- Norms of the room for the installation of a gas boiler, where it is better to install the device

- Standards for installing the appliance in the kitchen of wooden and other types of houses

- Requirements for a separate boiler room

- Chimneys and ventilation

- Technical requirements for equipment

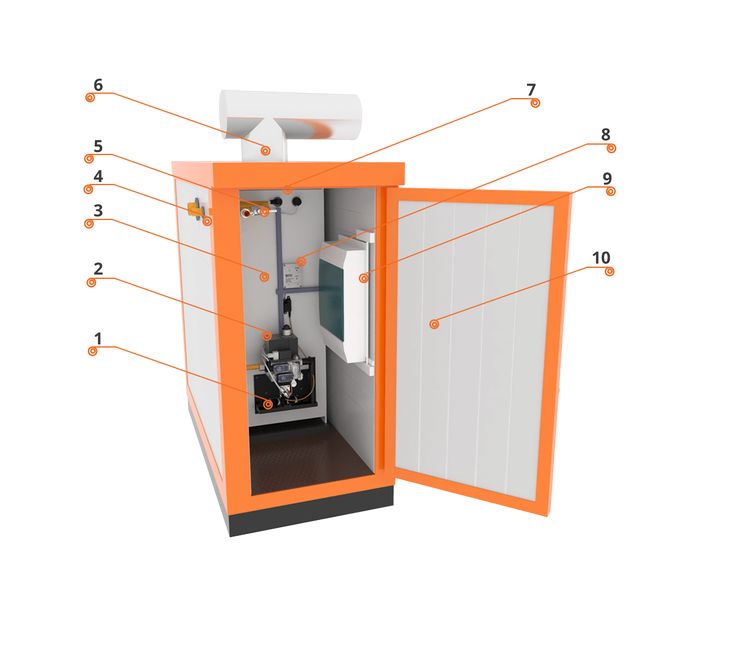

- Nuances and requirements for attached premises for the boiler

- Device types

- Compliance of the dimensions of the gasified building with the standards

- Unit installation requirements

- Distance from the boiler house to a residential building and public buildings

- Installation: recommendations and diagrams, the main stages of the installation of the chimney

- General requirements

- Installation steps

- Video description

- Connecting a ceramic chimney

- Video description

- Requirements for the room where the gas boiler is located

- Room norms for a unit with an open combustion chamber

- Room norms for a boiler with a closed firebox

- Requirements for different rooms

- What should be guided

- gas boilers

- Electric boilers

- Solid fuel boilers

- Oil boilers

- Basic standards

- Regulations and project documentation

Norms of the room for the installation of a gas boiler, where it is better to install the device

The most stringent requirements are imposed on the premises where the installation of a gas unit is planned.

According to current regulations, it is allowed to carry out their installation in non-residential premises, equipped with high-quality ventilation.

In addition to the presence of ventilation, the area of \u200b\u200bthe room must correspond to the power of the unit and the design of the combustion chamber. When the boiler and gas column are installed together, their capacities are summed up.

Important! According to existing standards, it is allowed to install two gas devices in one room. The following standards have been established: The following standards have been established:

The following standards have been established:

- gas boilers with a power of less than 30 kW are allowed to be installed in rooms with a volume of at least 7.5 m³;

- boilers with a capacity of 30-60 kW require a space of more than 13.5 m³;

- for the installation of more efficient boiler equipment, the minimum volume is from 15 m³.

Standards for installing the appliance in the kitchen of wooden and other types of houses

For homeowners planning to place equipment in the kitchen, it is important to know that there are special regulations for this room:

- The area is more than 15 m².

- The height of the walls is at least 2.2 m.

- A window that opens outward, equipped with a window leaf. There should be 0.03 m² of window area per 1 m³ of the volume of the room.

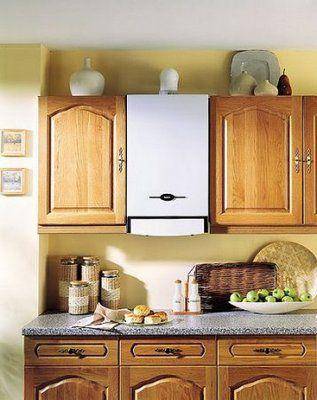

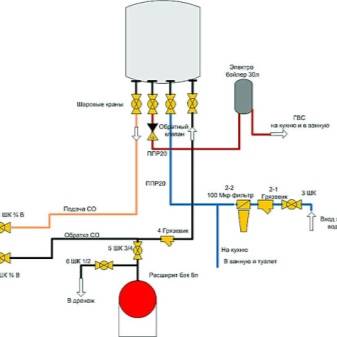

Photo 1. Gas boiler located in the kitchen. The device is installed in a special cabinet, which is closed with a lattice door.

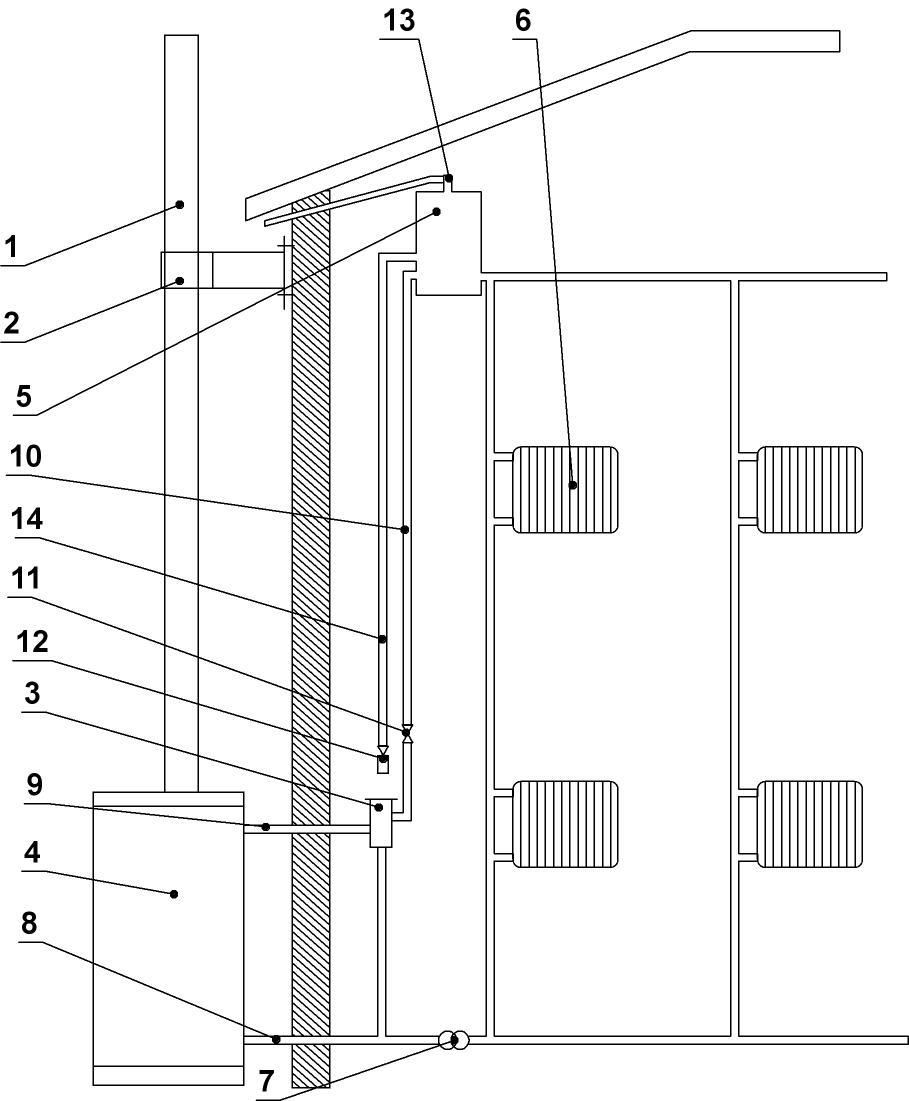

- If the building is wooden, then the wall adjacent to the boiler is covered with a fireproof shield. The size of the shield is determined so that it protrudes 10 cm beyond the boiler at the bottom and on the sides, and covers 80 cm of the wall from above.

- When choosing a floor model, a base made of fire-resistant material (brick, ceramic tile) is installed under it, protruding 10 cm on all sides of the boiler.

- In addition to the presence of exhaust ventilation, a gap is provided at the bottom of the door for fresh air to enter. It ensures constant air circulation.

- When installing the heating unit, a certain distance between the wall and the boiler must be observed (more than 10 cm).

Requirements for a separate boiler room

When erecting, for the placement of boiler equipment, an extension to the main building, the following conditions must be observed:

- the foundation of the extension is carried out separately from the main building;

- the design is made of fire-resistant materials, the same requirements are imposed on interior decoration;

- mortar is kneaded on sand;

- the foundation for installing the boiler is poured separately, after the completion of the extension;

- the base intended for the installation of equipment is 15-20 cm above the floor surface.

Further requirements correspond to the conditions for the installation of boilers in non-residential premises:

- a ventilation system that provides three air changes within an hour;

- the distance between the floor and the ceiling is at least 2.5 meters;

- the volume of the boiler room is more than 15 m³, a larger volume ensures the comfort of servicing all elements of the equipment;

- water is necessarily carried out, and a drain is arranged in the floor;

- all electrical outlets available in the room are grounded;

- daylight;

- when placing the boiler plant, a free approach to the unit is provided.

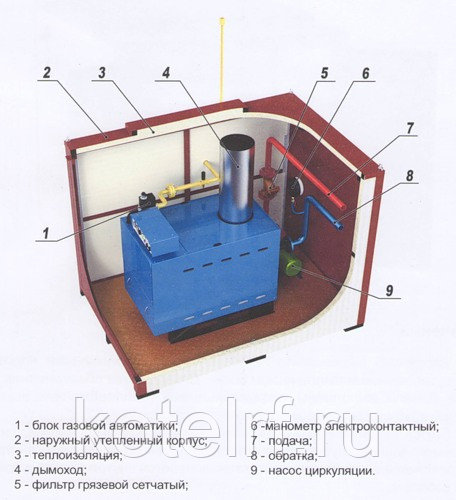

Photo 2. Boiler room with two gas boilers. The devices are installed on a special pedestal, access to sunlight is provided.

Certain requirements are also imposed on the equipment used in the operation of the boiler:

- gas pipelines are used only metal;

- the device is grounded using a separate ground loop;

- without a gas meter, an automatic valve that shuts off the gas supply in case of leakage, and a gas analyzer, the equipment is not accepted for operation.

Reference. Modern gas units are equipped with protective automation of varying complexity, which turns off the gas supply in case of malfunctions.

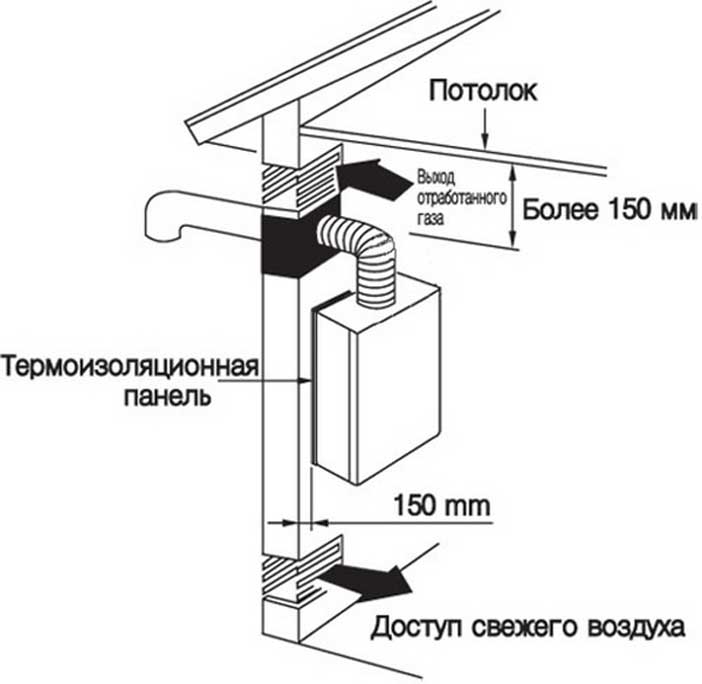

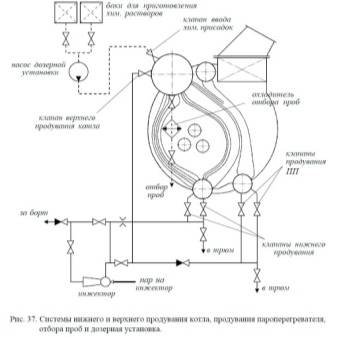

Chimneys and ventilation

The existing state regulations for the placement of gas boilers in the private sector provide for the requirements for the safe organization of air exchange, for example, the ventilation system must ensure an uninterrupted renewal of the air environment three times within one hour, otherwise the operation of the unit will be stopped due to oxygen deficiency during the preparation of the gas-air mixture. Insufficient air exchange causes the formation of a large amount of carbon monoxide, which is dangerous to others.

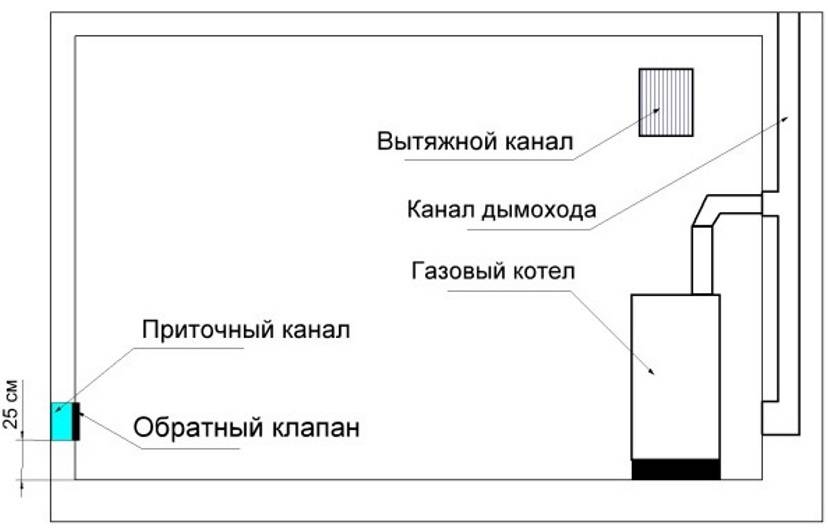

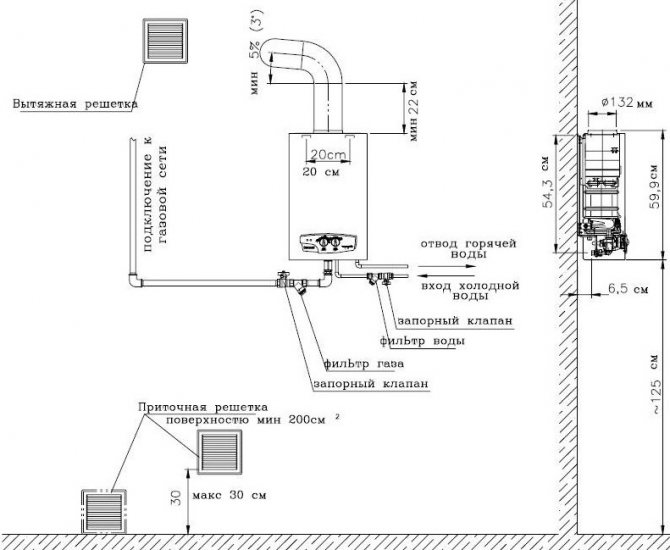

Forced ventilation is installed in the room, providing clean air and removing carbon monoxide. The supply duct is arranged opposite the unit, as close as possible to the front door opening. The inner diameter of the flue must be equal to the boiler flue outlet and be at least 110.0 mm.

The first 5 m in the flue at the outlet of the boiler are made of heat-resistant metal, then other heat- and chemical-resistant materials are used. According to the requirements of the SES, the use of materials containing asbestos is prohibited in residential premises.

Technical requirements for equipment

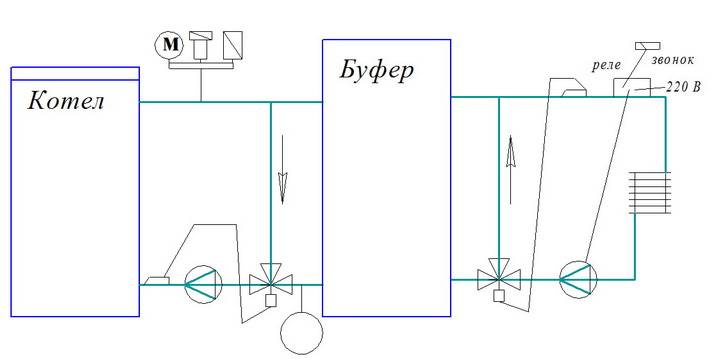

The piping of the boiler piping system is also regulated by:

- Install the tanks on the base and fix with anchor bolts.

- If there are two circulation pumps - one is placed on the return line between the boiler unit and the separator, and the second - on the supply line after the separator column.

- A safety relief valve is installed on the supply line of the hot coolant from the boiler to protect the equipment from overpressure.

- The drainage line for emergency draining from the boiler must not be connected to a plastic sewer.

- For automatic replenishment of the heating circuit, a replenishment regulator is installed on the water supply.

- Gas pipes are mounted only from metal.

- The installation of a gas meter on the boiler is mandatory.

- Boiler equipment must be well grounded, the quality of grounding must be checked annually by a specialized organization.

- A gas analyzer is mandatory installed in the boiler room to warn of a gas leak. In case of danger, it transmits a signal to an automatic shut-off valve for an emergency shutdown of the gas supply.

Nuances and requirements for attached premises for the boiler

Full compliance with state norms and requirements for the premises for placing a gas boiler will help the owner to get away from fines, supervisory authorities, but also to prevent the occurrence of explosive situations during operation. When placing a boiler room in basements or basements, it obliges the owners to install a door in such a room with a separate exit to the street.

When placing a gas boiler in the basement, it is necessary to install a door with a separate exit

When placing a gas boiler in the basement, it is necessary to install a door with a separate exit

Installing a gas boiler in an extension requires placing it against the wall of the house that does not have glazing. The requirements of SNiP 41-01-2003 and MDS 41-2.2000 establish the minimum distance of such a unit to the window - at least 4 m.The manufacturer of gas equipment for boiler circuits took care and indicated the exact boiler installation diagrams for different types of premises. Such information is mandatory transmitted to the user with a passport and operating instructions.

Device types

According to the method of fuel combustion, long-burning boilers with a double circuit can be divided into:

- Pyrolysis. Equipped with two combustion chambers. In one of them, the process of smoldering and gas release for pyrolysis occurs, in the other, the resulting gas is mixed with oxygen and burned. Equipment of this type is characterized by high environmental friendliness - a minimum amount of harmful substances is released into the atmosphere. During combustion, little soot is produced. If the boiler is equipped with automation, it will be possible to adjust the power.

- With upper combustion chamber. These boilers are very easy to maintain. The amount of automation for their stable operation is minimal, it is possible to function offline without electricity. There are also disadvantages - a lot of ash is formed during operation, there is a list of requirements for fuel types. For example, small chips or sawdust are not suitable for kindling.

- Pellet. For kindling such equipment, special pellets or compressed fuel briquettes are used. Such boilers are environmentally friendly, economical and efficient, have a long service life. One of the main disadvantages is the high price of the boiler and the special conditions that will have to be maintained for fuel storage. The room must be dry, high humidity will contribute to the deterioration of the pellets.

Compliance of the dimensions of the gasified building with the standards

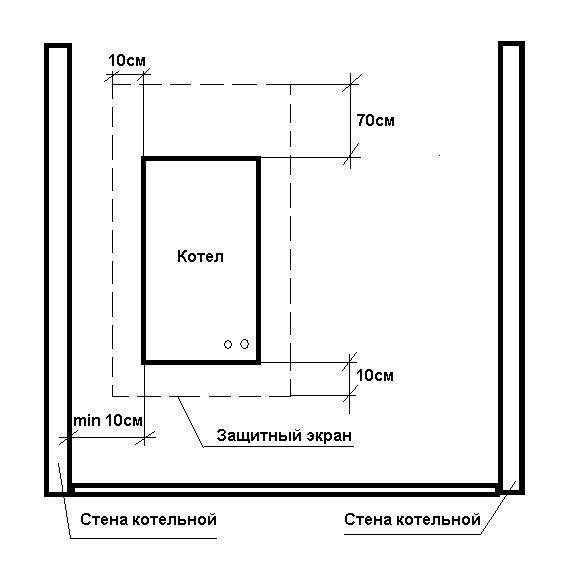

When designing a gas-fired boiler room, the power of the heating unit is taken into account. According to this parameter, the volume of the furnace compartment is calculated.

The table shows the minimum volume and location of the furnace equipment, corresponding to a certain power of the heating device:

| Device power | Room volume | Location of the unit |

| Up to 30 kW | 7.5 cubic meters | built-in office or kitchen |

| 30-60 kW | 13.5 cubic meters | outbuilding, separate room in the house |

| 60-200 kW | 15 cubic meters | free-standing building, extension, basement or basement |

The table shows that it is allowed to install devices with a power of not more than 30 kW in the kitchen. At the same time, its area should be about 4 sq.m.

If the heating equipment is located in the basement or on the basement floor, the walls and ceilings adjacent to other rooms must be vapor and gas tight. In addition, when using heaters with a power of up to 300 kW, it is necessary to provide for a separate exit to the street.

Unit installation requirements

When installing a gas boiler, the homeowner must strictly comply with a number of regulatory rules:

- the boiler is installed in such a way that it has a free approach from any side;

- the size of the entrance door to the boiler room where the device is installed cannot be less than 80 centimeters wide;

- the area of the boiler room or other room cannot be less than four square meters;

- the boiler room must have a window with an area of at least 30 cm² per 10 m³ of volume - to ensure lighting in any situation;

- the ceiling in this room must have a height of at least two and a half meters;

- water must be supplied to the boiler room;

- the ground loop is mandatory if the operation of the boiler is connected with the consumption of electricity;

- the walls of the boiler room must be plastered;

- the chimney must have a section corresponding to the power of the unit.

Having considered the requirements, we can conclude that a kitchen can become a good enough room for installing a hinged boiler, if it is not possible to arrange a boiler room. There it can be placed next to the gas stove.

Compact wall-mounted boiler can fit even in the kitchen

An additional advantage of installing a boiler in the kitchen is that it provides for all the above requirements - this is ventilation, gas supply, proper area of \u200b\u200bthe room, cold water supply. In addition, by installing a boiler there, you can save a lot on pipes and keep more than one wall intact.

The floor-standing boiler, which has massive dimensions and a power of 150 kW or more, must be installed in a separate room - the boiler room. At the same time, it should be taken into account that a device with a power of up to 60 kW can be installed in a room with a volume of at least 27 m³, which means that it can be installed in the kitchen.

For outdoor it is better to allocate a separate room

But you need to be aware that floor-standing boilers are quite noisy, so if you plan to install the unit in an apartment, then it is better to choose a wall-mounted option.

If the boiler is hung or installed against a wall made of combustible material, it must be protected with a heat-resistant insulator, for example, a special drywall or asbestos sheet will do.

Distance from the boiler house to a residential building and public buildings

The SanPiN standard regulates the distance from the boiler house to the residential building depending on the type of building and the fuel used, as well as the purpose of the building. For gas, industrial, free-standing cardinal requirements - 300 m.

- The distance to the residential building from the boiler room can be varied according to the norms of SNiP. When using solid fuels, separate calculations are made. It is necessary to provide for the installation taking into account the background noise. It is also necessary to take into account the incoming degrees of air pollution by combustion products. For extensions, there is a ban on building under the windows of apartments (at least 4 meters are left horizontally from the windows, and 8 meters vertically). An extension may not be erected from the front of the building.

- From kindergarten and school institutions of various types, as well as medical facilities, the norms provide for developed projects. Only detached ones are allowed, provided that the walls of the boiler room reach the required degrees of fire resistance, and the distance between the rooms is determined by the type of fuel and the necessary equipment from the boiler. In such establishments, it is not allowed to build rooftop, built-in or attached boiler rooms due to the need for a fuel store, namely coal, peat or flammable liquids. Sanitary standards determine the required distance to the nearest window (due to combustion products and background noise), and the allowable distance from the fuel storage and boiler room is calculated according to the minimum fire distances.

- The construction of built-in, attached and roof boilers in administrative buildings is allowed by federal law if the established standards for water temperature or pressure are observed.It is also necessary to have access or open areas for maintenance. In the above types, liquid fuels are prohibited.

In production

In production

| No. p / p | Building regulations | Set of rules |

| 1 | SNiP 30-02-97 | SP 53.13330.2011 |

| 2 | SNiP 2.07.01-89 | SP 42.13330.2011 |

One of the indispensable conditions is the presence of a fence between the boiler house and the urban area, which is designed according to SNiP 2.07.01-89 “Urban planning. Planning and development of urban and rural settlements. The minimum distance from the fence is calculated according to SanPiN standards, taking into account noise and pollution from the ongoing process. This also applies to neighborhoods with residential and public buildings.

Standard variant

Standard variant

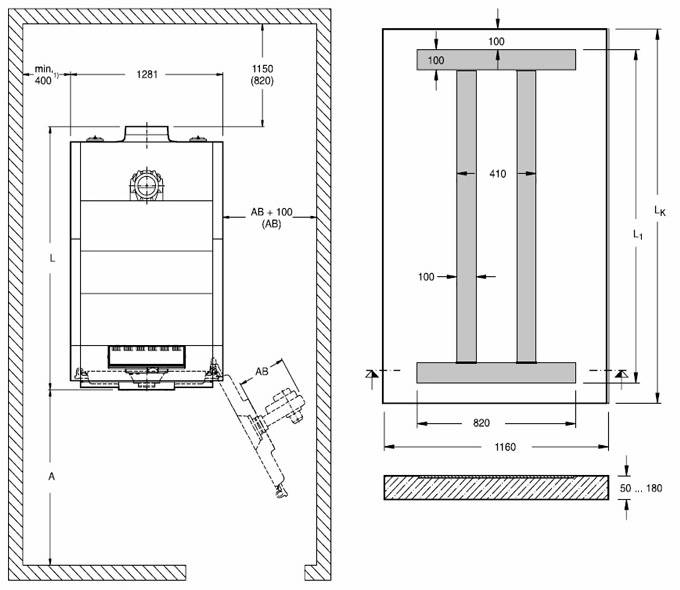

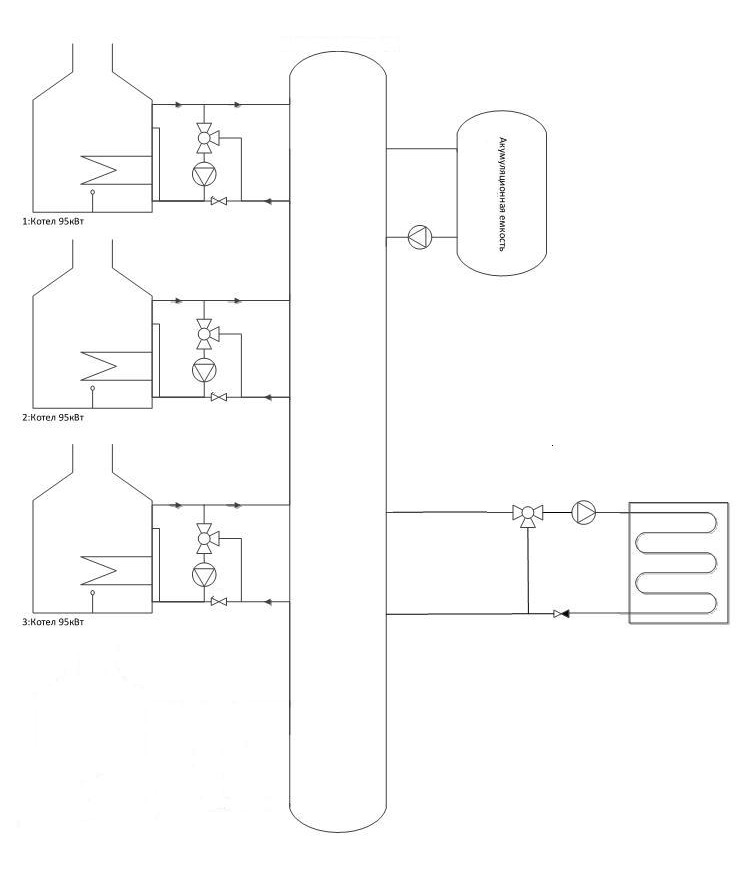

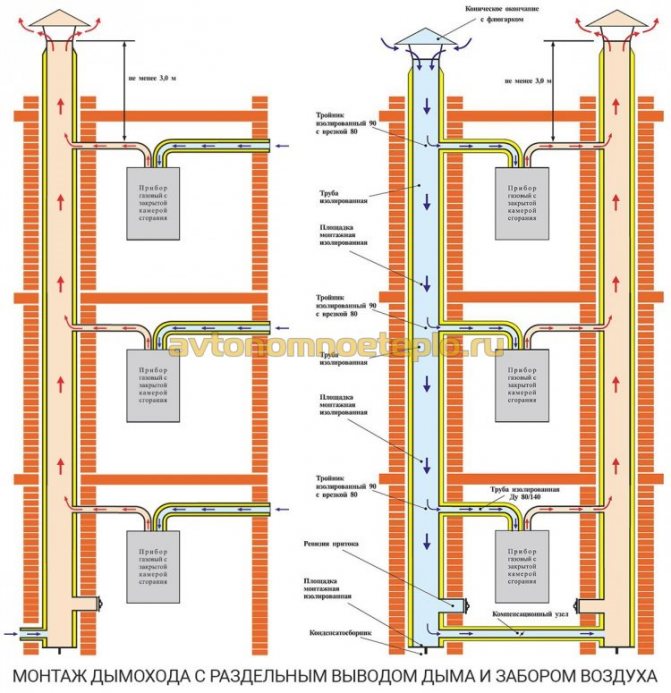

Installation: recommendations and diagrams, the main stages of the installation of the chimney

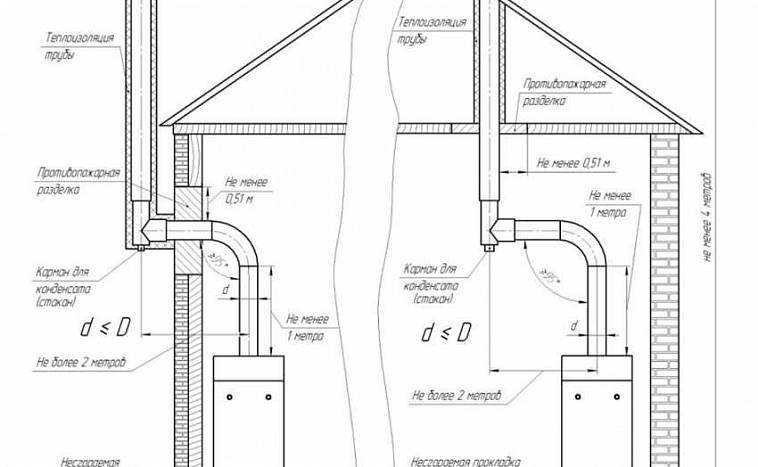

The installation of the chimney is divided into several stages - this is the preparatory work, the installation itself, then the connection, start-up and, if necessary, debugging of the entire system.

General requirements

When combining several heat generating installations, a separate chimney is created for each of them. In exceptional cases, a tie-in to a common chimney is allowed, but at the same time, a difference in height of at least one meter must be observed.

First, the parameters of the chimney are designed and calculated, which are based on the recommendations of the manufacturers of gas boilers.

When summarizing the calculated result, the inner section of the pipe cannot be less than the diameter of the boiler outlet pipe. And according to the check according to NPB-98 (fire safety standards), the initial speed of the natural gas flow should be 6-10 m / s. And besides, the cross section of such a channel must correspond to the overall performance of the unit (8 cm2 per 1 kW of power).

Installation steps

Chimneys for gas boilers are mounted outside (add-on system) and inside the building. The simplest is the installation of the outer pipe.

Installation of an external chimney

Installing a chimney at a wall-mounted boiler is done as follows:

- A hole is cut in the wall. Then a piece of pipe is inserted into it.

- A vertical riser is assembled.

- The joints are sealed with a refractory mixture.

- Fixed with wall brackets.

- An umbrella is attached to the top to protect it from rain.

- An anti-corrosion coating is applied if the pipe is made of metal.

Proper installation of the chimney guarantees its impermeability, good draft, and prevents soot from accumulating. Installation performed by specialists will significantly reduce the cost of maintaining this system.

In the case of arranging an opening for a pipe in the roof of a house, special boxes with aprons are used. In this case, the design as a whole is influenced by such factors as:

- The material from which the pipe is made.

- Exterior design of the chimney.

- Type of roofing.

The main factor influencing the choice of design is the temperature of the gas that passes through the pipe. At the same time, according to the standards, the distance between the chimney pipe and combustible materials must be at least 150 mm. The most advanced is the assembly system by segments, where all elements are assembled by cold forming.

Video description

How the chimney pipe is installed, see the following video:

Connecting a ceramic chimney

Ceramic chimneys themselves are almost eternal, but since this is a rather fragile material, you need to clearly imagine how the connection (docking) of the metal part of the chimney and the ceramic one is correctly performed.

Docking can only be done in two ways:

By smoke - a metal pipe is inserted into a ceramic

It is important to remember here that the outer diameter of the metal pipe should be smaller than that of the ceramic one. Since the thermal expansion of the metal is much greater than that of ceramics, otherwise the steel pipe, when heated, will simply break the ceramic one.

For condensate - a metal pipe is put on a ceramic one.

For both methods, specialists use special adapters, which, on the one hand, are equipped with a gasket for contact with a metal pipe, and on the other, which contacts directly with the chimney, are wrapped with a ceramic cord.

Docking should be carried out through a single-wall pipe - it has a higher heat transfer coefficient. This means that the smoke will have time to cool down a little before it reaches the adapter, which ultimately extends the life of all materials.

Video description

Read more about connecting to a ceramic chimney in the following video:

VDPO shows great requirements for chimneys for gas boilers, because of this, it must be installed by specialized teams. Since competent installation guarantees not only long-term operation of the device, but also makes living conditions in a private house safe.

Requirements for the room where the gas boiler is located

Depending on the power and type of combustion chamber, the norms of the room for installing a gas boiler may differ.

Room norms for a unit with an open combustion chamber

As already mentioned, a gas boiler with an open firebox should be located in a separate room, which is equipped and equipped in accordance with all standards. The boiler room must meet the following requirements:

- The room for installing the unit can be allocated on any floor of a private house, in the basement or in the attic. It is forbidden to mount such a unit in a bathroom or toilet.

- If the power of the gas boiler does not exceed 30 kW, then the volume of the boiler room must be at least 7.5 m³. If the performance of the device is from 31 to 60 kW, then the required size is from 13.5 m³. With power from 61 to 200 kW - 15 m³.

- Ceiling height - 2-2.5 m.

- The width of the doors is not less than 0.8 m.

- The door to the boiler room must not be hermetically sealed. It is necessary to leave a gap between the door leaf and the floor with a width of 2.5 cm.

- An opening window with an area of at least 0.3 × 0.3 m², equipped with a window, should be provided. It provides sufficient illumination of the boiler room.

- Have a ventilation duct.

- Electrical switches placed outside the boiler room.

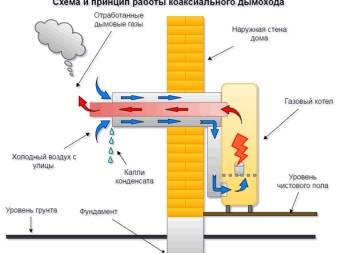

Room norms for a boiler with a closed firebox

The technical standards for installing a gas boiler with a closed combustion chamber are not so strict. In this device, flue gases are removed from a closed furnace into a coaxial chimney, and forced air is supplied through the same pipe. Therefore, gas boilers with a closed combustion chamber with a power of up to 60 kW can be installed in any non-residential premises that meets the following requirements:

- ceiling height over 2 m;

- volume - not less than 8 m²;

- well ventilated;

- the surface of the walls is made of fireproof materials.

It is even allowed to embed turbocharged units in kitchen furniture.

…

Requirements for different rooms

When designing a boiler room, at least three sets of rules (SP) should be followed:

- 62.13330 (valid since 2011, dedicated to gas distribution systems);

- 402.1325800 (introduced into circulation since 2018, reflects the design standards for gas complexes in residential buildings);

- 42-101 (working since 2003, in a recommendatory mode describes the procedure for designing and preparing gas distribution systems based on a non-metallic pipe).

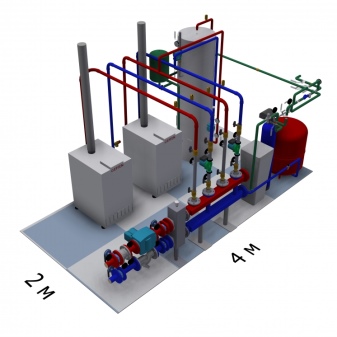

Separately, it is worth mentioning another advisory instruction, which refers to the installation of heat units responsible for heating and supplying hot water in single-apartment and block housing. When drawing up accurate projects, they are guided by all these documents, for example, in order to correctly stretch pipes and correctly position all connection points. When determining the size of the boiler room, they are also guided by the norms in terms of the distances between the components, in terms of the size of the passages.

If you install all the necessary equipment along one of the walls, then the devices usually occupy 3.2 m in length and 1.7 m in width, taking into account the required passages or distances. Of course, in a particular case, there may be any other parameters, and therefore one cannot do without consulting with engineers anyway. It must be understood that the estimated dimensions of equipment and platforms are always given without taking into account the space for opening doors and windows.

For your information: you should not be guided by the norms of SP 89. They apply only to heat generating installations with a power of more than 360 kW. At the same time, buildings for such boiler houses already occupy at least 3000 square meters. m. Therefore, references to such a standard when designing the heating system of a private house are simply illegal. And if they are trying to introduce them, then this is a sign of unprofessionalism of engineers or even a scam.

The volume of 15 m3 mentioned above is in reality extremely small. The fact is that in reality it is only 5 square meters. m, and for the installation of equipment this is very small.Ideally, you should focus on at least 8 square meters. m or in terms of a volume of 24 cubic meters. m.

The height of the boiler room must certainly be at least 2.2 m. In a variety of rooms, there must be at least 9 m between the floor of the boiler room and the window of the upper floor. This means that it is forbidden to equip windows above the boiler extension, and with them living rooms. With a total floor area of less than 350 sq. m, you can, in general, abandon the equipment of a separate boiler room in the full sense of the word, taking the kitchen (kitchen-dining room) under the boiler. State inspectors will only check that the power of the equipment is not higher than 50 kW, and the volume of the kitchen is at least 21 cubic meters. m (with an area of 7 m2); for the kitchen-dining room, these figures will be at least 36 cubic meters. m and 12 m2 respectively.

When installing the boiler in the kitchen, the main part of the auxiliary equipment (boilers, pumps, mixers, manifolds, expansion tanks) is placed under the stairs or in a 1x1.5 m cabinet. But when characterizing the size of the room for the boiler, one should not forget about the requirements for glazing dimensions. They are selected in such a way that the house definitely does not suffer from explosions or suffers minimally. The total glass area (excluding frames, bolts and the like) is at least 0.8 square meters. m even in the control room from 8 to 9 m2 area.

If the total space of the boiler room exceeds 9 sq. m, the calculation is also simple. For each cubic meter of the thermal structure, 0.03 m2 of clean glass cover is allocated. It is not necessary to consider a typical window size on purpose, it is enough to be guided by a simple ratio:

- hall up to 10 squares - glazing 150x60 cm;

- complex for 10.1-12 squares - 150x90 cm;

- 12.1-14 m2 - correspond to glass 120x120 cm;

- 14.1-16 m2 - frame 150 by 120 cm.

The above data for an 80 cm wide door is generally correct, but sometimes it is not enough. It is more correct to proceed from the fact that the door should be 20 cm wider than the boiler or boiler. In case of discrepancy, their values are guided by a larger apparatus. Otherwise, you can limit yourself only to considerations of your own convenience and practicality. A separate topic is the size of the ventilation duct (which is also directly related to the power of the boiler):

- up to 39.9 kW inclusive - 20x10 cm;

- 40-60 kW - 25x15 cm;

- 60-80 kW - 25x20 cm;

- 80-100 kW - 30x20 cm.

Dimensions of gas boilers in private homes in the video below.

What should be guided

When asked how to choose a heating boiler, they often answer that the main criterion is the availability of a particular fuel. In this context, we distinguish several types of boilers.

gas boilers

Gas boilers are the most common types of heating equipment. This is due to the fact that fuel for such boilers is not very expensive, it is available to a wide range of consumers. What are gas heating boilers? They differ from each other depending on what type of burner - atmospheric or inflatable. In the first case, the exhaust gas goes through the chimney, and in the second, all combustion products leave through a special pipe with the help of a fan. Of course, the second version will be a little more expensive, but it will not require smoke removal.

Wall mounted gas boiler

As for the method of placing the boilers, the choice of a heating boiler assumes the presence of floor and wall models. Which heating boiler is better in this case - there is no answer. After all, everything will depend on what goals you are pursuing.If, in addition to heating, you need to conduct hot water, then you can install modern wall-mounted heating boilers. So you will not need to install a boiler for heating water, and this is a financial savings. Also, in the case of wall-mounted models, combustion products can be removed directly to the street. And the small size of such devices will allow them to fit perfectly into the interior.

The disadvantage of wall models is their dependence on electrical energy.

Electric boilers

Next, consider electric heating boilers. If there is no mains gas in your area, an electric boiler can save you. Such types of heating boilers are small in size, so they can be used in small houses, as well as in cottages from 100 sq.m. All combustion products will be harmless from an environmental point of view. And the installation of such a boiler does not require special skills. It is worth noting that electric boilers are not very common. After all, fuel is expensive, and prices for it are rising and rising. If you are asking which heating boilers are better in terms of economy, then this is not an option in this case. Very often, electric boilers serve as spare appliances for heating.

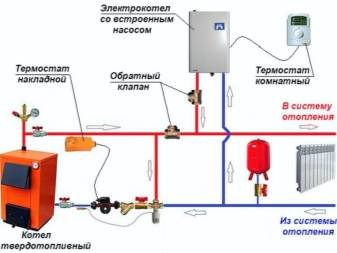

Solid fuel boilers

Now it's time to consider what solid fuel heating boilers are. Such boilers are considered the most ancient, such a system has been used for space heating for a long time. And the reason for this is simple - fuel for such devices is available, it can be firewood, coke, peat, coal, etc.The only drawback is that such boilers are not able to work offline.

Gas generating solid fuel boiler

Modification of such boilers are gas generating devices. Such a boiler differs in that it is possible to control the combustion process, and the performance is regulated within 30-100 percent. When you think about how to choose a heating boiler, you should know that the fuel used by such boilers is firewood, their humidity should not be less than 30%. Gas-fired boilers depend on the supply of electrical energy. But they also have advantages in comparison with solid propellant ones. They have a high efficiency, which is twice as high as solid fuel appliances. And from the point of view of environmental pollution, they are environmentally friendly, since the combustion products will not enter the chimney, but will serve to form gas.

The rating of heating boilers shows that single-circuit gas-generating boilers cannot be used to heat water. And if we consider automation, then it is great. You can often find programmers on such devices - they regulate the temperature of the heat carrier and give signals if there is an emergency danger.

Gas-fired boilers in a private house are an expensive pleasure. After all, the cost of a heating boiler is high.

Oil boilers

Now let's look at liquid fuel boilers. As a working resource, such devices use diesel fuel. For the operation of such boilers, additional components will be needed - fuel tanks and a room specifically for the boiler. If you are thinking about which boiler to choose for heating, then we note that liquid fuel boilers have a very expensive burner, which can sometimes cost as much as a gas boiler with an atmospheric burner.But such a device has different power levels, which is why it is profitable to use it from an economic point of view.

In addition to diesel fuel, liquid fuel boilers can also use gas. For this, replaceable burners or special burners are used, which are capable of operating on two types of fuel.

Oil boiler

Basic standards

Heating equipment is mainly installed in domestic boiler rooms, but it must be understood that such devices can be dangerous. The strict requirements enshrined in SNiPs should be taken into account. Typically, heating equipment is located in:

- attics;

- detached outbuildings;

- stand-alone containers (modular type);

- the premises of the house itself;

- extensions to buildings.

The minimum size of a gas boiler in a private house is:

- 2.5 m in height;

- 6 sq. m in area;

- 15 cu. m in total volume.

But the list of rules does not end there. The standards also introduce regulations for individual parts of the premises. So, the area of kitchen windows should be at least 0.5 m2. The smallest width of the door leaf is 80 cm. The size of the natural ventilation channels is at least 40x40 cm.

Additionally, you should pay attention to:

- SP 281.1325800 (5th section on room standards);

- 4th part of the set of rules 41-104-2000 (an earlier version of the previous document with somewhat stricter standards);

- paragraphs 4.4.8, 6.2, 6.3 of the code of rules 31-106 of 2002 (instructions for installation and for boiler equipment);

- SP 7.13130 as amended in 2013 (regulations on the withdrawal of the chimney part to the roof);

- set of rules 402.1325800 in the 2018 version (order of location of gas appliances in kitchens and boiler rooms);

- SP 124.13330 of 2012 (norms regarding the heating network when placing a boiler house in a separate building).

Regulations and project documentation

Absolutely all requirements for the installation of gas boilers are freely available in the following building codes and regulations:

- SNiP 31-02-2001;

- SNiP 2.04.08-87;

- SNiP 41-01-2003;

- SNiP 21-01-97;

- SNiP 2.04.01-85.

Further, data and figures taken from the relevant SNiPs are used.

1. You need to start by submitting an application for approval of specifications. The presence of this document entitles the applicant to begin installation and connection of heating equipment to the central gas main. The application is made in the gas service, where it is considered by specialists within thirty calendar days.

To speed up the receipt of the above document and avoid possible delays, the application must indicate the estimated average daily volume of natural gas that will be required to meet heating needs. This figure is calculated individually according to the standards given in the first of the listed SNiPs.

- For a domestic gas boiler with a hot water circuit and used in central Russia, the fuel consumption is 7-12 m3 / day.

- A gas stove for cooking consumes 0.5 m³/day.

- The use of a flowing gas heater (gear) consumes 0.5 m³ / day.

For a number of reasons, after consideration by the gas service of an application for a connection permit, a refusal may be given. At the same time, the responsible authority is obliged to issue a document to the owner of a private house, which officially indicates all the reasons for the refusal. After their elimination, the application is submitted again.

2.The next step after receiving the technical specifications is an even longer, but necessary process - the creation of a project. The main part of this document is a plan diagram, which indicates the location of the boiler, metering equipment, gas pipelines, as well as all connection points.

An appropriate specialist is always involved in the preparation of the project. He must have permission to do this work. It is not possible to develop a project on your own. In any case, the gas service will not take into consideration a document prepared by a non-specialist.

After drafting the project, it must be submitted for approval. This is done by the department of the gas service, which controls the gas supply in a particular settlement or area. As a rule, it takes up to 90 days to agree on a project, and only after receiving a positive response can work begin on the arrangement of the boiler room and the installation of the heating unit.

Together with the project and the application for its consideration, the following documents must be attached:

- technical passport (available with the equipment);

- official instruction manual (you can copy);

- certificates;

- a document confirming the compliance of specific equipment with safety requirements.

It is also recommended to consult with the specialist who drafted the project. He will provide the most up-to-date information on these issues, talk about possible innovations, changes in legislation and common pitfalls. This knowledge is guaranteed to save you a lot of time and nerves.

Approval of the project, similarly to the receipt of technical specifications, may end in failure.At the same time, the owner is issued a prescription in which errors, shortcomings or inconsistencies that need to be eliminated are indicated. After corrections, the application is submitted and considered again.