- Features of gas heat guns

- Important details, safety rules

- The principle of operation and application of the gas gun

- How to make an electric version of a heat gun?

- Overview of popular models

- Varieties of gas guns

- How to make your own

- Features of the repair of diesel guns for space heating

- How to repair a diesel heat gun yourself

- Rules for the safe operation of diesel appliances

- Basic provisions for designing a heat gun

- The main elements of the gun

- What you need to know about the electric gun?

- The device and principle of operation of the heat generator

- Advantages and disadvantages of homemade guns

- Making a heat gun with your own hands

- Video: do-it-yourself electric gun for heating a garage

- Heat gun on diesel fuel and diesel fuel

- Video: multi-fuel heat gun

- gas heat gun

- Video: homemade gas heat gun

- Varieties of diesel heat guns

- Advantages of indirect heat guns

Features of gas heat guns

Gas guns are often used not only in industry, but also in everyday life, for example, for heating country houses or garages. Such devices are inferior to electric in mobility, but are more economical. In addition, such devices have a fairly high power, the figure of which can reach 140 kW.

Heaters can run on natural gas or liquefied gas, but they also need access to electricity, since the operation of the fan, thermostat and other components is impossible without electricity.

For the operation of gas heat guns, various modifications of natural gas can be used:

- blue fuel passing through highways;

- butane or propane in specialized cylinders.

High power models can be connected to the gas pipeline with a special hose, which ensures their continuous operation. It should be noted that such units are usually stationary, since their movement is somewhat difficult.

Compact mobile devices operate on bottled fuel. In some cases, the gun is connected by a hose to a large cylinder, which is stationary. In others, a small gas tank is a structural element of the unit.

For the operation of portable gas devices (made independently or in the factory), gas is used in cylinders of various types

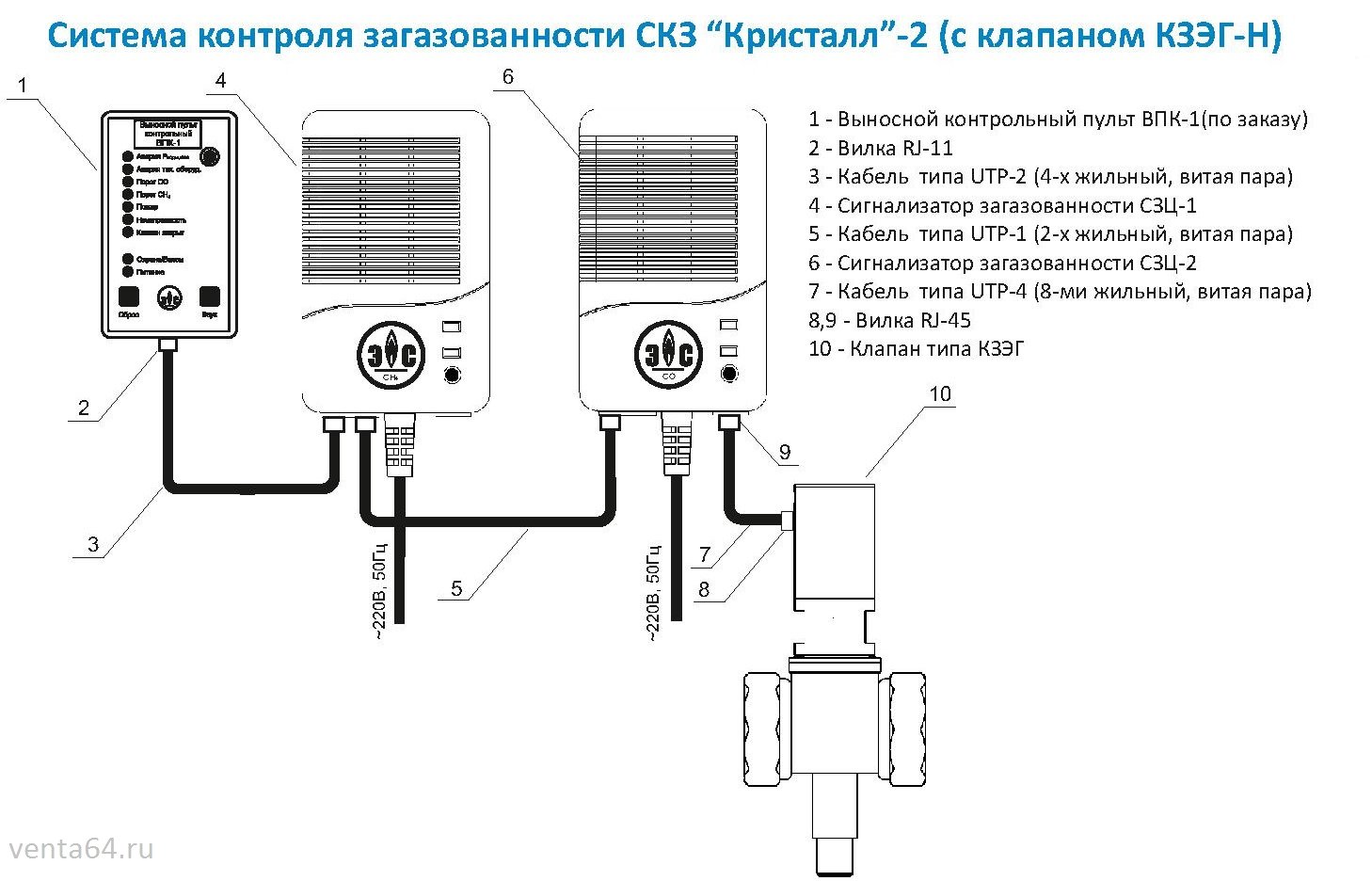

In many modern models of gas heat guns, additional functions are provided, for example, protection of the case from overheating, automatic shutdown of the device, and flame control.

Additional information about the device and various modifications of gas guns is given in this article.

Important details, safety rules

Homemade electric guns are much more dangerous than factory ones, because in the process of assembling them it is not always possible to take into account all the nuances. The main safety rules for heating such devices are:

- Never leave a working appliance unattended, even if it is equipped with residual current circuit breakers and seems perfectly safe.

- Do not leave diesel or gas heat guns switched on at night in a residential building, do not risk the lives of people and the safety of property.

- For heat guns on wood, diesel fuel or gas, be sure to equip a good hood and carefully monitor its serviceability, clean it from soot and combustion products in a timely manner.

- Tanks with fuel and gas cylinders should not be in the vicinity of a working gun, in order to avoid a fire.

- An open flame must be covered with a protective screen so that the coals or splashes of burning diesel fuel do not enter the room.

Subscribe to our Social Networks

The principle of operation and application of the gas gun

If you connect the gun to a centralized gas supply, then it turns into a full-fledged stationary device, which in a private house can completely replace the entire heating system without any damage to the quality of heating. Regarding the fuel used, in most cases it is propane-butane.

Note! When the gas is burned, almost no odor is emitted. Moreover, the multi-level protection system, which is available in the devices, completely eliminates gas leakage. More "advanced" models have a special case coating that protects it from damage.

More "advanced" models have a special case coating that protects it from damage.

Moreover, the multi-level protection system, which is available in the devices, completely eliminates gas leakage. More "advanced" models have a special case coating that protects it from damage.

Thanks to gas guns, you can not only heat, but also quickly dry any surfaces - for example, plaster, freshly poured concrete, etc., and high performance makes it possible to use the device in large rooms - warehouses, hangars - and in crowded places. This device is really mono turn on and forget, because temperature control, on / off initiates the thermostat. Finally, in terms of the amount of carbon monoxide, a gas gun does not exceed an ordinary stove.

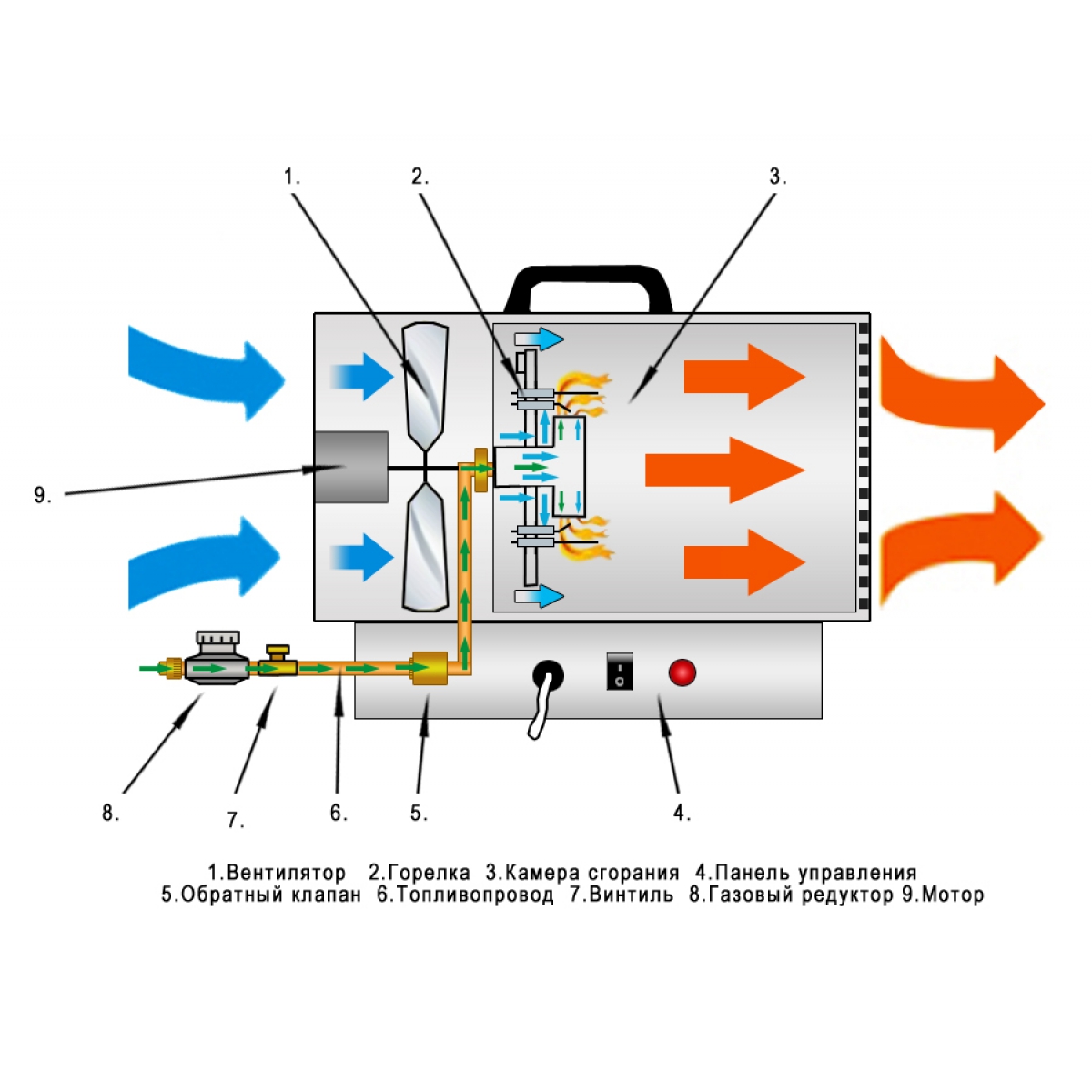

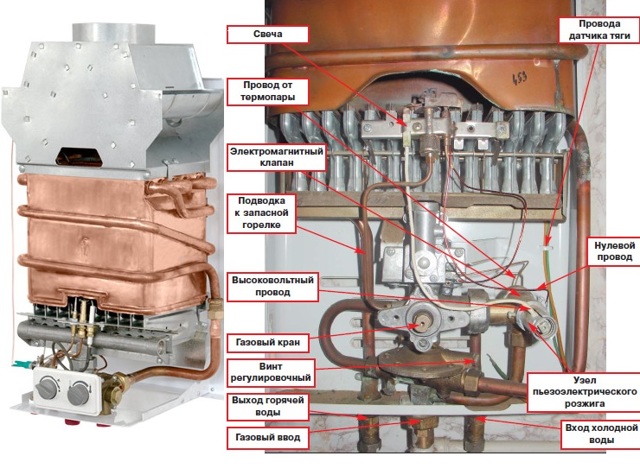

All devices of this kind consist of standard elements:

- heat exchanger;

- automatic device-controller;

- fan.

It is characteristic that the device requires very little electricity - after all, it is needed only to rotate the fan. When the gas burns, the heat exchanger warms up. The air driven by the fan passes through the heat exchanger, heats up and spreads throughout the heated room.

How to make an electric version of a heat gun?

It is considered the simplest design among the available options for such devices. It doesn't take much to make it. When using it, no harmful substances are released.

The design of the gun is a hollow cylinder, on one side of which there is a fan, and on the other, an electric heater. Passing through it, the air is heated and enters the room. Such a device can be used in any enclosed space in which electrical outlets are provided.

To make a heating device you will need:

- spiral of any heating device. One that is located on an old electric stove or iron may come up;

- fan;

- asbestos pipe or sheet metal for the heater body;

- switches;

- terminals;

- low power electric motor;

- wires;

- pads for fastening the spiral.

Work progress:

- Trim the coil to enhance its heat dissipation.

- Fix the spiral in the asbestos pipe on one side, and fix the fan on the other.

- Attach wires to the spiral that will connect to the network.

- Connect a rheostat that regulates the degree of heat.

- Put a propeller on the electric motor and mount it in the pipe.

The power supply of the fan and the spiral is carried out separately.

How to make a heat gun from improvised means can be seen in the video:

Overview of popular models

Analyzing information on thematic forums, the following popular gas burners among Russian consumers can be distinguished:

- MASTER BLP 17M. Ideal for garage heating. Reliable and durable equipment, the gearbox is “unpretentious” to the quality of the supplied gas. There is a power regulator from 10 to 16 kW, so it is suitable for garages up to 150 m2. The only negative is the manual ignition, although because of this the device almost never breaks down, the manufacturer generally gives a 3-year warranty. The average cost is 9 thousand rubles.

- SPECIAL IGE-15. Russian-made gun. It has a small size, suitable for use in the installation of stretch ceilings or for drying walls after painting. Power - 15 kW, but the flow is narrowly directed. It has 2 stages of heating, the kit includes a hose for connecting to a cylinder (with adapters). The average price is 5.2 thousand rubles.

- Caliber TPG-10. Also Russian-made, power - up to 10 kW, suitable for small rooms.The gearbox is collapsible, the manufacturer has provided for its complete replacement with an analogue. Also, the fan is serviced, not pressed into the bearing. But the functionality is minimal. But the cost is only 4 thousand rubles.

- Kroll P 10. Popular model of foreign production. It works when connected to cylinders, there is a piezo ignition, a protective thermostat and a pressure sensor. The productivity is small - up to 300 m3 per hour, but the flow of heated air is not narrowly directed, as in other models. The average price is 9.5 thousand rubles.

- Profteplo KG-57. Heat gun of industrial type with a capacity of up to 1400 m3 per hour. Available in two versions - with connection to 220V and 380V. The latter is noisy in operation, but it is not suitable for small spaces. There is a flame control, as well as a sensor that turns off the gun when it detects movement in front of it (it can be forcibly turned off). The average price is 11 thousand rubles.

MASTER BLP 17M, one of the best selling models

In total, a gas gun is an excellent option for quickly heating non-residential premises. For residential - not the best option, as it requires connection to the chimney. But you can make a gun yourself, all this will require only 2 - 3 thousand rubles (for all materials).

Varieties of gas guns

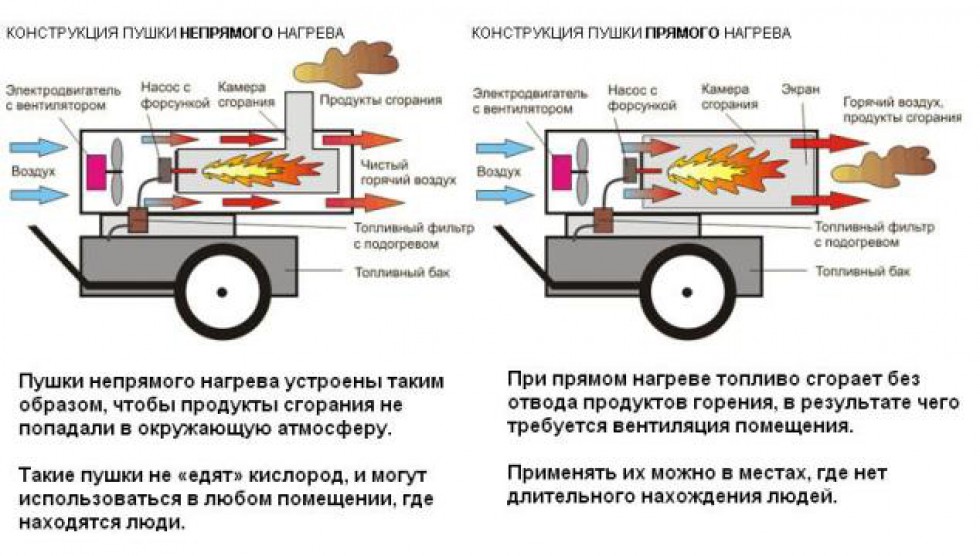

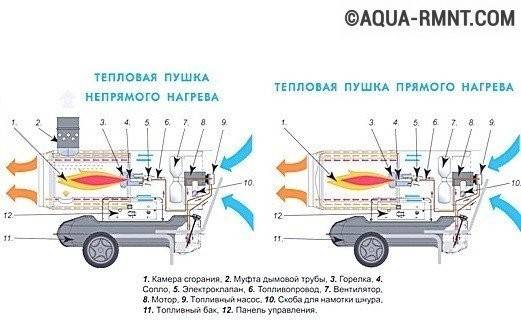

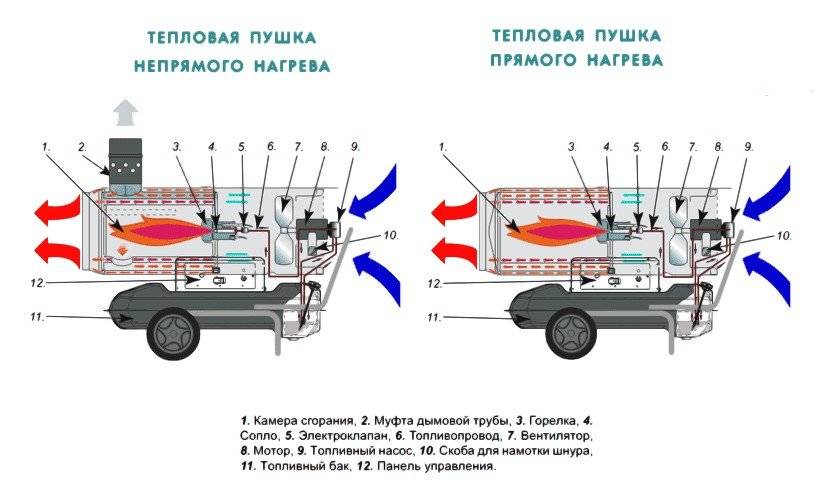

Air can be heated in one of two ways:

- direct heating;

- indirect.

Gas guns (do it yourself or factory-made) with direct heating have a fairly simple design, which is why their cost is low. The burner is not isolated in them, so that, in addition to heated air, gas combustion products also enter the room.For this reason, the device is compact and shows good efficiency. But if it is used to heat a dwelling, then you must first make sure that it (the room) has a good ventilation system that would remove combustion products.

Video

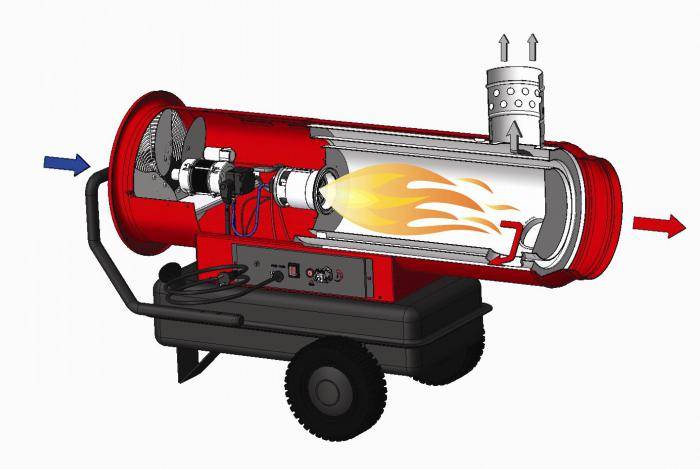

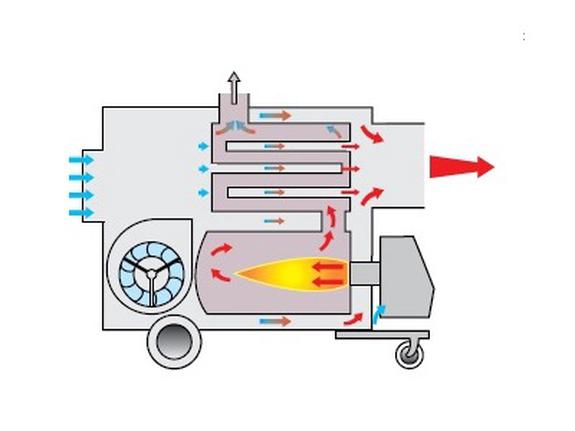

Guns operating on an indirect principle are equipped with isolated combustion chambers. They have special nozzles with which these products are discharged and which are connected to a common chimney. They are ideal for any type of space where many people gather.

All this is a description of stationary guns, but besides them, there are also portable or mobile guns. They are used together with gas cylinders. In order to make it convenient to transport and operate the device, it has special wheels and handles.

Note! Mobile guns require strict adherence to safety rules. The operating time of such devices is dictated only by the volume of the gas cylinder, fuel consumption ranges from 0.6-7 liters. in hour

In order to extend the battery life, there are special adapters that allow you to connect the device to several cylinders at once. The most economical option is a gun that is equipped with a thermostat. With it, the device turns off after the required room temperature is reached. In a word, heating the room with such guns - distinguishing the opportunity to save on heating

in hour. In order to extend the battery life, there are special adapters that allow you to connect the device to several cylinders at once. The most economical option is a gun that is equipped with a thermostat.With it, the device turns off after the required room temperature is reached. In a word, heating the room with such guns - distinguishing the opportunity to save on heating

The operating time of such devices is dictated only by the volume of the gas cylinder, fuel consumption ranges from 0.6-7 liters. in hour. In order to extend the battery life, there are special adapters that allow you to connect the device to several cylinders at once. The most economical option is a gun that is equipped with a thermostat. With it, the device turns off after the required room temperature is reached. In a word, heating the room with such guns is an opportunity to save on heating.

How to make your own

Gas guns began to be actively used in our country relatively recently. As already mentioned, this device is great for heating various rooms. It is especially popular for heating buildings that do not know how to supply gas. For example, country houses, country houses, garages, etc.

The gas gun has the following advantages:

- mobility;

- safety in operation;

- small size;

- high efficiency;

- ease of installation and dismantling;

- good power;

- ability to regulate the temperature.

Significantly affects the popularity of the gas gun and its objective and reasonable cost. Moreover, making it yourself will be much cheaper than buying a finished factory product.

Features of the repair of diesel guns for space heating

Repair maintenance of a diesel-fueled plant can result in a significant amount of money. Only one diagnostic procedure costs about 1000 rubles.For this reason, many owners of garages and storage facilities resort to self-repair of structures.

How to repair a diesel heat gun yourself

If warm air does not move, the fan motor may be defective. Repair involves stripping the terminals, checking the winding on the motor (an analog tester is suitable for this), as well as insulation. Sometimes the damage is so serious that a superficial adjustment is not enough. In such cases, one thing remains - replacing the engine.

An important part of the design are nozzles. The quality of the work of these elements depends on the full functioning of the entire heating system. These parts rarely break, and you can buy new elements to replace failed ones at any store.

These parts rarely break, and you can buy new elements to replace failed ones at any store.

Modern heat guns are equipped with a convenient control panel that allows you to adjust the air heating temperature.

Much more often, the need to repair a diesel gun arises due to filter clogging. To eliminate this breakdown, it is enough to open the body of the structure, unscrew the plug and remove the contaminated element. After washing with pure kerosene, the filter is ready for further operation. Before installing this part in place, it is advisable to blow it out with a jet of compressed air.

Rules for the safe operation of diesel appliances

When operating diesel appliances, it is very important to adhere to basic safety requirements. A container filled with fuel must not be placed closer than 8 m from sources of open fire and any heating devices.Important! Do not use gasoline instead of diesel

Volatile components of this substance increase several times the likelihood of an explosion.

Important! Gasoline instead of diesel is not allowed. Volatile components of this substance increase several times the probability of an explosion. A room with a working cannon must be left at the first appearance of these symptoms:

A room with a working cannon must be left at the first appearance of these symptoms:

- severe dry mouth;

- pain and discomfort in the nose and throat, as well as the eye area;

- headache that appeared suddenly;

- nausea.

Professional model of a heat generator on diesel fuel from the Master company

The presence of carbon monoxide in a closed room negatively affects the condition of people suffering from diseases of the cardiovascular system, lungs. The presence of pregnant women and patients with anemia in the room where the gun is working is not allowed.

Due to their efficiency, diesel guns are so in demand on the market. By following the basic rules of operation, you can avoid health problems. Otherwise, the use of a diesel gun is not dangerous. A high-quality device with suitable technical characteristics can provide a garage or warehouse with efficient heating for many years. The design of these devices is so simple that most of the breakdowns that occur during operation can be eliminated by the owner without the intervention of specialists.

Basic provisions for designing a heat gun

To design a heat gun yourself, you need to find a large-diameter pipe.Then, a little at the two ends on opposite sides, make two holes: one large caliber, the second small. The final products of combustion will exit through the large one, and fuel will flow through the small one. Then it is necessary to install a combustion chamber with an automatic catalyst, which will bring the gas mixture to a burning state.

It is very important to observe a high degree of tightness throughout the structure in order to avoid leakage. Then you need to attach the fan to the end of the pipe, where the small-caliber hole is located, and the design is ready.

How to make an electric heat gun - this question is not difficult, the main thing is to properly follow the safety rules when using it

This position is especially important for a tank with a gas mixture, it must be at least a meter away from other items in the room. If possible, it is advisable to temporarily remove very flammable materials while using a homemade heating device.

Because warm air can catalyze many chemical reactions.

A do-it-yourself electric heat gun does not require specialized skills or professional knowledge, and what is even more important is the absence of any material costs for design. However, when building, it is very important to observe the points that are indicated in the drawing.

(See also: Do-it-yourself greenhouse heating)

A home-made heat gun of the electric type allows you to properly provide heat to a large area.

Since from a practical point of view there is a double heating. The first source of heat is simple warm air, while the second source is a gas mixture, after the combustion of which a sufficiently significant amount of heat is released.

This design is mainly used for heating rooms in which, due to circumstances, it is impossible to ensure proper tightness, for example, repairs in the winter season. An electric-gas gun is mainly used for heating rooms that have a large footage or for quickly heating small residential areas.

For the manufacture of a diesel heat gun, you will need a number of components, namely:

- the combustion chamber;

- diesel fuel tank;

- large-caliber metal pipe;

- catalyst;

- fan.

First you need to make a hole at the two ends of the metal pipe: one large and one small. Then it will be necessary to mount the catalyst in the combustion chamber in the metal pipe itself. In no case should you start designing without having a plan for the future design, since in this case it will either not be possible to assemble the unit, or its final work will simply be energy inefficient. (See also: DIY gas-fired oven)

The smallest diesel heat gun is mainly used for heating a small room and its main advantage is efficiency. The main feature of its design is the use of a small metal pipe and the absence of a fuel tank. That is, such a unit functions solely by converting cold air into warm air.The main thing to remember is that the fan must always have a separate power source in order to avoid a short circuit in the mains.

To build a diesel heat gun, it is necessary to determine the footage of the future room, as well as take into account the degree of air insulation of the room where it is planned to use the future thermal unit. From a practical point of view, it is possible to determine the degree of air insulation by only one parameter: air ventilation is noticeable or not. Depending on this, you need to plan the future design. If the room is sufficiently insulated, then the gas mixture can be dispensed with and, consequently, the energy costs will be much lower.

Often many people ask the question, how to make a diesel heat gun on your own? The answer is very simple, it is paramount to draw up your own plan, and then carefully implement it point by point. The most common practical mistake of many people is just the same non-compliance with all points of the plan or lack of due attention. If you started designing, then take your time, otherwise you will have to redo it many times. The pipe must be wrapped with copper wire to ensure the proper functioning of the self-made heating device.

The main elements of the gun

To begin with, let's turn to engineering, which suggests that a heat gun should consist of several basic elements.

- Housing made of durable and heat-resistant material. Therefore, metal is chosen.

- Burner. A simplified design can be used here, for example, a burner from any gas heating boiler. Although you can use the option made by yourself.

- Fan.To supply oxygen and squeeze out heat from the body of the device, you will need some kind of unit. You won't find anything better than a fan. So you can use an old household appliance of low power.

- Gas supply source. It can be a gas pipeline or a gas cylinder.

An obligatory element that you have to do with your own hands is a combustion chamber. There is nothing complicated about this, so you can start manufacturing. But for assembly work, you will need a welding machine powered by an electric current.

So, we will make a heat gun from a large diameter pipe - at least 150 mm. Of course, the size of the unit will affect its performance, but for a small space like a garage, the unit may not be very large. Practice shows that a power of 2 kW is more than enough.

What you need to know about the electric gun?

Unlike other types of heat guns, almost any home craftsman who is familiar with the basics of electronics can make an electrical appliance.

Although the efficiency of an electric gun is much lower than diesel or gas devices, it does not emit combustion products harmful to health and can be installed in any room - a residential building, a greenhouse, outbuildings.

The power of guns for industrial use varies from 2 to 45 kW, and the number of heating elements in them can reach up to 15 pcs.

Consider how an electrical unit works.

The device and principle of operation of the heat generator

Any electric gun consists of three main components: a body, an electric motor with a fan and a heating element.Varieties of this type of devices are described in detail in an article on the classification and principles of operation of heat guns.

Additionally, the device can be equipped with any "bonuses" from factory units - a speed switch, a heat controller, a room thermostat, a case heating sensor, engine protection and other elements, but they increase not only comfort and safety during operation, but also the cost of homemade.

The rate of air heating in the entire volume of the room depends on the number and power of the heating elements - the larger their area, the more actively the heat transfer will occur

The electric gun works like this:

- when connected to the network, the heating element converts electric current into thermal energy, due to which it heats up itself;

- the electric motor drives the impeller blades;

- the fan drives air from the room inside the case;

- cold air flow comes into contact with the surface of the heating element, heats up and, forced by the fan, is removed from the "muzzle" of the gun.

If the appliance is equipped with a thermostatic element, it will stop the heater when the programmed temperature is reached. In primitive devices, you will have to control the heating yourself.

Advantages and disadvantages of homemade guns

The main plus of a thermal power generator is the possibility of its use in any room where there is a network of at least 220 watts.

Such devices, even in a home-made version, are mobile, weigh a little and are quite capable of heating an area up to 50 m2 (theoretically, more is possible, but it is better not to experiment with high-power devices and buy a ready-made unit, and a gun from 5 kW will already require connection to a three-phase network) .

The performance characteristics of the device must correspond to the heated area. On average, 1 kW will be needed for every 10 m2, but a lot depends on the room itself - building materials, glazing quality and the presence of insulation

Pros of a homemade electric gun:

- Cost savings - factory units are not cheap, and you can assemble a heating device with a minimum of purchased parts or even completely from improvised means by removing the missing elements from old appliances.

- Safety - of all home-made heat generators, an electrical appliance is the easiest to operate, since it does not require connection to gas or refueling with combustible fuel. With the correct assembly of the electrical circuit, the risk of spontaneous combustion in such guns is minimal.

- Fast heating of the room - the work of the heat gun is much more efficient than other options for homemade electric heaters, such as fireplaces or oil radiators.

Of the minuses, a large power consumption can be noted (the amount depends on the engine power and heating element). In addition, the operation of the fan is quite noisy, and the larger the wingspan and rotational speed, the louder the noise will be.

Well, any drawback of a home-made electrical device is the likelihood of an error during assembly or connection, which can cause a short circuit in the network, electric shock and spontaneous combustion of the device.

Making a heat gun with your own hands

The process of creating a homemade heat gun always begins with the manufacture of a frame from the corners, to which the body and other components will be attached. The next steps depend on the type of installation.

First, a diagram of the electrical circuit of the installation is drawn up. If the master does not have the relevant knowledge, he can use ready-made developments.

It looks like a drawing of a circuit diagram of a heat gun

An electric heat gun is made as follows:

Video: do-it-yourself electric gun for heating a garage

Heat gun on diesel fuel and diesel fuel

The manufacturing process consists of the following steps:

We draw the reader's attention to the fact that this heat gun operates according to the direct heating scheme, therefore it cannot be used in residential and other premises with the stay of people or animals.

To control the correctness of the assembly, it is advisable to invite a master from some auto repair shop.

The self-made model does not have a flame control sensor and an overheating protection system, so it cannot be left unattended during operation.

Video: multi-fuel heat gun

gas heat gun

This setup is made like this:

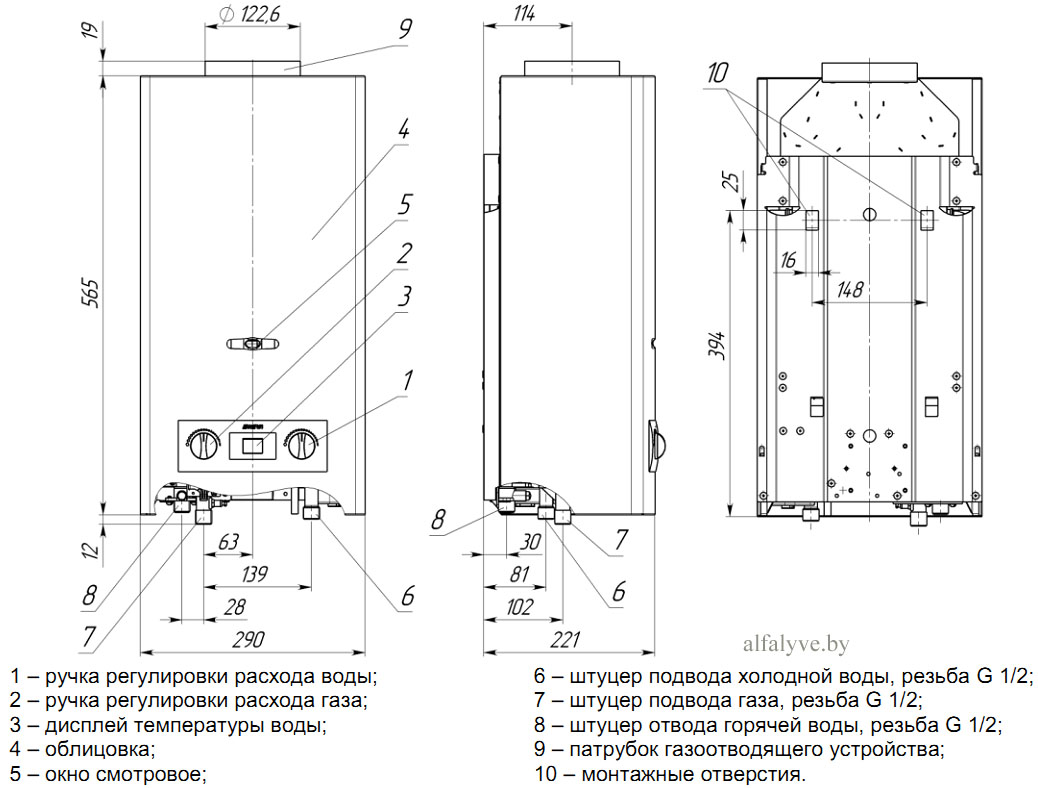

- A meter-long piece of pipe with a diameter of 180 mm is used as a body. In the absence of a finished pipe, it is made from galvanized sheet, fastening its edges with rivets.

- At the ends of the body, on the side, you need to cut out a hole - with a diameter of 80 mm (a pipe for the removal of heated air will be connected here) and 10 mm (a burner will be installed here).

- A combustion chamber is made from a meter-long piece of pipe with a diameter of 80 mm. It must be welded into the body exactly in the center, for which several plates must be used.

- Next, a disk is cut out of the steel sheet, which will be used as a plug. Its diameter must correspond to the diameter of the heat gun body (180 mm).A hole with a diameter of 80 mm is cut in the center of the disk - for the combustion chamber. Thus, a plug welded to the body on one side will close the gap between it and the combustion chamber. The plug must be welded from the side of the heated air supply.

- A pipe for supplying heated air is welded to a hole made in the body with a diameter of 80 mm.

- A burner with a piezoelectric element is installed in a 10 mm hole. Next, a gas supply hose is connected to it using a clamp.

- The manufacture of the heat gun is completed by installing a fan and connecting it and the piezo igniter to the power supply through a switch.

Video: homemade gas heat gun

The easiest way to make such a heater is from an old gas cylinder. If it is not available, a thick-walled pipe with a diameter of 300–400 mm can also be used as the main blank - then the cover and bottom will need to be welded on their own (these elements are already available for the cylinder).

One of the options for a wood-fired heat gun is shown in the drawing:

Drawing of a general view of a heat gun with an indication of its main dimensions

As you can see, the body of the heat gun is divided into a furnace and an air chamber with inlet and outlet openings. The partition between them and the improvised lamellar radiator act as a heating element for the air passed through the chamber. The location of the radiator fins is shown in the sections.

Sections - frontal and horizontal, which show the internal structure of the gun

By attaching a corrugated hose to the outlet pipe of the air chamber, the user will be able to supply hot air to any point in the room.

The installation is made as follows:

An overly powerful fan is not required for this heat gun. It is enough to install a model for extracting a bathroom with a capacity of about 50 m 3 / h. You can use a fan from the stove of the car. If the room is very small, a cooler from a computer power supply is also suitable.

Varieties of diesel heat guns

Guns of this type are also called liquid fuel: they can be used as fuel for both diesel and kerosene or diesel fuel. It is strictly forbidden to use gasoline, alcohol and other flammable liquids to refuel such devices.

Diesel heat guns can be not only mobile, but also stationary. Similar designs have an outlet pipe connected to a chimney through which combustion waste is removed.

The choice of fuel must be approached very carefully, since the use of poor quality or contaminated fuel can clog the nozzle and / or filter, which will require the intervention of repairmen. Diesel guns are characterized by high power, high efficiency, as well as compact size, so that such units are quite mobile.

All units operating on economical diesel fuel can be divided into two types: with direct and indirect heating.

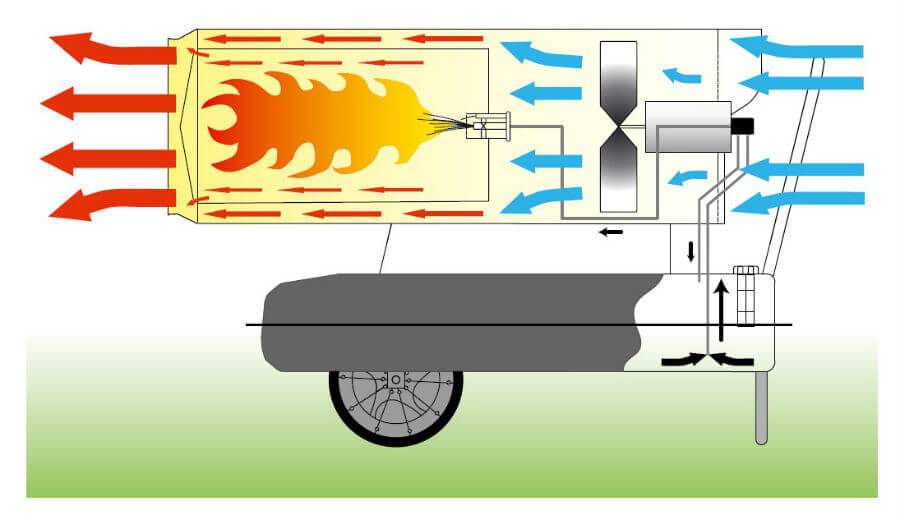

The basis of devices with direct heating is an elementary principle of operation: a burner is arranged inside the body, through the flame of which air blown by a fan passes. As a result, it heats up, and then breaks out, giving off heat to the environment.

A diesel heat gun with open heating cannot be used for heating residential premises, since its design does not provide for exhaust pipes.As a result, waste substances, including carbon monoxide, enter the room, which can lead to poisoning of people in it.

Such devices are distinguished by high power of 200-250 kW and almost 100 percent efficiency. They are inexpensive, easy to install, but they have an important drawback: not only warmed air flows into the outer space, but also combustion products: soot, smoke, fumes.

Even good ventilation will not be able to completely rid the air of unpleasant odors and the smallest particles, and if it is completely absent, living beings in the room can get severe poisoning.

A device with indirect heating is much more complicated. In such models, the air is heated indirectly, through a special chamber - a heat exchanger, where heat is transferred to the air flow.

Diesel heat guns with indirect heating have a higher cost and lower efficiency compared to similar products with a direct heat source. However, they are widely used due to the best indicators of environmental friendliness and safety.

In such units, the heated exhaust gases, together with the heat, enter the heat exchanger, from where they are discharged into the smoke channel, to which a special pipe is connected. With its help, the products of combustion are removed from the closed space to the outside, providing fresh air in the heated room.

Advantages of indirect heat guns

Particular attention of consumers, primarily owners of garages, is used by heat guns with indirect heating. Models of diesel heat guns with high power may have large dimensions

They are used for heating large premises: warehouses, factory floors

Models of diesel heat guns with high power may have large dimensions. They are used for heating large premises: warehouses, factory floors

The advantages of such models include:

- Mobility. Although the dimensions and weight of such devices are somewhat larger than those with open heating, they are still quite compact in size, which allows them to be transported around the room within the length of the connecting element and the chimney.

- Great power. Although this figure is higher for devices with direct heating, the power of indirect diesel guns is enough to heat a large area in a short time.

- Reliability. Such devices have a well-thought-out design, which minimizes the risk of fire, and also increases the durability of the guns.

- Many factory models have a special protection system that automatically turns off the gun immediately after the room temperature reaches the set point.

- Factory-made products are equipped with thermal insulation pads to prevent heat build-up in the case, reducing the risk of burns to the user.

- On some models, tanks of large volumes are provided, which allows them to be used for a long time without thinking about fuel.

The disadvantage of such structures can be considered a high noise level, especially for high-power units.