- Floor air heaters

- TC-series

- TE-series

- Condensing floor air heaters

- ENERGY series

- WIMBLEDON Series

- SR Series

- Household universal floor air heaters

- BA-S Series

- UT-series

- CF-GAS Series

- UTAK series

- KLIMAX series

- Series BOXY

- SUPERBEST series

- AZN series

- NT-series

- Fireplace for gas heating at home

- Types of air heating

- Choice of gas heat generator

- Heat exchanger size

- Power calculation

- Security requirements

- A little about the system

- Varieties of gas-type heat generators

- Gas heat generator device

- Rules for calculating and choosing a gas heat generator

- Popularity

- Features of temperature control in gas boilers with a thermocouple

- What is needed for

- Principle of operation

- Specifications

- About company

- Description of the work of gas air heaters caloric:

- Types of gas heat generators

- The device of gas heat generators

- Calculation and selection of a gas generator

- Features of industrial heating

Floor air heaters

TC-series

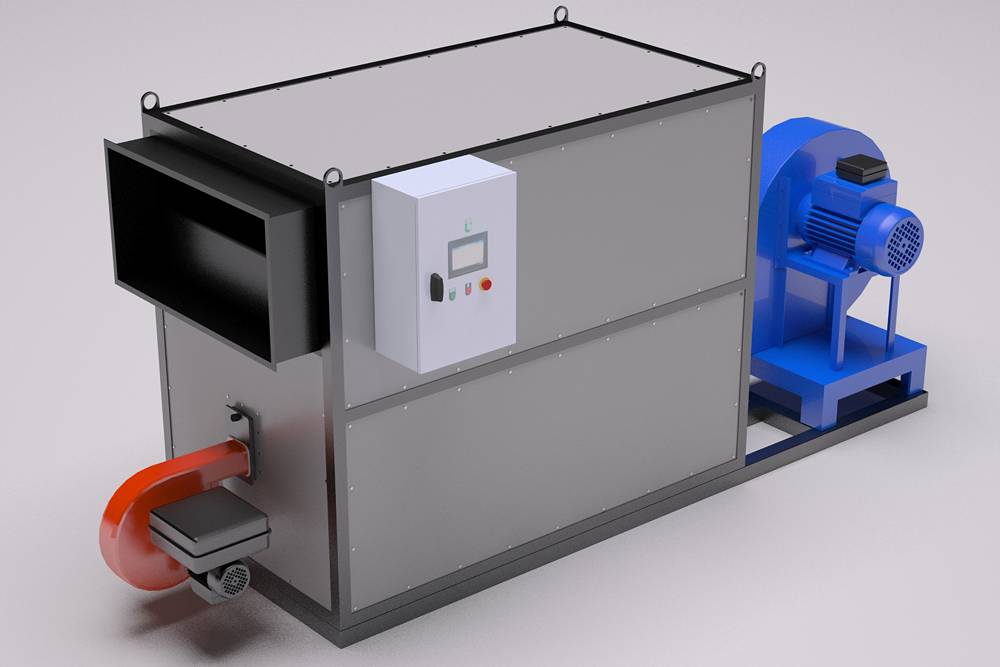

Versatile vertical and horizontal floor standing air heaters for indoor or outdoor installation

Thermal output from 60 to 1.160 kW

TE-series

Universal vertical floor standing air heaters with direct air supply

Thermal power from 47 to 391 kW

Condensing floor air heaters

ENERGY series

Universal condensing vertical and horizontal floor standing air heaters for indoor or outdoor installation

Heating output from 68 to 1.090 kW

Condensing air heaters with modulation of the flame and air flow

Thermal power from 116 to 600 kW

WIMBLEDON Series

Universal condensing air heaters for air-supported structures

Thermal power from 152 to 400 kW

SR Series

Universal air heating sections for indoor or outdoor installation

Thermal output from 122 to 1.160 kW

Household universal floor air heaters

Domestic liquid fuel universal air heaters

Thermal power from 22 to 41 kW

BA-S Series

Oil direct air heaters with built-in fuel tank

Thermal power from 34 to 105 kW

Domestic oil-fired air heaters with air supply through air ducts

Thermal power from 19 to 24 kW

Suspended gas air heaters with direct air supply

Thermal power from 17 to 37 kW

Suspended gas air heaters with direct air supply

Thermal power from 15 to 105 kW

UT-series

Suspended gas heaters with centrifugal fan for indoor or outdoor installation

Thermal power from 25 to 105 kW

CF-GAS Series

Autonomous monobloc air handling units

Thermal power from 34 to 590 kW

Cooling capacity from 24 to 440 kW

UTAK series

Self-contained modular condensing units with two airflow stages and built-in recirculation duct

Thermal power from 121 to 758 kW

KLIMAX series

Autonomous condensing units with gas heat exchanger, heat pump and recuperator

Thermal power from 22 to 57 kW

Cooling capacity from 19 to 52 kW

Series BOXY

Autonomous monoblock units with heat pump and electric heater

Thermal power from 25 to 200 kW

Cooling capacity from 49 to 210 kW

Universal heat generators for agriculture

Thermal power from 60 to 240 kW

Heat generators for greenhouses with air supply at ground level

Thermal power from 161 to 769 kW

Heat generators of direct heating for farms and poultry houses with afterburning of ammonia

Thermal power 80 kW

Mobile direct heat guns

Thermal power from 31 to 115 kW

Liquid-fuel mobile heat generators of indirect heating

Thermal power from 60 to 175 kW

High efficiency water chillers with environmentally friendly R410A refrigerant

Cooling capacity from 8 to 40 kW

SUPERBEST series

Highly efficient reversible heat pumps with environmentally friendly R410A refrigerant

Thermal power from 7 to 34 kW

Cooling capacity from 7 to 38 kW

AZN series

Water fan heaters for space heating or cooling

Thermal power from 13 to 115 kW

Cooling power from 5 to 13 kW

Combined system of condensing boiler and fan heater

Thermal power 35 kW

NT-series

Monoblock thermal air conditioners for heating and cooling air

Thermal power from 50 to 252 kW

Cooling capacity from 36 to 170 kW

Floor and ceiling fan coil units

Thermal power from 3 to 24 kW

Cooling power from 2 to 11 kW

Floor and ceiling fan coil units

Thermal power from 4 to 17 kW

Cooling power from 2 to 9 kW

Recuperators

Recuperated heat output from 2 to 102 kW

Fireplace for gas heating at home

At the cost of equipment, gas fireplaces are comparable to electric or wood-burning counterparts. But gas fuel is much cheaper.

And, unlike firewood, gas heating with a fireplace in a country house assumes that there are no problems with ash. Plus, you don’t have to constantly monitor the operation of the firebox and take care of splitting logs.

Fireplaces that convert gas into heat energy are used in heating systems, because. are not equipped with devices necessary for servicing two circuits

By type of installation, gas fireplaces are:

- wall-mounted;

- island;

- embedded.

According to the general design and internal content (burners, automation, combustion chamber arrangement), they completely repeat gas boilers. In both cases, the technology for connecting to networks is identical. Differences exist only in the principle of space heating.

According to the principle of connecting and organizing the heating system, gas fireplaces are similar to floor heating boilers

A hot water boiler was originally designed to heat water, and an ordinary fireplace was designed for air convection from the body and front screen, behind which fuel is burned.

Types of air heating

The principle of operation of the air heating system is implemented on the direct heating of the air of the heated room. In addition to the heating function, the complex can perform a number of other functions - air conditioning, ventilation, air purification and humidification.

Air heating has various configurations and is classified according to several criteria. According to the method of laying the air distribution network, the system is divided into 2 types:

- suspended;

- Floor.

Suspended (ceiling) laying of air ducts is carried out along the ceiling of the premises, air is supplied from top to bottom. The floor system is mounted along the perimeter of the room in the plinth area or directly in the floor structure.

The floor configuration is more advantageous, because the volume of warm air enters directly into the area of occupancy. The advantage of the ceiling system is to save space in the room - the network is laid in the upper part of the room.

According to the type of air circulation, the system also has two subspecies:

- natural circulation;

- Forced (pressure) circulation.

Natural circulation is based on the principle of convective air movement. Heated air tends to the upper part of the room, its place is taken by heavier cold air. The only advantage of convective circulation is complete energy independence. The disadvantages of this type of circulation - instability, low temperature in the zone of human presence - practically excluded it from implementation.

The main type of circulation of the air heating system is forced. It is implemented through the use of a fan. Depending on the size of the system, the air discharge pressure of the fan is in the range from 100 to 2000 Pa. The advantage of pressure circulation is high-speed heating, stable operation, maneuverability of the complex. Heating in this case is completely dependent on the constant availability of a stable supply of electricity.

On a qualitative basis - the method of heat exchange - air heating has 3 configurations:

- Straight-through;

- Recirculation;

- Combined (mixed).

The direct-flow system combines the functions of heating and ventilation. The air intake is carried out outside the room, after heating it enters the heated zone. At the same time, high microclimate indicators are achieved in the heated room, but fuel consumption is the highest among all system configurations.

The recirculation system works in a closed cycle - air is taken from the room, heated and re-supplied into it. This type of air heating is not the best in terms of air quality, but it consumes the minimum amount of air.

The mixed system includes the principles of operation of two main types - direct-flow and recirculation complexes. A certain amount of fresh heated air is constantly mixed into the recirculated volume in a certain proportion.

By appointment, air heating systems are divided into autonomous (individual) and centralized. Individual systems are designed for heating private houses, centralized - for heating large objects.

Air heating control and regulation systems have varying degrees of complexity, ranging from manual control to fully automated operation.

Choice of gas heat generator

Partly because this possibility is fairly new, partly because hunting is the best option, when buying a gas heater there are questions that can not always be answered competently. Therefore, buying a gas heat generator can lead to disappointment due to the incorrect operation of the system.

Heat exchanger size

And, perhaps, the first thing to be based on when choosing equipment for a private house is the size of the heat holder, it should be one fifth larger than the burner.

Power calculation

For the most competent selection of a heater, you need to calculate what kind of power of the heat generator is acceptable for the minimum heating of rooms, for this you need to use an example of the formula: P \u003d Vx & # 916; Txk / 860, where V (m3) is the final area of the heated space, & # 916; T (°C) is the difference between indoor and outdoor temperatures, k is an indicator focused on thermal insulation in the selected building, and 860 is a factor that converts kilocalories to kilowatts. Regarding the mark (k), if there are difficulties with this information about the room, then you can use a specialized directory.

In order to more clearly demonstrate how exactly the power of the heat generator device is calculated, consider an example:

- Given: area - 100 m2, height - 3m, inside temperature +20, outside temperature -20, k - 2.3 (a brick building in one layer).

- The calculation is carried out according to the example: Р=VхΔ Tхk/860

- Result: P \u003d 100x3x40x2.3 / 860 \u003d 32.09 kW

It is with these indicators in mind that we need to select gas heat generator for air home heating. The power parameters of the mechanism and its coincidence with the required ones, you need to look in the product description.

An equally important point: for the smooth operation of the mechanism, it is necessary to provide it with a constant supply of fresh outdoor air. For this, a ventilation system is always used in the premises, as soon as cold air can be taken from there, which is able to support combustion.In the event that there are problems with ventilation in the house itself, then it is better to purchase a suspended heat generator with an outlet to the street.

Air heating ventilation system

In addition, if the gas heater in the air heating system has a supply to street ventilation, this will allow warm air to be as breathable as possible, excess hot air will not be blown into the room, and therefore the possibility of a lack of dry air and additional mechanisms for humidifying the space will be preserved. .

Security requirements

Also, there are special safety requirements, the meaning of which is that 0.003 m2 of ventilation hole must be allocated per 1 kW. If there is no such possibility of organizing the room, then you will have to ventilate the space with your own hands, opening windows and vents for ventilation. At the same time, it should be borne in mind that in this case, the area of \u200b\u200binfluence of ventilation increases and a little more than 10 meters squared is already needed for 10 kW.

Examples of coefficients for calculating the heating power and thermal insulation:

- 2-2.9 - an ordinary brick structure, if one layer of brick is visible;

- 3-4 - houses from a wooden panel or profiled sheet;

- 1-1.9 - double insulated brick layer;

- 0.6-0.9 - houses of modern construction with new walls and windows.

A little about the system

If we briefly describe the principle of operation of gas-air heating, we can say that this is a system that heats a room by supplying a powerful jet of hot air.

It should be noted that recently gas-air heating systems are becoming more and more in demand.

There are several reasons for this:

- Fuel availability.Gas is by far the most inexpensive type of fuel used in heating systems.

- Low equipment cost. Since such a system requires only an air heater and an air duct system. That is, funds are not spent on pipes and radiators.

- Ease of installation.

- High level of safety - the possibility of a pipe or radiator break due to their absence is excluded. In addition, the heat generator itself is equipped with a significant number of sensors that help control its operation.

- High heating rate. Such a system allows you to warm up the room to a comfortable temperature in a short time.

- Wide range of applications. Gas-air installations are perfect for both heating private houses and maintaining heat in industrial and industrial premises.

- Profitability. If you set the heating level to low, you can significantly save fuel.

Varieties of gas-type heat generators

The most common type of device is a gas air heater for air heating. Modules are available in two types - mobile and stationary. Stationary can be hinged or floor.

Stationary gas heaters for heating are suitable for use in various areas, including everyday life.

Mounted differ in small dimensions and are fixed on the walls, floor differ in:

- vertical - devices of sufficient height, convenient for installation on the street or in a private house (in the basement);

- horizontal - have a small height and are suitable for compact spaces.

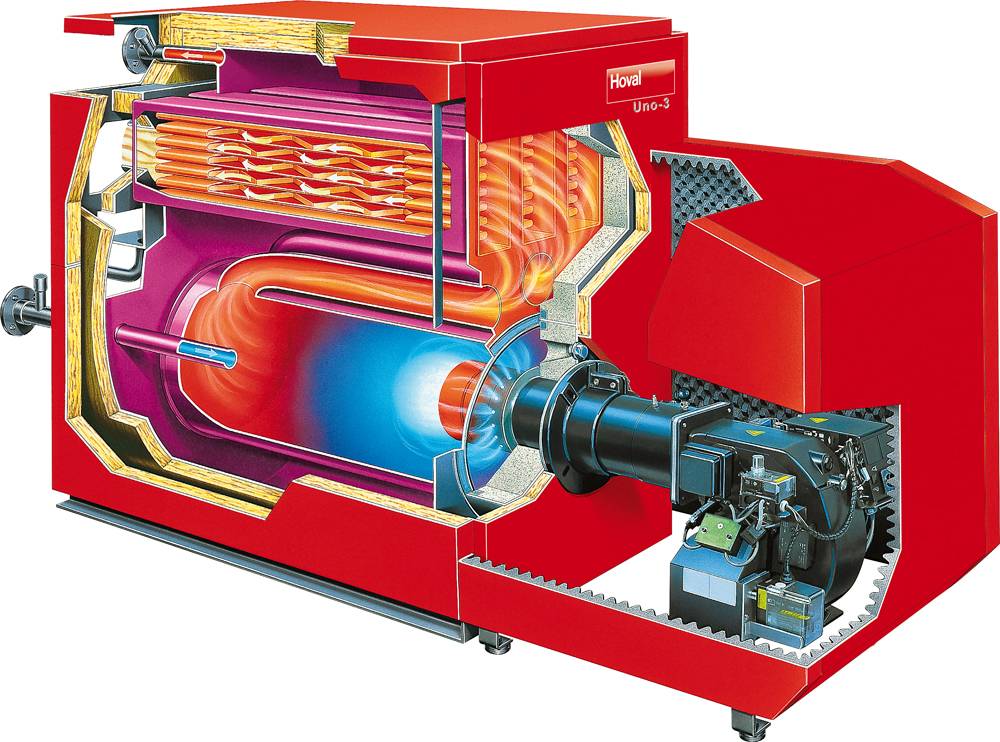

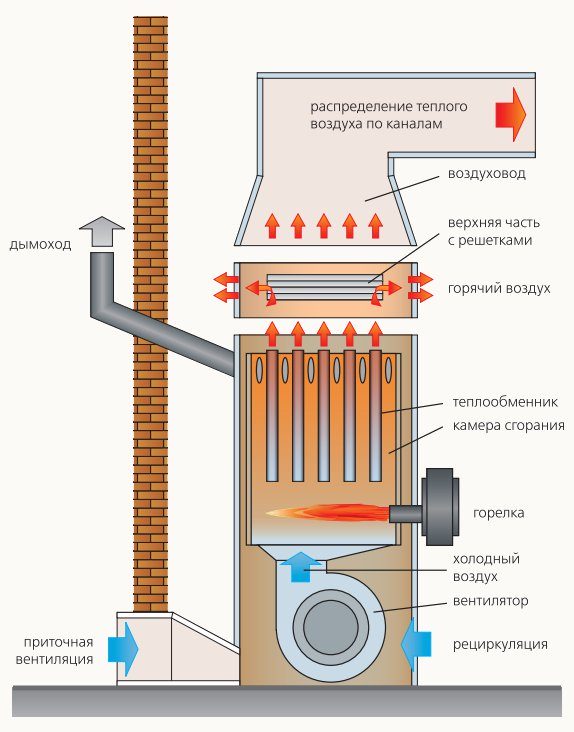

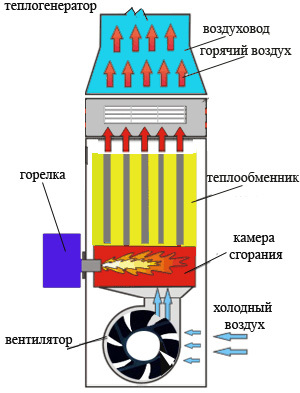

Gas heat generator device

This is an air heating unit that has a simple device:

- Fan.Designed to supply air for heating and removal of waste streams from the system. Working out is displayed up, out.

- The gas burner supports the combustion of fuel, due to which the coolant warms up.

- The combustion chamber in which the combustion of the energy carrier is carried out. With a sealed chamber, natural fuel burns without residue, that is, the amount of carbon dioxide emitted is minimal.

- The heat exchanger provides the process of heat exchange between the room and the heat generator. The heat exchanger also protects the equipment from overheating.

- Air ducts are needed to transport heated flows to rooms.

The principle of operation is simple - the fan sucks cold air into the heat generator, the flows receive thermal energy from burning fuel and are transported to the room through air ducts. The cooled air is then released outside or enters for secondary heating - the cycle is maintained as long as the heat generator is switched on.

Not only air ducts are responsible for the uniform distribution of heat flows, but also valves, as well as grilles - all pipelines that discharge flows through the rooms are equipped with devices.

Rules for calculating and choosing a gas heat generator

In order for the device to maintain the functionality of the system at the proper level, it is necessary to decide on some nuances. In particular, the size of the heat exchanger must be larger by 1/5 of the dimensions of the burner.

To calculate the power, the formula is used - P = VxΔTxK / 860, designations:

- V is measured in m3 - this is the area of \u200b\u200bthe room that needs to be heated;

- ΔT is measured in C (temperature) and denotes the temperature difference in the house and outside;

- K is an indicator of the thermal insulation of the building, a number is selected from a special directory;

- 860 is a coefficient indicator that converts kilocalories to kW.

Simple calculations will help you choose an air heat generator for each individual building. All technical parameters of the device are indicated in the device passport.

Popularity

If you check for positive reviews on the network, you can make sure that air heating heat generators are in demand. Firstly, this is fully explained by the type of fuel used - gas is rightfully considered the most accessible combustible material. Secondly, it is difficult to imagine a more efficient unit for heating non-residential premises.

Thanks to the forced air flow, heating is carried out many times faster. Also, do not forget that the consumer chooses the direction of the flow of warm air. This means that the part of the room that needs it most of all will be heated.

The price range allows you to purchase models of heat generators for almost everyone. Of course, there are more expensive models, but there are also affordable ones.

Features of temperature control in gas boilers with a thermocouple

The widespread use of equipment is due to the fact that this device is considered the main way to measure air temperature, as well as control the level of the flame.

After all, the device is not exposed to elevated temperatures and operates according to a special principle that allows you to get accurate readings and quickly respond to even minor changes.

What is needed for

Thermocouple is a device that is installed in heating equipment and is designed to convert thermal energy into electric current for electromagnetic coils and performs the function of the main component of gas control protection. The device works in combination with a special shut-off gas valve that shuts off the fuel flow.

Principle of operation

For the manufacture of the device, an alloy of metals is used. It withstands exposure to high temperatures. However, if the equipment fails, the operation of the gas boiler will be stopped.

Photo 1. Thermocouple for a gas boiler with automatics 345-1000 mm, Russia.

After all, this thermoelement functions in combination with a special electromagnetic shut-off valve that regulates the flow of gas into the fuel path, which closes immediately after the thermocouple breaks.

The principle of operation of the device is based on such a physical phenomenon: two metals are connected and when heated at the attachment points (the working area that is placed in the flame), voltage appears at the cold ends. This is called the Seebeck effect.

Attention! Many models of solenoid valves are sensitive, so they remain open until the input voltage drops to 20 mV

Specifications

The thermocouple has the following technical parameters:

- wide temperature range;

- high measurement accuracy;

- increased resistance to corrosion;

- electronic control mechanism.

About company

If you need to purchase first-class gas air heaters, but you have no idea where they could be ordered online, then we are ready to help you. For more than 18 years, our main activity has been the sale, installation and maintenance of high-quality gas heating equipment that meets all modern standards. On this page you will find a detailed description of gas heat guns. This will help you make the right choice and purchase the exact model that best suits your specifications.

Description of the work of gas air heaters caloric:

When the heater is turned on, fuel (natural or liquefied gas) is supplied to the burner, where an air-gas mixture is formed, which is sprayed under pressure through the nozzle assembly into the combustion chamber of the heat exchanger and ignited using high-voltage electrodes. After ignition of the burner, the heat exchanger is preheated.

When the heat exchanger reaches a certain temperature (factory setting 75 degrees C), the main fan starts. The fan takes cold air from the surrounding volume (inside or outside the object) or the supply air duct and drives it along the outer contour of the heated heat exchanger, as a result of which the injected air flow heats up from contact with the walls of the heat exchanger and enters the heated room.

Air heating occurs due to the transfer of heat generated during the combustion of the gas-air mixture in a sealed combustion chamber.Formation of a flame and maintenance of process of burning is carried out in the automatic mode by means of a monoblock gas torch. During the operation of gas air heaters, fuel combustion products (flue gases / exhaust gases) are formed.

If during operation the heat exchanger heats up above the critical temperature, the overheating protection is automatically activated and the heat generator control unit turns off the burner. At the same time, the main fan continues to operate, performing two functions: a) removing residual heat from the heat exchanger, that is, cooling; b) space heating.

Types of gas heat generators

Gas heaters for heating are divided into mobile and stationary. The latter, in turn, are divided into suspended and floor. At the same time, mobile units are less common, because gas cylinders are used for their operation, which is not always convenient and possible to provide. That is why such devices are used only in extreme cases, for example, when the main heating in the room is turned off, and it is urgent to heat it up with a sharp drop in temperature outside. Also, such units are used as the main heating in regions with a short winter season.

The stationary type of heaters is used in various fields. Mounted heat generators are hung on the walls inside and outside the premises. Floor type devices, depending on the features of the assembly, are horizontal and vertical. The former are more often used in low rooms, while the latter are suitable for installation in a private house or on the street. It is convenient to use floor devices for heating small rooms by installing them at the entrance and exit to the heated area.

The device of gas heat generators

A gas heat generator is a heater that heats the coolant (air) to the required temperature.

His device is as follows:

- The air fan is designed for uninterrupted supply of air masses and removal of exhaust air from the system. The exhaust air is discharged upwards.

- By means of a gas burner, fuel is burned and the coolant is heated.

- Complete combustion of the heat source occurs in the combustion chamber. If the fuel burns completely without residue, then the amount of carbon dioxide emitted by the system is small.

- The purpose of the heat exchanger is to ensure normal heat exchange between the room and the heat generator. In addition, the heat exchanger protects the heating equipment from overheating.

- Air ducts are used to remove heated air into the room.

The principle of operation of such heating equipment is as follows: the fan draws cold air into the device, it heats up in the process of fuel combustion to the required temperature and is discharged through the air ducts into the room.

The process of operation of a gas heater can be divided into the following stages:

- cold air from the street or premises is drawn by the fan into the device and enters the heating element;

- since gas is constantly burned in the combustion chamber, thermal energy is released, which heats the air;

- after that, the fan supplies heated air to the heat exchanger;

- air ceilings are distributed through the duct system through the use of air valves;

- heated air is fed into the room through the grilles and gradually heats it up.

Calculation and selection of a gas generator

In order for the efficiency of the system to be sufficient, the gas air heater for air heating must be correctly selected

To do this, first of all, you need to pay attention to the size of the heat exchanger. The dimensions of the heat holder must be 1/5 part larger than the dimensions of the burner

To choose the right gas generator, you need to calculate its power. To do this, use the formula - P \u003d VxΔTxk / 860, where:

- V in m3 indicates the heated area of \u200b\u200bthe building;

- ΔT in °C is the temperature difference between inside and outside the house;

- K is an indicator of the thermal insulation of the house (the number can be selected from the directory);

- 860 - this number is a coefficient that allows you to convert kilocalories to kW.

The power of the device is selected in accordance with the value obtained. As a rule, the operating power of the equipment is indicated in its technical characteristics.

For uninterrupted operation of heating equipment for air heating, it is necessary to ensure a continuous supply of air to the device. To this end, the ventilation system of the structure must be properly equipped. If there are problems with ventilation, then it is better to use a hanging type device that takes air from the street.

Features of industrial heating

- Firstly, most often we are talking about work on energy-intensive Objects of a fairly large area, and there is a requirement for the maximum possible energy saving for heating systems (as well as for all other auxiliary systems). It is this factor that is at the forefront.

- In addition, often in heated rooms there are non-standard conditions for temperature, humidity, dustiness.Therefore, the thermal equipment and materials used must be resistant to such adverse effects.

- Flammable and explosive substances may be used at a number of Sites, and, based on this, the installed system must comply with stringent explosion and fire safety requirements.

- Another important difference between the systems under consideration is, as a rule, their large total power. It can reach hundreds of megawatts. Therefore, boilers used for heating houses are often not suitable for the scale in question. The use of cascades from domestic boilers is simply becoming economically impractical

- In addition, the heating of industrial buildings is often designed and installed in a single complex with climate systems. This makes it possible to implement heating of industrial premises with large areas and at the same time save resources and the space occupied by the mains. First of all, this method is used in the organization of air heating.

- The next feature that industrial heating of a building has is its “unconventional”. There are certain standard solutions on the basis of which the heating of a country house is carried out. These solutions can be applied with small nuances almost everywhere and always. Technical solutions for large-scale Objects are much more diverse. Engineering art in this segment is the selection of the optimal technical solution. Before the start of the project stage, the most important stage will be the competent preparation of the Terms of Reference.And when the installation of heating of industrial facilities takes place, the Terms of Reference drawn up by qualified designers and engineers will help optimize the process of installation work. Designers carry out various engineering calculations. Based on an individually selected engineering solution, the most efficient way of heating the Object in question is determined

- Often, if we are talking about production, then technological equipment is located at the Facility - machines, conveyors, production lines. Also, perhaps, the people who work on it. This needs to be taken into account

- As a rule, uniform distribution of heat is necessary, unless the project involves the creation of zones with a special temperature regime. By the way, the presence of such zones is also a feature that must be taken into account when organizing the heating of industrial buildings.

- As already mentioned, the traditional method for heating the housing stock (in particular, cottages) using a domestic boiler and radiators in the conditions under consideration is, as a rule, inefficient. For this reason, industrial heating systems are built according to other principles. Recently, these are most often autonomous systems of the scale of the Object, and sometimes of its individual parts. Autonomous heating is easier to manage than centralized (through CHP) due to the ability to control and regulate the consumption of fuel resources

- There are some features and at the stage of operation. In the residential sector, often the level of service of the heating system is sometimes not professional enough.If heating is installed in an industrial building, then, as a rule, you can be sure that the maintenance service will be carried out by a qualified team (most often, this is the chief power engineer’s service or a staff unit of the enterprise similar in function). On the one hand, this somewhat facilitates the responsibility of the installation organization. Most likely, after the commissioning of the facility, no one will apply "on trifles". On the other hand, the requirements for the composition and level of writing as-built documentation are increasing. Employees of the operation service, being professionals, are well aware of what exactly it should include and how to compose it. All necessary licenses, certificates, permits, passports for equipment, acts of work performed must be provided without fail. Only after that the system will be put into operation.