- When and why to change the filter on HBO

- Replacing the filter on HBO 4 generations - instructions

- Varieties

- Polyphosphate

- Electromagnetic or magnetic for hard water softening

- Cleaning cartridges

- Classification of fittings for gas pipelines

- How to put on and store?

- We use a filter for a gas boiler

- Compact Gas Filter (70600 Series)

- Types of gas masks

- Filtering gas mask GP

- Insulating gas mask (IP)

- Autonomous

- Hose

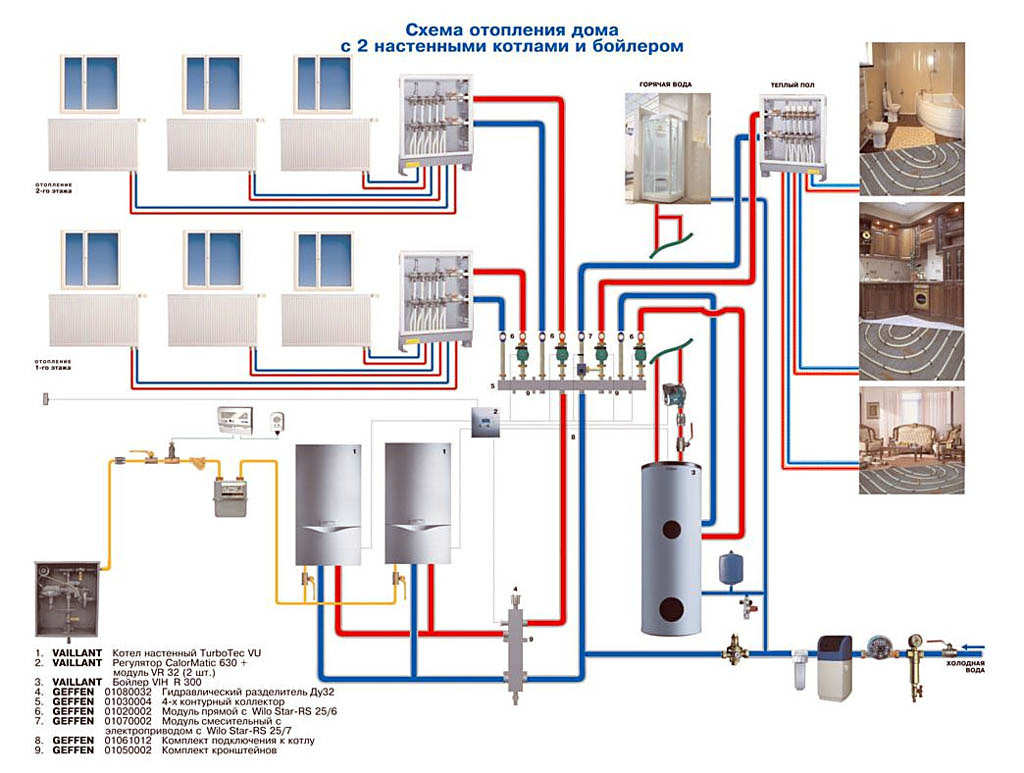

- Features of installation in the house

- Materials and tools

- Site selection and preparation before installation

- Mounting

- Starting the DHW system and checking

- Gas mask marking

- Benefits of using a heating filter

- Gas filter for boiler

- Functions and purpose

- Types and how to choose

- Popular Models

When and why to change the filter on HBO

timely replacement or cleaning HBO filters a very important procedure, since clogging leads to the creation of a high resistance to the gas flow.

The result is a rapid overheating of the engine. Besides, when clogged HBO filter, contaminated cardboard may tear due to the accumulation of dirt and enter the equipment, resulting in breakage.

For the design to work properly, purchase only original and proven spare parts.Devices of non-original production often do not meet the requirements and standards and can lead to a quick breakdown of the equipment.

VIDEO INSTRUCTION

Replacing the filter on HBO 4 generations - instructions

HBO 4th generation involves the use of two filters.

The first is installed between the nozzles and the reducer, and the second is located directly in the gas reducer.

The room in which the replacement will be carried out must be well ventilated, since even a small gas leak cannot be avoided, it is important to exclude proximity to any sources of sparks or fire

Required tools:

- screwdriver,

- octahedron,

- soap solution

- two filters.

VIDEO INSTRUCTION

HBO filter replacement procedure:

- Tighten the gas cylinder valve tightly, preferably half empty.

- Relieve pressure by starting the engine. This will start the consumption of the remaining gas in the system and the car will start running on gasoline. If possible, it is better to drive a few kilometers on gasoline before replacing.

- Unscrew the gearbox with an octagon.

- Remove the cover, dismantle the old device without touching the nearby rubber tubes (after analyzing the mud accumulations, you can understand how worn out the installation is, how it worked, what are the shortcomings of its work).

- Remove dust near the filter installation site with a vacuum cleaner. Treat the installation site of the new filter with a special liquid.

- Lay a rubber ring on the bottom, then a new filter, then another sealing ring.

- Close the cover, turn the screws.

- Loosen the two clamps with a screwdriver, remove the second old filter.

- Put a new one in its place so that the arrow points to the injectors.

- Open the valve on the bottle.

- Then, with a soap solution, check all unscrewed connections to identify possible gas leaks.

The cost of a new device starts from 1000 rubles. When buying it directly from the service, you can save on installation, as you can be offered free installation or a good discount.

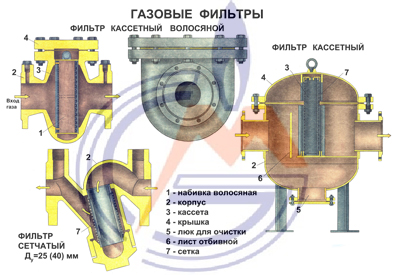

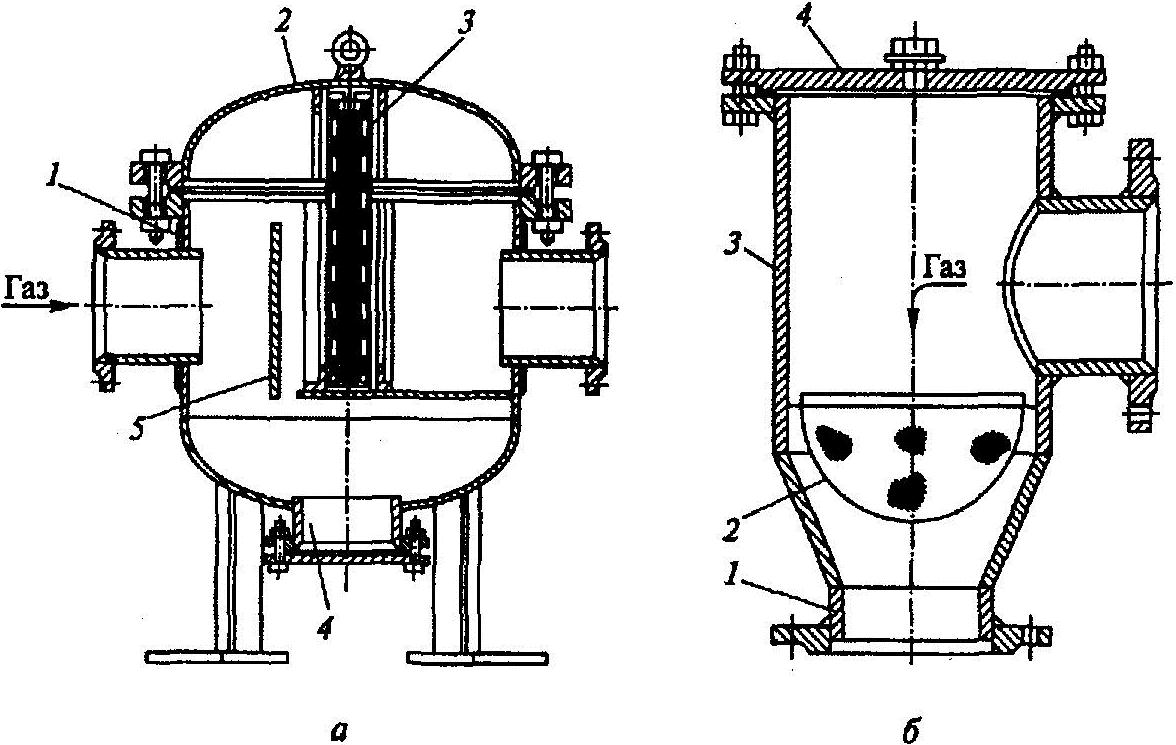

Any gas system must have a gas filter, including a gas boiler. The device is mounted on a horizontal section of the pipe. The filter for a gas boiler cleans the gas passing through it. This improves the error-free operation of flow meters and prevents gas equipment from failing.

You can find out the price and buy heating equipment and related products from us. Write, call and come to one of the stores in your city. Delivery across all territory of the Russian Federation and the CIS countries.

Varieties

To reduce the risk of boiler breakdown, increase the accuracy of measuring instruments and ensure a long service life of equipment, it is important to understand the main types of devices and choose the right one.

Polyphosphate

Polyphosphate plants are considered a budget option for pre-treatment and softening of water entering the boiler.

The principle of operation of such a device is to pass a liquid through a flask filled with special crystals. They ensure the formation of a protective film on the inner walls of the boiler, and also slow down the formation of scale.

Photo 1. Polyphosphate filter for a gas boiler filled with special crystals. They slow down the formation of scale.

The devices have a simple design:

- drain;

- flask;

- filler;

- lid.

The liquid through the lid enters the flask with filler, where it is passed through polyphosphate crystals.Further, it goes through the drain into the gas boiler tank.

Any device of this kind requires periodic replacement of the filler - sodium salt crystals. Strictly speaking, only in this lies the complexity of their maintenance. The service life of such a cleaning plant is on average up to one and a half years.

Electromagnetic or magnetic for hard water softening

Electromagnetic devices are expensive, but the price is fully justified: the installation lasts a long time and allows you to get perfectly clean water at the outlet.

The principle of operation is that when the liquid passes through the flask, the salts in it decompose. Thus, scale will not settle on the walls of the boiler. Instead, the filter itself will become clogged with the smallest particles of salt, which is washed periodically.

Photo 2. Three magnetic filters for the boiler of the heating system, the scale in them breaks up into tiny particles.

Another characteristic will be that under the influence of electromagnetic radiation, not only that the scale breaks up into small particles, but also the thinnest film is formed that covers the boiler heat exchanger. Thanks to this, it remains protected and does not corrode for a long time.

We should not forget that electromagnetic and magnetic devices are different installations. Both are based on a magnet.

Attention! Electromagnetic devices are more powerful, as they require connection to the electrical network. Ideal for gas boilers, as they perfectly soften water of any temperature

Magnetic installations are less strong and are not recommended for gas boilers if the water hardness is too high.

Magnetic devices consist of a metal case, inside of which there are a large number of strong magnets. Electromagnetic devices are additionally equipped with an electric drive, the operation of which allows you to multiply the action of magnets.

Cleaning cartridges

Cartridge devices have low throughput. There are the following types of devices:

- Mechanical - trap small debris. Such devices need to be cleaned frequently, and they do not soften the water.

- Coal - purify water due to activated carbon, which acts as a filler. If you do not change it in time, the water will become even more polluted as a result of passing through the filter.

Photo 3. Four low-throughput cartridge filters are needed to purify water.

- Ion-exchange cartridge devices are considered the best, as they change the hardness of water by entering into a chemical reaction with calcium and magnesium ions.

- Osmotic - pass through the molecules of water with gas. This allows you to purify the liquid from metal impurities and harmful microorganisms, but it will not work to soften the water by installing such a filter.

- Membrane - purify water from debris and impurities, but do not soften.

Important! Cartridge filters for gas boilers are not suitable (with the exception of ion exchange devices). They are more focused on purifying water that is supposed to be drunk.

Classification of fittings for gas pipelines

All existing types of gas fittings, depending on its purpose, can be divided into:

- shutoff. Fittings used for periodic shutdowns of individual sections of the gas pipeline, instruments, equipment. This type includes gas valves, gate valves;

- safety.Serving to prevent the risk of increasing gas pressure above the established norms. This type of fitting includes a relief safety valve;

- regulatory. Designed to change and maintain pressure within the specified limits. These are dampers, gates, etc.;

- reverse action. To prevent a change in the direction of gas movement;

- emergency and cut-off. For quick auto-stop of gas movement towards the emergency section in case of violation of the specified mode. This variety includes a shut-off safety valve;

- condensate drain. The one that automatically removes condensate that accumulates in condensate collectors and in the lower sections of pipeline networks;

- control. Determines the pressure of the passable mass, temperature, etc.

According to the control method, valves can be of two types: controlled and automatic. The first is driven by manual manipulation or by means of a drive: pneumatic, hydraulic, electromagnetic, electric.

The manual control process is characterized by the application of great effort and loss of time. More often, a drive is installed and the possibility of emergency control is retained in case of accidents. And the second operates with the help of auto-operation devices.

Flange connection of gas pipelines is used at transitions from an underwater or underground section to a surface one. This type of connection helps in the fight against electrochemical corrosion.

Flange connection of gas pipelines is used at transitions from an underwater or underground section to a surface one. This type of connection helps in the fight against electrochemical corrosion.

According to the method of connection, equipment and any fittings for gas supply systems are:

- flanged - used for fittings with a passage for a medium of more than 50 mm. Connection to pipes is carried out by screwing flanges. The main advantage of such a connection is the possibility of multiple reinstallations, greater strength and reliability. It can also be noted universal applicability. As a disadvantage, only a large mass and large dimensions of such parts are distinguished;

- coupling - used to connect equipment with a passage of 65 mm or less. Connection is made by means of couplings with a thread located from the inside. The disadvantage of coupling joints is that the thread is gradually erased;

- tsapkovye with cut external thread. One device is threaded into another device;

- welding - these are non-separable joints that are rarely used today. The advantages of this method are reliable tightness and minimization of maintenance activities. The disadvantages include the complexity of dismantling the connection, which arises when repair is necessary, when the gas pipeline section is simply cut off;

- nipple - fittings are connected using a nipple;

- coupling - pipes are connected to pipe flanges with studs with nuts, which are located along the reinforcement;

- fitting - fittings are connected using a fitting, union nut and sealing rings. This is a reliable method of connection with the possibility of dismantling.

In addition to those listed above, there are other ways to connect gas fittings, but they are not used so often.

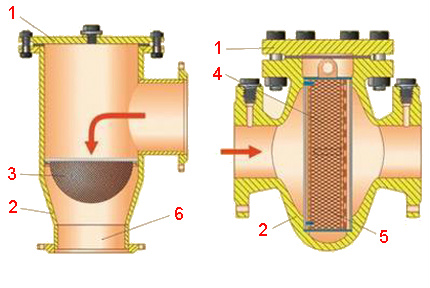

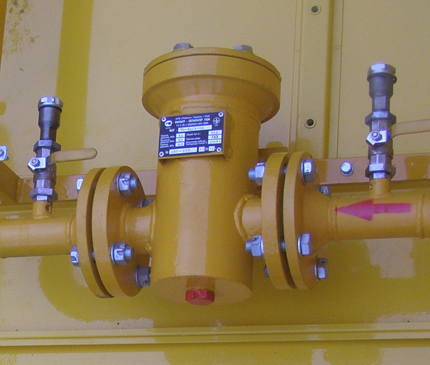

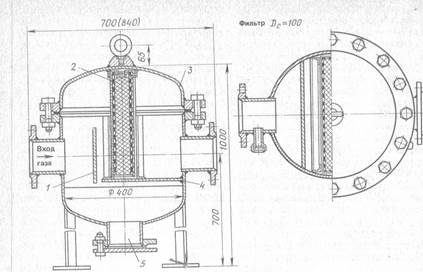

The gas flange filter is necessary for cleaning the gas medium from dust and impurities, thereby increasing the service life and reliability of gas appliances

The gas flange filter is necessary for cleaning the gas medium from dust and impurities, thereby increasing the service life and reliability of gas appliances

Also, do not forget that the functionality of the pipeline and the reliability of the entire gas distribution system will depend on the quality of the connection made.

How to put on and store?

Modern filtering gas masks are distinguished by the highest quality, reliability and unsurpassed protective abilities (in accordance with their class and type). But these products will be of no use if you do not follow the rules for their use.

It is important to wear a gas mask correctly and store it properly as well.

It may be a cloud or fog with an uncharacteristic color. You can take on the product even if you have received a signal that the area has been contaminated with toxic substances. Only then does it make sense to wear a filter gas mask. You need to do this in the following way:

- in order not to suddenly lose consciousness, you should hold your breath, close your eyes;

- if you are wearing a headdress, it will definitely need to be removed first;

- take out the filtering personal protective equipment, put it on, first sticking your chin into its lower half (meaning the bottom of the gas mask);

- make sure that there are no wrinkles on the product (if you find such defects, you will need to straighten them immediately);

- Now you can exhale and calmly open your eyes.

In whatever area you use a filtering gas mask, it is very important to store it properly. This means that throwing him into the first place that comes across is not worth it. Try to keep the product as far away from existing heating appliances in the house as possible.

It is advisable to store the protective equipment where it will not be subject to possible mechanical damage - follow this.Such a thing should be disassembled and put on only as necessary - you should not often take out a gas mask and “try on” it for yourself for the sake of a joke or entertainment. However, you may accidentally damage it.

Try to keep the product as far as possible from existing heating appliances in the house. It is advisable to store the protective equipment where it will not be subject to possible mechanical damage - follow this. Such a thing should be disassembled and put on only as necessary - you should not often take out a gas mask and “try on” it for yourself for the sake of a joke or entertainment. In doing so, you may well accidentally damage it.

Always make sure that the components of the gas mask are not covered with condensate. Subsequently, this can lead to rust on the metal components of the product.

What is inside the gas mask filter, see below.

We use a filter for a gas boiler

The gas filter for the boiler is a small structure that is installed in the gas pipeline. Its function is to collect dust particles and other debris in order to prevent it from entering the boiler system.

A filter for a gas boiler is a necessary addition to a traditional unit that will protect the main components of the structure from premature wear. If you want your boiler to serve you for decades, you should not ignore the need to purchase a filter element for the gas pipeline.

What does such a filter collect? The natural gas that enters our homes through the pipeline system contains all sorts of foreign particles. It can be resins, sand, the smallest elements of corrosion and much more.With the help of a complete purification of the gas entering the system, the tightness of the locking devices improves and their reliability increases. Moreover, devices such as meters will show the most accurate data without errors. As for the design of the unit itself, when using gas filters for the boiler, there is less wear on its main components, especially those that are extremely negatively affected by erosion.

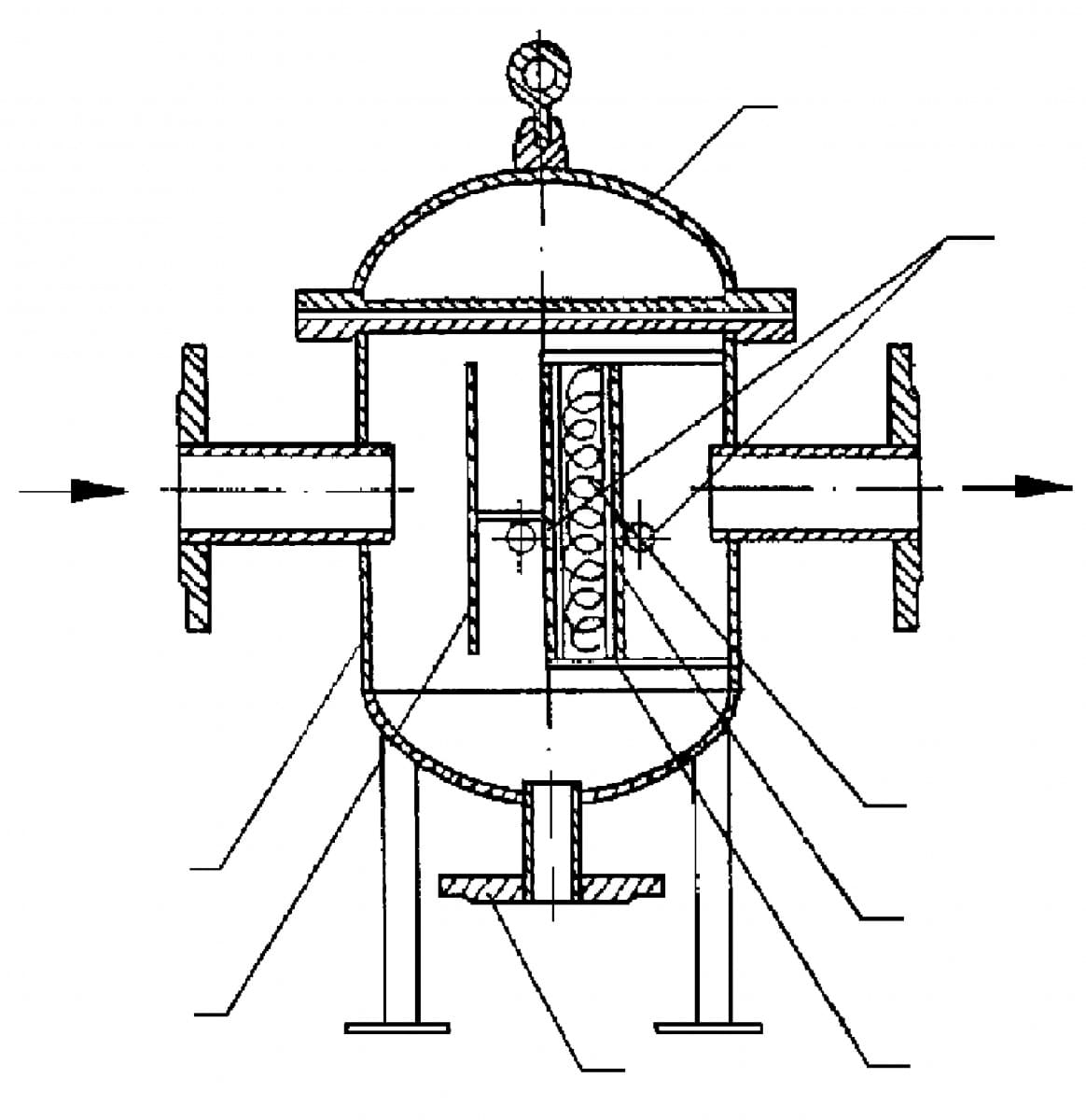

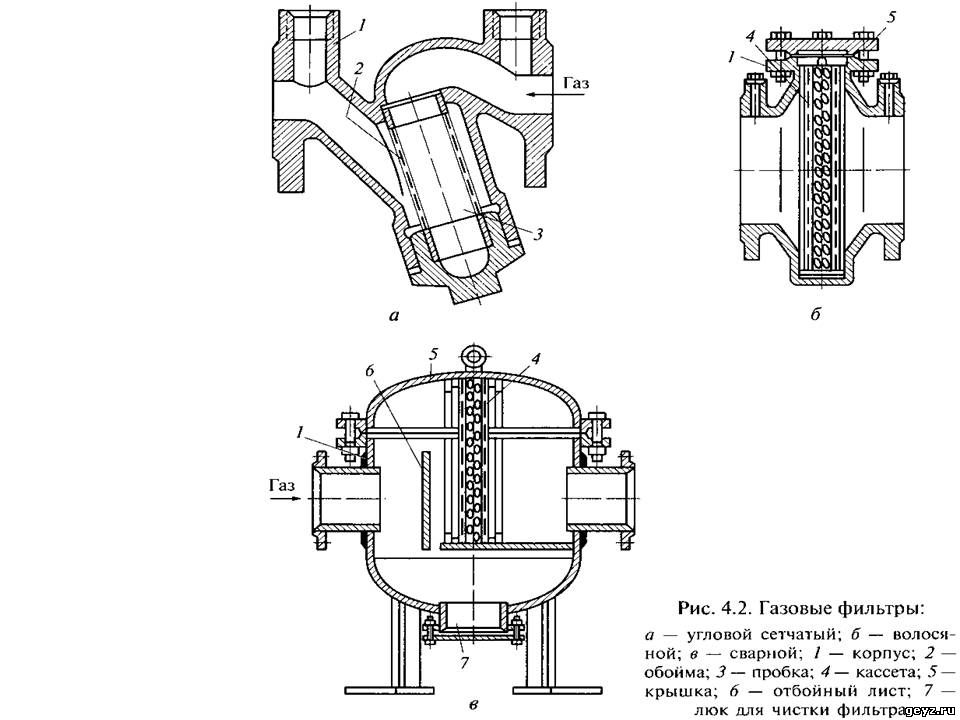

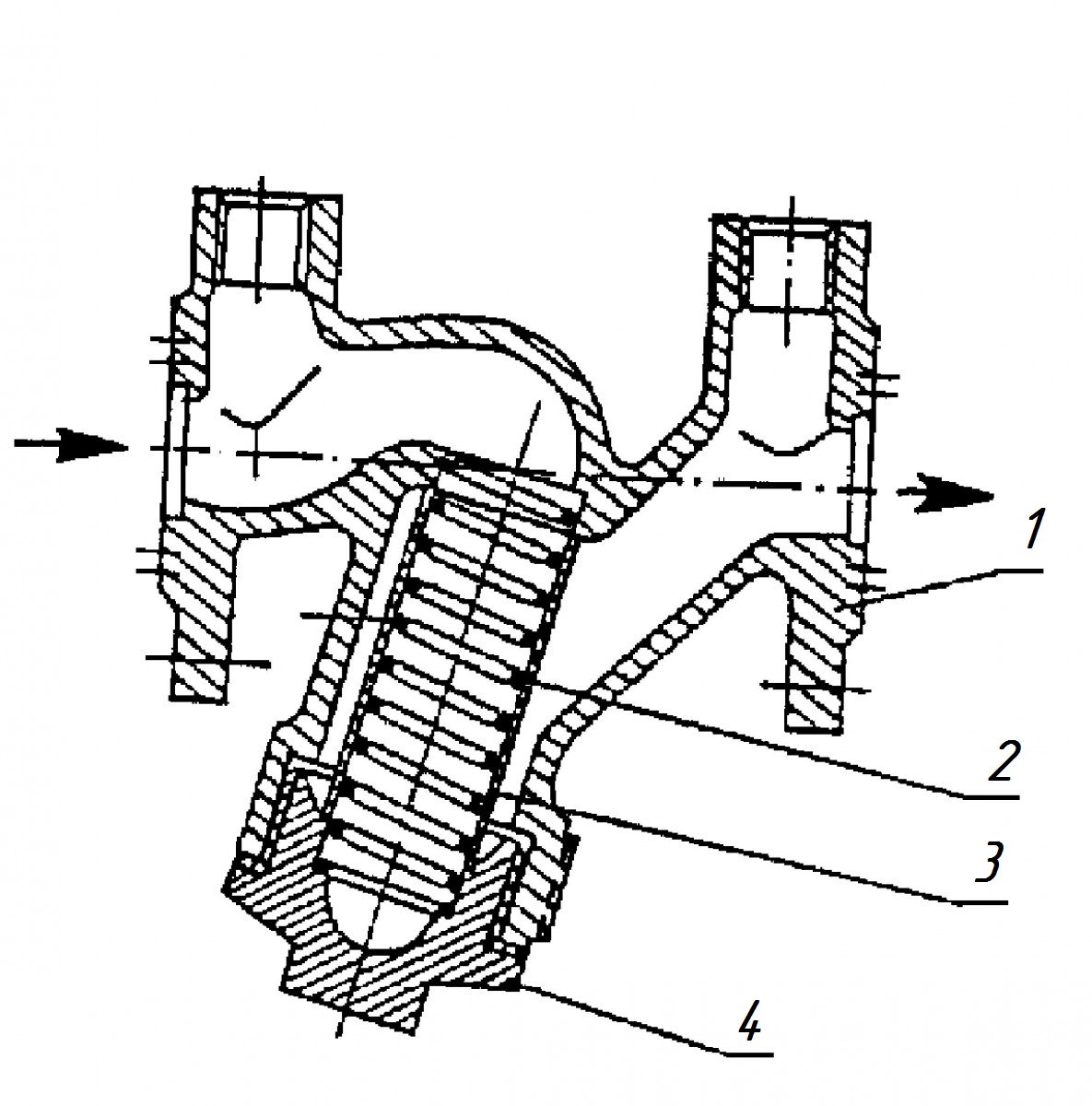

Choosing a filter for a gas boiler is a responsible task, since your decision depends on how reliable and safe your gas supply system will be. Today, a variety of filter units are presented on the market for heating equipment and components, which can be classified according to a number of criteria. In particular, there are direct-flow and rotary filters, which differ from each other in the direction of gas movement. Depending on the design features, angular and linear devices are distinguished. They are usually made from steel or aluminium. Moreover, it can be both welded-type structures and components produced by casting.

If you decide to purchase a filter for a gas boiler, start by evaluating the filter material. There are two main types of material - mesh and hair.

In the first case, a special metal woven mesh is used as a filter element, which effectively traps small dust particles. The hair filter is a cassette with pressed horsehair or nylon thread impregnated with viscin oil.

Consider popular products that are in demand in Russia in order to learn more about what a gas filter is.

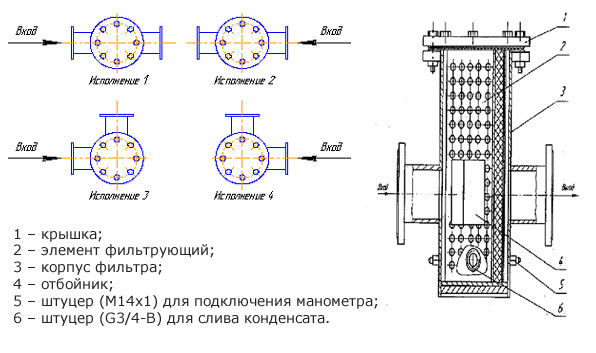

Compact Gas Filter (70600 Series)

This model, produced by the Italian company Giuliani-Anello s.r.l., is made of aluminum. It is completed with a cover made of galvanized steel. The construction is robust and according to UNI-EN161 this model is group 1 in terms of mechanical strength.

The filter is designed for a maximum inlet pressure of 0.5 bar and for operation in a temperature range from -10 to +80 degrees Celsius. The filter element is made of special material Viledon P15/500S, which has a high dust absorption rate and a long service life. Viledon P15/500S complies with the international standard DIN EN779, which says a lot.

The compact cleaner of the 70600 series will delight the owner with its small dimensions. It has been designed for operation with gas boilers and water heaters.

When purchasing this filter, you must follow the recommendations below:

- Make sure it is suitable for your heating system by checking the specifications;

- Do not install the filter in direct contact with plastered walls;

- During installation, use the appropriate tool;

- Mount the device in such a way that you have easy access to its cover;

- The direction of gas movement must correspond to the direction of the corresponding arrow located on the body of the unit;

- Mount the filter after the gas reducer.

The 70600 Series Compact Gas Filter can be used in both horizontal and vertical pipelines, making it a versatile solution for incoming gas filtration.

A filter for a gas boiler is a necessary option that will extend the life of your water heating equipment. A huge number of design variations in various price ranges will allow you to choose the optimal installation that will fully justify the money spent on it.

Types of gas masks

Depending on the situation in which there is a need to use a gas mask, different types are used. They differ in principle of operation, internal structure and purpose.

Filtering gas mask GP

This type of civil gas masks (GP) is recommended for use by the adult population in the event of a chemical, radioactive or bacteriological contamination of the environment.

Important! The percentage of oxygen in the air must be at least 18%. What is the GP made of?

What is the GP made of?

- volumetric mask covering the front of the head;

- the observation unit is made in the form of round glasses or a trapezoidal observation window, providing at least 70% visibility;

- mesh membrane for negotiations, protected by a sealed metal frame. Provides good sound transmission, sufficient for understanding intelligible speech and talking on the phone;

- the obturator is a thin elastic band that runs along the outer edge of the mask and ensures a snug fit of the gas mask to the face;

- the inhalation valve system is equipped with a thread that allows you to change and fix the filter box;

- separate valve exhalation system;

- the filter box is made in the form of a cylindrical housing made of metal or durable polymer material. Has a screw thread for attaching to the mask.Inside the box there is an absorbing layer (charge) consisting of activated carbon and a glass fiber filter to trap aerosol particles.

The filtering gas mask is attached to the head with a headband. It has a central part, located on the back of the head, and five straps with buckles and clamps that provide a snug fit to the face.

The action of a filtering gas mask is based on a natural chemical process, as a result of which poison gas passes through activated carbon and combines with it. The purified air enters the breathing mask.

Some harmful substances with low molecular weight and low boiling point can seep through the layers of activated carbon. To avoid this, additional components are installed in the filter box that can "weight" the gas molecules. Oxide compounds based on chromium, copper and other metals are used as "weighting agents".

Important! Filters must be replaced after the expiration date. Depending on the degree of air pollution, the period can vary from 10-15 minutes

up to several days.

Insulating gas mask (IP)

Such models of gas masks are equipped with a compression box, which allows them to be used regardless of the degree and type of air pollution. It is used when there is insufficient oxygen in the air (less than 18%). The difference from filtering gas masks is that a person receives air from an additional protected source and does not inhale it from outside. Like a filter, it is able to protect the respiratory organs, completely covers the head.

Consists of the following parts:

- helmet-mask - serves to effectively protect the respiratory system, supply oxygen and remove carbon dioxide. It has a spectacle assembly, connecting output tubes and an obturator. Equipped with a reliable head attachment system, an intercom for ease of communication and a special attachment for working underwater;

- excess pressure valve;

- regenerative cartridge into which exhaled carbon dioxide enters;

- breathing bag.

According to the method of supplying oxygen to a helmet-mask, there are two types of insulating gas masks: autonomous and hose.

Autonomous

The self-contained self-contained gas mask is equipped with a compressed oxygen cylinder. When inhaling, a person receives a portion of clean air and releases carbon dioxide through a special absorber.

Most often they are used by specially trained rescuers when extinguishing fires and carrying out rescue operations.

Hose

This type of gas mask differs from the autonomous one in that it has long tubes that extend to the oxygen tank. Fresh air is supplied by a compressor.

Hose breathing apparatus is used in enclosed spaces, sealed containers, wells up to 40 m deep.

On a note! There are combined gas masks in which the main air supply is through a hose. If necessary, in an emergency, it can be replaced with a compressed oxygen cylinder.

Features of installation in the house

The process of installing a water filter for a gas boiler depends on which filter we are talking about. But there is a general procedure.

Materials and tools

Before installation, you need to prepare everything you need so that the work does not take much time:

- brush for preliminary cleaning of pipes leading to the boiler;

- tool for threading plastic pipes;

- fum tape;

- tow;

- pliers;

- device for soldering plastic pipes.

All of the listed tools must be present in the arsenal during installation. And also on hand you need to have instructions for installing a specific type of device in front of a gas boiler.

Site selection and preparation before installation

The equipment is installed directly in front of the pump, since installation elsewhere would be pointless. The pipes into which the filter will cut must be free of dirt and scale, so they must first be cleaned with a brush or a special brush.

Important! The place where the device is supposed to be installed must be accessible for further maintenance of the device.

Mounting

Installation involves several steps:

- pipe cutting;

- installation and soldering of the first shut-off valve, which should be fixed on a fum tape or tow;

- installation of the filter, its fixation;

- installation of the second shut-off valve, its fixation.

Important! When installing an electromagnetic filter, the possibility of connecting to the mains should be taken into account. It is recommended to check in advance whether the diameters of the pipes, filter and taps are suitable for each other. In addition, experts advise mounting pipes and a filter on special brackets, thanks to which the installations will hold securely.

In addition, experts advise mounting pipes and a filter on special brackets, thanks to which the installations will hold securely.

It is recommended to check in advance whether the diameters of the pipes, filter and taps are suitable for each other.In addition, experts advise mounting pipes and a filter on special brackets, thanks to which the installations will hold securely.

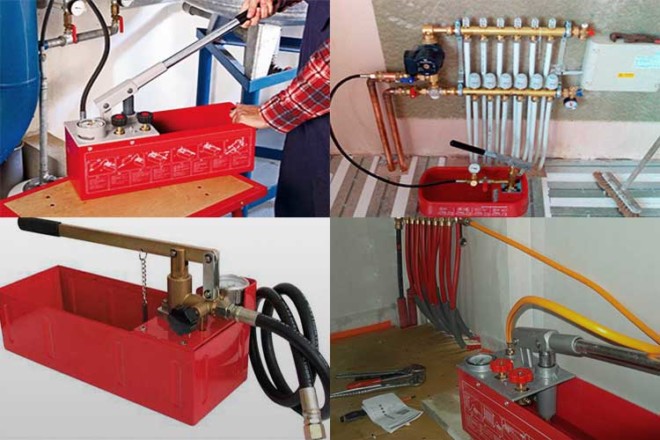

Starting the DHW system and checking

After the filter is installed, check the DHW system. To do this, first turn on the water: if nothing flows anywhere, turn on the gas.

The operation of an electromagnetic device will immediately be clear, since it works from the network.

But how effective a filter of another type is, it will be possible to understand only after a while.

In order to avoid mistakes, both for installing a filter on the boiler, and for checking and starting the system, it is better to invite an experienced specialist.

Gas mask marking

To distinguish between brands of gas masks, special letter markings are used. It is an abbreviation indicating the features of the protective device and its model. Consider examples of markings for different species.

GP for adults:

- GP-7 is the most popular means of protection for the adult population, which was discontinued more than 30 years ago. Its modified analogues are GP-7V (the presence of a device for receiving water), GP-7VM (has glasses made in the form of a trapezoid and two filter inlets), GP-7B (has a wide range of protection).

- GP-9 - has a large panoramic viewing window and a device for negotiations. Used to protect against mercury vapor, ammonia, radioactive emissions.

- GP-21 is a lightweight gas mask with a wide panoramic view. Used for effective protection against hazardous substances spread through the air.

- UZS VK 320 or UZS VK 600 - have a universal adjustable size.The kit uses filters of the first and third protection class, which surpass the standard ones in GP-7 in their properties. Recommended for use in emergency situations.

The marking of industrial gas masks differs from civilian ones. For classification, an alphanumeric code and color marking are used, which indicate the type of harmful substances and the level of protection.

The coding on the filters in letters means:

- A - organic compounds and gases with a high boiling point (more than 65 degrees), marked in brown;

- AH - vapors with a low boiling level (less than 65 degrees): gasoline, butane, acetone, kerosene, etc., (color - brown);

- B - gases of inorganic origin (gray);

- P - microbes and air suspensions (white);

- E is indicated in yellow - this category includes acid gases, including HNO3;

- K - from ammonia and its derivatives (indicated in green);

- CO (purple) - from carbon;

- SX - hanged hazard class of toxic substances, for example, sarin, fosten; (marking is purple)

- Hg - from evaporation of mercury vapor (red).

To indicate the degree of protection, numbers from one to three are used, where:

- 1 is low effective protection;

- 2 - protection with an average coefficient;

- 3 - a tool with a high protection index.

Other features of marking gas masks:

- Contains information about the manufacturer, for example, Breeze, DON, DOT, IZOD.

- The length of the used hose is indicated on the hose protective equipment, for example, PSh-1, PSh-20ERV, PSh-40RV.

Benefits of using a heating filter

Among the advantages that the installation of cleaning elements for heating carries, it is worth highlighting the following:

- the filter provides high-quality protection against any kind of pollution;

- draining the water in the system and filling the circuit with new coolant does not need to be done often;

- installation of a sump unequivocally allows you to save financial costs;

- a system equipped with such a filter will work for a long time and reliably.

Thus, the list of advantages of the cleaning element only confirms the fact that its installation is a guarantee of the stable operation of the entire heating system and the absence of the need for any kind of repair work. 1. 2. 3. 4. 5. 6.

The quality of the heat supply systems may deteriorate over time, for sure, most people had to deal with this at one time. Many people now have to live in houses built at least twenty years ago.

It is in such buildings that this problem is most often encountered. Poor circulation of the coolant, the role of which is most often played by water, causes poor heating. The corrosion process degrades the quality of water, impurities in which are deposited on the inner walls of pipes and radiators, preventing the normal passage of heat.

Naturally, there is a way out of this situation - or, for more “neglected” cases, its chemical purification (

Gas filter for boiler

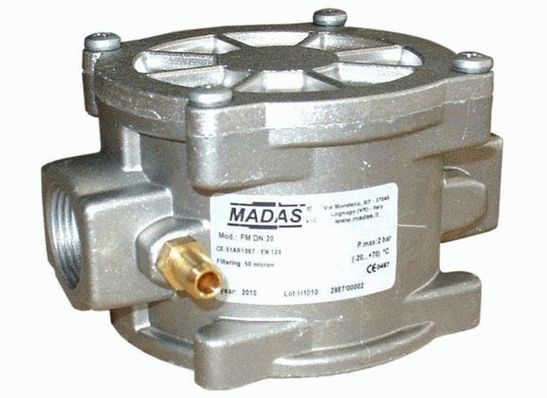

Any gas system must have a gas filter, including a gas boiler. The device is mounted on a horizontal section of the pipe. The filter for a gas boiler cleans the gas passing through it. This improves the error-free operation of flow meters and prevents gas equipment from failing.

Gas filter MADAS threaded

Functions and purpose

A gas filter for a boiler is an addition to boiler equipment that is necessary to protect components from early wear. If you intend to contribute to the long life of the boiler, then do not ignore the purchase of a gas filtration device.

The function of the filter is to collect excess particles (tar, sand, small pieces of rust) that come with the gas through the pipeline system. With the help of high-quality cleaning of the gas that enters the system, the tightness values \u200b\u200bof the shut-off valves become much higher, reliability is ensured. Plus, devices such as meters will show high-precision data without errors. The boiler room itself, using gas filters, will not fail so quickly, and the main components of the heating unit will not corrode.

Installed gas filter

Types and how to choose

The gas filter for the boiler must be chosen with full responsibility, because the level of reliability and safety of the gas supply system will depend on the choice. Currently, on the market for heating devices and components, you can see a variety of filtration units, classified according to some criteria.

Based on the direction of gas movement, gas filters can be distinguished:

Based on their design parameters:

Devices can be made from different materials, they distinguish:

Brass mesh filter for gas with a magnet

There may also be filters:

To select a gas filter, you need to evaluate the filter material. He can be:

- Reticulate. Here, the filtration element is a special woven metal mesh, which perfectly traps small dust particles.

- Hair.It is a cassette with pressed horsehair or nylon thread, which is impregnated with viscin oil.

Popular Models

Gas filters for boilers are quite popular in the Russian market. A popular model is a small device of the 70600 series.

The product is manufactured by Giuliani-Anello s.r.l. and made of aluminum alloy. The lid is made of galvanized steel. The advantage of the filter is high reliability, in accordance with UNI-EN161 the model has the first group in terms of mechanical strength.

Characteristics of the gas filter for the boiler series 70600 Giuliani-Anello.

Viledon P15\500S material is characterized by excellent and high-quality absorption of dust particles and a long service life. It meets the general standard DIN EN779.

Compact gas filter Giuliani Anello 70600

When buying this gas filter for the boiler, you need to remember the following rules:

- It is worth making sure that the filter element is combined with your heating system by examining those parameters.

- It is not necessary to install the device next to the walls on which plaster is applied.

- For installation work, use the appropriate tool.

- It is desirable to install the filter so that you can easily get close to its cover.

- The gas flow must correspond to the direction indicated by the arrow on the unit body.

- It is necessary to install the filter element after the gas reducer.

The 70600 series gas boiler filter is designed for installation on vertical and horizontal pipes, which ensures the versatility of the device.

The gas filter for the boiler is a small but very useful device for extending the operating period of the heating unit.A variety of design solutions and a variety of prices make it possible to choose the best device that fully justifies the money invested in it.