- Nuances of calculations

- Bottled gas convector

- Gas convector on natural gas

- The principle of operation and application of the gas convector

- How to choose power

- Features of functioning

- Combustion chamber type

- Heat exchanger material

- convection type

- Control automation

- Correct power calculation

- Disadvantages of the gas convector design

- What gas should be used

- Self-assembly

- Operating principle

- Convector gas consumption per day

- Features of functioning

- gas convector

- Manufacturers

- Alpine Air

- Akor

- Hosseven

- Karma

- Aton

- FEG

- Advantages of a gas convector

- Pros and cons

Nuances of calculations

Knowing the monthly gas consumption, it is possible to determine the annual need for gas fuel. These calculations are valid for main gas and will be somewhat different for liquefied gas. The heating season depends on the geographical location of the installation. It is determined in a tabular way according to SNIP 23.01.99 "Construction climatology and geophysics". For example, for the city of Moscow - 214 days.

Calculation of gas for heating: 36.96 X214 = 7909 m3, although in fact this is the maximum possible consumption, since the minimum outdoor temperature in winter will be only a few days, and the average temperature will be much higher. And it is she who will determine the actual fuel consumption.But for the choice of equipment, the maximum calculation is taken to ensure reliable operation of the heater at the lowest temperatures.

Bottled gas convector

This gas convector has its own characteristics that must be considered when choosing a model. The most optimal version of the device with a cast-iron heat exchanger and a control unit.

Similar to natural gas, power is also taken into account here, while it must be understood that these units are space-efficient, therefore, a separate one is installed for each. For apartments, devices with a closed chamber with a coaxial chimney are recommended, but even so it is not allowed to be installed in a multi-storey building due to the high explosion hazard of cylinder installations.

Bottled gas convector

Bottled gas convector

Many homeowners equip such heating together with the installation of gas tanks filled with gas for the entire heating season.

Calculations for determining the volume of required gas are similar to those above, except that the lower specific heat of combustion of liquefied gas is assumed to be 12.8 kW/kg, and the efficiency factor is 0.92.

For the above example, heating a house with an area of 150 m2, the calculation of the need for liquefied gas:

15 / 12.8 x 0.92= 1.27 m3 / h of liquefied gas.

Daily consumption - 1.27 x 24 \u003d 30.57 m3, and

Monthly consumption - 30.57 x 30 = 917 m3

Obviously, in the case of using liquefied gas, it will be required less per month by almost 170 m3. However, this does not mean that in general such heating will be cheaper, since its cost is much higher than mains gas.In addition, liquefied gas is inferior to natural gas in many other respects, so liquefied gas convectors are installed only in areas where there is no central gas supply.

Gas convector on natural gas

This model is preferable for autonomous heating, but in order for it to work effectively, you need to know the differences and advantages of modifications that are implemented through the distribution network

After determining the required power of the unit, the next thing you need to pay attention to is the installation method, which can be wall-mounted and floor-mounted. The former are small in size and weight, while being quite efficient, but limited to a capacity of 10 kW.

For heating large industrial premises, such as a garage or repair shops, it is recommended to choose floor options. These models have a large weight and dimensions due to the developed heating surface of the heat exchanger.

Modern gas convectors are equipped with closed combustion chambers. They are mounted together with a coaxial chimney. Due to the fact that the air is taken from the street, they do not burn oxygen during the heating process, which creates positive sanitary and hygienic conditions in the room and is a huge plus, despite the increased cost of installation, up to 30% compared to open furnace devices.

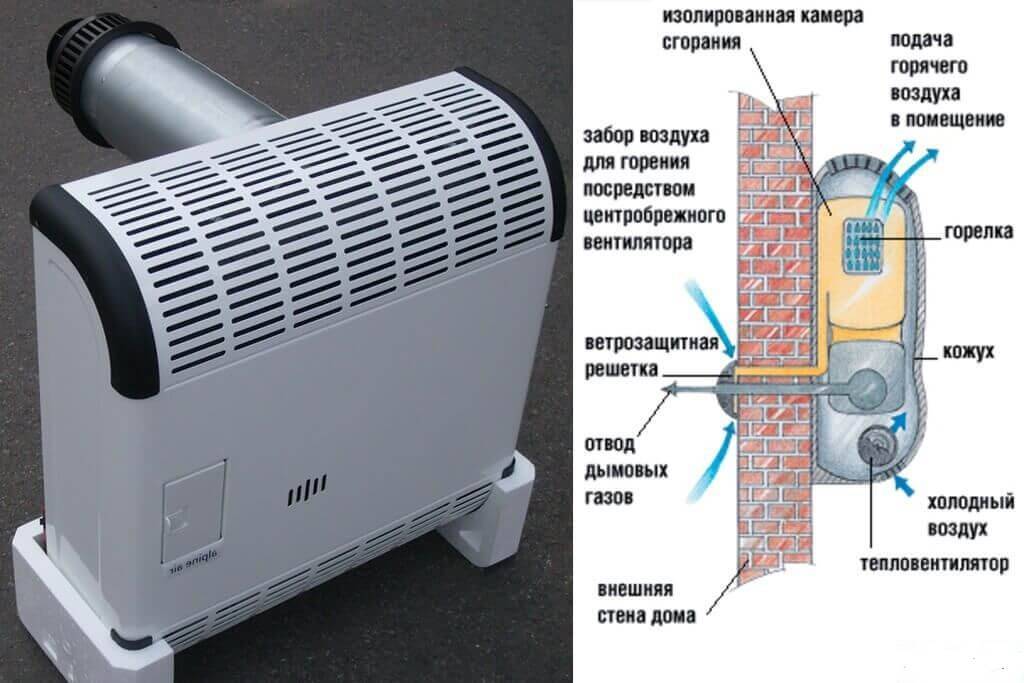

The principle of operation and application of the gas convector

Convection is a well-studied physical phenomenon of flow movement due to the difference in the masses of cold and heated air. The first enters the room, through doors, windows, cracks moves to the floor. Heating devices are also located here, heating cold air, passing it through its structural heating surface.Heated air with a lower density rushes up, and new cold air layers pass in its place, the process continues until the temperature equilibrium is reached.

This is a very efficient method of heat exchange, since it does not require a source, such as a fan, to move the masses. In addition, the advantages of this type of heat transfer are:

- Simple construction;

- developed heating surface;

- absence of overheated heating surfaces above 45 °C;

- mobility, the ability to change the location of the device;

- No need for piping.

What does a gas convector look like?

What does a gas convector look like?

The main components of the convective gas heater:

- Protective metal guard with grille to ensure entry and exit speed;

- gas heating component;

- automatic temperature control system.

Gas convectors on bottled gas are divided according to the method of installation into floor / wall, built into the floor or into the plinth. They work with a flammable energy carrier, therefore, when using it, it is required to follow the rules for the safe operation of gas installations.

The principle of operation of the convector on gaseous fuel:

- Air is taken from the atmosphere through a coaxial flue laid in the wall. It is made of two concentrically located pipes, in the central one - flue gases exit, and air enters through the annular space.

- Gas is supplied to the chamber from a pipeline or a gas cylinder.

- Cold air enters the convector from below due to natural circulation. For powerful systems, fans are sometimes installed for intensive air intake.

- The spent burnt gas is released into the atmosphere.The movement of cold air and hot flue gases occurs towards each other, that is, according to the principle of counterflow, which allows you to heat the air entering the combustion chamber, thereby increasing the efficiency of the thermal process of the installation.

- Flue gases give off heat energy through convective heating surfaces to cold air, which, when heated, rises to the top, sucking cold air into its place. The positive thing about this process is that the two air media do not come into contact with each other, that is, the process occurs without mixing of the media.

How to choose power

Each heater, and gas convector too, in the description has such a line as the recommended heated area. The data are given for "average" insulation and standard ceiling heights (up to 2.7 m). If your room goes beyond these parameters, you need to adjust the power up or down.

Power is one of the first selection criteria

If it is necessary to estimate the power of a gas convector in advance, the calculation is carried out according to the area: 1 kW of power is taken per 10 square meters. But this is if the insulation is “average” and the ceilings are 2.5-2.7 m. In case of differences, we again correct it in one direction or another. And one more thing: it is better to take power with a margin of 20-25%. The benefit is twofold:

- in case of extreme cold you will not freeze;

- the unit will almost never operate at the power limit, which will extend its service life.

If you need a more accurate calculation: taking into account wall materials, region, room location, etc., you can find information here.

Features of functioning

Bottled gas heaters can vary in many ways

It is necessary to pay attention to the characteristics of the equipment, which will allow you to choose the right heater for the features of a particular building and a private house

Main characteristics:

- Availability of automatic control.

- convention type.

- The presence or absence of a fan.

- Energy source used.

- type of combustion chamber.

- Installation power.

- heat exchanger material.

Depending on the version, these heaters can be floor-mounted or wall-mounted. Wall models are characterized by high efficiency and low weight. The power of wall convector heaters on liquefied gas can reach 10 kW, which allows them to heat large rooms. Floor-standing units can be equipped with a larger heat exchanger, but their performance usually does not exceed 5 kW.

When the operation of a propane boiler is already dangerous:

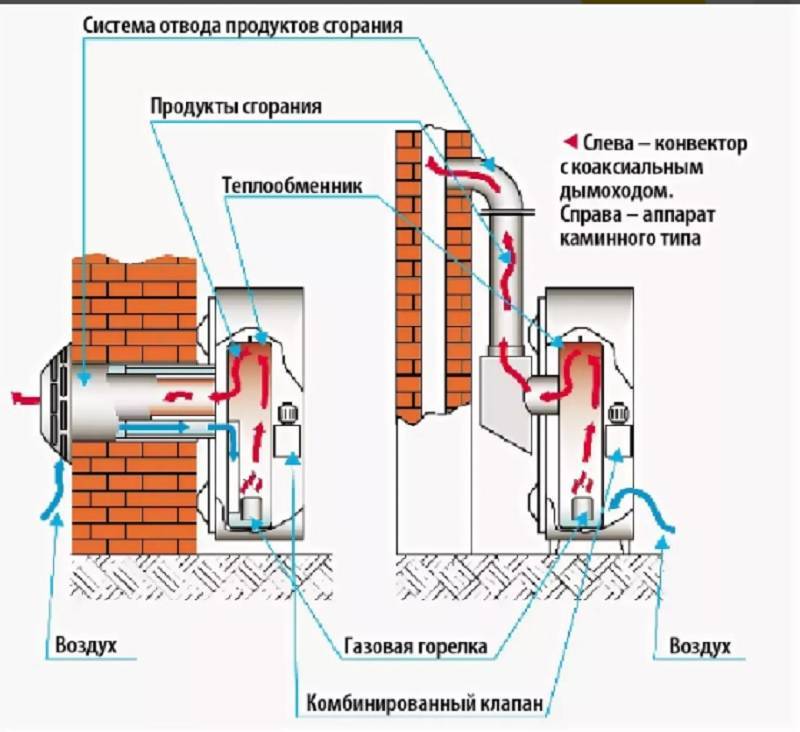

Combustion chamber type

The combustion chamber may be closed or open. In recent years, models with a closed combustion chamber have become the most popular, which ensures the highest possible efficiency and complete safety of equipment operation. Convectors with a closed combustion chamber can have a coaxial pipe instead of a classic chimney, which simultaneously takes fresh air from the street and effectively removes combustion products to the outside. The only drawback of convectors with a closed burner is their high cost.

Heat exchanger material

The material from which the heat exchanger is made will directly affect the durability, efficiency and reliability of the equipment.Today, convectors with heat exchangers made of cast iron and steel are on the market. The most durable, reliable and durable devices are those made with a cast-iron heat exchanger. With proper maintenance, they will last for 50 years. The disadvantage is the high cost of models with cast iron heat exchangers.

Some models of convectors will last you longer than others.

Some models of convectors will last you longer than others.

convection type

Depending on their type, thermal installations can use forced and natural convention. Heaters operating with natural convention make practically no noise, which allows them to be used in residential areas. The advantage of devices with forced convection is their improved performance and the ability to use such equipment to heat large rooms. Fuel consumption in a bottled gas convector can vary significantly depending on the power of the equipment and its type of convection.

Control automation

The proposed gas convectors can be equipped with both the simplest automation, which includes only thermostats and control relays, and advanced logic, which ensures maximum automation of the equipment. Depending on the automation used, the cost of heating installations will differ.

Correct power calculation

The universal formula for calculating power is 1 kW of thermal energy per 10 square meters of the area of the room. However, such calculations will be averaged and will not always allow you to choose the right converter for a particular room. It is necessary to take into account the features of the structure, the height of the ceilings, the presence or absence of windows, high-quality wall insulation, as well as the climate in the region.

When choosing a convector, you need to calculate its power

When choosing a convector, you need to calculate its power

When choosing fully automated installations that have a forced convention, one can proceed from the calculation of 0.7 kW of thermal energy per 10 square meters of room area. They can be used as the main heating method only in small buildings. A propane gas convector will be an ideal solution for a wooden or brick cottage.

Disadvantages of the gas convector design

Dimensions. This indicator for a gas convector loses significantly. These devices are not very compact, especially floor models. Taking into account the need to increase the thermal power, the dimensions and weight of the equipment are greatly increased.

The choice of several low-power convectors in a room where there are many windows. If there are several windows in the room, then when one convector is operating, the air in the corners of the room may be cold. To do this, it will be necessary to put a convector under each window, which is not always economically rational.

Low inertia. Ordinary metal gas convectors quickly cool down and heat up. This parameter is not always a negative advantage, it all depends on the type of heated housing.

The lack of mobility and the need to arrange a hole for a chimney in the wall are also a disadvantage of this type of heating device.

Gas convectors used for heating individual rooms and rooms using natural gas are considered economical heating systems. But if it is necessary to heat several rooms or large areas, they lose to more efficient and economical heating boilers with an autonomous system.

On December 30, we installed such a long-awaited convector. For several months we have beauty here - we have no water, we do not need light. In the first month, I burned about 150 rubles. The first month, of course, is longer until they warmed up their house.

And before that, the apartment is 20 sq. m., paid 800-1000 rubles a month and there were often interruptions: no light - it's cold here, no water - it's cold again. And now, there are no problems. Magnificent thing. Would recommend to everyone to install.

The main thing is that it is quickly installed, the costs are small. Nothing complicated - one hole was made, no pipes, and the hood is near the window. All. Exhausts all go there. We open the window - and that's it. Satisfied, I recommend to everyone.

Hello. Previously, I only looked at the reviews, today I want to share my experience. I have been building a house for four years now and I myself have accumulated personal experience. I chose a convector for home heating. Installed one first, then the other. Satisfied.

For a room of 80 sq. m. (a room made of fixed formwork, warm ceilings 2.80 m) in severe frosts, 60 liters of gas in a cylinder is enough for a week. Electricity is not needed at all! Really nice and warm. I advise everyone.

I bought it three months ago, read the gas convector reviews, Zhytomyr 5 KNS in a room of 25 sq. m. and in the bedroom an AGOK 2.5 convector with a cast iron heat exchanger. If you want to sleep in silence, do not regret it, add a couple of thousand rubles and choose with a cast-iron heat exchanger. Will run quietly and warm much better.

What gas should be used

But when using a special adapter kit, gas convectors quickly switch to operating mode on liquefied gas.Certain brands of convector models were originally designed with the possibility of switching to liquefied or bottled gas.

Features of work on natural gas:

- Clear technical requirements for the conditions of operation and installation of equipment. It is advisable to entrust the installation work to professionals, despite the possibility of installing it yourself. And you need to strictly follow the requirements and safety measures.

- Significant savings will not work: the price of natural gas is similar to the price of electricity in terms of 1 kilowatt of electricity.

The installation of a gas convector is justified and is an excellent way out in those regions where there are no centralized gas pipelines, and the supply of electricity occurs with great interruptions or is completely absent.

Self-assembly

You can install gas equipment in a private house with your own hands, but for this you need to have all the necessary tools and have certain skills.

The following materials and tools are used in the course of work:

- metal-plastic pipe with fittings;

- pipe cutter;

- wrench;

- sanitary silicone;

- gas tap;

- perforator with a crown "blade";

- drill with a drill;

- crosshead screwdriver;

- high-temperature polyurethane foam and silicone;

- dowels and plastic screws.

Stages of installation work:

- First you need to decide where the gas appliance will be installed. According to GOST, it is mounted under the window.

- The convector is tried on to the chosen place. You can use a tape measure and transfer the dimensions, or simply attach the unit to the wall and mark the locations of future holes.

- We look where the gas inlet is located.If at the bottom of the device, then you need to leave enough space for supplying a pipe with a fitting.

- A hole is punched in the wall along the diameter of the exhaust pipe. You can do this with a perforator. This procedure is not only laborious, but also dusty, so it is recommended to cover things with foil in advance.

- Holes are drilled and dowels are driven into them.

- The exhaust pipe is inserted into the convector. The joint should be treated with high temperature silicone. After the pipe is inserted into the wall, the convector is fixed with self-tapping screws.

- A gap is closed between the pipe and the wall. It is convenient to do this using high-temperature foam.

- A special cap is installed at the end of the pipe, which comes with the package. It prevents the burner from blowing out due to wind. Self-tapping screws are used for its fastening.

The order of work when supplying gas:

- The pipe leading to the heater must be laid along the street. This is the requirement of GOST. If the gas pipe already has a threaded connection, then it is enough to screw a tap on it and shut off the gas supply to the convector. If there is no withdrawal, then it will have to be made. To perform this work, it is necessary to invite an electric gas welder.

- After installing the gas valve, a metal-plastic pipe is connected to the convector. You can calculate its length using a tape measure.

- When laying the pipe through each meter, it should be fixed with clips, for which holes will need to be drilled in the wall.

- Installed fittings, like pipes, are lubricated with silicone, which provides additional sealing and facilitates installation work.

Now you need to check how the equipment works by doing a test run:

- The gas cock is opened and a soapy solution is applied to all fittings and connections. Inflating bubbles will indicate a leak. If any are found, the tap should be turned off and the problem fixed.

- Next, the convector starts. The gas supply button is pressed for about a minute, during which the gas will pass through all the pipes and end up in the combustion chamber.

- The piezo igniter is pressed, and a spark is formed in the furnace and a flame is ignited.

- The device is adjusted so that the temperature in the room is comfortable.

For the first time after starting, an unpleasant smell of burning oil may be felt. This is normal - this is how the camera burns on new devices. If the smell will be present for a long time, you need to make sure that the joint between the exhaust pipe and the outlet of the device is good.

Operating principle

The principle of operation of such devices is extremely simple. With the help of a gas burner, the heat exchanger is heated, the air masses are heated in a natural or forced way, passing through a hot heat exchanger, and then rise up, displacing cold air down.

Located near the floor, a gas-fired converter will effectively heat the air in the room, providing a complete solution to cold problems. Due to the possibility of choosing installations of various capacities, such devices can be used both in summer cottages, where the room usually does not exceed 15-20 m², and in private houses where it is required to heat rooms with a total area of 100 square meters or more.

This is interesting: varieties of gas tanks and refueling with liquefied gas.

Bottled gas convector:

The design of the gas convector consists of the following elements:

- A gas burner that burns fuel and heats the heat sink.

- The heat exchanger made of stainless fire-resistant steel.

- Control system responsible for gas supply and room temperature control.

- The chimney responsible for removing the products of combustion to the outside.

Everyone should know this! gas in the country, the cause of the fire:

Convector gas consumption per day

When choosing a convector for a home, it is imperative to take into account such indicators as gas consumption per day.

In addition, there are also other factors, such as:

- Gas type;

- Thermal insulation;

- Temperature of the environment;

- Operating mode.

All these indicators must be taken into account when making calculations. Standard indicators imply such consumption values per 1 kW of converter thermal power: 0.11 m3 of natural gas, as well as 0.09 kg of bottled gas. When using very powerful devices, 1 cylinder is enough for about 2-3 days.

During the calculations, it was found that heating with a gas convector is much more profitable than an electric heating model, however, only on condition that a standard main gas is located. The benefit of using bottled gas convectors is not so obvious, which is why it is recommended to use it only when it is required to create an autonomous system from the power supply.

Features of functioning

Gas-fired heaters differ in many ways

There is a huge variety of gas convectors on the heating equipment market, and if you decide to choose this option for heating your home, then be sure to pay attention to the following points:

- material for the manufacture of the heat exchanger;

- power;

- type of combustion chamber;

- used energy source;

- fan;

- type of convection;

- control automation.

Let's consider each indicator separately.

According to the method of installation, models are distinguished that are placed on the wall and on the floor. Wall-mounted are characterized by light weight and high efficiency, take up little space, but their maximum power reaches 10 kW. Floor-standing units weigh a lot, this is due to the fact that they are equipped with an increased heat exchanger, their performance can reach several mW. The combustion chamber can be open and closed. Currently, units with a closed combustion chamber are more popular. In such convectors, a coaxial pipe is used instead of a chimney. Such devices bring combustion products to the street and from there the process of air intake for the operation of the burner is carried out. Gas convectors with a closed combustion chamber have only one obvious drawback - high cost. Compared to classic models, their price is 40-50% higher. For the operation of convectors with an open combustion chamber, you need a traditional chimney that will go up. In addition, it is necessary to ensure the flow of oxygen into the room - this is carried out due to the vent, which is connected to the outside atmosphere or due to open windows. The material of the heat exchanger is an important factor in choosing a gas convector. Heat exchangers are made of steel and cast iron. If you want the heater to function successfully for many years, then purchase models with a cast-iron heat exchanger. They are not cheap, but with proper operation they can last 40-50 years.

If you want to save money, then pay attention to devices with a steel heat exchanger, such units are inexpensive, but their durability does not differ, besides, steel is prone to rust. Experts advise to purchase cast iron heat exchangers

Gas convectors can work on the type of natural and forced convection. Units operating on the principle of natural convection - practically do not make any sounds and do not cause discomfort to hearing. However, the speed of heating the premises with such devices is small, and this causes inconvenience at the stage of initial launch. Gas convectors with forced convection are more efficient. They, like natural draft units, operate on bottled gas, but are equipped with additional fans that force air through the heat exchanger. As a result, the room warms up quickly. However, they make noise. Control automation. More budget options are equipped with conventional thermostats. Thanks to the programmable control unit, you can control the temperature in the room and select the desired heating mode. When choosing the power of a gas convector, the following must be taken into account: for every 10 m² of area, 1 kW of thermal energy is needed.

It is recommended to choose convectors with a power reserve of 10-15%.

gas convector

this is a wall-mounted air heater that is great for heating cottages, offices, warehouses and industrial premises. The main distinguishing feature is that it has a combustion chamber with air intake from the street and all combustion products are also emitted outside.

Residential, service, industrial or administrative premises today can be efficiently heated without spending a lot of money and not depending on the work of utilities and centralized heating. Purchase an easy-to-install, convenient and inexpensive gas convector in our company and appreciate all the advantages of such autonomous heating.

Having bought and installed a heater at home or at work that provides the necessary amount of heat due to gas combustion, you will not be afraid of severe frosts, which often lead to freezing of water in the central heating system and its failure. In addition, you decently save on space heating. After all, gas convectors are cheaper than electric counterparts. And wall models also save space.

The advantages of this equipment are so obvious that many users prefer to use it not only as a spare, but also as the main source of heat.

All gas convectors presented in our catalog (Turkish - Alpine Air and Italian - Bartolini CALORAMA production) are characterized by: compact size and stylish design, fast heating and high efficiency, overheating protection and high wear resistance, long and safe operation. They will harmoniously fit into a room of any size and purpose and provide a comfortable temperature in the room during the cold season.

All proposed models take in air for heating from the street and thus do not burn oxygen indoors.In addition, they have a horizontal gas outlet pipe and a closed combustion chamber. Each device provides the possibility of using both main natural and liquefied gas in cylinders. Convectors differ in the presence of a cast-iron or steel heat exchanger, different weights and power. It is according to the latter indicator that the choice is often made in favor of one or another gas convector. Usually, the calculation of power occurs depending on the area of \u200b\u200bthe heated room (1 kW per 10 square meters). The differences between the models presented by us can also be attributed to a different type of ignition: electronic or piezoelectric (battery-powered).

Comparative description of Alpine Air gas convectors

Manufacturers

Among the manufacturers of bottled gas convectors there are brands from Russia and well-known foreign companies. Among the most famous firms, several can be noted.

Alpine Air

Turkish brand, widely known in Europe and Asia. It is his equipment that today is considered the most reliable and safe in operation. All models use cast-iron heat exchangers, there are built-in thermostats. The gas fittings and burner are made in Italy, the operation of the equipment is guaranteed for 50 years. Leading among popular models Alpine Air NGS-50F.

Akor

A Russian manufacturer of gas convectors that produces universal models suitable for working with both main gas and bottled gas (when installing replaceable nozzles). The equipment uses natural convection, a coaxial pipe is installed to remove the exhaust gas, there is a built-in thermostat to control the heating of the air in the room.

Hosseven

Another Turkish brand that is very popular. Its package includes a durable cast-iron heat exchanger, Italian gas fittings, and a forced ventilation system. Can work on liquefied bottled fuel or through the main connection. Popular models include Hosseven GDU-5 DK, HDU-3 DK, HP-3.

Karma

Czech manufacturer providing European quality of its products. The brand's assortment includes models that can heat from 50 to 100 square meters. m area. Components for the burner and fittings are Italian, the design of the models is concise and quite modern, the heat exchanger is steel, which somewhat reduces the efficiency of the equipment in comparison with analogues.

Aton

Russian manufacturer with a wide range of products. The brand produces floor convectors for bottled gas, the most popular model is Vektor AOGC-3. The package includes an Italian burner, enameled steel heat exchanger with increased corrosion resistance. Built-in automation provides complete protection of the flame, even with a draft or a gust of wind.

FEG

Hungarian manufacturer of gas convectors, its factories are part of the same holding with the Czech Karma. One of the leaders in the European market, all products are certified according to ISO 9001. The latest technologies are used in convectors to increase their safety for the environment. Among the popular series is Zeus.

Advantages of a gas convector

- Economic indicator. The price of an electric converter is much cheaper. But, as the reviews show, the advantage of gas convectors is the low cost of operation.For example, popular heating devices with cast-iron heat exchangers and a power of approximately 3 kilowatts cost half as much as electric ones with the same characteristics.

- Operation of the converter on liquefied gas. The gas convector is very easy to rebuild for balloon equipment. This allows the use of these heating devices in regions where there is no electricity or it is supplied with some interruptions. But in economic terms, convectors on a cylinder or liquefied gas are also economically imperfect, as well as electrical equipment.

- There is no coolant. This is a noticeable advantage in the absence of running water in houses where it is planned to connect heating devices. It is also a great factor if you need to leave the house for a long time in the winter season - the water in the convector will not freeze, because it simply does not exist here. This is a great option, for example, for utility rooms, garages, cottages.

- Environmental Safety. The gas convector does not burn oxygen into the room and is safe if all operating rules are observed.

- Possibility of temperature regulation. In gas convectors, you can easily set the desired temperature and adjust it.

- But this difference quickly overlaps during operation. Just according to calculations, the cost of heating the same area of a house when using natural gas is often 15 times less than when connected to electricity. The price of a kilowatt of electricity and a cubic meter of gas is approximately the same.

But the savings are achieved due to the fact that only 0.1 cubic meters of gas is needed to produce one kilowatt of thermal power.All these statements are justified only when the gas device is connected to the main gas pipeline and natural gas is used.

Pros and cons

Among the obvious advantages of choosing bottled gas convectors for giving or heating a house, the following points can be noted.

- Full autonomy of heating. It does not require the connection of a gas main, laying pipes, pumping water into the system. The device successfully works only on fuel coming from a cylinder.

- The use of convection. It provides the fastest possible heating of the air, makes it possible to quickly raise the temperature even in a very cold room.

- Automation of the heating system. When choosing a convector with a thermostat, you can maintain the set temperature in the room, practically without worrying about system maintenance.

- Closed combustion chamber. Burning does not burn oxygen.

- Modern design. Heating appliances from leading manufacturers harmoniously fit into the interior design of a country house or cottage.

- High installation speed. It is not necessary to obtain the approval of the gas services, it is enough to ensure the tightness of the connection.

- The efficiency of the device is above 90%. It is the best option for heating small to medium sized rooms, adjoining rooms and general areas.

- Minimum costs for the deployment of the heating system.

There are also disadvantages. It is quite difficult to accurately calculate fuel consumption, therefore, standard calculations are used, in which a device with a power of 2 to 5 kW consumes approximately 0.13-0.29 cubic meters. m of fuel per hour. At the same time, the indicators increase by 2 times when warming up a cold room and decrease by 30% when operating in a support mode.

Another significant drawback is the need for regular replenishment of gas reserves. Such a system cannot be legalized in a city apartment - it will not be possible to obtain permission to operate such a system in an apartment building. In addition, one convector is definitely not enough to heat the whole house. On average, one device is designed for 20-50 square meters. m area.