- How to make gas heating of a private house with your own hands

- Work order

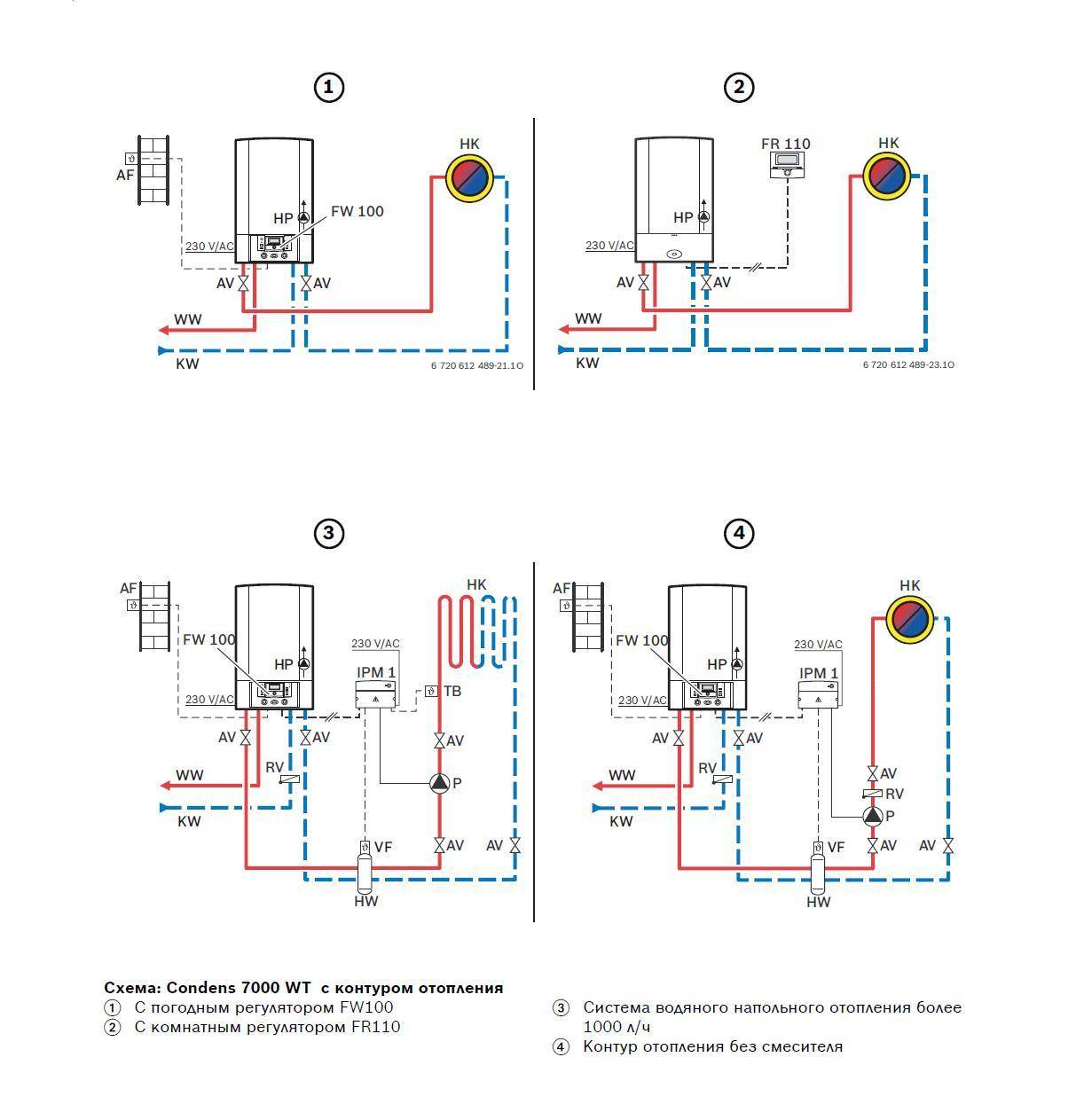

- Autonomous heating wiring diagrams

- Gas heating installation process

- Gravity system

- Materials and tools

- Characteristics of liquefied gas

- Convector gas heating

- Types of boilers for heating a private house

- Choosing a heating scheme for a heating boiler in a private house

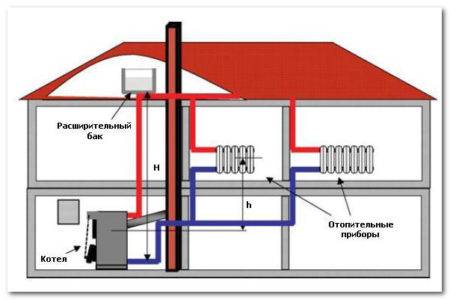

- Gravity scheme

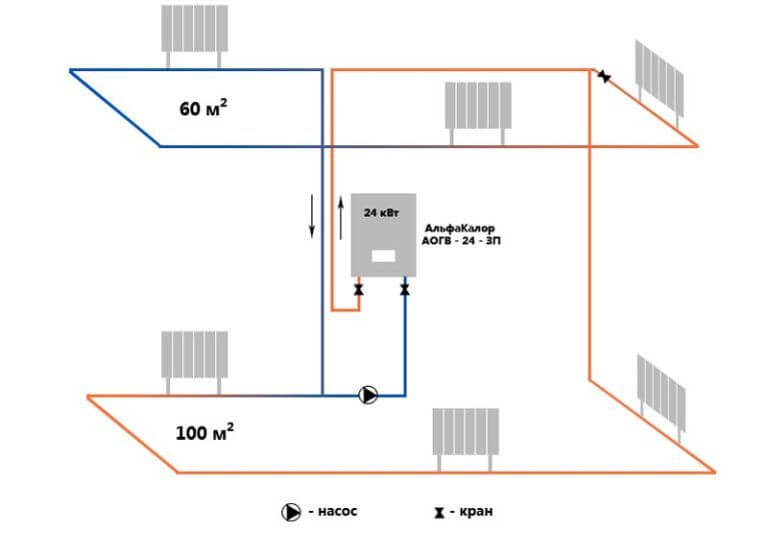

- Forced circulation scheme

- Number 3. Gas boiler for summer cottages and country houses

How to make gas heating of a private house with your own hands

Do-it-yourself installation of autonomous heating is quite within the power of a person who has the skills of such work

Various installation schemes are considered in detail, attention is paid to individual details

You can independently perform all work on the installation of a home heating system, except:

- tapping the heating system of the house into the gas network;

- design of gas heating of the house.

Insertion and designing are carried out only by specialized organizations that have licenses.

Work order

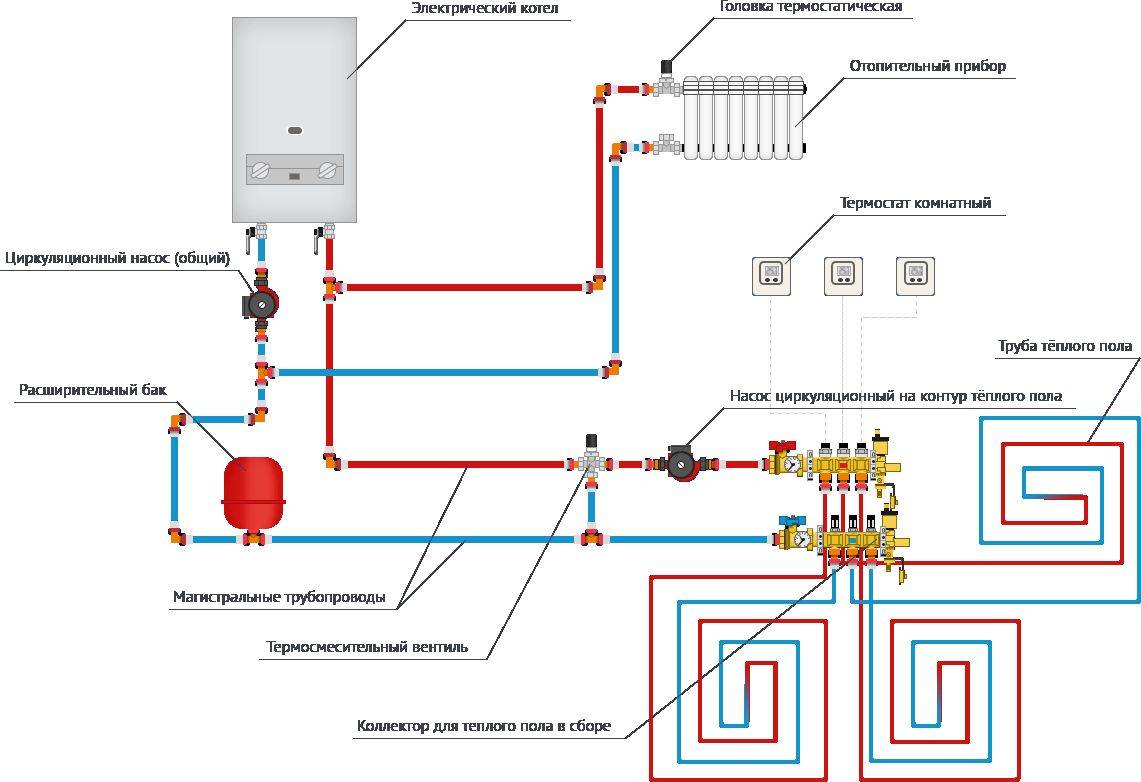

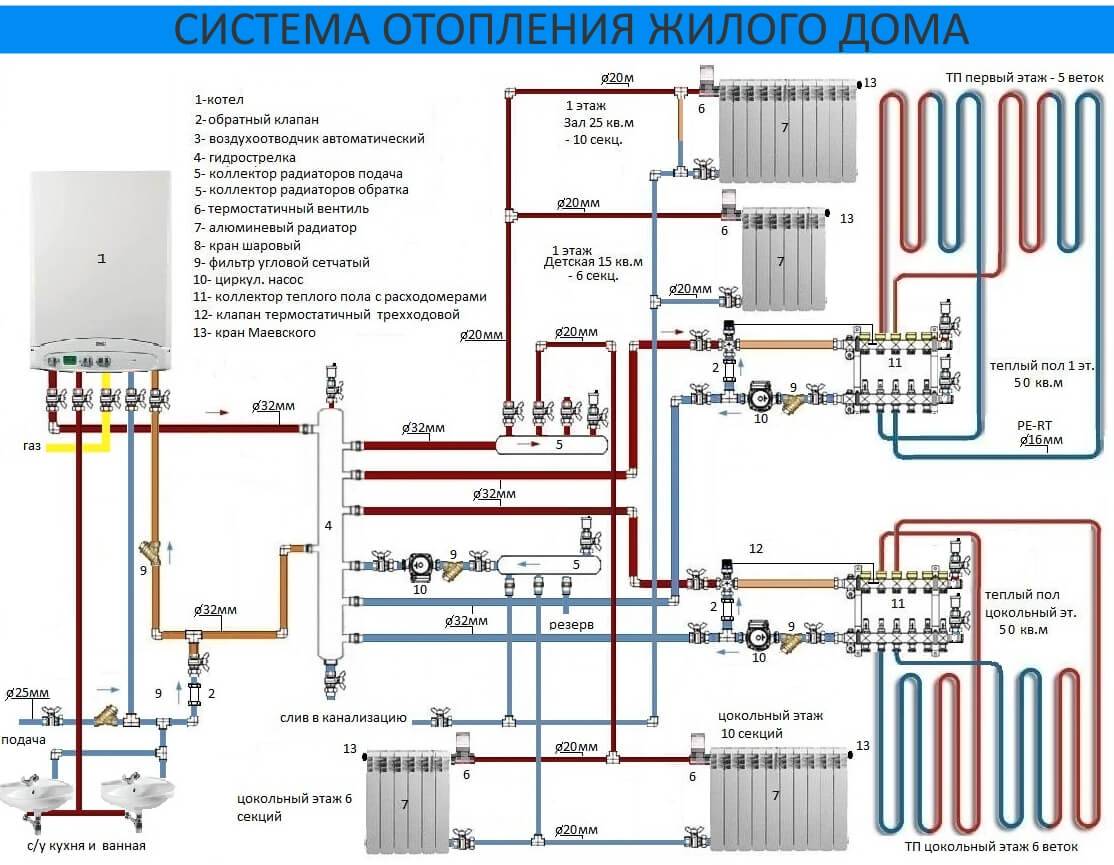

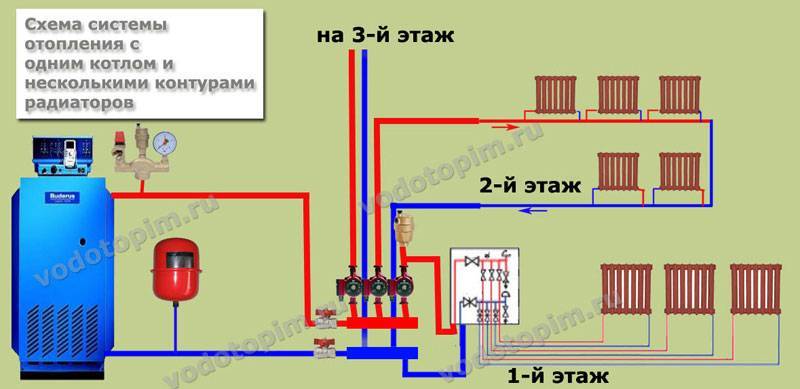

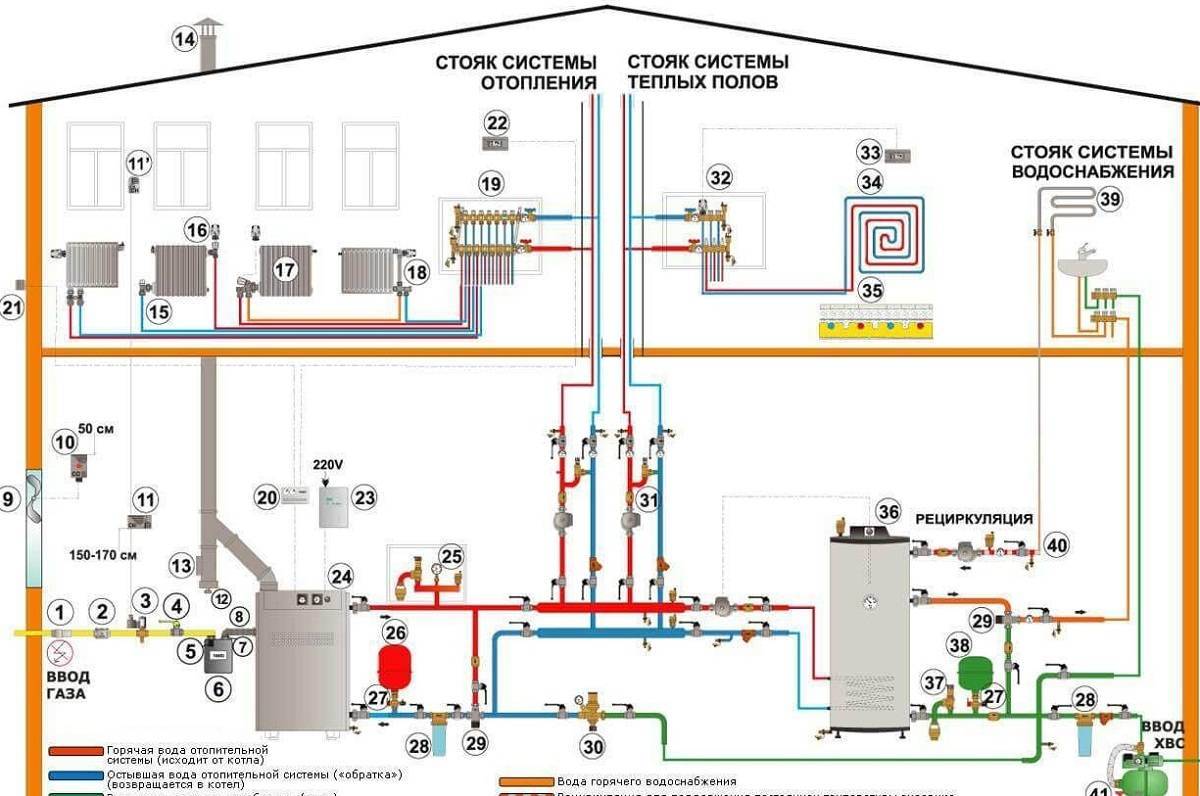

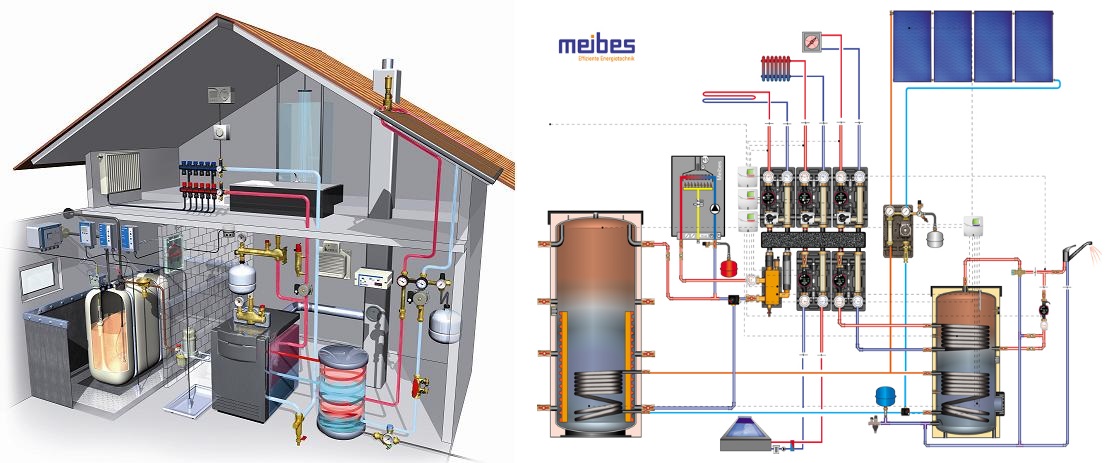

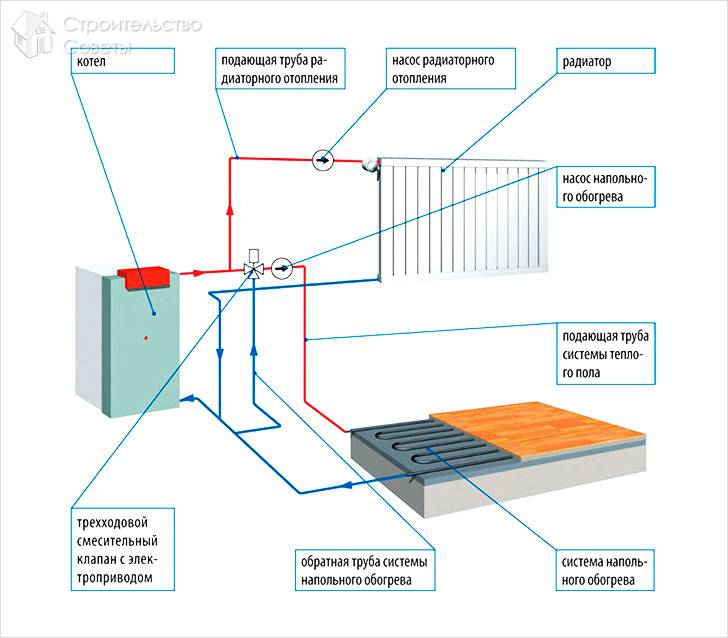

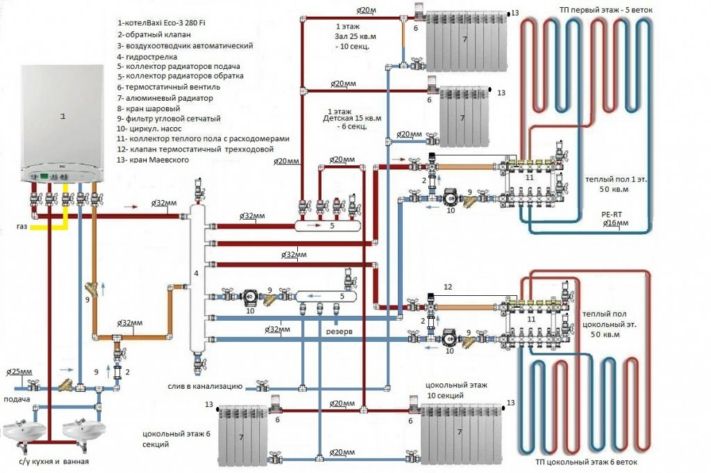

The principle of operation of water heating is as follows: water heated by a gas boiler naturally or forcedly circulates through pipelines, giving off heat to the premises. The optimal heating scheme for a two-story private house includes a system with underfloor heating on the first floor and radiator heating on the second floor.The circulation of the coolant can be natural (gravity flow) or forced (circulation pump).

Consider the procedure for installing autonomous gas heating using the example of a 2-storey building:

- installation of the boiler in the boiler room on the ground floor;

- installation of a safety group, expansion tank, circulation pump

- installation of a pumping and mixing unit for underfloor heating to circulate the coolant at the required temperature;

- installation of a collector for a warm floor;

- laying a warm floor (the specification of materials and the procedure can be found on the Internet);

- installation of radiators and their connection to the collector in all rooms on the second floor;

- at the end of the complete installation of the heating, the floor heating is poured with concrete.

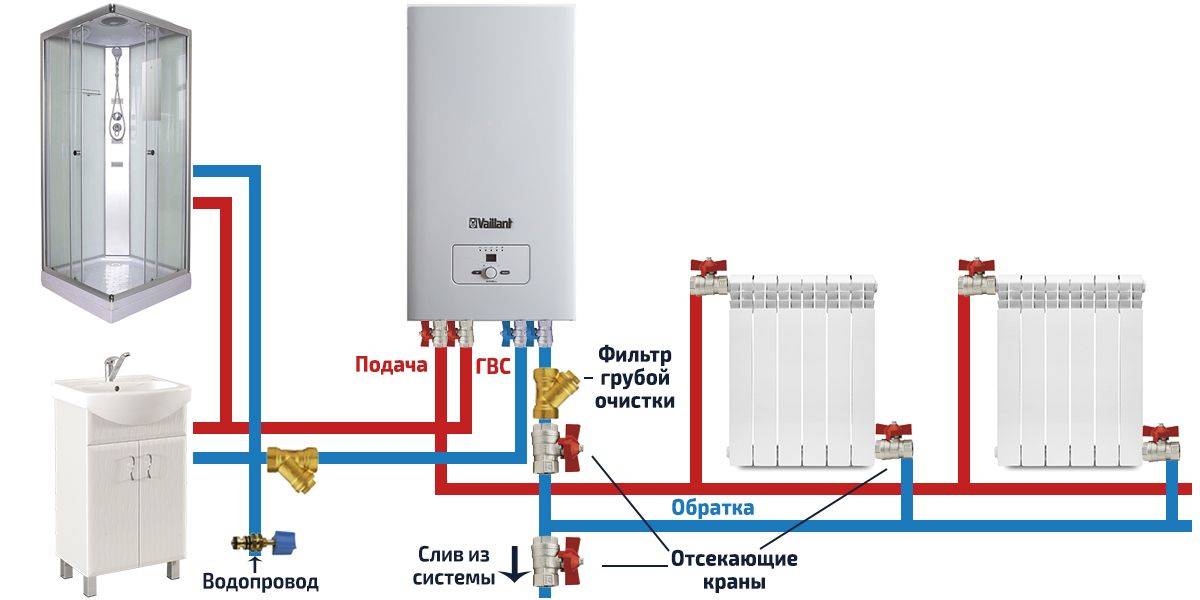

Heating schemes for a private house with a gas boiler can be of two types:

1. Single-circuit heating scheme of a private house with a gas boiler (closed, designed only for space heating)

2. Double-circuit scheme using a special boiler (simultaneously heating and heating tap water)

Autonomous heating wiring diagrams

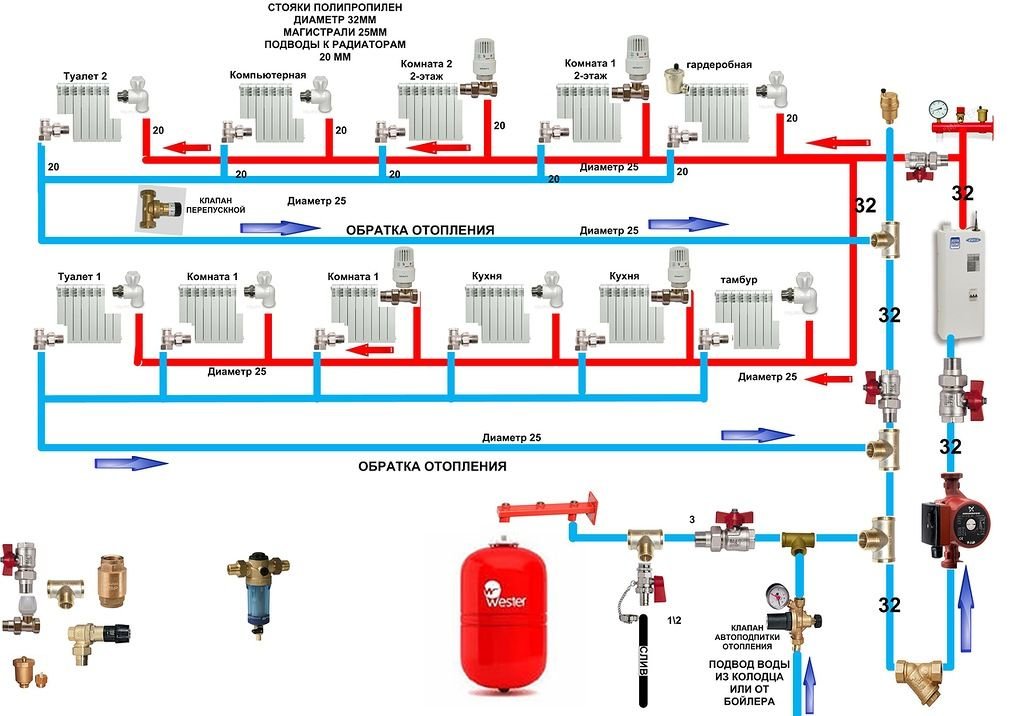

Heating wiring from a gas boiler is based on several typical heating schemes, which differ in the type of circulation of the coolant (usually water) and in the methods of piping. There are the following types of heating installation:

- Single-pipe heating distribution, in which the pipes are looped, and the radiators are arranged in series. The coolant, leaving the boiler, passes through each radiator in turn. The temperature of the coolant decreases as you move. It is primitive and imperfect, since the coolant temperature drops by the end of the cycle.

- The Leningradka system with dedicated bypass radiators is intermediate and allows you to eliminate some of the problems of a single-pipe circuit;

- Improved "Leningradka" system with shut-off and balancing valves;

- Two-pipe wiring represents supply and return pipes running parallel to each other. Allows the coolant used in the radiator to be returned to the boiler for heating. The supply of coolant to the radiator according to this scheme occurs without heat loss.

- Radial (collector) wiring distributes the collected coolant to individual radiators. The scheme is complex, used infrequently.

Heating schemes for a 2-storey private house can be as follows:

1. Open type heating system

Expansion tank - an open container with an inlet pipe connected to a supply riser. It is installed at the highest point of the heating system - the coolant does not overflow to the outside, and the expansion tank additionally acts as an air vent.

Scheme of autonomous gas heating of open type

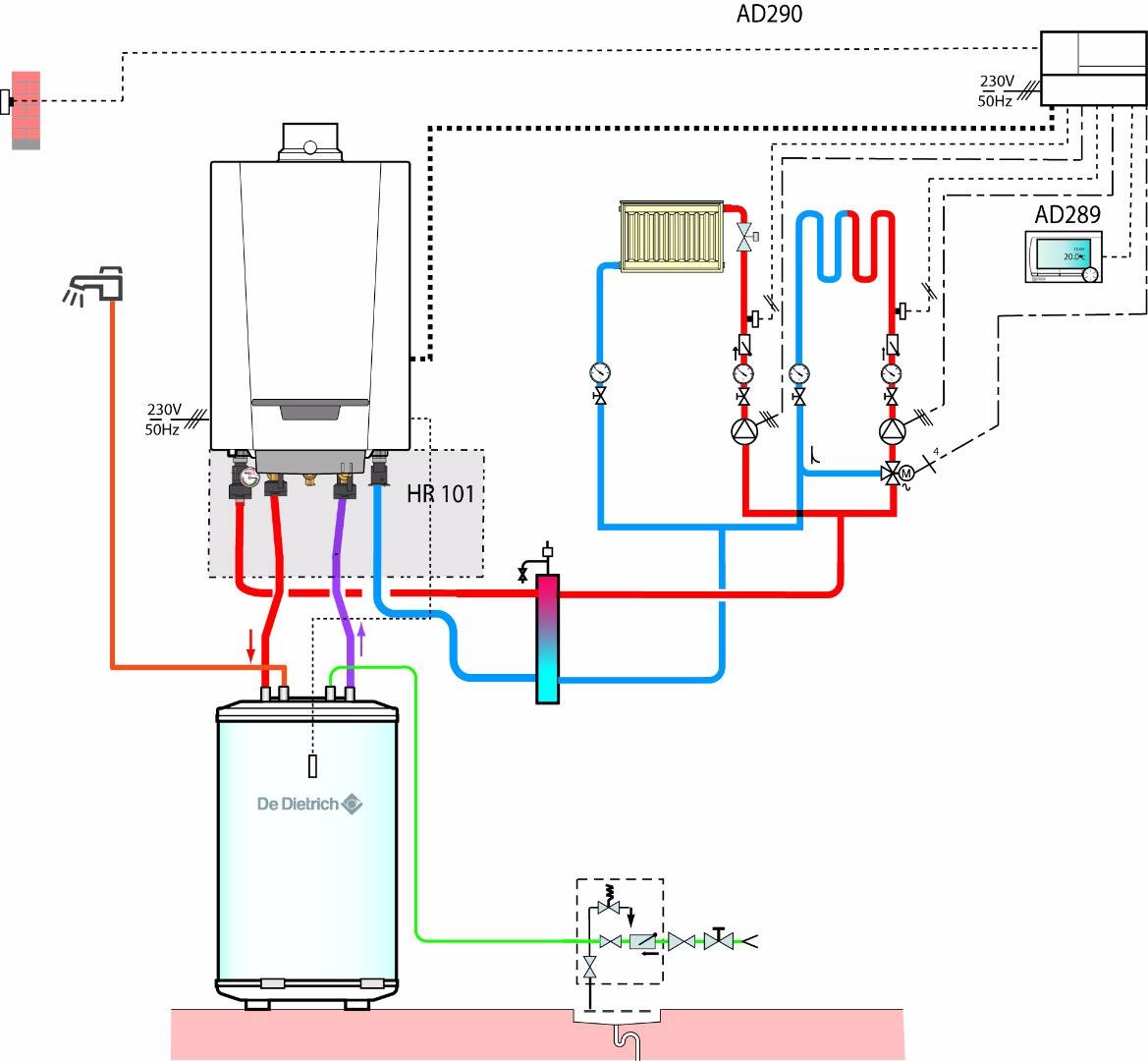

2. Closed type heating system

A sealed expansion tank is installed in the system, divided by an elastic membrane into water and air chambers. With thermal expansion, excess coolant enters the water chamber of the tank. The pressure in the air chamber increases, and when the pressure drops, the coolant returns to the pipelines. The tank can be installed at any point, but it is usually mounted next to the boiler on the return pipe. A pressure relief valve is installed.

Scheme with natural and forced recirculation, which are used when heating a two-story private house

Gas heating installation process

It’s nice to do everything in the house with your own hands, but when connecting and installing a gas boiler, it’s better to turn to specialists; on each instruction for the boilers "Aton", "Siberia", "Conord", "Ariston" this warning is indicated. Gas is a dangerous thing: special knowledge and experience are required to work with it.

Preparation for begins with checking its quality, the presence of components in the composition. Then

When installing the heating system, any negligence can cause the equipment to explode.

wash the pipes of the boiler. Examine the wall under the boiler; it must be solid. A gasket made of non-combustible material is attached to it. The boiler is located at a distance of 5 cm from the gasket; must have ventilation or a chimney.

Having permission to, you need to prepare the necessary tools:

- self-tapping screws large with a diameter of 6 mm - 4 pcs.;

- marker;

- victorious drill;

- drill;

- plastic dowels;

- level;

- parapet.

Acquire the necessary materials:

- three-core wire;

- chimney elbow;

- parallel bracket;

- corner strainer;

- Ball Valves;

- paronite gasket;

- gas alarm;

- gas certificate.

Gravity system

Gravity is a natural pull. The circulation of water along a given contour is carried out by a pulling device, the laws of physics. No electrical connection or pump required.

Boiler gravitational heating is a frequent guest of cottages, country houses, where power outages occur. However, in homes that use a boiler, it is possible to organize to save electricity.

Proper wiring for natural circulation is essential.If there is a violation in the installation, the heating will turn out to be non-functioning.

The installation feature is a slope that does not interfere with the rise of water from the in-line pressure. The boiler is installed below the radiators, the angle provides traction for lifting the carrier, decreasing as it cools.

Gravity

Gravity

Materials and tools

To build a gas boiler, prepare the following materials and tools:

- electric drill;

- pliers;

- level;

- corner;

- roulette;

- metal pipe;

- steel sheet;

- gas pipe;

- doors for creating a firebox;

- red brick;

- fittings;

- clay;

- galvanized sheet;

- welding tool;

- thermostat;

- automation;

- deflector.

If everything is clear with most of the above, then choosing the right automation, deflector and thermostat is not an easy task. What to look for when choosing them:

thermostats are wired and wireless. The former are slightly cheaper than the latter. Choose programmable models, with their help it is easier to control and regulate the temperature of the boiler. Structurally, the thermostat consists of two devices. One is placed in the room, the other - on the facade of the boiler. When the room temperature drops, the thermostat turns on the heater.

Pay attention to domestic device models. They are in no way inferior to expensive foreign analogues;

the concept of "automation for gas boilers" includes: a flame control module, overheating protection, a draft controller, a blast valve

These devices are sold separately. For normal operation of the heater, all of the listed devices are needed. Do not choose the cheapest or overpriced models. Stop at the average price;

the deflector provides a good hood. It is installed on top of the chimney.For a homemade gas boiler, a model in the form of a cone-shaped stainless steel umbrella is suitable.

Characteristics of liquefied gas

The properties of liquefied gas are not much inferior to natural material. It is widely used in everyday life, for example, for heating the house. Of course, such systems are less convenient to operate than main gas wiring. But, if we compare liquefied gas with other alternative solutions for a country house, then there are definitely more advantages. In particular, such material burns perfectly. At the same time, this process can be fully automated due to the presence of a huge range of modern equipment. In other words, boilers operating on its base can work without stopping. In this case, it is not necessary to monitor the operation of such equipment.

Schemes of individual heating of the house. based on the use of liquefied gas are also good because they are silent in operation. This cannot be said about analogues that use liquid fuel. The gas heating scheme of a private house may include converters as a base. In this case, a separate envelope is installed in each room.

This equipment is especially effective in cases where it is necessary to heat two adjacent rooms.

Convector gas heating

Similar models of convectors operate on liquefied gas. It is not safe to make wiring for natural gas in a private house for each such heater. The room in this case is heated by heated air, so heating is called air heating. Any boiler can be configured for this type of heating, only it will need to change the burner or nozzle.

Gas convectors are best used if necessary to quickly increase the temperature, and in non-residential premises. These devices begin to heat the air immediately after being turned on, but as soon as they are turned off, they quickly cease to provide heat.

Types of boilers for heating a private house

The principle of operation of the boiler is always the same - heating the coolant, most often it is standard tap water, at best passed through a filtration system. Various types of fuel can be used for heating. Depending on this, there are:

-

Gas boilers. Stable leaders in the field of heating units. The reason for the popularity is the low (relative to other energy carriers) price in Russia. By the way, in Europe and other countries where natural gas is purchased at the state level, such boilers are much less common. Pluses - stability of work, price, features - it is necessary to equip the gas outlet channel, obtain permits, crash into the gas supply line. Despite the high costs at the initial stage, gas boilers are one of the fastest paybacks.

Gas boiler -

Solid fuel boilers. A wide range of materials can be burned in these devices: from coal and firewood to special granules called pellets. Of the benefits - complete autonomy from both gas and electricity. A solid fuel boiler can be used in any conditions in the presence of gravitational circulation of the coolant in the system. Cons - increased fire hazard when loading fuel, special requirements for the room and the presence of an exhaust chimney. Unlike gas, which is supplied automatically, a solid fuel boiler must be periodically equipped with fuel.The installation of thermal accumulators and automatic feeding systems allows solving this issue, but only in part.

Solid fuel boilers -

Liquid boilers. The fuel in such devices is liquid fuel, most often diesel fuel (diesel fuel). It is used because its ignition hazard is lower than that of gasoline. After the diesel-air mixture is supplied through the nozzle, it is burned in the combustion chamber, outside of which there is a heat exchanger with a water circuit. Advantages - high efficiency and the possibility of long-term operation in automatic mode. Cons - the need to equip tanks for storing fuel reserves, increased requirements for the placement of units and exhaust gas exhaust systems.

-

Electric boilers. They have a lot of advantages in installation and placement. Electric units do not require a separate room and exhaust ducts, because nothing is burned. Among the boilers, they are the most environmentally friendly. Due to their operation on electric current, they have a high level of automation, and the absence of pipelines for supplying combustible energy carriers greatly simplifies the design, excluding nozzles, burners, furnaces and similar elements of fuel boilers from it. They have only two disadvantages, but they are significant: the high cost of electricity when paying utility bills and the vulnerability of the heating system in the event of a power outage. If there is no “light” in the house, the electric boiler ceases to function.

Despite the differences in fuel, all boilers that generate heat in the process of burning something have a lot in common, including installation rules.Such a parameter as power can also be determined without taking into account the type of boiler.

Table 1. Required boiler power for heating a house by area

| House area, sq. m | Boiler power, kW |

|---|---|

| 90 — 200 | up to 25 |

| 200 — 300 | 25 -35 |

| 300 — 600 | 35 — 60 |

| 600 — 1200 | 60 — 100 |

Choosing a heating scheme for a heating boiler in a private house

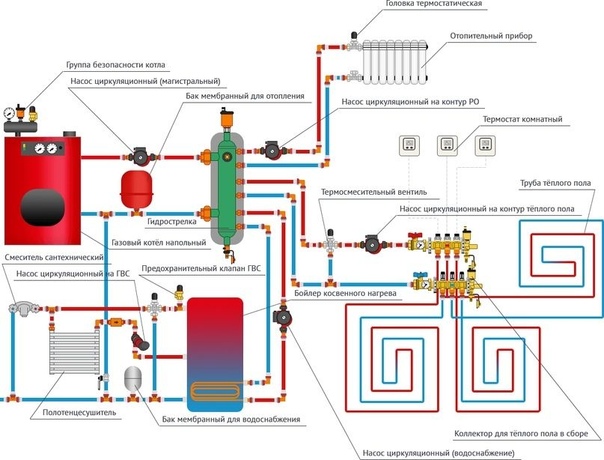

The boiler itself is just an element of the heating system. Without pipes and radiators through which the coolant circulates, its work is useless. Therefore, heating wiring must be provided in advance, before buying a unit that provides heat. The task is facilitated by the fact that the heating circuit for all types of boilers has more similarities than differences.

Gravity scheme

Most often, such a scheme is used for connection with a solid fuel or liquid boiler. If we approach the issue strictly, taking into account the preservation of efficiency, then modern gas boilers do not imply gravity circulation of the coolant. Many electronically controlled wall and floor models already have a built-in circulation pump that forcibly drives water or antifreeze through pipes and radiators. In conditions of frequent power outages, such a boiler will be inactive.

General view of the gravity scheme

However, in many homes, gravity circuits continue to work in conjunction with a gas-fired non-volatile boiler of a simple type with mechanical control. With the use of heating pipes of large diameter, sufficient water pressure is created in the system to start the gas burner. In old systems, pipes with a cross section of 100 - 150 mm were taken, which surrounded the rooms around the perimeter. The heat transfer of such a design is small, but it itself is reliable and durable. When installing radiators, the diameter of the supply pipes must be at least 40 mm to reduce hydrodynamic resistance.

In gravity systems, an indispensable element is an expansion tank. If the water in the system reaches high temperatures, its excess enters the tank due to the increased volume. The tank insures the system against leaks and depressurization in the event of an abrupt increase in pressure. In open systems, the tank is always located at the highest point.

The gravitational scheme is one-pipe. This means that the coolant sequentially passes through all the radiators, and then returns through the “return”. For the installation of batteries with such a system, bypasses are used - bypass pipes with shutoff valves, thanks to which it is possible to dismantle and replace the batteries without stopping the boiler and draining the coolant. Also, a Mayevsky crane is placed on each radiator to bleed the air that accumulates inside the wiring.

Mayevsky crane

Forced circulation scheme

The only disadvantage of this type of heating wiring is the dependence on the presence of voltage in the household electrical network. In addition to the boiler, the second important node of such a scheme is the circulation pump, which crashes into the “return” before returning it to the boiler. Modern pumps are silent, productive and consume electricity in the same way as an incandescent light bulb. But thanks to such a device, it becomes possible to make a choice in favor of a two-pipe system. In this case, the binding pipe passes through all the heated rooms of the house. From it, a separate stream of hot water is supplied to each battery, and from it the cooled coolant is drained into the “return”, which is the very second pipe in the circuit. This allows you to evenly distribute heat over all radiators and maintain the same temperature even in the rooms farthest from the boiler.

The expansion tank, in the presence of a circulation pump, is made mandatory closed so that a certain pressure can be created in the system. In case of excess of normal values, an emergency pressure relief valve is provided.

Visual representation of a two-pipe scheme

In both schemes, a make-up unit must be provided through which the coolant is poured into the system. If water is used, then a branch pipe from the water supply network is cut in to fill the pipelines, installing a filtration system at the inlet. When using antifreeze, an inlet valve with shutoff valves is arranged, and pumping is carried out using a “baby” submersible pump or other pumping equipment.

Number 3. Gas boiler for summer cottages and country houses

Most gas boilers are versatile and can be used with any gas source. The thing is that even those devices that were originally developed to work with the main gas pipeline can be adapted to use liquefied gas. As a rule, it is enough just to change the burner or buy a new one if there was no suitable one in the kit. The rest of the "alterations" will be minimal. Such versatility of gas boilers is especially convenient when the area where the country house is located is just developing: for the first time, you can use cylinders, and then connect the system to the gas pipeline - investments will be minimal.

If you plan to use only gas cylinders in the heating system of a country house, then when choosing a boiler, pay attention to those models in which the lower threshold for the working gas pressure is minimal - this will save money during operation. In addition, the boiler must be selected with a high level of efficiency, certainly not lower than 90%

The choice of gas boilers is huge, and it all depends on the requirements put forward. By functionality (number of circuits), boilers are divided into:

- single-circuit. Are applied only to the organization of heating;

- double-circuit. They are equipped with an independent hot water circuit, so they solve another problem - warm water in the tap. Such boilers can be of a flow type, if the required amount of warm water is insignificant, or they can be equipped with a built-in boiler, which ensures full heating and hot water supply.

Depending on the type of traction, boilers are:

- with natural traction. Ideally suited when the house already has a chimney. Such a boiler will cost less, although its installation will be somewhat more difficult, and during operation it will sometimes be necessary to clean the chimney;

- forced draft, or turbocharged. The products of combustion in this case are discharged through a small pipe equipped with a fan. The pipe can even be built into the wall, but it is better to place it away from windows and ventilation systems. Forced draft allows combustion products to leave the boiler faster, does not require the construction of a chimney, but constantly uses electricity during operation.

The type of ignition may also differ:

- manual, i.e. with a match, this is the most ancient method, often unsafe.Today, such boilers are almost never produced;

- piezo ignition. Here, instead of a match, a spark is used, which is obtained by pressing a special button. This is a more advanced method and, according to many experts, is best suited for the conditions of a country house, because electricity is not used for ignition, which can be problems;

- electric ignition is convenient, economical, safe, but for areas where power outages occur, it is not an option.

According to the installation method, boilers are divided into:

- wall;

- floor.

The question here is not only in personal preferences, but rather in the required power. Floor boilers are more powerful, productive and durable devices, but they also cost a little more than wall-mounted ones. Wall-mounted boilers have less power (as a maximum, they provide heating for a house with an area of 300 m2), they take up a minimum of space.

To the room where the boiler will be installed, some safety requirements are put forward. The room should be at least 7.5 m2, with a ceiling height of at least 2.5 m. If the house is wooden, then it is better to insulate the room with the boiler with roofing steel, in extreme cases - asbestos sheets 3 mm thick.