- Modernization of heating equipment. Protective automation system. Gas supply to the bath

- Which burner is better to choose?

- Other differences

- What is a gas burner

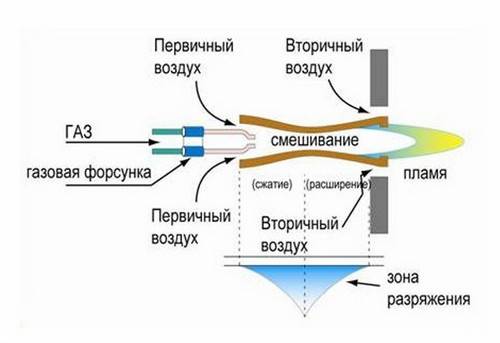

- Principle of operation

- Fan

- Dependence of the choice of device on the size of the group and the level of fuel consumption

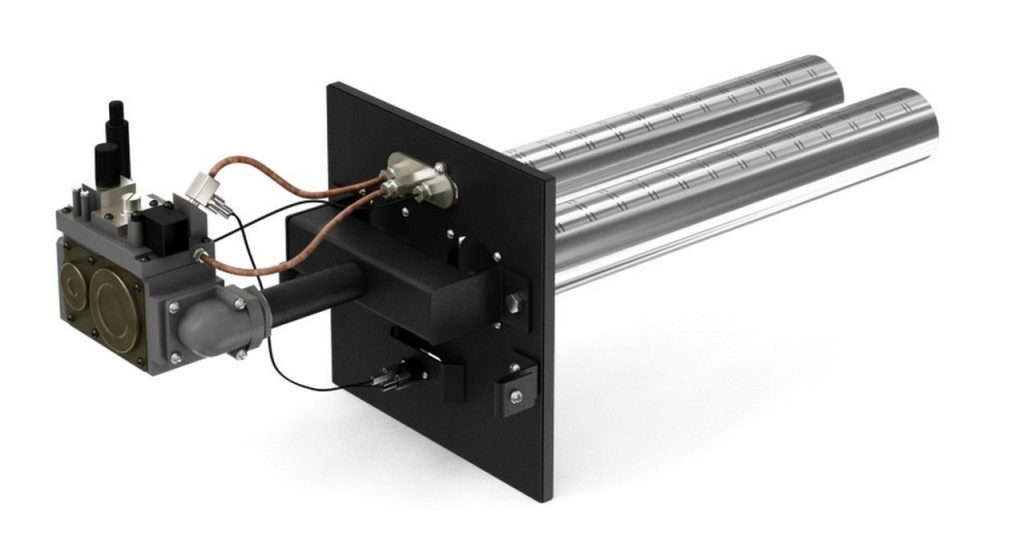

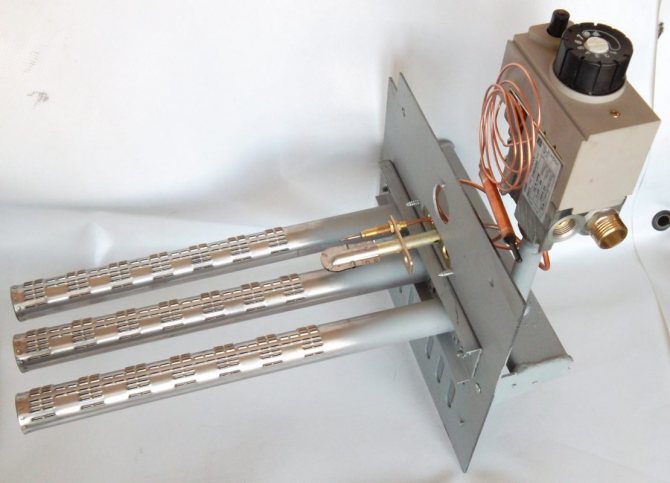

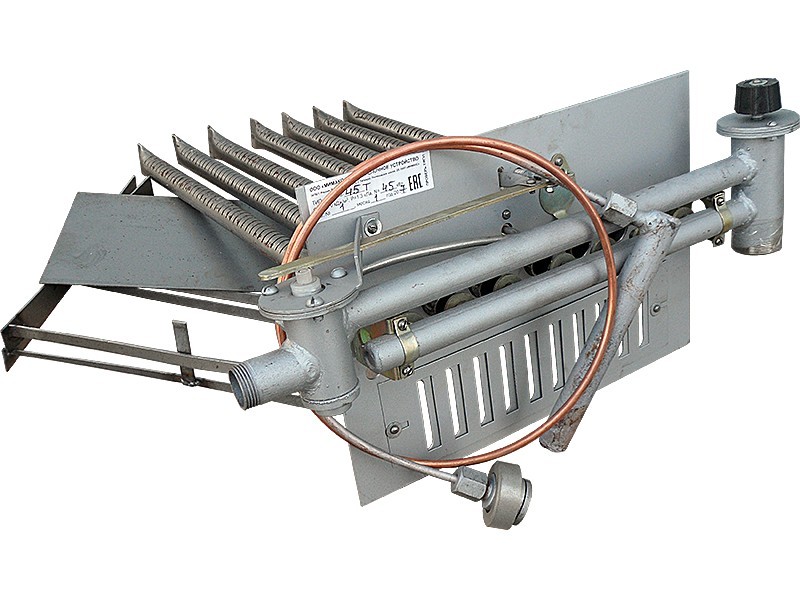

- Atmospheric gas burners for gas boilers

- Advantages and disadvantages of equipment

- Pros and cons of single-circuit units

- Advantages and disadvantages of double-circuit boilers

- How to choose a tourist burner for a hike: climate features

- Manufacturing materials

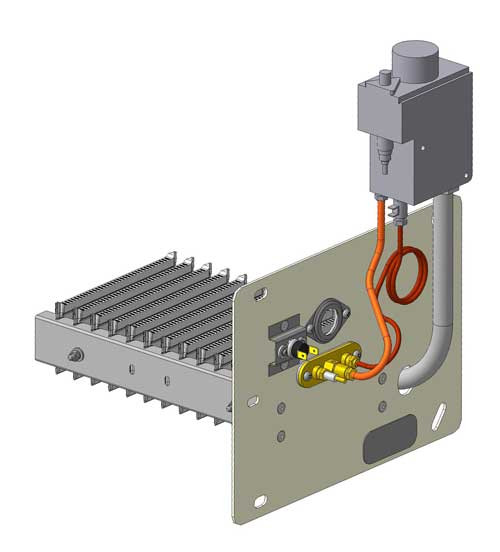

- Pulse burner design

Modernization of heating equipment. Protective automation system. Gas supply to the bath

Consider in detail modernization of heating equipment.

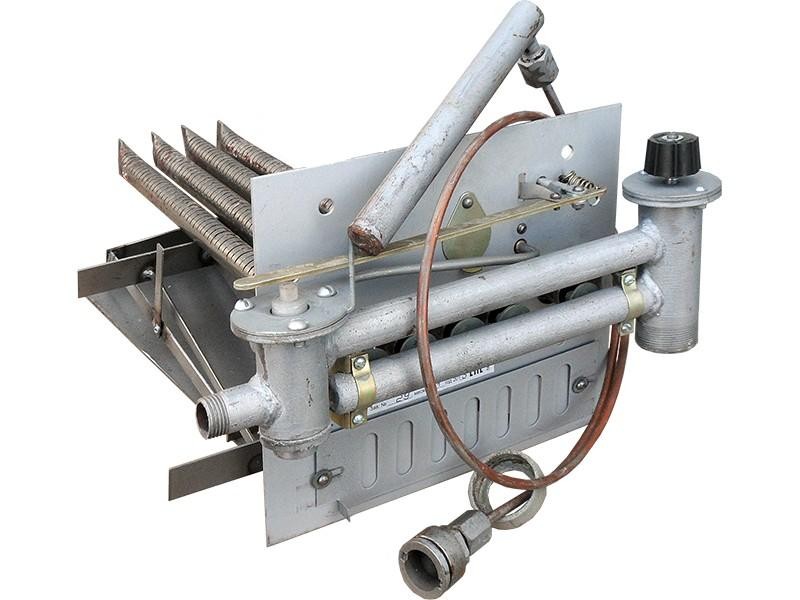

Installing a homemade atmospheric-type gas burner for a bath stove is within the power of any home craftsman. So, without significant costs, a solid fuel boiler can be converted into a gas one.

The equipment of the existing solid fuel stove in the bath with a factory-made gas burner block requires a specific fit. You will be faced with the need to refine the dimensions of both the burner and the combustion chamber of the wood stove.

For uniform heating of the furnace chamber, the burner should be located closer to the bottom of the furnace and strictly in the center.In this case, the camera will not warm up completely. It is unacceptable to place the source high and offset in any direction. And the flame from the burner can touch metal parts or the heater sauna stove.

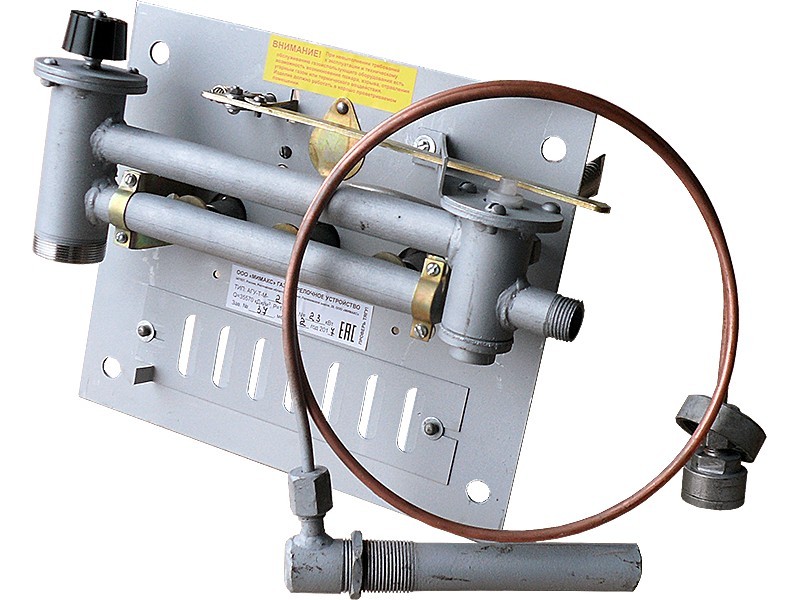

Now let's take a closer look protective automation system.

Unburnt fuel in sauna stove sometimes causes an explosion of a gas-air mixture. This can be done visually or using automation with light-sensitive modern photocells. therefore, it is necessary for your safety to supervise the flame of a working nozzle.

The burner protection system automatically provides the following functions:

- completeness of gas combustion.

- power regulation;

- fuel and air supply;

It is necessary to take into account the increase in the dimensions of the modernized design. For compactness, all automation can be placed outside, in case the size of the device is an important criterion for you. Especially when the size of the bath room is small.

_

The size - geom. numerical value of a linear quantity in the selected units. (GOST 21778-81)

Automation - the use of technical means that free a person partially or completely from direct participation in the processes of obtaining transformation, transfer and use of energy, materials and information. Automation of management is aimed at the use of computers and other technical means of processing and transmitting information in the management of production and the economy.

To control the combustion process, you can use a factory-made automatic installation of the SABK-8-50S type. It provides a high level of security thanks to four levels of protection. The operation of furnace gas equipment with such devicem will automatically stop in the event of a dangerous emergency mode.

Next, consider in more detail gas supply to the bath.

Sauna stoves with gas nozzles have become a technological breakthrough for people living far from forests

Taking into account the low cost of gas fuel compared to firewood, the cost of heating with a burner becomes completely negligible.

Fans of the steam room can not limit themselves and use such a bath every day. Only, without a doubt, if health permits.

Uninterrupted supply sauna stove gas fuel can be provided from:

- A gas tank installed on the site permanently or in a mobile version suitable for periodic refueling.

- The main network laid to the suburban area and connected to the bath.

- Gas cylinders, which will need to be refilled periodically.

The most time-consuming procedure will be cutting into the general gas system of a city or rural settlement. It will require the purchase, installation and registration of gas meters. You will also need to issue permits, technical and payment documentation.

Connecting a conventional gas cylinder also requires an invitation from a gas service representative and the preparation of technical documentation. Tanks have special placement requirements.

For example, speaking, it is not necessary to install gas cylinders in the bathhouse. They should be outside in an easily accessible, ventilated area. Nearby must be fire-fighting protective equipment - a fire extinguisher, sand.

_

Fire extinguisher - portable or mobile device to extinguish fires by releasing the stored fire extinguishing agent. (GOST 12.2.047-86)

Which burner is better to choose?

From the above overview, it becomes clear that there is a wide variety of gas burners, both in design and in their area of \u200b\u200buse. The choice is very large and the question arises of how to choose a burner and not miscalculate?

If you decide to purchase a gas burner for a sauna stove, you should focus on several criteria, and the main one, of course, is power. The stove must be able to perform its direct function - to heat and maintain the set temperature in the steam room.

It is generally accepted that one kilowatt of power is needed per cubic meter of a steam room. At first glance, it seems that there is nothing complicated in this. However, the approach works only in rooms with thermal insulation correctly performed according to all technical standards.

In fact, it turns out that there are areas in the bath that allow heat to pass through. They also need to be taken into account. Windows are one of the main sources of heat loss. 3 kW of power is needed per square meter of a single pane window and 1.5 kW per double glazing window.

Log walls have a high heat capacity. Log bath without internal thermal insulation will require an increase in power by one and a half times.

The result can be quite a lot of power. When choosing a burner, it is necessary to focus on its technical characteristics. The resulting power value must be in the range of values \u200b\u200bspecified in the passport.

Each of these options has its own advantages and disadvantages. It is necessary to focus on the tasks that this equipment must perform.

For example, to heat large rooms with poor thermal insulation, infrared heaters with gas supply from a domestic cylinder are best suited, since they heat the surface, not the air.

Electric boilers are small, compact, silent, can work offline and last a long time. Gas boilers with gas burner automation are the most efficient and economical. In addition, this fuel is the cheapest.

The most important thing when choosing to focus on proven models of boilers, as well as on reliable stores. After all, no one is immune from buying a fake.

Thinking about converting the stove to gas fuel, you will sooner or later face the question of choosing the most suitable burner for this purpose.

There are the following alternatives:

- Atmospheric or supercharged. Owners of large baths and saunas are increasingly preferring more expensive, but convenient forced-air type burners. Their important advantage is that they require a minimum of attention and personal participation from the user, working regardless of external conditions and air pressure drops. An inexpensive atmospheric burner is quite suitable for heating a small steam room.

- One or two stage. Devices of the first type automatically turn on and off the fuel supply, while the second type has an economical heating mode. There are also models with floating adjustment, which allow you to change the power of the equipment as smoothly as possible. The choice of a gas burner for a sauna stove depends in this case on the mode in which you plan to heat your steam room.

- Exclusively gas or combined.Gas burners are relatively simple device and affordable price. However, they justify themselves only if there is an uninterrupted supply of fuel. Combined type burners are designed to work with natural and liquefied gas, as well as with diesel fuel. The latter option is especially good for large baths, as it provides quick heating of rooms of any size.

Other differences

Consider the division of gas burners according to the type of ignition. The easiest option is with a burning igniter (wick). When the automation is triggered, the wick ignites the gas and the boiler begins to heat the coolant. There are two disadvantages here - increased gas consumption and low security (the igniter can go out). Primary ignition is carried out with matches or with the help of a piezoelectric element that gives a spark.

Natural gas from the mains gives even combustion, without forming excessive soot on the walls of the chimney.

Electronic ignition of the burner provides for the presence of a high-voltage converter in the gas boiler. Energy is taken from batteries or the mains. The first option is used in non-volatile boilers that do not have electronic automation. The second option is relevant for complex units with electronics on board. Together with such ignition, modules for ionization control of the presence of a flame are often installed.

There is also a division according to the type of fuel used. Natural gas supplied from the pipeline is cleaner, it is supplied with optimal pressure (we do not consider cases of pressure surges in both directions). The flame in the boiler is clean, without soot.The equipment is connected to the network without alterations. There are burners that can run on propane - this requires setting up the system and installing a jet. The flame from the combustion of propane gives off yellow, there is an increased deposition of soot on the chimney.

Jets allow you to normalize propane pressure to an acceptable value - they are supplied as a kit or purchased separately.

What is a gas burner

A gas burner is one of the most important components of any boiler. She is responsible for creating a sustainable flame. This is where the fuel is burned. The received heat rises up to the heat exchanger, where it almost completely passes into the coolant. Combustion products, together with the remaining heat, are somehow removed into the atmosphere.

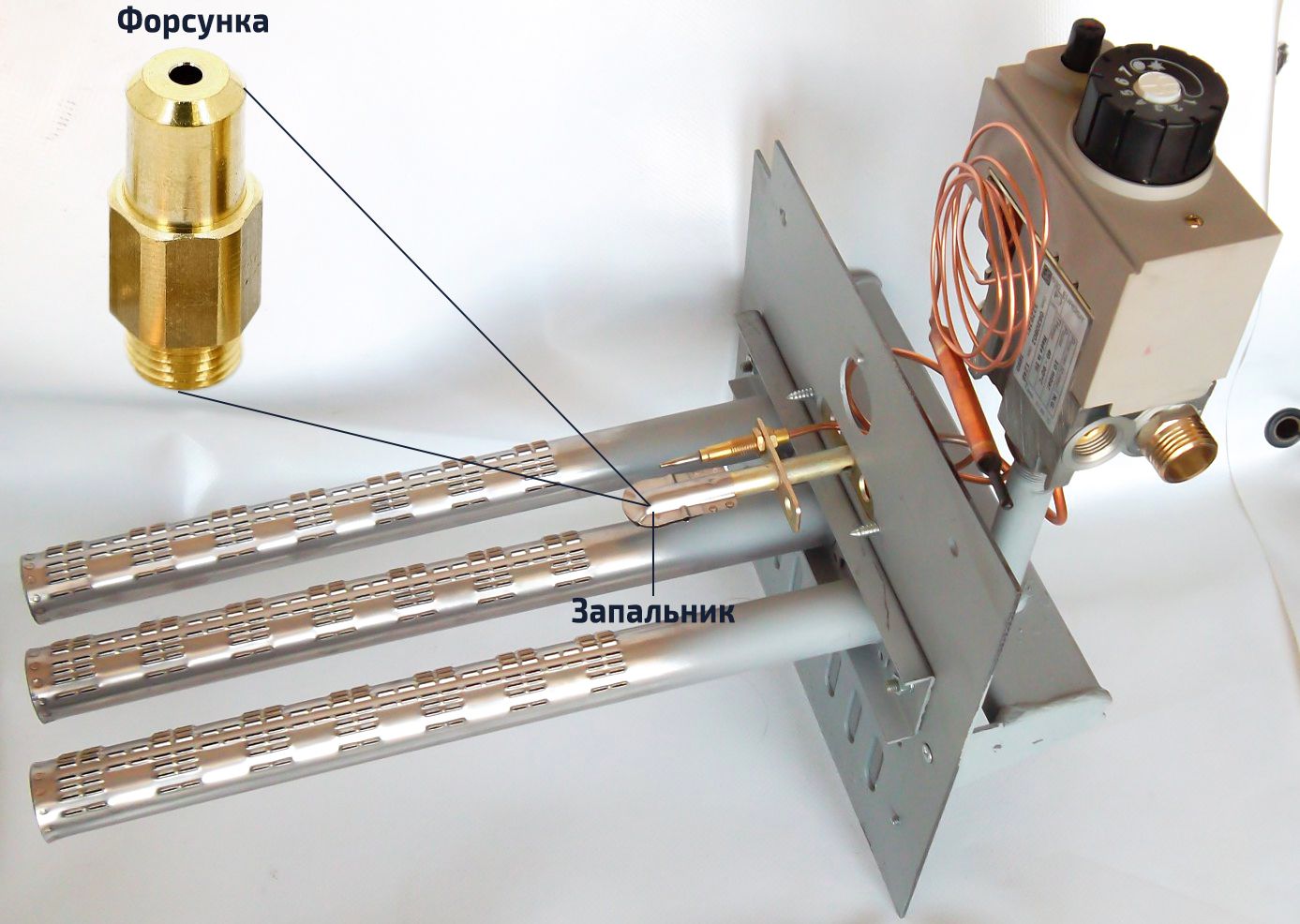

The device of a gas burner for a boiler is extremely simple - it includes several main components:

The low emission of nitrogen oxides and carbon monoxide during combustion makes the boiler almost ecologically perfect.

- Nozzle - gas is ejected from here;

- Ignition system - provides gas ignition;

- Automation system - controls the temperature;

- Flame sensor - monitors the presence of fire.

Simply put, this is exactly what it looks like. And how these or those types of gas burners differ from each other in various models of boilers, you will find out a little later.

A modern gas burner for a heating boiler is a device that has certain requirements. First of all, quiet operation is important. I immediately recall some models of Soviet instantaneous water heaters, where the flame was noisy with the force of a hurricane

Modern samples burn relatively quietly (attention is also paid to quiet ignition, without pops and explosions). An additional influence on the noise level is exerted by the design of the combustion chambers. Long service life - if you remember the old gas units, they served for quite a long time (in those days everything was done for centuries)

Today, such technologies no longer exist, so burners in boilers often break. There is only one way out - to buy units from trusted brands, which use components of normal quality. As for any Chinese junk from obscure manufacturers, everything is obvious here - you should not take

Long service life - if you remember the old gas units, they served for quite a long time (in those days everything was done for centuries). Today, such technologies no longer exist, so burners in boilers often break. There is only one way out - to buy units from trusted brands, which use components of normal quality. As for any Chinese junk from obscure manufacturers, everything is obvious here - you should not take it.

The same applies to cheap Russian-made boilers - short-lived burners are often installed in them.

Complete combustion of the gas is another important requirement. The burner for a gas boiler must burn the fuel completely, with a minimum release of carbon monoxide and other related components. However, everything depends not only on it - the quality of combustion is also influenced by other nodes.

We must not forget about proper gas removal, for which you need to have a clean chimney with good draft at your disposal.

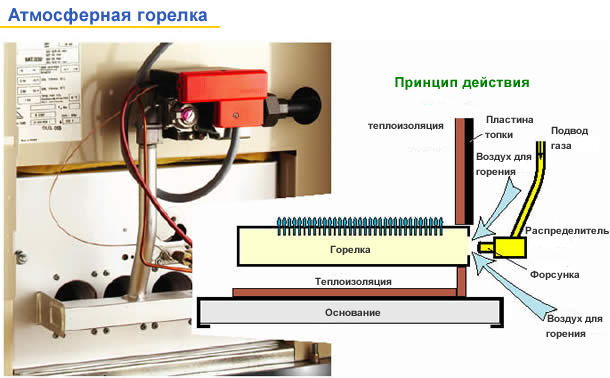

As for the principle of operation of a gas burner, it is simple:

However, everything depends not only on it - the quality of combustion is also influenced by other nodes. We must not forget about proper gas removal, for which you need to have a clean chimney with good draft at your disposal.

As for the principle of operation of a gas burner, it is simple:

In the burner, the combusted gas is combined with air. At high temperatures, a chemical reaction occurs with the formation of carbon dioxide and water.

- The boiler fixes the discrepancy between the temperature in the heating circuit and the parameters set by the users;

- The gas valve opens, gas begins to flow into the burner;

- At the same time, the ignition system is activated;

- The gas is ignited and a flame is formed.

At the same time, the control of the presence of a flame begins to work - if the fire suddenly goes out, the automation will cut off the supply of blue fuel. As soon as the temperature in the heating system reaches the set limit, the gas supply will be shut off.

The implementation of flame control is implemented in gas burners in different ways. Somewhere there is a simple thermoelement, and advanced boilers with electronics-based automation are endowed with ionization control systems.

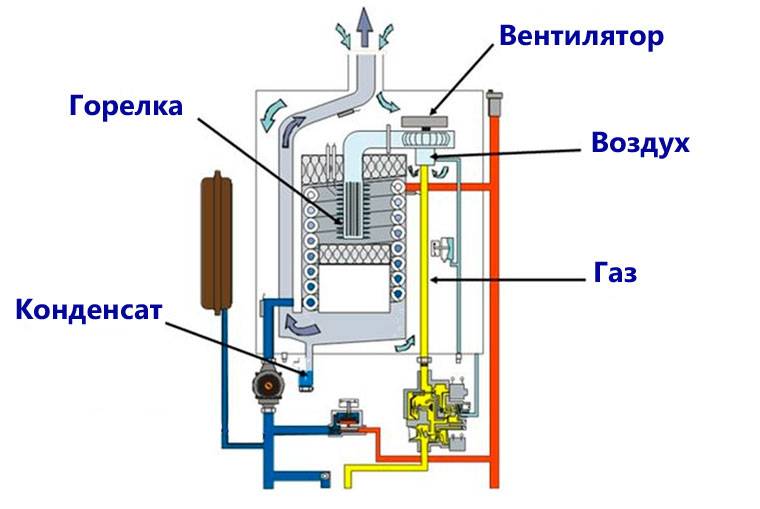

Principle of operation

Gas industrial boilers, regardless of their power, practically have the same control scheme and principle of operation. Structural differences are observed only in water-water and steam-water boilers. Boiler plants of industrial enterprises consist of main and auxiliary equipment.

The main ones include the boiler itself and the devices enclosed in its body - pipe packs, separators, collectors, drums.Auxiliary equipment includes a gas burner, pumps, fans, smoke exhausters, fittings, a headset, an automatic control and safety system.

In hot water boilers, water is heated to a maximum temperature of 150 C, as a result of fuel combustion and heat transfer from flue gases to the main heat carrier. The panels are made gas-tight to increase heat transfer; for this, steel pipes are welded together.

After the furnace, the flue gases of the waters, under the influence of the discharge created by the smoke exhauster, enter the convector unit, where the pipes are mounted in a checkerboard pattern, which increases the heating surface and the rate of water transfer to the network coolant.

In a hot water boiler, water moves forcibly, the speed of movement is determined by network pumps that provide the necessary performance and pressure. Water enters and exits through the boiler manifold.

The principle of operation of a steam boiler is different from a hot water boiler. The movement of water in its internal circuit occurs due to the natural circulation of cold and heated steam-water media.

As a result of the heat transfer process, saturated or superheated steam is produced at the boiler outlet. To collect it in modern boilers, drums and separation devices are installed in the upper drum in order to remove the smallest particles of boiler water from the steam.

Network water does not circulate through the steam boiler, it is fed with chemically treated feed water using special feed pumps.The network water circuit does not intersect with the feed water, and it is heated in steam-to-water network heat exchangers, in which steam from the boiler through the pipe system heats the supply coolant to a maximum temperature of 150 C.

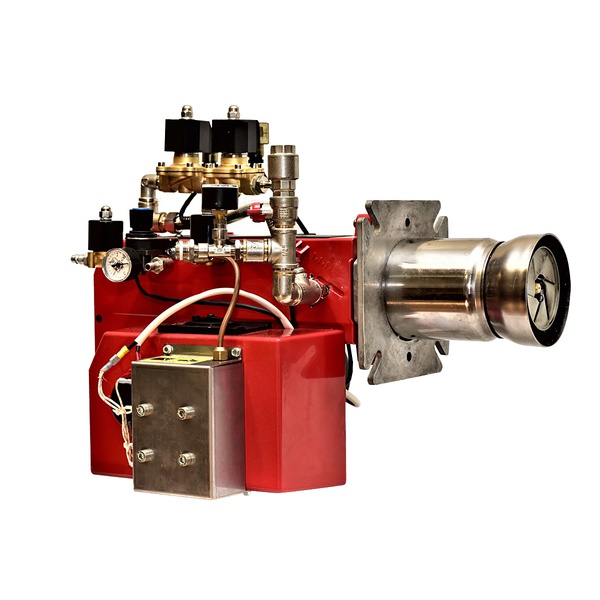

Fan

In these elements, air is forced to the place of mixing and ignition using fans that are built into the gas equipment. Therefore, such burners are called blast or pressurized. Their use increases the efficiency of the boiler, which leads to economical fuel consumption. Unlike atmospheric models, fan burners are optional equipment and must be purchased separately.

These devices are usually installed in boilers with a closed combustion chamber. Air is supplied to the burner in certain doses, but it mixes with gas instantly.

Modern fan models have a high level of automation. This is a kind of unit consisting of a device for burning fuel, a fan and automation that ensures the safety of gas equipment.

If the device does not receive enough fuel or with an excess, then an automatic shutdown occurs, which prevents the occurrence of accidents. To restart the gas equipment, you will have to completely eliminate all existing problems.

Scheme of operation of a fan gas burner

Gas fan burners are:

- Vortex. The holes in them have only a circular cross section;

- Direct-flow. These devices are equipped not only with round holes, but also with rectangular and in the form of a slot.

The advantages of pressurized devices are due to the special design of the heat exchanger, which ensures high efficiency of gas equipment.In addition, the combustion of fuel takes place in an isolated chamber, and this is an additional safety during the operation of the boiler.

But fan burners also have disadvantages:

- Relatively high noise level from the fans. Although the hum is mostly created due to the flow of the gas mixture leaving the nozzle under pressure. To reduce noise, modern boilers are equipped with a silencer;

- Dependence on electricity and its excessive costs;

- Higher price than units with atmospheric burners.

But still, the use of supercharged devices allows you to increase the productivity of gas equipment and ensures its efficient operation at any gas pressure in the line. In addition, they have proven themselves well when used in boilers as liquid (fuel oil, diesel fuel) and solid (wood, coal) fuel.

Dependence of the choice of device on the size of the group and the level of fuel consumption

One of the most important factors to consider when choosing a burner is group size. For a group of 10 people, it is best to purchase several burners. This is due to the fact that if there are several devices, the cooking process will not be delayed.

As for fuel consumption, most products have enough standard gas cylinder weighing 230 grams to boil 14 liters of water. It should be taken into account that this indicator is influenced by factors such as:

- Weather.

- Air temperature.

- The presence of wind protection.

- Water temperature.

Therefore, taking into account all these factors, about 15-20 servings can be prepared on one gas cylinder.

Fuel burners are much easier to operate.In order to check their level of liquid fuel, it is enough just to open a flask and inspect the supply, while determining the level of gas in a cylinder can only be done by sound. As a rule, it is extremely difficult to determine the amount of fuel by sound, therefore, when using burners on such fuel, you should always have a spare bottle.

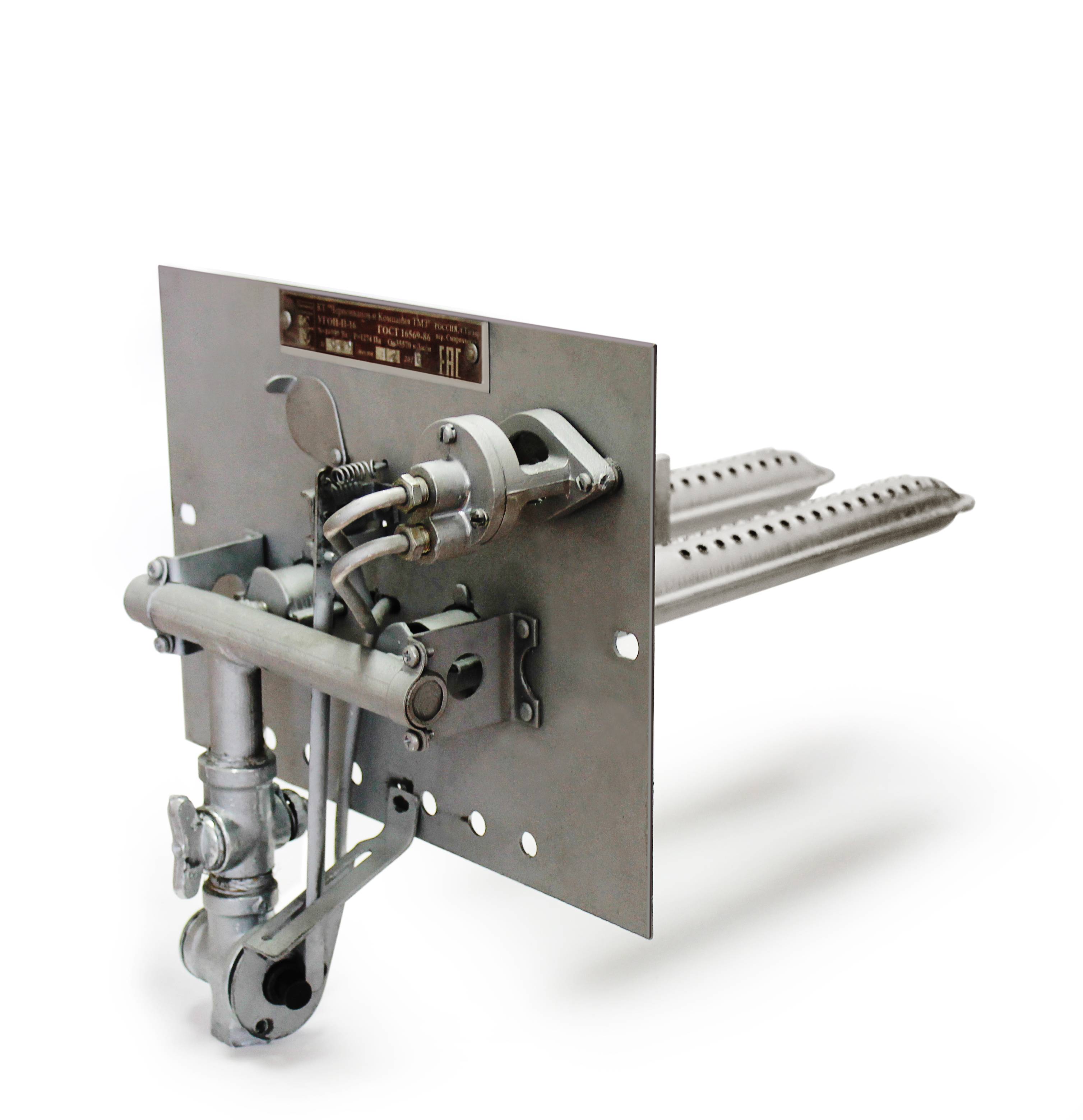

Atmospheric gas burners for gas boilers

Atmospheric gas burner stands in boilers with an open combustion chamber. By the type of work, they are very similar to a simple gas stove: the gas enters the burner and burns when mixed with the air coming from the room.

The positive features of the atmospheric burner are the simplicity of design and silent operation. Disadvantages, low efficiency (up to 90-93%) and rarefaction of air in the room. That is why such boilers are placed in specially equipped rooms, furnaces, which are equipped according to special rules.

There are several nuances in the use of imported atmospheric gas burners.

According to EU standards in the lines there must be a stable gas pressure of at least 150 atmospheres. In Russia, these standards are similar, but may fall in winter and rise in spring. Such pressure drops lead to burnout of the burner in winter, and burning of the heat exchanger in summer. This means that in areas with unstable gas pressure, it is better to use inflatable burners, whose operation does not depend on gas pressure.

Advantages and disadvantages of equipment

Both types of gas boilers are easy to operate, efficient and durable. And they also have an attractive appearance.

The design of each type of gas boiler is designed to meet the needs of various categories of users, which clearly demonstrates their advantages and disadvantages. And they also provide an opportunity to understand the differences between a single-circuit gas boiler and its double-circuit counterpart, helping a potential buyer make the right choice.

Pros and cons of single-circuit units

Such products are able to provide stable heating of premises of any size, number of storeys, remoteness from the heat exchanger.

And, in addition, single-circuit boilers:

- more reliable than their double-circuit counterparts, the design of which is more complex, which leads to a slightly larger number of breakdowns;

- easier to maintain, which is also caused by design features;

- cheaper.

An important advantage is that single-circuit units can become the basis for connecting other equipment. That will expand their functionality and increase the comfort of living.

You should always remember that if necessary, provide hot water in the premises, along with a single-circuit boiler, you will have to buy a storage boiler. And this will lead to significant additional costs. And a set of the listed equipment will take up a lot of space, which can be critical for small apartments.

Connecting storage boilers will provide the premises with hot water. Moreover, water will be supplied hot at any time, which is not always possible to achieve from double-circuit analogues.

In this type of equipment, in the absence of the need for hot water supply, there are no pronounced shortcomings. But otherwise, the lack of universality immediately affects. Which leads to the need to purchase an additional electric heater.

As a result, its joint operation with a single-circuit boiler leads to:

- high costs for the purchase, installation, maintenance;

- a limited amount of water for domestic needs - boilers are most often bought for sharing with single-circuit units, so the question may arise about the rational consumption of water, the volume of which depends on the storage capacity;

- greater load on the wiring.

The last drawback is relevant in cases where the house or apartment has old wiring or powerful electrical equipment is used in parallel. So, it may be necessary to upgrade the wiring and select a cable with a larger cross section.

You should also be aware that a set of a single-circuit boiler and a boiler takes up significantly more space than one double-circuit boiler. And with limited space, this can be a significant drawback.

Advantages and disadvantages of double-circuit boilers

Units that belong to the specified type with some restrictions, but are still capable of providing hot water to two systems at once (heating, hot water supply). They also take up less space than their boiler counterparts. As a result, double-circuit boilers are more convenient to use.

Both types of gas boilers are easy to operate, efficient and durable. And they have an attractive appearance.

In addition, the competitive struggle of manufacturers has led to the fact that the difference in the cost of both types of units is gradually leveled.

Therefore, today you can find a double-circuit boiler whose price exceeds that of a single-circuit product slightly. Which in some cases can also be considered an advantage.

If we talk about the disadvantages of double-circuit boilers, then the most important is the inability to instantly provide hot water of the same temperature to all points of water consumption in a house or apartment.

So, in their heat exchangers, the amount of water that is needed right now is heated. That is, the stock is not created. As a result, the water temperature may differ from what is expected or change during use. This happens when the pressure changes, for example, after opening / closing the second tap.

When using a double-circuit boiler, often the water temperature differs at two different points of water intake - hot water can be delivered to the desired point with a delay, and significant. Which is inconvenient and leads to additional costs

As for installation, the installation of double-circuit boilers is a more complicated procedure, especially at the design stage. Since you will have to follow the numerous recommendations of the manufacturer

How to choose a tourist burner for a hike: climate features

There are quite a few different models of burners. It is customary to distinguish 3 main types of devices:

- Working on gas.

- Liquid fuel powered.

- Working on any kind of fuel.

All of them can be classified based on the conditions in which they are intended to operate. The best choice for travel:

In the warm season.

When preparing for travel in warm climates, look for lightweight, compact models with Epi-Gas fuel tanks. In the cold season

In the cold season.

For operation at low temperatures, it is best to give preference to liquid fuel devices.

In addition, you need to take into account the need for air travel. If you need to fly, then you should choose multi-fuel models. Since, most airlines prohibit the transportation of cylinders with gas fuel.

If during the trip there is a need to quickly boil water, then you need to pay attention to integrated systems such as those that run on gas fuel. Also, when choosing a burner, it is worth considering the required volumes of cooking.

When organizing a large campground, it is best to purchase a large, stable burner with a continuously adjustable flame.

Manufacturing materials

The most expensive boilers are those in which the heat exchangers are made of cast iron. This is because cast iron components last longer and are resistant to corrosion and thermal stress. Heat exchangers made of stainless steel and copper treated with an inhibitory composition are highly valued. Boiler models with components made of aluminum are cheaper.

The material for the boiler should be as resistant as possible to the appearance of cracks, rust. The service life of high-quality heat exchangers is at least 20-30 years. Cast iron boiler components have a special crystal structure to ensure uniformity of heat flows.

Pulse burner design

It has a higher efficiency compared to natural ones, is more efficient and complex in design.The fuel burner consists mainly of seven elements:

- Fuel pump, it supplies the boiler with fuel from the tank (liquid fuel) and is equipped with a pressure regulator that returns the excess fuel necessary for combustion.

- The fan, it provides the combustion process with the air necessary for burning fuel.

- A solenoid valve is a valve that works automatically. It is used to supply a jet of fuel in sufficient quantity for combustion.

- Nozzles are the central part of the burner. The nozzle allows the fuel to be very finely atomized to promote thorough mixing with air to form an air-fuel mixture for combustion.

- Fuel heater, it allows the liquid fuel contained in the tank to be made less viscous to promote combustion. This initial viscosity is related to the storage temperature in the tank as well as to the specific characteristics of the fuel.

- Electrodes, they allow you to ignite the gas-air mixture to create the desired flame.

- The combustion head, which consists of two elements. A tip that directs the flame and a reflector that holds the flame in the stove.

The operating mode of the burner can be divided sequentially into stages:

- pre-ignition. Turning on the fan, which allows the engine to run.

- Ignition. Opening the solenoid valve that directs the fuel into the nozzle.

- Ignition. A spark is created to maintain a stable flame.

- Operating mode. Turn off the igniter after the flame has stabilized.

- Stop. Closing the solenoid valve, turning off the burner and after 15-20 minutes ventilation of the furnace in order to free the furnace space from explosive mixtures, turn off the fan.