- Boiler for a bath with a tank

- Types of heat exchangers

- Prices for heat exchangers

- Which stove for a bath is better to choose - wood, electric or gas

- Types and characteristics of bath boilers

- Long burning sauna stove

- Pyrolysis heating devices

- Electric bath boilers

- gas boilers

- Other types of boilers

- Electrical

- Do-it-yourself installation of a gas boiler in a bath

- New quality of a gas-fired boiler

- Gas oven in the bath

- Foundation for a gas furnace

- Construction of a gas oven for a bath

- Using a gas stove in a bath

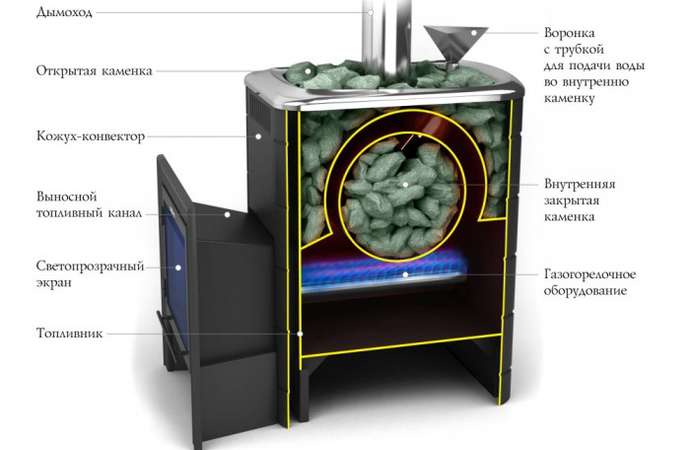

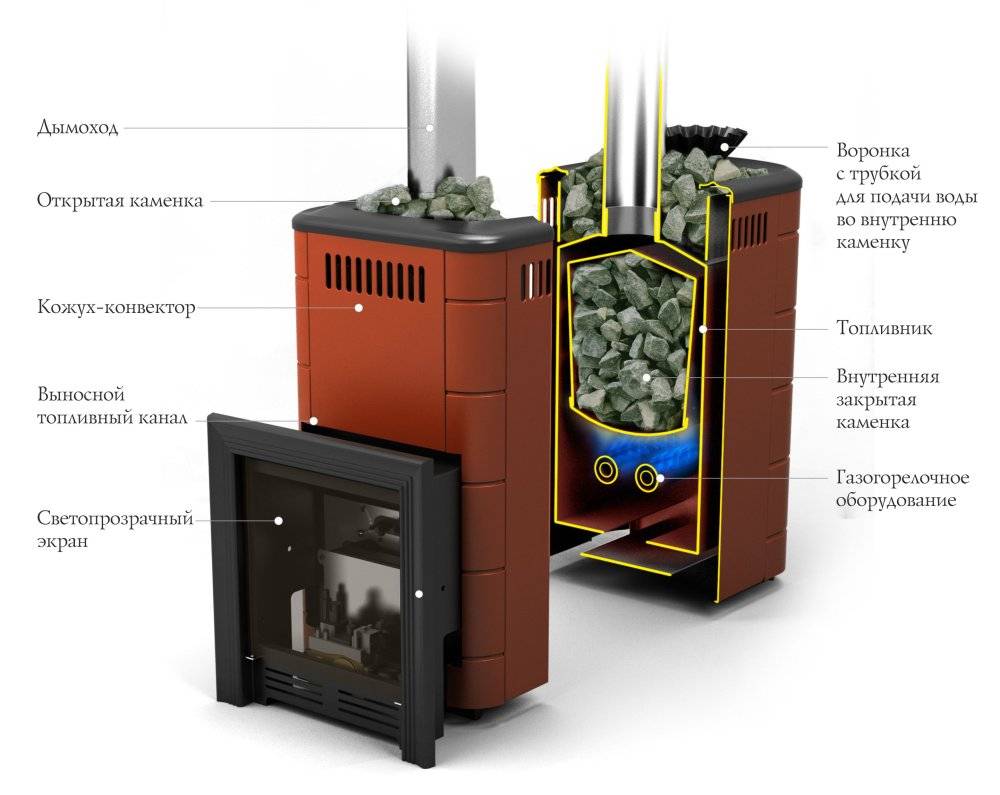

- Gas oven device

- atmospheric

- supercharged

- Video

- Choice

- stones

- Water tank location

- Gas stoves

- Burner

- Sheet metal oven

- Stage 1. Preparing everything you need

- Stage 2. Assembly of the structure

- Conclusions and useful video on the topic

Boiler for a bath with a reservoir

It is also a fairly simple, yet reliable option for heating water. Structurally made of two parts:

- The lower one is designed for burning firewood, other solid fuels (but not coal);

- The upper part is a reservoir. which warms up the contents due to the heat of the chimney pipe passing inside the container.

It is connected to the cold water supply system or equipped with a separate container installed on the roof of the bath.Under the action of physical forces, the hot liquid is displaced by the heavy cold liquid during the washing process. The water tank must always be filled during use.

A wood-burning boiler for a bath with a capacity is equipped with a shower head, a faucet of a special device, which the manufacturer prohibits from changing to ordinary mixers.

Advantages of a wood-burning boiler: compactness, efficiency, ease of use, a small amount of solid fuel is required.

Types of heat exchangers

Heat exchangers

A heat exchanger is a device used to heat water. The more efficiently it works (the greater the efficiency), the better the heating furnace heats, the higher the temperature in the rooms can be. The heat transfer coefficient depends on the material of manufacture and the total area.

Example of a copper heat exchanger

It is best to make heat exchangers from copper, but this option has three significant drawbacks:

- high cost of copper. For a heat exchanger, a large number of thick-walled copper pipes are needed; at current prices, the cost of such material can be equal to the cost of the entire boiler;

-

manufacturing complexity. Copper can only be welded in an inert gas environment; it is impossible to do this at home. Another method of manufacturing a copper heat exchanger is soldering. Unfortunately, such joints do not have satisfactory strength indicators, especially at high temperatures;

Welding (soldering) of copper

- copper under the influence of an open flame quickly oxidizes, becomes fragile and burns out.

Copper pipe heat exchanger

For heat exchangers in solid fuel boilers, it is optimal to use ordinary quality carbon steel sheet materials with a thickness of at least one millimeter.

Thick-walled pipes

An important factor in the efficiency of the boiler is the area of the heat exchanger. There are two options for solving the problem here.

Tubular heat exchanger

Prices for heat exchangers

heat exchanger

The first. Increase the internal area of the furnace and thereby the dimensions of the heat exchanger. The option is good, but difficult to implement. A large firebox is not always appropriate in a sauna stove, an increase in its dimensions causes significant difficulties during manufacture, waste of materials, etc.

Second. Increase the area of the heat exchanger. Heat exchangers can be in the form of containers with flat walls or be tubular. The second option significantly increases the effective heat exchange area, the water heats up faster, the efficiency increases markedly.

Heat exchanger - photo

Which stove for a bath is better to choose - wood, electric or gas

In the age of modern technology and innovation, manufacturers of sauna stoves quickly found an alternative to the usual wood stoves. Which stove for a bath is better to choose? Let's figure it out.

Electric - easy to install and use, do not need firewood, heat the room quickly. They can be turned on and off at any time. A great option for the ever-hurrying city dwellers. But! They consume a lot of electricity, they can only heat a small room.

Photo from the site

Gas - have a fast heating rate, are able to maintain a given temperature level in the steam room. Among the shortcomings - they require connection to the central gas heating system, otherwise the consumption of gas cylinders will be too high and will not pay off the costs.

Photo from the site Comfortable in the house

Wood-burning - are considered the best option. They are metal and brick, heated with wood

How to choose a sauna wood stove? Here it is worth paying attention to all the parameters that we have listed above - the type of heater, furnace, principle of operation and the material from which it is made

Photo from the site Narvi stoves Narvi and smokehouses wholesale

Types and characteristics of bath boilers

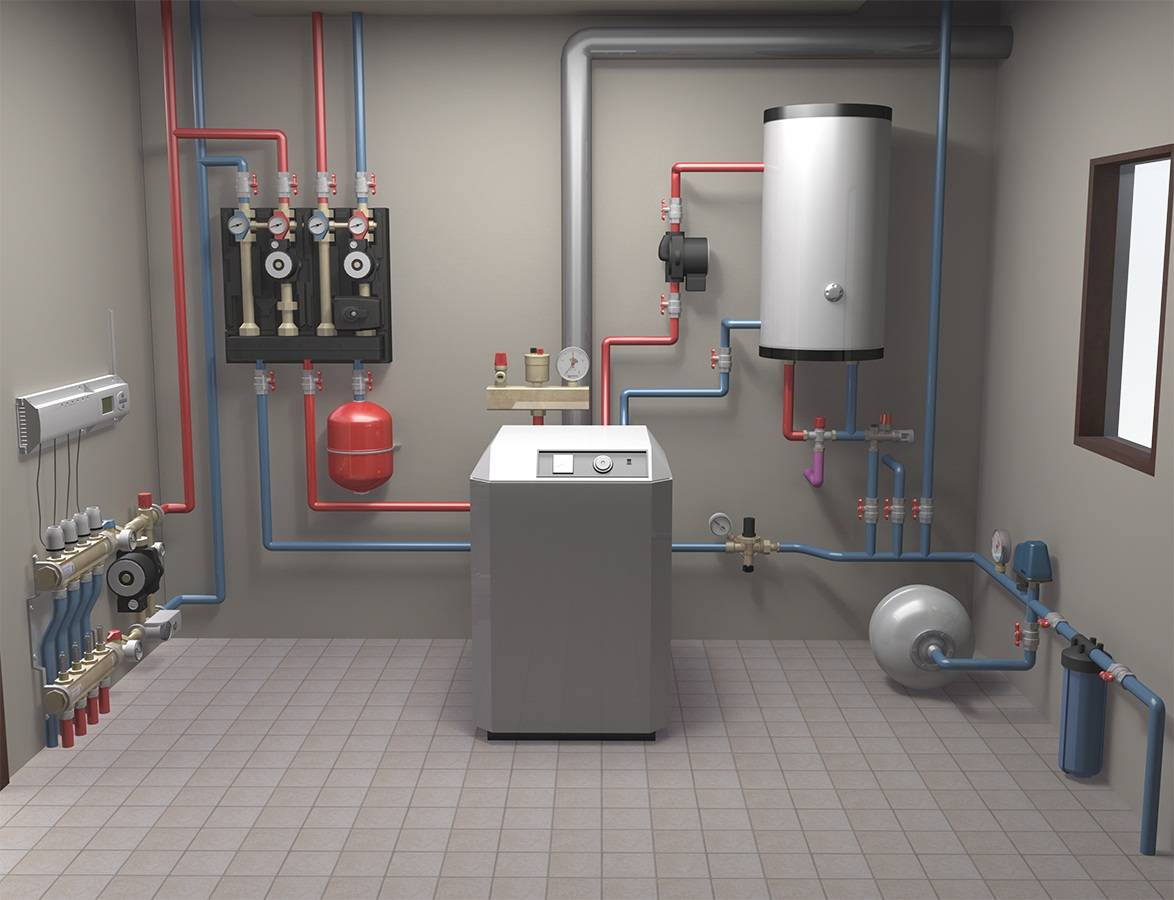

Boilers for a bath are divided into two main categories: units designed for heating a steam room, and models for heating the entire bath. There are solid fuel, liquid fuel, gas, electric and combined boilers. By type of heat exchanger, the units are:

- single-circuit - they heat only the steam room;

- double-circuit - they heat the premises and heat the water in the washing room;

- three-circuit - they heat the floors in the bath and in the pools.

The sauna boiler consists of a firebox, at the bottom of which there is a grate. An ash pan is placed under it: through it the air necessary for the combustion of fuel is pumped. Another important element is the heater, which heats the steam room. There are models without it, but it will be uncomfortable to bathe in a bath without a heater. Boilers for a bath on wood with water tank give very dense and heavy steam. The products of combustion are expelled through the chimney of the stove.

Many bath units are made of steel, but products are also made of cast iron. They are resistant to high temperatures and have a longer service life. But such models have one significant drawback: they become very fragile when water gets on their hot surface. Therefore, cast-iron boilers are lined with brick or stone.

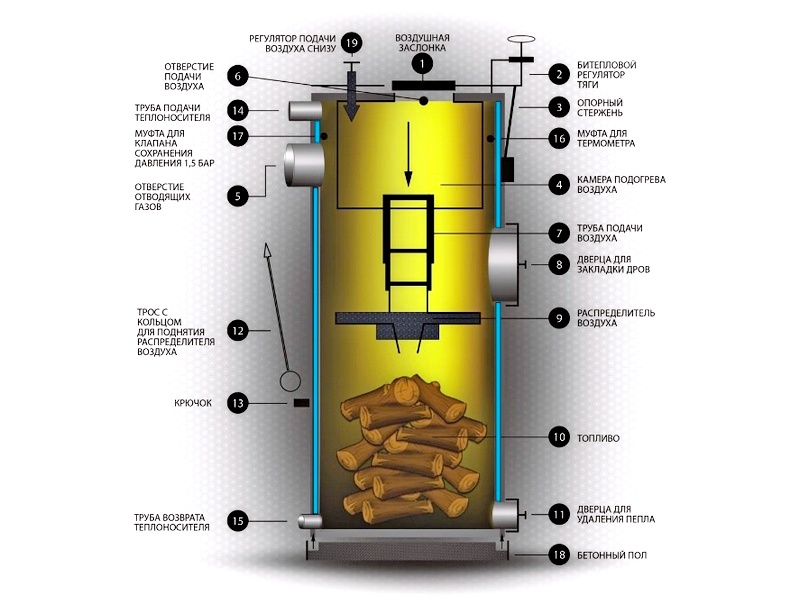

Long burning sauna stove

Long burning stoves burn fuel very slowly. Due to the fact that the air flows in them are regulated, the firewood in them does not burn, but only smolders.The combustion chamber in such furnaces is completely sealed, and air is forced into it. The advantages of these ovens include:

- high level of efficiency - 75-80%;

- the combustion time of one refill of firewood is about 10 hours;

- the possibility of using any solid fuel;

- increased loading of firewood;

- have control automation;

- service life - up to 30 years.

The disadvantages of long-burning sauna stoves include:

- does not work on liquid fuel;

- the chimney should only be straight (no bends) due to the small draft;

- forms a large amount of soot and condensate in the pipe, therefore it requires regular cleaning.

To burn out the condensate, the unit must be strongly heated once a week at high power. This measure will prevent slagging of the furnace.

Pyrolysis heating devices

The pyrolysis unit differs from other long-term combustion furnaces in greater efficiency. The term "pyrolysis" means the decomposition of solid fuel into combustible elements under the influence of high temperatures with a lack of oxygen. The increased efficiency of pyrolysis boilers is ensured due to the fact that the wood gas that is released during the decomposition of the fuel is always afterburned. Therefore, soot does not form in such stoves. But these boilers are not recommended for heating the steam room due to insufficient heat transfer in the infrared range.

Electric bath boilers

These units are considered the most environmentally friendly. They take up little space in the room and do not require the installation of a chimney. Electric boilers are made of a metal case, inside which heating elements are installed.They heat the stones, which then give off heat to the room. Such models are also called electric heaters. They are often used in saunas. They work automatically and are easy to manage. But for such units, a three-phase power supply from electrical networks is required. There are boilers that use 220 V.

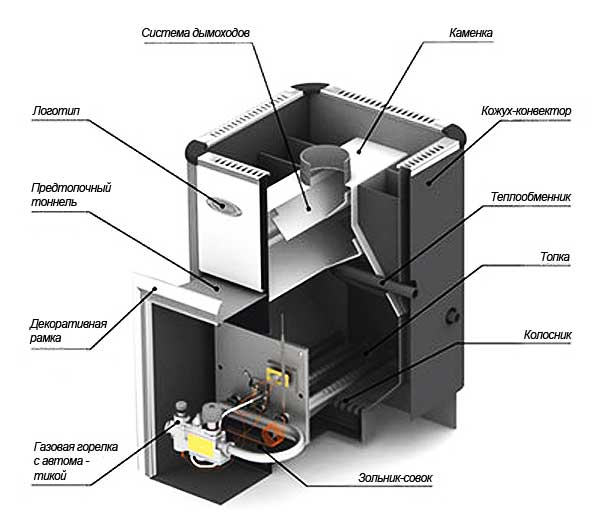

gas boilers

The gas unit is an alternative to wood stoves. Installation will require additional permission from special organizations. Equipment in this category is characterized by compact dimensions and economical operation. A burner is mounted inside the furnace body, which is designed for a certain gas flow rate.

The oven where the fuel is burned is located under the stove. As a result, the stones heat up quickly and provide the desired temperature in the steam room. During the operation of the gas heater, no unpleasant odors are emitted. If the fire suddenly goes out, the built-in fuse will automatically stop the gas supply. Such boilers, like wood-burning ones, require a chimney.

Other types of boilers

Units operating on diesel fuel or waste oil are considered efficient and convenient to use. But they have a very significant drawback: during operation, they emit a sharp and persistent odor. Therefore, for the installation of liquid fuel stoves, it is necessary to equip a separate room.

Electrical

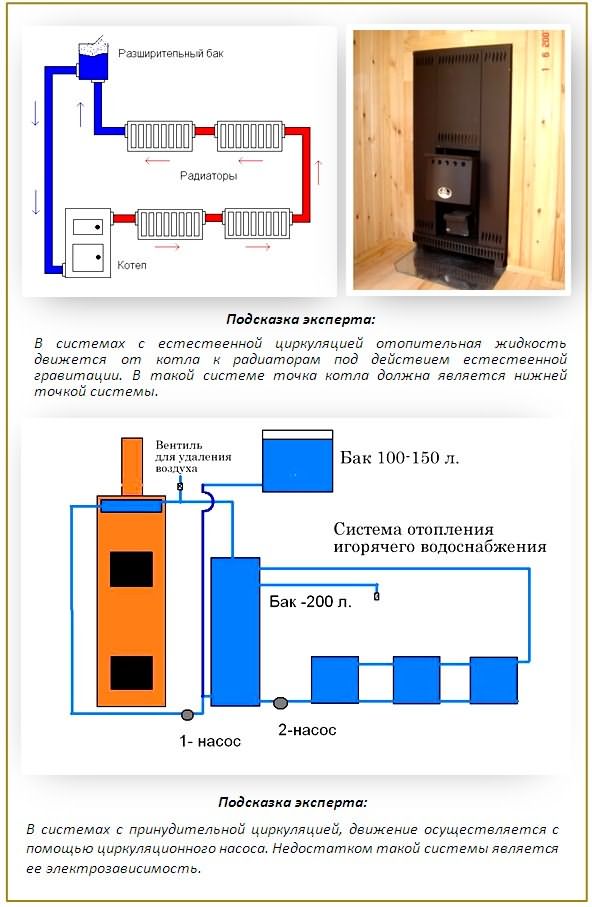

And finally, we will analyze several ways to use electricity to heat a bath. I must say right away: take care of the electrician in this case. Since the load on thermal electrical appliances is large, the quality of the electrical wiring should not be in doubt.Consider the total load, wire size, wiring diagram and the quality of electrical work.

Electric heating

Electric heating

Firstly, your room can be heated with an electric heater. True, in this case, you will have to take care of heating the water in the shower room in advance (for example, by installing a direct or indirect heating boiler). This type of heater does not need additional arrangement of the chimney and is considered environmentally friendly.

Secondly, the sauna room (in particular, the rest room) can be heated using electric convectors placed on the walls.

And, thirdly, infrared film can come to your aid - the latest type of heater that allows you to easily and quickly make warm floors both in the house and in the bathhouse. Detailed floor heating device technology is discussed in other articles.

It is quite possible to use infrared heaters as an additional source of heat. Hung it on the ceiling and forgot.

Infrared heaters

Infrared heaters

The use of electricity to heat the bath, of course, has its advantages. You can safely use all the structural elements (heater, floor heating, boiler) at any time all year round. At the same time, you do not have to worry about fuel and fear for pipes freezing. The only serious drawback can be considered a high power consumption.

Do-it-yourself installation of a gas boiler in a bath

Before connecting the equipment, it is necessary to issue the appropriate permits and coordinate the project with the authorities. Develop a gas supply project in a specialized service, and then send it and related documents for approval, for example, to Gorgaz.You will need papers from the manufacturer: equipment data sheet, instructions, certificate of conformity.

Work with gas equipment is carried out by specialists in accordance with the accepted rules and regulations: SNiP 42-01-2002 and II-35-76, set of rules: SP-41-104-2000. They give a detailed description of how to properly perform these works, and what to do is strictly prohibited. For example, the diameter of the chimney is selected in accordance with the power of the device using special formulas.

Having received the necessary permits, you can begin work: bring the gas pipeline and water supply, line the wall with fire-fighting material, make a hole for the chimney.

- Flush the tubing system of the device.

- Attach wall fixtures to slats.

- Make holes in the wall, fix the planks with anchors or self-tapping screws.

- Fix the boiler on the mounting brackets.

- Attach taps, filters to the pipes;

- Connect taps at the inlet, outlet;

- Install spurs;

- Connect the heating system;

- Connect the squeegee with heating;

- Connect water supply;

- Connect chimney.

A separate room is allocated for outdoor equipment. The walls and floor are covered with special fire-fighting materials. The unit is screwed to the floor. The rest of the connection scheme is identical to the wall version.

New quality of a gas-fired boiler

From an economic point of view, it is advisable to use bottled gas for small and tiny steam rooms, for example, for a sauna on a trailer or a sauna in a fisherman's house.

Using a gas boiler for a sauna or bath allows you to solve several serious problems:

- Get rid of the fumes and the smell of scale that accompany almost all wood-burning stoves.Gas fuel combustion products are 99% harmless carbon dioxide and water;

- Ensure smooth and accurate heating of the air in the bath; in many modern gas boilers for saunas, automation can maintain the temperature even more accurately than in the case of electric heaters;

- Get the desired compactness of gas equipment. A modern gas boiler in its dimensions is only slightly larger than the size of an electric heater.

Note! The temperature of the combustion front of methane fuel in the gas furnace of the boiler is only 850 ° C, while the intensive formation of deadly carbon monoxide, the release of fine soot begins at 1000-1100 ° C. For comparison, firewood during combustion gives a flame 150-200 ° C higher than in the case of gas fuel. This means that a branded gas boiler is much safer than any wood-burning stove. If you do not interfere with the operation of burners and control equipment installed by a specialized specialist, the chimney will remain sterile, and the risk of fire or poisoning is practically zero.

Gas oven in the bath

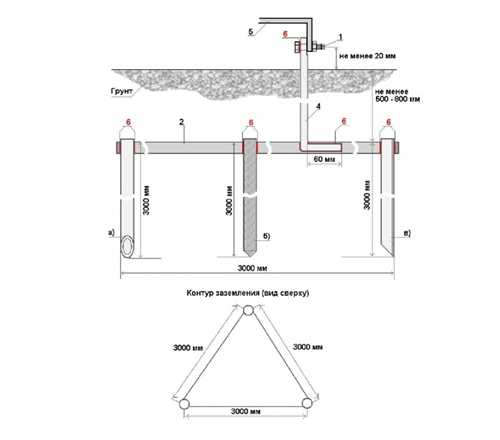

Foundation for a gas furnace

We build the foundation of the gas furnace of the bath in the following sequence:

- We swarm a pit with a depth of 70 cm, given that the bottom of the pit should be slightly wider than the base.

- We fill the bottom of the pit with sand 15 cm thick, fill it with water and wait until the water is absorbed.

- After the water has been absorbed, about 20 cm thick we pour pieces of brick and stone.

- Let's cover it all with rubble.

- We make formwork and create a reinforced frame.

- We fill it with concrete and wait until it sets a little, then we remove the formwork.

- We cover the surface in several layers with tar.

- We cover the place where the formwork was with a mixture of sand and fine gravel.

- We put moisture insulation - and the foundation is ready for the construction of a gas furnace.

Construction of a gas oven for a bath

The procedure for making a gas stove for a bath looks like this:

- We prepare a solution of sand and clay in a ratio of 1: 1. Mix all this with water until a homogeneous mass without lumps is formed.

- Soak bricks in water for 10 minutes before laying.

- We put the first layer of brick on the bitumen, which we previously placed on the foundation. After laying the first row of bricks on the mortar, let it rest for a couple of minutes.

- The second and subsequent rows are laid so that each brick lies on the joint between two bricks of the previous row. Make sure that the seams have a thickness of no more than 5 mm.

- In the process of laying the third row, you can make a door for the blower. Use strips of steel or galvanized wire to secure the door.

- In the fourth row we create a hole for ash one centimeter in size.

- In the sixth row we finish with the installation of a blower, and in the seventh we install the door for the firebox and the grate.

- Eighth row - we make a partition for the chimney and continue to lay bricks until the channels are placed in the 14th row.

- We install a water tank on the channels, so that it is located on the front wall, and the side walls support it vertically.

- The fifteenth row is the basis for a separate wall, so we put it in half a brick. We also put the next three rows.

- We put the door for releasing steam in the nineteenth row.

- Between 20 and 21 rows we put strips of steel, then we put a tank for hot water.

- The chimney is installed starting from the 23rd row.Remember that the pipe should rise half a meter above the roof, and the thickness of the pipe itself should be half a brick.

When the work with the laying of the furnace is completed, we proceed to the plaster. We clean the walls of the furnace from excess mortar and plaster with a mixture of sand, clay, gypsum and alabaster.

Using a gas stove in a bath

- We recommend burying a bottle of liquefied gas on the street near the bathhouse.

- Be sure to install an automation system that will regulate the fuel supply and when to turn it off.

- After the stove is ready, let it dry for at least two weeks, and after the first kindling, do not immediately bring it to high temperatures.

- Make sure that the refractory base under the stove extends 100 mm beyond the boundaries of the stove.

- The gas pipeline to the stove must be made of steel or copper.

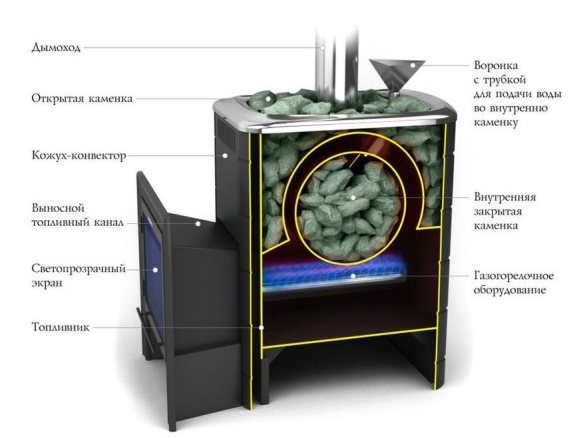

Gas oven device

The foregoing already, as it were, hinted at the fact that a gas stove is not much different from a wood stove. And indeed: if desired, you can remake the existing wood-burning stove by putting a gas burner in it.

Note! There are limitations, for example, it is better to install a microtorch burner so that the metal does not burn out, it is necessary to ensure that the flame does not touch the walls and top.

An internal heater can also become a source of problems - flowing or closed, it is not designed for a torch temperature of 1600 degrees.

Keep in mind! Even in the case when the gas is completely burned in the air, problems remain. After all, all the heat goes up, and the lower part is not heated. Therefore, the steam room heats up unevenly, and therefore longer.

By the way, the dimensions of the fuel compartment in the initially gas stove will still be smaller than in the wood stove, but this is understandable - the firewood is voluminous, so additional space in the furnace was allocated for them. Gas doesn't need that much space. He only needs air.

IMPORTANT! But this is a really significant point: for complete combustion, gas needs an influx of fresh, oxygenated air. Because any combustion is oxidation, interaction with oxygen

If it is not enough, combustion will be incomplete, and incomplete products are dangerous for humans!

To better understand this issue, let's look at the structure of the main part of a gas sauna stove:

To date, there are two types of burners:

- atmospheric;

- supercharged.

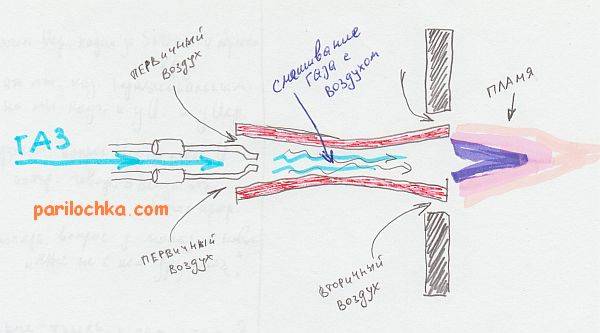

atmospheric

A cheap kind of gas burner, because it is arranged quite simply. It is a tube or tubes through which one or another natural gas flows under pressure. Before burning, it must be mixed with air, and air in this type of burner is supplied solely by means of draft. And if there is no well-conducted ventilation, then it is better not to experiment with such burners.

Well, if you are sure that your ventilation is good, the draft will work properly, then the atmospheric burner will be good - it is silent, does not depend on electricity.

True, it depends on the movement of air in the room itself - this makes changes in the proportions of the mixing gas and air. The result is uneven heating. Yes, and efficiency suffers - a lot of heat goes into the pipe in the literal sense. In addition, gas combustion is often incomplete.

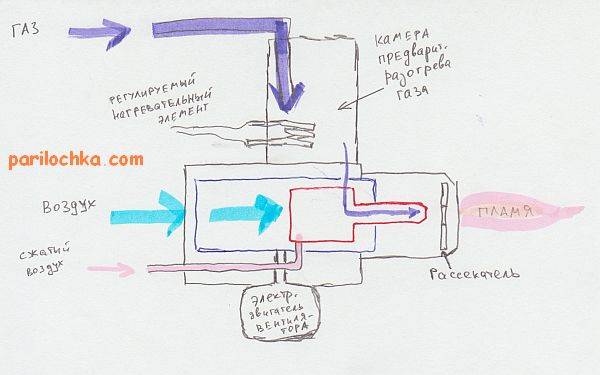

supercharged

The second type differs significantly from the first in design. The meaning of the differences is to make the thrust uniform.To do this, you need a fan, and therefore electricity.

As in an atmospheric burner, in a pressurized burner, the gas must first be mixed with air. The fan is adjusted so that the ratio is optimal. When this is achieved, the dependence on the movement of air in the steam room disappears, and with it the unevenness in the formation of the mixture and its combustion.

It is worth mentioning the advantages and disadvantages of blower or fan fans right away (yes, these are also options that are structurally the same thing). It is clear that dependence on electricity is difficult to attribute to advantages.

IMPORTANT! If someone has problems with electricity, then it is better to secure the gas oven fan with an emergency power source.

The second, less important drawback is noise. The third is the cost, which is 2-3 times higher than the cost of an atmospheric burner. As for the latter, it’s worth estimating how quickly the choice will pay off, because the pressurized burner has a big advantage: it is twice (!) More economical than atmospheric.

In addition, forced draft burners are normally installed in wood stoves. But it's up to the owner to decide, because the transfer of a wood-burning stove to gas can significantly reduce its life due to burnout of the metal.

Of the advantages, one more thing is worth mentioning: the ability to adjust the power.

Pressurized burners work both from main gas and from liquefied gas. At the same time, the transition from one type to another is quite simple.

Video

For a better understanding of the subject, watch the video, which clearly demonstrates the operation of a forced draft burner installed in a metal sauna stove.

As you can see, not everything is so simple with a gas stove, as the sellers say. Therefore, it is worth comparing the advantages of all existing types of furnaces.

Choice

On what grounds can gas stoves designed for a bath differ?

stones

The traditional stove for a Russian bath - a heater - is distinguished by a large number of rounded stones laid in a pallet. The pallet is located above the furnace and after kindling the furnace it heats up rather quickly; stones are heated to a temperature of 200 degrees or more.

They perform a dual function:

- By accumulating heat, the stones maintain a high temperature in the steam room after the firewood burns out.

- The very name "steam room" implies the presence of steam. The traditional regime for a Russian bath is 60 degrees with very high humidity. To give steam, it is enough to splash water from a bucket on the stones.

Gas heater Ermak.

If you are a fan of the Russian bath, the heater is your obvious choice. If you want to use a sauna characterized by high temperature with minimal humidity, stones are not needed. Heat storage in the case of gas, you understand, is of no value.

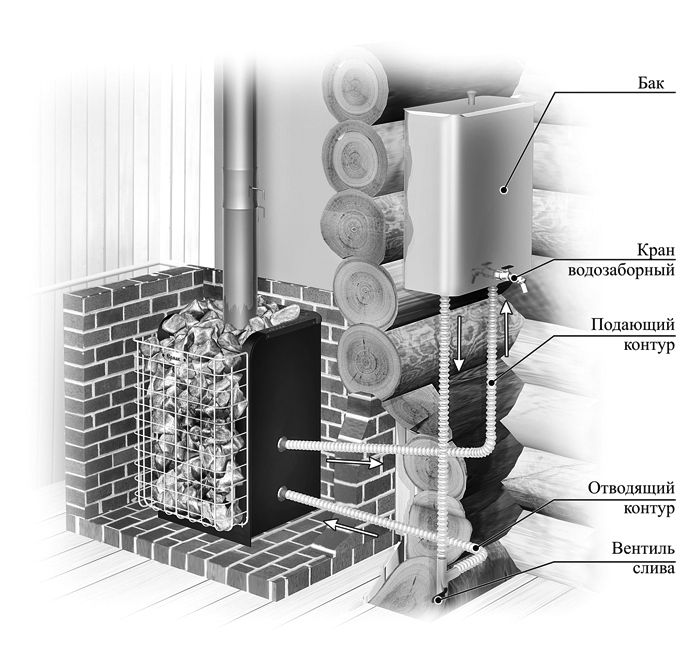

Water tank location

It can be located in the furnace body or encircle the chimney. In the first case, the source of heat for heating water is the flame of the burner, in the second, combustion products. In the humble opinion of the author, the second option is preferable: the tank additionally cools the combustion products, increasing the efficiency of the device.

Gas stoves

If you use bottled gas, an oven that combines two types of fuel is an excellent solution for you. When the tank runs out, you can fire wood into the stove.

Burner

Often it is purchased separately.

What should you pay attention to when buying?

- With a steam room volume of 18 m3, a reasonable maximum gas consumption by the burner is 1.5 m3 per hour. It is easy to recalculate the required performance for your volume.

- Registration certificate and marking must be present. Automatic shutdown when the flame goes out is mandatory (in fact, now it is almost everywhere).

- Any damage, even outwardly non-critical, puts an end to the device. Big and fat. It is about the life and health of people.

Domestic burner Teplofor.

Sheet metal oven

Sheet metal oven

Consider another version of the stove for a bath - an open metal heater lined with bricks.

Stage 1. Preparing everything you need

Most of the consumables can be purchased at a hardware store, but the components of the firebox are sold only in specialized outlets. So, in the work you need:

- sheet steel (5 mm) for the walls of the structure;

- steel (10 mm) for the bottom - it should be thicker, because the lower part of the boiler is usually more exposed to high temperatures;

- factory elements of the boiler (doors, taps, tank, etc.);

- reinforcement rods ø3 mm - a mesh for stones will be built from them;

- channels;

- 1.5 mm thick tin for the manufacture of a chimney (more precisely, its lower part);

- asbestos for the top of the pipe.

Stage 2. Assembly of the structure

Kamenka stoves with a built-in water tank: a - single-walled stove; b - a heater with a side wall in the form of a water tank; c - a heater with water tanks and an air gap in the wall

Step 1. First, a drawing of the future boiler is created - this is a very important and mandatory stage of work.The drawing should contain: a top, side and sectional view of the structure, the main parameters of all elements separately (in millimeters), sketches of the most important nodes, and so on.

To do this, you need to clearly understand the principle of operation of the boiler, own special terms and the "language" of the scheme.

Marking of a metal sheetWelding of the body from steel sheets cut out according to the markingWelding of the bodyWelding of the body

Step 2. Buying everything you need (this was described in the previous section).

Step 3. Metal is being cut. A thick-walled box is formed from sheet steel, which will serve as a body for the boiler.

Step 4. The cut sheets are welded. To do this, you need to be a professional welder or hire one (for an appropriate fee), because the welds must be perfect.

We weld a pipe section into the furnace body We weld a pipe section into the furnace body We form a water tank. We cut a hole for the chimney in the combustion chamber. Water tank and chimney with a valve. We equip the furnace with a furnace door. We weld a pipe to the boiler at the back to connect the tap

Step 5. A brick screen is being built. It is necessary to mitigate the effects of high temperatures, the source of which will be a metal structure. A kind of brick box is being constructed with ventilation holes around the perimeter (as in the previous version).

An example of lining a stove in a bath with bricks An example of lining a stove in a bath with bricks

Conclusions and useful video on the topic

All the most interesting details about electric heaters for home saunas and steam rooms.

How to properly lay stones in an electric bath and sauna stove - valuable tips from an experienced user.

What to look for when choosing a home sauna stove.

Installing an electric heater in a home sauna or bath increases the level of comfort in your home and allows you to enjoy steam treatments at any convenient time. You can place the device on the floor or on the wall.

For a correct installation, it is not necessary to invite a specialized specialist. The owner of the house can easily cope with the task. The main thing is to do everything without haste and strictly observe the current fire safety rules and the manufacturer's instructions during the installation process. So, some models suggest, when connecting, the installation of an RCD and an automatic machine on a line allocated for an electric heater. And others categorically forbid installing an RCD, in which case you can install a difavtomat.

Are you choosing an electric furnace, but do you have a number of issues that we have not covered in this article? Feel free to ask other users or our experts for advice - ask your questions in the comments section.

If you use an electric heater, go to the comments and tell beginners about your experience, add a photo showing the model of your stove, share your impressions of using it.