- At what scale thickness should boilers be cleaned?

- What is an electric boiler

- Device

- Electric heating elements

- induction

- Ionic

- The main error codes and malfunctions of the gas boiler Proterm (Protherm)

- What does f1 error mean and how to fix it

- Error f3

- f4 error

- The gas boiler shows error f04 (malfunction of the ionization device)

- Error f7

- Malfunction f20

- Error f28 how to fix

- What does error f75 mean in the gas boiler Proterm

- Why does the pressure increase in the device

- Electric Boiler Protherm Skat 12K

- F1

- The reasons

- Electric boilers Proterm Skat

- Installation Features

- How to install

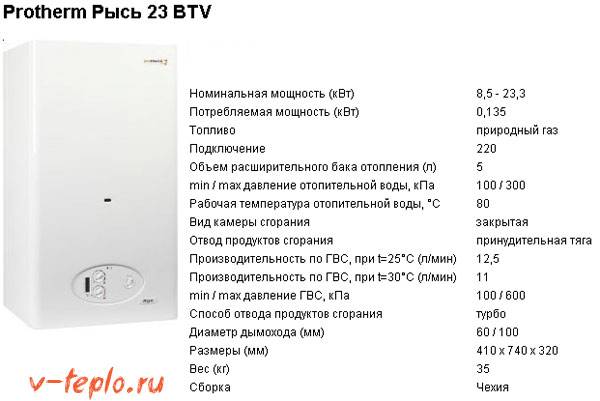

- Boilers Protherm wall type

- Model "Tiger"

- Model "Scat"

- Model "Panther"

- Model "Cheetah"

- Overview of the Proterm brand series

At what scale thickness should boilers be cleaned?

The requirements for scale thickness in boilers are regulated by various guidelines.

So, there is RD 10-165-97 - Guidelines for the supervision of the water chemistry regime of steam and hot water boilers. Clause 2.5. The document states: “For boilers with a steam capacity of less than 0.7 t / h, the period between cleanings should be such that the thickness of deposits on the most heat-stressed areas of the heating surfaces of the boiler does not exceed 0.5 mm by the time it is stopped for cleaning.”

The same figures are contained in PB 10-574-03 Rules for the design and safe operation of steam and hot water boilers.

What is an electric boiler

The electric boiler is a special high-tech equipment designed for heating various types of premises. A distinctive feature of such a unit is the use of a special type of fuel - electrical energy. In many respects, the boiler is superior to equipment operating on other types of fuel: liquid, solid, gas.

Electrical equipment is considered the safest to use. But in order for it to function well, it is necessary to strictly follow the rules for its operation and to carry out timely technological maintenance.

Watch the video, which tells about the principle of operation and the device of the electric boiler P rotherm Skat.

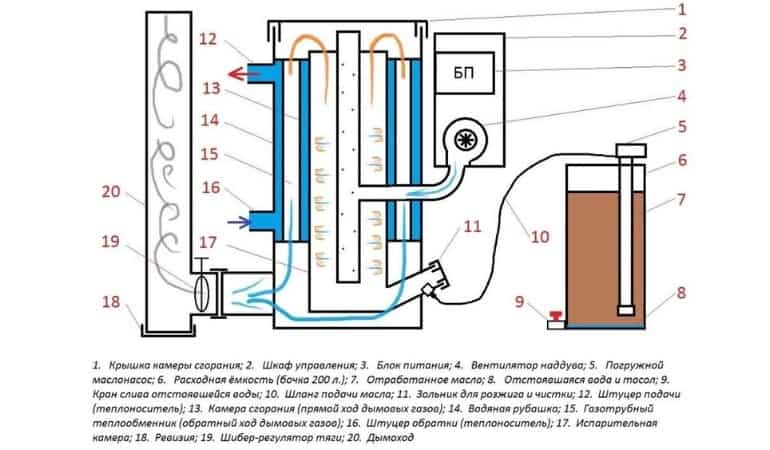

Device

Despite the wide variety of boilers with different operating principles, the device of all models is approximately the same. The main place in the structure is given to the heating element. Depending on the type of heater used and the principle of its operation, there are several types of boiler units.

All heating elements are located in heat exchangers, which are considered the main structural elements of the boiler. If they fail, heating of the coolant is impossible.

Depending on the design and manufacturer, the equipment may have a different configuration.

- Electronic control unit. Regulates the temperature regime, turning the equipment on and off at the right time.

- Circulation pump (heat pump). It is a mandatory component of the system, maintains a stable speed of the coolant in the circuit.Produces forced circulation of the liquid and creates the necessary pressure in the system, while ensuring the most efficient heat transfer and heating of the room.

- Expansion tank. Not all types of electric boilers with a pump are equipped with an expansion tank. Therefore, if equipment is purchased without a tank, it will be necessary to purchase this part separately and install it by cutting into the heating pipe circuit.

- Filters. Purify and extract various impurities from water.

- Safety valves. Protect the system from unwanted deviations in operation.

- Safety valve. Connected to the return pipe. Carries out an emergency discharge of water when the pressure rises above the established norm.

- Pressure gauge. This device determines the pressure of liquids, gases inside the boiler and pipes of heating systems, it is necessary for monitoring.

- Thermal switch. It turns off the equipment when it overheats. Connected to a temperature sensor located at the top of the electric boiler.

- Automatic air valve. It is located above the heating tank and produces an emergency air release from the tank in case of overpressure.

Electric heating elements

The principle of operation is based on simple electrical heating of elements that give off their heat to the liquid. Heating element - heating element. Water or other permitted liquids are used as a heat carrier, in accordance with the operating instructions.

induction

Their action is based on the principle of electromagnetic induction. The heating element is a coil, inside which passes a pipeline filled with water. When an electric current passes through the coil under the influence of an electromagnetic field, the coolant is heated.

Ionic

The working element in such structures are electrodes placed in a special aqueous medium, where the process of heating the coolant occurs when an alternating current passes through it.

Features of this type of application boilers is a mandatory control of the electrical conductivity of the liquid and the adoption of measures to regulate it. The phenomena of electrolysis and breakdown should not be allowed. Failure to comply with these requirements may result in damage to the equipment.

The fluid used must not be used for domestic purposes. The heat carrier, which circulates through the pipes and enters the working tank of the boiler, comes into direct contact with the electric current. It is not recommended to carry out repair and commissioning work without the involvement of an experienced craftsman.

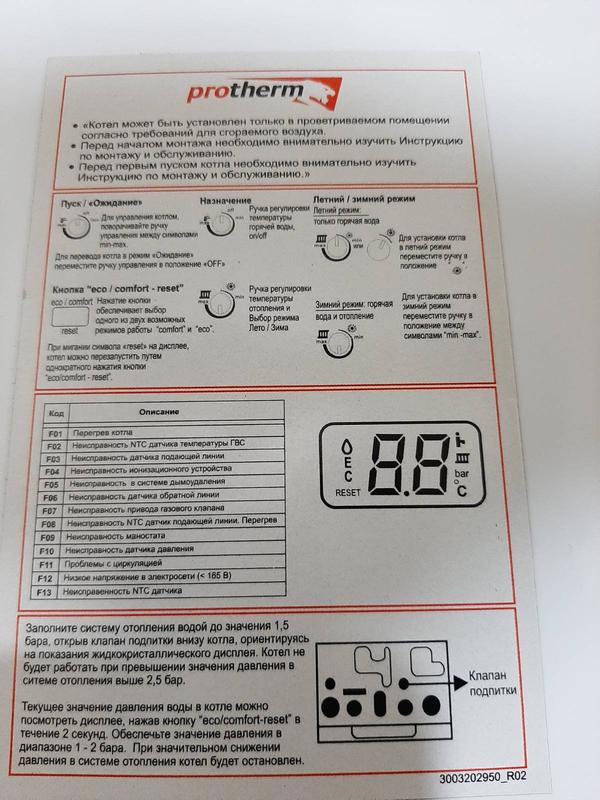

The main error codes and malfunctions of the gas boiler Proterm (Protherm)

All problems are promptly identified by the self-diagnosis system, which includes thermistors and other parts that respond to changes in service settings. The sensor sends a signal to the electronic board, which displays the error on the screen.

An alert consists of a certain combination of a letter and a number. Each fault has a specific code. The detailed list of errors is quite long and is written in repair instructions, which is attached to the heating equipment. The frequency of propagation of certain failures depends on the modification of the installation.

The most common error of the Proterm Cheetah boiler is a breakdown gas pressure regulator (F28-29)

and Jaguar malfunctions are usually associated with sensors or changes in operating parameters to critical ones.

When the antifreeze overheats, F01 knocks out. If there are problems with ignition, the code F04 appears. Sensor malfunctions are signaled by the values F02, F03, F09.Often, the F10 cipher is observed on the screen, signaling pressure failures.

The most common malfunctions of Proterm Bear are associated with errors F10, F73, F20, F28. The first two codes signal a short circuit in the water supply circuit or on the housing. F20 indicates overheating, and F28 indicates no ignition. The causes of the problems are related to incorrect temperature settings, which you can adjust yourself.

The Proterm Panther 30 ktv boiler is popular, the malfunctions of which are often associated with system overheating (F20-21) and pressure failures (F22). Also, the operation of pumping equipment (F23, F24, F25) is often disrupted. Boilers Proterm Leopard, quite common in private homes, whose errors are associated with indicators of the supply voltage. So the code F0 signals a drop in pressure, and F2-F8 indicates problems with the sensors.

What does f1 error mean and how to fix it

Error f1 notifies about ignition blocking. The reasons for the breakdown are associated with the lack of a signal about the presence of fire. In this case, the gas valve remains open, the security system is activated and the equipment is switched off. To eliminate the malfunction, it is necessary to restart the unit by pressing the corresponding button on the housing.

Read more: Why does a gas boiler go out? Main reasons

Error f3

Code f3 indicates overheating of the heating equipment. When the temperature reaches 95 degrees, the protective mechanism automatically activates and the system turns off. To resume the operation of the boiler, it is enough to wait until the temperature indicators return to normal. If the failure persists, the thermal fuse must be reset.

f4 error

If the domestic hot water sensor fails, the code f4 appears on the display. The equipment continues to heat the house, but does not heat the water. To get rid of such a Protherm boiler error, you will need to replace the sensor or clean the oxidized contacts.

The gas boiler shows error f04 (malfunction of the ionization device)

Error f 04 indicates problems with ionization. To troubleshoot the ionization device, you need to reset it and check if the gas cock is open.

Error f7

Error f7 signals a break in communication. To eliminate the breakdown, you need to inspect all wires for visible damage, ring the wires, check all inputs and the control board. If the source of the failure could not be determined independently, then you need to contact the service center.

Malfunction f20

Error f20 selects when the safety thermostat trips. The causes of the problem are overheating of the equipment or an open circuit. For repair, you need to ring the wiring and reconnect the device. You should also inspect the pumping equipment, release air.

Error f28 how to fix

The causes of the f28 error in the Protherm gas boiler are related to gas supply failures, breakage of the ionization electrodes and the electronic board, and grounding faults. Hardware repair depends on the source of the problem.

How to fix error f28:

- Make sure the gas valve is open, reboot the system several times, check the equipment settings;

- Clean the ionization electrodes with fine sandpaper;

- Reverse the polarity of the socket and check the grounding of the unit;

- Replace electronic board.

What does error f75 mean in the gas boiler Proterm

Error f75 is related to pressure sensor malfunction. The causes of the failure are the occurrence of air jams in the pipes. Also, the source of the problem may be insufficient coolant pressure.

Why does the pressure increase in the device

Rising pressure is an extremely dangerous situation, fraught with mechanical breakdowns and even an explosion.

The liquid is incompressible, it fills the entire volume of pipelines. If the pressure on the pressure gauge has approached 3 mbar and continues to grow, it is time to take action.

One of the reasons is the failure of the expansion tank. When heated, the liquid expands, and its volume increases by 4%.

A normally functioning expansion tank absorbs these extra interest, but if it is already full, there is simply nowhere for excess fluid to go. You can determine such a situation by the state of the relief valve - OM will constantly ooze from it.

The main failure of the expansion tank is a rupture of the membrane. With it, the water fills the tank completely, leaving no room for the expansion of the liquid. The solution is to replace the membrane or the entire expansion tank.

Another reason is possible - the feed tap is not closed or has failed. Water continues to flow into the system, increasing pressure.

It is necessary to check the condition of the tap and close or replace it. You should check the condition of all valves, clean the strainer. There may also be problems with the automation of the boiler, which can only be solved with the help of a specialist from the service center.

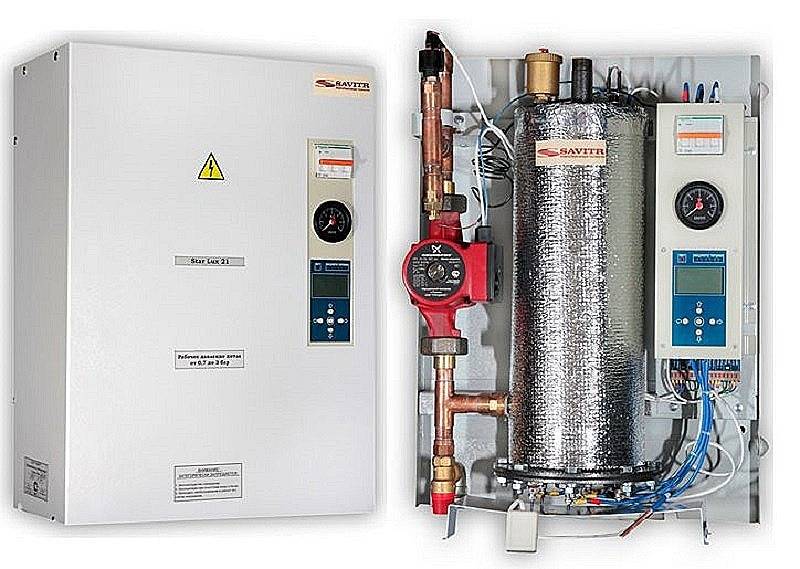

Electric Boiler Protherm Skat 12K

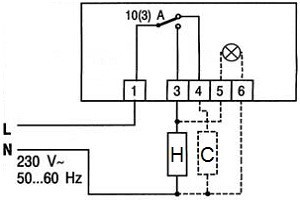

Operation of a copper practically does not demand service and almost does not create noise. The boilers are equipped with all working and safety elements, including control elements.

The boilers are equipped with a steel cylindrical heat exchanger with rheostatic heating elements and an integrated hydraulic unit.

A modern element used in gas boilers, which includes a pump with an automatic air release valve, a pressure sensor, a safety valve and a 10 liter expansion tank connection for the heating system. The boiler is equipped with an electronic switching unit, which allows you to select the power of the electric boiler using two switches.

Electric boilers "Skat" are equipped with electronic control with the function of stepped power on and off with a delay of approximately 20 seconds, which avoids unwanted impulses at the distribution substation when the boiler is turned on and off.

The circulation pump only works for a certain amount of time, which saves energy and reduces mechanical wear.

The pump continues to operate for another two minutes after the boiler is switched off, so that the warm water that remains in the boiler body and distribution pipes can also be used after switching off.

Electric boilers are designed for permanent connection to a stationary three-phase power distribution network.

Since it is a high power consumption, it is necessary to choose the right size fuses and suitable cables.br /br /

Wall-mounted electric boiler PROTERM SKAT21 (21 kW) - heat supply + GW (in an external boiler), convenient control, power 4 degrees, display.

An alternative to gas heating with many undeniable advantages: easy installation, high efficiency throughout life, quiet operation, environmental friendliness, the ability to quickly and accurately control.

Electric boiler Protherm SKAT 21K Designed to supply heat (as a main or backup source) for premises of various sizes and purposes: residential buildings and houses, houses, shops, warehouses, garages, etc.

F1

An error is generated when a signal about the absence of a burner flame is sent to the board: “blue fuel” does not enter the Proterm boiler.

The reasons

-

Production of LPG volume (with autonomous gas supply), pressure drop in the line.

-

Ice plug, debris in the pipe.

-

Boiler error Proterm is caused by a malfunction devices: counter, filter, reducer.

-

Tripping of the shut-off valve: occurs even when the power supply to the boiler is interrupted for a short time.

-

Emergency thermostat. In a number of Proterm models, a return type sensor. It is brought to the working position by pressing the button, the error is removed. If the thermostat is without a control, the boiler will start after the contact group of the device has cooled down.

-

Ionization sensor. It should detect the presence of a flame, but does not “see” for a number of reasons: breakage of the signal line, carbon deposits on the electrode, insulator crack, incorrect position. When cleaning the chamber of the Proterm boiler, the sensor goes astray with an inaccurate movement, loses sensitivity. Remove contamination, set so that the gap between the wire and the burner is no more than 5 mm, the error will disappear.

Ionization sensor (ignition electrode) of the Protherm boiler

-

Nozzle blocking, which prevents the combustible mixture from entering the chamber. Soot falling from the heat exchanger, dust entering the Proterm atmospheric boiler with air from the room, clog the holes. The error is removed by cleaning.

-

Igniter. Large distance between electrodes. The spark does not jump, an error is displayed.

-

Ignition transformer. The winding is independently checked for an open (R = ∞) or short circuit (R = 0).

-

Code F1 is triggered by a gas valve failure. It should not be changed immediately - the fittings of the Proterm boilers are reliable. A common cause is a suitable gas pipe. Disconnect and clean from the accumulated sludge, the error will disappear. In addition, check the winding coils identical to Tr ignition.

-

Parameter failure. Enter the menu, check the value in the Proterm power setting for the minimum pressure. The change in value that causes the boiler error is the result of instability of the mains voltage (jump, sudden shutdown).

-

Electronic board. The “brain” of Protherm is examined in order to detect damage, condensation, dust. Accurate cleaning, drying removes the errors of Proterm boilers.

Electric boilers Proterm Skat

This single-circuit equipment is made in a wall-mounted variation. It is possible to connect a water heater. Most models require a three-phase mains connection, but 6 kW models and 9 kW can be operated from a 220 V network. The required level of hot water and heating temperature is selected using the display, which, when adjusted, helps to control the operation of the equipment. Also, control is carried out using a thermostat or an outside temperature sensor.

To create a certain level of warmth, the parameters are adjusted individually.Power supply is controlled remotely from the tariff meter. For domestic needs, you can install units of 24 kW and 28 kW in a cascade.

Protherm Skat has:

- double-sided pump;

- expansion tank;

- safety valve;

- automatic air valve.

Also, the Protherm boiler can be connected through a voltage stabilizer. The electric boiler in operation is characterized by a slow start, that is, for two minutes it “accelerates” and its power is minimal. Heating elements are protected from overload, their work is uniform, this is achieved by the possibility of setting the rhythm (1.2 or 2.3 kW).

Electrical boilers Protherm Skat They are distinguished by their light weight (only 34 kg) and convenient dimensions, thanks to which it is possible to carry out installation on almost any area. The operation of the boiler is reliably protected by several functions:

- pump blocking protection;

- a pressure sensor that monitors the level of water pressure;

- frost protection;

- protection against valve blocking and freezing of the water heater (when connecting a boiler).

If errors occur in the operation of the boiler, automatic diagnostics occur, ending with the display of the results in the form of a code. The deciphering of the codes is given in the instruction manual for the product.

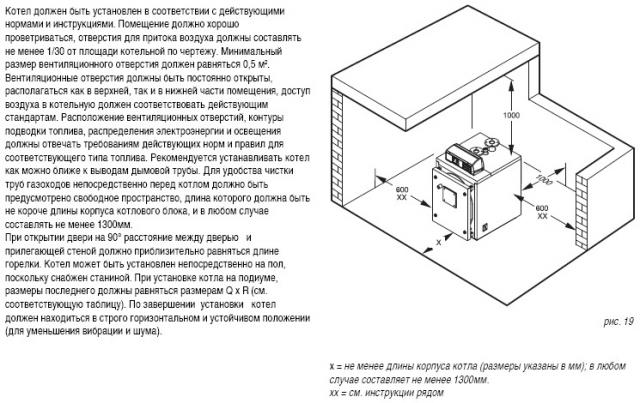

Installation Features

Boilers Proterm Skat 9 kW are supplied with all necessary fasteners and elements. In addition, the kit includes instructions that describe the process of connecting and setting up the unit step by step. It is worth noting that models that differ in power have exactly the same principle of installation, operation, and configuration.

Before installing heating equipment Proterm Skat, it is necessary to coordinate all work with electrical distribution services.

Electric boilers Proterm Skat with a power of 9 kW can be connected to a conventional 220V power supply. Installation of such heating equipment is carried out using a mounting plate. This unit has no specific restrictions. by choice of mounting location. Of course, there are some requirements - you need free access for service, maintenance, adjustment and repair of heating equipment.

How to install

The Proterm Skat electric boiler is connected to the pipe system using branch pipes. The heater is connected in such a way that, in the event of malfunctions during operation, the coolant can be freely drained without affecting the entire system. Additional valves allow you to fill the system with coolant and drain it. also, in order to exclude freezing of water in houses with seasonal residence during cold periods, experts recommend removing the coolant completely from the system before the temperature drops.

The Proterm Skat boiler is connected to the mains through a power line connected separately. The network cable is connected to the terminals, which are located in the lower corner of the case. All screws on the connectors must be carefully tightened. A boiler with a power of 9 kW can be connected to a single-phase network.

Electric boilers are the easiest to install and connect, they do not require the organization of a chimney and supply and exhaust ventilation, a separate room for the boiler room. Since standard heating elements already contain all the necessary elements and components (circulation pump, expansion tank, safety group, etc.), when organizing a simple heating system, there is a minimum of communications around the electric boiler.

All these factors allow, having basic skills and knowledge, to install and connect an electric boiler on your own, without the involvement of craftsmen.

But note that the condition for granting a guarantee from most manufacturers is the installation by a specialized service organization. However, the ease of installation has a positive effect on the cost of the work of the masters.

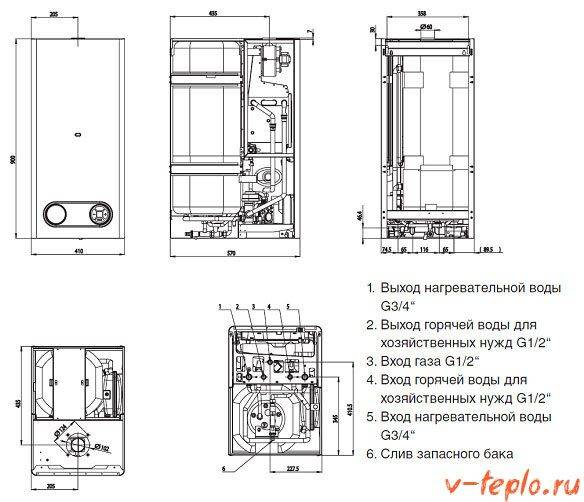

Boilers Protherm wall type

Let's start with the most popular model - the Tiger.

Model "Tiger"

The power of the heating equipment of this model varies between 3.5 and 23 kilowatts. All devices are economical and reliable, developed in accordance with the latest trends in technology and design. They also comply with all norms and requirements that apply to heating systems.

"Tigers" are equipped with a 25-liter boiler, which has a unique "Spin" system and a hot water temperature sensor. Thanks to all this, boiler owners receive not only high speed and efficiency, but also constant hot water. The specifications in this case are as follows:

- the device is reliably protected from frost;

- by means of a special electronic device, the pressure indicator in the system is read;

- it is quite possible to place the device in the bathroom;

- heating and hot water parameters are set separately;

- power is regulated smoothly;

- the boiler is protected from possible overheating;

- built-in microprocessor;

- a special display shows the main operating parameters;

- there is a pump protection function that prevents jamming.

The approximate cost of "Tigers" varies between 60.5 and 90.5 thousand rubles, depending on the specific variety.

Model "Scat"

The gas unit called "Skat" is characterized by a modern design, step-by-step power adjustment, low noise output and ease of use. All devices are quiet and practically do not need maintenance, and are used mainly in apartments / houses of small areas. Comply with all safety standards, environmentally friendly (do not harm the environment). For this reason, they can even be used in protected areas!

Finally, such Protherm gas boilers are easy to maintain and can heat up a room almost instantly. The average cost of Skats ranges from 26.3 to 152 thousand rubles.

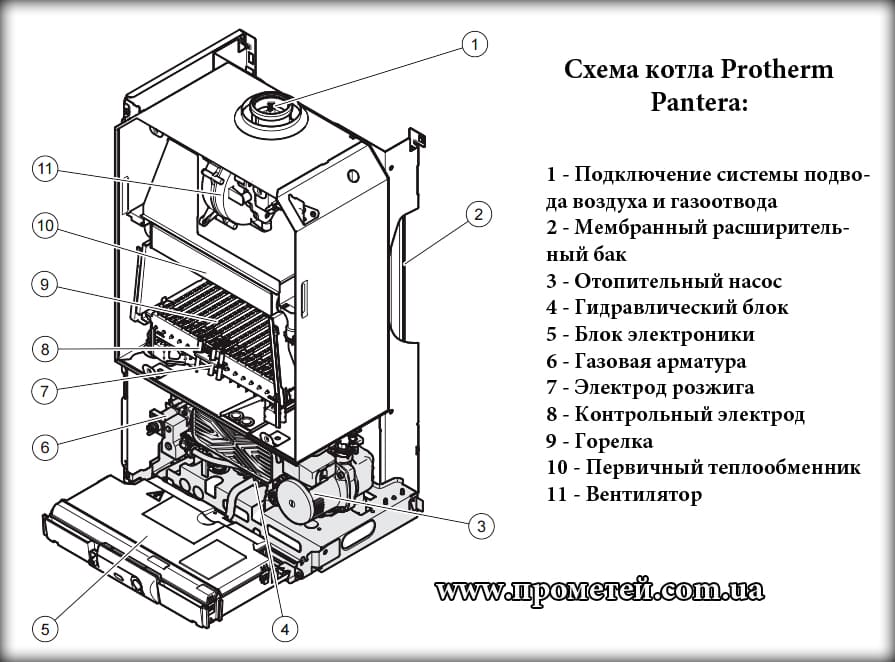

Model "Panther"

Specifically, this model is different in that it has a special “Comfort” function, which provides extremely fast heating of the water. Built-in microprocessor, "i-BAS" communication bus, it is possible to adjust the power boiler, the management of all parameters is convenient and simple, as it is regulated on the monitor. There are two heat exchangers, as well as electric ignition.

All "Panthers" can be attributed to the middle class of gas heat generators. They are able to heat and heat water not only in private homes, but also in offices, apartments and other premises. "Panther" is produced in three models:

- devices with a sealed combustion chamber (28-KTV);

- 24-KTV;

- devices with an open combustion chamber, designed for two circuits (24-KOV).

In terms of hot water supply, the performance of such a model ranges from 12-15 liters, and the area of \u200b\u200bthe heated room can reach 270 square meters. Possibility of functioning in the conditions of low pressure is provided.

Separately, it is worth talking about special protective functions, including:

- preventing freezing of the system;

- shutdown of gas supply;

- heat generator anticyclicity;

- prevention of pump jamming.

The approximate cost is from 35.2 thousand rubles.

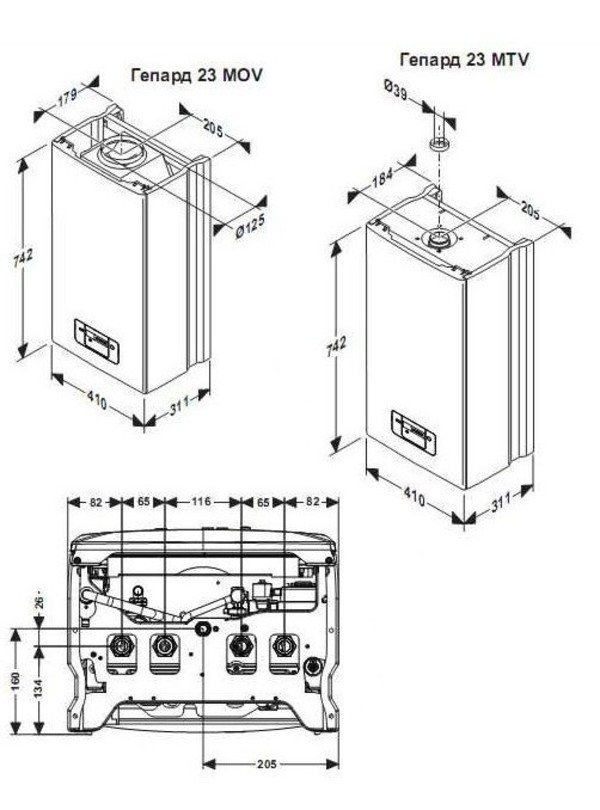

Model "Cheetah"

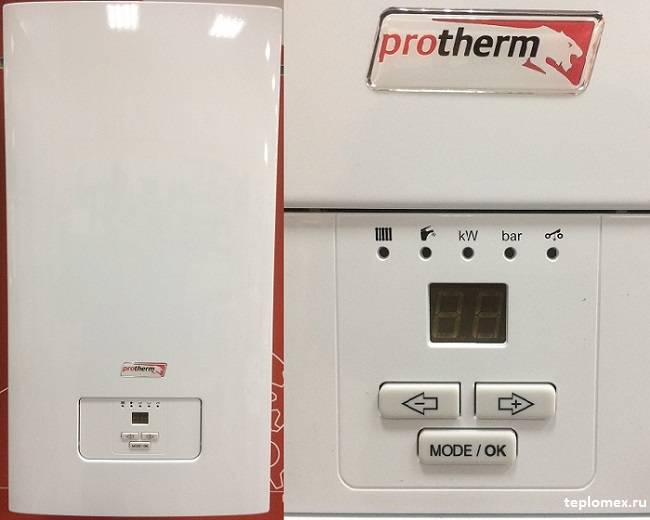

All boilers of the Cheetah model are not too different from similar middle-class appliances. They have a fairly low functionality, although they are relatively inexpensive. To adjust the power of the device, a special modulating burner is provided. If we talk about efficiency, then for the period of the heating season it can reach 92 percent. As in the previous version, there is an i-BAS communication bus.

The functions of the "Cheetah" include:

- the ability to select the operating mode (summer or winter);

- monitor performance adjustment;

- heat exchanger made of "stainless steel";

- working fluid pressure sensor;

- diagnostic system;

- burner, which is made of chromium-nickel steel.

The approximate cost is from 32.2 thousand rubles.

Overview of the Proterm brand series

If we consider equipment that runs on gas, then at the place of installation, all boilers can be divided into two large categories:

- wall-mounted - "condensation Lynx" ("Lynx Condence") and "Lynx" ("Lynx"), "Panther" ("Panther"), "Jaguar" ("Jaguar"), "Gepard" ("Gepard");

- floor - "Bear" (series KLOM, KLZ17, PLO, TLO), "Bison NL", "Grizzly KLO", "Wolf (Volk)".

Despite the Turkish and Belarusian assembly, the quality of equipment is high in European style.

Among wall models - 1- and 2-circuit, atmospheric and turbocharged, with a capacity of 11-35 kW.

Floor models are made of steel or cast iron, equipped with injection or fan burners, can operate on natural and liquefied gas.The power range is wide - 12-150 kW - so it is not difficult to choose a device for specific conditions.

The main purpose of the equipment is the organization of hot water supply and heating in private residential buildings, and some units are designed for industrial use.

The main purpose of the equipment is the organization of hot water supply and heating in private residential buildings, and some units are designed for industrial use.

Each of the series has distinctive features regarding design, dimensions, installation method, technical characteristics, additional functions:

- "Lynx" - condensing models work 12-14% more economically than non-condensing ones, therefore they are recognized as energy-efficient devices for heating country houses and cottages.

- "Panther" - the latest models are available with a convenient eBus communication bus and an updated security system

- "Jaguar" - the main advantages are the low price of the unit and the possibility of separate adjustment of two circuits - heating and hot water.

- "Cheetah" is a popular wall model that can be installed both outside the city, in a country house or cottage, and in a city apartment.

- "Bear" - among the representatives of various series - reliable units with a built-in boiler, a cast-iron heat exchanger and a power of up to 49 kW.

- "Bizon NL" - universal models for the fuel used: they work equally efficiently on gas, fuel oil or diesel fuel, power - up to 71 kW.

- "Grizzly KLO" - able to heat private homes and office space up to 1500 m², maximum power - 150 kW.

- "Volk" - an electrically independent boiler with a steel heat exchanger, steadily supplies heat to country houses and residential buildings even in the absence of electricity.

According to consumer reviews, Proterm units are reliable, efficient, easy to install and operate, and with regular maintenance they almost never fail.

However, durable materials, good fuel and excellent assembly do not guarantee flawless service, so boilers of all the listed series sooner or later require replacement of spare parts, cleaning or repair.