- Device

- Startup and operation instructions

- Floor standing boilers Ferroli for gas and liquid fuels with forced draft burner

- Price comparison for Ferroli boilers

- Connection and setup instructions

- TOP-5 double-circuit gas boilers

- Vaillant turboTEC pro VUW 242/5-3 24 kW

- Buderus Logamax U072-12K 12 kW

- Bosch Gaz 6000 W WBN 6000- 12 C 12 kW

- BAXI LUNA-3 240 Fi 25 kW

- Navien DELUXE 16K 16 kW

- Advantages and disadvantages of products

- User manual

- The lineup

- Advantages and disadvantages

- Device

- Main malfunctions in operation

- What are Ferroli boilers?

- Mounted condensing

- Wall mounted with atmospheric burner

- Outdoor atmospheric

- Boilers Ferroli Domiproject F24 D

- Wall mounted gas boilers

Device

The main element of the Ferroli Fortuna F24 PRO gas boiler is a gas burner and a primary heat exchanger combined into adjacent units. They produce heating of the coolant, which moves through the system with the help of a circulation pump.

The hot coolant leaves the primary and immediately enters the secondary flow-type heat exchanger, where hot water is prepared for the DHW system. After that, the liquid leaves the boiler and enters the heating circuit.

The combustion process is supported by a turbofan, which supplies air and creates draft for a stable removal of smoke and other combustion products.

Management is carried out using an external panel, control over the operation of the nodes is carried out by a control board and a system of sensors.

When something goes wrong, the control-panel display alerts you with an alphanumeric code called an error.

Startup and operation instructions

The installation of the boiler is carried out by a hinged method indoors or outdoors, in a partially protected place (canopy) with a temperature not lower than -5°. All communications are connected in accordance with their purpose.

It is necessary to carefully monitor the accuracy of connecting pipelines, in particular pay attention to the tightness and tightness of the gas line connection. Then, using a make-up tap, the system is filled with water, controlling the process according to the pressure gauge.

Do not pour water into a hot boiler, this will cause cracking of the heat exchanger. It is no longer possible to pour water up to a value of 1 bar, due to the risk of rupture of the heat exchanger during the thermal expansion of the liquid.

The boiler starts up when the required temperature of the coolant is set on the display. The command to start the burner passes and the boiler starts the task.

After that, you can dial the required value of the DHW temperature.

During operation, you should not try to repair or reconfigure the boiler functions yourself, this may cause destruction or gas leakage.

All arising malfunctions should be eliminated only with the participation of specialists from the service center.

Floor standing boilers Ferroli for gas and liquid fuels with forced draft burner

In this category, Ferroli today produces five lines, there are several more discontinued (their technical characteristics are worse than those of new ones). The units differ in design: the burner unit is located outside and is inserted into a hole specially provided in the door. The performance and technical characteristics of the boiler to a greater extent depend on the parameters of the burner, since it is responsible for the completeness of fuel combustion.

ATLAS ("Atlas") - a cast-iron floor boiler with a cast-iron sectional heat exchanger. It has a three-way structure of the furnace: a labyrinth is arranged inside the furnace in such a way that the heated air passes through this labyrinth before leaving the chimney and gives off the maximum amount of heat. This heat is then transferred to the coolant. These models have an analog control panel on which data is set using switches.

ATLAS D boilers have a different range of capacities, a cylindrical furnace with a three-way chimney, other capacities, slightly lower efficiency. The control system is digital, the panel is LCD, you can connect a remote control, room and external thermostats, based on the readings of which the automation will adjust the power of the equipment. You can connect an external water heater (indirect heating) or use the ATLAS D K 100_130 model with an integrated stainless steel tank of 100 or 130 liters.

Floor boilers Atlas with forced draft burners. Can work with gaseous or liquid fuel

Floor-standing cast iron boilers of high power GN2 N and GN4 N also work with pressurized burners for liquid or gaseous fuels (natural or liquefied gas).

The body of the GN2 N units is assembled from several sections, which are connected using special steel studs and bushings. The body is insulated from above, and a metal casing painted using powder technology is installed on the insulation.The furnace of the boilers is reversible, the geometry of the heat exchanger with a large number of fins guarantees high efficiency - over 90%. The updated control panel is located under the hinged cover.

Control panel for floor standing boilers GN2 N and GN4 N

There is an on / off button, an adjustment thermostat, a thermohydrometer, a restart thermostat. There is also a place for installing an electronic adjustment and control unit.

Powerful boilers for heating private houses, offices, etc.

GN4 N have high power (220-650 kW). In this line, a three-way firebox with cooling. The boiler can operate in a conventional or low-temperature circuit, it is possible to install an external electronic control and cascade connection.

Today, the Ferroli concern also produces solid fuel and condensing boilers. Moreover, all solid fuel models can be turned into full-fledged pellet boilers by installing a burner, a hopper and an auger.

Price comparison for Ferroli boilers

To make it clearer, the average market prices for which you can purchase a Ferroli gas boiler are given in the form of a table. Let's make a reservation right away that all prices are average, and specific figures largely depend on the type of model.

| Ferroli boiler model | Number of circuits | Method of output of combustion products | Average cost, in rubles |

| DomiProject D | 2 | Chimney/turbo | From 39700 to 60000 |

| Divatop Micro | 2 | Chimney/turbo | From 63500 to 89200 |

| Domitech | 2 | Chimney/turbo | From 49000 to 71000 |

| Divatop (with boiler) | 2 | Chimney/turbo | From 107700 to 121800 |

| ECONCEPT | — | Turbo | From 115800 to 117400 |

| Pegasus (56 kilowatts) | 1 | Chimney | Approx. 117000 |

| Pegasus 2S | 1 | Chimney | From 163000 to 236700 |

| Pegasus D | 1 | Chimney | From 79200 to 101000 |

| Pegasus D K | — | Chimney | From 20000 to 225300 |

| Atlas | — | Chimney | From 81500 to 131600 |

| Atlas D (supercharged burner) | — | Chimney | From 230000 to 252000 |

| Atlas (supercharged burner) | — | Chimney | From 68200 to 99800 |

Connection and setup instructions

Connection and adjustment of Ferroli double-circuit boilers must be carried out by specialists from service organizations with appropriate training.

All communications are connected:

- Direct and return pipelines of the heating circuit.

- Water supply pipeline.

- Gas pipeline.

- Power supply.

After connecting the communications and checking the tightness of the connections, the boiler parameters are adjusted to the existing operating conditions.

The limits of gas pressure, water pressure, temperature in the heating circuit and hot water are determined. These settings are needed to obtain maximum gas savings.

All other adjustments are made by the user in working order and only concern changes in the room temperature or switching the boiler to summer/winter mode.

It is strongly not recommended to adjust the boiler parameters on your own in order to avoid the loss of the warranty contract and the unit's failure.

TOP-5 double-circuit gas boilers

Double-circuit boilers among users are considered the most preferred option.

This is true, although for families with a large need for hot water, it is better to use single-circuit models with an external drive. Double-circuit units are convenient for small families or for use in public buildings. Popular Models:

Vaillant turboTEC pro VUW 242/5-3 24 kW

German boiler from one of the most reliable manufacturers. It has a power of 24 kW, which allows heating rooms up to 240 sq.m. with simultaneous hot water supply.

Unit parameters:

- installation type - wall-mounted;

- power consumption - 220 V 50 Hz;

- type of heat exchanger - separate (primary copper and stainless secondary);

- Efficiency - 91%;

- gas consumption - 2.8 m3/hour;

- dimensions - 440x800x338 mm;

- weight - 40 kg.

Advantages:

- fully provides housing with heat and hot water;

- reliable stable operation;

- developed network of service centers.

Flaws:

- needs to stabilize the power supply;

- high price for boilers and spare parts.

Vaillant units are considered the most stable and reliable in operation. This is confirmed by ordinary users and service specialists.

Buderus Logamax U072-12K 12 kW

Gas boiler made in Germany. Refers to the elite samples of European heat engineering. The power is 12 kW, allowing you to heat 120 sq.m.

Characteristics:

- installation type - wall-mounted;

- power consumption - 220 V 50 Hz;

- Efficiency - 92%;

- type of heat exchanger - separate (primary copper, secondary stainless);

- gas consumption - 2.1 m3/hour;

- dimensions - 400x700x299 mm;

- weight - 29 kg.

Advantages:

- stable and reliable operation;

- no noise;

- Ease of controls.

Flaws:

- high price;

- the need to use a power stabilizer and a water filter.

If, during installation and first start-up, filtering units and a stabilizer are not immediately installed, you can quickly disable the unit and incur unnecessary costs for repair and restoration of the boiler.

Bosch Gaz 6000 W WBN 6000- 12 C 12 kW

Gas double-circuit convection boiler with electronic control. Designed for rooms up to 120 sq.m., since its power is 12 kW.

Characteristics:

- installation type - wall-mounted;

- power consumption - 220 V 50 Hz;

- Efficiency - 93.2%;

- type of heat exchanger - separate (primary copper, secondary stainless);

- gas consumption - 2.1 m3/hour;

- dimensions - 400x700x299 mm;

- weight - 28 kg.

Advantages:

- reliability, stability of work;

- no noise;

- low gas consumption.

Flaws:

- the high cost of spare parts and repairs;

- demands on the quality of water and electricity.

Bosch products are known all over the world and need no introduction. The quality and reliability of heat engineering are considered reference and serve as an example for other manufacturers.

BAXI LUNA-3 240 Fi 25 kW

Italian double-circuit convection boiler. With a power of 25 kW, it can heat an area up to 250 sq.m.

Options:

- installation type - wall-mounted;

- power consumption - 220 V 50 Hz;

- Efficiency - 92.9%;

- type of heat exchanger - separate (copper-stainless steel);

- gas consumption - 2.84 m3/hour;

- dimensions - 450x763x345 mm;

- weight - 38 kg.

Advantages:

- reliability;

- high performance;

- high-quality components and parts of the unit.

Flaws:

- high cost;

- the dimensions of the boiler are too large for a wall model.

Italian boilers are famous for their quality and reliability. However, to work in Russian conditions, it is necessary to use additional equipment - a stabilizer and filter units.

Navien DELUXE 16K 16 kW

Korean boiler, characterized by relatively low cost and high quality. With a power of 16 kW, it is able to heat 160 sq.m. area.

Boiler characteristics:

- installation type - wall-mounted;

- power consumption - 220 V 50 Hz;

- Efficiency - 91.2%;

- type of heat exchanger - separate (both units are made of stainless steel);

- gas consumption - 1.72 m3/hour;

- dimensions - 440x695x265 mm;

- weight - 28 kg.

Advantages:

- reliability, high build quality;

- relatively low price;

- adapted to Russian conditions.

Flaws:

- high noise level (relative);

- some parts are made of unreliable plastic.

South Korean boilers are classified as a budget segment of heat engineering. However, their quality is not inferior to European counterparts, and the price is much lower.

Advantages and disadvantages of products

The most important difference between the wall-mounted devices of the Italian manufacturer is automation based on a microprocessor system. It controls the intensity of the flame and allows you to adjust the power of the boiler. This makes it possible not only to save gas, but also increases the safety of the entire heating system as a whole.

The advantages of this model include a copper heat exchanger. This is a patented development of the company's specialists.

A distinctive feature is the large distance between the fittings used to mount the device on the wall, which greatly simplifies the installation process. The company also took care of spare parts. Complete with a gas boiler are supplied:

- copper fittings

- taps for water and gas

- wall template

This is very convenient, as it allows you to start installation immediately, without wasting time and money looking for the necessary parts.

Also, all models of boilers are equipped with a pump protection system from a blocking situation. The principle of its operation is the following.

Also, all models of boilers are equipped with a pump protection system from a blocking situation. The principle of its operation is the following.

At the end of the heating season, the Ferroli gas double-circuit boiler can be turned off and in this case, so that the system does not stagnate, it will automatically turn on for a couple of minutes a day, and thereby prevent the pump from blocking.

A feature of this type of boilers is the need to equip them with an additional expansion tank if there is more than 200 liters of water in the heating system. This is due to the small volume of the standard tank.

It is worth noting separately the convenience of the design of the device.All systems and components located inside the boiler are accessible from the front, which simplifies the process of maintenance and repair of equipment.

You can not ignore and protection against exposure to low temperatures, which allows the equipment to operate smoothly regardless of the type of gas:

- natural

- liquefied

The ability to connect a remote control makes it possible to control the operation of the boiler from a distance, which is very convenient. And if you add light weight and compact dimensions to the advantages, then there can be no better choice. Moreover, he copes equally well with maintaining a comfortable temperature in the house and preparing hot water for its residents.

User manual

Most Ferroli models are equipped as standard or optionally equipped with automated controls, which make operation easier. The user sets the modes and configures through a special panel. To start the equipment, it is necessary to open the burner and perform ignition. But before that, you should turn on the unit in the network, and then press the special start button, which is equipped with the Ferroli gas boiler. The instruction also provides for a situation in which the start of the equipment will not work. If the boiler does not start within 15 seconds, the system must be restarted. The boiler should be turned off not only by closing the valve and turning it off with the button

It is recommended to disconnect the unit from the mains, but it is important to consider that in this state the boiler will not be protected from freezing. To avoid this, either drain the water or add antifreeze to it.

The lineup

The Italian company Ferroli offers a wide range of various modifications of gas boilers. Each model is CE certified. This means that Ferroli products meet European quality standards and meet safety requirements. It should be noted that double-circuit gas boilers Ferroli, as well as single-circuit options, are constantly being improved by the manufacturer.

The Italian company Ferroli offers a wide range of various modifications of gas boilers. Each model is CE certified. This means that Ferroli products meet European quality standards and meet safety requirements. It should be noted that double-circuit gas boilers Ferroli, as well as single-circuit options, are constantly being improved by the manufacturer.

At the moment, the following models of gas boilers from the Italian manufacturer Ferroli are the most popular:

- Ferroli Pegasus. This is a floor version, the heat exchanger is made of cast iron, and the burner is of atmospheric type. Such a gas floor boiler Ferroli Pegasus is volatile. The unit is equipped with a backlit LCD screen. The control panel is digital. It is possible to connect a boiler. Thanks to the presence of a shut-off valve with two thermostats, it is possible to monitor the safety of the device. It is also possible to install a thermostat and an outdoor pump. Among the advantages are: low thermal inertia, silent and efficient operation, high amount of heat exchange, protection against low and high temperatures, external temperature compensation mode, the ability to connect remote control devices, there is an option for pump anti-blocking.

- Ferroli Diva F24. A model such as the Ferroli Diva F24 gas boiler is a wall-mounted option. The unit is equipped with electric ignition. There are two copper heat exchangers. The combustion chamber is closed. Power reaches 25.8 kW. The level of efficiency is high - about 93%. The device works on both liquefied gas and natural gas. The control panel is understandable even for an inexperienced user and very convenient. Access to the internal elements from the front is easy.Therefore, servicing the Ferroli F24 gas boiler is much easier.

- Ferroli Arena F13. The model is double-circuit, belongs to the wall type. The main heat exchanger is made of copper and the DHW heat exchanger is made of stainless steel. The combustion chamber can be open and closed. Analog control. The wall-mounted gas boiler Ferroli Arena F 13 can work in different modes. The device is equipped with a security system. The design is quite attractive and elegant. Ferroli Arena is environmentally friendly and highly reliable.

- Ferroli Domiproject F24D. This is a hinged, double-circuit version. The Ferroli24 gas boiler is distinguished by its compactness, economy and high performance. The display is liquid crystal. There is a wide range of customization options. The unit is chimneyless. Closed combustion chamber. Boiler power 24 kW. The efficiency is within 93%. The system runs on natural gas. But it can also run on solar power. When buying a device, instructions are attached to the FerroliDomiproject F24 d gas boiler, which must be carefully studied before proceeding with the installation of the device.

Advantages and disadvantages

The advantages of double-circuit boilers Ferroli should be considered:

- High quality parts, elements and assemblies made on the basis of modern technologies.

- Full functionality of boilers that allows you to heat the premises and provide it with hot water.

- Economical, relatively low gas consumption.

- Stability, sustainable operation.

- The presence of several types of design and functionality of the units.

- Wide choice of power.

- Ease of controls.

- The presence of a self-diagnosis system.

- Compact, small size.

- Attractive appearance of the units.

The disadvantages of Ferroli double-circuit boilers are:

- Energy dependence. The need to use a voltage stabilizer and the correct connection of the phase electrode. Required grounding.

- Excessively high sensitivity of the electronics, often leading to the failure of an expensive control board.

- The combined (bithermic) heat exchanger, installed on some models, requires the use of softening water filters, replacing it costs almost half the cost of the boiler.

Most of the shortcomings are not an exclusive feature of Ferroli double-circuit boilers and apply equally to all similar models from any manufacturer.

Although this does not reduce their negative value, such shortcomings should be treated as design costs.

IMPORTANT!

Harmful consequences can be avoided by installing a voltage stabilizer and a softening water filter. This must be done from the first days of operation of the boiler. As a result, breakdowns and failure of the electronics and heat exchanger can be excluded.

Device

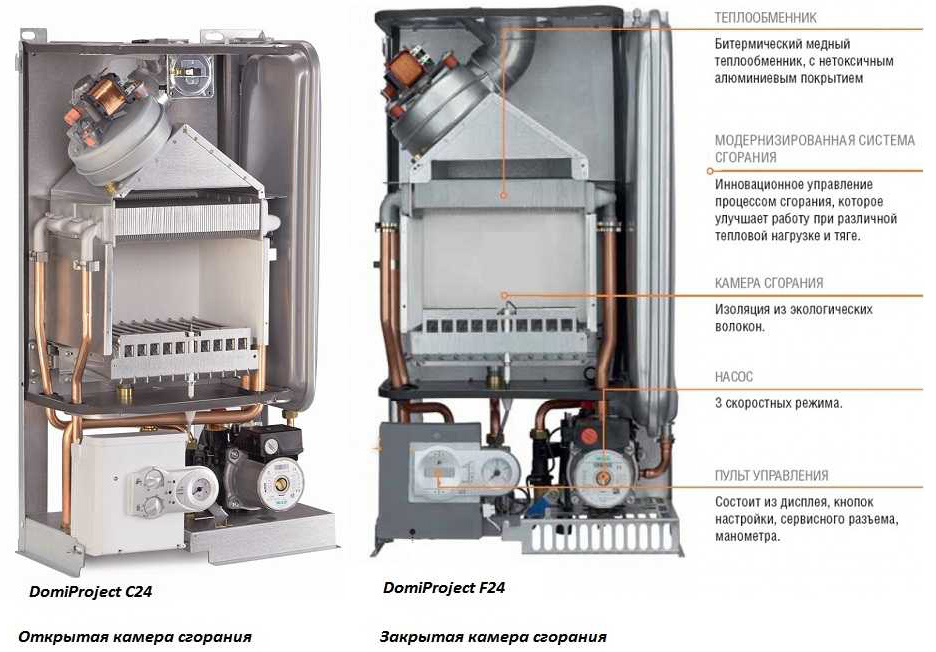

Ferroli double-circuit boilers are designed on the basis of the most efficient designs used in the global heating industry. The main elements are a gas burner, which is located in close proximity to the heat exchanger.

The hot coolant passes into the secondary heat exchanger, where it gives off some heat for the preparation of hot water.

IMPORTANT! In models with a bithermic heat exchanger, both processes run simultaneously. At the outlet of the secondary heat exchanger, the RH enters a three-way valve, where the hot and colder return flows are mixed in the required proportion to obtain the desired temperature, after which the liquid is sent to the heating circuit

At the outlet of the secondary heat exchanger, the RH enters a three-way valve, where the hot and colder return flows are mixed in the required proportion to obtain the desired temperature, after which the liquid is sent to the heating circuit.

All processes are controlled by an electronic control board equipped with an extensive network of sensors.

They form the core of the self-diagnosis system, which constantly monitors the state of the boiler units.

Main malfunctions in operation

Despite the fact that the equipment of the Italian manufacturer Ferroli is considered high quality, reliable and durable, breakdowns still take place. Therefore, we will consider malfunctions on the Ferroli gas boiler in more detail.

Some users have this problem: the boiler does not turn on. The reason may be the lack of gas in the network. It is possible that air has accumulated in the pipeline. Or there is a malfunction of the ignition electrode and gas valve.

Sometimes the water pressure starts to drop in the boiler. The most common cause of this situation is a malfunction in the circulation pump. If there is a coolant in the system, there is no pressure switch, then low pressure may be caused by insufficient ignition power. By increasing the power, the problem is immediately solved. Among other reasons, there may be damage to the electronic control board of the gas boiler.

Sometimes the water pressure starts to drop in the boiler. The most common cause of this situation is a malfunction in the circulation pump. If there is a coolant in the system, there is no pressure switch, then low pressure may be caused by insufficient ignition power. By increasing the power, the problem is immediately solved. Among other reasons, there may be damage to the electronic control board of the gas boiler.

Of course, there may be other problems as well. Here are the most common breakdowns. In any case, it is better not to try to repair the equipment yourself. Only a highly qualified specialist who is well versed in all the nuances of the operation of a gas boiler should fix problems.Otherwise, you can only aggravate the situation and repairs will need to be more serious and expensive.

What are Ferroli boilers?

Mounted condensing

Such devices clearly demonstrate the quality and advantages of Ferroli products. Their efficiency is 109%. The thermal energy of the steam generated as a result of gas combustion is used. Heated flue gases provide additional heat, which is used for work, and not pushed into the chimney, as is customary in conventional design. There are single- and double-circuit condensing units with a closed firebox. Their characteristics:

- Fuel economy. flame modulation. Automatic adjustment of gas supply - depends on the set mode and weather.

- Thanks to the control system, you can set the level of heating of the home - taking into account the time of day, a week in advance. Some modifications have taps for "warm floors". Automatic adjustment of the heating of the coolant in two circuits - each has its own temperature.

- Dependence on electricity. Due to voltage drops, the microprocessor board burns out. If the voltage drops in the network, the equipment turns off, you have to turn it on again. This is perhaps the main drawback of Ferroli products.

- Operates at reduced gas pressure.

- The coolant can be water or antifreeze (non-freezing liquid).

Wall mounted with atmospheric burner

The classic version is an open combustion chamber. The air on the burner comes from the room - through the natural movement of air masses. The main plus is constructive simplicity.Cons - the gas consumption is higher than that of condensing analogues, and the performance is less.

Installation is no problem. The device is equipped with all the necessary components that ensure the operation of the system - a circulation pump, an expansion tank, a gas valve. Ignition - electric or piezo.

Outdoor atmospheric

Non-volatile boilers are represented by various modifications, among which Pegasus models are especially popular, differing from their counterparts in such technical details:

- Cast iron heat exchanger. With thermal insulation and shielding.

- By making some changes to the operation of the device, liquefied gas can be used as fuel.

- Some floor versions are equipped with a built-in boiler - after opening the tap, hot water flows - immediately, without delay.

- Power consumption is regulated.

- There is a self-diagnosis - the display shows encrypted information about breakdowns and malfunctions. Operation and repair of the equipment is simplified - once you know the error code, you can immediately know the nature of the problem and perform the necessary maintenance.

- Safety is ensured by thermostats and a safety valve.

- The device is combined into a single system with all heating equipment. Automation will control the operation of all devices.

- "Pegasus" is completed additionally - if the buyer wishes, with thermal sensors and a remote control.

Boilers Ferroli Domiproject F24 D

Ferroli was founded in 1955 as a small workshop producing steel gas-fired boilers to order.Today, Ferroli is a world-class corporation with a number of subsidiaries and engaged in the production of a wide range of heating and climate equipment.

The Ferroli Domiproject series is a line of wall-mounted double-circuit units with the ability to heat a house and supply hot water.

This functionality is optimal for owners of private houses or other types of residential premises.

The difference of the Ferroli Domiproject line is its adaptation to Russian technological conditions, which makes them resistant to loads, gas and water pressure drops, and power supply voltage instability.

A feature of the boilers is the presence of a bithermic heat exchanger of the "pipe in pipe" type, which makes it possible to obtain high efficiency in the preparation of hot water and increased productivity of the DHW line.

There are additional options, such as connection to a solar installation and the creation of an integrated control of the heating system.

Wall mounted gas boilers

This equipment is provided by a large number of modifications: the lines that are put into production - 9. There are six more old lines of boilers that have already been discontinued today.

Three models of Ferroli wall-mounted gas boilers: Diva, DivoProject, DomiProject

Most of the units are designed for space heating using a heat carrier + DHW (hot water supply). Only one model works for heating - DIVATOP H.

Water for domestic hot water is heated according to the principle of flow heating. An exception is the DIVATOP 60 model: indirect water heating in a stainless steel boiler.The rest of the boilers are equipped with heat exchangers of two configurations - traditional plate type: models DIVAproject, DIVA, DIVATOP MICRO, DIVATECH D. In others, there is a patented device from Ferroli - three larger diameter pipes connected in series, in which coils made of thin pipes are placed. Heat exchangers of this type are in the DOMIproject D, DOMINA, DOMITECH D lines.

Heat exchangers for gas boilers Ferolli

The heat carrier in the heating circuit is heated by a copper heat exchanger. As a heat carrier, you can use either water of a certain hardness: not higher than 25 ° Fr (1 ° F = 10 ɩɩɦ CaCO3), or antifreezes, inhibitors and additives. There is one limitation for non-freezing liquids: only those that are designed specifically for heating systems and do not harm the copper heat exchanger are allowed to be used. The use of fluids, additives, general purpose additives, and even more so automotive additives, is prohibited.

Ferroli wall-mounted gas boilers are available:

- with open combustion chambers, marked with the Latin letter "C", these modifications require a chimney;

-

with closed combustion chambers - marked with the letter "F", the output of combustion products using a turbine.

Combustion chambers in Ferolli boilers made of steel. They are covered with an aluminum-based anti-corrosion coating to increase their service life. Almost all models (except DIVATOP 60) use an injection burner with stainless steel heads. The flame is ignited without an igniter (no pilot burner) using an electric spark. The correct operation is controlled by a special sensor, which shuts off the gas supply in case of failure. Burners are used on-off, controlled by a microprocessor.

Each wall-mounted boiler has:

- a system that prevents the pump from blocking (when the equipment is idle for more than a day, the pump turns on for a while to maintain performance);

- anti-freeze system (when the coolant temperature drops below 5oC, the burner turns on, the temperature rises to 21oC);

- control of the removal of combustion products (with a high content of smoke, the operation of the burner is blocked);

- built-in automatic bypass that protects equipment in case of a sharp change in water pressure;

- self-diagnosis (the equipment automatically checks the main indicators, if it deviates from the reference value, the work stops, the corresponding message is displayed on the panel or indicators, after a while the testing is repeated, if the system has returned to normal, the work automatically resumes);

- at the factory, the burners are set to work with natural gas; if a special kit is available, the burner can be reconfigured for liquefied gas (performed by employees of service centers).

The set of functions, capacities and capabilities of wall-mounted boilers is very similar. The main and main difference is in the control board. Outwardly, all the difference is in the control panel and indication: somewhere it has an LCD screen, somewhere it has LEDs; the way of changing the parameters is also different: there are switches, and there are buttons.

Diva boiler control and indication panel (click to enlarge)

The DIVA and DOMINA N models do not have the ability to connect weather-compensated automation, but the DIVATOP DOMIPROJECT D, DIVATECH D and DOMITECH D models do.

Divaproject control and indication panel (click to enlarge)

They produce boilers of different capacities: 24 kW, 28 kW, 32 kW.Depending on the modification, the DHW performance may differ slightly: with an increase in the power of the unit, the performance increases. But it should be noted that the amount of hot water does not depend on the type of heat exchanger used (lamellar or patented) (judging by the technical data provided).

Divaitech control and indication panel (click to enlarge)