- Connecting the electric boiler to the heating system

- How to connect a solid fuel boiler

- How the scheme works

- Way to reduce the cost of strapping

- Hydraulic gun in a parallel connection system

- Power Requirements

- Tying a wall-mounted double-circuit gas boiler

- Water filtration

- Collectors and hydraulic arrows

- Homemade electric heating boilers

- Features of the power supply of electric boilers

- Electrode heating boilers

- Electrode boiler Scorpion

- Disadvantages of electrode boilers

- Floor-mounted automatic boiler with a wall-mounted double-circuit gas boiler

- Types of boilers

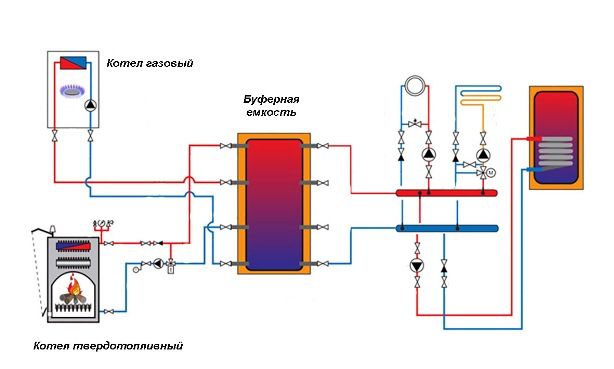

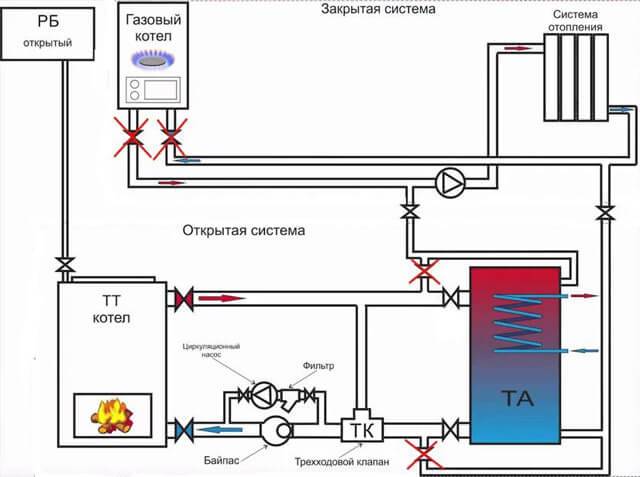

- Arrangement of a heating system with a heat accumulator

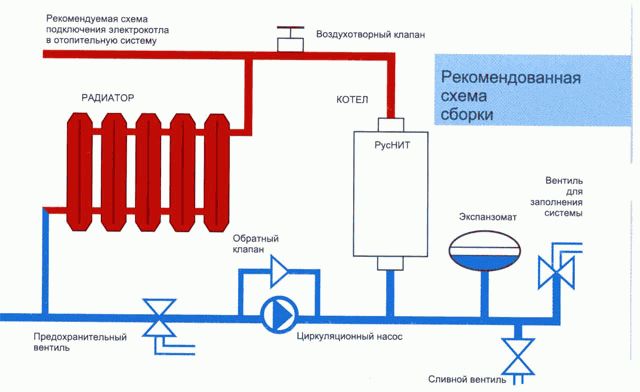

- Tying an electric heating boiler: an important step

- Features of connecting an electric boiler

- The need for piping an electric boiler

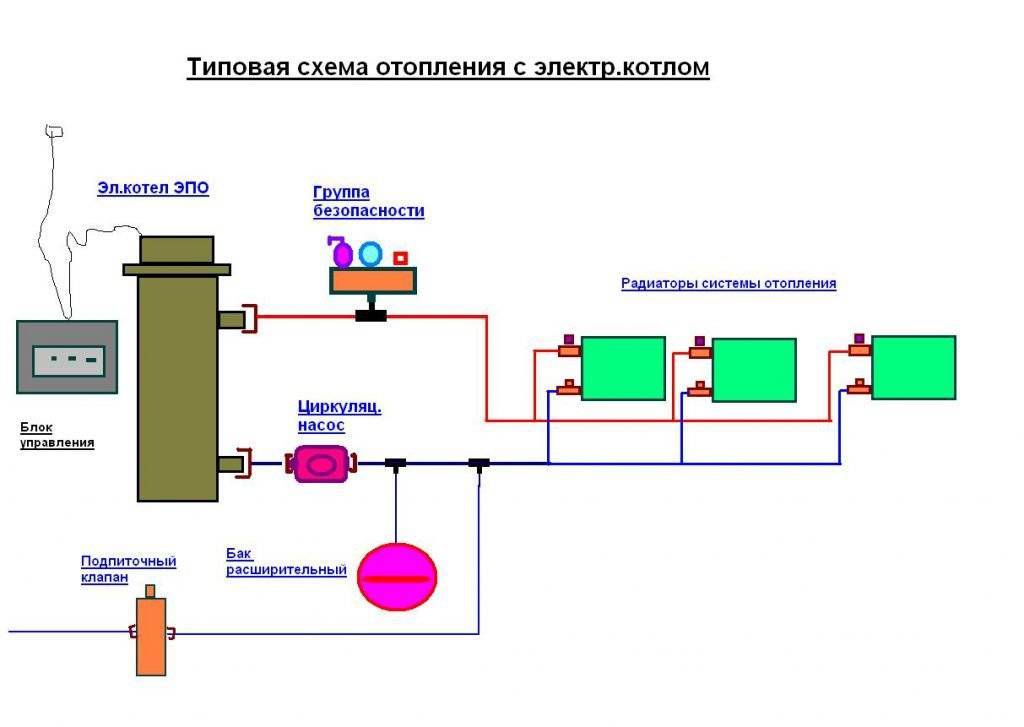

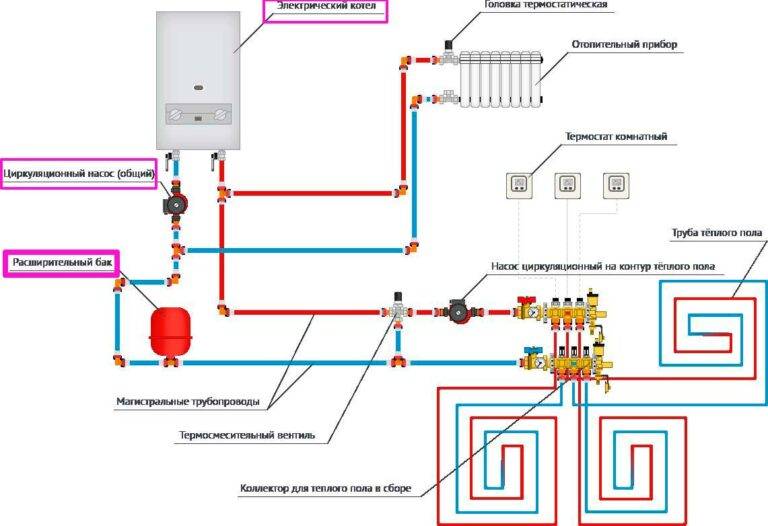

- Electric boiler piping scheme

- Emergency piping of the electric boiler

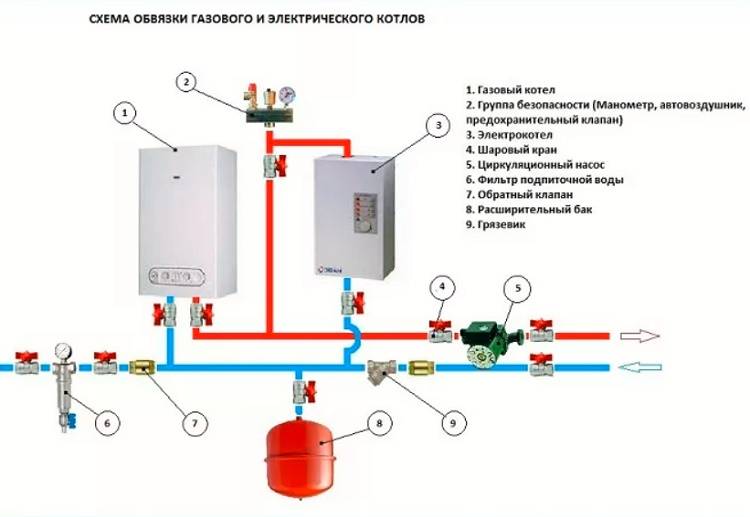

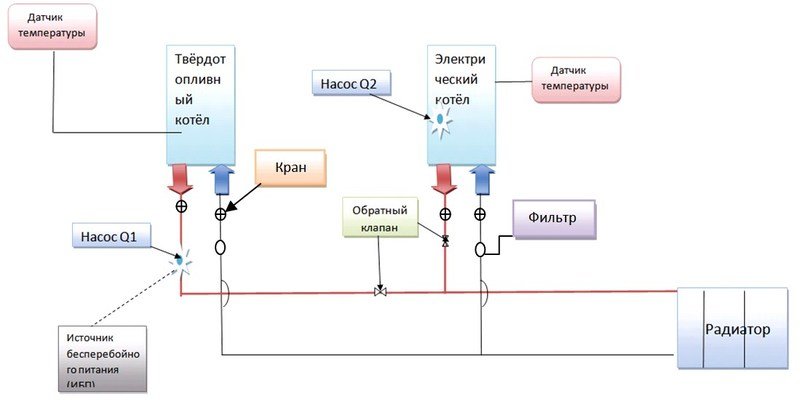

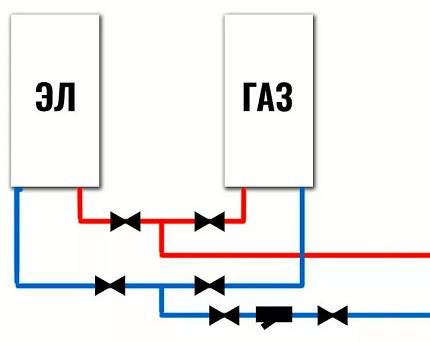

- How to make heating with two boilers

- Connection of electric and gas boilers

- Connection of gas and solid fuel boilers

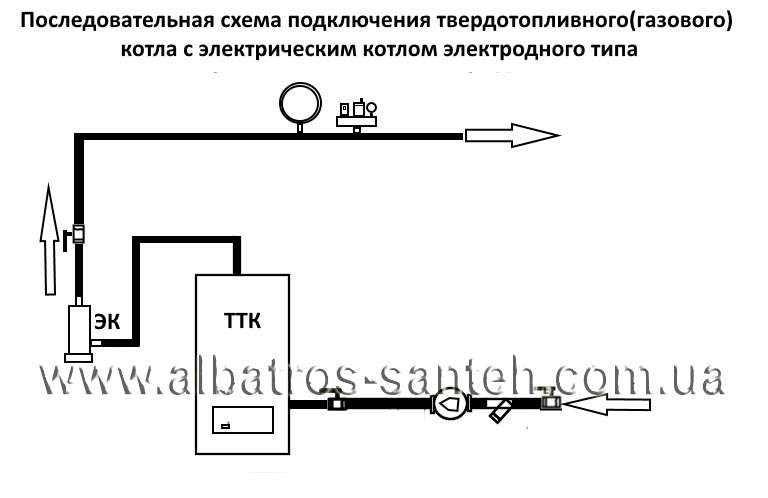

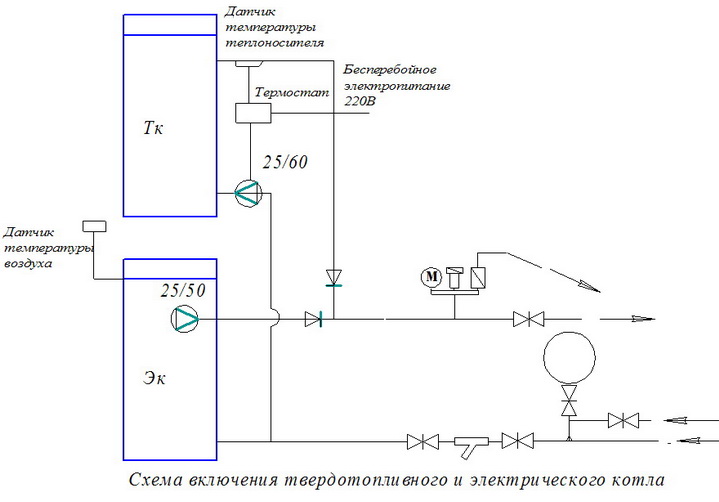

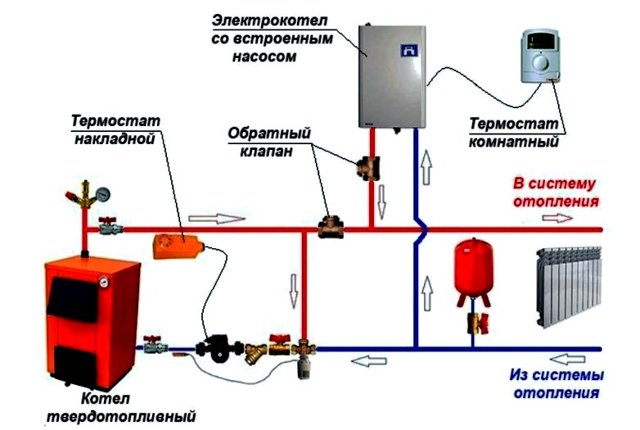

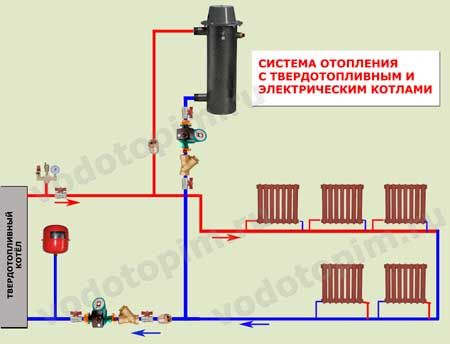

- Connecting a solid fuel and electric boiler

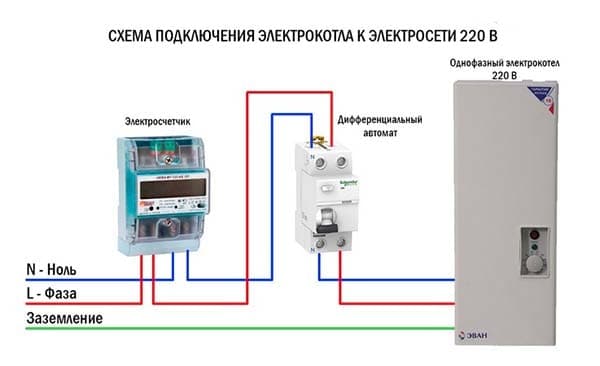

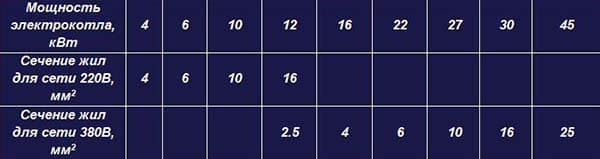

- Electrical connection

- Closed system with heat accumulator

Connecting the electric boiler to the heating system

piping of an electric heating boilerElectric heating convectors: how to choose - little tricks

To reduce the amount of electricity consumed, it is advisable to resort to the following scheme:

- equip a floor heating system that evenly distributes heat throughout the room;

- install a heat accumulator - a heat-insulated storage tank. In it, the water will be heated at night, when a lower electricity tariff is in effect, and during the day it will slowly cool down, giving off heat to the room (for more details: “The correct heating scheme with a heat accumulator”).

Connecting an electric boiler to a heating system: instructions

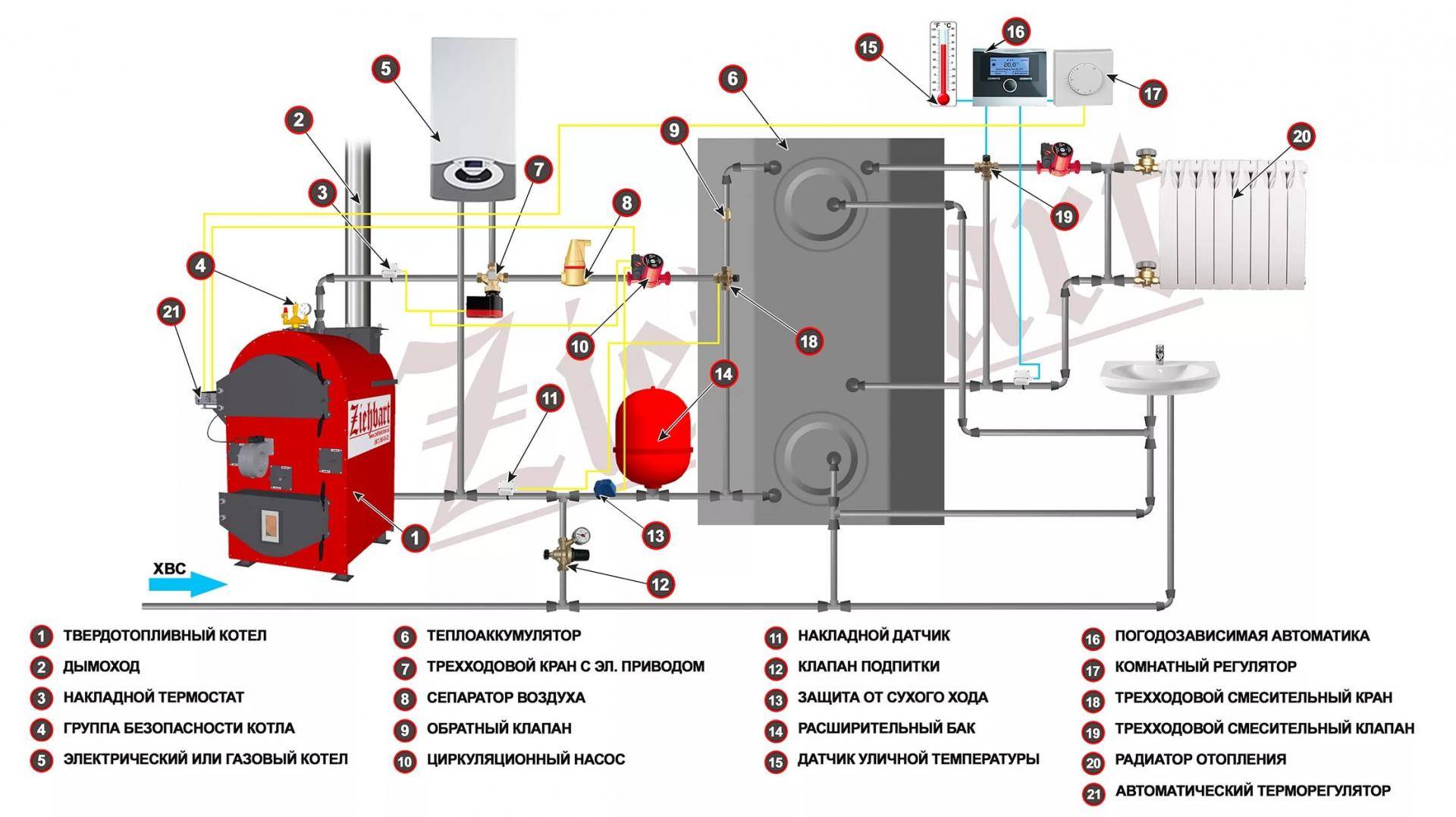

How to connect a solid fuel boiler

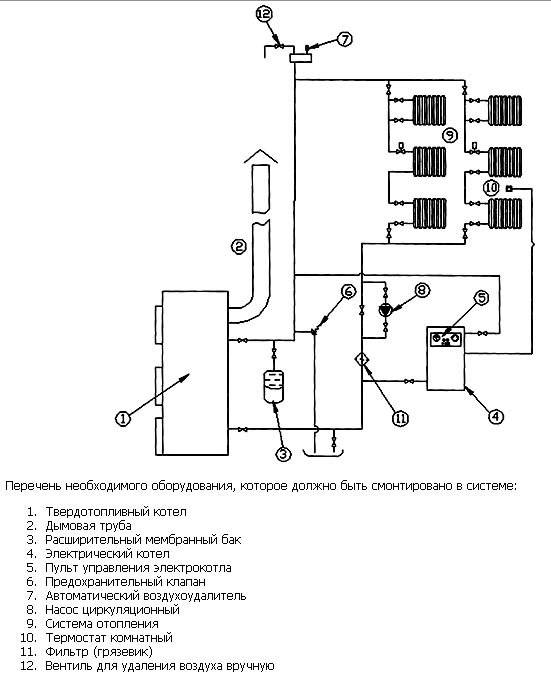

The canonical scheme for connecting a solid fuel boiler contains two main elements that allow it to function reliably in the heating system of a private house. This is a safety group and a mixing unit based on a three-way valve with a thermal head and a temperature sensor, shown in the figure:

Note. The expansion tank is conventionally not shown here, since it can be located in different places in different heating systems.

The presented diagram shows how to connect the unit correctly and should always accompany any solid fuel boiler, preferably even a pellet one. You can find various general heating schemes anywhere - with a heat accumulator, an indirect heating boiler or a hydraulic arrow, on which this unit is not shown, but it must be there. More about this in the video:

The task of the safety group, installed directly at the outlet of the solid fuel boiler inlet pipe, is to automatically relieve the pressure in the network when it rises above the set value (usually 3 bar).This is done by a safety valve, and in addition to it, the element is equipped with an automatic air vent and a pressure gauge. The first releases the air that appears in the coolant, the second serves to control pressure.

Attention! On the section of the pipeline between the safety group and the boiler, it is not allowed to install any shut-off valves

How the scheme works

The mixing unit, which protects the heat generator from condensate and temperature extremes, operates according to the following algorithm, starting from kindling:

- Firewood is just flaring up, the pump is on, the valve on the side of the heating system is closed. The coolant circulates in a small circle through the bypass.

- When the temperature in the return pipeline rises to 50-55 °C, where the remote-type overhead sensor is located, the thermal head, at its command, begins to press the three-way valve stem.

- The valve slowly opens and cold water gradually enters the boiler, mixing with hot water from the bypass.

- As all the radiators warm up, the overall temperature rises and then the valve closes the bypass completely, passing all the coolant through the unit heat exchanger.

This piping scheme is the simplest and most reliable, you can safely install it yourself and thus ensure the safe operation of the solid fuel boiler. Regarding this, there are a couple of recommendations, especially when tying a wood-burning heater in a private house with polypropylene or other polymer pipes:

- Make a section of the pipe from the boiler to the safety group from metal, and then lay plastic.

- Thick-walled polypropylene does not conduct heat well, which is why the overhead sensor will frankly lie, and the three-way valve will be late.For the unit to work correctly, the area between the pump and the heat generator, where the copper bulb stands, must also be metal.

Another point is the installation location of the circulation pump. It is best for him to stand where he is shown in the diagram - on the return line in front of the wood-burning boiler. In general, you can put the pump on the supply, but remember what was said above: in an emergency, steam may appear in the supply pipe. The pump cannot pump gases, therefore, if steam enters it, the circulation of the coolant will stop. This will accelerate the possible explosion of the boiler, because it will not be cooled by the water flowing from the return.

Way to reduce the cost of strapping

The condensate protection scheme can be reduced in cost by installing a three-way mixing valve of a simplified design that does not require the connection of an attached temperature sensor and a thermal head. A thermostatic element is already installed in it, set to a fixed mixture temperature of 55 or 60 ° C, as shown in the figure:

Special 3-way valve for solid fuel heating units HERZ-Teplomix

Note. Similar valves that maintain a fixed temperature of mixed water at the outlet and are designed for installation in the primary circuit of a solid fuel boiler are produced by many well-known brands - Herz Armaturen, Danfoss, Regulus and others.

The installation of such an element definitely allows you to save on piping a TT boiler. But at the same time, the possibility of changing the temperature of the coolant with the help of a thermal head is lost, and its deviation at the outlet can reach 1–2 °C. In most cases, these shortcomings are not significant.

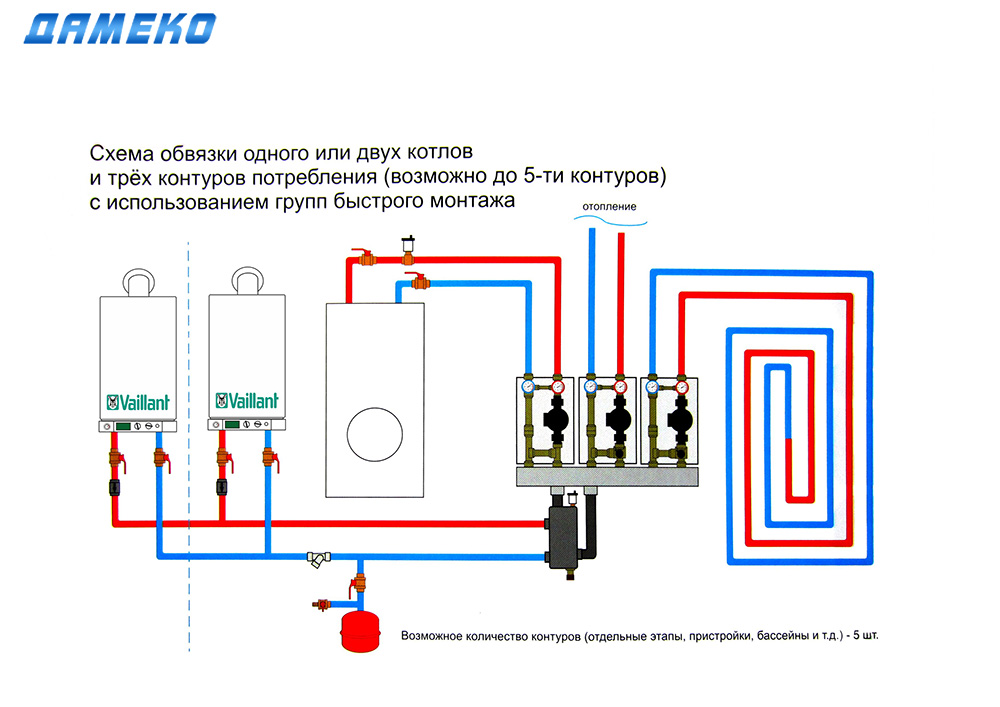

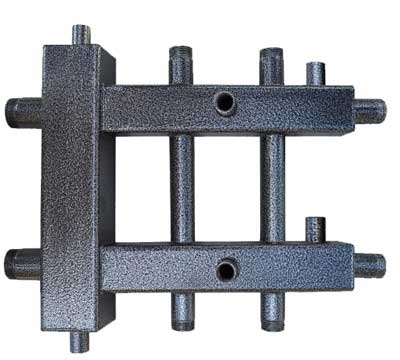

Hydraulic gun in a parallel connection system

A hydraulic arrow is a device that provides hydraulic decoupling of flows supplied to individual circuits of the heating system. It plays the role of a buffer tank that receives the flow of coolant heated by boilers and distributes it to consumers in an extensive system.

Often, the volume of coolant required for them varies, the speed of movement of heated water and its pressure differ. And in the situation under consideration, the movement of heated water from each of the boilers also stimulates its own circulation pump.

When a powerful pump is turned on, an uneven distribution of the coolant along the circuits occurs. So, the task of the hydraulic arrow is to equalize this pressure. Due to the fact that there is virtually no hydraulic resistance inside it, it will freely accept and distribute the coolant flows from both boilers.

Let's figure out if it is really necessary in a parallel system for connecting 2 boilers, especially since if you buy and install a hydraulic separator with the help of a master, and not with your own hands, the total amount will unpleasantly surprise you.

The device is a piece of pipe with nozzles, hollow or with filter meshes to remove bubbles and filter out incoming contaminants. It can be placed in any position, but more often vertically, equipping an air vent on top and a shut-off valve for cleaning from below. A hydraulic arrow is installed between the boiler and heating circuits

In the classic connection scheme, a hydraulic separator is usually not required, since the conflict of 2-3 pumps can be leveled without this device.Accordingly, if you have 2 boilers used exclusively as a backup and there are no more than 3-4 pumps in the system, there is no special need for it.

But if there are more circuits with forced circulation or heating boilers work simultaneously for power, it is best to install this device. Again, it is not known whether you will use the second boiler permanently or only in standby mode, so it is better to play it safe.

Power Requirements

This input load on the power grid requires a dedicated line to connect the converter.

The supply cables to it are laid directly from the metering device (electric meter). For emergency or planned shutdown of the generator, circuit breakers are used, which in parallel act as a fuse in case of a short circuit.

It is allowed to connect models with a power of up to 9 kW inclusive to a single-phase network, more powerful equipment in terms of selection operates on three phases.

Please note: the boiler must be connected to an electrical network with grounding

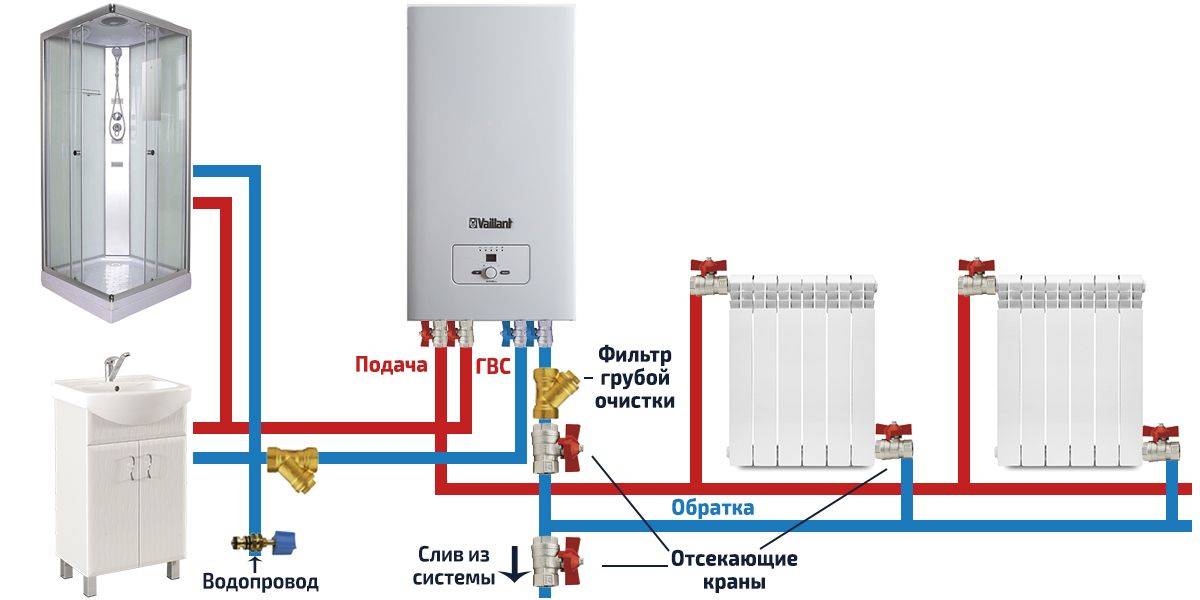

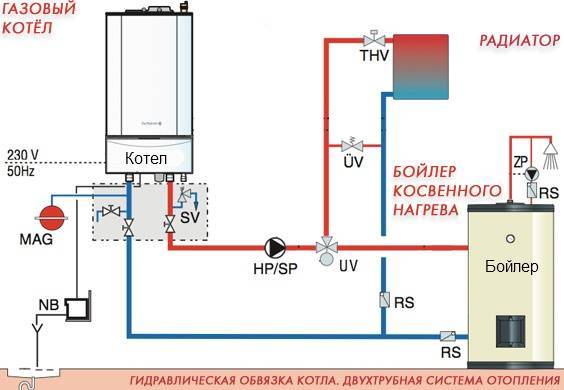

Tying a wall-mounted double-circuit gas boiler

Modern double-circuit gas boilers are distinguished by the complexity of their design. They are ready-to-use devices, ready to be integrated into heating systems. Usually they contain:

- Sealed membrane tanks (the average volume is 8-10 liters, which is quite enough for a private house heating piping scheme);

- Circulation pumps - no need to purchase them separately;

- Safety groups - safety valves, automatic air vents, as well as pressure gauges or thermomanometers are installed here.

Thus, they do not need to purchase additional equipment.

Nevertheless, additional circulation pumps and air vents can still be used in piping schemes for double-circuit heating boilers - it all depends on the complexity of the systems being laid.

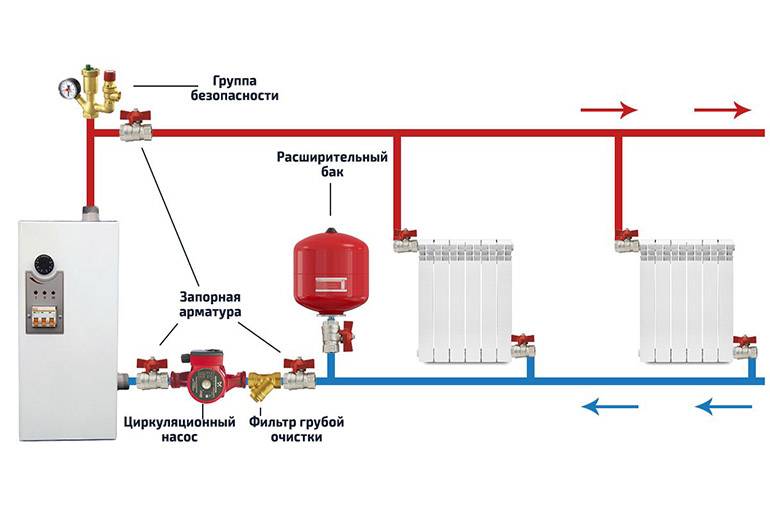

Water filtration

Water filters can also be attributed to the piping of heating boilers, both electric and gas. They protect equipment from damage resulting from banal blockages. Filters purify water mechanically, capturing small fractions of contaminants, and also provide its softening. The last point is especially important, since the high salt content causes clogging of the heat exchangers with lime deposits.

The simplest filters work on the basis of an ion exchange resin. They replace the metal atoms in the salts, making the water softer. As a result, the likelihood of limescale deposits on the insides of the boilers is reduced. But before buying filters, it is recommended to check the hardness with the help of special test strips. Membrane filter systems are considered the most reliable, but they are very expensive.

The inclusion of a filter in the piping circuit of the heating boiler allows you to reduce the cost of servicing heat exchangers, which involves cleaning them with special liquids - the procedure is notable for its high cost and the need to call a wizard.

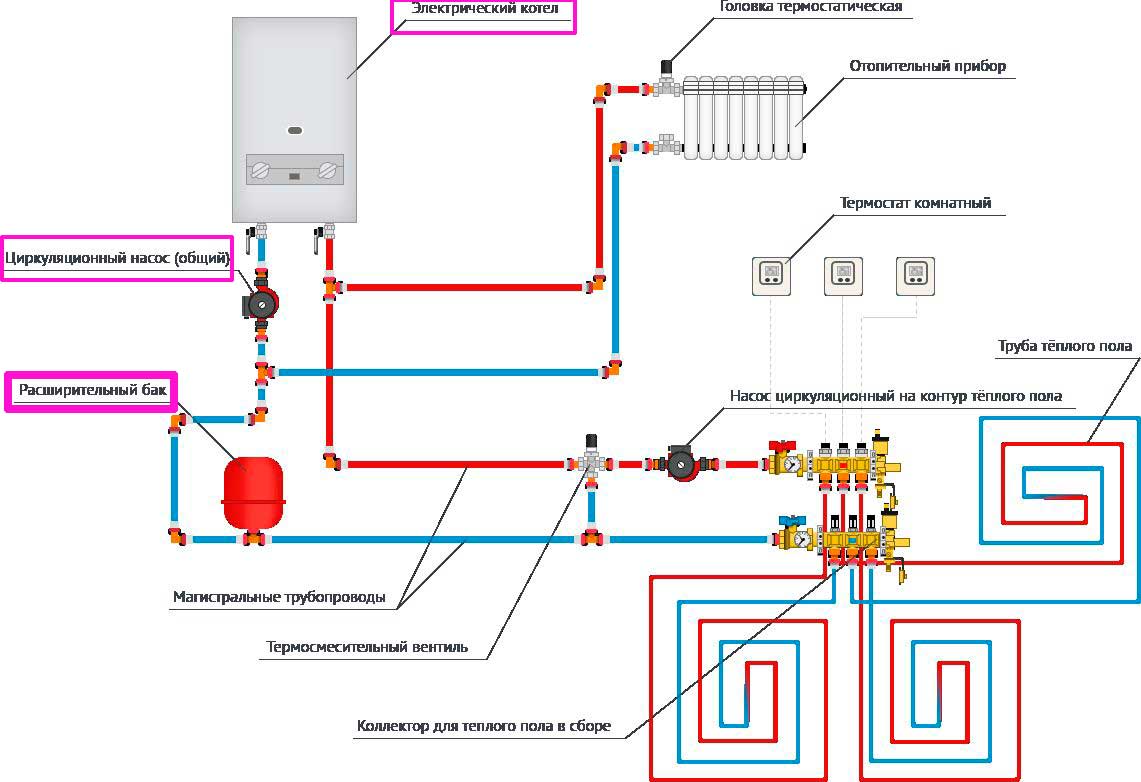

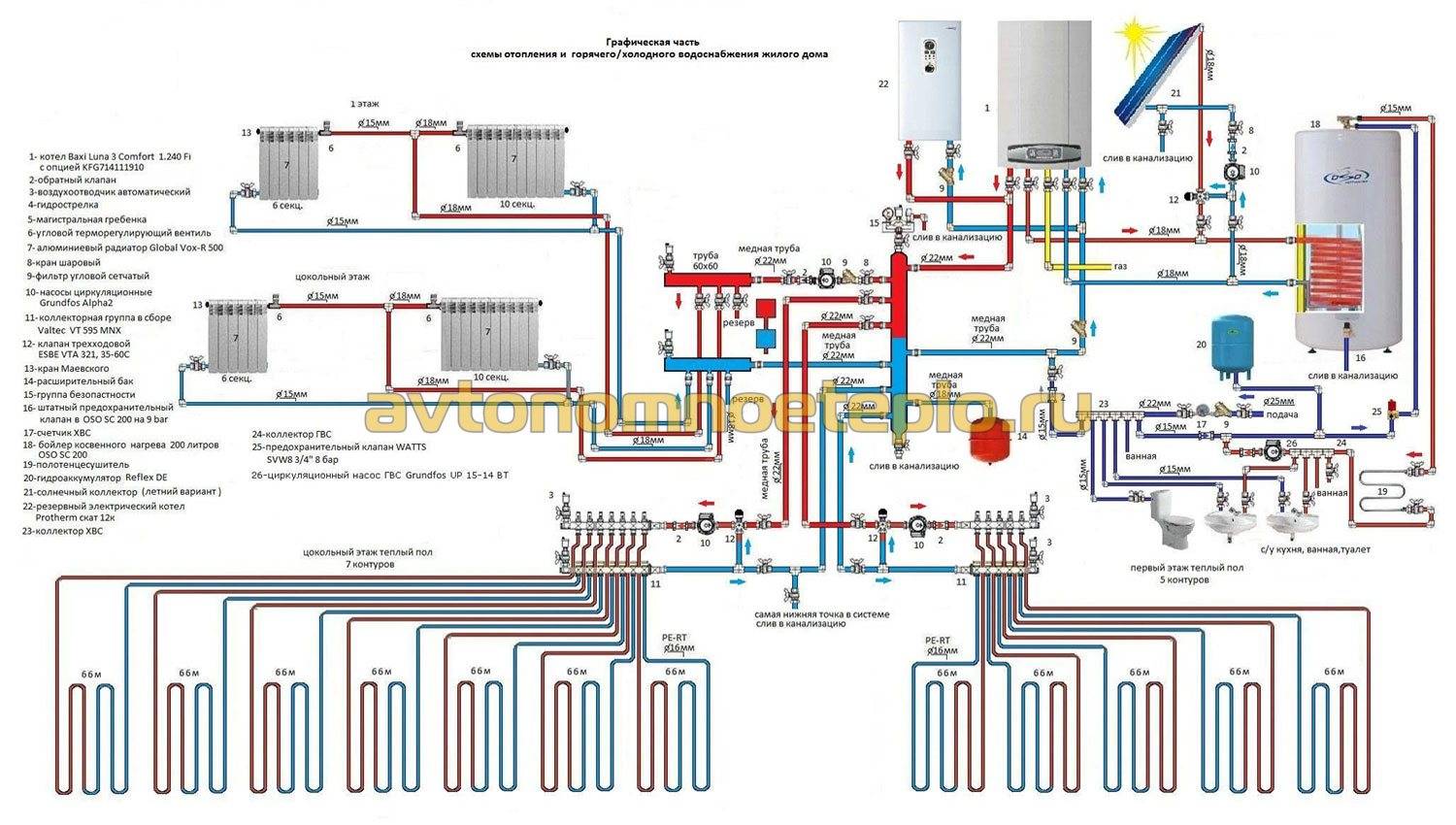

Collectors and hydraulic arrows

These devices are used to distribute the coolant over several separate circuits. Collectors are placed in the amount of two pieces - one on the supply pipe, and the second on the return.Heating circuits are connected to the collector through separate circulation pumps - room radiators, cascades of floor convectors, as well as underfloor heating. The cooled coolant returns to the return manifold and returns to the boiler through one pipe. Such a heating piping scheme is used in large households.

The hydraulic arrow resembles a collector in its design, but it is connected immediately to two pipes. It is installed strictly vertically. In its upper part there is a hot coolant, and in the lower part it is cooler. By making tie-ins, it is possible to distribute the coolant in separate circuits in accordance with its temperature. Batteries are usually connected to the upper part, and warm floors are connected to the lower part.

Homemade electric heating boilers

Having the skills to work with metal, having the necessary material and tools, it is easiest to make home-made electric boilers - electrode or heating elements. If a heating element is used as a power converter, then it is necessary to make or select a steel case in which it will be installed. All other components - regulators, sensors, thermostat, pump and expansion tank are purchased separately in specialized stores. Electric boilers can be used in closed or open heating systems.

What is needed and how to make a do-it-yourself 220v electric heating boiler efficient and reliable?

You need a container made of steel, in which one or more heating elements are placed in accordance with the drawings or sketches for the product being created. Even at the project stage for do-it-yourself heating boilers, the drawings should provide for the possibility of prompt and easy replacement of a burned-out heating element.For example, the body can be made of a steel pipe with a diameter of 220 mm with a body length of about 0.5 m. Flanges with supply and return pipes and seats in which heating elements are installed are welded to the ends of the pipe. The circulation pump, expansion tank and pressure sensor are connected to the return line.

Features of the power supply of electric boilers

Heating elements consume significant power, usually more than 3 kW. Therefore, for electric boilers, you need to create a separate power line. For units up to 6 kW, a single-phase network is used, and for large power values, a three-phase network is required. If you supply a home-made heating boiler with a heating element with a thermostat and connect it through RCD protection, then this is ideal. When installing conventional heating elements, the thermostat is purchased and installed separately.

Electrode heating boilers

Boilers of this type impress with their extreme simplicity. It is a container in which the electrode is installed, the boiler body serves as the second electrode. Two branch pipes are welded into the tank - supply and return, through which the electrode boiler is connected to the heating system. The efficiency of electrode boilers is close, like that of other types of electric boilers, to 100% and its real value is 98%. The well-known electrode boiler "Scorpion" is the subject of heated discussions. Opinions are extremely diverse, from excessive admiration to complete denial of the application for heating circuits.

It is believed that electrode boilers were designed for heating submarines.Indeed, the manufacture of heating boilers requires a minimum of materials, sea water with dissolved salts is an excellent coolant, and the hull of a submarine, to which the heating system is connected, is an ideal ground. At first glance, this is an excellent heating circuit, but can it be used for heating homes and how to make an electric heating boiler with your own hands, repeating the design of the Scorpion boiler?

Electrode boiler Scorpion

In electrode boilers, the coolant heats the current passing between the two electrodes of the boiler. If distilled water is poured into the system, the electrode boiler will not work. A special saline solution for electrode boilers with a specific conductivity of about 150 ohm/cm is commercially available. The design of the unit is so simple that it is quite simple to make a Scorpion electric boiler with your own hands, if you have the necessary skills.

Two pipes are welded to this pipe for connection to the heating system. Inside the device there is an electrode isolated from the body. The boiler body plays the role of a second electrode, a neutral wire and a protective ground are connected to it.

Disadvantages of electrode boilers

The main disadvantage of electrode boilers is the need to use saline solutions, which adversely affect the batteries and heating pipelines. The heating system for several years may require a complete replacement of radiators, especially aluminum ones (more information about which you can read here), and pipelines. Circulation pumps that are designed to work with antifreeze or clean water are at great risk.The second huge drawback is that electrode boilers require an ideal protective grounding of the case, otherwise they pose a huge danger of electric shock. It is forbidden to sell and install such equipment in foreign countries!

Floor-mounted automatic boiler with a wall-mounted double-circuit gas boiler

Below is a diagram where the two boilers indicated in the header are in one system with one radiator branch:

According to this scheme, two boilers in one system can work either simultaneously together or separately.

I have already told you how to get hot water for hot water in this case.

The same two boilers in one system with several radiator branches:

Please note: the wall-mounted boiler has an expansion tank outside. This is because, most likely, the volume of his own built-in tank may not be enough.

Due to the large flow of coolant through the thin tubes of the wall-mounted boiler, this scheme uses a hydraulic arrow and a collector, which you can not buy separately, but for ease and speed of installation, use this:

For DHW, a double-circuit boiler will be used in the same way as in the example with one radiator branch. However, an indirect heating boiler can be easily added to this multi-circuit system by connecting it to the nozzles of the same collector.

By the way, instead of one or more radiator circuits, you can connect a water-heated floor.

Types of boilers

Types of boiler equipment:

gas. Highly effective, but not worth making at home. The units are classified as high-risk devices. Creation requires skills, technologies;

Gas boiler

- electric boilers. Unpretentious in the matter of creation, operation.You can make your own heater. There are no increased security requirements;

- liquid fuel. The design is simple. Any man can do the job. Difficulty adjusting nozzles;

- solid fuel. Efficient and versatile. Easy to use and manufacture. Easily modified, rebuilt to another fuel. The units are also used for heating industrial areas.

Heat-resistant stainless steel has good technical parameters. But she's expensive. Equipment is needed to process the material. You can choose cast iron.

When self-manufacturing, it is better to take sheet steel or a pipe with a thickness of at least 4 mm. Cast iron properties are good. Simple, easy to process. It can be handled by ordinary household devices.

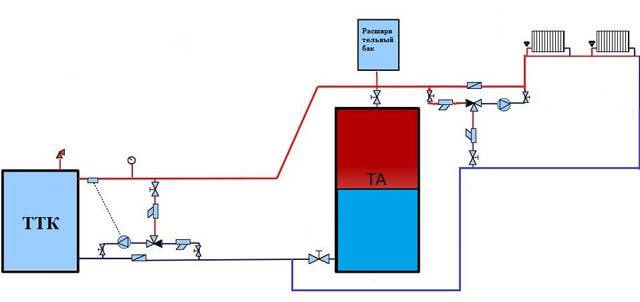

Arrangement of a heating system with a heat accumulator

The use of such an element in a scheme with two boilers in one heating system has several features, depending on the installed units:

- The heat accumulator, gas boiler and heating devices form a single closed system.

- Solid fuel boilers, working on wood, pellets or coal, heat water, thermal energy is transferred to a heat accumulator. It, in turn, heats the coolant circulating in a closed heating circuit.

To independently create a heating scheme with two boilers, you must purchase the following:

- Boiler.

- Heat accumulator.

- Expansion tank of the appropriate volume.

- Hose for additional removal of the heat carrier.

- Shut-off valves in the amount of 13 pieces.

- Pump for forced circulation of the coolant in the amount of 2 pieces.

- Three-way valve.

- Water filter.

- Steel or polypropylene pipes.

Such a scheme is characterized by operation in several modes:

- Transfer of thermal energy from a solid fuel boiler by means of a heat accumulator.

- Heating water with a solid fuel boiler without using this device.

- Receiving heat from a gas boiler connected to a gas cylinder.

- Connecting two boilers at the same time.

Tying an electric heating boiler: an important step

Features of connecting an electric boiler

On the one hand, the installation of a heating boiler cannot be called a very difficult job, and on the other hand, the arrangement of a home heating system requires compliance with a certain technology for installing an electric boiler. The advantages of the electric boiler shown in the photo over other types of heating devices are that it can be installed at any point in the heating system, and it will function well, but subject to the correct piping of this heating device, according to the connection diagram of the electric heating boiler.

Regardless of the heat supply scheme with an electric boiler, it must necessarily have a device grounding. The device can be connected to the electrical panel, but the zero phase must not be used. This is not just dangerous: the equipment perceives such actions as a short circuit.

Proper connection of the electric boiler to the network is one of the conditions for the reliable operation of the heating system. It is also necessary to select high-quality components, and besides this, you need a professionally executed piping of an electric heating boiler. Properly done work will provide a slight difference in the temperature of the heat transfer fluid at the inlet and outlet of the device.For this, the correct placement of the electric boiler with its subsequent connection is of great importance (read: “Connecting the electric boiler to the heating system: instructions”). Only if these rules are observed, the coolant will be able to give heat to the radiators as efficiently as possible.

The need for piping an electric boiler

First of all, the binding is required for the electric boiler to protect the device from overheating. As practice shows, if the piping scheme for an electric heating boiler is correctly executed, then heat losses are reduced, and, accordingly, money is saved. It also eliminates the need to purchase expensive equipment to control the operation of the system.

If the model of the heating electric boiler was not initially equipped with an automatic unit that controls the functioning of the system, then the correct piping is of great importance for the device. It will allow you to achieve maximum efficiency even when installing a not very powerful boiler.

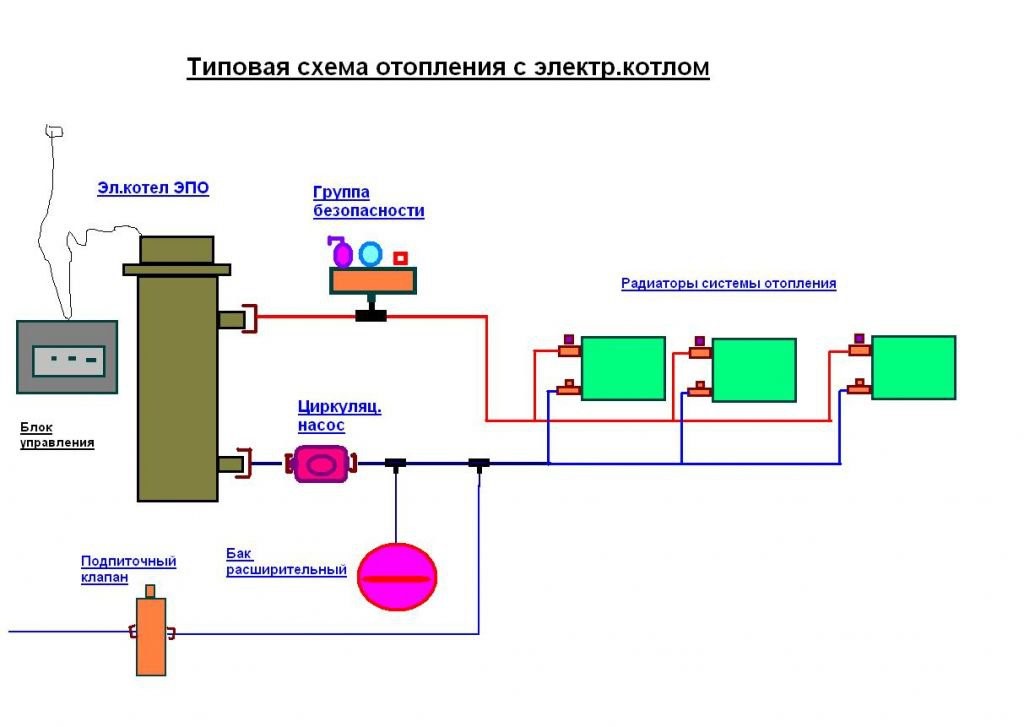

Electric boiler piping scheme

When performing the piping scheme, it should be borne in mind that in addition to calculating the power for an electric heater, one must not forget about its main purpose - to control the temperature drop of the liquid at the device inlet and outlet.

- pipes of different diameters;

- heating radiators (read: “Polypropylene piping of heating radiators is simple and affordable”);

- circulation pump;

- manometer;

- balancing crane;

- distribution valve;

- pass filter.

Of the equipment and tools, a welding machine and wrenches should be available.

As for additional and fasteners, then of them you will need:

- tees, adapters;

- safety, check, air valves;

- bolts, nuts, couplings.

The piping of an electric heating boiler is carried out according to one of four different principles:

- with forced circulation of water;

- with natural circulation of the coolant;

- classic version of the wiring;

- using primary-secondary rings.

The space heating system with natural water circulation consists of:

The scheme providing forced circulation includes the following elements:

- room temperature controller;

- radiators;

- electric boiler;

- expansion tank of open type;

- safety block consisting of a safety valve and a pressure gauge;

- tap to replenish the amount of coolant;

- pump;

- check valve;

- anti-condensate pump;

- minimum temperature sensor.

If the heating structure operates using a wall-mounted electric heater, then all its elements are also included in the piping, which, in addition to heat supply, can provide hot water supply and the operation of the “warm floor” heating system.

Emergency piping of the electric boiler

The piping of an electric heating boiler of a double-circuit scheme must necessarily provide for methods that allow you to control and manage the system if an unforeseen emergency occurs. For example, there may be a power outage. Sometimes the problem with a temporary lack of electricity can be solved by using uninterruptible power supplies or batteries (they should be recharged periodically if necessary).

How to make heating with two boilers

Creating a circuit for two heating boilers is associated with an obvious decision to maximize the functionality of diverse types of heating systems for a private house. To date, several connection options are offered:

- gas boiler and electric;

- solid fuel and electricity boiler;

- solid fuel boiler and gas.

Before proceeding with the selection and installation of a new heating system, we recommend that you familiarize yourself with the brief characteristics of the operation of joint boilers.

Connection of electric and gas boilers

One of the easiest heating systems to operate involves combining a gas boiler with an electric one. There are two connection options: parallel and serial, but parallel is considered preferable, since it is possible to repair one of the boilers, replace and shutdown, and also leave only one to work in the minimum mode.

Such a connection can be completely closed, and ordinary water or ethylene glycol can be used as a coolant for heating systems.

Connection of gas and solid fuel boilers

The most technically difficult option, as it requires careful preparation of the ventilation system and premises for overall and fire hazardous installations. Before installation, read the installation rules separately for gas and solid fuel boilers, choosing the best option. In addition, the heating of the coolant is difficult to control in a solid fuel boiler, and an open system is required to compensate for overheating, in which the excess pressure is reduced in the expansion tank.

Important: a closed system when connecting gas and solid fuel boilers is prohibited and is considered a serious violation of fire safety. Optimum performance of two boilers can be achieved using a multi-circuit heating system, which consists of two circuits independent of each other. Optimum performance of two boilers can be achieved using a multi-circuit heating system, which consists of two circuits independent of each other

Optimum performance of two boilers can be achieved using a multi-circuit heating system, which consists of two circuits independent of each other.

Connecting a solid fuel and electric boiler

Before connecting, evaluate the technical characteristics of the selected electric boiler and read the instructions. Manufacturers produce models for open and closed heating systems. In the first case, the best option is to focus on the operation of two boilers on a common heat exchanger; in the second, it can be easily connected to an already operating open circuit.

Electrical connection

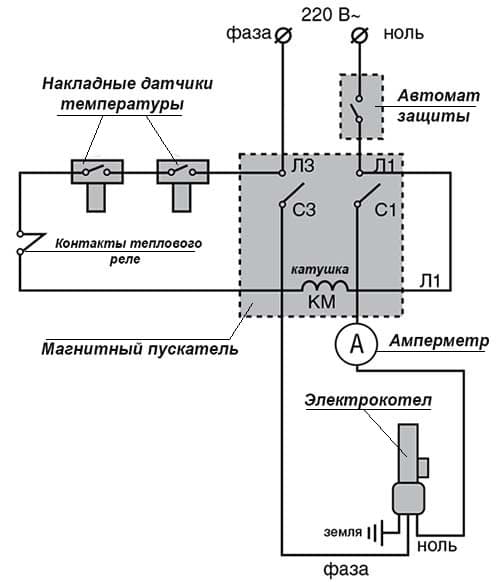

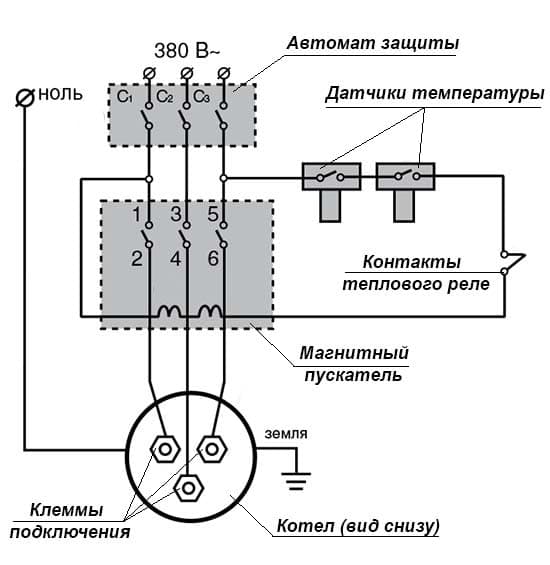

The power supply schemes are the same for all electric boilers, the difference is only in the number of phases. Devices with a power of up to 12 kW are connected to a single-phase network of 220 V, more than 12 kW - to a three-phase (380 V). What you need for installation:

- power cable with copper conductors;

- differential circuit breaker or a bunch of RCD + conventional circuit breaker;

- ground loop.

A cable of the VVG brand of any kind is used as a power line, the number of cores depends on the number of phases - 3 or 5. Select the cross section of the current-carrying part according to the power of the heat generator, usually this parameter is indicated in the instruction manual for the product.To simplify the task, we present data for different boilers in the form of a table.

The rating of the differential machine also depends on the power consumption of the heater, the operating current is 30 mA. For example, to protect the power line of a 3 kW (220 volt) unit, you need a device rated for 16 A; for a power of 16 kW (380 V), you need a 32 A difavtomat. The exact ratings are indicated in the product passport.

To independently connect a wall-mounted electric mini-boiler room, you need to remove the front panel, run the power cable inside and connect the wires of the corresponding colors to the terminal block contacts. As a rule, the neutral wire is indicated in blue, grounding in yellow-green. In the same way, the control box of the induction and electrode boilers is connected.

Electrical connections between the control cabinet and the heating block of the electrode or induction boiler are made according to the individual scheme presented in the instructions. As an example, we give a connection diagram for the popular Galan electric boiler.

Automation scheme for a single-phase network 220 V

The coolant temperature here is controlled by overhead sensors installed on the metal sections of the supply and return pipelines. The devices are connected in series with the contacts of the thermal relay that controls the magnetic starter. When the upper temperature threshold is reached, the circuit breaks and the starter turns off the heating.

Connection diagram when connecting the boiler to a three-phase network 380 V

Closed system with heat accumulator

A closed heating system does not require the installation of an expansion tank, so the installation process is greatly simplified.Most often, gas boilers are equipped with an expansion tank and a safety valve.

For the correct assembly of such a heating circuit, it is necessary to follow certain instructions:

- A tap and a pipe going to the heating appliances are connected to the supply fitting of the gas boiler.

- A pump for forced circulation of the coolant is installed on this pipe. It should be placed in front of the radiators.

- Each radiator is connected in series.

- A pipe leading to the heating boiler is diverted from them. At the end of the pipe at a short distance from the unit, powered by a gas cylinder, a shut-off valve is installed.

- Pipes leading to the heat accumulator are connected to the supply and return pipes. One of the tubes is connected in front of the pump, the second tube is connected behind the heating devices. Each tube is equipped with a tap, and tubes should also be connected here, which were previously embedded in front of and after the heat accumulator.