- Malfunctions of the gas boiler Navien

- The Navien boiler does not reach the set temperature

- The Navien boiler quickly gains temperature and cools down quickly

- How to fix error 03 in Navien boilers

- Technical device and principle of operation of the Navien gas boiler

- How to connect and set up

- Brief operating instructions: operation and adjustment

- Common mistakes and causes of problems

- Gas boiler Navien

- Setting up a gas boiler Navien

- Heating setting

- Heating with air temperature control

- Hot water temperature setting

- Away Mode

- Setting the Timer Mode

- Elimination of some problems in the operation of the boiler

- Error 01e

- 02e

- 03e

- 05e

- 10th

- 11th

- Noise and hum

- No hot water

- Elimination of some problems in the operation of the boiler

- Error 01

- Error 02

- Error 10

- Noise and hum without errors on the display

- Error 011

- Innovative solutions in navien products

- Common malfunctions and their elimination

- E 01-02

- Conclusion

Malfunctions of the gas boiler Navien

In order for you to be able to repair of gas boilers Navien on our own, we compiled this guide. It will provide invaluable assistance in eliminating breakdowns and failures. Let's see what self-diagnosis systems can tell us - imagine boiler error codes Navien as a list:

Despite the huge number of possible breakdowns, most of them do not pose a serious problem and are solved fairly quickly and with little money.

- 01E - overheating occurred in the equipment, which was evidenced by the temperature sensor;

- 02E - in Navien boilers, error 02 indicates an open in the flow sensor circuit and a decrease in the coolant level in the circuit;

- Error 03 in Navien boilers indicates the absence of a signal about the occurrence of a flame. Moreover, the flame can burn;

- 04E - this code is the opposite of the previous one, as it indicates the presence of a flame in its absence, as well as a short circuit in the flame sensor circuit;

- 05E - an error occurs when there is a malfunction in the temperature measurement circuit of the coolant in the heating circuit;

- 06E - another temperature sensor failure code, indicating a short circuit in its circuit;

- 07E - this error occurs when the temperature sensor circuit in the DHW circuit malfunctions;

- 08E - an error of the same sensor, but diagnosing a short circuit in its circuit;

- 09E - error 09 in Navien boilers indicates a malfunction of the fan;

- 10E - error 10 indicates problems with smoke removal;

- 12E - the flame in the burner went out;

- 13E - error 13 indicates a short circuit in the flow sensor of the heating circuit;

- 14E - code for the lack of gas supply from the main;

- 15E - a rather ambiguous error indicating problems with the control board, but without specifically indicating the failed node;

- 16E - error 16 in Navien boilers occurs when the equipment overheats;

- 18E - malfunctions in the smoke exhaust system sensor (sensor overheating);

- 27E - electronics registered errors in the air pressure sensor (APS).

Any repair manual not included with the boilers, as the repair work should be carried out by a service company. But nothing prevents us from repairing a faulty node on our own, without resorting to the help of specialists. Let's see how Navien boilers are repaired at home.

The Navien boiler does not reach the set temperature

In order to prevent the appearance of scale, install a system for cleaning and softening tap water - the costs will not be the biggest, but you will extend the life of your boiler.

First you need to clean the heat exchanger of the Navien gas boiler. At home, this is done with citric acid, toilet bowl cleaners, or special products (if available). We remove the heat exchanger, fill it with the selected composition, and then rinse it under high water pressure.

In a similar way, clean the heat exchanger of the DHW circuit, if the Navien boiler does not heat hot water. In the most advanced cases, the exchanger must be completely replaced.

The Navien boiler quickly gains temperature and cools down quickly

A very complex error indicating some kind of malfunction or imperfection in the heating system. Try to correct the situation by adjusting the speed of the circulation pump, make sure that there is no air in the system. It is also necessary to check the filter and the clearance of the heat exchanger. In some cases, it may be necessary to replace the coolant.

How to fix error 03 in Navien boilers

For some reason, the electronics do not receive a signal about the presence of a flame. This may be due to a lack of gas supply or a malfunction of the flame sensor and its circuit. Sometimes an error appears after carrying out any work on the gas line. More one possible reason - ignition does not work. Troubleshooting:

- We check the presence of gas supply;

- We check the performance of the ignition;

- We check the ionization sensor (it could be dirty).

When using liquefied gas, it is recommended to check the operation of the reducer.

If there is no malfunction in the Navien gas boiler, error 03 may occur with some problems with grounding (if any).

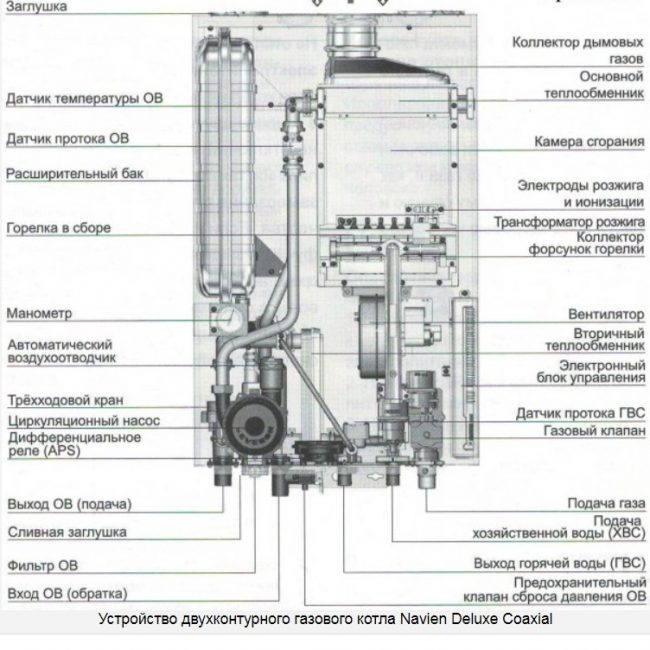

Technical device and principle of operation of the Navien gas boiler

Consider the device of the double-circuit gas boiler Navien Deluxe Coaxial.

Navien gas boiler device

The device has two heat exchangers that prepare the heat carrier (main) and domestic hot water (secondary). Gas and cold water supply lines are connected to the corresponding pipes, which enters the heat exchangers, where it is heated to certain temperatures. Then, with the help of a circulation pump, the coolant is sent to the heating system of the house.

All operation of the device is controlled by an electronic unit that provides timely shutdown / on of the burner, which controls the temperature of the water in both circuits by means of special sensors. The control board is protected from power surges, but in areas with frequent or significant power surges, a stabilizer must be used.

Navien boilers have a remote control unit equipped with a display that shows the current mode, temperature, and other operating parameters of the device. In addition, the display shows the error code detected by the control unit in any system of the device.

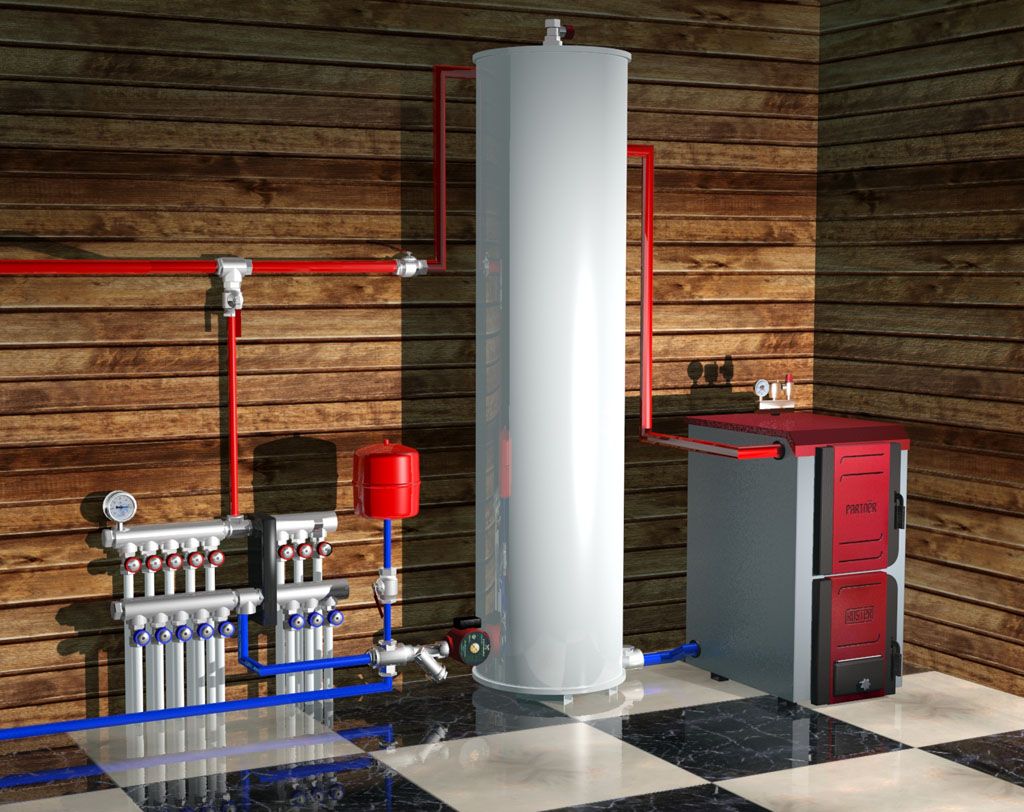

How to connect and set up

Installation of the boiler does not require any specific actions.Floor devices are installed in a certain place, mounted devices are hung on the wall using a standard hinged rail.

The boiler is hung through damper pads (rubber, foam rubber, etc.) so that the noise during operation does not spread throughout the house. Gas and water pipes, heating system and domestic hot water are connected to the corresponding branch pipes. An air supply and smoke extraction system is also connected (depending on the type of construction).

The boiler is adjusted by bringing the gas pressure to the standard value. To do this, turn off the water supply and adjust the minimum and maximum gas pressure corresponding to operation in different modes with the adjusting screw. Then restart the water supply. During operation, it is necessary to periodically check the condition of the boiler connections with a soapy solution - if they are leaking, bubbles will appear. If noise or other signs of an unplanned change in operating mode appear, turn off the gas supply and check the condition of the equipment.

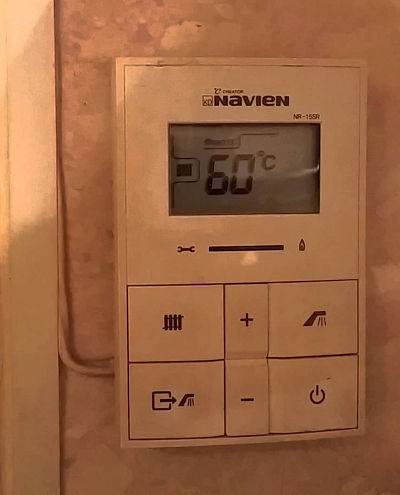

Brief operating instructions: operation and adjustment

All actions with the boiler are performed using a remote control panel. The water temperature in the heating system is adjusted by pressing the "+" or "-" buttons on the remote control with the "heating" mode selected, which is indicated by a stylized battery image. The display shows the numerical value of the set temperature. It is also possible to set the mode according to the air temperature in the rooms, for which you need to turn on the corresponding designation on the display (the symbol of a house with a thermometer inside).The flashing display shows the desired temperature value, while the constant display shows the actual temperature. Hot water is adjusted in a similar way, you just need to switch the mode.

Common mistakes and causes of problems

Sometimes the boiler displays a special code on the display, indicating an error in the operation of any system. Consider typical errors and codes:

This table shows the common errors of Navien boilers

To solve the problems that have arisen, you should eliminate the source of the malfunction yourself or contact specialists. There are some special requirements that are specified in the instructions. For example, code 10 - an error in the smoke exhaust system - can occur when the system is working properly, just a strong wind has risen outside. In order to avoid errors, you should carefully study the user manual.

Navien gas boilers are practical and easy-to-use devices that are economically beneficial, with full functionality and capabilities. At relatively low prices, South Korean equipment is optimally suited for harsh Russian conditions, it allows you to create a comfortable temperature in the house, organize the supply of hot water. Installation, operation, maintenance of Navien boilers does not cause any difficulties, all actions are described in detail in the attached instructions. Detected malfunctions or problems that have arisen are promptly eliminated by specialists from service centers.

Gas boiler Navien

The heating boiler is manufactured by the South Korean company Navien, their products are intended for organizing gas heating of small and large country houses from main gas.But it is easy to convert it to an autonomous heating system by connecting liquefied gas in cylinders to it.

Compact size, ease of installation and use attract buyers, and more and more consumers are inclined to choose just such heaters from a Korean manufacturer.

Two types of products are produced:

- Single-circuit - provides heating only for the heating system of a residential building;

- Double-circuit - is able not only to heat all heating equipment, but to provide residents with hot water for washing, washing dishes, etc.

Setting up a gas boiler Navien

Next, we will consider how to set up the Navien Deluxe gas boiler with your own hands. Manipulations are performed using a remote control with a built-in room temperature sensor.

Heating setting

To set the heating mode and set the temperature of the coolant, hold down the button with the image of a radiator until the same icon appears on the screen. If the “radiator” picture flashes, it means that the set coolant temperature is displayed on the screen. If the symbol does not flash, the actual water heating level is displayed.

Wall-mounted gas boilers Navien - model range, pros and cons

How they work and what are the advantages of Navien Ace gas boilers

To set the desired temperature, use the "+" and "-" buttons with the "radiator" icon flashing. The possible range is between 40ºC and 80ºC. After setting the temperature, it will be automatically saved. The “radiator” icon will flash for a few seconds, after which the actual coolant temperature will be displayed on the screen.

Heating with air temperature control

To set the desired air temperature in the room, hold down the “radiator” button until the “house with a thermometer” image appears on the screen. It stands for "Heating with room temperature control".

When the “house with thermometer” symbol flashes, the desired room temperature is displayed on the screen. When the icon is fixed, the display shows the actual room temperature.

When the icon flashes, the desired level of heating in the room is set using the "+" and "-" buttons, adjustable in the range of 10-40ºC. After that, the temperature is automatically saved and the icon stops flashing.

Hot water temperature setting

To set the hot water temperature it is necessary to hold down the “faucet with water” button until a similar flashing symbol appears in the right corner. The desired hot water temperature can then be set between 30ºC and 60ºC. The settings will be automatically saved and the water faucet symbol will stop flashing.

Note! In Hot Water Priority mode, the hot water temperature is controlled differently. Now let's look at how to set up the Navien Deluxe gas boiler in the "Hot Water Priority" mode. To activate it, hold down the "faucet with water" key until the symbol "faucet and light" appears on the screen

Now you can set the desired temperature using the "+" and "-" keys. When the DHW temperature changes, the icon “faucet with water” should flash above the “faucet and light” symbol

To activate it, hold down the "faucet with water" key until the symbol "faucet and light" appears on the screen. Now you can set the desired temperature using the "+" and "-" keys. When the DHW temperature changes, the icon “faucet with water” should flash above the “faucet and light” symbol

Now let's look at how to set up the Navien Deluxe gas boiler in the "Hot Water Priority" mode. To activate it, hold down the "faucet with water" key until the symbol "faucet and light" appears on the screen. Now you can set the desired temperature using the "+" and "-" keys. When the DHW temperature changes, the icon “faucet with water” should flash above the “faucet and light” symbol.

The "Hot water priority" mode means the preparation of a supply of water at a given temperature even if it is not used. It allows you to supply heated water to the consumer a few seconds earlier.

Away Mode

The "Away from home" mode implies the operation of a gas boiler for the preparation of hot water only. To transfer the unit to this mode, you need to press the button, which shows an arrow and a tap with water. If the water faucet symbol appears on the screen, it means that the Away mode is set. It displays the actual room temperature next to it.

Note! This mode is convenient for use in the warm season, when hot water supply is necessary, but there is no need for heating.

Setting the Timer Mode

The "Timer" mode is necessary to set the time to stop the operation of the gas boiler in the range from 0 to 12 hours. The unit will work for half an hour, turning off for the time of the specified interval.

To set the "Timer" mode, hold down the "radiator" button until the "clock" symbol appears. When the icon is flashing, use the "+" and "-" keys to set the interval time. The set value is saved, the “hours” stop flashing, and the display shows the actual air temperature.

Elimination of some problems in the operation of the boiler

Like any, even the most reliable technique, some problems may occur in Navien boilers, some of which the owner of the device can fix on their own.

Like any, even the most reliable technique, some problems may occur in Navien boilers, some of which the owner of the device can fix on their own.

First of all, it is important to recognize the cause of the breakdown. So that the owner can quickly find out about the problem and respond competently, the self-diagnosis system displays data with an error code

So that the owner can quickly find out about the problem and respond competently, the self-diagnosis system displays data with an error code.

Here are the Navien boiler trouble codes:

- 01e - the equipment has overheated.

- 02e - there is little water in the heating / the circuit of the flow sensor has broken.

- 03e - there is no signal about the flame: it may not really exist, or there may be problems with the corresponding sensor.

- 04e - false data about the presence of a flame / short circuit in the flame sensor.

- 05e - problems with the heating water t sensor.

- 06e - short circuit in the heating water sensor t.

- 07e - problems with the hot water supply t sensor.

- 08e - short circuit in the hot water supply t sensor.

- 09e - a problem with the fan.

- 10e - problem with smoke removal.

- 12th - the flame went out during work.

- 13e - short circuit in the heating flow sensor.

- 14e - no gas supply.

- 15e - a problem with the control board.

- 16th - the boiler is overheated.

- 17e - error with the DIP switch.

- 18e - the smoke removal sensor is overheated.

- 27e - a problem with the air pressure sensor (open or short circuit).

Error 01e

Overheating of the equipment can happen due to the fact that the ducts have narrowed as a result of blockage, or the circulation pump has broken.

What you can do yourself:

- Examine the impeller of the circulation pump for damage to the impeller.

- Check if there is resistance in the pump coil, if there is a short circuit.

- Check the heating system for air. If there is, it needs to be bled.

02e

An error that there is little coolant can be generated by the boiler if there is air in the system, little water, the impeller of the circulation pump is damaged, the distribution valve is closed, or the flow sensor is broken.

What can be done:

- Bleed the air.

- Adjust pressure.

- Check if there is resistance in the pump coil, if there is a short circuit.

- Open distribution valve.

- Check the flow sensor - is there a short circuit in it, is there resistance.

- Open the sensor housing, clean the flag (moving mechanism with a magnet).

Most often, the problem is the presence of air in the hot water system.

03e

No flame signal. The reasons for this may be:

- Damage to the ionization sensor.

- No gas.

- No ignition.

- The faucet is closed.

- Faulty boiler grounding.

The blockage on the flame sensor must be cleaned. The gray coating on the electrode is cleaned off with fine sandpaper.

05e

What can be done:

- Check the resistance on the entire circuit from the controller to the sensor. Having found a malfunction, replace the sensor.

- Disconnect the controller and sensor connectors and reconnect.

10th

Smoke removal problems may occur due to a malfunction of the fan, kinking or improper connection of the sensor tubes to the fan. In addition, the chimney may be clogged, or there was simply a sharp and strong gust of wind.

What can be done:

- Repair the fan or replace it.

- Check the correct connection of the sensor tubes.

- Clean the chimney from blockages.

11th

A problem with the water filling sensor - this error is provided only for European-made boilers equipped with the appropriate sensors.

Noise and hum

It may happen that the error does not appear on the display, but an unnatural buzz or noise appears in the device. This happens when water hardly passes through the pipes due to scale, overheats and boils. The reason may be a bad coolant.

Coolant Navien

Troubleshooting procedure:

- You can fix the problem by disassembling the unit and cleaning the heat exchanger. If this fails, the part must be replaced.

- In addition, you need to check the taps - whether they are open to the maximum.

- Turn the water temperature down. It is possible that the boiler capacity is excessive for the pipeline to which it is connected.

No hot water

It happens that the heating boiler heats up as it should, but the water for hot water supply has stopped heating. This is a problem with the three way valve. Cleaning and repairs will not save - you need to change the part! The problem is not rare, the valves work normally for about 4 years.

So. Navien boilers are reliable and economical equipment. With proper operation and a competent approach to the difficulties that have arisen, problems can be eliminated even without the involvement of specialists from the service.

Elimination of some problems in the operation of the boiler

Of course, when a particular error code appears, you should immediately seek help from specialists who will eliminate it and advise on all issues of operation. But some owners can independently identify this or that malfunction and bring their gas heating boiler into working condition.

Error 01

Gas boiler Navien KDB

The most common cause of such a malfunction is a blockage or a decrease in the flow in the heating system, as well as a breakdown of the circulation pump.

To resolve this issue, follow these steps:

- Check the heating system and filter for air and bleed if necessary.

- Check the condition of the pump and the resistance of the coil for a short circuit.

- Check the impeller in the circulation pump for any damage.

Error 02

If a double-circuit boiler gives error 02, warm water flows from a hot tap for several seconds, and then cold water, the water temperature rises sharply on the remote control to a maximum, and then drops sharply. At the same time, everything is fine with heating.

The reasons for such an error in the Navien boiler may be:

- The airiness of the heating system.

- Lack of water.

- The circulation pump is in working condition, but cannot gain rated speed, or the impeller has mechanical damage.

- The flow sensor in the coolant system does not function.

- The heating distribution valve is closed.

How to troubleshoot?

- The system pressure needs to be adjusted.

- Bleed off the air in the system.

- Check the resistance of the pump coil for short circuit, inspect the impeller for damage.

- Check if there is a short circuit resistance of the flow sensor.

- Open the distributing valve of the device.

- Disassemble the sensor housing and clean the flag.

Most likely, the problem arose due to an air lock in the hot water supply system. The water in the circuit heats up as it should, but after air enters the heat exchanger, the temperature rises sharply to a critical one, which results in error 02.

Error 10

Connecting a gas boiler to the heating system

Error number 10 is usually issued in the following cases:

- The operation of the fan is disturbed, a kink has occurred, or the pipes from the air pressure sensor to the fan volute are incorrectly connected.

- Chimney clogged.

- There are strong gusts of wind.

The faults described above are corrected as follows:

- It is necessary to repair or replace the fan of the Navien boiler.

- Check and, if necessary, clean the chimney.

- Check the correct connection of the tubes from the air sensor to the fan coil and the presence of their kink.

Noise and hum without errors on the display

The problem is that the Navien double-circuit boiler, when hot water is turned on, makes noise or buzzing, which is not like the noise from pumps. At the same time, the pressure in the heating circuit according to the pressure gauge is more than 1.5, and boiler on error display does not issue.

Elimination - the described situation is quite common in gas boilers. It is associated, as a rule, with clogging of the heat exchanger due to poor-quality coolant. There are two ways out of this situation - dismantling the heat exchanger and cleaning it or replacing the heat exchanger.

Error 011

011 is a coolant filling error. It is not provided for in Navien boilers adapted for the Russian consumer, but is allowed only in those designed for the European market.

Innovative solutions in navien products

The products of the Navien brand implement the most advanced ideas and technologies. The products of this manufacturer are characterized by:

- Reliability - the designs provide for mechanisms that completely exclude emergency situations.

- Convenience - all information about the state of the system is constantly displayed on the LCD, and process management does not require skills.

- Versatility - brand appliances can be used both for heating the house and for hot water supply. And as a fuel, you can use the main and liquefied gas.

- Safety - closed combustion chambers and the installation of a coaxial chimney guarantee the safety of the operation of the devices.

Common malfunctions and their elimination

E 01-02

This error indicates that the equipment is overheating due to the lack of RH in the system. The solution to the problem is to clean the pipelines or check the pump. Alternatively, it is necessary to remove air from the system (primarily from the pump).

The function of the flame sensor is checked. Cleaning the ignition electrodes.

It is also necessary to check the presence of gas in the line or cylinders.

Temperature sensor malfunction eliminated by checking its condition. The resistance of the sensor is measured at a certain temperature. If the readings correspond to the reference, it is necessary to clean the contacts.

If the sensor readings do not correspond to the table values, a replacement with a new, working instance is required.

Check if there is power at the terminals. If serious problems are found, the fan is completely replaced.

Most often, the problem lies in the sensor itself. It is necessary to check its condition, clean the contacts, if necessary, replace

If there is no result, the sensor is replaced.

Overheating of the boiler can have several causes, the most common of which is the clogging of the heat exchanger and poor flow of RH. The protection is activated at 98°, the alarm is turned off when the boiler cools down to 83°.

There are two ways to solve the problem - first you should clean (in difficult cases - replace) the heat exchanger, in the absence of a positive result, the sensor is replaced.

Overheating of the smoke exhaust sensor occurs when the chimney is blocked. The reason may be the freezing of condensate, a strong wind outside, the ingress of foreign objects or debris into the chimney. If the elimination of interference with the removal of combustion products does not bring any results, the sensor should be replaced.

Conclusion

Repair and adjustment of Navien boilers are not particularly difficult, but they require experience and a thorough knowledge of the design of the unit.

Do-it-yourself attempts to solve problems often only exacerbate the problem that has arisen, exacerbate unrecognized problems.

Unskilled repairs can permanently destroy important systems and components of the unit, which will require a complete replacement of the boiler.

Therefore, it is strongly recommended to contact a specialist, even if you are confident in correctly identifying the source of the problem.

The experience of a professional is the most reliable option for accurately identifying and eliminating a malfunction.

![How to fix error 10 gas boiler navien [navien]](https://fix.housecope.com/wp-content/uploads/a/d/6/ad666e74f0200dcd68598d045ae6dd69.jpg)

![How to fix error 16 gas boiler navien [navien]](https://fix.housecope.com/wp-content/uploads/b/1/0/b10b5db2fbe3d16c937ee8665652ef68.jpg)

![How to fix error 09 gas boiler navien [navien]](https://fix.housecope.com/wp-content/uploads/b/2/b/b2bdb47a0d6c1fe626cdf299eb2824cc.jpeg)