There are gas boilers with atmospheric chimneys and open combustion chambers, there are turbocharged boilers (they have a closed combustion chamber). Atmospheric ones require a good chimney and draft in it, oxygen for combustion comes from the room in which the unit is installed, therefore there must be an air inflow channel and a working chimney (all this is checked when the system is started).

Boilers with forced draft (turbocharged) can be installed without a chimney. The smoke outlet of the boiler through a coaxial pipe (also called a pipe in a pipe) can be output directly to the wall. At the same time, smoke comes out through one pipe (it is pumped by a turbine), through the second, combustion air enters directly into the combustion chamber.

This type of equipment is heatpoint everyone is good, except that in winter the coax is overgrown with frost, which worsens traction. In case of poor draft, the automation extinguishes the boiler - so that combustion products do not enter the room. Switching on is possible only when traction is restored, that is, you will have to upholster or in some other way remove snow growths.

There is also a separate type of boilers - condensing. They are distinguished by very high efficiency due to the fact that heat is taken away from the flue gases (they condense vapors). But high efficiency is achieved only when operating in low-temperature mode - in the return pipeline, the coolant should not have a temperature above +40°C. If the temperature is even lower, even better.

Condensing boilers are the most efficient

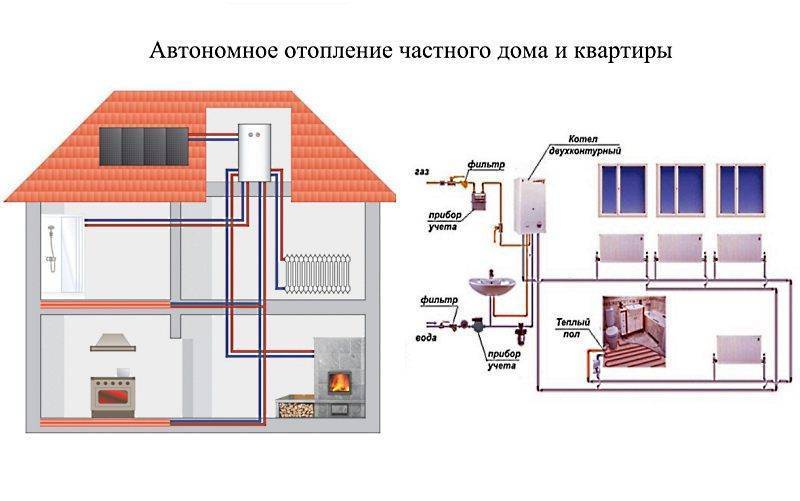

Such conditions are suitable for heating with water heated floors. So if you have conceived such gas heating of a private house - with warm floors, then a condensing boiler is what you need. It has few disadvantages - a high price (compared to conventional ones) and caustic condensate, which places special demands on the quality of the chimney (made of good stainless steel).

Floor standing gas boilers

If you need more power, the wall-mounted option will not work - they have a maximum performance of 40-50 kW. In this case, put a floor boiler. Here they are of high power, and there are also models that can work in a cascade. In this way, large areas can be heated.

Some of the floor boilers can operate not only from main gas, but also from liquefied gas. Some can still work with liquid fuel. So these are pretty handy units. Their body is made of steel, and the heat exchanger can be steel or cast iron. Cast iron weigh and cost more, but have a longer service life - by 10-15 years. Inside the case there is a burner, automation and a heat exchanger.

When choosing, you need to pay attention to the functionality of automation. In addition to the standard set - control of the presence of gas, flame and thrust, there are many more useful functions:

- maintaining the set temperature,

- the ability to program modes by day or hour,

- compatibility with room thermostats;

- adjusting the operation of the boiler to the weather,

- summer mode - work for heating water without heating;

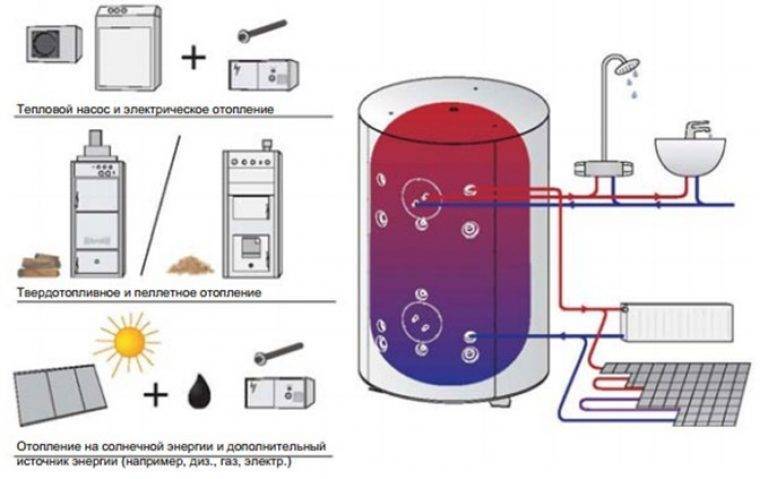

- the ability to work in parallel with solar panels or other alternative heat sources, etc.