- Design and installation of a gas heating system

- Installation and connection of the boiler

- Gas heating boiler device

- Installation of a floor boiler

- Installation of a wall-mounted boiler

- Liquefied gas in the house: features, preparation

- The main advantages of heating with liquefied gas

- Stages and features of the organization of heating using liquefied gas

- Liquefied gas in cylinders: compact and cheap

- Types of gas boilers

- Types of wall-mounted boilers for home heating

- Floor standing gas boilers

- Air (convector) heating

- Heating system installation

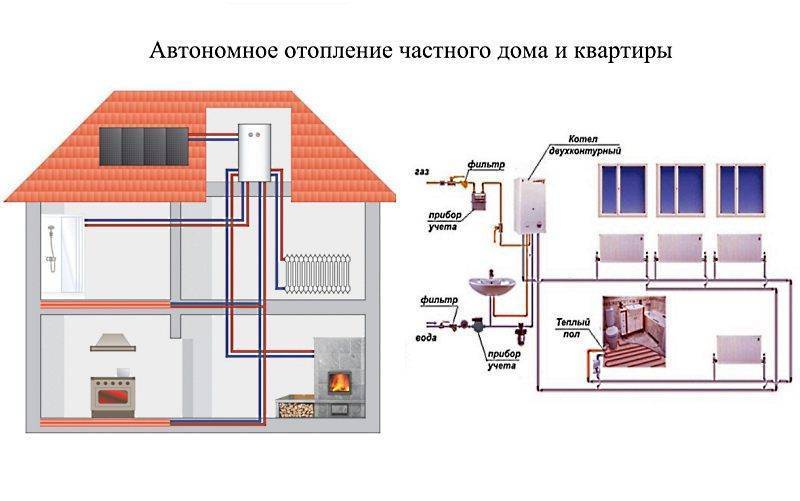

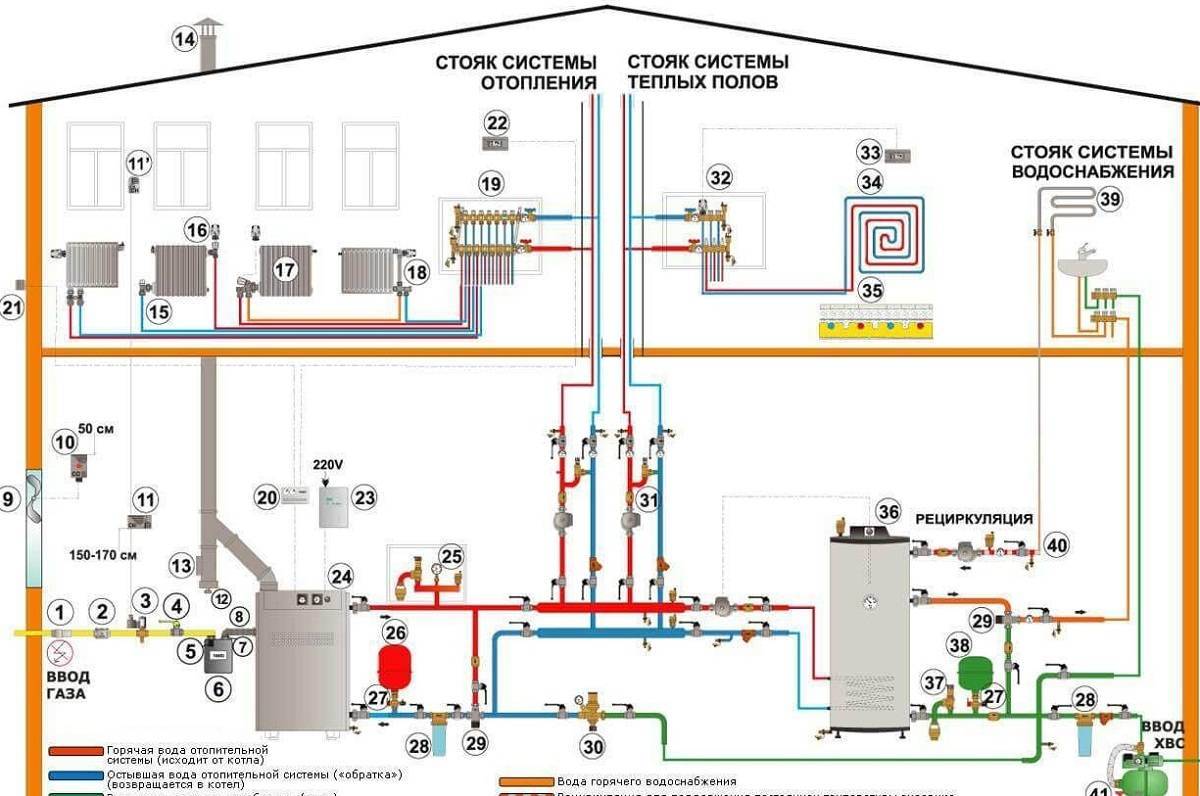

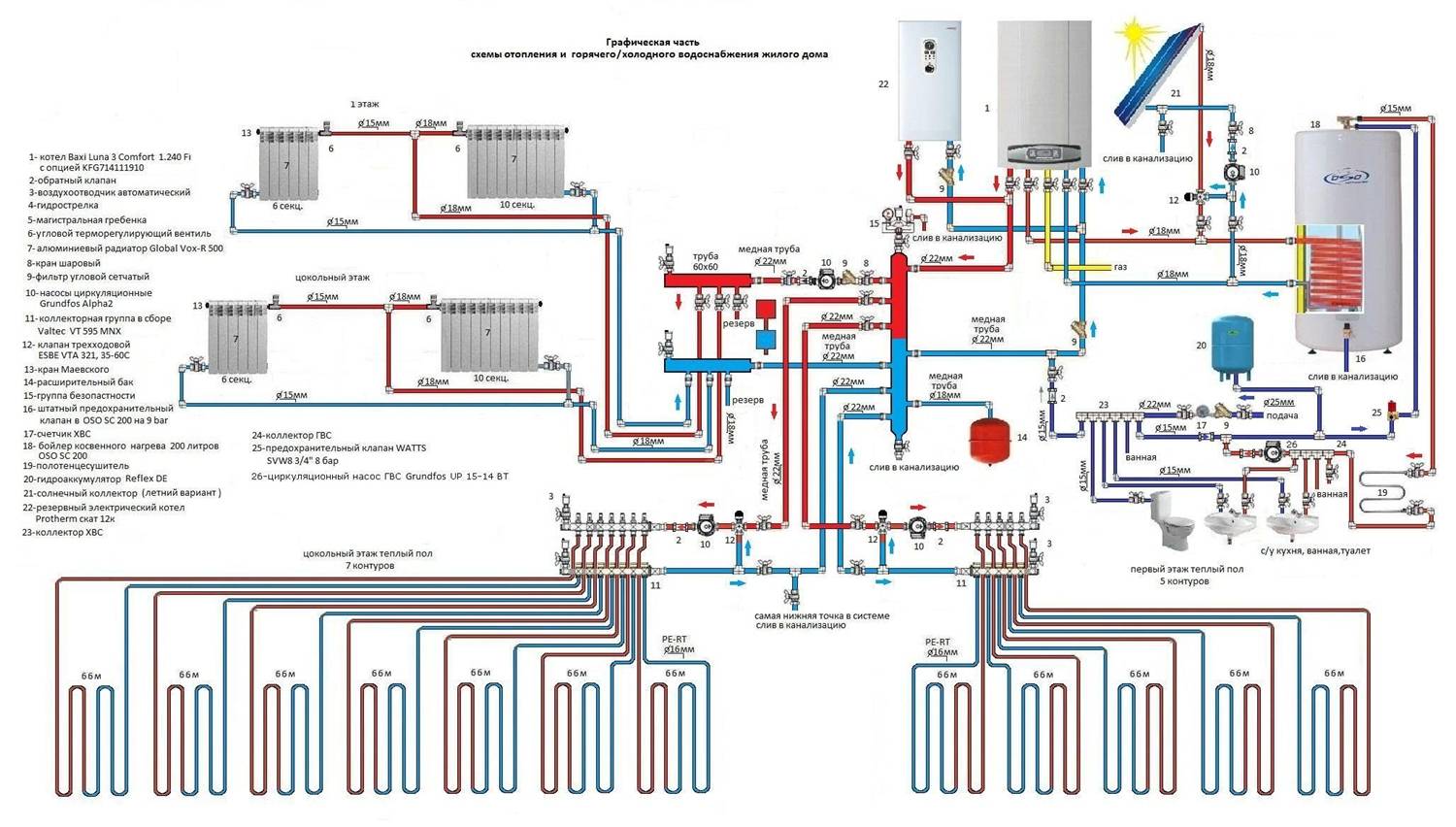

- Schemes of gas heat supply at home

- The device and elements of a single-pipe heating system

- What is the difference between solid fuel boilers

- gas fireplace

- Convection and condensing gas boilers

Design and installation of a gas heating system

special permission

The latter confirms their right to carry out such work. For this reason, you can only prepare everything for the installation of equipment yourself.

And entrust the installation of the boiler to specialists. They will quickly and correctly design the system.

It includes a whole package of documents:

- hydraulic and thermal calculation of the system;

- heating scheme with radiators;

- Hardware Specification;

- final estimate.

Only after all the necessary approvals and approvals have been obtained, materials and equipment can be purchased.

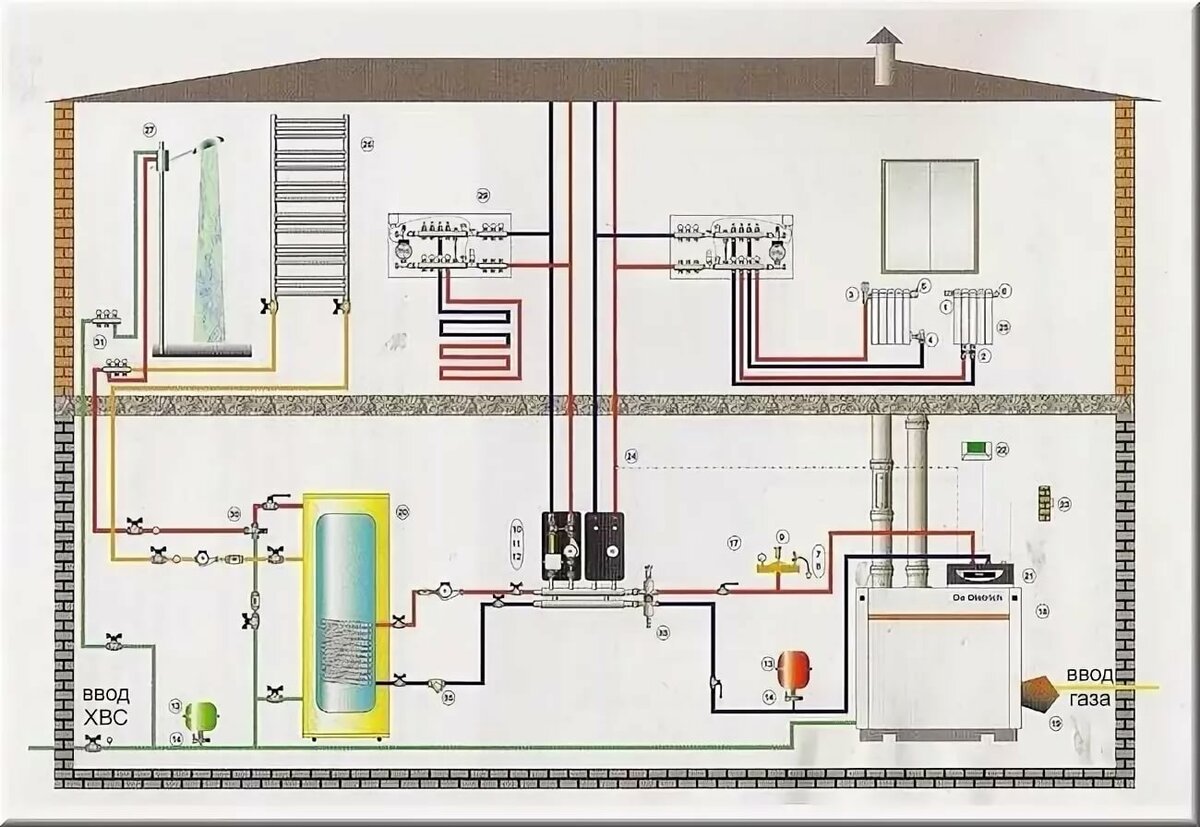

Installation takes place in several stages. First you need to install boiler equipment. Then comes the installation of the highway, as well as heating risers. An important stage is the installation of control equipment and control automation. In conclusion, commissioning and testing of the system in different modes is carried out.

Installation and connection of the boiler

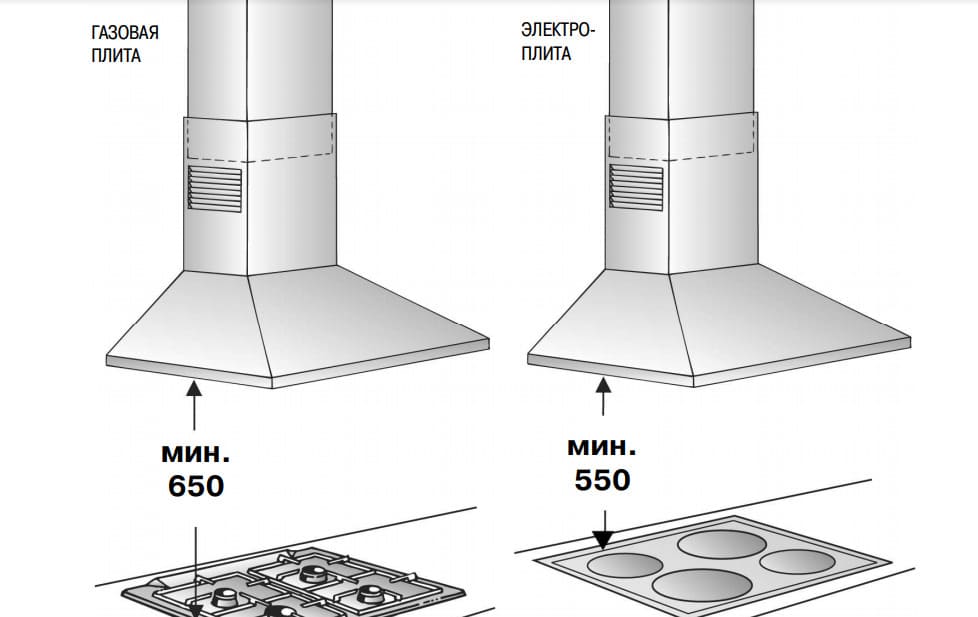

Now let's talk about how to make gas heating in a private house. For the installation of a gas boiler, it is necessary to allocate a separate room, to which the following requirements are imposed:

- fire resistance limit of enclosing structures - not less than 45 minutes;

- ceiling height - 2.5 m;

- unhindered access to the boiler;

- the presence of a separate exit to the street and a window opening;

- the presence of a gas analyzer.

Gas heating boiler device

Before you talk about the installation of gas heating, it is worth understanding the boiler device. The device of a gas heating boiler in a private house:

- Rectangular gas burner with nozzles for uniform flame distribution and efficient fuel combustion.

- The heat exchanger is a metal box with a built-in battery. A coolant circulates inside the pipes, which is heated by the heat released during the combustion of gas. In single-circuit boilers there is one heat exchanger, and in double-circuit devices there are two.

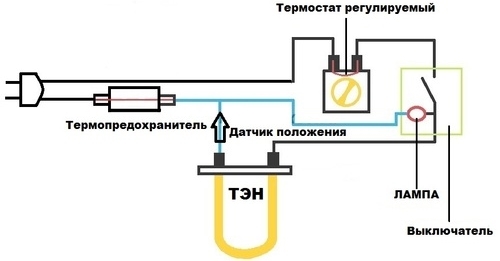

- The circulation pump is needed to regulate the pressure in systems with forced circulation. This part is not available in all boilers.

- Expansion tank for temporary removal of coolant.

- Automatic boiler control system.

- A device that is responsible for the removal of products of combustion of gas. In atmospheric units, this part is connected to the chimney, and in turbocharged boilers there is a double pipe with a built-in fan.

Installation of a floor boiler

If the installation of gas heating is carried out using a floor-type boiler, then a solid base with a fireproof floor covering must be prepared. The walls around the appliance to a height of more than 10 cm must have a fireproof coating. The minimum distance of the gas burner from the wall is 1 m.

First, the unit is connected to the chimney, then connected to the heating system inside the house. A coarse filter is mounted at the return inlet. Shut-off valves are installed on all pipelines suitable for the boiler. The two-pipe device is connected to the cold water supply pipeline.

Installation of a wall-mounted boiler

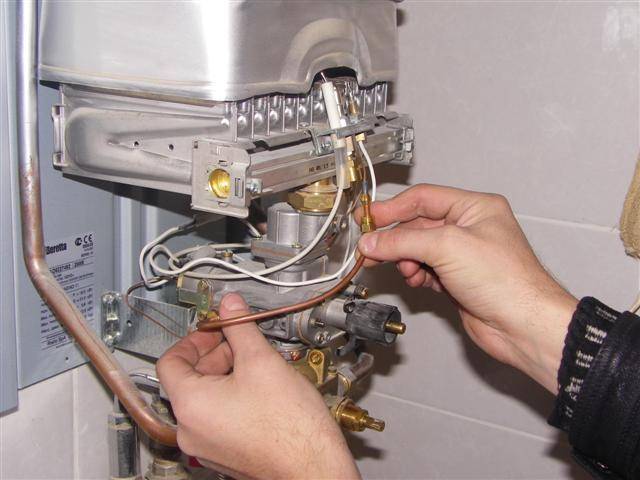

Before installing a wall-mounted device, the plugs are removed from it and the tubes inside are washed with a pressure of water supplied under pressure. So from the device remove debris that could get during assembly and transportation.

The unit is hung only on a flat and solid wall, on which a non-combustible gasket is installed. The device is mounted so that a gap of 45 mm remains from it to the wall surface. From other equipment, the boiler is installed at a distance of at least 20 cm. A socket must be equipped nearby.

To fix the boiler, special strips are used, which are set according to the level. After that, the equipment is connected to the water supply. Filters are installed on the incoming water pipes. To connect the gas pipeline, a steel pipe with a paronite gasket is used.

Liquefied gas in the house: features, preparation

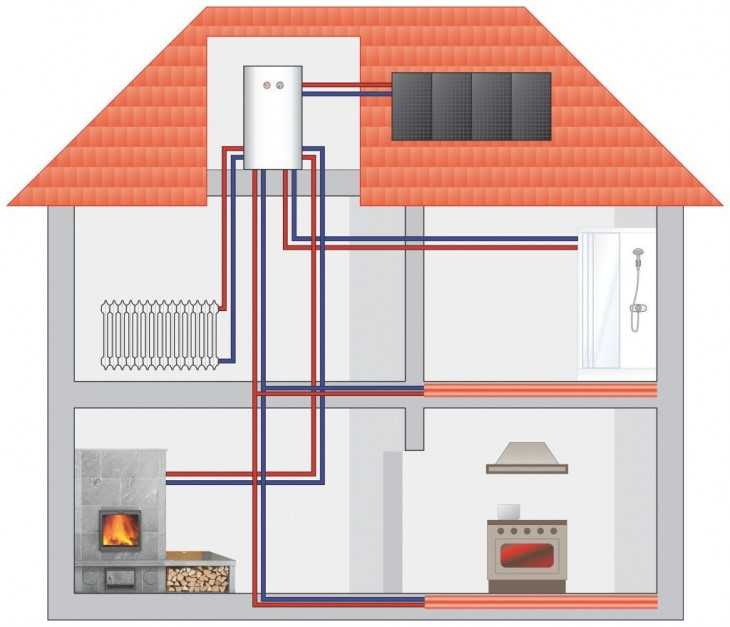

To organize this type of heat supply to a dwelling, special containers for fuel are used - gas holders. Located underground, the tanks feed the thermal unit, ensure the continuity and efficiency of work.

As a rule, gas tanks are installed at a distance of more than 10 meters directly from the house itself and 2 meters from all kinds of communications.

gas holder

Currently, a wide variety of containers for propane-butane mixtures are offered on the market, among which you can easily choose the best option for each specific house and boiler, thereby providing housing with high-quality heat.

For heating a private house with liquefied gas, as a rule, boilers with a capacity of 18-90 kW and tanks of 3-9 cubic meters for fuel storage are sufficient. The storage is filled by 85% from a special tank truck, which delivers propane-butane as it burns in the boiler.

LPG heating system

The main advantages of heating with liquefied gas

Currently, heating a private house with liquefied gas is a process that has many advantages over more traditional options.

Among the main advantages of this method are:

- the possibility of using liquefied gas all year round;

- convenience in delivery, operation and storage of fuel. Many photos of such heating systems show that the gas tank is compact and does not take up much space on the site, as it is buried in the ground;

- environmental friendliness - during combustion, gas does not emit such an amount of harmful substances as the same diesel fuel or gasoline;

- durability and reliability of the heating system.

Refueling the gas tank

Stages and features of the organization of heating using liquefied gas

The process of performing installation work, which requires heating the house with liquefied gas, does not forgive amateur performance. The design, installation of the gas tank and all additional equipment must be carried out by professionals who have all the permits, and their activities are licensed.

Today, the autonomous gas supply market is rich in various offers from companies that have extensive experience and are able to create the most optimal gasification system for any facility.

Nevertheless, despite all the complexity and increased requirements, do-it-yourself liquefied gas heating can still be done. To do this, it is necessary to know the main stages of work, their features and requirements.

Such an instruction will help ensure high performance, reliability and high quality of the heating system, as well as the safety of its operation.

System design

The initial event, during which the type of system, price, performance and many other parameters are determined.

At this stage, it is important to comply with all the requirements of the standards and regulations of SNiP, because without them it will be impossible to start the equipment and ensure its normal operation.

Supply of equipment. As a rule, today there are no problems with equipment for autonomous gas supply, because many companies offer a lot of options, ranging from budget ones to more expensive ones.

With all this, each consumer can view a video of the operation of the equipment, thereby making sure of its performance and functionality.

Installation and commissioning

You can, of course, do all the work yourself, but it is best to entrust them to qualified professionals - this is the only way to ensure that the autonomous heating of a country house with liquefied gas will work efficiently and without fail, and remain safe for a long time.

Filling the system with liquefied gas.

Equipment service.

Liquefied gas in cylinders: compact and cheap

For those people who do not want to install gas tanks on their site, heating a country house with liquefied gas in cylinders can be an excellent alternative.

In this case, the entire heating system will operate on the same liquefied gas, but it will no longer enter the boiler from a large gas tank, but from compact but capacious cylinders.

This heating option will be an ideal choice for small cottages, summer cottages and other buildings where the size of the site does not allow the installation of even the most compact gas tanks. With all this, the cost of maintenance and the fuel itself will be more than affordable.

LPG cylinder

Types of gas boilers

The wall-mounted version is more compact, but less powerful

Types of wall-mounted boilers for home heating

First of all, it is worth dividing the gas heating equipment by functionality: it will be used only for heating or also for preparing hot water for technical needs. If water heating is expected, a double-circuit boiler is needed, only a single-circuit boiler works for heating.

Wall-mounted gas boilers - a small cabinet that is fashionable to install in the kitchen

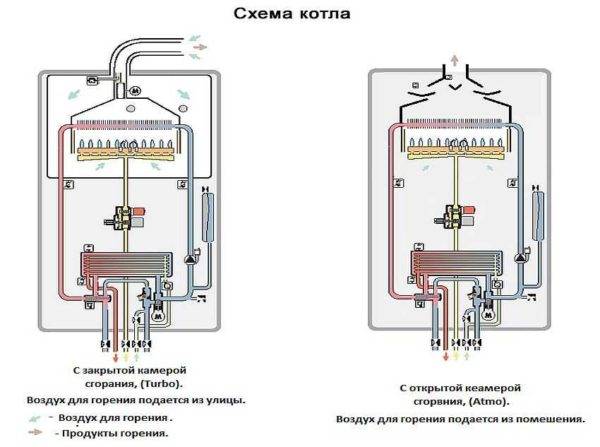

Next, you should decide on the type of smoke extraction. There are gas boilers with atmospheric chimneys and open combustion chambers, there are turbocharged boilers (they have a closed combustion chamber). Atmospheric ones require a good chimney and draft in it, oxygen for combustion comes from the room in which the unit is installed, therefore there must be an air inflow channel and a working chimney (all this is checked when the system is started).

Types of combustion chambers

Boilers with forced draft (turbocharged) can be installed without a chimney. The smoke outlet of the boiler through a coaxial pipe (also called a pipe in a pipe) can be output directly to the wall. At the same time, smoke comes out through one pipe (it is pumped by a turbine), through the second, combustion air enters directly into the combustion chamber.

This type of equipment is good for everyone, except that in winter the coaxial is overgrown with frost, which worsens traction. In case of poor draft, the automation extinguishes the boiler - so that combustion products do not enter the room. Switching on is possible only when traction is restored, that is, you will have to upholster or in some other way remove snow growths.

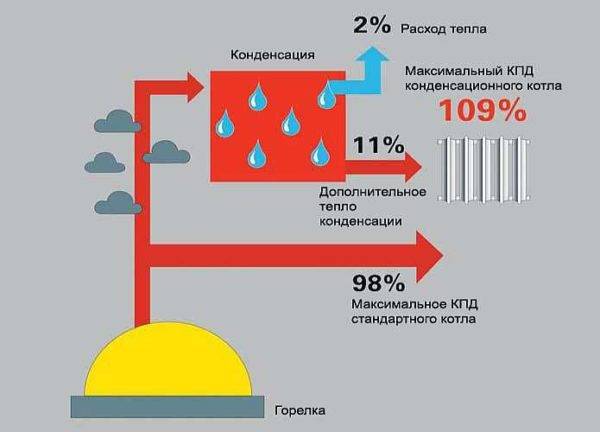

There is also a separate type of boilers - condensing. They are distinguished by very high efficiency due to the fact that heat is taken away from the flue gases (they condense vapors). But high efficiency is achieved only when operating in low-temperature mode - in the return pipeline, the coolant should not have a temperature above +40°C. If the temperature is even lower, even better.

Condensing boilers are the most efficient

Such conditions are suitable for heating with water heated floors.So if you have conceived such gas heating of a private house - with warm floors, then a condensing boiler is what you need. It has few disadvantages - a high price (compared to conventional ones) and caustic condensate, which places special demands on the quality of the chimney (made of good stainless steel).

Floor standing gas boilers

If you need more power, the wall-mounted option will not work - they have a maximum performance of 40-50 kW. In this case, put a floor boiler. Here they are of high power, and there are also models that can work in a cascade. In this way, large areas can be heated.

Some of the floor boilers can operate not only from main gas, but also from liquefied gas. Some can still work with liquid fuel. So these are pretty handy units. Their body is made of steel, and the heat exchanger can be steel or cast iron. Cast iron weigh and cost more, but have a longer service life - by 10-15 years. Inside the case there is a burner, automation and a heat exchanger.

The structure of the floor gas boiler

When choosing, you need to pay attention to the functionality of automation. In addition to the standard set - control of the presence of gas, flame and thrust, there are many more useful functions:

- maintaining the set temperature,

- the ability to program modes by day or hour,

- compatibility with room thermostats;

- adjusting the operation of the boiler to the weather,

- summer mode - work for heating water without heating;

- the ability to work in parallel with solar panels or other alternative heat sources, etc.

The wider the functionality of automation, the more expensive the boiler and its maintenance

But also many programs allow you to save fuel, which is no less important. In general, you choose

Air (convector) heating

In air heating systems, heat is transferred by convection. The air in the room is heated by special devices - convectors. Natural or liquefied gas during combustion is converted into energy without the participation of a coolant.

Convectors with the help of sensors maintain the set temperature in the room. The devices are equipped with a closed type combustion chamber. Exhaust gases go outside through a coaxial pipe built into the wall. There is no smell in the room, the level of oxygen does not decrease, which the residents of private houses are afraid of in vain.

Air heating is much more economical than traditional water heating. Pipe laying, coolant pumping is not required. Energy is spent on heating the room, and is not lost when passing through the pipeline and for heating radiators. Gas consumption - 0.13-0.51 m³ / hour at a power of 2-10 kW.

Heating system installation

Installation of the heating system of a country house is carried out in several stages:

- project development, obtaining permits from the relevant authorities;

- procurement of materials, equipment and preparation of tools;

- tie-in to the gas pipeline, which runs along the street and through which gas is supplied to residential buildings;

- preparation of a place for a gas boiler, piping;

Installation of gas equipment

boiler installation;

filling the system with coolant;

diagnostics.

The main criterion by which the amount of materials is calculated, the choice of the model of heating equipment is carried out, is the area of \u200b\u200bthe house. The larger it is, the more powerful the device will need. For a small house, a small-sized boiler is suitable, which can be installed in the bathroom or in the kitchen. For a cottage or a two-story mansion, it is better to choose a large, powerful device.

The heating system of a private house installed in accordance with all the rules will function for a long period. Before starting installation work, you should familiarize yourself with the heating scheme and the rules for installing heating equipment.

Schemes of gas heat supply at home

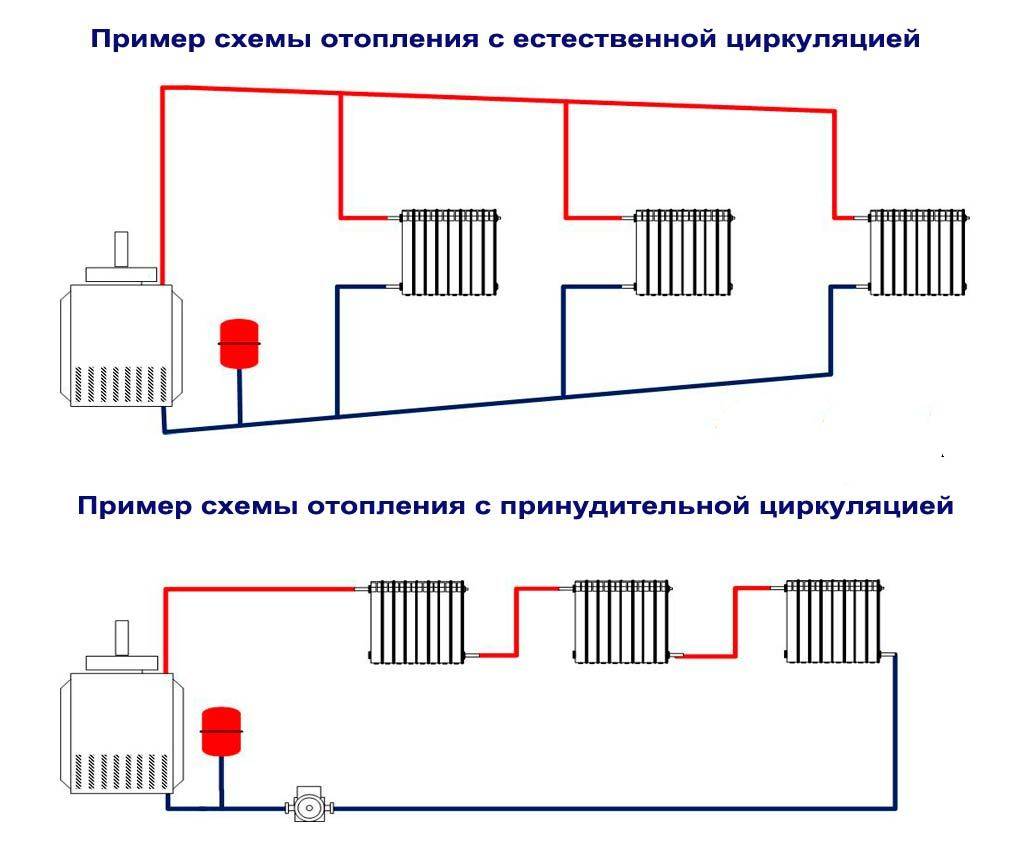

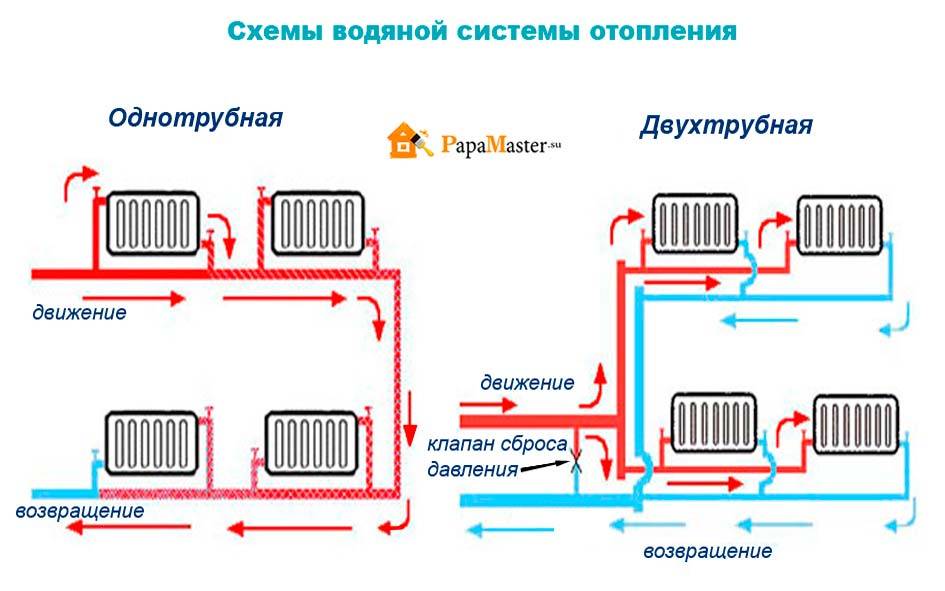

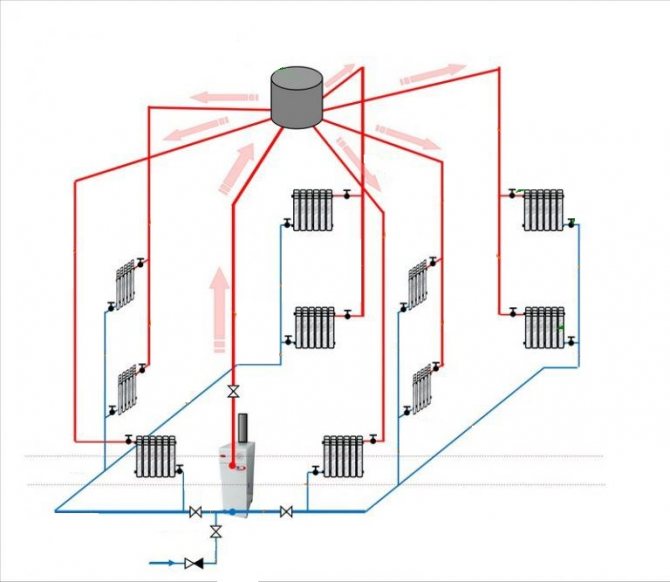

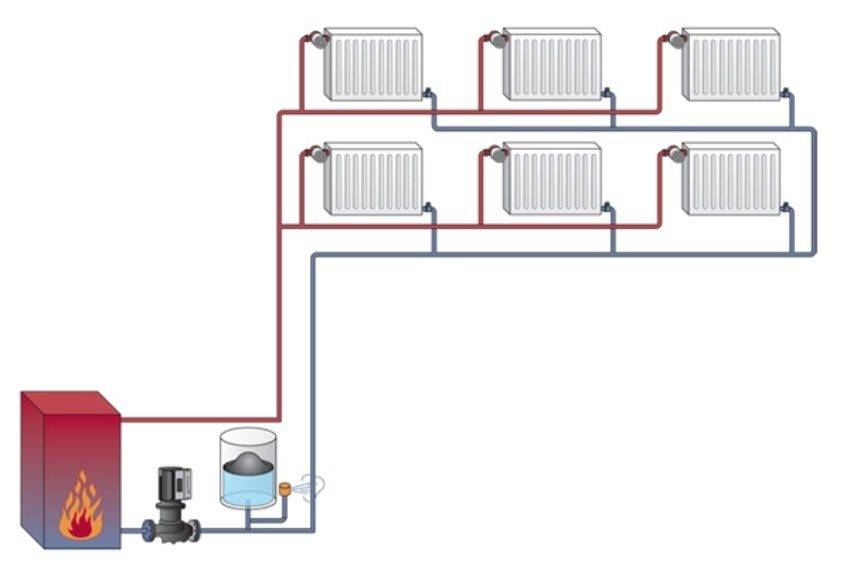

If it is planned to carry out gas heating of a water type, first of all, experts advise to decide on the option of circulation of the coolant, which happens:

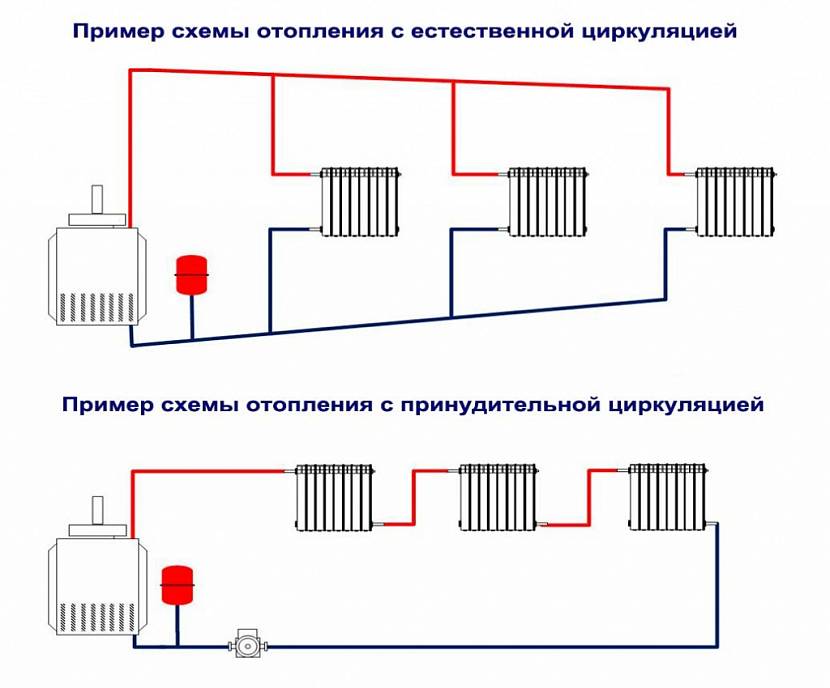

- Forced type using a pump. In such heating systems, the coolant moves at a given speed and heat enters all of their elements. Due to the presence of the pump, pipes of a small cross section are used and therefore the volume of liquid in the system is small - it heats up quickly. The house provides conditions for a comfortable stay. But the circulation pump requires electricity to operate. In order for it to be constantly in the house, you need to provide backup power. With a rare blackout, a few batteries will suffice. With frequent power outages, an expensive generator must be present in the system.

- Natural (gravitational). In this case, it will be necessary to install a pipeline of large diameter, which means that there should be a lot of coolant in the system.In addition, the liquid moves through the pipes at a low speed, and the heating efficiency is negligible. As a result, distant batteries in long branches remain cold. But on the other hand, a system with natural circulation does not depend on the availability of electricity.

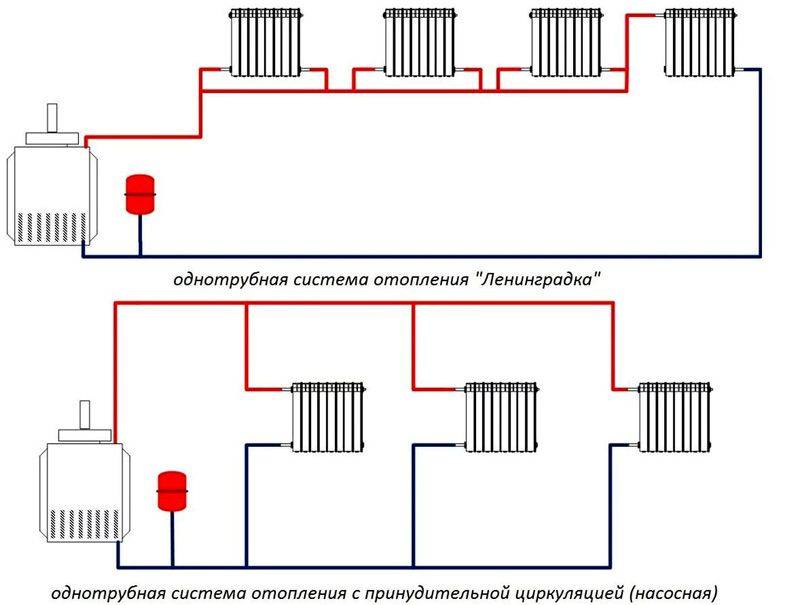

The device and elements of a single-pipe heating system

A single-pipe system, as already mentioned, is a closed circuit that includes a boiler, a main pipeline, radiators, an expansion tank, as well as elements that circulate the coolant. Circulation can be natural or forced.

With natural circulation, the movement of the coolant is ensured by different water densities: less dense hot water, under the pressure of cooled water coming from the return circuit, is forced into the system, rises up the riser to the upper point, from where it moves along the main pipe and is disassembled through radiators and other elements of the system. The slope of the pipe must be at least 3-5 degrees. This condition cannot always be met, especially in large one-story houses with an extended heating system, because the height difference with such a slope is from 5 to 7 cm per meter of pipe length.

Forced circulation is carried out by a circulation pump, which is installed in the reverse part of the circuit right in front of the boiler inlet. With the help of a pump, pressure is created sufficient to maintain the temperature of the heating water within the established limits. The slope of the main pipe in a system with forced circulation can be much less - usually it is enough to provide a difference of 0.5 cm per 1 meter of pipe length.

Circulation pump for one-pipe heating system

To avoid stagnation of the coolant in the event of a power outage, in systems with forced circulation, an accelerating collector is installed - a pipe that raises the coolant to a height of at least one and a half meters. At the upper point of the accelerating manifold, a pipe is drained into an expansion tank, the purpose of which is to regulate the pressure in the system and exclude its emergency increase.

In modern systems, expansion tanks of a closed type are installed, excluding the contact of the coolant with air. A flexible membrane is installed inside such a tank, on one side of which air is pumped with excess pressure, on the other side, the coolant exit is provided. They can be installed anywhere in the system.

An example of connecting an expansion tank to a single-pipe heating system

Open-type expansion tanks are simpler in design, but require mandatory installation at the top of the system, in addition, the coolant in them is actively saturated with oxygen, which can lead to premature failure of steel pipes and radiators due to active corrosion.

The sequence of installation of elements is as follows:

- Heating boiler heating (gas, diesel, solid fuel, electric or combined);

- Accelerating manifold with access to the expansion tank;

- The main pipeline that bypasses all the premises of the house along a given route. First of all, it is necessary to draw a circuit to the rooms that need heating the most: a children's room, a bedroom, a bathroom, since the water temperature at the beginning of the circuit is always higher;

- Radiators installed in selected locations;

- Circulation pump immediately before the inlet of the return part of the circuit into the boiler.

What is the difference between solid fuel boilers

In addition to the fact that these heat sources produce heat energy by burning various types of solid fuels, they have a number of other differences from other heat generators. These differences are precisely the result of burning wood, they must be taken for granted and always taken into account when connecting the boiler to a water heating system. Features are as follows:

- High inertia. At the moment, there are no ways to abruptly extinguish a burning solid fuel in a combustion chamber.

- Formation of condensate in the firebox. The peculiarity manifests itself when a heat carrier with a low temperature (below 50 °C) enters the boiler tank.

Note. The phenomenon of inertia is absent only in one type of solid fuel units - pellet boilers. They have a burner, where wood pellets are dosed, after the supply is stopped, the flame goes out almost immediately.

The danger of inertia lies in the possible overheating of the water jacket of the heater, as a result of which the coolant boils in it. Steam is formed, which creates high pressure, tearing the body of the unit and part of the supply pipeline. As a result, there is a lot of water in the furnace room, a lot of steam and a solid fuel boiler unsuitable for further operation.

A similar situation may arise when the heat generator is connected incorrectly. After all, in fact, the normal mode of operation of wood-burning boilers is the maximum, it is at this time that the unit reaches its passport efficiency.When the thermostat responds to the heat carrier reaching a temperature of 85 ° C and closes the air damper, combustion and smoldering in the furnace still continues. The temperature of the water rises by another 2-4°C, or even more, before its growth stops.

In order to avoid excess pressure and a subsequent accident, an important element is always involved in the piping of a solid fuel boiler - a safety group, more about it will be discussed below.

Another unpleasant feature of the operation of the unit on wood is the appearance of condensate on the inner walls of the firebox due to the passage of an unheated coolant through the water jacket. This condensate is not God's dew at all, since it is an aggressive liquid, from which the steel walls of the combustion chamber quickly corrode. Then, having mixed with the ash, the condensate turns into a sticky substance, it is not so easy to tear it off the surface. The problem is solved by installing a mixing unit in the piping circuit of a solid fuel boiler.

Such a deposit serves as a heat insulator and reduces the efficiency of a solid fuel boiler.

It is too early for owners of heat generators with cast-iron heat exchangers that are not afraid of corrosion to breathe a sigh of relief. They can expect another misfortune - the possibility of destruction of cast iron from temperature shock. Imagine that in a private house the electricity was turned off for 20-30 minutes and the circulation pump, which drives water through a solid fuel boiler, stopped. During this time, the water in the radiators has time to cool down, and in the heat exchanger - to heat up (due to the same inertia).

Electricity appears, the pump turns on and sends the cooled coolant from the closed heating system to the heated boiler.From a sharp temperature drop, a temperature shock occurs at the heat exchanger, the cast-iron section cracks, water runs to the floor. It is very difficult to repair, it is not always possible to replace the section. So even in this scenario, the mixing unit will prevent an accident, which will be discussed later.

Emergencies and their consequences are not described in order to scare users of solid fuel boilers or encourage them to purchase unnecessary elements of piping circuits. The description is based on practical experience, which must always be taken into account. With the correct connection of the thermal unit, the likelihood of such consequences is extremely low, almost the same as for heat generators using other types of fuel.

gas fireplace

In terms of cost, gas fireplaces are almost the same as wood or electric appliances. But gas is much cheaper. And also, unlike firewood, gas heating implies the absence of ash. At the same time, you do not need to constantly monitor the operation of the combustion chamber and take care of the constant availability of firewood.

According to the type of installation, fireplaces are divided into:

- embedded;

- island;

- wall-mounted.

In terms of internal elements and design, fireplaces are similar to gas boilers. The method of connecting to the network is also identical. The difference is only in the method of heating the premises. The gas boiler is designed to heat the liquid, and the fireplace is to heat the air from the front screen or body.

Convection and condensing gas boilers

Gas convection boilers are standard type devices that use only the energy of fuel combustion. Such units have a simple device and relatively inexpensive cost.The main problem of the convection device is the formation of condensate on the heat exchanger, consisting of water and acids. The way to combat dew is to maintain a high temperature in the heat exchanger, and for this, the temperature of the coolant in the return must be at least 60 degrees. Of the heaters with boilers of this type, it is allowed to use wall-mounted radiators, registers and convectors. The underfloor heating system and underfloor appliances are not combined with a convection unit, since they will not warm the legs, but burn them.

Condensing units do not always fully use their energy, which is produced in the process of fuel combustion. They convert the energy of water vapor condensation into heat.

For a condensing boiler, it is important that the heat exchanger has a low temperature, as well as the return. A typical gas heat supply scheme in a private house with a heating unit of this type is as follows: radiators are placed under the windows and a system of underfloor heating is installed, for which they use the return of heating batteries, where the coolant gives off the last heat.

When heating a private house with the help of gas equipment, boilers are used:

- with natural circulation - they take air from the room into an open burner and remove combustion products, directing them to the general ventilation. Their installation requires a separate room with an area of at least 4 "squares" with a wide door and window;

- with forced circulation . In this case, in order to maintain combustion, air is taken from the street, and combustion products are discharged there through a separate duct. The boiler may be installed even in a residential area.

Boilers with both natural and forced circulation, when autonomous gas heating systems are equipped, must be connected and started only by gas service workers.