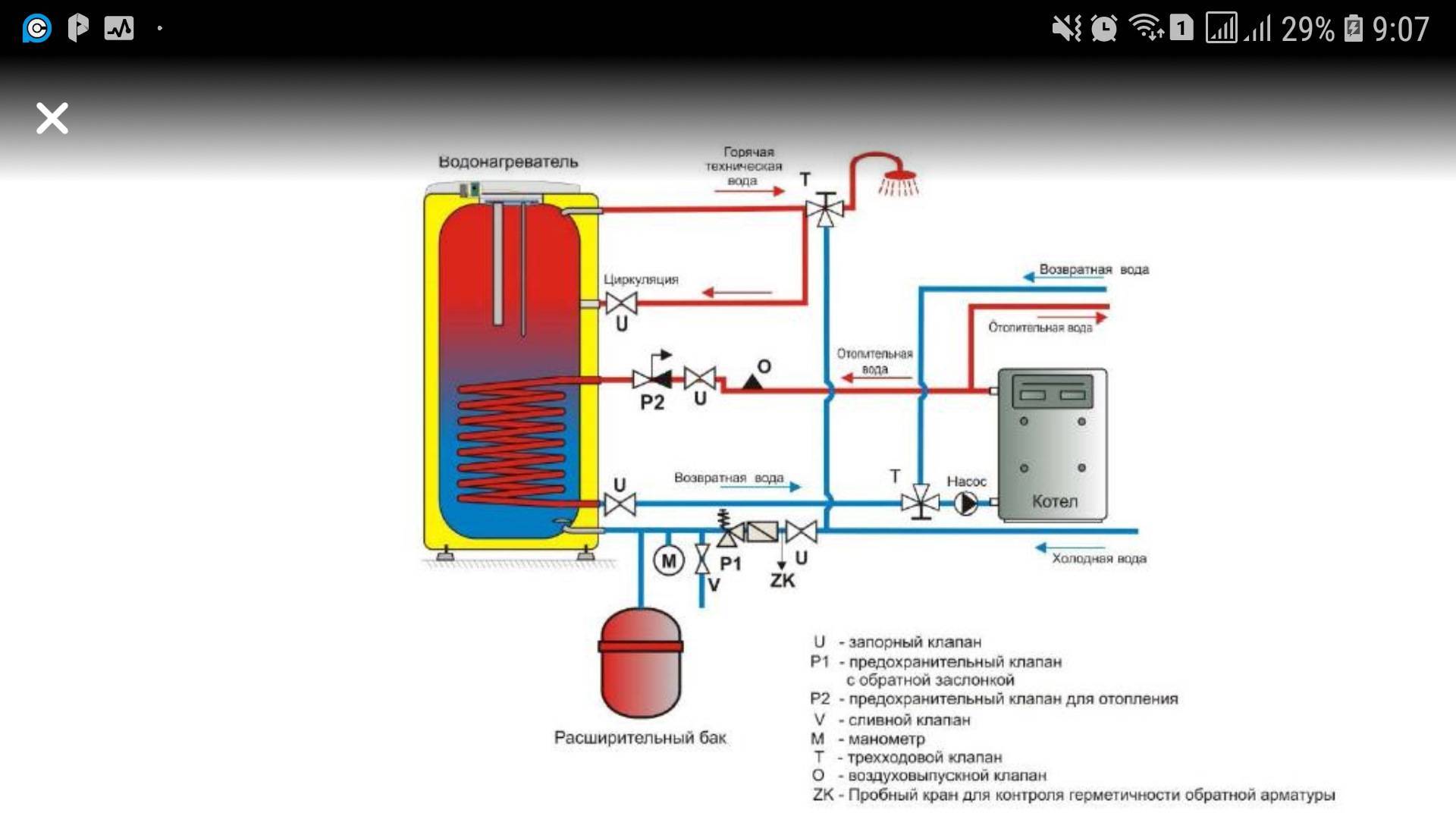

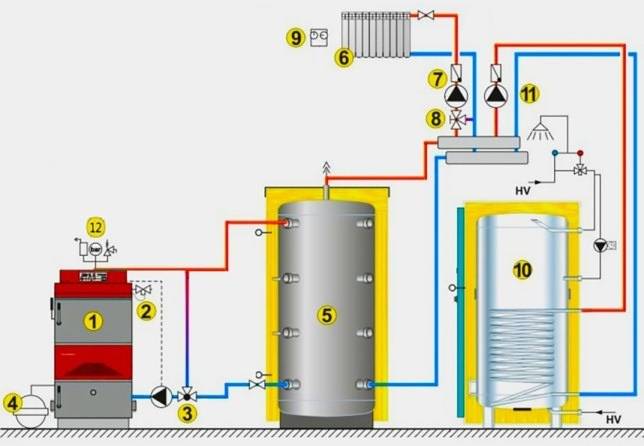

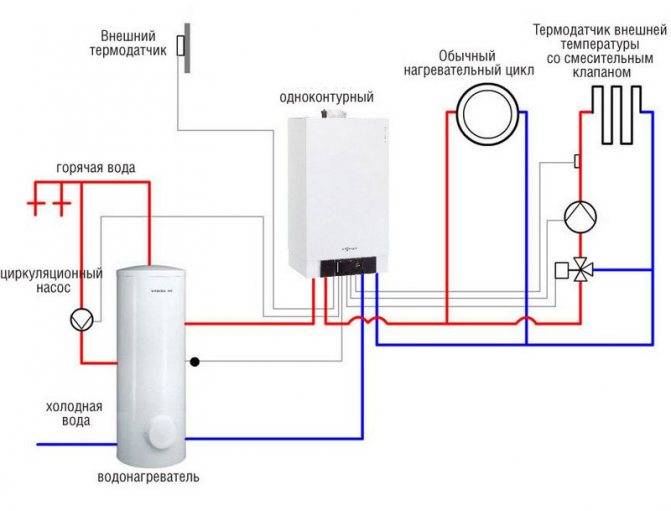

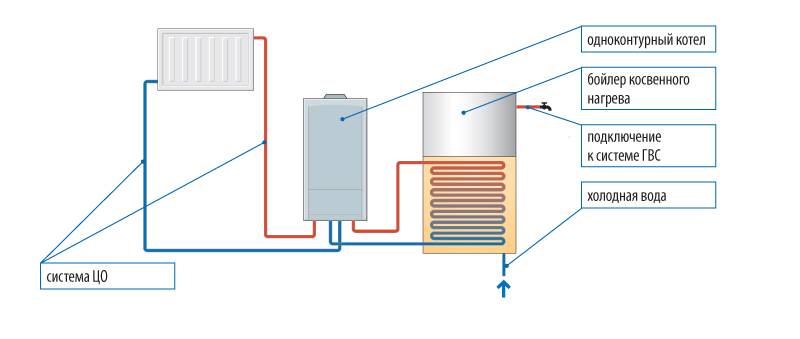

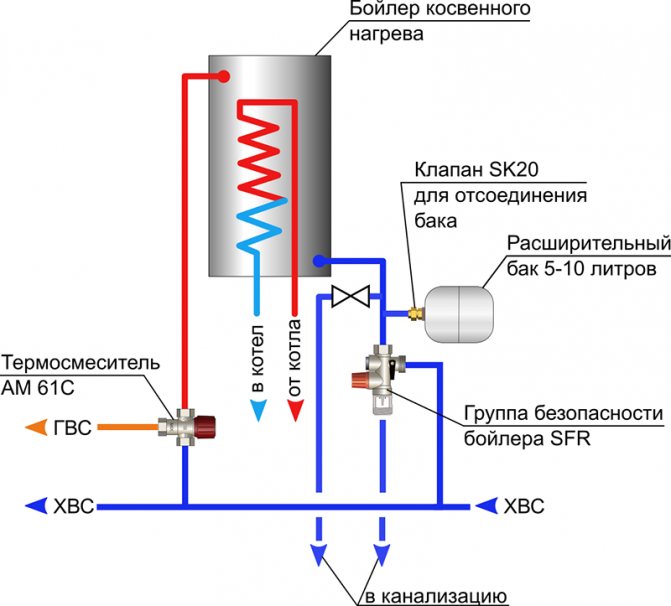

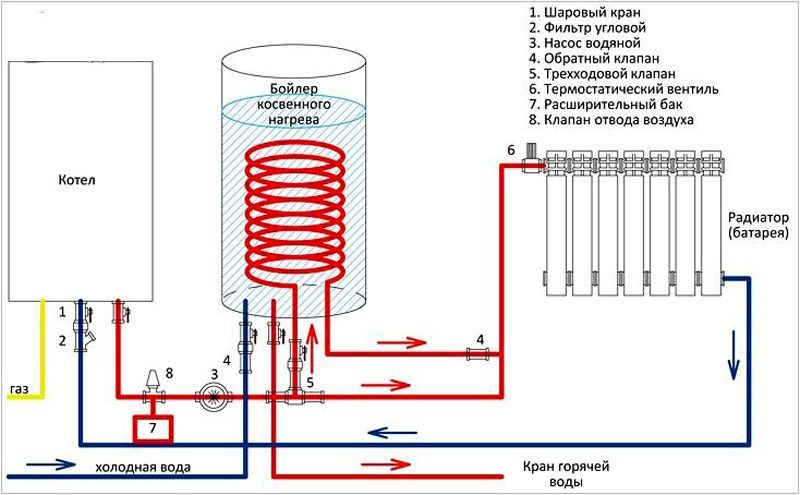

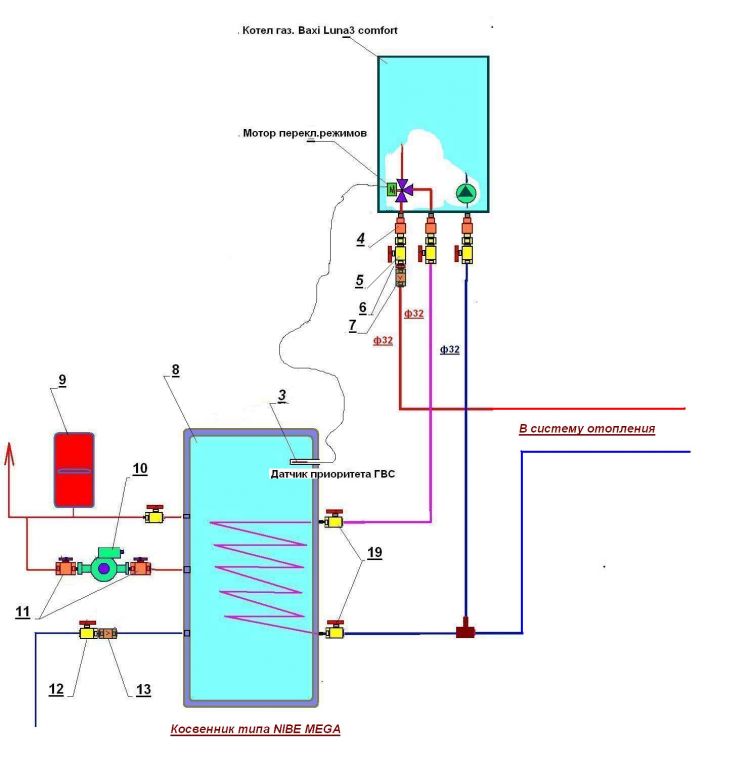

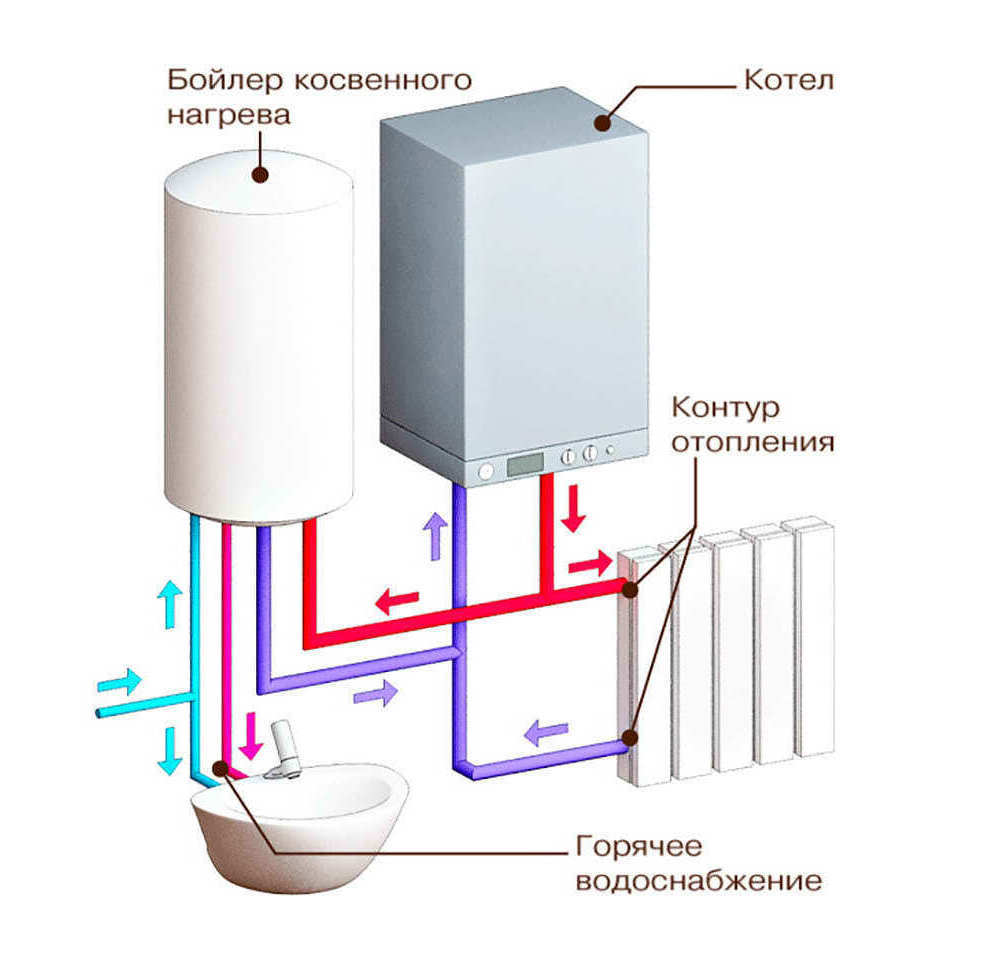

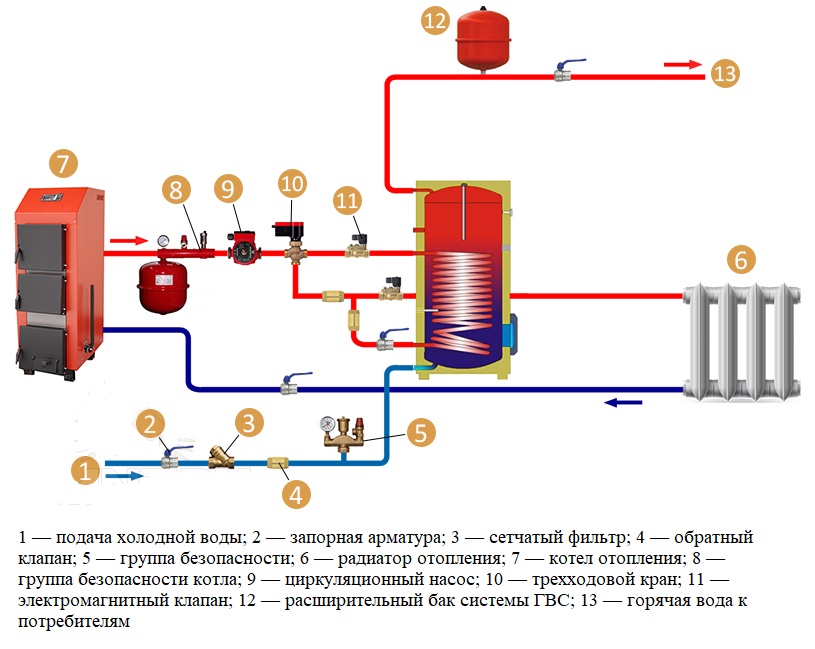

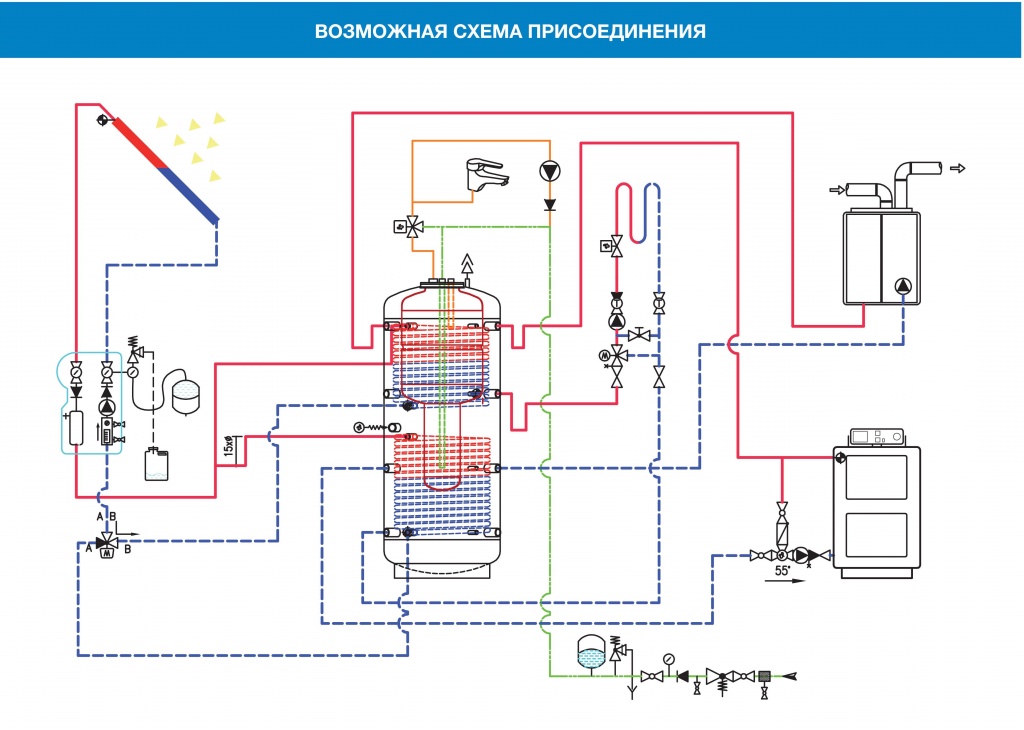

- Connecting an indirect heating boiler to a single-circuit boiler - diagram

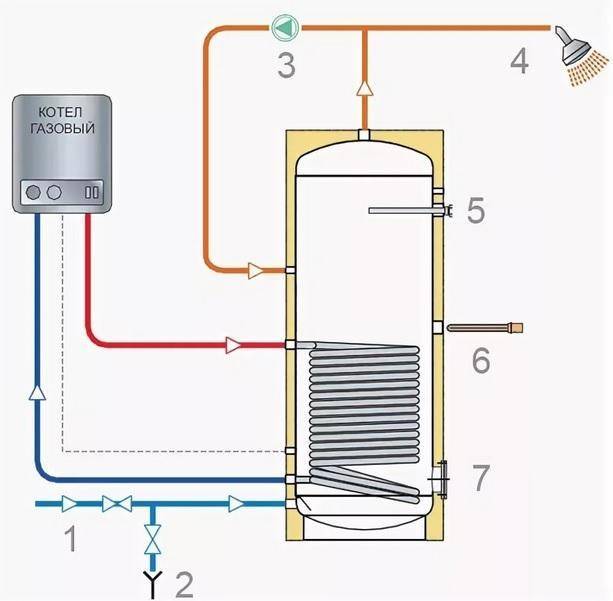

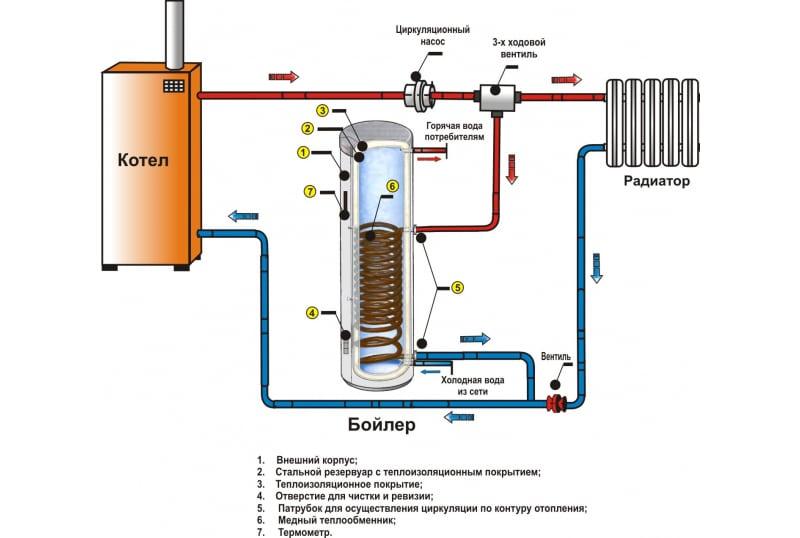

- Design of an indirect heating boiler

- How to connect an indirect heating boiler (water heater)

- Advantages and disadvantages

- How to choose the right boiler for the boiler

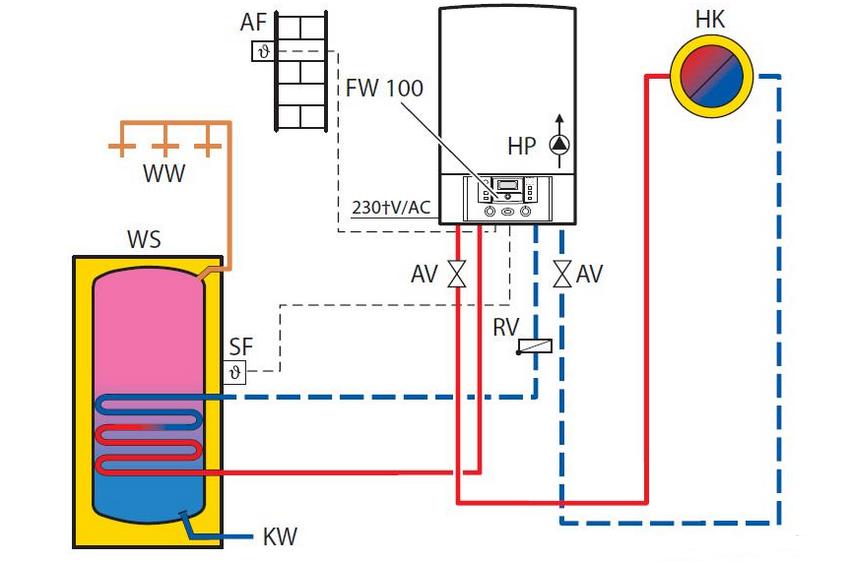

- Double-circuit storage device for heating

- Advantages and disadvantages

- Recommendations

- Operation features

- Common mistakes during installation

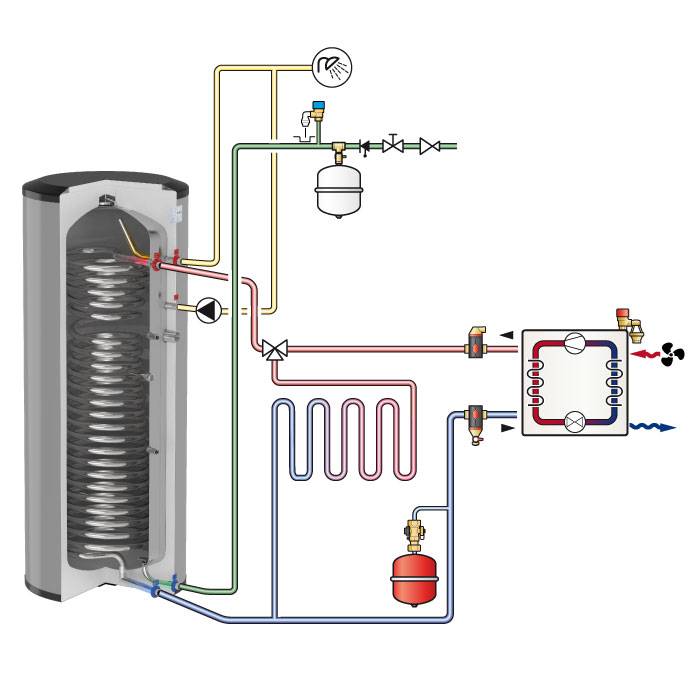

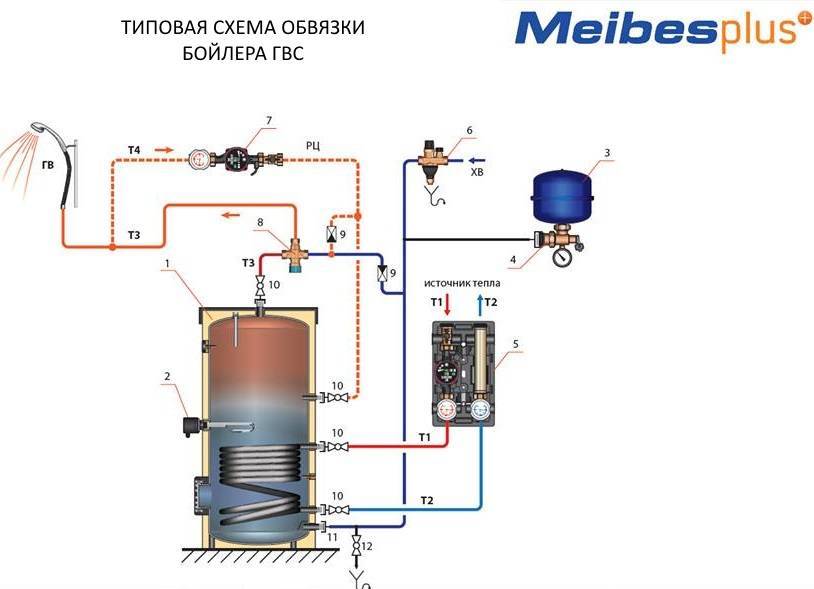

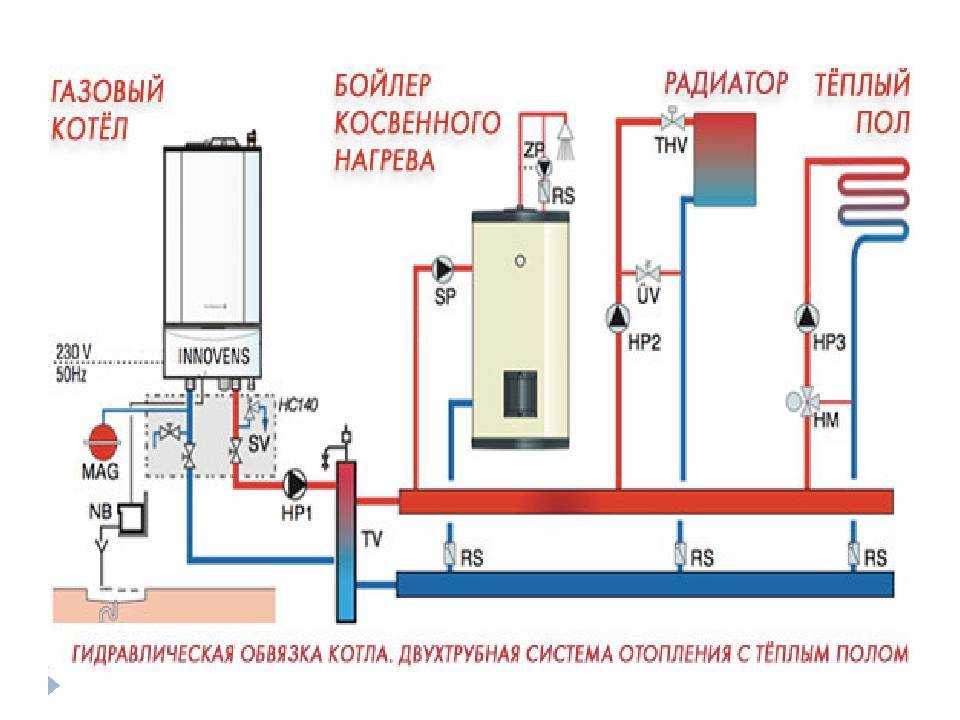

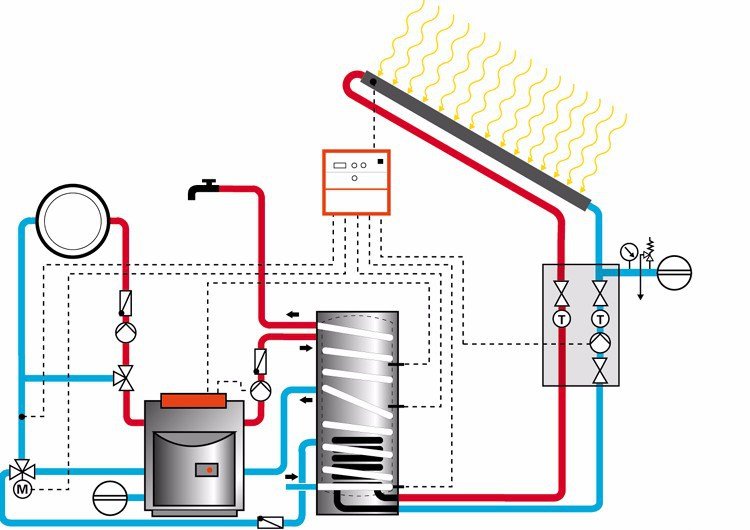

- Piping of indirect heating boiler and boiler

- Layout types

Materials and tools

Materials:

- Pipes, valves, check valves - there are no special requirements for them: use the same materials as for working with hot water or heating systems.

- Expansion tank - a separate one is required for the domestic water supply system, it serves to prevent sudden pressure drops when opening / closing taps.

Attention! The tank must be designed for use with hot water, usually such devices are marked with special markings. Circulation pump - a separate pump is usually installed in the heat exchange circuit with the water heater

Circulation pump - as a rule, a separate pump is installed in the heat exchange circuit with the water heater.

In addition, in DHW systems with recirculation, a separate pump is required to circulate the water in the DHW circuit.

This eliminates the need to wait for hot water to flow through pipes of great length from the installation site of the water heater: the water will immediately be hot.

- Wires and small electrical piping - if you plan to connect the water heater thermostat to the boiler automation.

- Fasteners - especially in case of wall mounting, also for fixing pipes and pumps.

- Standard plumbing set of sealants, seals, gaskets.

Tool:

- gas key;

- wrenches of various diameters;

- Adjustable wrench;

- building level;

- perforator, screwdrivers, screwdriver;

- minimum electrician set: knife, wire cutters, electrical tape, phase tester.

Installation process: how to connect

Ideally, the boiler should be located as close as possible to the heating boiler to minimize heat loss.

Cold water is always supplied to the lower pipe of the boiler, and hot water is taken from the upper one.

- Choose the location of the water heater so that it does not interfere and is easy to maintain. Mount the brackets, stands, fix it on them.

- Connect to the cold water network: make a tap, put a stopcock and a coarse filter.

- Through a tee, divert the cold water line to consumers, connect the second outlet to the boiler through a safety valve.

- Connect the hot water line in the house to the boiler, not forgetting the expansion tank on it. In addition, install bypass valves so that you can disconnect it from the circuit for the duration of the service.

- Now connect the boiler to the gas boiler according to one of the above diagrams.Do not forget to turn off the boiler and shut off the system before connecting!

- Connect electronics, sensors, pumps according to the instructions.

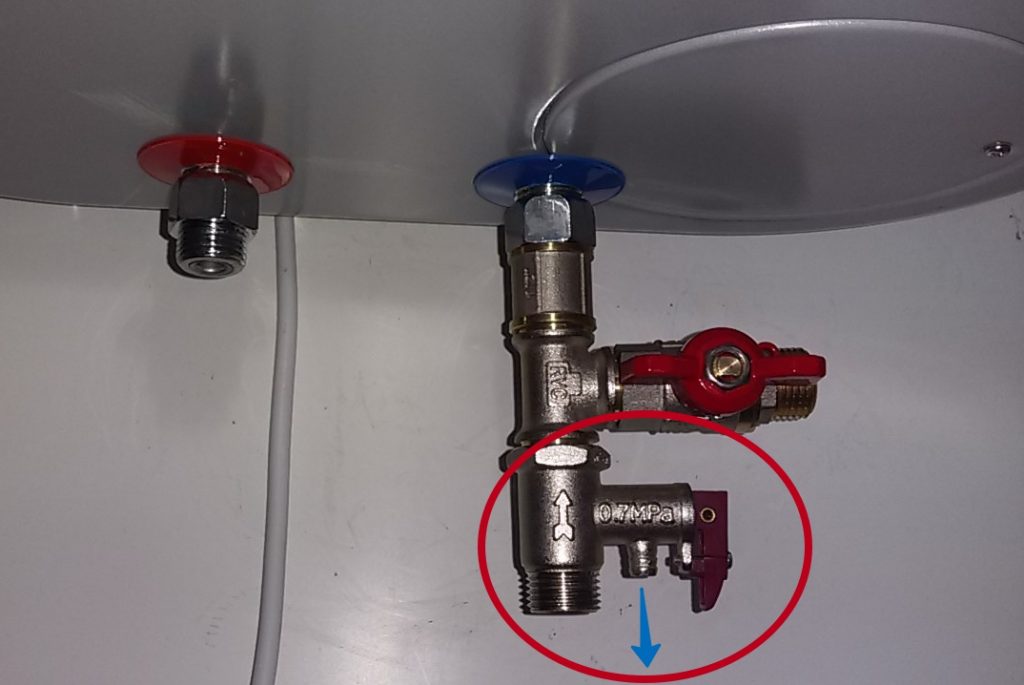

Startup and verification

After installation, it is first necessary to connect and fill the boiler with cold water. Make sure that all air pockets are removed from the system, and the boiler is completely filled so as not to cause it to overheat.

When the boiler is full, set the desired temperature using automation. Start the boiler, open the supply of coolant from the heating system to the boiler.

When the system is operational, check that the safety valve (usually set to 8 bar) is not leaking, i.e. there is no overpressure in the system. You should also check all connections, seals and taps for leaks.

Two in one. Gas boiler with boiler

To save space in interior planning, as well as to simplify the connection, you can resort to innovations in the field of plumbing. Ready-made solutions have been developed that allow the use of a boiler and a boiler in one inseparable complex. Such models are a floor unit, where a tank containing water is located directly under the boiler. The volume of water can be 40, 60, 80 liters or more. A single-circuit boiler with a boiler is attached using fixing plates, without the need for additional screwing. In addition, thermostats, monometers, liquid crystal panels allow you to independently monitor and adjust the water supply, monitor the temperature and change it using a rotary mechanism from anywhere in your property, or from a remote digital panel. A striking example of such a model is the Baxi Luna 3 Comfort Combi boiler.

Possibility to connect a boiler

A boiler for a gas boiler is a storage tank, inside of which a heat exchanger is placed. This model, in fact, is a double-circuit, as it has a connection for both the heating system and the hot water supply.

Double-circuit models have a built-in flow-type water heater, which single-circuit models cannot boast of. The advantage of a gas boiler with a built-in storage tank is that there is no need to create an indirect heating boiler. In addition, water is heated much faster than in single-circuit versions and does not reduce the efficiency of the heat carrier for heating.

A separate boiler can also be connected to double-circuit boilers to provide more hot water. Such equipment belongs to the technique of layer-by-layer heating. You can also buy a double-circuit gas boiler with a built-in indirect heating boiler. Such devices are combined with the boiler, although separate devices can be purchased. Depending on what is best for you: ease of transport and installation or compact placement, you can choose a separate or adjacent model.

If a single-circuit boiler is already installed, a special layer-by-layer heating boiler can be purchased for it, which is equipped with a flow-through liquid heater. If you need to save space in the apartment, you can opt for a single-circuit boiler with a built-in indirect heating boiler.

Heater power

Depending on the power of the gas burner, the flow rate of the liquid in the instantaneous water heater varies. Also, the rate of water heating depends on the design features of the heat exchanger.A feature of heating the liquid is its short contact with the heat exchanger, therefore, in order to warm the coolant to the desired temperature, a lot of heat is needed. To increase the performance of the heating element, it is necessary to increase the burner power and increase the gas flow.

In order for the water temperature in the shower to be 40 degrees, you will have to adjust the burner to a generated power of 20 kW, but if the burner is not designed for such power, then it is impossible to take a warm shower. The bath also requires a powerful burner, as the water must be heated quickly in large volumes for a normal set.

Most boilers have a capacity of about 20–30 kW, and 10 kW is enough to heat a house. Thus, all the difference can be used to provide domestic hot water. For hot water boilers, modulating burners have been developed that cover a range from 30 to 100 percent of the maximum output.

However, even the weakest boilers have excess power, which leads to frequent switching on and off of the burner. This process leads to rapid wear of equipment and increases fuel consumption. These problems make buying a more powerful boiler model to provide more hot liquid an unprofitable and unjustified solution.

That is why in dual-circuit models a boiler is provided that contains hot water, which allows it to be given in large volume while taking a shower or bath. Thus, layer-by-layer heating of water is optimal: it ensures the normal operation of the equipment and does not lead to burner wear.

Features of layer-by-layer heating of a liquid

Features of layer-by-layer heating of a liquid

In double-circuit models with stratified heating, water is heated using a plate radiator or a tubular water heater. The presence of an additional heat exchanger is beneficial in condensing models, as it provides additional heat from the combustion products. The liquid enters the boiler with layer-by-layer heating already heated, which allows you to quickly prepare the hot liquid in the required volume.

Floor double-circuit gas heating boilers with a boiler have a number of advantages.

- The flow of hot water into the upper layers of the boiler allows you to take a shower 5 minutes after turning on the heat exchanger. In contrast, boilers with an indirect heating boiler provide longer heating of the liquid, since time is spent on the convection of warm water from below the heat source.

- The absence of a heat exchanger inside the storage tank allows you to collect more warm water for domestic needs. The performance of such boilers is 1.5 times higher than in models with indirect heating.

Types

Manufacturers of water heating devices do not skimp on the development of ultra-modern models, correctly orienting themselves in the interest of the population that emerged several years ago in autonomous heating and hot water supply devices for private dwellings.

Currently, there are two types of single-circuit heating devices:

- floor;

- wall.

Floor options are more powerful, but their placement requires separate rooms in the form of an extension. Wall-mounted water heater - compact, small-sized, mounted on the wall.That is why the first of these models became widespread among the owners of suburban and urban private houses, summer cottages and cottages, and wall-mounted boilers found their admirers in urban areas.

Both of these boilers have a simple and understandable device, attractive appearance, and a high degree of safety. To form your own opinion about which of them is better, you need only depending on the tasks facing them. Sometimes it is more profitable to purchase a single-circuit wall-mounted unit with less power, but which is enough for a full-fledged heating system at home, and make a simple piping to connect the wall structure to a column that serves to heat cold water for one's own needs (the column can be electric or gas). Hose tying kit can be purchased separately.

Connecting an indirect heating boiler to a single-circuit boiler - diagram

It is necessary, according to the diagram, to find the terminals for the boiler sensor in the boiler and connect the ends of the wire in them.

Conventional indirect heating boilers work mainly with automated boilers.

Connecting the boiler to the boiler using a three-way valve This connection scheme is perfect for gas boilers equipped with a circulation pump and automation. Preference is given to wall models that can be hung at a height of 1 m above the floor.

The best position is when the bottom of the hot water tank is higher than the boiler and radiators. How to properly connect an indirect heating boiler to the heating system? Less often they are connected to free-standing boilers of the same volume.

Design of an indirect heating boiler

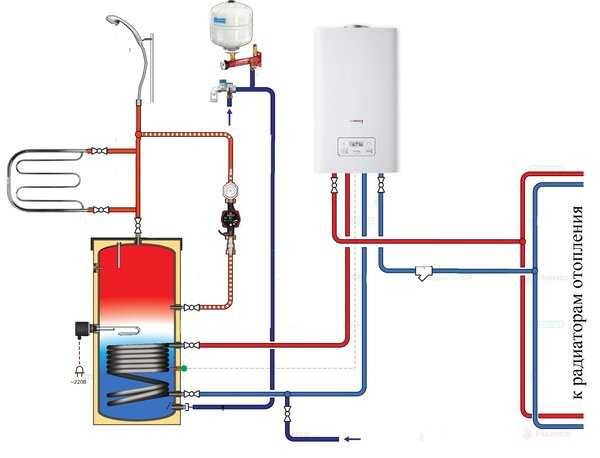

Indirect heating These water heaters are thermal do not produce energy on their own. If you need to create a connection diagram for a solid fuel boiler that runs on wood, we recommend choosing the option shown in the picture below. Some manufacturers intentionally produce equipment with standard dimensions for connectors and fittings.

In this scheme, there is no three-way valve; the circuit is connected through conventional tees. With this part, the unit lasts much longer. Operation at very high temperatures can cause premature damage to the inside of the tank. Types of double-circuit gas boilers with a built-in boiler whether they are needed Boilers are used in conjunction with single- and double-circuit gas boilers. The circulation pump is common here, it drives the coolant through the heating circuit and through the water heater.

How to connect an indirect heating boiler (water heater)

Scheme for connecting an indirect heating water heater to a gravitational system When implementing this scheme, the circuit that goes to the water heater is made with a pipe with a diameter 1 step larger than the heating one. They have a coil and a built-in heating element.

This piping method is useful for those who use the boiler in constant mode 2: Option with two circulation pumps . The heating system of an apartment or house is working, and, as if casually, as a side effect, the water in the boiler heats up.Boiler connected to heating equipment and electric heaters This method is possible only if there is a separate boiler equipment that can operate from natural heating sources in the form of liquefied gas, coal or wood all year round. The hot water circuit also has a higher priority than the heating circuit, but this is achieved only by setting the switching algorithm. The implementation of the strapping requires preliminary competent thermal engineering calculations.

Ufa. Wiring diagram for an indirect heating boiler.

Advantages and disadvantages

The strong qualities of indirect water heaters can be safely considered:

- Significant volumes of hot water and uninterrupted supply of hot, not warm water.

- Simultaneous provision of several sources of hot water consumption of the required temperature.

- During the heated period of the year, the cost of heated water is the lowest in terms of costs. Since heating occurs due to the heat already received from another carrier (heating system).

- Water heating, unlike flow heaters, occurs without an inert delay. Opened the faucet and hot water came out.

- Depending on the availability of heat sources, several energy options can be applied, including solar energy.

Weaknesses include:

- Additional financial investments are required. The water boiler works in conjunction with other equipment.

- It will take a long time for the boiler to heat up initially. During this heating period, the heating temperature of the house may decrease.

- The boiler must be installed in the same room as the heating system. The volume of the room must provide a complete installation of both the heating system and the boiler.

How to choose the right boiler for the boiler

Connecting the BKN to a single boiler requires a rather fine selection of equipment, fulfilling a number of requirements, because otherwise an inoperative system will be created due to the mutual blocking of two types of heating - heating and hot water.

Source

Source

Necessary aspects that need to be taken into account before installing a gas boiler:

- Analysis of the financial and economic feasibility of the purchase. It is believed that the purchase will be justified with a hot water flow rate of at least 1.5 l / min, which is sufficient to provide a DHW service for a family of 4 people.

- The volume of the storage tank. Experts note that one consumer needs about 100 liters of hot water per day.

- Boiler performance. It solely depends on this parameter whether the device is able to guarantee the simultaneous heating of the apartment and the operability of the BKN.

- Hourly pumping of the heated coolant. Often, buyers mistakenly choose pumping equipment that does not load the heat exchanger.

- Type of material of the inner surface of the water heater. The water tank must not be exposed to corrosive processes.

- heating period. The larger the useful volume of the container, the longer the liquid medium will warm up. The main heating of 100 liters of water will take up to 2 hours. However, a container made of non-corrosive metal can heat the same volume in just 30 minutes.

- Thermal insulation building material.In inexpensive samples, the insulation is equipped with foam rubber coatings, while in powerful high-strength water heaters, mineralized wool or polyurethane foam is used for this purpose.

- Dimensions. It must be remembered that BKN water heaters are of considerable size and are mounted near the boilers. It is necessary to select a boiler taking into account the dimensions of the room where it will be placed. For a capacity of 1000 liters, a separate room will be required.

- Availability of safety and regulation automation.

- Warranty period and proximity of service centers to the installation site. Manufacturer. It is advisable to give preference to well-known companies that have proven themselves well and have branded offices in Russia.

Double-circuit storage device for heating

Boiler - a tank for heating and accumulating water of the desired temperature, which will be issued as needed by the owner. The simplest model: a tank equipped with four holes with reinforced and insulated walls, inside of which there is a coil.

The work is carried out according to the following algorithm:

- Supply of hot water from the heating system to the coil.

- Return.

- The flow of cold water directly into the tank.

- The output of the heated liquid from the tank to the tap.

Additionally, the device includes:

- Circulation pump.

- Temperature sensor.

- Safety valve.

- Locking mechanism.

- Check valve.

- Anti-corrosion protection.

Reference! Some models provide circulation of heated water from the boiler between the walls of the outer and inner tanks. So, it takes much less time to wait until it heats up, but such a device also costs more.

The water heater is connected to the heating system right next to the boiler, parallel to the main wiring to the appliances. Own circuit allows you to keep the heating priority in relation to the heating system. Reduces the temperature fluctuation on storage heaters when the heater is turned on.

The temperature sensor detects a decrease in heat in the tank, followed by a command to the circulation pump in the circuit.

Water from the heating system is supplied to the coil, passes through it, giving off part of the energy to the still cold water already in the tank.

After it heats up to the desired level, the automation turns off the pump. When the tap on the mixers is opened, the incoming cold water gradually displaces and dilutes the hot water. Then the cycle repeats.

The cold water inlet is equipped with a non-return valve that prevents it from draining when the pump is turned off. The pressure in the tank increases, since the mixers are not constantly used, and water cannot pour back. The safety valve does not allow the pressure to reach a critical point, releasing a certain volume of liquid into the drain.

Important! The water heater is mounted on a flat surface next to the boiler. For suspended models, a log or brick wall is suitable at the same level as the boiler or slightly higher

Under the floor, part of the space on the floor is leveled or a special ramp is placed on it, on which the boiler is installed.

Advantages and disadvantages

The undoubted advantages of boilers with indirect heating heaters include savings on electricity.

No gas burner or power source is needed as with direct heating devices.The heating system will do everything itself, which significantly reduces financial costs.

Other pluses:

- Productivity: a tank with a capacity of one hundred liters, produces approximately 400 liters of hot water per hour.

- Almost instantaneous supply of hot water.

- Ability to use multiple energy sources, such as a geothermal system.

- Democratic price.

- Simplicity in the device.

Minuses:

- Warm-up speed, even in the latest models, it will not be instantaneous.

- Bulky.

Attention! If the family is quite large, then one room will have to be given over to the boiler room, squeezing yourself out. Small models will not solve the problem of washing

Recommendations

When choosing a model, it is necessary to pay increased attention to the following characteristics:

- Capacity: for two people - 80-100 liters, for three - 100-120 liters, four need at least 120-150 liters, five - 150-200 liters.

- Power: - directly depends on the number of users, while it should not overload the potential of the heating system. According to experts, for the normal coordinated operation of the boiler and water heater, a power of at least 24 kW is needed.

- Tank material: it is better to choose tanks made of medical steel or stainless steel.

- Warm-up time.

It is recommended to purchase an automated version with a temperature sensor - this will make it easier and safer to use even for the younger members of the family.

Operation features

- Pump filters need to be systematically checked and cleaned.

- Any model implies the correct setting of the thermostat, otherwise the boiler may overheat.

Photo 3. The master adjusts the thermostat of a gas boiler with a boiler to avoid overheating.

- It is necessary to ensure that the temperature in the tank does not rise above the antifreeze values.

- Check anodes for corrosion. If one is found, the part is replaced. This should be done every six months, and when the water is not hard, then once a year.

Common mistakes during installation

The indirect heating boiler is a rather new type of storage heater and, despite its simple appearance, this is a complex heat engineering device that requires careful selection, precise installation and functionality adjustment. When installing the BKN, mistakes are often made, the most common of them:

- Incorrectly chosen place of installation of equipment. For example, a plastic or stainless steel housing must be placed as close as possible to the boiler.

- Incorrect piping of the tap water source.

- Incorrect piping of the circulation pump.

- Violation of the DHW insulation with a layer of less than 20 mm and the thermal conductivity of the insulating layer - 0.030 W / m2. This not only insulates the hot heating surfaces of the pipes, but also all operating components.

- Incorrect water connection or lack of insulation is the main cause of condensation on these lines.

- A common mistake in the BKN system is the absence of an expansion vessel that compensates for pressure from the thermal expansion of water in the tank.

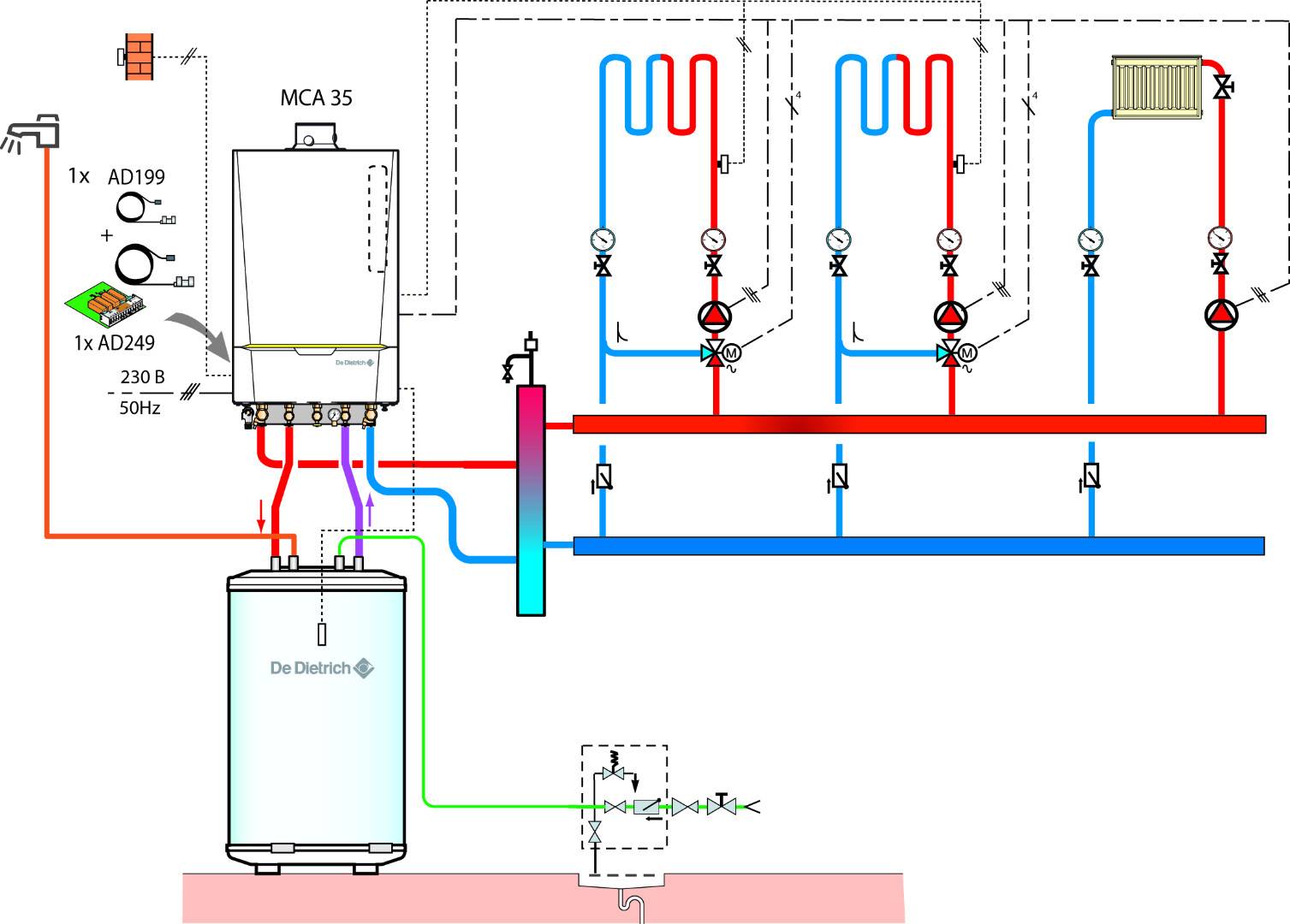

Piping of indirect heating boiler and boiler

According to the mind, the possibilities of the second circuit of a double-circuit boiler do not need to be used when heating an indirect heating boiler. It is necessary to tie the work of the primary circuit to simultaneous operation with heating and hot water heating. To do this, it is necessary to connect the boiler and the boiler through the distribution manifold.The collector will act as an intermediary and will distribute the hot coolant throughout the heating system and the indirect heating boiler. All this will heat the double-circuit boiler.

In order to avoid overexpenditure for heating hot water, it is necessary to connect your own pump to the boiler circuit. A remote thermostat must be purchased for the boiler. The remote thermostat must be connected to the pump so that it works to turn the pump on and off.

When the boiler cools down, the thermostat will signal the pump to turn on. The boiler will start heating up. Upon reaching the desired temperature, the thermostat will give a signal to turn off.

Such a scheme for connecting a double-circuit boiler and an indirect heating boiler cannot be called ideal, but it allows you to heat normally hot water. The best and economical solution would be to buy a single-circuit boiler with a boiler connection function. Such a scheme would not have to be fenced.

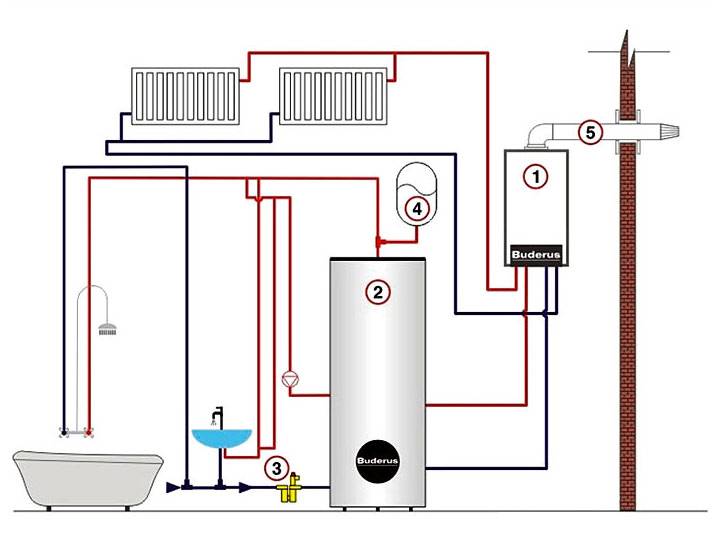

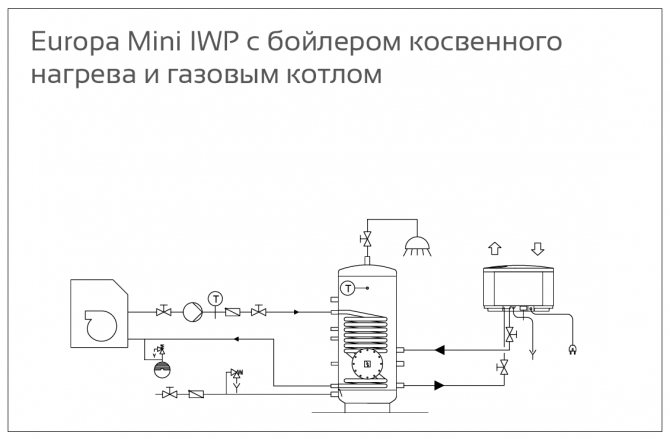

Layout types

The advantages and disadvantages of double-circuit gas boilers are well known, they are good enough to serve 2-3 small consumers. But what if there are more consumers, and the use of electric water heaters is excluded? There are several modern solutions for this:

- Wall-mounted gas boilers with built-in boiler.

- Heating installations with an external storage tank for hot water.

- Boilers of indirect heating.

Practice shows that for a family of 3 people for household and sanitary needs it is enough to have a capacitive electric heater with a capacity of 50 liters in the house. Of course, the use of hot water within reasonable limits is implied.In order not to purchase such a heater and not to engage in laying extra cables and pipelines, you just need to choose a wall-mounted heating unit, inside which there is a tank with a capacity of 46-50 liters. Its design is two in one: a gas boiler with an indirect heating boiler inside. The principle of operation is also preserved: one part of the coolant goes to the heating system of the house, and the other goes to the coil of the internal boiler. Having reached a certain temperature of the water in the tank, which is determined by the sensor, the entire volume of the coolant switches to heating the house.

1 - fan - smoke exhauster; 2 – high performance heat exchanger; 3 - combustion chamber; 4 – storage tank made of stainless steel; 5 - control unit with display.

The design of the heater includes 2 circulation pumps, one pumps the coolant through the heating system, and the second through the boiler coil, while the burner operates at maximum for the fastest heating of the water in the tank. Later, the circuit switches to the water temperature maintenance mode, which reduces fuel consumption.

More powerful wall-mounted gas boilers are equipped with tanks and larger capacity, but usually it does not exceed 100 liters.