- Safety

- Types of gas hoses

- Connection instructions and features

- How to buy a hose

- How to choose the right flexible gas tube?

- Installation

- Connection to the gas pipeline

- Varieties of gas hoses

- Rubber-fabric hose

- Rubber reinforced hose

- Bellows metal hose

- Corrugated

- Other

- What should be considered for connection security?

- Bellows hoses: the leader of sympathy among specialists

- What should be considered for connection security?

- Instructions for self-connection

- Step #1: Dismantling the old stove

- Step #2: Performing a Faucet Replacement

- Step #3: Connecting the Flexible Hose to the Stove

- Mounting

- What you need to install and connect

- Balloon material and size

- Reducer

- Hose for gas stove

- Metal-plastic for gas

- Bellows gas hose: best for gas stove

- Main advantages and disadvantages of using bellows hoses

- Types of gas valves

- Reinforced hoses: polymer, rubber, steel

- Secure connection instructions

Safety

Any installation work performed with gas appliances requires the obligatory fulfillment of all safety requirements. The connected flexible hose must always be in front of your eyes. It is strictly forbidden to close it.It should always be located in a place accessible for visual inspection.

It is forbidden to use a non-standard size gas hose. They must comply with existing regulations.

The hose does not need to be painted, as paint can cause it to crack quickly. If you want to make the sleeve look prettier, you can cover it with self-adhesive paper.

The rubber sleeve is directly connected to the tap if it is located on vacation. If the thread has non-standard dimensions, an adapter is allowed.

When operating gas equipment, it is very important to comply with safety rules and existing operating standards. The fire safety of gas-fired installations depends on this.

Types of gas hoses

In order to use a gas flexible hose, it is not necessary to use the services of only public services. Installation today is carried out even by stores that sell household appliances and other services. Hose types:

- Rubber hose with fabric braid. This is an elastic, flexible hose that is highly flexible, but does not have the ability to pass electrical discharges. In order to install it, serious skills are not required, especially since options of any length are offered for sale and at the request of even the most demanding customers. The disadvantage of such accessories is low rigidity, but, despite this indicator, the service life is up to 10 years. During this time, the sleeve is able to withstand sufficient pressure, but after the expiration of the period, it must be replaced, even if there is no visible damage.

- Hose made of high-strength rubber, which has a metal braid.Such hoses are outwardly similar to the models that are used to supply water to taps, the only difference is that there is a polymer material inside. A yellow thread is woven into the braid of gas products. Threads of red and blue colors are woven into water models. These options are distinguished by an acceptable price, the ability to purchase hoses of different sizes and easy installation.

- Bellows sleeve. This product is the strongest, most durable and reliable. This model got its name due to the fact that the main sleeve is protected by a special corrugated sheath. Such a model can work up to 25 years. The cost of this model is higher than others. Moreover, the length of the product also affects the cost.

Connection instructions and features

Regardless of the type of connection, the connection is carried out according to certain requirements:

- The length of the sleeve corresponds to the distance at which the household appliance will be located from the gas source. On the riser there are branches that end with taps. The product must not be equipped with additional couplings or connections.

- Before connecting the hose, preparatory work is carried out. The gas supply is blocked at the central riser in the apartment. The appliance must stand level so that there are no distortions in the hose connection.

- A seal is applied to the fitting of the sleeve and it is twisted when the pipe is released. If the threads on the device and the diameter of the tube do not match, an adapter will be required. A seal is also used for it to prevent gas leakage.

- Checking the tightness of the connection. To do this, a soap solution is applied to the joint. If the bubbles are not blown, there is no problem.

How to buy a hose

In order to buy a product that will help you effectively connect a gas stove to a gas pipeline, you must follow the instructions of specialists.

It is necessary to purchase products only in those stores that offer to buy only certified products. Saving on your own safety in this situation is irrelevant.

Don't buy cheap Chinese products. It is made of thin rubber, and therefore has a low cost, and after a while it requires replacement.

There is no need to talk about safety in this case.

When buying, be sure to pay attention to the presence of a special yellow label. It is she who says that the model is designed to be connected to a gas pipeline, and not to a water supply system.

Be sure to check the product for mechanical damage before purchasing.

Even if the seller is not happy, exclude the presence of scratches, cuts and other damage. Flexible gas hoses must be sold in perfect condition.

How to choose the right flexible gas tube?

It is safest to purchase a gas hose from a specialized store that has a state-issued certificate of conformity. It is best to opt for a bellows style hose.

Important! Beware of poor quality fakes. There is a high probability of buying counterfeit goods on the market. This threatens that the sleeve will be made of thin cheap rubber, which will quickly fail.

Most fakes can only be distinguished from the original by a professional

This threatens that the sleeve will be made of thin cheap rubber, which will quickly fail. Most fakes can only be distinguished from the original by a professional.

To identify a fake, you need to carefully study the technical characteristics of the product, the passport and the certificate of conformity. You should not buy goods at a suspiciously low price.

Before buying, you must measure, then add 20% to the length. You should not purchase a gas hose with a margin. Standard sizes are 1–2 m. In everyday life, 1/2 or 3/4 inch diameters are usually used.

The sleeve comes with two types of fasteners: with two union nuts with internal thread (female-female) or with a nut at one end and a fitting at the other (female-male). The thread is selected depending on the output on the device. It is preferable to stop the choice on welded structures, and not on those where the fitting is connected to the corrugation with glue.

Installation

It is most reliable to contact a professional who will ensure the correct connection and provide a guarantee. After all, everyone knows from childhood that it is dangerous to joke with gas.

An unqualified connection to the gas pipeline can lead to an accident, the consequences of a domestic gas leak have all been seen in the news.

Nevertheless, a modern gas hose allows you to independently connect the boiler to the mains. Any adult can carry out the installation in compliance with safety regulations.

In work, you must adhere to the following rules:

- The length of the eyeliner is selected taking into account the distance over which the equipment is likely to move.

- The system is located in a place accessible for revision.

- There must be no other connections on the device.

- The product must not be painted to avoid cracking of the material.

- The dimensions of the gas hoses must comply with GOST standards.

- Do not twist, bend or stretch the sleeve.

- Do not solder or weld the joint.

- Replace the hose with a new one in accordance with the manufacturer's recommendations.

Connection to the gas pipeline

To install the gas hose to the riser, you will need an adjustable wrench, a screwdriver, a sealant, a brush and a soapy solution.

First you need to prepare the room and shut off the gas supply to the network. Then the boiler is installed at the installation site and carefully leveled.

Each apartment has a gas riser, which has branches with taps at the ends, this is called a vacation.

A seal is applied to the hose fitting and screwed into the tap on vacation. If the diameters do not match, then an adapter is needed, which is also sealed. The sleeve is connected to the boiler.

The system is then tested for leaks. To do this, with a brush, a soapy solution is applied to the joints and the valve is slightly unscrewed. If the connection is leaky, then the solution will begin to bubble, otherwise nothing will happen. If a leak is detected, it is necessary to shut off the gas and check the winding of the seal.

Lastly, the equipment is checked for operability, gas is supplied.

Attention! If there is any doubt, the best solution is to turn to specialists. The master will connect the gas safely, reliably and in compliance with all regulations, and will also give a guarantee for the correct operation of the system for many years

Varieties of gas hoses

Gas connections are bellows, reinforced, made of fabric and rubber. All of them differ in duration and operating conditions, technical characteristics. The choice depends on the specific situation.

Rubber-fabric hose

Households are often made from rubber and fabric. This type of product is cheap and simple. The sleeve is soft, flexible, but reinforced with textile thread. The device is used at temperatures from -10 to +50 degrees. In installation and use, the hose is unpretentious. However, after a while, the rubber begins to harden and crack, which is fraught with gas leakage.

To increase the service life of the product, elastic components are introduced into the rubber composition. The advantage of flexible gas pipes is considered to be good elasticity and non-conductivity of electricity. They are quickly mounted, you can choose fixtures of different sizes and diameters.

However, there are some disadvantages:

- instability to mechanical influences;

- insufficient level of rigidity;

- little protection against temperature changes.

The use of rubber hoses is not recommended as they are subject to natural wear. If the product is connected, then not to the main pipe, but to the cylinder. It should be changed every 2 years. There are no special fasteners at the ends of the product, so it is simply put on the outlet fitting. Metal clamps are used for fastening. If there are fasteners, paronite gaskets are required during installation.

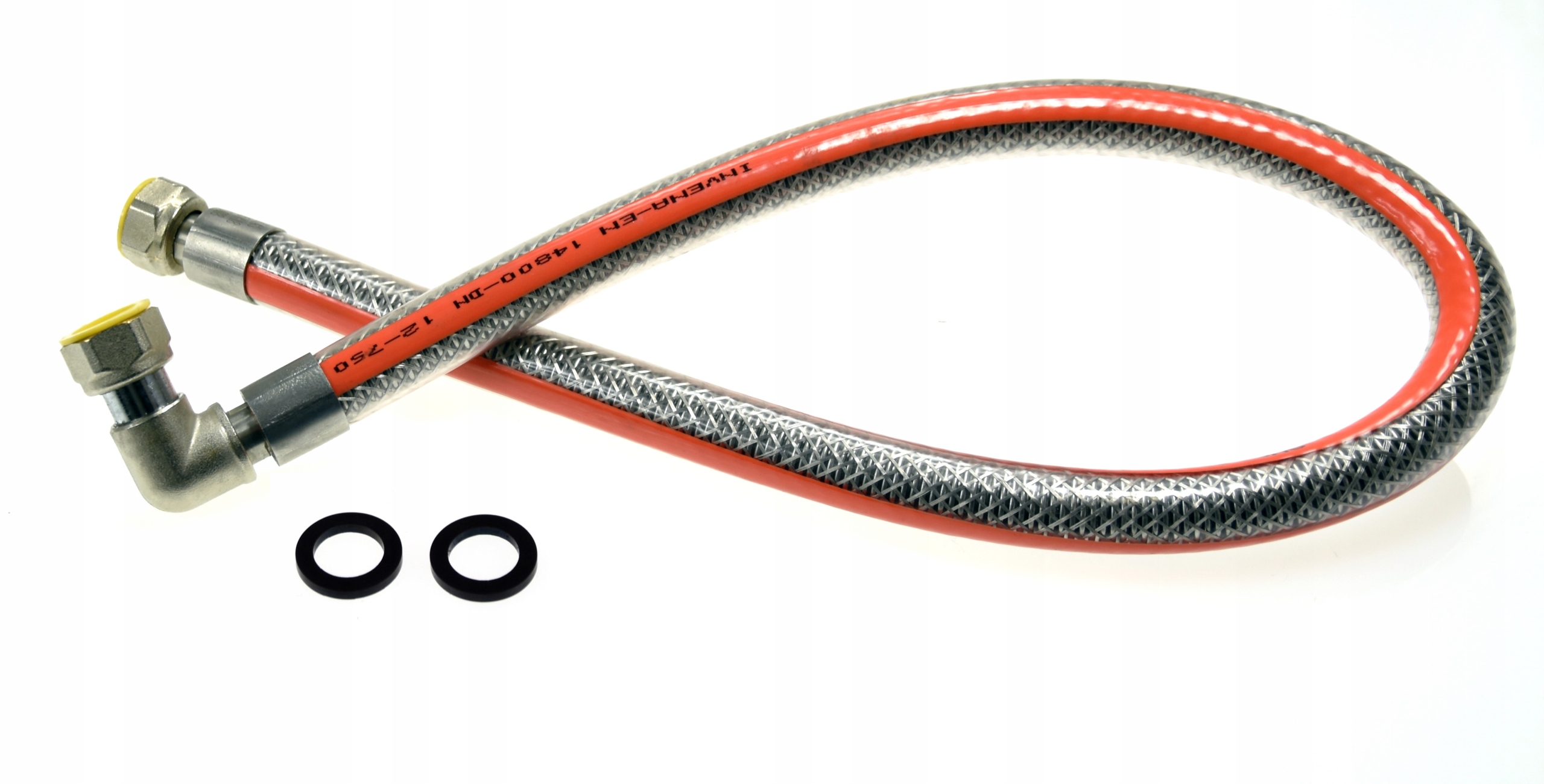

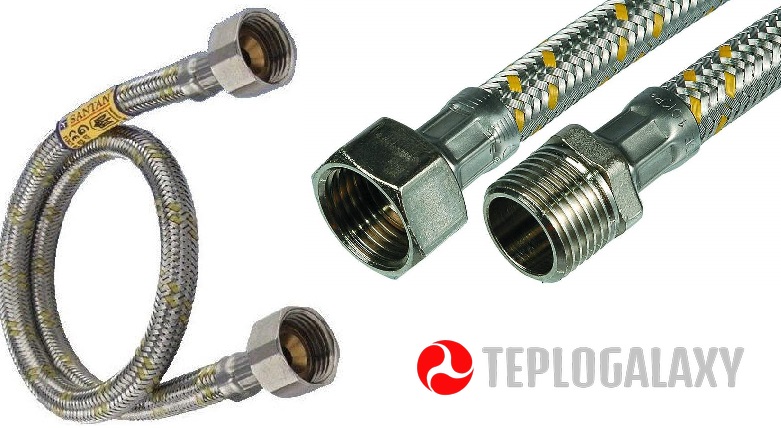

Rubber reinforced hose

For the manufacture of a gas hose, vulcanized rubber is often used, reinforced with a yellow steel braid. The inner layer of the tube is made of polymers. It is a conductor of electricity, and is also capable of quickly breaking down. This type of product has the following features:

- small price;

- the ability to withstand temperatures up to 50 degrees;

- wide range of diameters: 12-25 mm and more;

- ease of installation (there are fittings and union nuts at the ends of the tube), ease of operation.

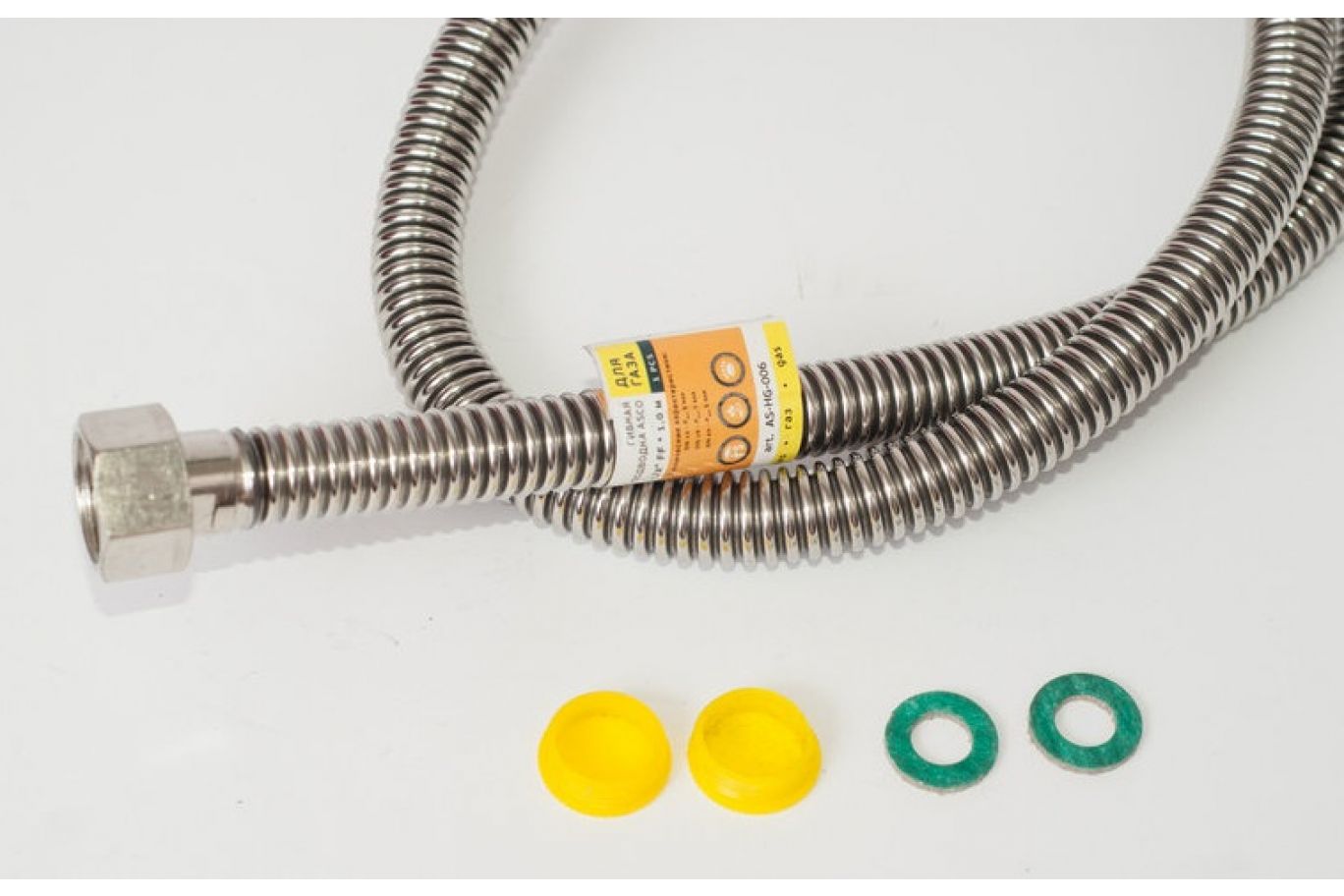

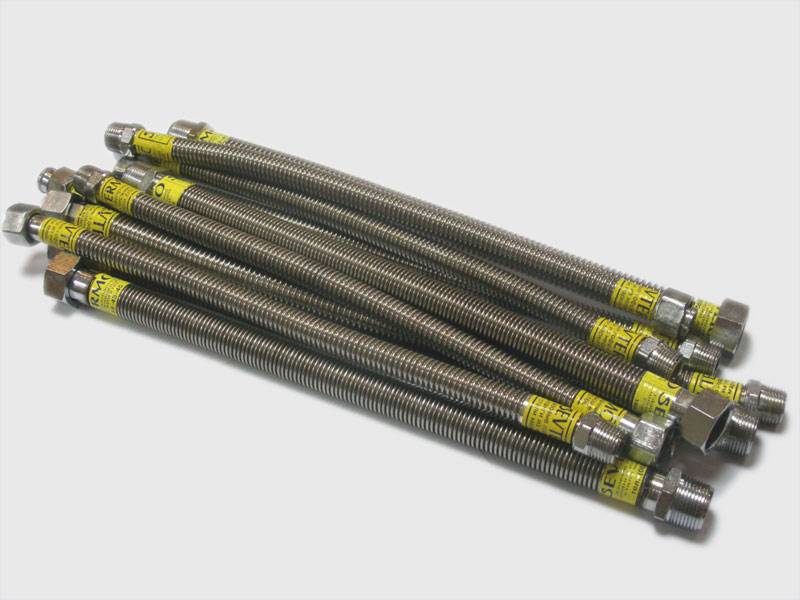

Bellows metal hose

The most reliable is the bellows hose for gas. This is a flexible metal element, which contains polymeric materials, stainless steel. The sleeve is sealed, able to withstand high pressure, as it is reinforced with wire. It has a sufficient margin of strength and rigidity.

At the ends of the device there are connecting fittings made of steel and brass. With their help, the hose is connected to the pipe. Products are easily bent, resized, while they retain performance, elasticity and strength. Even when bent, the inner diameter of the tube does not change. Linear expansion and contraction is compensated by the structure of the product.

The reinforced part is protected from electrical impulse breakdown and stray currents. The dielectric insert is mounted at the production stage. The product has the following specifications:

- tube diameter: 12-25 mm and more (on request);

- maximum working pressure: 6 atm;

- length: 30-200 cm.

Installation requires the installation of copper or aluminum gaskets.

Corrugated

The corrugated hose is made of metal. It easily changes shape and length. The original technical properties do not change even with frequent reshaping or stretching. The corrugation can be operated in a wide temperature range: from -50 to +250 degrees.

Other

In the past, an oxygen hose was often used to connect household appliances to a gas pipe. It is cheap, durable, copes well with high pressure, even if the figure reaches 20 atm. Now such a product is practically not used. Sometimes it is installed temporarily.

Polyvinyl chloride hoses have the following advantages:

- application without a dielectric (the product does not conduct electricity);

- the ability to connect to a cylinder or a central line;

- normal functionality at high pressure (up to 0.63 MPa);

- many length options (up to 5 m);

- high strength, resistance to cracking;

- long service life: up to 20 years.

What should be considered for connection security?

Jokes are bad with gas, therefore it is better to entrust the work to a professional who is familiar with all the nuances. But if you familiarize yourself with the basic rules, you will be able to control its work from the outside, and if the opportunity arises, you will be able to show off the acquired knowledge. So:

- In order not to run into problems in the future, you need to figure out in advance how far you are going to push the stove in case, for example, of cleaning. It depends on the length of the required hose.

- The product must be visible so that it can be constantly checked.

- Its excessive tension, bending and twisting are unacceptable.

- Exposure to high temperatures is excluded.

- The elements are interconnected only in this way: copper to brass, steel to steel.

- They are tightened firmly, but without excessive enthusiasm, otherwise the thread may be damaged.

Now you have learned about gas hoses for gas stoves: which one is best for you? If you value reliability and durability, then there is only one way out - to buy a bellows product that will provide you with safety, which means comfort for a long time.

Bellows hoses: the leader of sympathy among specialists

The greater reliability of bellows hoses is the reason for their obscenely high price. They are made of stainless steel, and covered with polyvinyl chloride on top.These products are able to guarantee your safety for 25-30 years, and this figure is an average value.

The corrugated surface and metal braid provide protection against mechanical damage, while chemical resistance and electrical insulation are provided by a PVC coating. Let's list all the advantages:

- widely used to connect any equipment;

- impressive temperature range - from -50° to +200°;

- the ability to withstand a pressure of 6 atmospheres;

- guarantees tightness even under extremely adverse conditions.

What should be considered for connection security?

Jokes are bad with gas, therefore it is better to entrust the work to a professional who is familiar with all the nuances. But if you familiarize yourself with the basic rules, you will be able to control its work from the outside, and if the opportunity arises, you will be able to show off the acquired knowledge. So:

- In order not to run into problems in the future, you need to figure out in advance how far you are going to push the stove in case, for example, of cleaning. It depends on the length of the required hose.

- The product must be visible so that it can be constantly checked.

- Its excessive tension, bending and twisting are unacceptable.

- Exposure to high temperatures is excluded.

- The elements are interconnected only in this way: copper to brass, steel to steel.

- They are tightened firmly, but without excessive enthusiasm, otherwise the thread may be damaged.

Now you have learned about gas hoses for gas stoves: which one is best for you? If you value reliability and durability, then there is only one way out - to buy a bellows product that will provide you with safety, which means comfort for a long time.

Instructions for self-connection

Payment for the services of a gasman for installation work is not too high, but many home craftsmen prefer to do everything on their own. This is a feasible occupation that requires the purchase of components and theoretical knowledge.

And to connect, you will need to prepare the following tools and buy materials:

- keys: gas No. 1, adjustable 22-24;

- a screwdriver to tighten the clamp, if required;

- seals (thread loctite 55, linen, FUM - tape);

- gasket ½;

- gas sleeve;

- ball valve 1/2';

- brush and soap solution, which will be required to control the progress of work.

A rag and a plastic stopper will also come in handy. The rag will be used as a temporary cover against a gas leak. The narrowed edge of the plug must be adjusted to the opening of the supply pipe. If during the extraction process, a homemade part gets stuck, it can be easily removed with a corkscrew.

Step #1: Dismantling the old stove

Closing the crane on the descent is a top priority to ensure the safety of the work performed. Next, you need to unscrew the lock nut located on the outlet and remove the coupling. If the coupling and locknut of the old plate were previously painted, this will greatly complicate the process of their dismantling.

Sometimes this procedure cannot be performed, then you will need to cut the eyeliner with a grinder.

The dismantling of the gas stove is carried out after disconnecting from the pipe-conductor of the gas main. Difficulties encountered with unscrewing the locknut on a metal pipe are solved by trimming the liner

In the process of unscrewing the drive located in the lowering tap, it is necessary to hold the tap itself with a key. It will not have to be removed if the crane is not planned to be replaced.When it is planned to postpone the installation of the plate, an additional plug is installed on the descent.

Step #2: Performing a Faucet Replacement

There are situations when the wall is located very close to the crane and there is no way to dismantle it. In this case, it is necessary to bend the fastening and install a wedge between the wall and the pipeline. However, this is done in such a way that it is possible to continue to do the work.

It is necessary to prepare a piece of rags sufficient to completely cover the pipe after dismantling the old faucet. The next will be its tearing without full untwisting. And you will also need to prepare the selected type of sealant. Do not forget to thoroughly ventilate the room during work to eliminate gas vapors.

After unscrewing the faucet, the outlet from the pipe is tightly fixed with a finger, and then with a wet rag. The main actions are aimed at the maximum elimination of gas exit from the pipe. In this case, the thread on the branch should not be closed, since it will be covered with the selected sealant.

Before winding the sealant, the thread on the descent must be thoroughly cleaned. Further, its winding is carried out directly. This process ensures a secure and airtight fixation of the new faucet, which is then tightly twisted. The last step is to install the previously removed handle on the faucet.

With the help of soap foam, the tightness of the connection of the faucet and the gas pipe is checked. If the work has been carried out correctly, the installation of the gas hose can be continued.

If the gas equipment is connected to the main for the first time, it will be necessary to call the gas master.In his presence, a control check of the equipment for gas leakage with the valve open is carried out. In the event that the gas service employee did not find any violations, he must enter the established stove brand in the register.

Step #3: Connecting the Flexible Hose to the Stove

Using a sealant, the external thread of the hose fitting is wrapped around. After that, it must be screwed into the faucet on the branch pipe. The connection of the flexible hose to the manifold is carried out at the finishing stage.

Next, the stage of test opening the faucet on the descent for gas leakage is mandatory. Using soap foam, the docking points are processed with a brush. If foaming occurs when the gas valve is opened, the work must be redone.

It is necessary to check the thread located on the plate manifold. Quite often it is 3/8′. In this case, you will need to install a 1/2 ′ adapter, with a seal

When work on replacing a gas hose is carried out in a private house where bottled gas is used, an additional replacement of the nozzle with a smaller diameter will be required. If this is not done, the burners will release too much soot, which likes to settle on furniture and utensils in the kitchen.

Mounting

After the consumer decides which gas hose is suitable for the heating boiler, he will have to think about the installation. This procedure is not difficult, but it must be carried out, realizing the need for strict adherence to the algorithm. To connect the boiler to the mains using a flexible hose, it is necessary to prepare an adjustable wrench, soap solution, a screwdriver, a brush and a sealant.

Then the user must follow the following procedure:

- Stop gas supply.

- Install and align the boiler near the holiday.

- Place the seal on the fitting.

- His fixation on vacation. If the parameters do not match, use an adapter.

- Connecting the hose to the boiler.

- Carrying out a leak test using a soapy solution.

If a leak occurs, check the condition of the valve and winding.

What you need to install and connect

You will need:

- gas stove for giving under the cylinder (configured for the use of liquefied gas);

- gas cylinder;

-

reducer;

- a hose for connecting a gas stove or copper pipes of a suitable diameter.

- clamps 2 pcs for attaching the hose (on the one hand - to the adapter for connecting the stove, on the other - to the gearbox);

- gas cock (not required, but desirable).

How to choose a gas stove is already clear, we will now deal with the rest of the components. Nothing complicated, but there are features.

Balloon material and size

First, let's talk about the material from which the liquefied gas cylinder is made. Until recently, there were no such conversations. The gas cylinder was exclusively metal, and made of metal of decent thickness. Now there are also composite gas cylinders (also called Eurocylinder) and they are approved for use by gas services. If possible, it is better to buy just such. Why are they better? Here is a list of their advantages:

- Easier 2 times.

- They have a fusible link that prevents an explosion in case of overheating / fire.

- Approved for transportation in conventional cars.

-

Do not accumulate static voltage.

- There are polymeric cylinders with transparent inserts. They allow you to control both the degree of refueling and the presence of gas.

There are few disadvantages of a polymer balloon.The first is that it costs two to three times more than a metal one, but it is much easier to carry / transport it. The second - with an equal volume in size, it is larger than the metal counterpart.

Now about the size of gas cylinders. The larger the volume of the gas cylinder, the longer the period between refueling. But, on the other hand, larger cylinders have large dimensions and weight, and it is more difficult to carry / transport them. In addition, it is easier to find a place for installation under a small cylinder.

In general, the choice is yours. Moreover, with the advent of composite, they appeared in different sizes - high and narrow, low and wide.

Reducer

Why do you need a reducer on a gas cylinder? It performs several functions at once:

- Stabilizes the pressure at the outlet of the cylinder.

- The gas in the cylinder is under high pressure, for a stove it should be lower. This is what the reducer does.

-

When there is little gas left in the gas cylinder - 5-10% - the pressure reducer increases.

- Prevents air from getting inside. When combined with oxygen, an explosive mixture is formed, so this function is also important.

- There are models that work as a pressure relief valve. If the specified parameters are exceeded, part of the gas is released - until the indicators normalize.

So the reducer on the gas cylinder helps to increase safety and stabilize the operation of the stove. Without it, it is better not to connect the stove. In this case, the more you open the tap on the stove, the more powerful the gas flow will come out. In addition to being uneconomical, it can create a situation where the balloon starts to jump. In general, it is better not to operate without a gearbox.

Please note that different types of reducers are used for metal and composite cylinders.Therefore, when buying, specify the type of cylinder and its volume.

And most importantly, to work with a liquefied gas cylinder, you need a propane reducer.

Beware of Chinese made gearboxes….

If we talk about manufacturers, it is better to take Russian or European products. Chinese are better avoided. Even those that have passed certification are made of very thin metal and quickly fail (begin to poison). In addition, many do not withstand the size of the fittings. When connected, this becomes a problem, since the hose is not put on tightly, you have to somehow seal the connection.

Hose for gas stove

You can buy it in Gorgaz stores or in hardware stores / markets. But be sure to specify that you need it to connect the gas stove. It is correctly called "gas hose-sleeve". The inner diameter should be 16 mm, the outer one depends on the type of hose, there should be an inscription (in yellow) on the surface that the hose is gas.

There are such gas hoses:

To connect the cylinder to the gas stove, you need a hose about a meter long - in order to fulfill the condition about the distance between the cylinder and the stove of 0.5 meters and leave a margin for freedom of movement.

On one side, a union nut with a gasket must be installed on the hose. This end is connected to the outlet from the gas stove. If you buy just a piece of hose, you can install the corresponding gas adapter yourself by tightening the mount with a metal clamp (do not forget the silicone thick gasket for sealing). On the other hand, the hose is connected to the reducer - it is pulled onto the fitting, then tightened with a clamp (do not forget to put the clamp on the hose, and then connect it to the fitting).

Metal-plastic for gas

Metal-plastic pipes can also be used for gas supply. From the inside, pipes of this type are polyethylene already familiar to us.

Due to the fact that metal-plastic pipes are supplied in coils, it becomes possible to lay a sufficiently long gas pipeline without using a large number of connections.

If the pipes still need to be connected, then only press fittings must be used. With their help, it is possible to ensure the tightness of the connection, which will retain its properties for a long time. However, a special device is required to make such a connection.

Bellows gas hose: best for gas stove

If you ask a specialist what kind of hose for a gas stove should be, most likely, he will offer to purchase exactly the bellows version for installation. It is this type of hose that is considered the most reliable for connecting the hob to the central gas supply. In addition to gas stoves, it is used to connect columns and gas boilers used for individual heating. The bellows is an elastic corrugated shell that protects the inner layer from mechanical and other types of damage.

The high demand for bellows hoses is due to the high technical characteristics and reliability of the devices. Products easily tolerate high pressure, which is created by the gas flow in the pipe. Ease of connection is provided by two fittings designed for connection to the gas pipe and directly to the device. All components of the hose are made of high quality stainless steel, which guarantees maximum service life.

The bellows gas hose is considered the most reliable for connecting the hob to the central gas supply.

The price of a gas hose for a gas stove of this type is much higher than the cost of other product options, but the service life is at least 10 years longer than the service life of other devices. So, the minimum time during which you can safely use a bellows hose is 25 years, although some companies give a 30-year warranty. The final price is usually influenced by the manufacturer and the size of the product.

You can find out how much a gas hose for a gas stove costs (depending on the characteristics) from this table:

| Connector diameter, inch | Length, m | Price, rubles |

| 1/2 | 0,4 | from 250 |

| 0,8 | from 290 | |

| 1 | from 320 | |

| 1,5 | from 400 | |

| 3 | from 780 | |

| 4 | from 950 | |

| 5 | from 1150 | |

| 3/4 | 0,6 | from 350 |

| 1 | from 450 | |

| 2 | from 700 | |

| 2,5 | from 900 | |

| 3 | from 1050 |

Main advantages and disadvantages of using bellows hoses

Simple models of bellows hose are presented in the form of corrugated products, which are distinguished by the presence of a round section. If you choose a more expensive option, then additionally for protection there will be a metal sleeve or a polymer coating. The modernized version of the bellows hose has a built-in thermal protection valve, which automatically shuts off the gas supply when the temperature rises critically. Of course, this option will also affect how much the hose costs, but the losses that can be incurred in the event of a gas leak will be much higher. Other advantages of bellows hoses:

- easy to bend and stretch;

- withstand loads up to 6 atm.;

- are operated in a wide temperature range from -50 to +200 °С;

- are made of high-quality materials that comply with all GOST standards;

- meet the technical requirements of domestic use;

- the maximum possible service life is up to 30 years from the date of installation;

- withstand the influence of electric current up to 1.5 kW;

- a large selection of hose lengths for connecting a gas stove - from 0.4 to 5 m;

- compatibility with most types of gas equipment and various fittings;

- the presence of a coating that protects the base of the hose from the effects of various household chemicals used for cleaning and disinfecting the kitchen.

Simple models of bellows hose are presented in the form of corrugated products

Additional safety of the hose is provided by an electrically insulating polymer layer that protects not only from mechanical stress, but also from high-frequency currents that are created by some household appliances, such as a microwave oven. Due to the strength of the hose, manufacturers guarantee the integrity of the connection even under the condition of natural anomalies, such as an earthquake, when the stability of the building is violated.

The relative disadvantages include only the price, which is several times higher than the cost of similar products from other groups. However, the presence of a large number of positive characteristics, which include a significant service life, cover this drawback.

Types of gas valves

In old buildings, two types of cranes were usually installed on vacation:

- petal;

- suberic.

What is the difference between the designs of these products can be seen in the figure.

When a plate is changed or a valve fails, it is best to install a new ball valve.

This device is much better, but more expensive. Installing an Italian faucet will cost $10. You can also install a cheaper domestic crane, costing $ 5.They are no worse than their foreign analogues, but sometimes they have defects. Therefore, do not forget to take a receipt with you when buying so that you can exchange a defective product for a good one.

Reinforced hoses: polymer, rubber, steel

Polymeric materials are inside such a hose. The next layer is vulcanized rubber. Outside, it is braided with threads of steel. In order not to confuse the products with similar water hoses, a yellow thread is woven into them.

Reinforced hoses are quite popular, the reasons for which are:

- simple installation and ease of operation;

- reliability and decent shelf life;

- a variety of assortment - both in diameter and in length;

- safe use at temperatures from -35° to +50°.

We also note a significant minus - an unimportant level of electrical insulation, the culprit of which is a metal braid. Therefore, when installing between the plate and the liner, it is usually necessary to insert a dielectric coupling. There is another drawback - the unreliability of the internal polymer material. For this reason, they have become "persona non grata" in some European countries, and recently we have seen the same trend.

Secure connection instructions

If you have at least minimal skills, you can connect the gas to the device with your own hands.

In work, you must adhere to the following rules:

- choose the length of the eyeliner taking into account the distance over which the equipment will supposedly move;

- place the device in a place accessible for visual inspection, without hiding it under the floor or in the wall;

- make sure that there are no other connections on the device (the exception is the wire that performs the function of lighting in the stove oven);

- do not paint the product, as this leads to rapid cracking of the material;

- use gas hoses of standard sizes provided for by the standards established by GOSTs;

- do not provoke electrolytic damage by connecting copper tips with steel ones (safe combinations: steel-steel, brass-copper);

- avoid twisting, bending and stretching the sleeve;

- do not expose the connections to high temperature effects (soldering, welding).

In multi-storey buildings, a common gas riser is installed, which has branches with taps at the ends. They are present in every apartment and are called omission.

Connecting gas to the stove is easy: just a little free time and a minimal set of tools

At the first stage of work, the room is prepared and the gas supply to the network is shut off. Then the equipment, whether it be a column or a plate, is exposed to the installation site and carefully leveled.

After that, you need to put a seal on the hose fitting and screw it into the tap on the lower. If the thread on the device does not match the diameter of the hose, an adapter is required, which also seals. Next, the hose is connected to the equipment.

To connect, you will need the flexible hose itself, a ball valve, a seal (Fum tape, Loktite), a screwdriver, an adjustable wrench, as well as a soap solution (water + soap or gel) and a brush

At the end, the tightness of the connecting elements is tested by opening the tap. This is easy to do with an ordinary soap emulsion and a small brush.

If the connection is not tight, the applied soap solution will foam and bubble, if everything is in order, no reaction will occur.

If insufficient tightness of the connections is detected, the tap handle is slightly unscrewed and the winding is checked. The last step is to diagnose the functionality of the equipment and gas supply.

The surest solution in case of insufficient self-confidence is to contact the gas workers. Specialists will perform the connection in compliance with all standards, which will guarantee the serviceable, safe and reliable service of the system for many years.