- Models

- The best manufacturers of double-circuit wall-mounted gas boilers

- Characteristics of the boiler 100-W WH1D262

- Types

- Varieties

- About the manufacturer

- Which series and models are dual-circuit

- Which series and models are floor standing

- Double-circuit gas boilers Viessmann

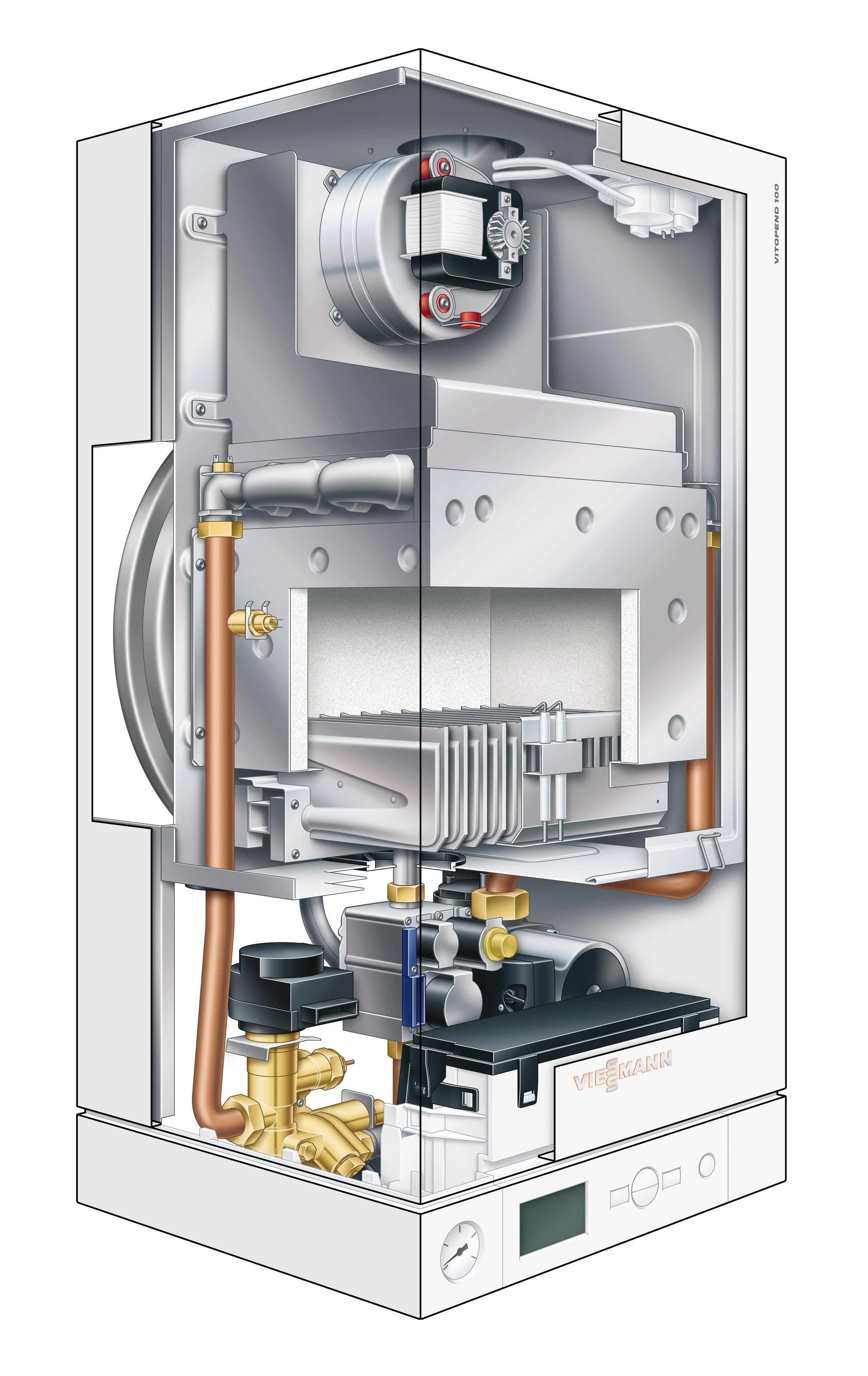

- Device

- Advantages and disadvantages

- Price range

- Connection and setup instructions

- Device

- Conclusion

Models

The range of Viessmann gas boilers is quite diverse. The line includes floor and wall models of different capacities, made in both single-circuit and 2-circuit versions.

The Vitopend modification is represented by two-circuit devices, the power of which varies from 10.5 to 30 kW. A distinctive feature of the models of this series is efficiency and compactness. The chimney of the units is made according to an improved technology, which excludes freezing of pipes in the winter. The efficiency of the devices is 90-93%, the performance is 14 liters of hot water per minute. An atmospheric sensor can be installed on all devices, which independently controls the heating temperature and allows you to significantly save on heating.

The Vitogas modification is represented by one floor model 100-F, produced in two power options: in domestic boilers this figure varies from 29 to 60 kW, and in industrial boilers it can reach 140 kW. A distinctive feature of the devices of this series is high efficiency and a minimum amount of exhaust gases. Due to the fact that graphite-coated gray cast iron is used for the manufacture of heat exchangers, this type of device is considered the most durable and safe. The devices are a single-circuit unit and are well suited for heating a private house. In the event that hot water supply is required, an indirect heating boiler is purchased in addition to the device.

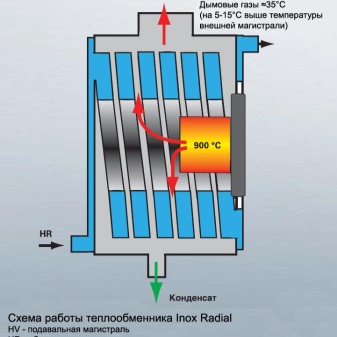

Vitodens modification is represented by Viessmann 100/200W condensing wall models. The devices are characterized by beautiful design, high reliability and efficiency, and their efficiency reaches 109%. The boilers are equipped with a MatriX cylindrical burner capable of electronically modulating the intensity of combustion depending on the degree of heating of the coolant. This allows you to avoid excessive fuel consumption and save money. The models have a double-circuit design and are made using the Inox-Radial technology, with the help of which the heated surfaces are independently cleaned of soot and soot. The boiler is fully volatile and in the event of a power outage, it stops its work. For the DHW system, a plate-type heat exchanger is used, which significantly reduces the time for heating water and increases productivity.

The Vitocrossal 300 modification is represented by floor-standing condensing models with power from 29 to 60 kW with an efficiency exceeding 100%. The heating elements are made of high-alloy steel, and the MatriX gas burner operates silently and ensures an environmentally friendly process. When installing boilers of this type, the arrangement of a coaxial chimney system is required.

The best manufacturers of double-circuit wall-mounted gas boilers

In the market of gas heat generators, the leading positions are shared by several leading manufacturers:

Baxsi

Founded in 1924, the company still produces high-quality gas equipment, both floor-mounted and wall-mounted. All products of the company are certified accordingly and are exported to more than 70 countries. The most demanded are double-circuit models of the Main Four series with a capacity of 18 up to 24 kW and efficiency 93 %.

Vaillant

The company was founded in Remscheid in 1875. Currently, the company is a leader in the production of heating boilers of various modifications, including double-circuit gas units. In the group's lineup, you can find models with power from 5 to 275 kW. Impeccable quality and reliability have made Vaillant boilers popular not only in Russia, but throughout the CIS.

Buderus

The history of the company begins in 1731. The company specializes in the production of heating units, which are of high quality and reliability. Especially popular are wall-mounted models of Logamax plus gas boilers with a power of 15 to 100 kW. Many models of the company are equipped with a remote control function via the Internet.

Ariston

The world famous company, founded in the 30s of the last century and registered in 1946, produces all types of household appliances, and heating systems are no exception. A wide range of gas, solid fuel and oil boilers are consistently distinguished by high build quality and long service life. The most demanded modifications are Egis Plus, Clas Evo, Clas Premium Evo System.

Protherm

The Slovak company started the production of heating systems in 1991, and already in 2017 it was a serious competitor to the world's leading manufacturers. The high quality and affordable price of the manufactured equipment is the hallmark of the company. Currently, the most popular boilers are the Panther series with a capacity of 12 to 35 kW, and the Jaguar series with a capacity of 11 to 24 kW.

Domestic companies are represented on the market by Zhukovsky Machine-Building Plant, Lemax and Neva. The products of these enterprises are quite competitive and have an affordable cost with quite acceptable quality.

Characteristics of the boiler 100-W WH1D262

This Viessmann Vitopend 100 boiler will cost the consumer 33,800 rubles. This boiler is a gas convection equipment with a power of 24.8 kW. Double-circuit equipment has a bithermic heat exchanger. The thermal power can be 10.7 kW, as for the thermal load, it varies from 11.7 to 26.7 kW.

The efficiency of this device reaches 92.8%. The described Viessmann Vitopend 100 boiler can be controlled using an electronic panel. This device must be installed on the wall. The design has a built-in circulation pump and an expansion tank of 6 liters.LPG or natural gas can be used as fuel. For an hour of natural gas, 2.83 m 3 will be consumed, as for liquefied gas, this figure decreases to 2.09 m 3 / h. If you decide to consider the described Viessmann Vitopend 100 gas boiler, then you should be aware of its nominal pressure, which varies from 13 to 30 mbar. The maximum temperature of the coolant is 76 °C. Permissible liquid pressure gas is 57.5 mbar.

The temperature in the hot water circuit can show from 30 to 57 ° C. The Viessmann Vitopend 100 WH1D brand boiler has a capacity of 11.5 l / m. In the heating circuit, the maximum water pressure can reach 3 bar, while the maximum water pressure in the hot water circuit is 10 bar or less.

Today, Viessmann boilers are in great demand among buyers of heating equipment. This German company has been manufacturing boilers for a long time and has long established itself in the international market from the best side. Viessmann produces heating equipment of completely different models, among which you can choose a product for any preference.

Types

There are different types of Viessmann floor-standing boilers, which differ in design and method of transferring heat energy.

Offered:

- convection boilers. Their work uses the traditional method of heat transfer, the efficiency of which is brought to a high limit.

- Condensing boilers. They are equipped with an additional unit - a condensation chamber, in which water vapor from flue gases is deposited.In this case, a significant amount of thermal energy is released, which is transferred to the coolant. Pretreatment reduces the heating temperature in the heat exchanger, which automatically reduces gas consumption.

Almost all models of floor-standing boilers are single-circuit, except for the only Vitodens 222-F range, equipped with an integrated boiler.

The absence of a DHW module does not mean that the supply of hot water to the premises is impossible. All models have branch pipes for connecting an indirect heating boiler, in which a hot coolant circulates through a copper coil, which heats the water.

Models of floor boilers have different capacities, as a rule, quite large, designed to work in rooms with an increased area.

Varieties

The range of gas heating equipment of the Viessmann concern is represented by wall and floor models, which, in turn, are divided into condensing and traditional types. The first ones are represented by the Vitodens series and, in terms of the method of heating the coolant, are fundamentally different from traditional ones. Such models are much more efficient in operation and have a higher efficiency. The principle of operation of these units is that when gas is burned, water vapor is formed, which in traditional models is simply discharged outside through the chimney system. The condensing boiler is equipped with a modulating gas burner Matrix, made of stainless steel and having a cylindrical shape.

Around the burner is a coil, also made in the form of a cylinder and wound on pipes with a square section. Hot steam formed from the combustion of gas passes through this coil and, settling on its surface, gives up its thermal energy to the coolant inside.After that, the cooled drops flow into the receiver and are collected in a specially designated container.

Condensing units have high efficiency, which is 100 percent or more, and are in high demand in European countries. In Russia, these models are not so popular. This is due to the rather high cost, which is 100 or more thousand rubles. Condensation models are double-circuit, due to which they provide the consumer not only with heat, but also with hot water, the flow rate of which can reach 14 l / min. The power of the devices varies from 17 to 150 kW.

Viessmann gas boilers with a traditional heating system are represented by double-circuit models of the Vitopend series. Due to low cost, a wide range of models and a large range of capacities, these devices are much more popular than condensing ones. The principle of operation of traditional units is quite simple: the water in the heat exchanger is heated by gas combustion and supplied to the heating and hot water system. The efficiency of devices is 90-99% and depends on the type of combustion chamber and the power of the unit. Models equipped with a closed chamber have a slightly higher efficiency than boilers with an open system. This is due to the absence of heat loss in closed models and more powerful heat transfer. All traditional models are equipped with modulating burners, which are able to automatically increase or decrease the intensity of fire burning in a given range.

The burner is controlled by the Vitotronic 100 controller in all models.The device monitors the temperature regime of the coolant, controls the boiler security system, regularly diagnoses all units of the device, and in boilers with a closed combustion chamber ensures synchronous operation of the modulating burner and electric fan.

All Viessmann models have the ability to connect remote Vitotrol thermostats, with which you can maintain a certain thermal regime of the coolant, taking into account the ambient temperature. Depending on the modification, traditional devices can be equipped with two heat exchangers, one of which is made of copper and is the main one, and the second is made of steel and is designed to heat running water. The performance of the devices is from 10 to 14 liters of hot water per minute and depends on the power of the device. The boilers are volatile and operate on a voltage of 120-220 V.

Among the devices with a traditional heat exchanger, there are also single-circuit models. The power of such devices is from 24 to 30 kW. The boilers are designed for space heating and, due to the lack of a secondary circuit, are not suitable for organizing hot water supply.

About the manufacturer

The trademark "Viesmann" belongs to the family business Viessmann Werke GmbH & Co. kg. The company was founded in 1917, in addition to heating boilers, it is engaged in the production of boilers and water heaters, heating radiators and other heating equipment.

On the territory of the Russian Federation, the company is represented as Viessmann LLC, the official representative office of Viessmann in Russia.Also in Lipetsk there is a plant that produces heating equipment according to German standards and under the control of the parent company. During its activity, the company has established itself as a manufacturer of expensive, but extremely reliable and functional equipment by domestic standards.

In practice, boilers are indeed among the most reliable on the market. In private houses, there are wall-mounted Vitopend 100-W of the first generations, which have been working without problems for more than 12-14 years. In terms of efficiency, almost all Viessmann models are second only to some analogues, but at the same time they comply with high safety standards, have many control and measuring systems, are environmentally friendly and functional.

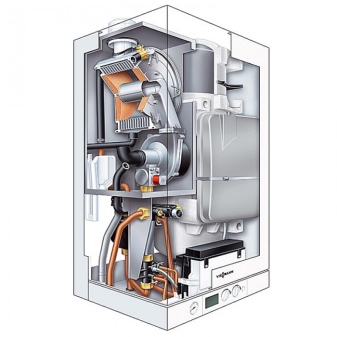

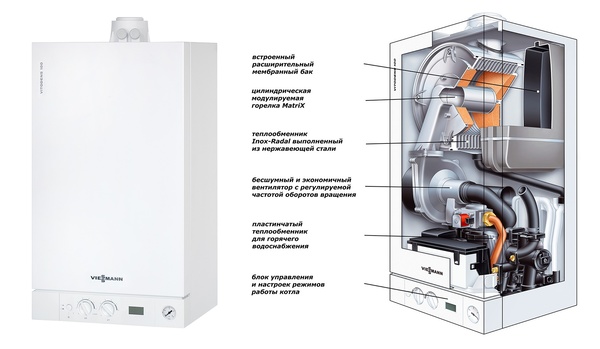

Modern Viessmann boilers have a stylish design and do not require service space around; a minimum of communications is required to connect them. Pictured is the Viesmann Vitodens 200-W.

Modern Viessmann boilers have a stylish design and do not require service space around; a minimum of communications is required to connect them. Pictured is the Viesmann Vitodens 200-W.

For example, in floor-standing gas boilers, heat exchangers made of modern gray cast iron alloys are used, which retain all the advantages (corrosion resistance and durability, longer cooling), while eliminating the main drawback of classic cast iron - vulnerability to temperature extremes and mechanical damage.

In all, even the most budgetary models, modulating burners are used to achieve the optimal combustion mode - continuous operation at minimum power. This affects not only the efficiency, but also the life of the boiler (by reducing the clock frequency: the boiler on-off cycle).

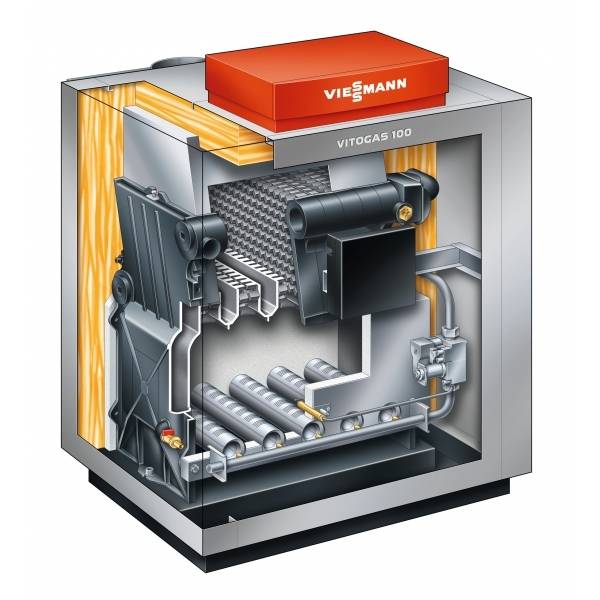

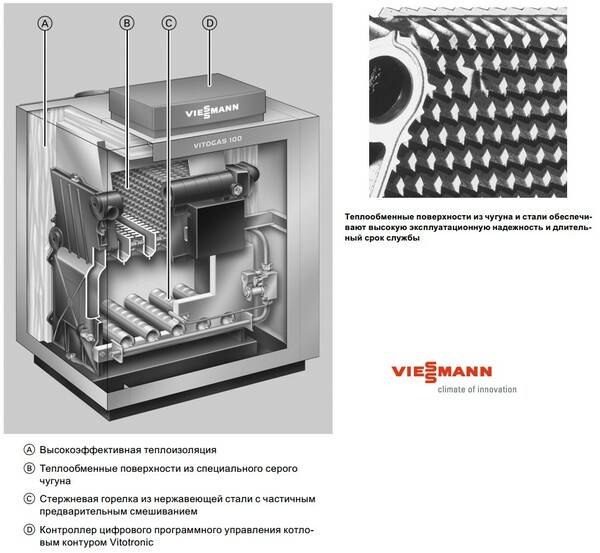

Floor Viessmann Vitogas 100-F in section.

Floor Viessmann Vitogas 100-F in section.

All, even floor-standing, models have wide functionality and variability of work settings, all models have a built-in programmer with which you can set the boiler operation pattern for a day or a week, which greatly facilitates operation and saves money, for example, by setting a temperature drop to 19 ° C at sleep time. Any of the models is also equipped with all the security systems available today: protection against overheating, freezing, stopping the circulation pump, reverse thrust, auto-ignition and auto-diagnostics, informing about what specifically caused the failure with the corresponding error code.

However, there are also tangible shortcomings, despite the fact that the equipment is considered a reference in the world market. First of all, these are high requirements for installation, connection, commissioning and operating conditions. Despite the fact that all Wisman boilers carry a coolant of absolutely any quality, it is advisable to connect them through a voltage stabilizer. Even with factory protection against voltage surges, in real conditions, failure of automation is the most common malfunction.

It is also important to pay special attention to cleanliness in the boiler room, otherwise it is necessary to clean the boiler annually (at least once every 3-4 years).

Which series and models are dual-circuit

Double-circuit models of Viessmann boilers are marked A1JB.

Among the entire range of products there are two series:

- Viessmann Vitopend. They represent a model line of convection boilers with power from 10.5 to 31 kW.The most popular models are boilers with a capacity of 24 and 31 kW, which is explained by the optimal correspondence of their parameters and the needs of a medium-sized private house. Their efficiency reaches 90-93%, the installation feature is the possibility of installation in a narrow compartment - there is no need to leave gaps on the sides, all maintenance is carried out from the frontal plane of the boiler.

- Viessmann Vitodens. This is a range of condensing boilers. The Vitodens series is divided into three ranges, 100 W from 12 to 35 kW, 111 W from 16 to 35 kW and 200 W from 32 to 150 kW. The 24 kW models are in the highest demand, although condensing boilers have specific operating conditions and are not always able to demonstrate full efficiency.

IMPORTANT!

There is a series Vitodens 222-F, which is a floor model with a capacity of 13-35 kW, equipped with a built-in storage water heater, which allows them to be classified as double-circuit boilers.

Which series and models are floor standing

There are 4 main series of Viessmann floor standing boilers:

- Vitogas. An extensive series of boilers with power from 29 to 420 kW. All models have a cast iron sectional heat exchanger and an atmospheric burner with partial mixing.

- Vitocrossal. A series of boilers with a total capacity of 2.5 to 1400 kW. Equipped with a heat exchanger having a smooth inner surface with a self-cleaning function. can be connected to a long chimney, which allows them to be used in tall buildings.

- Vitola. Heat exchanger with self-cleaning capability. The power of the boilers is 18-1080 kW. It is possible to replace the burner with the transition to diesel fuel.

- Vitorond. Boilers similar in design to the Vitola series with minor differences.

IMPORTANT!

The ability to work on liquid fuel does not increase the capabilities of the boilers, since for a complete conversion it is necessary to organize the correct supply and storage of diesel fuel, which is very difficult and costly.

In addition, there is a line of floor-standing boilers of the Vitodens 222-F series, the remaining models of which are wall-mounted.

The cost of these models is very high, so only Vitogas series boilers are common.

Double-circuit gas boilers Viessmann

Double-circuit (combined) boilers have two functions that are performed simultaneously - heating the coolant for the heating system and preparing hot water for household needs.

As a rule, the power of double-circuit boilers is relatively small, up to 34 kW, which corresponds to the size of residential buildings, apartments or office premises of small and medium size. This has its own calculation - the higher the boiler power, the greater the volume of hot water it must prepare.

However, the heating of the DHW flow in the unit produces a plate secondary heat exchanger, whose capabilities are limited, and it is not able to give a high performance.

Therefore, powerful Viessmann boilers are single-circuit, but they have the ability to connect an external indirect heating boiler, whose performance is much higher and is able to satisfy large demand for hot water.

Device

Floor boilers of the Viessmann Vitogas 100-F series have a simple and reliable design. The main element is a rod-type burner with premixing.

This means the process of adding a certain amount of air to the gas flow, which changes the combustion mode to increase or decrease the temperature of the coolant.

The design of the sectional type heat exchanger is assembled from a certain number of unified compartments.

They are cast from gray cast iron, have a high heat transfer capacity and high strength, resistance to temperature changes or varying degrees of heating at individual points.

The heated coolant is removed from the heat exchanger and enters the three-way valve, where it is connected to the cooled return flow in a predetermined proportion.

NOTE!

The output of combustion products is carried out in a natural way, due to furnace-type draft. If it is unstable or subject to external distortion, it is possible to connect an external turbo nozzle, which stabilizes the draft and improves the smoke removal mode.

Advantages and disadvantages

The advantages of Viessmann Vitogas 100-F boilers are:

- High quality and work efficiency.

- Simple, intuitive controls.

- The design is thought out in such a way as to exclude all secondary elements in order to increase reliability.

- Cast iron heat exchanger with increased performance and durability.

- Possibility of remote control via the Internet.

- Control of the mode of heating of the heat carrier, based on changes in the outside temperature.

The disadvantages of the units are considered to be:

- Volatile design, creating a risk of turning off the heating system in cold weather.

- Natural traction is unstable, depends on many external conditions and is practically unregulated.

- There is no possibility of heating hot water.

- The prices of the Vitogas 100-F floorstanding boilers are high, which reduces their affordability for the average user.

IMPORTANT!

All the pros and cons of Vitogas 100-F boilers are design features inherent in all installations of this type.

Price range

The cost of Viessmann boilers can range from 40 to 400 thousand rubles.

Such a difference in the upper and lower limits is due to a large assortment and a significant difference in the power and features of the installations. Before buying, you should consider in detail all the Viessmann series and model lines, decide on your needs and choose the option that is optimal in design and power.

Immediately it is necessary to take into account the additional costs for the chimney, additional devices (turbo nozzle, stabilizer, etc.).

Viessmann boilers work stably and steadily only if all the requirements of the instructions are met. The installation of a stabilizer, filter units or other auxiliary devices should not be neglected, as this will immediately affect the durability and quality of the unit.

Connection and setup instructions

After delivery of the boiler, it is necessary to install it in a pre-selected and prepared place. Do not hang the units on plasterboard or other weak partitions, the wall must have sufficient bearing capacity.

After hanging, the chimney is connected and the pipelines for supplying gas and water, the heating circuit are connected.

Viessmann double-circuit boilers are set up after installation and a complete check of the quality and tightness of the connections.

Particular attention is paid to gas pipe connections, checking them with soapy water.The pressure limits for gas and water are set, the operating mode, current temperature and other parameters are set

It should be borne in mind that all units undergo initial configuration at the factory, therefore, in most cases, no specific actions are taken.

All work on connecting and setting up the boiler must be carried out by a qualified representative of the service center. Unauthorized intervention can cause damage to the unit.

Device

The main unit of Viessmann wall-mounted boilers is a cylindrical gas burner. It is located in the center of the stainless steel spiral heat exchanger.

It is wound from a rectangular tube, which allows you to use the energy of the flame with maximum efficiency.

The coolant supply is provided by a circulation pump. Entering the heat exchanger, the RH receives maximum heating and immediately passes into the secondary heat exchanger, where it gives some of the energy to heat water for hot water supply.

Then the coolant passes into a three-way valve, where it receives the set temperature by mixing the required amount of return flow, and is sent to the heating circuit. The combustion process is provided by a turbocharger fan, which in parallel creates draft to remove smoke.

The control board constantly monitors the workflow.

Through a system of self-diagnostic sensors, it constantly monitors the status of all boiler components and displays a notification of any malfunctions.

Conclusion

The products of German manufacturers, regardless of the type and purpose of the equipment, are famous for their quality and carefully thought-out design.

Boilers Viessmann Vitogas 100-F are a vivid illustration of this statement.

They are efficient, reliable, easy to manage and set up, fully comply with all European requirements and standards.

Since most of the products are exported, the boilers are adapted to the technological conditions of the operating country in terms of supply voltage, parameters of water supply networks and other items.

To obtain the maximum effect, the user must follow the instructions and perform maintenance in a timely manner.