- Operation and maintenance

- Advantages and disadvantages of Danko gas boilers

- Floor boiler "Danko"

- Instructions ↑

- Inexpensive and high-quality boiler for an apartment

- Model "Danko 10/12": design and installation features

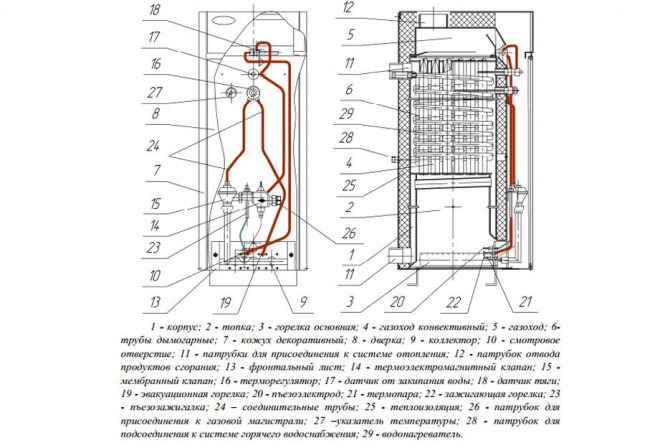

- What does the Danko 10/12 floor boiler consist of?

- Mounting Features

- Gas boilers "Danko"

- Gas boilers are available in various models and types.

- What are the problems?

- Common Problems

- Possible malfunctions of the boiler

- How to light a Danko gas boiler?

- Gas boilers "Danko"

- Before starting the heating equipment

- How to choose?

- Assortment of gas boilers Danko

- The best and most famous models: features and prices

- 8C

- 12VSR

- 12.5US

- 16hp

Operation and maintenance

Commissioning is possible after acceptance by representatives of the gas service. The installation diagram is attached to the instructions. Installation is quite simple, but it is better to trust it to specialists. Gas workers who take the device into operation conduct the appropriate briefing. The modification is selected according to the project carried out by the gas service, in which the power of the apparatus and its type are necessarily noted. Safety regulations:

- Maintenance of the device can be performed by those who have listened to the instruction.

- In the event of a breakdown, turn off the taps immediately.

- If you smell gas, turn off the valve, open the windows and call the gas workers.

- Keep your device clean and in good condition.

- Clean your chimney as often as directed in the instructions.

- Check weekly that the system is full - whether there is water in the expansion tank.

- At the end of the service life of the device, provided by the manufacturer, invite a specialist for advice - whether it can continue to be used.

Advantages and disadvantages of Danko gas boilers

Consumers agree that the main advantage of Danko brand products is assembly according to European technologies, which distinguishes them favorably from domestic counterparts. Other benefits include:

- no noise;

- reliable and safe automation;

- a copper coil that allows you to quickly heat water;

- steel heat exchanger providing high heat transfer;

- warranty period - 3 years from the date of issue;

- the average period of operation of cast-iron boilers is about 25 years, the rest - about 15 years, respectively.

The disadvantages of Danko products are much less, but nevertheless they are:

- in models with horizontal gas ducts there is a risk of extinguishing the flame by the wind;

- the need to clean the chimney;

- wall-mounted boilers are less powerful than floor-standing boilers, but floor-standing ones are louder.

The cost of Danko boilers depends on the type of model chosen and its power, as well as on automation of one kind or another.

Floor boiler "Danko"

The company "Agroresurs" produces floor-standing boilers with high-quality, thick and high-temperature-resistant ISOVER insulation, which retains thermal energy to the maximum. A layer of thermal insulation, 50 mm thick, covers all the walls of the heat exchanger and the flue. Floor boilers can be both single-circuit and double-circuit (have the function of hot water supply).

The company "Agroresurs" produces floor-standing boilers with high-quality, thick and high-temperature-resistant ISOVER insulation, which retains thermal energy to the maximum. A layer of thermal insulation, 50 mm thick, covers all the walls of the heat exchanger and the flue. Floor boilers can be both single-circuit and double-circuit (have the function of hot water supply).

- Single-circuit boilers are used for heating relatively small buildings, apartments or rooms up to 300 m2.

- Double-circuit boilers are capable of heating not only the premises, but also water. Thus, there is no need to purchase an additional water heater.

Instructions ↑

The instruction manual for Danko gas boilers prescribes that commissioning begins only after acceptance by the gas facilities specialists and their briefing. All repair or maintenance work is carried out by specialists who have permission to carry out such work.

Attention: When choosing a boiler, it is necessary to take into account the type and power of the equipment, which are indicated in the project developed by the gas management. Installation of gas boilers is carried out only by specialists licensed for this type of work

During operation, a number of safety rules must be observed:

1. The boiler may only be operated by persons who have been instructed.

2. If the boiler does not work, the taps must be closed.

3. If there is a smell of gas, you need to turn off the gas valve, open the windows in the room where the boiler is located, and call the emergency gas service.

4. The boiler must be kept in good condition and clean.

5. If there is a chimney, it is necessary to clean it periodically.

6. It is necessary to check the filling of the system once a week, this is determined by the presence of water in the expansion tank.

7. After the end of the service life (15-25 years), you will need to call a specialist from the service company, who will decide on the possibility of its further use.

Irkutsk, Irkutsk region

Tatarenko Inna Igorevna

In connection with the move to a new house, we needed to change the boiler.

I wanted to buy a wall. That was what was important to me. And I didn’t want to buy a cheap wall-mounted boiler, but then overpay for fuel consumption. Of course, the reviews and discussions about such boilers that I found on various forums were striking in their advantages, but for myself I chose several manufacturing companies, among which was the Danko wall-mounted boiler.

Makhachkala, R. Dagestan

The modern market provides a wide range of goods and services. And every time you are faced with which manufacturer to choose. It would seem, what difference does it make, because a car is a car, an iron is an iron. But when you come to the store, you are offered the same product in different versions. This is where the problem arises – “What to choose?!”.

Recommend a gas boiler for the country

requirements

1. single circuit

2. there is a chimney (from an old "Soviet" boiler), so if you can connect a new boiler to an old chimney, then a chimney is better, they seem to be cheaper)

3. so that it works depending on the temperature in the room (it would be possible to set the temperature as you want, if we leave for a few days - set a non-freezing minimum)

4. Now the old boiler is working with natural circulation batteries. however, the circulation is poor, the house at minus 20 with the boiler at the maximum warmed up to 16 degrees and that's it. But in not so severe frosts everything was fine. I would like to put it with a pump, it saves gas consumption, but there are power outages for 8-12 hours. There hasn't been more yet, but anything is possible. Are there boilers in which the pumps can be turned off (during a power outage) and it would continue to work on natural circulation?

5.wall or floor I don’t know, they say floor is more reliable and durable

6. room area 100 sq. m.

7. price - the lowest, but not at the expense of quality and reliability. Foreign boilers of such a plan come from 4000 UAH. Domestic from 2000 UAH. Is there something more or less suitable from domestic boilers? Which brands are worth considering, and which ones are definitely not?

Inexpensive and high-quality boiler for an apartment

Price-quality ratio

Ease of use

Advantages: Closed combustion chamber Can be installed in an apartment Takes up little space There is a water heating function (DHW) Works well at low gas pressure.

Review: More than a year ago, they took care of installing individual heating in the apartment instead of the central one, because they turned it on late and turned it off early - as a result, the whole family froze in early spring and mid-autumn. Since there was not a lot of money at that time, they chose a domestic boiler for a long time (European ones were almost 2 times more expensive) and eventually settled on such a Danko wall-mounted boiler: Next

25 October 2014

If you want to purchase a suitable boiler for connecting to a heating system, it is better to look at not expensive Italian options, but to focus on more affordable, but no less efficient models. So, gas boiler Danko is the best among popular domestic products. Its main quality is the variety of models. Due to the wide range, you can always choose the right model.

Model "Danko 10/12": design and installation features

Using the example of the Danko 10/12 model, let's look at the structural features of the boiler, as well as what needs to be taken into account when installing it, regardless of the fact that the installation will be carried out by specialists.

What does the Danko 10/12 floor boiler consist of?

Its main parts are:

- heat exchanger;

- burner;

- gas automation;

- decorative cover.

The automation of the system is needed to supply fuel to the main and ignition burner, it also regulates the water temperature. In addition, the gas supply can be urgently turned off in such cases:

- if the ignition burner goes out;

- if the gas pressure is below the minimum;

- if there is no draft in the chimney;

- if the coolant has warmed up over 90 degrees.

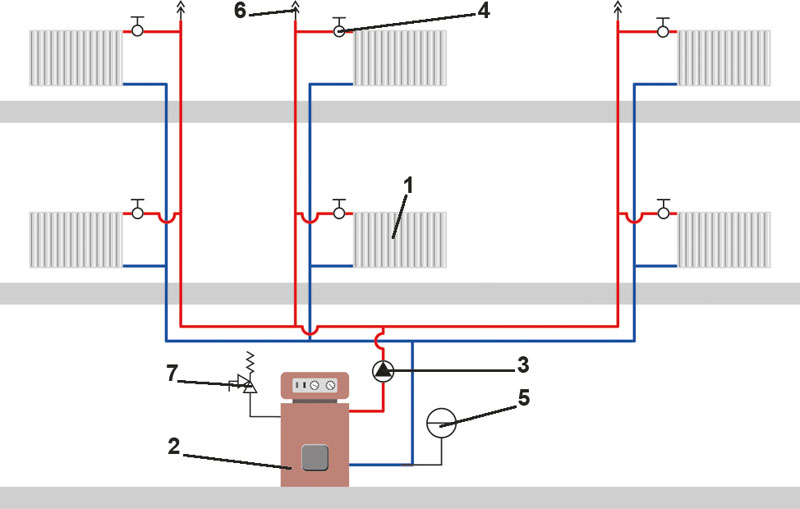

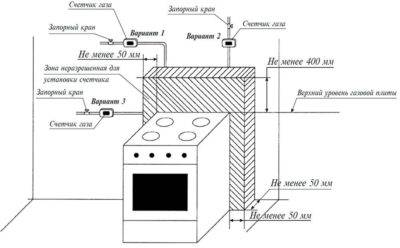

Mounting Features

When installing Danko equipment, the following must be considered:

- the power of the equipment must correspond to the heating project;

- the unit is installed on a refractory horizontal base at a distance of at least 25 cm from non-combustible walls;

- if the walls are non-combustible, the device can be installed with hardly combustible walls, provided that they are insulated with steel sheets;

- the passage in front of the boiler must be at least a meter wide;

- so that the water circulates better, the boiler is placed below the level of the heating devices;

- the expansion tank is installed at the highest point of the system;

- the chimney in the room must be at least 5 meters in length from the level of the main burner;

- if the chimney is placed along the outer wall, its outer part is insulated along the entire height;

- the section of the chimney channel must be greater than the section of the chimney pipe;

- the junction of the boiler with the chimney must be sealed with clay or cement mortar.

Gas boilers "Danko"

In this category of heating equipment there are units in different designs.

Wall-mounted gas boilers Danko 23 ZKE and Danko 23 VKE (with open and closed combustion chamber).

Gas wall-mounted boiler "Danko 23 ZKE"

They are highly reliable and consume little electricity. The HoneyWell control board provides a set of functions familiar to this type of equipment:

- electronic ignition,

- monitors the presence of a flame on the burner (a Worgas burner is installed) and controls its power (from 30% to 100%),

- conducts automatic testing of equipment and, in the presence of malfunctions, displays the results on the scoreboard;

- DHW priority function (capacity from 2 liters/sec to 11 liters/sec when heated to 30 o C),

- pump anti-blocking program (when the equipment is not working for 24 hours, it turns on the pump for a while),

- frost protection.

Gas wall-mounted boilers "Danko" in terms of their technical characteristics are not inferior to the best world examples of such equipment. They only have much lower prices.

Double-circuit floor-standing boilers for systems with forced circulation (with a pump) R_vneterm-20 D (power 20 kW) and up to R_vneterm-40 D (power 40 kW).

Floor standing gas boilers for systems with forced circulation

The main (primary) heat exchanger is made of stainless steel 3mm thick. To heat water for domestic hot water, a Zilmet stainless steel plate heat exchanger is used. The presence of draft, the temperature of the coolant (protection against boiling), the smooth shutdown of the burner, the presence of a flame on the burner are controlled. There is a DHW priority mode.

Coppers gas floor steel Danko from 8 kW to 24 kW. Single-circuit and double-circuit, with vertical and horizontal flue. The peculiarity of this model is that it operates at a very low gas pressure - from 635 Pa, has a steel welded tubular-type heat exchanger.

Boilers gas steel type "Rivneterm" increased power from 32 kW to 96 kW. Equipped with modern gas automatics, it is possible to connect programmers from which the temperature regime is set for a day or a week. Micro-torch burners have been installed to ensure economical operation. They can work in cascade (without modifications). There are modifications with forced removal of combustion products (marking R_vneterm-40, R_vneterm-60, etc.) or weather-dependent automation (marking R_vneterm-40-2, R_vneterm-60-2, etc.).

Steel gas boilers "OK" with power from 10 kW to 18 kW. They can be used in circuits with forced or natural circulation (non-volatile). In double-circuit models, for the preparation of hot water, a copper heat exchanger is used, mounted in the main tubular one. The flue can be vertical or horizontal.

Non-volatile parapet boilers Danko with a power of 7 kW -15 kW single-circuit and double-circuit.

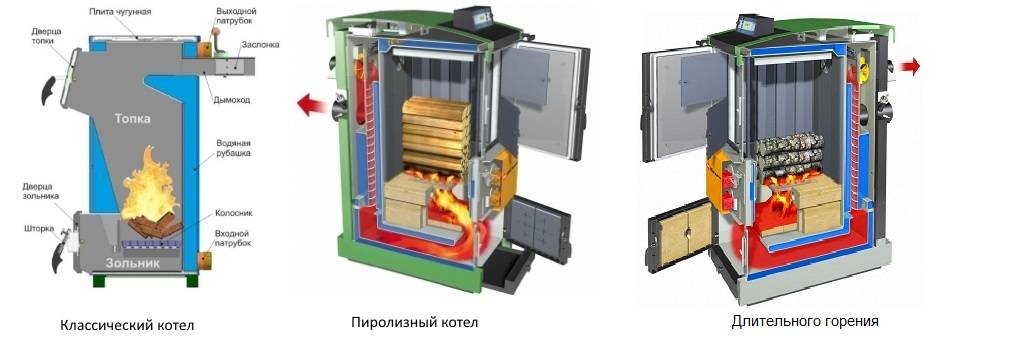

Technical characteristics of parapet gas boilers "Danko"

They have a sealed combustion chamber, so they do not need to be connected to a chimney. Connection pipes for the heating and gas circuits are located on both sides, which makes installation easy and fast. The heat exchanger of a new design is made of 3 mm steel, the ignition is piezoelectric, the burner is microtorch, modulated. Automatic Sit or HoneyWell. On the front panel there are adjustment knobs and controls (pressure gauge and signal lamps).

Cast iron floor gas boilers "Danko". The power of the units is from 16 kW to 50 kW. This model uses cast-iron heat exchangers from the Czech company Viadrus, which are highly efficient due to the high degree of finning.These heat exchangers are very reliable - their service life is up to 25 years. The units are equipped with non-volatile automation of three companies: Polish Kare (LK marking), American HoneyWell (LH marking) and Italian Sit (LS marking). Boilers work in systems of any type: open and closed. with natural or forced circulation.

Excellent equipment, good features, more than reasonable prices. It really pleases. And all gas equipment works reliably. This is guaranteed by the design features and the materials used in the production.

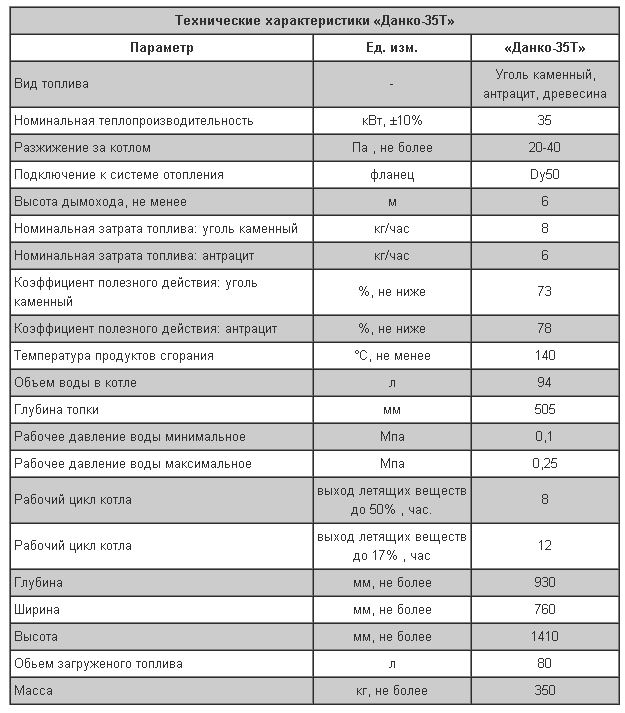

Gas boilers are available in various models and types.

- Double-walled.

- Double floor.

- Parapet with heated water.

- Floor cast iron.

Cast iron boilers have the longest service life (up to 25 years). Suspended units are lighter and more compact than floor units, but the former have more power, and therefore they have a correspondingly larger area for heating rooms. The heat exchanger is produced using a German-made flux-cored welded wire. To prevent heat leakage, the heat exchanger is insulated with a thickness of 50 mm. This increases the heat transfer and efficiency of the gas boiler.

The burners of the devices are made of smoke tubes, into which turbulators are screwed, where the complete combustion of the fuel takes place. The rooms warm up quickly due to the increase in the number of fire tubes in the heat exchanger. An electronic board built into the equipment is responsible for the operation of the heating and water supply system. With the help of the board, diagnostics of interruptions in the operation of the boiler and adjustment of the flame in the burners are carried out.

The thermostat allows you to reduce the consumption of gas fuel to a minimum.A temperature sensor automatically regulates the temperature of the equipment. The copper coil built into the heat exchanger is designed for heating and hot water supply.

The Danko wall-mounted double-circuit boiler has small dimensions and light weight, electronic ignition, protection from cold winter temperatures. It combines two functionalities, such as space heating and water heating for production needs. The unit uses a European, plate, speed heat exchanger made of stainless steel brand Zilmet. Boilers with an open combustion chamber create pressure in the heat and water supply systems of 0.3 MPa, and with a closed combustion chamber - 0.6 MPa. With a gas flow rate of 2.76 cubic meters and an efficiency of 91.2%, the boiler has a capacity of 23.3 kW and heats rooms up to 210 square meters.

The floor double-circuit boiler Danko is made of high-quality steel, equipped with a chimney. To ensure the operation of the system in case of insufficient gas pressure, or in case of extinction of the fire, it is equipped with an automatic water pump. The heat exchanger itself consists of steel pipes with a wall thickness of 3 mm. The device is equipped with a security system and settings, European brands: Italian company Sit, English - Honeywell, and Polish - Kape. Low flare burners are made of the highest quality steel and ensure complete combustion of the gas. With a power of 20-40 kW, the boiler is able to heat an area from 180 to 360 square meters with a gas flow rate of 2.4-4.5 square meters. meters per hour. With a useful 90% work coefficient, it creates a pressure of 0.3 MPa for heat supply, and 0.6 MPa for water heating.

The Danko parapet heating boiler with water heating is equipped with a sealed combustion chamber and is produced without a chimney. They have two types of connection on the right and on the left side.Such boilers are convenient in rooms where there is no central heating. When they are connected, it is not required to obtain permission to install the boiler, as well as to install an expensive chimney. The device has an independent system of a coaxial chimney and comes complete with a boiler. The consumed volume of gas is 0.8 - 1.8 cubic meters per hour with a power of 7 - 15.5 kW, and area heating from 60 to 140 square meters, respectively. The maximum pressure of hot water in heating is 0.6 MPa. With an efficiency factor of 92%, the heat supply pressure ranges from 0.15 to 0.2 MPa.

What are the problems?

The simplicity of the Danko design allows its owners to independently carry out minor repairs. One of the most common problems is blowing out the burner. This is especially true in strong winds. Usually no malfunction is found, the wind is the culprit of the problem, but it is better to check such points:

- Is there a non-return valve installed in the chimney? If not, then there will be no reverse thrust, which is why attenuation occurs.

- If the chimney is installed incorrectly, it is clogged with soot and other products of combustion - you need to clean it.

It happens that extraneous noise is heard before attenuation or increased fuel consumption is observed - this may indicate a controller failure. The task is to repair or replace the spare part.

Another common problem is the fading of the igniter. It goes out due to the operation of the thermostat, which shuts off the gas supply if the burner does not heat up to the desired temperature.

Common Problems

There are several typical problems with gas boilers that you can deal with on your own.

These include:

- the smell of carbon monoxide;

- malfunctions in the operation of the combustion sensor;

- overheating of the unit;

- breakdown of the blower fan;

- difficulties with the chimney;

- periodic shutdown of the structure.

Before the arrival of the master, you can protect yourself by eliminating these problems. In some cases, in the room where the boiler is located, you can feel a persistent smell of gas. This indicates that a valve has become faulty in the system.

After that, a qualified craftsman is invited, since it is very difficult to identify the place of a gas leak on your own.

It is possible to repair the combustion sensor when repairing double-circuit boilers with your own hands. If it breaks or malfunctions in the gas supply pipe, the unit is turned off. It is necessary to close all the valves and give the structure time to cool completely. The room is ventilated, then returned to it and checked for the presence of released gas. If there is draft, then you need to reconnect the boiler. With a persistent smell of gas, its leakage, you need to call a specialist.

The most common problem with modern devices is overheating. The main cause of the problem is the clogging of the heat exchanger or a malfunction of the automation system. Stainless steel or copper parts are usually installed in the boiler, they can be easily cleaned at home. In the instructions for the unit, manufacturers indicate the frequency of cleaning the heat exchanger from soot deposits and other combustion products. For example, when repairing the Immergaz boiler with your own hands, the part is removed and cleaned with a metal brush. Copper parts are cleaned with a sponge for washing dishes.

Boost fans, or rather, their bearings, can become problem areas.If the part has stopped rotating as before, then this problem must be fixed as soon as possible. The back of the fan is removed, the stator is removed and the bearings are lubricated. To do this, use machine oil or a special carbon composition with heat-resistant components.

Sometimes the main reason for the breakdown of the unit is the clogging of the chimney. It must be removed and thoroughly cleaned of soot. The chimney is installed back, which will not only restore the previous efficiency of the boiler, but also increase its efficiency. When the boiler is turned off on its own, the main problem is the pollution of the pipe. It must be removed, rinsed under running water and cleaned with a cotton swab. The branch pipe is returned to its place and the boiler is turned on. If it turns off again, then the problem is a broken flame sensor. For its repair call a specialist.

Possible malfunctions of the boiler

From the frequent questions of users regarding failures in the operation of this Ukrainian equipment, the following can be distinguished:

- Why is the Danko gas boiler blowing out?

- Why does the unit shut down?

- What causes high gas consumption?

If we summarize the practical experience of the owners, take into account the opinions of experts, then we can compile a small list of possible causes of these problems:

- Failures of the gas line (gas is supplied unevenly).

- Problems with the chimney (most likely, soot and soot have accumulated on the inner walls, which prevent the high-quality removal of combustion products).

- Possible damage to any structural elements. For example, failure of the ventilation device, which does not supply air flow to the combustion chamber.

- Electrical supply problems that directly affect the operation of boiler equipment. In other words, interruptions in the functioning of the circulation pump or the blower fan, which affects the poor-quality heating of the room.

- There is no valve in the smoke structure, this does not allow the reverse draft to work normally, as a result, the system is blown out and attenuated.

Experts recommend thoroughly cleaning the chimney from deposits.

How to light a Danko gas boiler?

The boiler is ignited in a semi-automatic way in stages:

- The mechanical regulator is brought to the extreme position.

- Press the wheel down for 5-6 seconds. The gas is fed into the burner.

- Ignition occurs with the use of a piezoelectric element.

- After ignition of the ignition burner, continue to hold the regulator in the lower position for about 5-10 seconds. In the case when, after lowering the wheel, the igniter dies out, the procedure is started anew. The burner has a sensor that records the temperature on the body. In case of insufficient heating of the burner device, the gas supply valve is not opened.

Gas boilers "Danko"

In this category of heating equipment there are units in different designs.

Wall-mounted gas boilers Danko 23 ZKE and Danko 23 VKE (with open and closed combustion chamber).

Gas wall-mounted boiler "Danko 23 ZKE"

They are highly reliable and consume little electricity. The HoneyWell control board provides a set of functions familiar to this type of equipment:

- electronic ignition,

- monitors the presence of a flame on the burner (a Worgas burner is installed) and controls its power (from 30% to 100%),

- conducts automatic testing of equipment and, in the presence of malfunctions, displays the results on the scoreboard;

- DHW priority function (capacity from 2 liters/sec to 11 liters/sec when heated to 30oC),

- pump anti-blocking program (when the equipment is not working for 24 hours, it turns on the pump for a while),

- frost protection.

Gas wall-mounted boilers "Danko" in terms of their technical characteristics are not inferior to the best world examples of such equipment. They only have much lower prices.

Double-circuit floor-standing boilers for systems with forced circulation (with a pump) R_vneterm-20 D (power 20 kW) and up to R_vneterm-40 D (power 40 kW).

Floor standing gas boilers for systems with forced circulation

The main (primary) heat exchanger is made of stainless steel 3mm thick. To heat water for domestic hot water, a Zilmet stainless steel plate heat exchanger is used. The presence of draft, the temperature of the coolant (protection against boiling), the smooth shutdown of the burner, the presence of a flame on the burner are controlled. There is a DHW priority mode.

Coppers gas floor steel Danko from 8 kW to 24 kW. Single-circuit and double-circuit, with vertical and horizontal flue. The peculiarity of this model is that it operates at a very low gas pressure - from 635 Pa, has a steel welded tubular-type heat exchanger.

Boilers gas steel type "Rivneterm" increased power from 32 kW to 96 kW. Equipped with modern gas automatics, it is possible to connect programmers from which the temperature regime is set for a day or a week. Micro-torch burners have been installed to ensure economical operation. They can work in cascade (without modifications).There are modifications with forced removal of combustion products (marking R_vneterm-40, R_vneterm-60, etc.) or weather-dependent automation (marking R_vneterm-40-2, R_vneterm-60-2, etc.).

Steel gas boilers "OK" with power from 10 kW to 18 kW. They can be used in circuits with forced or natural circulation (non-volatile). In double-circuit models, for the preparation of hot water, a copper heat exchanger is used, mounted in the main tubular one. The flue can be vertical or horizontal.

Non-volatile parapet boilers Danko with a power of 7 kW -15 kW single-circuit and double-circuit.

Technical characteristics of parapet gas boilers "Danko"

They have a sealed combustion chamber, so they do not need to be connected to a chimney. Connection pipes for the heating and gas circuits are located on both sides, which makes installation easy and fast. The heat exchanger of a new design is made of 3 mm steel, the ignition is piezoelectric, the burner is microtorch, modulated. Automatic Sit or HoneyWell. On the front panel there are adjustment knobs and controls (pressure gauge and signal lamps).

Cast iron floor gas boilers "Danko". The power of the units is from 16 kW to 50 kW. This model uses cast-iron heat exchangers from the Czech company Viadrus, which are highly efficient due to the high degree of finning. These heat exchangers are very reliable - their service life is up to 25 years. The units are equipped with non-volatile automation of three companies: Polish Kare (LK marking), American HoneyWell (LH marking) and Italian Sit (LS marking). Boilers work in systems of any type: open and closed, with natural or forced circulation.

Excellent equipment, good features, more than reasonable prices. It really pleases. And all gas equipment works reliably. This is guaranteed by the design features and the materials used in the production.

Before starting the heating equipment

Important! Before installing the boiler equipment, you must carefully study the instructions that come with it. By operating the boiler correctly, it will be possible to increase its service life, to receive heat safely

Starting the boiler is a responsible event for which several operations must be performed:

By operating the boiler correctly, it will be possible to increase its service life, to receive heat safely. Starting the boiler is a responsible event for which several operations must be performed:

- It is necessary to fill the heating system with coolant and check the gas connections for leaks using a special device or a soap emulsion

- Check the chimney for draft, and also make sure that there is no gas content in the room where the equipment is installed

- Be sure to ventilate the room by first shutting off the gas cock

Before installing the boiler in a previously operated system, flushing of pipes and radiators will be required. Filling the system and feeding it with polluted water or water with rust, sand is highly undesirable! Otherwise, you risk getting a noisy boiler, a high probability of damage to the heat exchanger. The correct solution is to monitor the operating equipment in an appropriate way, as indicated in the instructions.

How to choose?

Before proceeding with the choice of model, it is necessary to determine the functional purpose of the boiler and its power. Double-circuit units should be chosen if it is planned to equip not only heating, but also hot water supply

Particular attention should be paid to the heat transfer coefficient of the device, which is especially important when calculating the power of the heating system in regions with a cold climate. Convection models have the highest efficiency. This type of construction is presented in many Danko outdoor appliances and is recommended for use in the northern regions.

This type of construction is presented in many Danko outdoor appliances and is recommended for use in the northern regions.

Judging by the reviews of the owners, it was convection boilers that showed their best side when heating a private house in harsh conditions. In addition, outdoor appliances are non-volatile. In the event of a power outage, they will not leave the house without heat. The most purchased model among floor-standing devices is the Danko 18VS model. The boiler has dimensions of 41x85x49.7 cm, weighs 81 kg and is designed for space heating up to 170 m².

For heating country houses or when arranging a heating system in southern and temperate latitudes, wall and parapet appliances are quite suitable. These devices are able to effectively warm a medium-sized room and provide residents with uninterrupted hot water supply. The disadvantage of such devices is the presence of electronic ignition, which does not allow the boiler to be ignited in the absence of electricity.

Many models are equipped with frost protection, which is important when operating the device in conditions of temperature extremes in the absence of owners, when it is not possible to force the device to turn on or off

When choosing equipment, you should pay attention to fuel consumption. Single-circuit devices consume significantly less gas than dual-circuit models

For example, a floor-standing single-circuit unit of the Danko 8 brand, having a heat transfer coefficient of 92% and capable of effectively heating a room of 70 square meters, consumes only 0.9 cubic meters of gas per hour, while some double-circuit boilers consume 2.5 and more than cubic meters of fuel.

Assortment of gas boilers Danko

Danko's product range includes:

- parapet gas boiler;

- wall;

- with circulation pump;

- cast iron;

- steel.

The special characteristics of each type of aggregates lie in some important aspects.

Features of parapet devices of this brand:

- They have the ability to connect a hot water circuit.

- In the presence of a closed combustion chamber, so the boilers can be used to heat the apartment.

- The gas enters through microtorch burners, and this makes the system performance significantly higher.

- The material of the heat exchanger is steel (3 mm thick).

- The maximum efficiency is 90%.

- Possibility to heat areas up to 140 m².

- This type of equipment is represented by the following models: parapet boiler Danko 7 U, 7VU, 10 U, 10 VU, 12.5 U, 12.5 VU, 15.5 U, 15.5 VU.

You can learn more about the features of the device of parapet gas boilers here.

Wall devices of this brand are distinguished by:

- Modification 23VKE with a closed-type combustion chamber.

- Modification 233KE with an open combustion chamber.

- Built-in automation units that control the electric ignition and the level of the flame of the burner.

- The Danko wall-mounted gas boiler has a steel heat exchanger for supplying warm liquid.

- Heating circuit with copper heat exchanger.

- Equipment efficiency 90%.

- Space heating up to 210 m².

Models installed on the floor are characterized by the following parameters:

- These are devices with two circuits (for heating and hot water).

- They have high-quality steel heat exchangers (3 mm thick).

- With circulation pump.

- The Danko outdoor gas boiler allows the owner to sleep peacefully, as the heater has a security system that controls the flame, draft level and liquid boiling point.

Information about non-volatile wall and floor gas boilers can be found at this link

Cast iron gas devices are distinguished by:

- Scheme with one circuit (heating only).

- Open combustion chamber.

- Cast iron heat exchanger.

- Production of automation in foreign countries: Italy, Poland, America.

- Efficiency 90%.

The line of steel boilers of the Ukrainian manufacturer includes 22 models of devices, which are characterized by the following parameters:

- chimneys can be both horizontal and vertical (it all depends on the model);

- built-in automation for safety;

- ability to control the system.

The best and most famous models: features and prices

8C

The boiler has a high efficiency of 92% and a particularly low gas consumption - 0.9 cubic meters. m/hour. Unlike other models, it is equipped with a vertical flue, which prevents the burner from being blown out by the wind. From protection only prevention of overheating and gas control.

The average cost is 18,000 rubles.

12VSR

Double-circuit floor boiler with a capacity of 12 kW, designed for heating a house up to 120-130 m2. This is one of the best Danko boilers for heating a private house.

It is distinguished by the presence of a second circuit, that is, water heating (B in the name), the productivity of hot water at a temperature of 35 ° C is 4.93 l / min. The volume of hot water supply is sufficient for a single consumption, with more intensive use (for example, bathing and a tap in the kitchen at the same time), the capacity may not be enough. It has a steel heat exchanger, is able to work not only on natural, but also on liquefied bottled gas (P in the title).

Efficiency is 91.5%, and natural gas consumption is 1 cubic meters. m/hour. The boiler is non-volatile, the gas outlet is arranged vertically, which greatly reduces the risk of blowing out and subsequent attenuation. The disadvantages are also the loud sound of ignition, the lack of auto-ignition and flame modulation, however, for such a price on dual-circuit models, these functions are rare.

Cost - 24,000 rubles.

Overview of gas boilers Siberia One of the most reliable among domestic boilers

12.5US

An improved parapet boiler with a power of 12.5 kW is designed for installation not only in private houses, but also in an apartment.

Parapet boiler plants have a closed (hermetic) combustion chamber and do not require connection to a traditional chimney. They can be installed in any room where there is at least one outer wall, through which a side coaxial chimney (pipe in a pipe) is subsequently led out. The apartment is installed in the window sill space, it requires only a gas pipeline, since it is non-volatile.

Gas consumption 1.4 cu.m/h is optimal for this power and price category, although it is higher than the classic convection models 12VR or 12R. One of the few truly quiet Danko boilers. In addition to the dubious build quality and narrow functionality, no shortcomings were found during the practice of use.

Cost - 24 thousand rubles.

Is it worth considering parapet gas boilers for heating a private house

16hp

Cast iron single-circuit boiler with a capacity of 16 kW, designed for heating a house up to 150 square meters. m. The cast-iron heat exchanger is usually used in more expensive modern models and has a much longer service life - over 25 years. It takes longer to heat up, but it also cools down much longer, continuing to give off heat even after the burner is turned off.

Gas consumption is not outstanding, but the optimal 1.9 cubic meters. m / h, and efficiency - 90%. The disadvantages are the absence of any automatic protection systems and the significant weight of the heating unit - 97 kg. The cost of the boiler is on average 34-37 thousand rubles, which is still significantly lower than foreign analogues, the prices for which start from 45-49 thousand rubles.