- 3 Components and views

- Popular brands

- Pathfinder

- Kovea

- Topex

- Tramp

- Jetboil

- Research

- How to choose for the burner

- 1 Equipment features

- Design features of the gas burner

- How to use?

- Device device

- Cylinder gas tourist. What's inside?

- Types and advantages of gas burners

- Varieties of gas burners

- Atmospheric gas burners

- Fan gas burners

- Diffusion-kinetic burners

- The main criteria for choosing gas camping stoves

- Classification of gas burners

3 Components and views

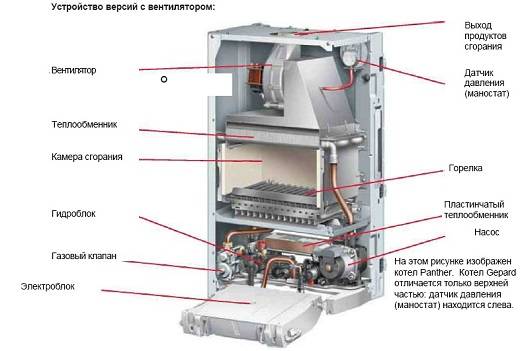

The burner is an element of heating system schemes that make it possible to simplify the process of heating a house. In addition to it, the design includes the following parts:

- heat exchanger;

- heating element;

- frame;

- balloon.

The devices themselves may differ from each other depending on the type of fuel used. The most common of them are gas, since gas is the most affordable type of fuel for most consumers. Such types of equipment are divided into pressurized and injection.

The device of the burner of the first type is distinguished by the fact that it has a built-in fan, and the oxidizer in the form of air enters the working area mechanically.The fan is needed to adjust the power, which has a positive effect on the efficiency of the device. However, it is quite noisy, but even this problem can be solved by installing special noise suppression accessories.

Injection devices are otherwise called atmospheric. They are an integral part of gas boilers. The principle of their operation is that air is supplied to the working area due to the so-called injection effect. The oxidizing agent in the amount necessary to maintain a full-fledged combustion process enters the gaseous fuel stream under high pressure.

If the listed types of burners are designed exclusively for working with gas, then combined ones can be used for heating systems using different types of fuel, while installing additional parts of the structure is not required. They are significantly more expensive and more difficult to maintain.

Less common are liquid fuel burners that run on petroleum products, waste oil or biofuels. Some of them, such as fuel oil, are used only for industrial purposes.

Popular brands

The range of gas cylinders for burners is presented on the market by many manufacturers. Of these, the following brands are considered the most famous and popular.

Pathfinder

Domestic brand of the Result group of companies. The range is represented by attributes for tourism: portable stoves and burners, cans for them and other equipment. All products are tested in real conditions and improved taking into account the identified shortcomings.

Kovea

South Korean brand. It has been on the market since 1982 and is famous for its gas equipment and accessories.The brand's products are in demand by tourists, motorists, professional craftsmen and home craftsmen. The company constantly replenishes the range with new modernized models.

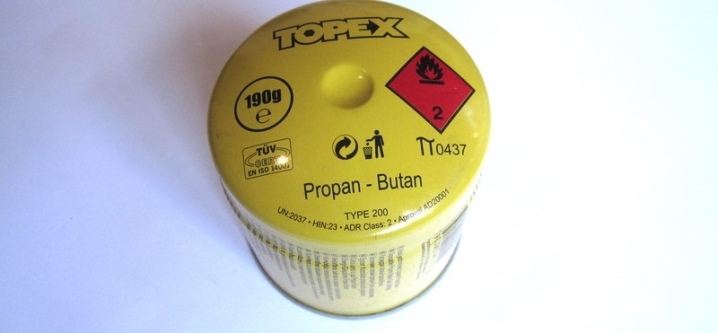

Topex

Polish brand, the quality of which is marked by many international certificates. Products of this brand are widely known and very popular.

Topex 44E 150 cartridge. Contains butane and meets all EN417 regulations. Safety is guaranteed by the presence of a system that blocks gas leakage. Designed for use with gas burners, camp stoves and blowtorches.

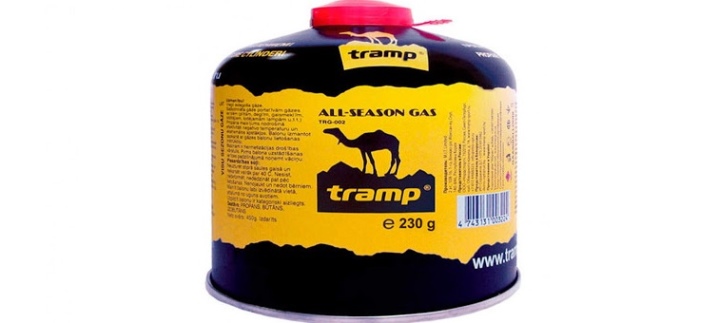

Tramp

Russian brand, whose products are manufactured in South Korea. The company produces 2 types of cylinders - collet and threaded.

Tramp TRG-003. The threaded cartridge is designed for portable burners and year-round use. The gas mixture contains 25% propane, 70% isobutane and 5% butane.

Jetboil

An American manufacturer that produces a kit for cooking in field conditions, consisting of a burner, a food container and threaded cartridges for the appliance. The cylinders are filled with a mixture of isobutane and propane and can be used all year round.

Research

Czech brand specializing in composite cartridges.

The HPC Research LPG 262l model is equipped with a reducer with a special connector that allows connection without an adapter. The product is characterized by reliability, explosion safety and corrosion resistance. Refilling is possible.

How to choose for the burner

So, you want to buy a gas bottle for your burner, but you don’t know which one you need, there are a few things to understand:

- Why do you need a cylinder (burner for tourism, burner for work).

- Under what conditions will it be used?

- Decide on a budget.

- Find out which balloon size is best for you.

What size cans do you prefer to buy?

SmallLarge

Most often, burners are used for two purposes - in tourism and as a blowtorch. If you need a blowtorch tank, then just buy a regular propane or butane tank. They are cheap, there are no special requirements for them. The main thing is to choose a cylinder that fits the size and shape of attachment to the blowtorch.

In the case of tourist balloons, everything is more interesting. You need to choose based on how long you will be hiking or traveling and what climatic conditions await you. Based on the distances and duration of the trip, you need to choose the size of the balloon - the longer, the more balloon you need. The exception is trips to "civilized" places where you can find a store with gas cylinders. On autonomous trips far from populated areas, it is worth taking spare cartridges with you.

In the case of climate, you need to look at the marking of the cylinder model. There are universal cylinders that are designed for 4 seasons, but they will not withstand too extreme temperatures. If you go somewhere where the temperature is below -15 degrees, then you need to choose winter cylinders. The same is true in very hot, humid climates.

Expert opinion

Torsunov Pavel Maksimovich

According to the budget: choose only those cylinders that will not burden your budget too much. The main thing is that they should not be some kind of handicraft or without certification. It is better to take one more spare cylinder with you than to spend all your money on one expensive one.The composition of the mixture for extremely expensive and medium-priced cylinders rarely changes so much that it affects the quality of the burners.

1 Equipment features

Heating boilers operating with gas have a high efficiency. Properly selected burners play an important role in them. They differ in type and principle of operation. According to their purpose, burners are divided into domestic and industrial. In the first case, the devices have low power. It is they who are placed in private houses for boilers. The second type of equipment is intended for:

- boiler rooms;

- heating large premises or several residential buildings at once;

- enterprises.

In each case, different gas burners are needed. Their principle of operation and device may differ in this case.

Design features of the gas burner

This element of the unit creates a stable flame, it is in the burner that the fuel entering the device is burned. Then the received heat moves up, where the heat exchanger is located, through which the heat transfer fluid moves. Combustion products and excess heat go into the atmosphere in one way or another.

The gas burner has a simple device, it consists of several main components, including:

- Nozzle - used to release gas.

- Ignition system - designed to ignite gaseous fuel.

- A sensor that monitors the presence of a burning flame.

- Automation system - monitors temperature indicators.

This is how the design looks simplistic.

Modern gas burners for heating boilers are devices that must meet a number of requirements:

Silent operation. It is an important quality.Many consumers are familiar with Soviet-era instantaneous water heaters, in which the flame was very noisy.

But modern models operate relatively quietly.

Also, when choosing a device, you should pay attention to ignition, since there should be no explosions and pops. The design of the combustion chamber additionally affects the noise level.

Long period of operation

In older models of gas units, the burners worked for a long time, since at that time the equipment was made to last for centuries. Now such technologies are not used, therefore, these elements installed in gas boilers break down quite often. In this case, experts recommend purchasing devices manufactured under well-known brands, for which high-quality components are used. You should not buy Chinese equipment of incomprehensible manufacture and cheap domestic-made boilers, since short-lived burners are often mounted in them.

Complete combustion of gaseous fuel

This is an important requirement, since the burner must burn natural gas completely with a minimum release of combustion products and other related compounds, including carbon monoxide. The degree of combustion is also affected by other nodes. We should not forget about the arrangement of high-quality exhaust gases - for this you need to make a chimney with good draft

We should not forget about the arrangement of high-quality exhaust gases - for this you need to make a chimney that has good traction.

The principle of operation of a gas burner is simple:

- The unit detects the presence of a discrepancy between the temperature in the heating circuit and the indicators set by the users of the equipment.

- After opening the gas valve, fuel enters the burner.

- At the same time, the ignition system is activated.

- After the gas is ignited, a flame appears.

At the same time, the operation of the flame sensor begins, which controls its presence: if the fire suddenly goes out, the automation shuts off the fuel supply. After reaching the desired temperature in the heating system, the gas supply is stopped.

How to use?

The operation of the canister does not require much effort. First of all, it must be connected to a gas appliance. Fastening different types of balloons is carried out in this way:

- threaded models are fixed by simply screwing the burner or its hose onto the thread of the can;

- a cartridge with a collet mount - the connecting unit of the cartridge is inserted into the groove of the burner and slightly rotated to one side until it is fixed;

- valves are attached with a retainer;

- pierced are connected by gentle pressure on the balloon.

To connect a collet cartridge to a threaded burner, you need a special adapter that allows you to fix the cartridge and various types of gas appliances. The adapter must be installed in the collet mount of the gas container, and then its upper part must be turned clockwise until it stops.

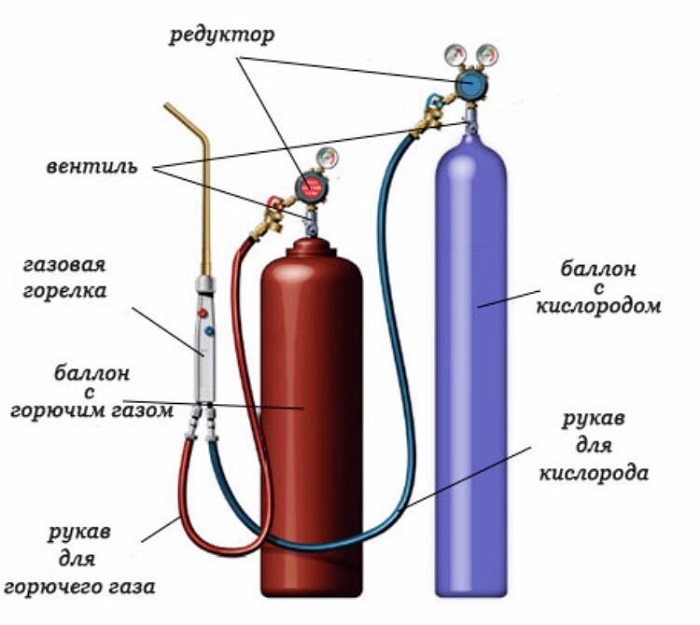

To connect cylinders and burners, a reducer is often used, which serves to reduce gas pressure and normal operation of the device.

When using spray cans, it is recommended to adhere to the following rules.

- In order to save fuel, do not cook at the maximum flame setting.

- To prolong the life of the burner and make it more efficient, it is necessary to keep the cartridges warm and prevent them from cooling. The easiest method is to keep the containers warm.Before use, it is recommended to warm the container by holding it for a while in your hands.

- During operation, it is necessary to protect the burner from the wind, since even a slight breeze increases gas consumption by almost 3 times. Propane tanks are an exception, since such protection can lead to an explosion.

- It is necessary to isolate the can from the ground by laying a refractory lining. This will allow the container to retain heat, which means that the fuel supply to the burner will be more efficient.

- Before discarding the used gas tank, you must check that it is completely empty.

- Do not place the gas cartridge near an open flame.

Often several cylinders accumulate with the remains of unused fuel. They can be charged from each other. Refueling is carried out using a special adapter, so you can use different types of gas cartridges.

To fill a threaded cylinder from a collet, you must perform the following steps.

- The threaded spray can should be cooled by placing it in the refrigerator (freezer), and the collet, on the contrary, heated in warm water. The procedure will take about 10-15 minutes. It is strictly forbidden to heat the container on fire.

- You need to put an adapter on the collet model, turn the container upside down, and then insert the tip of the adapter into the neck of the threaded cylinder.

- In order for the gas to pass from the upper (collet) reservoir to the lower (threaded) reservoir, it is necessary to press the upper cartridge. At the same time, you can hear the mixture pouring from container to container.

Thus, changing the empty tanks, you can repeat the procedure until the lower cylinder is completely filled.

All actions during refueling must be carried out carefully and accurately.

For information on whether to choose a collet or threaded cylinder, see the following video.

Device device

This product is actively used by travelers, hunters, fishermen, shift workers due to a wide range of applications. Structurally, piezo ignition burners are divided into several types. The most productive option is the injection system with a check valve. Such modifications increase the performance of the unit, reduce fuel consumption. Cheap options include elementary devices with a nozzle.

Most portable gas burners with a cylinder are classified as injection models, in which air is sucked into the equipment in a natural way. In the working chamber, the fuel is mixed with the atmospheric flow, a spark is supplied, and ignition occurs. In compact gas burners with an adjustment mechanism, you can accurately set the required power and size of the torch. High-temperature units produce a bluish-blue flame, low-temperature counterparts - orange-yellow.

The device of the gas burner is made in such a way that the mixture is fed from the mixing compartment into the nozzle of the nozzle variety, being distributed through the channels. There are special holes on the tip with the formation of a flame. According to the structure of the nozzle, there are annular, slotted, tubular types.

Cylinder gas tourist. What's inside?

Standard gas cylinders for burners use a mixture of butane, propane, isobutane.It depends on the proportions in which they are “mixed” how well the burner will work, and, first of all, in the cold.

The vast majority of cylinders contain a mixture of propane / butane (isobutane) (either 30:70 or 20:80). Burns much more stable, incl. and at sub-zero temperatures, a cocktail in which instead of butane is isobutane (or butane + isobutane), because. it is more homogeneous in its chemical properties and has a higher octane number. Problems when using such a tourist gas cylinder begin at minus 15 degrees.

Propane tank Coleman Propane Fuel

Burner fuel is more expensive the higher the propane content. In special gas mixtures that are intended for use at low air temperatures, the so-called "winter gas" (the designation on the cylinders is the word "winter" or a snowflake), the propane content is 50% or more. Manufacturers claim that they are suitable for use at air temperatures up to minus 25-30 degrees.

100% propane gas for Coleman Propane Fuel camping torches that can be used in air temperatures down to minus 42 degrees (the boiling point of propane). Cylinder with a volume of 465 gr. costs about 600 rubles. For this gas, a special, thick-walled cylinder is used, since more pressure is needed to compress propane. Such a cylinder is intended only for use in propane burners and lamps of the same brand, its weight is much more noticeable than that of cartridges of the same volume filled with butane or gas mixtures.

100% isobutane / butane filler is found in tourist gas cylinders, in particular domestic production, such as Eurogas and Tierra (they are also called Kazan cylinders) and Korean Pathfinder and Neogas. They, without a doubt, can be used in summer trips, when the thermometer does not fall below plus 5-10 degrees, although manufacturers also declare sub-zero temperatures.

Experienced tourists have a whole arsenal of little tricks that help the gas burn in the cold. But, in our opinion, it is easier not to pervert, but to take either a liquid fuel burner or a multi-fuel burner on a winter trip. Gasoline burns cheerfully even in severe arctic frost.

Types and advantages of gas burners

Portable burners are compact, economical, heat level and flame can be controlled with a valve regulator. Devices are used instead of chemicals for disinfestation of premises for animals, beehives. In the absence of power supply, the devices are simply indispensable in terms of fast food preparation, boiling water.

Burners are produced with the usual type of ignition (lighter, matches) and with a more convenient and expensive piezoelectric element. When you press a special button, a spark is generated to ignite the fuel. Today, manufacturers produce several types of gas burners for different purposes: soldering irons, camping, blowtorches, cutters.

Gas soldering irons are economical in fuel consumption. Such devices are equipped with a flame regulator. The package of devices includes 2 nozzles - a sting and a second type as a cutter. The first nozzle, when heated, is capable of melting solder, applying it to microcircuits, and connecting wires.The second nozzle can be used to light a fire and cut tins and aluminum cans.

Camping or tourist burners are used for heating, cooking, boiling water. Typically, such burners must be covered from the wind due to the fact that when the flame is blown out, the gas continues to exit the cylinder. The burner can be installed directly on the cylinder, have a side connection or be connected to the cylinder through a special hose.

This is interesting: Freezing device for making ice cream: we consider thoroughly

Varieties of gas burners

Atmospheric gas burner

Before classifying gas burners for boilers, you should decide what is happening inside, and these are:

- the passage of combustible material through the burner (in our case, gas),

- adding air to the fuel.

The design of the device must maintain the stability of the combustion of the gas-air composition.

According to the method of supplying air to the gas stream, there are several types of burners:

- atmospheric;

- with fans;

- diffuse-kinetic.

Also, a homemade gas burner differs in the number of stages:

- One step. First of all, this is the operation of the device with a stable power: the temperature indicators of the air in the premises or the heat carrier are maintained at a certain level. This is the merit of lighting up or turning off the burner at the required time. In this case, jumps in temperature are noted within a certain spectrum. It is worth noting the rather modest operational life of such a burner.

- Two steps. The operation of the device is two-mode. With a low load on the heating network, a half mode operates, ensuring stable operation of the boiler and less equipment wear.The nominal mode is activated at high loads. The power of the device can be controlled gradually from zero to nominal. Therefore, gas equipment can work continuously and in optimal mode for many years.

As for the characteristic features of a good burner, this is: the efficiency of the device, nitrogen oxide and carbon monoxide enter the air;

- decent operational life of the device;

- simplicity of design;

- ease of installation;

- noise within sanitary standards;

- quick reconfiguration from one type of fuel to another. This criterion applies to combined versions.

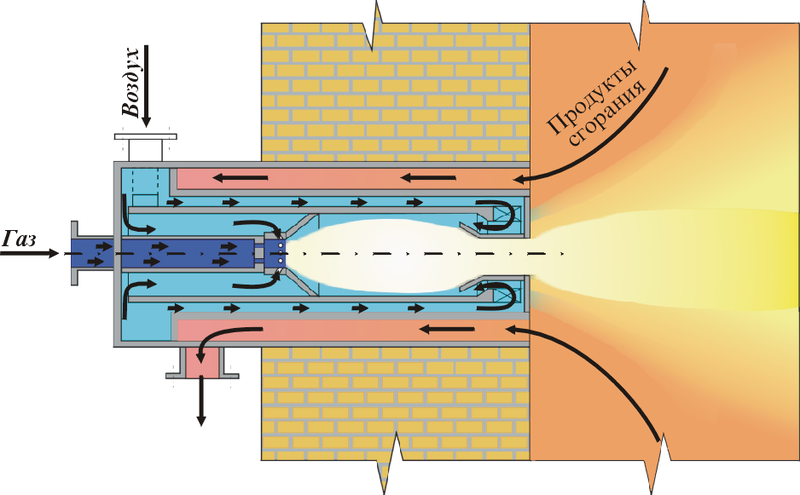

Atmospheric gas burners

They suck in air like a jet pump. That is, the gas flows through the ejector, where, due to the high dynamics, its pressure decreases. Air is introduced into the gas stream due to pressure surges.

Advantages of varieties:

- simple design;

- compact dimensions;

- energy independence;

- low noises;

- attractive prices.

With such a burner, a solid fuel boiler can be converted to work on gas. To do this, you need to mount the burner in the ash pan section.

Impressive volumes of air cannot be introduced into the gas flow by jet action. For this reason, atmospheric versions in boilers are not very powerful. Their limit is 9 kW (average value).

Fan gas burners

In them, a fan is responsible for pumping air. Air is introduced in the required volumes. Oxygen is forced. That's why:

- There are no power limits. Thanks to the fan, various volumes of gas fuel can be supplied with the necessary amount of air to ensure total combustion.

- The combustion section (gas) can be isolated from the boiler room. Air enters it from the outside - through a special air duct. This reduces the threat of penetration into the house of gases from smoke.

In analogues of the atmospheric type, a closed department is impossible. Reason: natural draft cannot cope with the air resistance in the duct and provide the burner with the necessary air volumes.

A boiler with a closed gas chamber can operate without installing a separate air duct. This is due to the use of coaxial chimneys. They have an inner pipe to eliminate flue gases. There is a cylindrical tunnel for new air to enter. It is arranged between the outer and inner pipe.

Versions with forced air injection can be self-adjusted. They require minimal user interaction.

Cons of fan gas burners:

- high prices;

- powerful noise during operation;

- dependence on electricity - they need sources of stable power.

Diffusion-kinetic burners

Usually they are present in powerful industrial heating units. They combine the basics of the previous two types of burners.

The main criteria for choosing gas camping stoves

Before you go to the store to buy a tourist stove, you need to carefully weigh your choice, considering the main parameters of these devices.

The primary attention deserves such an indicator as power. On average, it takes about 1 kW of thermal energy to cook 1 liter of food. On a hike, one person needs approximately 0.5-0.7 liters of the product at one time. Based on these data, it is easy to calculate the required power level of the unit.For example, three tourists for the expedition will need a stove with a power of 1.5-2 kW. The weight of standard units is in the range from 0.8 to 2 kg.

This indicator depends on several factors:

- the material from which the tile is made;

- burner area;

- body size;

- design features, for example, the nature of the placement of the fuel tank, which can be built-in or removable.

Since you have to carry all your things on a hike, the weight of the tourist tile is of great importance. When choosing a suitable model for expeditions, it is necessary to take into account fuel consumption. This indicator is usually prescribed in the technical data sheet, which is attached to the stove. It is expressed either by the time it takes to boil 1 liter of water, or by the amount of gas consumed in 1 hour. There is one pattern here: the more time it takes to boil the liquid, the lower the fuel consumption.

The dimensions of the hob impose restrictions on the width of the dishes used, and therefore on the amount of food that can be cooked at one time. If a container with a capacity of 5 liters is placed on the tile, then such a unit is capable of feeding approximately 5-7 people in one cooking.

Note! Camping stoves equipped with ceramic gas burners do not need wind protection, since the flame is hidden inside the burner

Classification of gas burners

Burners can be not only gas, but also liquid. In the latter case, they run on diesel fuel, but they are less common, since their effectiveness is manifested only at low outside temperatures of +10 ... + 15ºС.

This type of burner is distinguished by the following features:

- According to the type of combustible mixture used. In addition to the liquid and gas mentioned above, combined structures are also used, when air or oxygen is supplied to the working area simultaneously with combustible gas (propane and, much less often, acetylene).

- By the number of working nozzles. Gas burners for roofing can have from 1 to 4 nozzles. In the latter case, the technological capabilities of the device are expanded (for example, the width of the roll material), but at the same time, the consumption of combustible gas increases.

- By the presence or absence of a gearbox. Gearless burners, although structurally simpler, do not have the function of regulating the gas flow, which is inconvenient in the practice of their application.

- According to the method of igniting the gas jet. Modern designs of the devices under consideration have a piezo ignition unit, which is much more functional than using matches or a lighter for the same purposes.

- According to the design of the gas supply tube. It can be straight or bent at an angle, normal and shortened length.

Such burners work from cylinders. A reducer or other gas distribution device is installed on the cylinder. For propane cylinders, with a small amount of work, they can be installed on the roof, in other cases, hoses are used, the length of which should not exceed 12 ... 15 m.

Most propane designs roof burners can be used for other purposes, for example, to remove old paint (successfully replace a blowtorch), to heat up copper or brass pipes before welding them, to heat up cooled bitumen, etc.

Being devices that use combustible and explosive mixtures, industrial versions of gas burners are manufactured according to the technical requirements of GOST 17356-89. The following performance indicators are normalized by the standard:

- One hundred percent tightness of the shut-off organs that control the gas supply;

- Smooth supply of propane;

- The presence of anti-wind protection against spontaneous blowing;

- Reliable shutdown of the device and response time;

- Limits of thermal power regulation.