- What is the difference between kitchen faucets and bath faucets?

- Operating rules

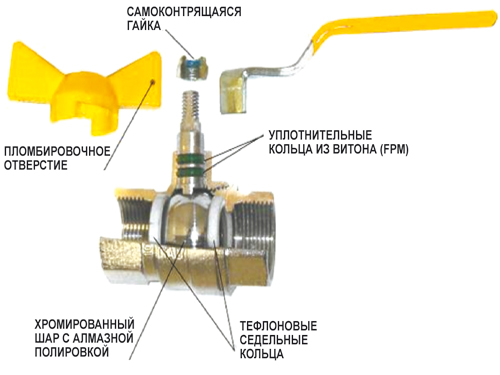

- What is a ball valve made of?

- Distinctive features of heat exchangers

- Operational Features

- Classification by installation site

- Floor type boilers

- Features of wall equipment

- The nuances of parapet devices

- Features of coloring gas cylinders

- Device and principle of operation

- Burner features

- Types of ball gas valves

- Analysis of typical installation errors

- Safety

- Features of replacing a gas valve

- Boiler power

- Stuffing boxes

- Features of gas heating

- Solving the problem with the help of specialists

- Selection of gas valves

- Kinds

- Basic selection parameters

- Valve types

What is the difference between kitchen faucets and bath faucets?

If you become more familiar with the design of kitchen faucets and their counterparts for the bathroom, then they can highlight the following features:

- The presence of a long high spout, which most often has an arched shape. This design is very practical, since it greatly simplifies the process of washing dishes. The same can be said about filling tall pots with water.

- Use of a swivel spout. Thanks to him, the user can independently regulate the zone of water jet supply.

As for bathroom faucets, these products are equipped with a flexible hose for supplying water to the shower head. But not so long ago, models of kitchen faucets with a pull-out spout appeared on the market, in which they began to use a similar mechanism.

Operating rules

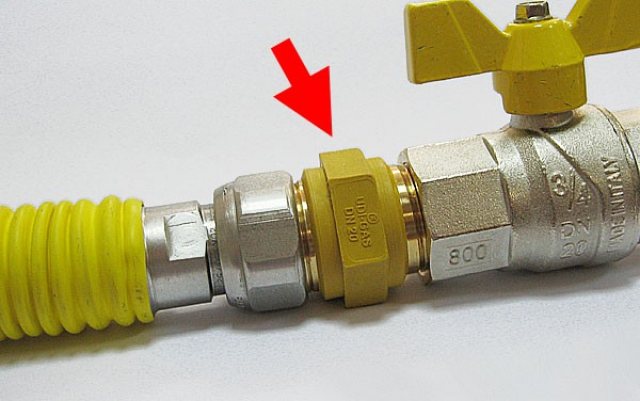

A dielectric coupling is required for reduce the impact of stray currents

In order for the city gas ball valve to last as long as possible, standard recommendations must be followed during its maintenance. The element is designed to quickly shut off the gas flow inside the pipeline. It can only be opened and closed using the factory handle; it is forbidden to use any tools for this purpose.

The design of the valve itself is not intended for flow regulation, the element has only two operating positions: open and closed. If it is half open, the fast flow of pumped fuel can cause deformation of the sealing rings, as a result of which the valve will quickly become unusable and will have to be replaced. The element must not be used in environments with contamination that can lead to mechanical damage to the gaskets. Sometimes the fastenings of the rotary handles are weakened, in such cases it is necessary to tighten the screws securing them. In the presence of leakage of stuffing box seals of the rods, adjust the nuts located under the valve handles.

What is a ball valve made of?

For the production of this shut-off valve, a variety of materials are used:

- Brass. An excellent option for water and gas supply networks. Brass ball valve is an ideal solution in terms of price and quality ratio. The main disadvantage is that it does not tolerate high media temperatures.

- Steel. Such a ball valve is the most budgetary and affordable option with a large selection of sizes. However, it has performed poorly in cold water networks due to its susceptibility to corrosion.

- Stainless steel. It has many advantages over its counterparts. Preferred home option.

- Cast iron. Very heavy, so almost never used at home.

- Polypropylene. A product made of such a material is most often used for the installation of plastic piping systems. Lightweight, comfortable, non-corrosive and inexpensive.

Distinctive features of heat exchangers

The heat exchange unit of the heating device is cast iron, steel or copper. The cast iron version retains heat for a long time, is almost not affected by corrosion due to the high wall thickness and is resistant to aggressive coolants. It is heavy and therefore mainly integrated into floor standing boilers.

It requires great care during installation, since any impacts violate the structural integrity of the material and lead to the formation of microcracks.

The steel structure weighs little, is not afraid of mechanical impact, calmly tolerates temperature changes in the coolant, is easily transported and mounted. Has some tendency to rust. The control system of the boiler helps to avoid it, which prevents the temperature of the coolant from falling below the critical point.

Copper elements are an order of magnitude more expensive than their cast-iron and steel counterparts, but they compensate for the solid cost with a large number of advantages. Inside the copper heat exchanger, sediment and scale are formed at a minimum and do not interfere with the normal circulation of the working fluid.The walls of the device are heated evenly and do not cause local overheating of the coolant.

Operational Features

Considering this locking mechanism, the following points can be noted:

- High tightness. The case is made by casting, which will determine the high insulating qualities.

- The use of metal and special alloys made it possible to reduce the weight of the structure.

- Increased reliability. As previously noted, a swivel crane can be operated for many years without failure.

- The temperature regime of the working environment can vary in a fairly wide range.

- Special performance qualities determine that the crane can withstand the effects of ambient temperatures from -60 to +80 degrees Celsius. That is why the crane in question can be installed both inside and outside. Strength and other performance characteristics remain virtually unchanged with temperature changes.

- Well-known manufacturers of hinged locking structures give a fairly large guarantee.

As practice shows, articulated cranes can last for more than 10 years.

Classification by installation site

According to the installation principle, boilers serving two communication circuits are floor, wall and parapet. Each option has its own special characteristics.

Focusing on them, the client can choose the most suitable installation method for himself, in which the equipment will be located conveniently, will not “eat up” the usable area and will not cause problems during operation.

Floor type boilers

Floor-standing units are high-power devices capable of heating and providing hot water not only to a standard apartment or residential building, but also to a large industrial premises, public building or structure.

If a double-circuit boiler is planned to be used not only for heating and supplying domestic hot water, but also for feeding warm water floors, the base unit is equipped with an additional circuit

Due to their large size and solid weight (up to 100 kg for some models), floor-standing gas boilers are not placed in the kitchen, but are placed in a separate room directly on the foundation or on the floor.

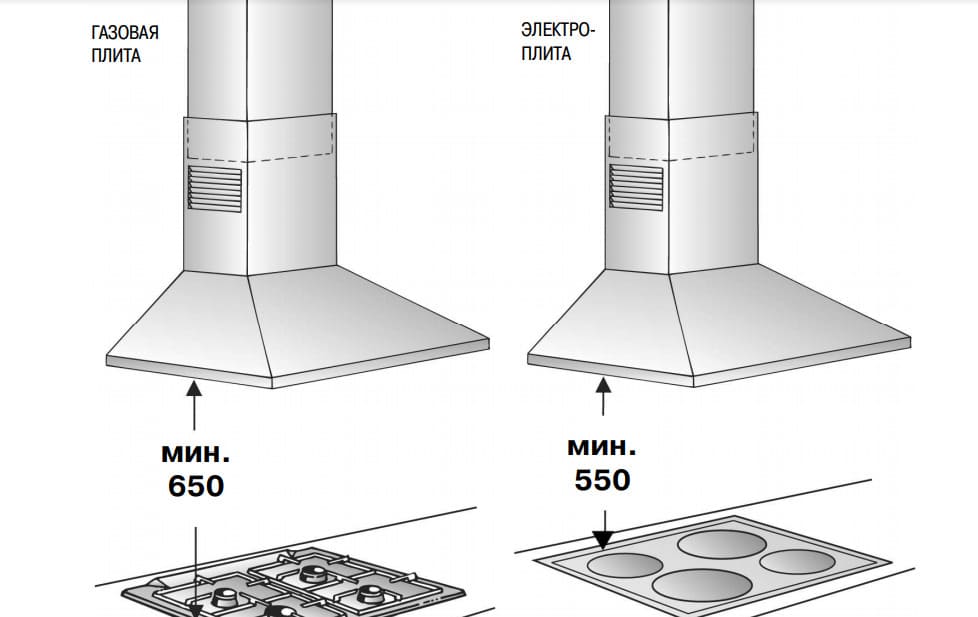

Features of wall equipment

The hinged appliance is a progressive type of household heating equipment. Due to its compact size, the installation of a geyser can be done in the kitchen or in other small spaces. It is combined with the interior solution of any type and organically fits into the overall design.

A double-circuit mounted boiler can be placed not only in the kitchen, but also in the pantry. It will take up a minimum of space and will not interfere with furniture or other household appliances.

Despite its small size, the wall-mounted boiler has the same functionality as the floor-standing device, but has less power. It consists of a burner, an expansion tank, a pump for the forced movement of the coolant, a pressure gauge and automatic sensors that make it possible to use the fuel resource with maximum efficiency.

All communication elements are "hidden" under a beautiful, modern body and do not spoil the appearance of the product.

The flow of gas to the burner is controlled by a built-in security system.In the event of an unexpected cessation of the resource supply, the unit will completely stop functioning. When the fuel begins to flow again, the automation automatically activates the equipment and the boiler continues to operate in standard mode.

The automatic control unit allows you to set the device to any operating parameters that are most suitable for the user. It is possible to set your own temperature regime for different times of the day, thus ensuring economical consumption of the fuel resource.

The nuances of parapet devices

The parapet boiler is a cross between a floor and wall unit. It has a closed combustion chamber and does not create harmful emissions. Does not require the arrangement of an additional chimney. The removal of combustion products is carried out through a coaxial chimney laid in the outer wall.

A parapet-type boiler is the best option for heating equipment for small rooms with a weak ventilation system. The device is designed in such a way that during operation it does not emit combustion products into the atmosphere of the room in which it is installed.

The device is mainly used to provide hot water and full heating for small houses and apartments in high-rise buildings, where it is not possible to mount a classic vertical chimney. The base power ranges from 7 to 15 kW, but despite such low performance, the unit successfully copes with the tasks.

The main advantage of parapet equipment is the ability to connect heating and water supply communications to the central gas system and pipelines from any side convenient for the user.

Features of coloring gas cylinders

Cylinders with compressed gas in Russia and abroad are painted differently. At the same time, each type of gas corresponds not only to a certain color of the case, but also to the color of the strip, inscriptions.

The table shows the identification colors of cylinders with some types of gases, as well as the color of the inscriptions and stripes.

| Gas | Balloon color | Inscription | Band |

| Ammonia | Yellow | Black | Brown |

| Nitrogen | Black | Yellow | Brown |

| Argon technical and pure | Black, gray respectively | Blue; green | Blue; green |

| Acetylene | White | Red | Green |

| Butylene | Red | Yellow | Black |

| Butane | Red | White | Black |

| Hydrogen | dark green | Red | Black |

| compressed air | Black | White | Black |

| Helium | Brown | White | Black |

| Oxygen | Blue | Black | Black |

| hydrogen sulfide | White | Red | Red |

| Carbon dioxide | Black | Yellow | Yellow |

Nitrous oxide is pumped into a gray cylinder with a black inscription and the same stripe. A protective-colored phosgene cylinder has a yellow inscription and a yellow stripe, and a cylinder of the same color, but with a black inscription and a green stripe, contains chlorine. Aluminum coloring of the cylinder, black inscription on it and two yellow stripes indicate that it is filled with freon-22.

For sulfur dioxide, a black cylinder with a white stripe and a yellow inscription is intended. Ethylene is enclosed in a purple bottle with a red inscription and a green stripe. For other combustible gases, red vessels with a white inscription and a green stripe are intended.Non-flammable gases are indicated by a yellow inscription on a black background of the case and a green stripe.

Device and principle of operation

The body of the locking device is a piece of pipe, expanded in the middle part. In the extension, a seat made of sealing material is installed, inside of which is the main element - a ball, also known as a shutter or plug.

The ball can rotate freely inside the seat. It has only one through hole in the shut-off valve.

Regulating devices and valves that redirect the flow may have 2 or 3 holes. If the tap is used to regulate the pressure of hot or cold water, then there are two holes, if the device is a mixer, then there are three holes.

A ball valve is actuated by turning a lever to which a ball valve with a hole is connected through a stem. By turning the hole relative to the axis of the pipeline, we open / close the passage to the medium or pass it partially

The principle of operation is very simple: when the axis of the hole in the ball is aligned with the axis of the faucet body, water will begin to flow from it.

Those. when the plug is turned so that its opening coincides with the direction of the pipeline, as if continuing it. In this position, the flow of liquid, steam, gas passes through the pipeline, including through the valve, freely.

When the ball valve is rotated 90º, the passage for water, steam, gas is blocked by the side on which there are no holes. In this position, the flow of the medium stops completely, because it rests against the solid wall of the shutter.

However, this simple device can also regulate the flow parameters. When turning 45º, for example, the flow will be blocked only half.

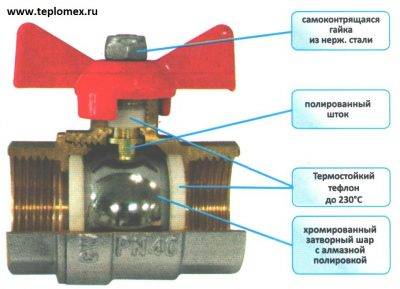

To control the ball, a rod connected to a lever is used.O-rings are located on both sides of the stem. The hole in the body through which the stem passes is also equipped with a washer and an o-ring.

The ball single-lever mixer is equipped with a shutter with two holes for passing cold and hot water and another hole for the outlet of the mixed jet

Ball valves are made of brass or various steel grades. Brass devices are considered more reliable, their service life exceeds 10 years. Steel products are very rarely used in everyday life, mainly used for industrial piping systems.

More recently, manufacturers began to produce cranes, the body of which is made of high-strength plastic. Unlike brass, such devices are not subject to corrosion, they are much cheaper.

The only drawback of plastic products is that they cannot be used for hot water.

All o-rings are made of high density rubber, these are the “weakest” points of the faucet that cause leaks, but are easily replaced with a regular repair kit

These taps are the most widely used in everyday life. A feature of their design is that the ball is not rigidly connected to the stem and can move under the action of water, pressing against the sealing ring, thus sealing the valve.

The floating ball is used in mechanisms whose nominal size does not exceed 20 cm. Such devices are installed in internal water and heat supply systems. Practically in all household mixers of domestic and foreign production, a floating ball mechanism is also installed.

Execution of the body of cranes with a floating ball can be either welded or collapsible.Sealing elements can be of different hardness. Small household appliances are usually collapsible and have soft seals.

Floating gate valves are installed on lines with a diameter of up to 200 mm with a constant movement of the working medium. The ball under the pressure of the medium is pressed against the sealing rings, sealing the fittings

There are valves in which the locking element is fixed on the stem axis, and the seals are pressed against the ball with the help of tie bolts or springs. To facilitate closing/opening, the trunnion is equipped with bearings.

This design is the most reliable, but due to the high cost it is rarely used in everyday life and usually in the most critical sections of the water supply system.

Burner features

To select the right type of equipment, it is necessary to consider the general purpose of gas burners. Classification allows you to select several groups among the variety of equipment. A gas burner is a device that mixes oxygen and gas, and then delivers this mixture to the outlet. When ignited, a stable torch is formed.

How are gas burners for boilers arranged? The fuel mixture is supplied through pipelines under pressure. Air and oxygen are combined into a single substance in a special device. When it leaves the system, the fuel mixture ignites. A constant, steady flame is formed. Such equipment is used for domestic and industrial purposes. It is installed in various boilers.

There are two main types of burners on the market today. They are separated according to the principle of preparation of a combustible composition. There are atmospheric and inflatable devices. The first type of burners is also called injection burners.Inflatable varieties can be called ventilation.

Injector varieties are almost always part of the heating unit. They are supplied with it in the kit, are included in the price of the boiler. Inflatable burners are sold separately. They are more efficient, since the air supply to the structure is carried out using a fan.

Gas burner systems perform 4 functions. They mix gas with air in the correct proportion and then feed them to the combustion front.

Also an important function of the apparatus is the stabilization of the ignited torch. It should not deviate from the established level. The burner provides the necessary intensity of heat release

Therefore, the choice must be made, focusing on the need for equipment power.

The burner provides the necessary intensity of heat release. Therefore, the choice must be made, focusing on the power requirements of the equipment.

Types of ball gas valves

In addition to the fact that the valves under consideration differ in diameter, the differences lie in the installation method. The following types of devices are used much more often in gas pipelines:

| Threaded (coupling) | They have a small diameter. In most cases, these products are used in domestic gas pipelines. The connection to the pipeline, as the name suggests, is carried out using a threaded connection. |

| Flanged | They are used in external gas pipelines of huge diameter. The connection is carried out by the flange method using bolts. Like threaded ones, these devices are collapsible, i.e. they can be dismantled and then reinstalled. |

| Welded | Like flanged ones, they are used for external gas pipelines. Their diameter can be from 10 to 70 millimeters. The connection to the pipeline is carried out by welding. Accordingly, this mounting option is non-separable. The advantages of such products include complete tightness and high reliability. In addition, welded shut-off valves do not require maintenance, i. tightening flange connections. |

Analysis of typical installation errors

Although the operation to replace the gas valve is quite simple, it can fail for inexperienced craftsmen.

Typical shortcomings are:

- The impossibility of connecting a tap with a pipe. Most often it happens due to the fact that these elements do not correspond in size or thread. Adapters and extension cords of various shapes and sizes will help correct the situation. In order not to get into a similar situation, it is advisable to take into account the parameters of the pipes at the stage of selecting a crane.

- Valve leakage. The threads must be secured by hand, but a wrench must be used at the end. If this is not done, the connection will not be secure enough, resulting in gas leakage and structural instability.

- Tightening the tap exclusively with a wrench. When working with a tool, the possibility of damaging the part or stripping the thread increases.

- Insufficient tightness of the connection. If an inspection of the replaced faucet shows that natural gas is being released into the air, turn off the stove immediately and correct the error as described above.

Do not use poor quality faucets

In order for the equipment to serve for a long time, it is important to choose models of well-known companies.It is desirable to use brass devices that require a minimum of maintenance while maximizing efficiency and durability.

Silicone and other similar materials dry out, lose their elasticity, as a result of which they begin to pass gas. To prevent this from happening, it is better to use graphite-based lubricants.

Safety

Any installation work performed with gas appliances requires the obligatory fulfillment of all safety requirements. The connected flexible hose must always be in front of your eyes. It is strictly forbidden to close it. It should always be located in a place accessible for visual inspection.

It is forbidden to use a non-standard size gas hose. They must comply with existing regulations.

The hose does not need to be painted, as paint can cause it to crack quickly. If you want to make the sleeve look prettier, you can cover it with self-adhesive paper.

The rubber sleeve is directly connected to the tap if it is located on vacation. If the thread has non-standard dimensions, an adapter is allowed.

When operating gas equipment, it is very important to comply with safety rules and existing operating standards. The fire safety of gas-fired installations depends on this.

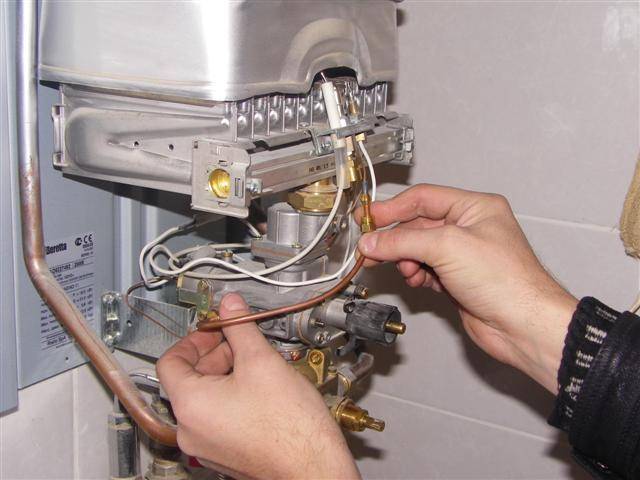

Features of replacing a gas valve

Certainly, each shut-off valve can fail, for example, gas valves are not insured against breakage. If a malfunction of this device is detected, it must be replaced immediately.

Immediately go to declare that doing this work with your own hands is not allowed! But, some actions still need to be performed independently.

So, the instructions for replacing this shut-off valve are as follows:

- First of all, it is necessary to tell about the problem to experts from gas work or a personal organization that owns a license to perform similar work.

- After that, you need to purchase a new crane in a specialized store. First you need to measure the diameter of the pipeline, so as not to make a mistake when choosing a product.

- By the arrival of the experts, they will be sent to prepare a technical passport and a contract for gas supply. A technical passport is needed to make a note about the work performed.

- After that, you need to light the gas on the stove and close the central valve. The burner should be left until it is completely attenuated, so that the whole gas comes out of the pipeline.

- Upon the arrival of experts, it is necessary to open a couple of windows in order to create a draft in the room. This is necessary in case of a gas leak.

- Upon completion of the work, be sent together with experts to diagnose the installed shut-off valves for leakage.

- At the end of the work, it is necessary to give the workers a technical passport and ask them to make a note in that direction.

At the end of the work, leave the windows open for another 15-30 minutes, which will ensure complete ventilation of the room.

Boiler power

One of the key points in choosing a heating boiler is determining the required power. If we approach this with full responsibility, it is necessary to consider the heat loss of each room, if we are talking about an apartment or a building as a whole, if the boiler is selected for heating a private house.The calculations take into account the materials of the walls, their thickness, the area of windows and doors, the degree of their insulation, the presence / absence of an unheated room at the bottom / top, the type of roof and roofing material

Geographic location and a whole bunch of other factors are taken into account

Such a calculation can be ordered from a specialized organization (at least in GorGaz or a design bureau), if desired, you can master it yourself, or you can take the path of least resistance - calculate based on average norms.

Where does the heat leave the house?

Based on the results of all calculations, the norm was derived: 1 kW of heating power is required for heating 10 square meters of area. This standard is suitable for rooms with ceilings of 2.5 m, with walls with an average degree of thermal insulation. If your room falls into this category, divide the total area that needs to be heated by 10. You get the required boiler output. Then you can make adjustments - increase or decrease the resulting figure, depending on the actual conditions. It is necessary to increase the power of the heating boiler in the following cases:

- The walls are made of a material with high thermal conductivity and are not insulated. Brick, concrete fall into this category for sure, the rest - according to the circumstances. If you are choosing a boiler for an apartment, you need to add power if the apartment is corner. For "internal" heat loss through them is not so terrible.

- Windows have a large area and do not provide tightness (old wooden frames).

- If the ceilings in the room are higher than 2.7 m.

- If in a private house the attic is not heated and poorly insulated.

- If the apartment is on the first or last floor.

The design power is reduced if the walls, roof, floor are well insulated, energy-saving double-glazed windows are installed on the windows. The resulting figure will be the required power of the boiler. When looking for a suitable model, make sure that the maximum power of the unit is not less than your figure.

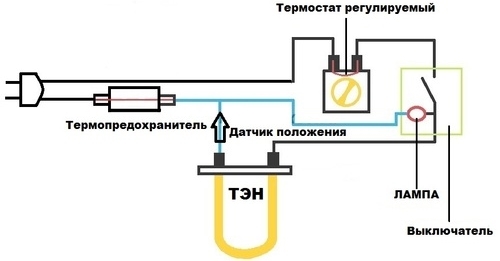

Stuffing boxes

The gland assembly of the ball valve ensures its tightness in relation to the external environment. The design solutions of these nodes can be different (table 2) and in many respects they specifically determine the performance characteristics of the crane.

Table 2.

Common designs of stuffing boxes for ball valves

The most reliable and practical today is the design with a clamping nut with an external thread, see pos. 7, table 2, it is used, in particular, in the Valtec Base crane.

When choosing a valve, it should be taken into account that ball valves with non-repairable stuffing boxes will last until the first leakage along the stem, after which the entire valve must be replaced.

On a valve where the stem is inserted from the outside instead of from the inside of the body, the pressure can dislodge the stem.

On the one hand, this solution makes the valve repairable, but on the other hand, there is a danger of the stem being knocked out by the pressure of the working medium. The stuffing box nut may not keep the stem from being squeezed out - an unlocked threaded connection under the action of a longitudinal force in the conditions of alternating loads and vibration tends to unwind even with a self-braking thread.

During vibration, the friction force in the thread is significantly weakened, which leads to spontaneous unwinding.The same problem occurs in the union nuts of the compression fittings. That is why they are supposed to be twisted from time to time.

The pressure force of the working medium tends to push the stem of the ball valve out of the stuffing box.

If the stem is inserted from the inside, this buoyant force is taken by the shoulder of the stem, which rests on the valve body (Fig. 4; pos. 5, 7 of Table 2).

When the stem is inserted from the outside, the threads of the gland nut take up the buoyant force (Figure 5). Valve vibrations and alternating temperature overloads lead to spontaneous unscrewing of the stuffing box nut and the occurrence of a leak. In the absence of proper control, the nut may partly disengage from the threaded engagement. In this case, at the slightest pressure surge, the part of the thread remaining in engagement will be crushed and the stem will be knocked out of the valve.

The worst option for a stuffing box assembly is if the support shoulder of the rod is shifted up and pressed against the stuffing box nut (Fig.

6). In this case, according to the plan of the designers, the stuffing box nut immediately performs the function of a stem travel limiter and a pressing element in the seal.

In addition to the possible knocking out of the stem by pressure, this design adds the risk of complete jamming of the ball by the stem. This can happen when the packing is pinched by the stuffing box nut.

Features of gas heating

Despite the presence of a large number of alternatives (electricity, diesel, diesel fuel, fuel oil, firewood, coal), it is gas heating that is still the leader in the world. And there are good reasons for this:

Profitability. Compared to other options, gas is relatively cheap and has a high efficiency.At the same time, not only the cost of the fuel itself is taken into account, but also additional costs for its storage (for the consumer), maintenance of the entire system, and so on. So, parts for rare types of boilers can be difficult to get, sometimes you have to overpay

This is also taken into account.

Minimum human involvement. Space heating with wood or coal requires mechanical addition of fuel

Here everything is automated, including the flow of gas and control of the flame.

Cleanliness, lack of soot, soot and other things. Boilers can be easily installed in the kitchen.

Possibility of heating large rooms. One powerful boiler can cope with a building on several floors.

At the same time, gas heating has its drawbacks. Or rather specific.

Installation must only be carried out by specialists

In particular, the installation of the boiler requires coordination with Gaztekhnadzor. You can entrust the installation only to an organization with a license that gives the right to provide such services.

In addition, you need to take care of ventilation. The products of combustion can be removed from the building in a natural way. But if there are problems with traction, you need to change the installation location of the boiler (which is not always possible) or provide it forcibly.

Solving the problem with the help of specialists

Leakage is one of the most dangerous problems that residents can face. If there is a smell of gas, it is necessary to check the tightness of the tap using soapy foam, which must be applied to the pipe connection and valve. If the foam bubbles, there is a leak at that location. In this case, you should immediately seek help from specialists to replace worn parts of the system.

To solve the problem, you need to prepare:

- gas tap (you first need to call the service company and find out the need to purchase it);

- documentation (contract for gas supply, registration certificate).

Selection of gas valves

If a malfunction is detected in the operation of the gas valve, it is recommended to replace the device as soon as possible. First of all, you need to choose a new valve. When choosing, experts recommend considering:

- valve type;

- basic device settings.

Kinds

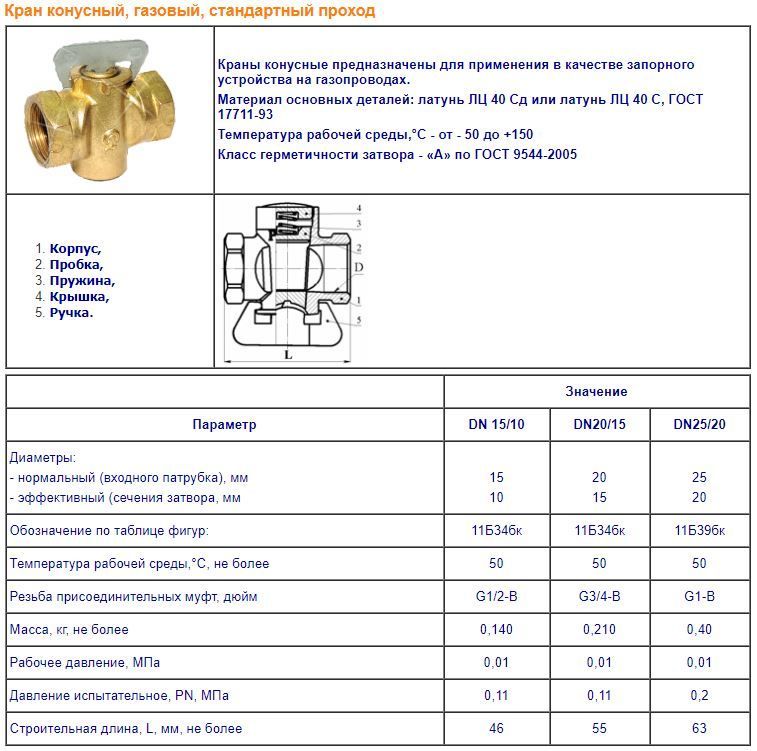

The gas pipe valve can be:

cork. A conical element driven by a flywheel is placed in the cork faucet body. In the conical element (plug) there is a hole, which, when aligned with the hole in the pipe, passes gas to the equipment. The stuffing box acts as a sealing material sealing the connection of the faucet with pipes;

Cross sectional valve

ball. The device of a ball-type gas valve differs from a cork one in that the locking mechanism is based on a ball made of durable metal. The ball has a hole, which, when the flywheel is turned, is located along the gas pipeline and in this way passes gas to the consumer.

Valve for gas pipeline with ball locking mechanism

Experts recommend using ball valves for a domestic gas pipeline, as they are more reliable.

According to the method of connection with pipes, a household ball valve can be:

threaded. The valve is connected to the gas pipeline pipes with a threaded connection;

Threaded valve

flanged. Connection with pipes is carried out using flanges, which in turn are fixed with bolts;

Gas valve fixed with flanges

welded, that is, installed using a welding machine.

Welded gas cock

Threaded and flanged valves are reusable, that is, if necessary, you can remove the device from the gas pipe, check its performance, carry out repairs and install it in its original place. The weld valve can only be installed once.

Basic selection parameters

To select a shut-off valve for gas, it is recommended to pay attention to the following factors:

- pipeline diameter. The shut-off element of the valve must completely cover the pipe in the apartment. If the valve is larger or smaller, then the tightness of the tap will not be complete;

- pitch and diameter of the thread on the pipeline. To quickly replace the device, a complete match of the specified parameters is necessary. Otherwise, you will need to purchase and install additional adapters;

- the material from which the gas pipeline valve is made. It is more expedient to purchase brass taps, as they have a longer service life. On sale you can also find silumin, zinc and plastic taps. It is possible to distinguish the material used for the manufacture of the valve by weight. Brass faucets are heavier than faucets made from other materials. In addition, you can inspect the place where the thread is cut. Brass has a yellow tint, and all other materials (except plastic) are gray;

Gas valve made of nickel-plated brass

- The valve body must be free of chips, bulges, cracks and other defects. The presence of these factors indicates non-compliance with the rules for manufacturing the product, which will lead to a reduction in service life;

- it is more expedient to purchase valves from well-known manufacturers. For example, you can choose cranes manufactured by Bugatti (Italy), Dungs (Germany), Broen Ballomax (Poland).

Compliance with simple rules when choosing a gas valve will allow you to choose a reliable device with a long service life.

Valve types

Depending on the design characteristics, ball valves are of several types.

- Direct-flow. The main characteristic feature is low hydrolosses. Most of them are mounted to regulate the supply of liquid medium to heating systems.

- Checkpoints. Gas through valves and valves for liquid medium are mounted on a straight section of the pipe and are designed to completely stop the flow of the incoming medium.

- Corner. Installation of corner devices is carried out on the bend of the pipeline system. The function of the valves is to block (cut off) the incoming flow.

- Three-way or mixing. They are mounted on systems when there is a need to mix two streams of incoming liquid medium with different temperatures.