How to choose the best option?

Choosing a hose for connecting a stove to a gas pipeline is not an easy and very responsible task, because you risk the safety of your home and life, as well.

In order to choose the appropriate option from the whole variety described above, you need to decide on several parameters:

Hose length. When connected, it should sag a little - enough so that the plate can be moved away for cleaning or if something falls behind it. Installing the hose taut is unacceptable - it is dangerous. The most popular sizes are from 1 to 2 m, but there are products from 40 cm, and the maximum length of domestic hoses reaches 4.5 and even 7 meters.

Connection type. At one end of the hose, which is screwed to the stove, there will always be a nut with an internal thread - “mother”, but at the other end, on the side of the gas valve, there can be either the same nut or a fitting with an external thread - “father”

Pay attention to which connector your gas valve has.

Connection diameter.Most commonly used are half-inch nuts, but ¾-inch and more exotic options are also found.

Remeasure the thread on your equipment.

Connection metal. Avoid contact of white metal (steel) with yellow (brass) - this is not safe.

The cross-sectional diameter of the hose for the full operation of all burners must be at least 1 cm.

See what output is on your stove. If it is angular - excellent, but if it is directed to the wall - it can be dangerous. A hose wound directly onto such an outlet can break when the stove moves towards the wall, and this is fraught not only with a weak gas pressure, but also with a leak. To avoid this situation, purchase an additional metal fitting-corner. If there are 2 outlets on the stove, you will also need a plug.

Assess your financial capabilities. Remember that expensive hoses will not only be safer and more beautiful, but will also last many times longer.

If the hose can touch a microwave, dishwasher or other electrical equipment, insulation is required. Choose PVC hose or resin coated bellows hose.

For use in the country, with a gas cylinder, you can also purchase an inexpensive rubber-fabric hose - it will be more convenient and more likely to be found with the right diameter

For use in the country, with a gas cylinder, you can also purchase an inexpensive rubber-fabric hose - it will be more convenient and more likely to be found with the right diameter

Contact only specialized stores and demand quality certificates for the goods - this is your right and a guarantee of safety.

Do not believe the offers to buy a branded sleeve at half price - most likely it is a low-quality Chinese fake. But do not refuse to buy just because it is made in China - many brands transfer their production of certified goods to this country without lowering control and quality standards.

See how the fitting is connected to the braid. Soldering or solid casting is excellent, glue is bad.

Familiarize yourself with the warranty period and service life in the product passport, compare them with the hose type and price.

In addition, when buying an expensive branded bellows gas hose, beware of counterfeiting. Carefully inspect the product - it should be neat, with inconspicuous seams, without flaws, even small ones.

Must have yellow markings. Even on rubber hoses, a yellow tag is glued in a visible place, while on others it may be present in the braid, the color of the top layer, on the packaging. Without such a marking, it is easy to confuse gas and water hoses, and the latter will begin to “poison” gas, if not immediately, then in a month

Must have yellow markings. Even on rubber hoses, a yellow tag is glued in a visible place, while on others it may be present in the braid, the color of the top layer, on the packaging. Without such a marking, it is easy to confuse gas and water hoses, and the latter will begin to “poison” gas, if not immediately, then in a month

Look at the technical data sheet and check that the description corresponds to reality. Demand a certificate of quality or at least a copy of it. Too low a price should alert, but a normal market price is not a guarantee of quality.

Types of gas hoses

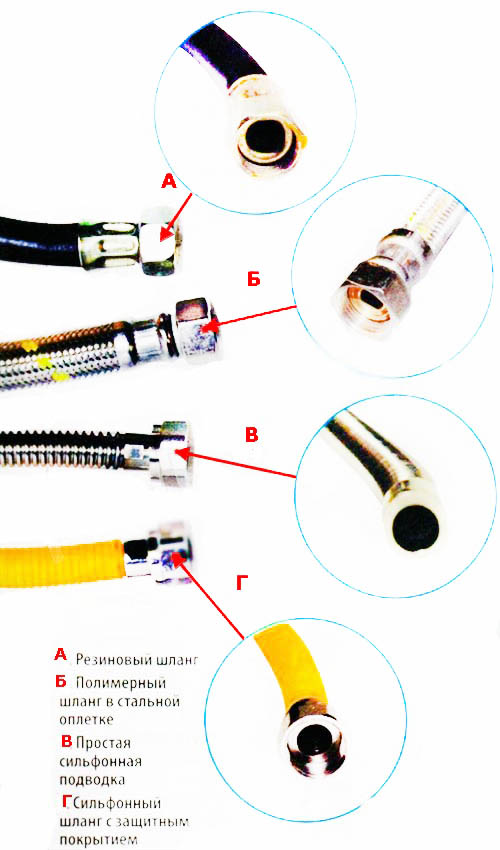

More recently, metal pipes were used to connect gas appliances, "tightly" connecting the stoves to the gas main laid through the apartment. This was rather inconvenient, since it was impossible to move the kitchen stove to another place. However, new technologies and innovative materials have made it possible to connect gas appliances to the gas pipeline using flexible pipes. Numerous hoses perfectly cope with this role, which in general can be divided into:

- rubber-fabric;

- rubber with a metal braid;

- corrugated (bellows).

Rubber-fabric hoses

Hoses made from rubber with the addition of elastic materials are among the cheapest flexible natural gas piping options for kitchen equipment. They are made from a rubber sleeve GOST 9356-75, the design of which provides for the presence of:

- inner rubber layer;

- thread frame made of cotton or chemical fiber;

- outer rubber layer painted red.

This structure ensures the performance of products at ambient temperatures from -35° to +70°C. In this case, the nominal gas pressure in the gas pipeline should not exceed 0.63 MPa. Rubber-fabric sleeves are highly elastic and have good dielectric properties.

However, such hoses have significant disadvantages:

- poor resistance to mechanical stress and temperature changes;

- natural aging of rubber, as a result of which the hose loses its elasticity;

- the appearance of cracks on the surface over time, through which gas leakage can be observed.

Due to the high level of danger, the service life of rubber-fabric hoses is limited to two years, after which they must be replaced.

Rubber reinforced hoses

Sleeves made of vulcanized rubber, which are braided with steel threads on the outside, are more reliable in operation. Some of the threads are dyed yellow. Quite often, instead of rubber sleeves, polymeric materials are used, which over time, like rubber, are subject to destruction and degradation. Gas hoses of this type are recommended to be changed after 5-7 years of operation.

Using reinforced hoses to connect gas appliances, you need to remember that metal threads conduct electricity well. Thus, when using them, special dielectric gaskets will be required. In addition, the wire braid does not allow visual assessment of the condition of rubber or polymeric materials, so flexible connections of this type are gradually being phased out and replaced by bellows hoses.

Bellows type hoses

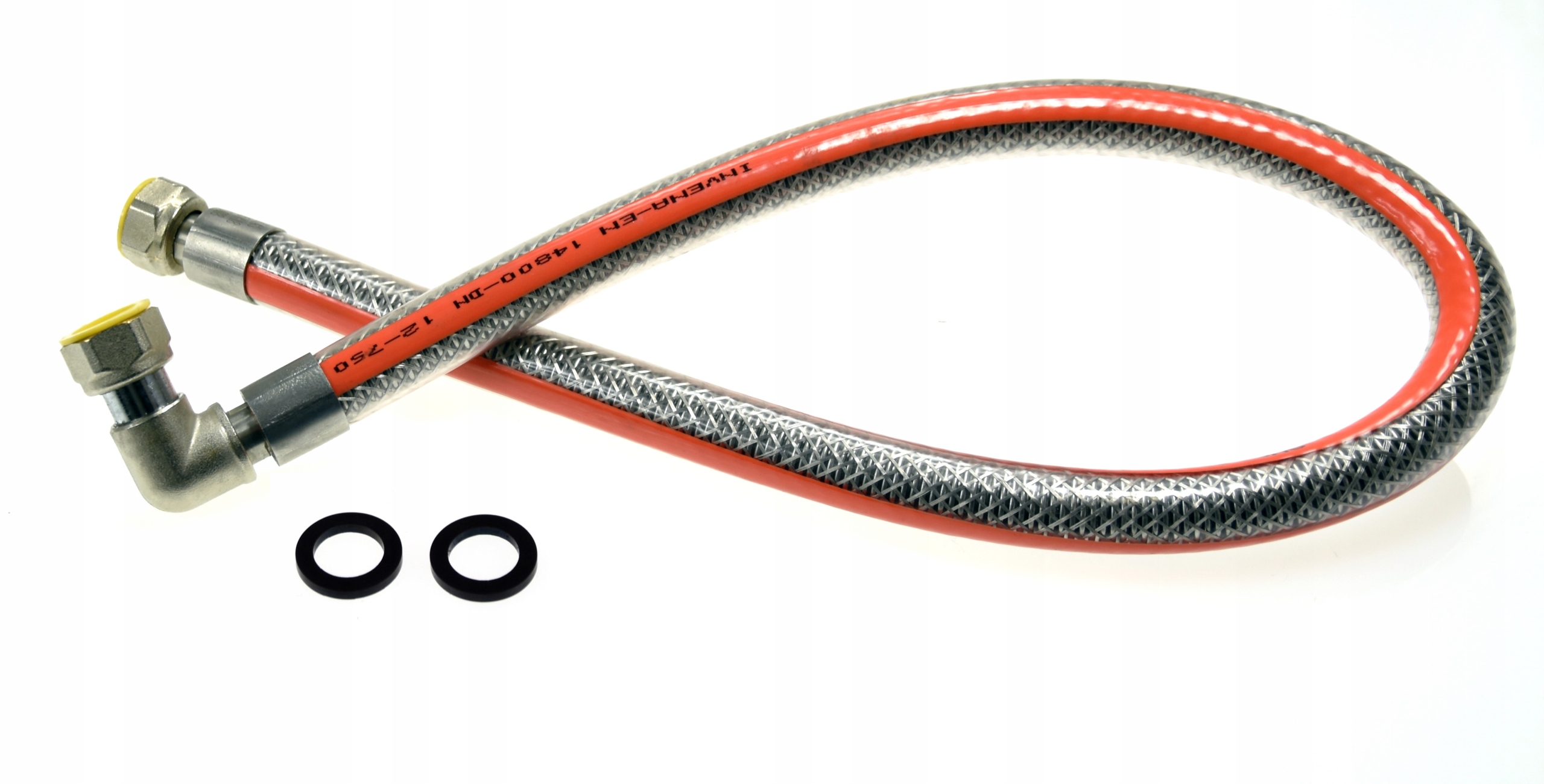

Currently, bellows hoses are the most reliable flexible gas supply to household appliances. They are quite durable - their service life is at least 25 years. In addition, such hoses are resistant to all types of external influences (mechanical, temperature, etc.) and are able to operate in the temperature range from -50 to +250°C.

Metal bellows hoses are made of stainless steel. At the same time, they are structurally divided into two types:

- in a metal braid without insulation;

- with a polymer electrical insulating coating of yellow color.

A bellows without insulation is needed when connecting gas appliances, which are ignited in the traditional way (matches, piezo lighter, etc.). For stoves with electric ignition, dielectric inserts are required.

Bellows with an electrically insulating coating are used to connect stoves with an electric oven or equipped with electrical components (electric grill, lighting, electric ignition, etc.) to a gas pipe.

There are also polymer bellows hoses reinforced with a special bright yellow corrugation that looks like a screw. In their manufacture, high-strength wire is used that can withstand high pressure.In addition, the corrugated surface is able to elongate by about 50%, which allows it to compensate for the expansion and contraction of the hose during sudden temperature changes.

Sometimes bellows hoses are equipped with a thermal safety valve that cuts off the gas supply when the temperature rises sharply. However, such designs are quite expensive.

How to connect?

There can be no two opinions here: whenever possible, you should turn to professionals. Gas is too much of a responsibility. However, there are times when a do-it-yourself connection has no alternative. For example, you do not have to wait for the prompt arrival of gas workers in a country or country house. Many owners wait their turn for weeks and even months.

Meanwhile, with basic knowledge, you can mount everything yourself. What should be categorically avoided is the use of outwardly similar components intended for the construction of a water supply system. Usually, an additional branch is removed from the gas riser, ending in a tap. Immediately behind this tap is a boiler, stove, column, and so on. It is this area that is called the descent.

Old houses and apartments are often equipped with descents with petal cranes. With a new connection, ball valves are used. Compared to older designs, they are more compact and more practical. If gas appliances are powered from a cylinder, self-assembly of the hose is not allowed at all. When installing a channel connected to a centralized highway, the following are used:

-

½ inch ball valves;

-

gas and adjustable wrench;

-

gasket with a diameter of 0.5 inches;

-

a screwdriver with which the clamp is tightened;

-

seals at your discretion;

-

small paint brush and soap suds;

-

dry rag and plastic tube

Rags are needed to temporarily block the gas hose and prevent leakage. The narrow edge of the plug is adjusted exactly to the pipe entry. This will allow you to pull out the stuck element with a corkscrew. A prerequisite for operation is the closing of the lowering valve. Then they twist the outlet lock nut and the coupling, if necessary, remove the paint layer.

When the old eyeliner is "tightly entrenched", it should be cut off with an angle grinder. When dismantling the drive connected to the lowering cranes, the cranes themselves are held in place with a key. If there is no need to replace the crane itself, it is completely left in place. If the household appliance is planned to be connected later, a plug is installed on the lowering. The fitting, or rather, its external thread, is wrapped with a sealant.

Only then is the fitting inserted into the faucet on the descent. The flexible hose itself is connected last. When the installation is completed, check its correctness by lubricating all joints with soapy foam. Noticing that bubbles appear in it, it is necessary to disassemble the entire structure and redo it again. Be sure to check the thread.

If it is made in size 3/8, a 0.5 inch adapter with sealing material is mounted. If a gas hose is changed or re-installed in a private house to be connected to a cylinder, the nozzle is changed to a reduced diameter. Otherwise, the burners will emit a large amount of soot. Putting things in order in the kitchen will become much more complicated

It is important to carefully select each nut, any other part, in order to eliminate errors.

The invitation of the master does not relieve the owners of the house from the need to carefully study all the work. You can not leave extra spurs on the slopes.It is only allowed to connect a flexible piping to the taps on the pipes of the descents and to the outlets from the gas appliances. This connection is made either directly or (as required) via adapters.

Gas stoves, as the most dangerous of household appliances, are connected only with hoses up to 4 m long. Better to move the slab itself and ruin, perhaps, the design than to fly into the air. Read the manufacturer's instructions carefully before connecting any hose to any gas appliance. It is strictly forbidden to check the joints with open fire! Also, do not place the hose behind non-separable partitions.

When attaching the hose to the inlet of the plate, use a metal mesh, which should be included. If it is not installed, the burner will become more clogged and more likely to fail. Adjustable wrenches are used to tighten the connection. Next, the sleeve is properly fixed on the shut-off valve. These places will also need to be tested with soapy water.

What hoses are needed for gas stoves?

A gas stove is a technique that allows you to use ordinary natural gas for cooking. True, it makes sense to use just such a type of household appliances as a gas stove only in gasified cities. However, even if there is no gas line in the house, then you can use liquefied gas cylinders as a fuel source.

A gas-fired household stove is equipped with several burners, and it may also have an oven. A gas burner is supplied to the burners, and there is also a gas distribution device that directs fuel to one or another burner. The flame can be adjusted using special levers that change the rate of gas flow into the burner.You can light the burner with any source of open fire, there are also options for stoves with auto-ignition, which uses a spark ignition system due to electricity.

This is what a gas burner looks like

Immediately after buying a brand new gas stove, it can already be connected to the gas supply line. There are special services that deal with such work, but they will need to pay for the service. Therefore, many decide to connect the oven on their own, especially since the procedure seems very simple at first glance. But, like any job, it has its own nuances.

Interestingly, earlier gas stoves were simply soldered tightly to the gas source pipe, without requiring any more connection options. Moreover, this method of connecting the plate was used only some 30 years ago. It was safe, but very inconvenient - it was impossible to wipe the floor under such a stove, if necessary it could not be moved, well, and if it came to replacing the kitchen set, then it was that sad story. So when special thin and flexible hoses began to be used when connecting gas stoves, the joy of the owners of gas stoves knew no bounds.

The process of connecting a gas stove to the main

Now a special flexible hose is used to connect the gas stove to the main. It has fittings (nuts and fittings) on one side and the other, which make it possible to obtain reliable connections both with the place where the gas exits the main line and where the gas enters the furnace. Such a hose can be made of different materials, but in any case it is flexible, strong, durable and, most importantly, inexpensive.

Connecting a gas stove to the mains using such a hose is the work of an experienced specialist.Otherwise, there is a big risk that the connection will be wrong, which means that the likelihood that the whole kitchen will fly into the air increases.

Gas is no joke, you need to work with it with extreme caution

No one will forbid you to try to connect the furnace to the main on your own. With some experience with various connections, as well as taking full responsibility, you yourself can buy a hose that is suitable for the parameters and connect the oven. The main thing is to responsibly treat both the work itself and the choice of the hose.

Gas connection installation

For installation of a gas supply, you should choose an easily accessible place. For safety, it would be wrong to partially ditch the wall or dismantle the floor. As well as communications that are hidden are not available for service inspections.

In order to avoid tension, twisting or bending when assembling flexible connections, the bending radius must be observed. Usually it is equal to 3 times the diameter. But you can increase the radius by increasing the flexible connections with the elbow. A small margin should be made along the length of the hose. Since it shortens under pressure, as a result of which excess stress may occur in the structure.

It is impossible to connect steel and copper, so that electrolytic damage to the tips does not occur. Brass must be joined to copper, and steel to steel. Condensation causes oxidation of the metal. Therefore, parts made of metal should be protected from condensation. All flexible connections must have metal ferrules. It would be better to use 2 wrenches.

Be sure to tighten the tip to ensure the required tightness of the connection. In order not to damage the structure, excessive tightness of the connection should not be ensured. After installation is completed, the hose should be checked, as it may be kinked.

After the entire system is installed, a strength test must be carried out. To do this, leave the system under load for a certain time and check the tightness and strength of all connections.

Under no circumstances should the connections be exposed to open flames. If soldering occurs next to the hoses, then it is necessary to protect the liner with a heat shield. When buying, you must carefully study the service life of the gas supply. It can be 2 years old, 5 years old or even 20 years old. After the expiration date, it is necessary to replace the eyeliner. If its gasket was done correctly, then the replacement will take no more than 15 minutes.

Basic installation rules

After choosing and purchasing a plate, you can proceed to its installation. When choosing an installation site, you must adhere to some rules:

The structure of a flexible gas hose.

- Installation of this equipment should be carried out at a distance of no more than 4 m from a rigid gas pipeline.

- A dielectric insert is used between the flexible hose and the gas cock to prevent static discharge.

- Modern stoves are equipped with electric ignition and oven lighting. They require a supply voltage to be used. If there is no outlet with reliable grounding in the kitchen near the installation site of the stove, you need to conduct the electrical wiring yourself with a three-core cable with a core cross section of at least 1.5 mm.

Connection of kitchen heaters is carried out using flexible hoses. This method of installation is by far the most optimal. In this case, the slab will not be rigidly attached to one place, because the flexible hose will allow it to move within a few meters. This will greatly facilitate the process of cleaning in the kitchen. In addition, such a connection of a gas stove is safer than a rigid one. If you accidentally move the plate, the hose will serve as a kind of shock absorber that will not break the existing fasteners.

Rubber hoses for connecting gas are made up to 5 m long. It is necessary to purchase sleeves in a white metal braid with yellow marks, since the presence of red and blue marks indicates that such hoses are used to supply water.

The choice of hoses is wide enough. The main types are the following:

- A rubber-fabric sleeve that is softer and more flexible than other types, but inferior to them in rigidity. It should be noted that such a sleeve is a dielectric, which will allow you to do without a dielectric insert when connecting.

- The rubber hose in a metal sheath has medium rigidity and high protection against mechanical damage.

- Metal bellows hose, which is the best option when connecting gas equipment, as it is recommended by regulatory documents and is the most durable and resistant to gas pressure. Its only drawback is the relatively high price.

You need to purchase a gas hose only certified

In this case, special attention should be paid to its output, which must correspond to the output on the stove. If the stove has a direct outlet, then you should choose a sleeve with a square

Also, do not forget about the threaded connection. The standard thread size is 1/2', so if the threaded connection is 3/8', then you need to buy a special adapter for 1/2'. Such an adapter can be included in the kit.