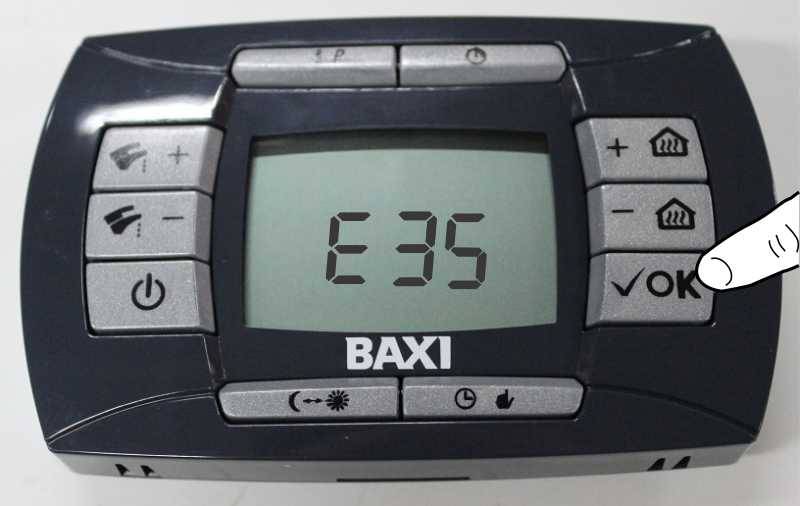

- Error e35 on the baxi boiler how to fix

- What to check

- Presence of condensate

- Solution:

- Mains parameters

- grounding

- gas valve

- Electronic board

- Check more

- Supply voltage

- Burner status

- Chimney

- Electronic board

- A series of the most popular Baksi boilers

- Baksi mine 24 boiler does not turn on

- elimination

- E 00

- E 01

- E 03

- E 05 - 06

- E 10

- E 25

- E 35

- E 98 - 99

- Error e01

- Characteristics of Baksi boilers

- Important nuances

- Advantages and disadvantages

- Varieties of models

- Error decoding

- First steps

Error e35 on the baxi boiler how to fix

Restart boiler. On the Baxi panel, the Reset (R) button: after pressing and holding for 2 seconds, the false error e35 will disappear. If the code reappears, the following procedure is recommended.

Restart the boiler boiler Baxi

What to check

Presence of condensate

Dampness is the cause of the e35 gas boiler error. If Baxi is in an unheated room, after a long downtime, the appearance of the 35th code is expected: you need to evaluate the condition of the ionization sensor. From it, in conditions of high humidity, a false signal of the presence of a flame is received even when the valve on the pipe is closed. Located in the chamber, it serves to fix the current between the metal of the boiler burner and the sensor electrode; in some models, Baxi is combined with an ignition device.When the unit is not working, in damp conditions, it gives a spurious signal to the board, which generates an e35 error.

Boiler ionization sensor Baxi

Solution:

-

dry the combustion chamber with a stream of warm air (building hair dryer, air heater or the like);

-

if the Baksi boiler is installed in the kitchen, organize an effective hood. The reason for the e35 error is high humidity.

Mains parameters

Deviation from the value specified in the instructions for Baxi (~ 230V) initiates malfunctions in the electronics, causing the boiler to stop with an error.

Tips. If a power line is located near the object, another source of powerful EM radiation, the error of the Baksi e35 boiler is not uncommon. Under such conditions, the operation algorithm of the electronic board is violated, a false fault code is generated. Incorrect functioning of the external stabilizer also causes the 35th code.

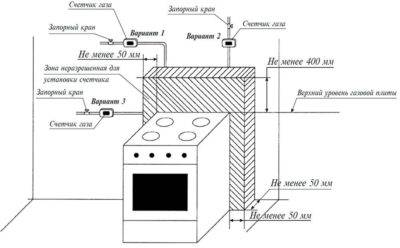

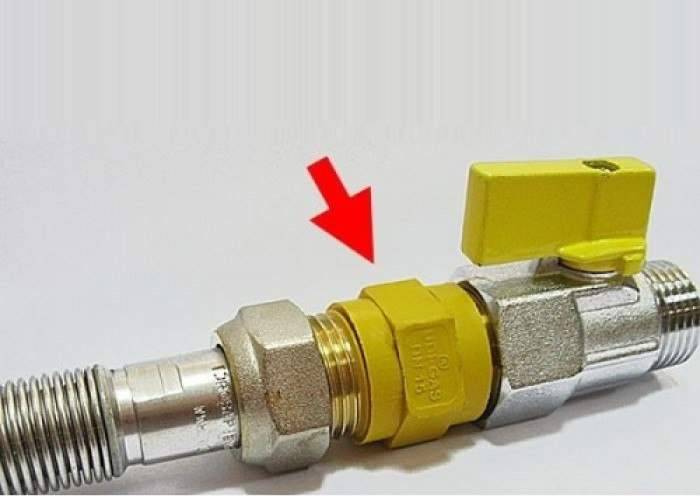

Recommendation. One way to get rid of the e35 error is to put a cut-off fitting (dielectric coupling) on the gas pipe between the boiler and the tap. It will prevent the influence of stray currents, pickups on Baxi's electronics. Power lines, tram lines, electrified railway tracks and the like in case of random breakdowns become sources of interference. Electricity "dumped" into the ground, passing to the metal of the gas main, affects the "brain" of the boiler, causing an e35 error.

dielectric coupling one

Connecting the Dialectic Clutch

Wiring diagram for a dielectric coupling

grounding

This is faced by users involved in piping the Baksi boiler on their own, and owners of apartments in high-rise buildings. The connection must be checked during the initial start-up of the unit.It is not for nothing that the violation of the grounding procedure, its non-compliance with the requirements of the PUE is the basis for removing the heating installation from the factory warranty.

Grounding the baxi boiler

This is specifically stipulated in the manufacturer's instructions, which, unfortunately, not everyone carefully studies. Poor connection of the Baxi boiler to the circuit causes malfunctions in the control board, emergency stop and error e35 on the display. At home, reliability, grounding efficiency is easy to determine using an indicator screwdriver by the absence of glow at the moment the probe touches metal parts, assemblies, the body of the Baksi boiler.

gas valve

Its leakage is the cause of the e35 error. If the solenoid valves, after removing the opening command, do not completely block the gas path, the Baksi boiler ionization sensor detects the burner flame. Its repair is a separate issue, but it is more rational to replace it: the defect is associated with the development of a resource.

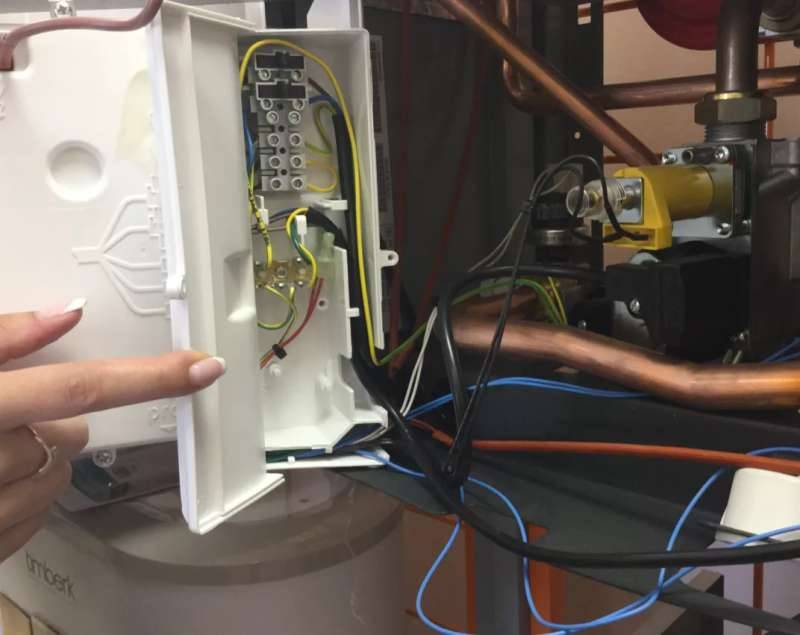

Electronic board

If error e35 is present, after the measures taken, this node must be checked. Baksi boilers (depending on the year of manufacture, series) are equipped with different boards. With identical functioning, they differ in their response to external factors (power supply, interference, grounding). Honeywell boards are the most "sensitive" to dampness.

How to proceed

Rinse the surface. To remove dust, which becomes a conductive layer when moistened, isopropyl alcohol and a brush (with medium-hard bristles) are used, in laboratory conditions an ultrasonic bath is used. After removing the contamination of the electronic board and drying it, the e35 error will disappear.

Put a new node in the boiler. On this issue, it is worth consulting with a professional - not all boards are interchangeable.Product specification (numbers, letters) is indicated on the panel

When ordering (selecting) an electronic assembly, this code must be taken into account - there will be no error. The owners of Baxi mainfour should be aware that these boilers have boards of 3 options: one differs in circuitry and is not interchangeable.

Check more

Supply voltage

Network failures are the main cause of heating unit errors. Using a multimeter, it is easy to measure the voltage supplied to the Baksi boiler. The manufacturer has set: 230V/1f. If the value deviates by ±10%, an emergency stop of the unit is possible.

Burner status

Often the e04 error is caused by untimely, unprofessional boiler maintenance. The Baksi burner needs regular cleaning from dust and soot that clogs the nozzle holes. The accumulated dirt prevents the normal passage of gas into the chamber, hence the weak flame that causes the e04 error. Toothbrush, vacuum cleaner, 10 minutes of operation - the fault code will disappear after starting the Baksi boiler.

Chimney

Error e04 may be due to a violation of thrust when combustion products enter the chamber

It happens when weather conditions change, if during the installation of the boiler the wind rose at the point where the pipe exits the building is not taken into account. Other errors indicate malfunctions of the fan (for turbocharged Baksi boiler models)

The nuance is that they are formed on the basis of signals from the corresponding sensors, characterized by a response threshold. Therefore, the code e04 can be caused by a decrease in thrust, which negatively affects the combustion process.

Electronic board

An independent search for the cause of the e04 error is unlikely to give a positive result.If suspicion falls on the control module of the Baksi boiler, you need to contact the service workshop. Diagnostics is carried out on the stand, using special equipment, based on the manufacturer's guidelines. An ordinary user, not having diagrams, tables, devices at hand, is not able to accurately determine the faulty element of the board.

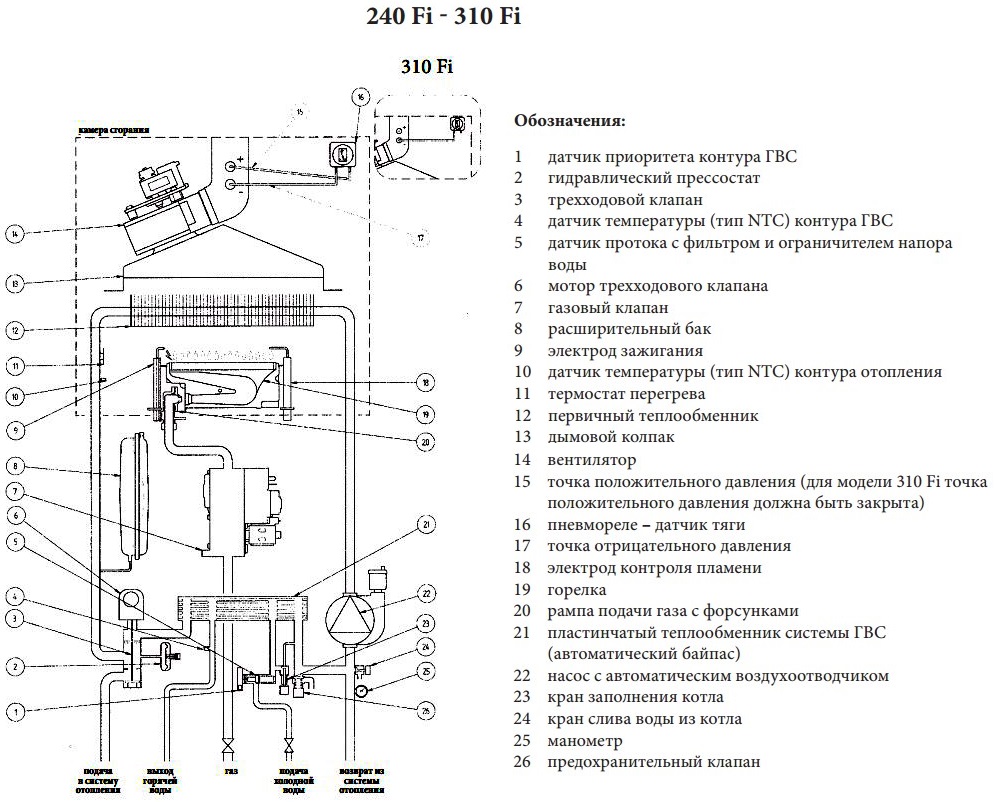

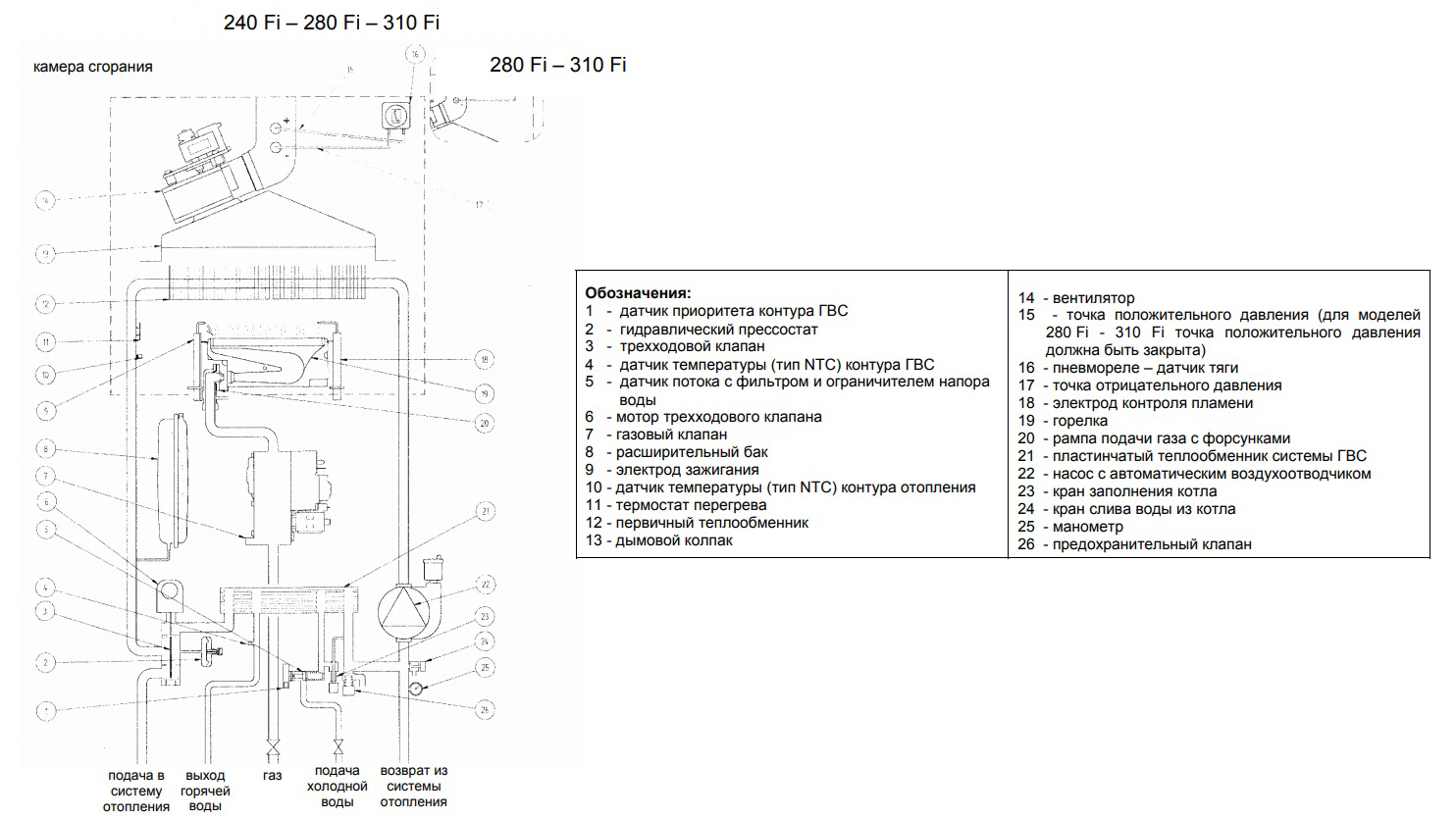

A series of the most popular Baksi boilers

In Russia, wall-mounted gas boilers are sold in the following popular series: Prime, Luna, Eco, Nuvola, Baxi Main.

Prime are condensing boilers with a capacity of 4.5-33 kW and an efficiency of 110 percent with a biometric heat exchanger. Such a heat exchanger can save a year up to 35 percent gas. The combustion chamber is made of composite material, it perfectly suppresses noise, so the boiler works almost silently. A typical Baxi wall-mounted gas condensing boiler has a self-diagnosis system, as well as an automatic system that controls the operation of the boiler depending on the weather.

Luna-3 is also a Baksi wall-mounted condensing gas boiler with a power of up to 65 kW and an efficiency of up to 110 percent. Designed for outdoor installation, able to operate at t - 15°C. More than 10 boilers can be connected in cascade. They have a self-diagnosis system. Two temperature settings. Although understandable in use, the Baksi Luna 3 gas boiler instructions will still tell you under what conditions they work optimally and will have good performance. The control system is designed for the convenience of the consumer. It informs about the state of operation, sets the necessary parameters, diagnoses the status of all nodes

Eco - boilers with a capacity of up to 24 kW and an efficiency of up to 92.9 percent.The main plus is that they clearly work with pressure surges in the line. Even inlet pressure decreases, it will not affect the operation of the boiler. This model can work on natural gas and liquefied. Very environmentally friendly, with minimal emissions of harmful substances into the atmosphere. You can hook up a boiler, a room thermostat and an outside temperature sensor.

Nuvola - boilers of the 3rd generation with a capacity of up to 32 kW and up to 93.2 percent efficiency. Such a gas double-circuit wall-mounted boiler Baxi is equipped with a large stainless steel boiler with a capacity of up to 60 liters. This is practically a volumetric water heater. Able to work if the pressure in the pipeline decreases. There is a temperature sensor in the house and a portable digital panel that controls the operation of the boiler from anywhere.

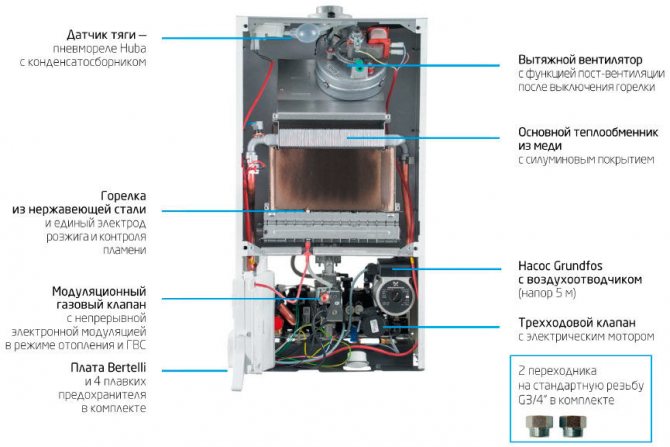

Baxi Main Four 24 is the 5th generation of gas boilers. The boiler embodies all the most advanced, created to anticipate the desires of customers. Therefore, we dwell on it in more detail. Power up to 24 kW and up to 92.9 percent efficiency. The state-of-the-art draft control mechanism allows the boiler to be operated in the most difficult conditions. The modern gas boiler Baxi MAIN Four 24 is equipped with a copper bithermic heat exchanger; it works on both circuits in turn. If the consumer turns on hot water, the boiler switches to domestic water heating mode. The automatic bypass is responsible for switching to the hot water supply mode. Energy-saving circular pump - removes air in automatically.

The boilers have electronic ignition, working draft sensors in the chimney, temperature control.

The liquid crystal display shows all operating parameters. Self diagnostic system. Protection against scale, freezing and overheating.In addition, an expansion membrane tank for 6 liters, an overpressure relief valve.

The Baksi 24 gas boiler combines everything you need. Smooth modulation of the burner, automatic maintenance of the temperature in the radiators, the ability to connect a room thermostat and outdoor temperature sensor allow the boiler to choose its own mode of operation. There is even a mode of "warm floors". If you decide to buy such a double-circuit gas boiler Baksi, the user manual is a must. It is necessary to check that it is included in the kit and in Russian.

Baksi mine 24 boiler does not turn on

Since modern boilers are equipped with electronics, they simply will not function without electricity. Moreover, some models are very demanding on the quality of the power supply. Therefore, if the boiler has stopped, first of all it is necessary to check whether it is connected to the network. There can be several malfunctions of the Baksi boiler due to the power supply: one of the household members accidentally pulled the plug, for some reason the machine turned off, and there is no power in the boiler connection socket. In our practice, there was a situation when substations changed the connection scheme (changed the phase and zero), respectively, we have a stop due to a phasing error.

Potential on the metal parts of the boiler can also cause malfunctions in the electrical components (the body and metal parts must be properly grounded).

If, for example, there was a power surge in the network, the fuses could blow, the health of which can be assessed visually and, if necessary, replaced independently, but only with the fuses that come with the boiler (usually they can be found on the lid). If the fuses are intact, you also need to inspect the details of the control unit on subject of damage.

Damage to the electronic board can only be repaired by a qualified technician.

In other cases, most likely the user will receive a code on the display or other indicators of the boiler, by which it will be possible to understand in which particular boiler node the problem has occurred.

elimination

Consider possible problems and what needs to be done to fix them:

E 00

This error indicates a problem with the control board. The solution of the issue is possible only by the employees of the service center, since there can be many reasons and possible consequences of the intervention.

E 01

No ignition (no flame). The reason may be both the lack of gas in the line, and the failure of the ignition system.

The solution to the issue is phased - first checking the presence of gas, then examining the condition of the gas equipment, checking the ignition system, etc. This error occurs most often, since there can be quite a few reasons for its occurrence.

An independent solution to the issue is not recommended, it is better to invite the master.

E 03

The cause can equally be a clogged chimney and a lack of fan contacts with the control board.

It is recommended to inspect both positions and perform work both with the chimney and with the contact group of the fan (pressure switch).

E 05 - 06

A failure in the operation of these sensors indicates the failure of either the elements themselves, or a violation of contact with the control board.

First of all, it is necessary to check the temperature of the RH and DHW in order to determine whether the readings of the sensors are generally correct.

Then you should restore contacts with the control board. If a positive result cannot be achieved, the sensors need to be replaced.

E 10

A drop in water pressure indicates a leak. Needs to be examined heating circuit and check boiler drain valve.

If no problems are found in them, check the sensor contacts. If necessary, change it.

E 25

A sharp increase in the RH temperature indicates the absence of circulation. The most likely reason for this is the airing of the elements of the heating circuit. The solution to the problem will be to bleed air from the system. If this does not help, the sensor must be replaced.

E 35

The signal about the appearance of a parasitic flame indicates either a short circuit of the sensor contacts due to the appearance of water droplets (condensate) on the board, breakdown through a layer of soot, or other similar situations.

The solution to the problem will be cleaning the board, installing high-quality grounding and additional insulation on the contact group of the sensor.

E 98 - 99

This error indicates the failure of the control board for unknown reasons. The solution of the issue must be entrusted to a specialist; self-correction of the situation is unacceptable.

Error e01

Malfunction e01 of Baksi boilers indicates a malfunction in the ignition system. This error is generated by the Baxi sensor, which controls the flame. The error code can be reset by hand, and for this you need to hold down the "R" button. After 3-5 seconds after pressing and holding this button, the boiler should start. If the flame did not appear and error e01 is displayed again on the screen, then only one thing will help in this situation - calling a boiler repairman. An error with this code can be caused by several reasons. This may be a failure of the ignition system, as well as incorrect operation of the electronic control unit.There have also been cases that this malfunction occurred due to an incorrectly adjusted gas valve. This error can also be caused by:

- weak draft in the chimney;

- weak gas pressure.

Let's take a closer look at the causes errors e01 on boilers Baxi, and ways to fix it. This error is sometimes very difficult to correct, since many factors can cause it. This malfunction is associated with the difficulty of ignition. On some models of boilers from this manufacturer, there is also a flame sensor in the electrode, and this bundle sometimes does not work correctly.

When the ionization current that passes from the electrode through the burner to the ground loop without any obstacles, then the ignition works without any deviations. The control board fixes the parameters of the ionization current. If its strength is in the range from 5 to 15 microamps, then this can be considered the normal mode of operation of the ignition system. When for some reason the ionization current strength deviates from the norm, the electronic control unit of the boiler records these deviations, and the Baksi gas boiler is blocked with an e01 error.

Also, this error appears if the contact of the electrode with the control board is broken. Also, if an error e01 occurs, you immediately need to check the gas pressure in the line. On natural gas, the pressure should not be lower than 2 mbar, and on liquefied gas - 5-6 mbar. Also, the pressure can be adjusted with a special nut, which is located on the gas valve. It is also necessary to thoroughly check the operation of this valve - measure the resistance of the coils with a multimeter. The first coil should have a resistance of 1.3 kOhm, and the second - 2.85 kOhm.

The conductor that connects the gas valve to the electronic board may contain a diode bridge, which may also fail. This is a feature of some models of Baksi boilers and the diode bridge must also be checked with a multimeter. You also need to check the resistance of the electrode itself. It should not exceed 1-2 ohms. Also, the edge of the electrode must be at the right distance to the burner. This distance should be 3 mm.

Error e01 can also appear if ignition occurs, but the flame immediately goes out. This may be due to the fact that the polarity on the 220 volt plug is reversed. By turning the plug 180 degrees, you can get rid of ignition problems. These problems can also be caused by a ground fault. The voltage between the phase and neutral phase, and the ground must be the same. The voltage between zero and ground should be no more than 0.1 volts. If this setting is violated, then this may be the reason fault e01.

You also need to make sure that the gas line is isolated from the boiler. This line may carry a small electrical potential, which can cause a malfunction of the heater. For insulation, a special dielectric spacer is used, which is placed between the gas pipe and the boiler.

Characteristics of Baksi boilers

The equipment of this manufacturer can be used both in a small apartment and in a spacious country house. But the space in which the heating system will be installed must meet certain criteria:

- The size of the room should not be less than 15 m³.

- Ceiling height - at least 2.2 m.

- Good ventilation is required to withstand heavy loads.

This is important: maintenance of Baxi boilers. In this video you will learn how to flush the heat exchanger:

In this video you will learn how to flush the heat exchanger:

3 id="vazhnye-nyuansy">Important nuances

In addition to grounding, other factors must be taken into account when installing equipment. Consider the following:

- For the boiler to function properly, 170-250 V is required. At a lower voltage, the device will turn off, and at a higher voltage, the varistor will burn out.

- The equipment is very sensitive to voltage fluctuations. Professionals advise installing additional devices that stabilize the voltage. It is not necessary to use a UPS when installing gas boilers.

- The connection must be made through a separate functionality.

- For phase-dependent varieties, the correspondence between phase and zero should be observed.

Advantages and disadvantages

Baxi is a leader in the heating equipment market.

The following advantages of the equipment of this manufacturer can be distinguished:

- environmental friendliness and safety;

- ease of operation and flexible adjustable settings;

- reliable frost protection;

- automatic diagnostic function;

- profitability;

- a wide range of models, the ability to choose a unit for any requirements;

- stylish thoughtful design.

Of course, any equipment has its drawbacks, Baksi products are no exception. The cons are:

- Sensitivity of technology to voltage drops. For the device to work reliably, you need to connect it through a stabilizer.

- Installation is quite complicated, so it is best to entrust it to a professional.

- High price compared to models from other manufacturers.

In this video, you will learn about the main malfunctions of Baksi boilers:

Varieties of models

The company has a wide range of wall and floor heating systems. Wall mounted boilers are ideal for private homes. They are available in three series: Luna, Prime and Eco3.

Models from the Luna line have built-in automatic diagnostics and electronic modulation. Such units are distinguished by the presence of two temperature controllers, which is very convenient. These are two-circuit devices with an acceptable cost.

Equipment from the Prime line is high-quality and reliable economy class boilers. They have a closed combustion chamber and are made of special composite materials. The devices operate almost silently. Models of this series are condensing and have a biothermal heat exchanger. As a result, they work very economically.

The Luna-3 Comfort and Eco Four models are very popular on the Russian market. Both systems can be presented with both open and closed combustion chambers. Eco Four has a capacity of 14-24 kilowatts. It can be connected to a thermostat or timer. This boiler is equipped with high-quality sensors and reliable protection against temperature changes. Among all Baxi devices, it has the least power.

In addition, models from the Main line are in great demand. The most famous in the Russian market was the Main Four 240, which was discontinued in 2017. It was replaced by Main Five, made using new technology. This system is similar to the previous one, but it contains additions, such as a draft system in the chimney.

How to repair gas boiler control board:

Error decoding

Overheating is indicated by the error code e02 of the Baxi boiler. The transcendent increase in the temperature of the coolant is caused by:

- insufficient volume of liquid in the heating circuit;

- its weak circulation;

- complete blockage of the pipeline;

- a defect (malfunction) or failure of a component of the Baksi boiler.

Understanding the meaning of the e02 error, it is easy to outline an algorithm of actions to eliminate it.

First steps

Before looking for the cause of the malfunction, you need to do the following. This applies to almost any Baksi boiler error, and not just the e02 code.

Perform a reset. There is a button on the gas Baxi panel (indicated by the symbol of a crossed out tongue of flame; analogous to R or REZET). If it is not on some model, remove it and turn on the power again. Imported equipment is sensitive to the parameters of the electric network, and phase imbalances, power surges cause malfunctions in the electronic board. Hence the errors on the display.

Press the R button to reset the Baxi Mainfour boiler

Click on the “Reset Settings” button on the Baxi Luna gas boiler control panel

Check the voltage value and the reliability of the grounding of the Baksi boiler. According to the manufacturer's instructions, ~230 V is considered the norm.

The reason for the exit of the Baxi boiler out of order was the absence grounding

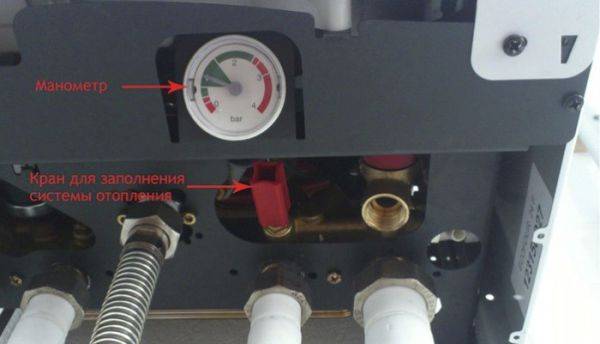

Raise the pressure. In other words, bring the volume of the coolant to normal. If after that the e02 error disappears, and Baxi enters the mode and continues to work stably, you need to periodically monitor the readings of the pressure gauge. The appearance of the same code after a while is evidence of a microcrack in the circuit, some device of the system (boiler, expansion tank, heating radiators) and a small leak.

Pressure gauge and tap filling the heating system

Relief valve Baxi. Do not pour water through the valve.

Bleed the air.Depending on the intensity of gas formation, with an increase in the temperature of the liquid or "leakage" associated with a violation of the tightness of the circuit, the bubbles partially or completely block the circulation channel. Its speed drops sharply, down to zero. Hence the overheating and error of the Baxi e02 boiler.

Advice. Do not rely on the correct operation of automatic valves (air vents), which are equipped with heating radiators. These devices often do not fulfill their function: illiterate settings, weakening of the spring, clogging of the channel - there are enough reasons. You need to walk around the house and check the degree of heating of pipes and batteries by touch: this way you can identify the area where the plug has formed.

Not everyone knows that it is also necessary to bleed from the pump of the Baxi boiler: there is a plug (under the slot) on the end part. The accumulation of air in the body of the device can also cause an e02 error. The technique is simple: the head turns away one and a half turns and twists after a thin continuous stream arrives, without bubbles.

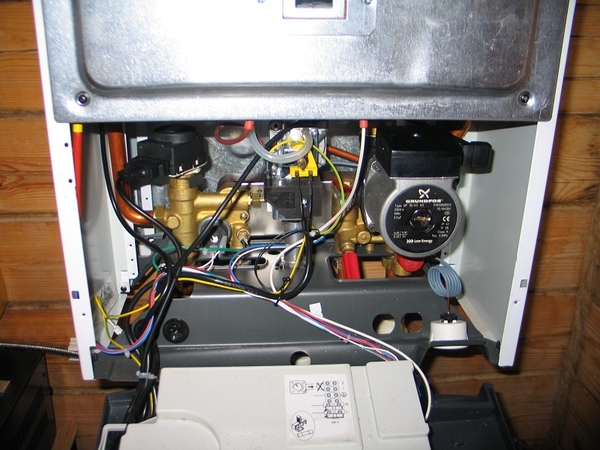

Usually a Grundfos pump is installed in the Baxi boiler

![How to fix the e26 error on a gas boiler baxi [baxi]](https://fix.housecope.com/wp-content/uploads/1/3/a/13ac96c63dab846420d07da1e21d36dd.jpg)

![How to fix the error e35 gas boiler baxi [baxi]](https://fix.housecope.com/wp-content/uploads/c/9/0/c90115854812c2fc3b1b1b67ce9e94ea.jpeg)

![How to fix error 12 on a baxi gas boiler [baxi]](https://fix.housecope.com/wp-content/uploads/1/f/9/1f90e98f8b7b85e0b94d3b8474cebb07.jpeg)

![Instructions: how to fix error e99 on a gas boiler baxi [baxi]](https://fix.housecope.com/wp-content/uploads/d/f/2/df278ec6d0a116ade2321f3707fef73c.jpeg)

![How to fix the error e35 gas boiler baxi [baxi]](https://fix.housecope.com/wp-content/uploads/6/f/0/6f05367440e53bc07bf24e5bc83ba29b.jpeg)

![How to fix the error e04 boiler baxi [baxi]](https://fix.housecope.com/wp-content/uploads/b/4/2/b4289b9c1c1ad0a2236213afa8562727.jpeg)

![How to fix error 12 on a baxi gas boiler [baxi]](https://fix.housecope.com/wp-content/uploads/1/9/7/197619c51b2ca16e68bc39e8b3b4abd3.jpeg)