- Reasons for the popularity of rooftop boilers

- Types of gas boilers

- Mounting

- Selection Tips

- Design standards for gas-fired rooftop boilers

- Which boilers to use

- How to supply gas

- Roof power supply

- Fire safety

- Compliance of the dimensions of the gasified building with the standards

- Rules and regulations for installing a gas boiler in a private house

- Separate building for the boiler room

- Requirements for boiler rooms for the installation of solid and liquid fuel boilers

- Advantages and disadvantages of an autonomous boiler house

- Some features of the device autonomous boiler rooms

- Room for the installation of a gas boiler

- boiler room requirements

- Requirements for the room for the installation of a turbocharged unit

Reasons for the popularity of rooftop boilers

Due to the large number of disadvantages of placing boilers in the basement or in a separate building, boiler rooms on the roof have gained the most popularity. Here you can use any type of fuel, in particular, gas, which is the most economical, easy to use and energy efficient carrier.

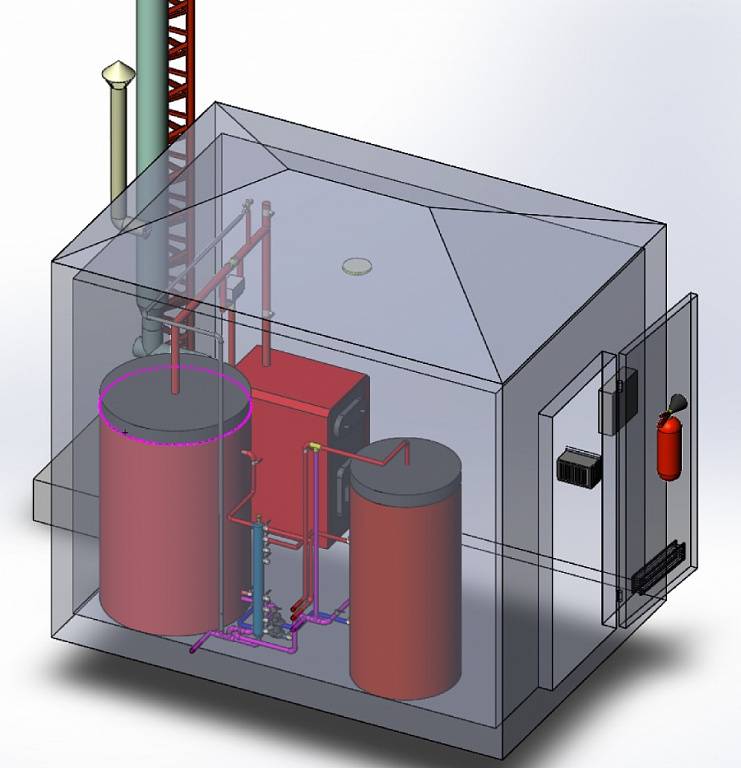

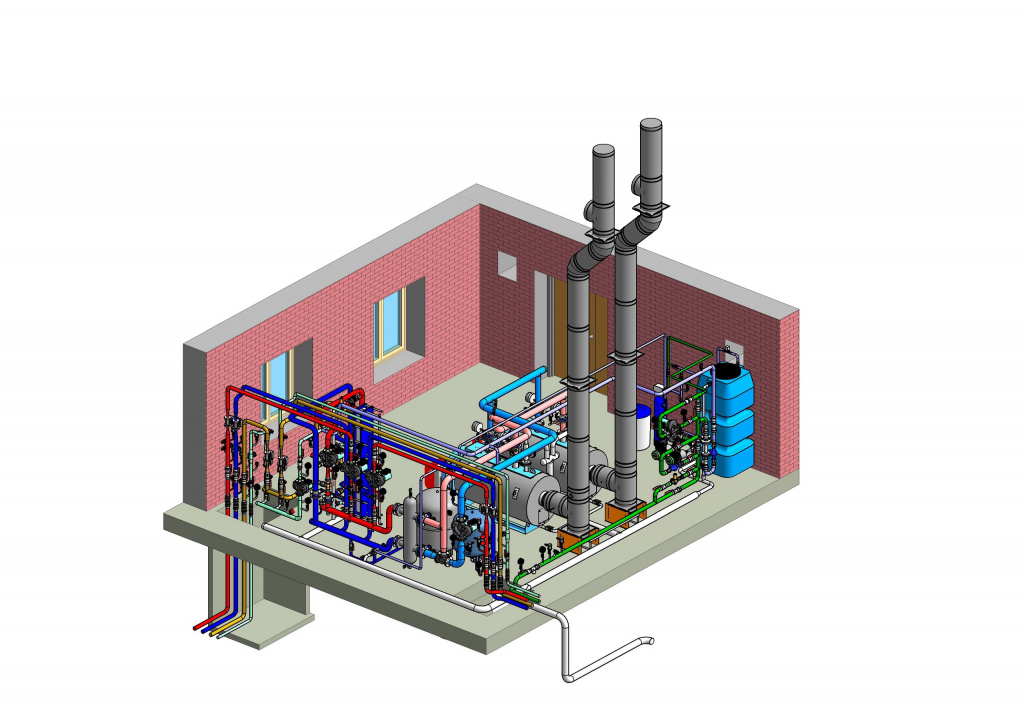

A rooftop boiler room can be installed on an already built house if a modular design is used. This is how it will look like

A rooftop boiler room can be installed on an already built house if a modular design is used. This is how it will look like

If the boiler room is installed on the roof, it does not require a complex ventilation system, the construction of a huge chimney and other bulky structures.

Thanks to the use of gas as an energy source, the process of organizing an autonomous boiler house is greatly simplified. And the installation of a simple automation system allows you to set the range within which the temperature of the coolant (water in the pipes) should be.

This significantly saves both fuel and money for apartment owners. Thus, there is no need for a stove-maker who will constantly monitor the boiler room and turn it on as the temperature drops. Instead, everything will be done by automation.

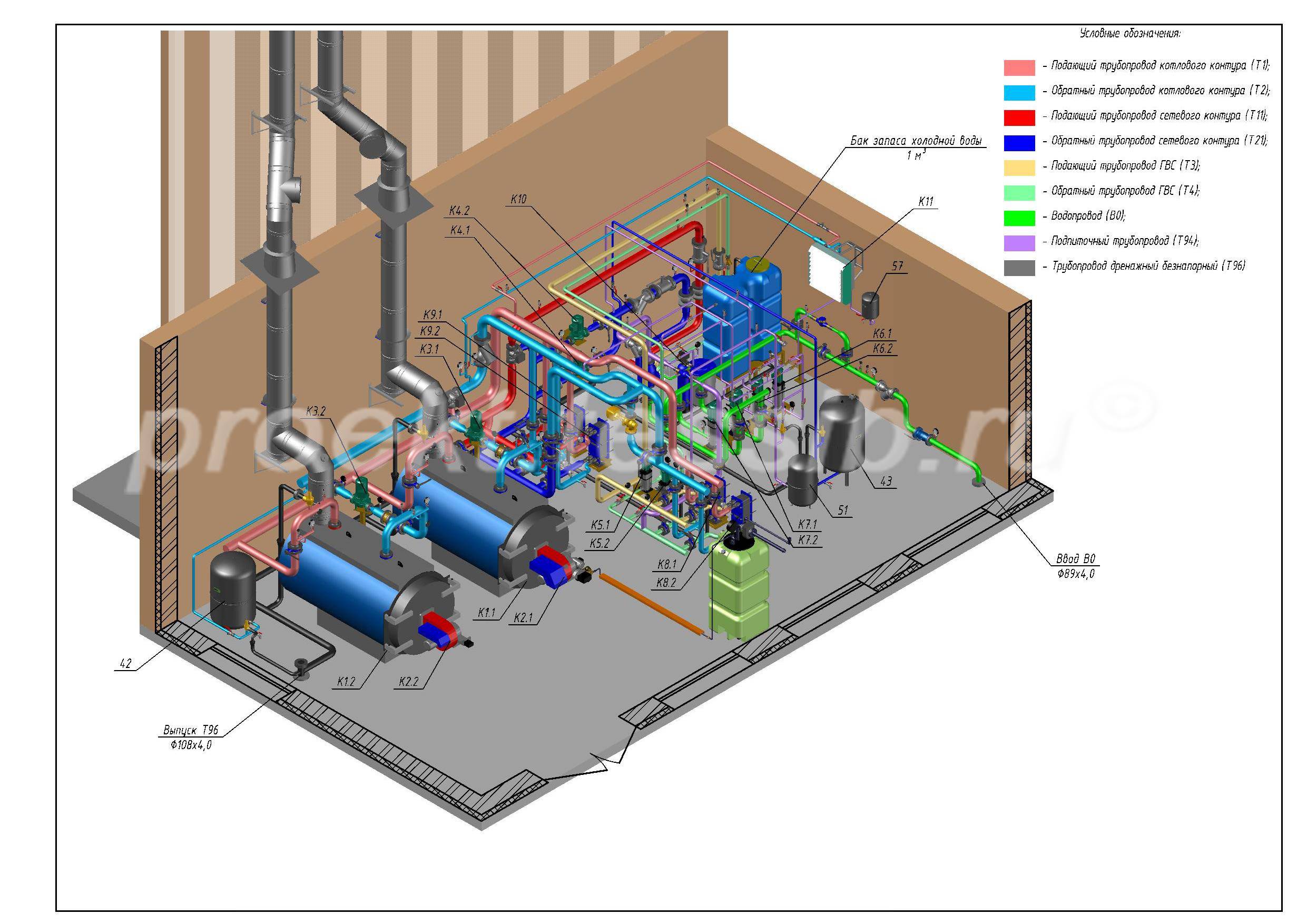

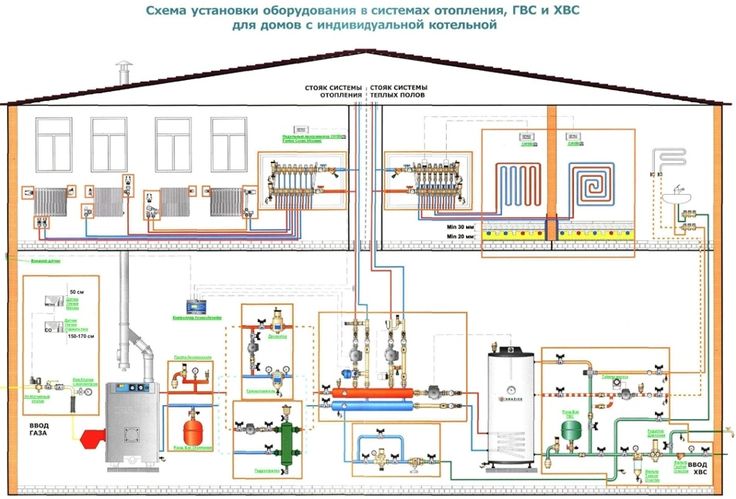

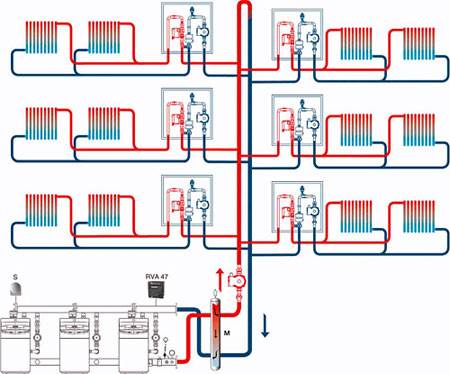

Approximate diagram of the arrangement of the roof boiler. A small modular building on the roof contains all the elements to provide heat to a multi-storey building

Approximate diagram of the arrangement of the roof boiler. A small modular building on the roof contains all the elements to provide heat to a multi-storey building

Gas boilers for boiler rooms are considered the easiest solution to operate. Even a simple user becomes clear how to handle the equipment so that it gives the desired result. Every resident of the house can learn how to adjust the temperature, turn the boiler on and off.

Types of gas boilers

A boiler room is a separate room that is allocated for the installation of heating equipment. Installation of a high-power gas boiler in a separate room allows you to create the necessary safety for the operation of potentially explosive equipment.

Depending on the location of the premises, the following types of boiler rooms are distinguished:

- When constructing a separate building for the installation of gas equipment, they talk about a separate boiler room. The heating lines that go from this building to the house are well insulated so that there is no heat loss.The advantage of such options is reliable protection against noise emitted by operating equipment, as well as safety for people in case of poor carbon monoxide removal.

- The attached variety is adjacent to a residential building. This option is more advantageous in that you do not need to pull communications from a separate building to the house and insulate them well. Moreover, the entrance to this room can be organized directly from home, so that in winter you do not have to walk down the street to adjust the operation of the boiler and check the system.

- The built-in type of such premises is located inside the house. In this case, it is much easier to lay the heating circuit and other necessary communications.

Mounting

Installation of boiler equipment under the residential area of the house is not allowed. Therefore, it can not be done freely in any part of the basement. Optimum heat supply is provided only by low-pressure complexes. You can put them on the ground floor or underground. But it is worth noting that experts clearly prefer installation in a separate building.

Equipping with a mixing unit allows you to use all the possibilities provided by the buffer tank. But first you have to calculate everything. Modular industrial boilers almost never require a strong foundation.

The most reliable solution is a banal reinforced concrete slab

Important: you will need a separate base for the chimneys. The place for installation is chosen in accordance with SNiP

It is best to install equipment where there is already gas, water and drainage. In the absence of such communications, it is necessary to look where it will be easier to make them.

In preparation for the installation itself, the projects and estimates are rechecked once again.The installation site must be calibrated and cleared of everything that could interfere. Consider where to place access roads, temporary technological structures. A sand and gravel layer is poured under the foundation, contours are prepared for drainage. Backfilling and tamping of the soil is carried out up to 0.2 m; then crushed stone is poured, concrete is poured and a layer of asphalt concrete is formed.

Pumping systems can play a big role; It is worth choosing those that are designed for quick installation. They are also more aesthetic than those assembled randomly from different parts.

Important: if during installation air exchange is provided not 3, but 4-6 times per hour, the owner will only benefit. Ventilation ducts must be sealed

At the end, commissioning works are being carried out.

Selection Tips

The main function of an autonomous boiler house is to provide heat and hot water to all residential or technological facilities. The advantage of such a complex is that it is ready for operation immediately after installation.

In order for the complex to fully perform the functions assigned to it, close attention must be paid to the process of its selection.

Gas are considered the most popular and in demand. The principle of heat generation here is based on the fact that the gas burns and produces heat, while heating all the necessary premises. The main advantage of such a system is the relative cheapness of fuel and the efficiency of the equipment itself. With proper installation and use, such boilers can last for many years.

As for the disadvantages of gas options, explosiveness can be noted.However, all modern boilers boast the presence of various protective mechanisms that prevent fuel from leaking.

It is on them that you need to pay close attention in the process of choosing an autonomous gas boiler house.

The second most popular is considered to be a diesel autonomous boiler house, in which diesel fuel is used to heat the coolant. It should be noted that the efficiency here is also quite high. Among the main advantages of this option, it is worth noting its low fire hazard, which usually makes people prefer it. However, it should be borne in mind that the fuel smells extremely unpleasant, so there is always a terrible smell in the boiler room itself.

In addition, the equipment used in such complexes is distinguished by its demanding fuel quality. If you do not follow the basic rules, then the boiler will quickly fail and you will have to purchase a new one.

In recent years, boilers that run on waste oil have become very popular. The unique burner is designed in such a way that it burns fuel without problems. The main advantage of using such a complex is its affordable cost, because mining is several times cheaper than diesel fuel. At the same time, the efficiency is as high as that of diesel installations, so the user will not feel the difference in the amount of heat received, but he will be able to save money.

The main advantage of such models over gas ones is that it will not be necessary to develop any projects and obtain permission to install or equip the complex. The benefit of using such a boiler house also consists in a quick payback.

The power of the boiler house is also important in the selection process. It is worth calculating how much space it will have to warm up, and then start arranging an individual heating system

The region where such a complex will be installed should also be taken into account. For example, if the area is far from the gas main, then it makes no sense to install gas boilers, but it is better to give preference to other options.

See the following video for an overview of the Prometheus boiler company.

Design standards for gas-fired rooftop boilers

The design of KKg is carried out by companies that have a license for the corresponding type of work. Before approval, the project must be coordinated by architectural supervision, SES, fire inspection with operating organizations that have drawn up technical specifications in the design process.

The KKg floor is made with waterproofing capable of providing a flood of water up to 100 mm high. Window openings should provide natural light, and therefore they are set from a ratio of at least 0.05 m2 per 1 m3 of the total volume of the heat supply facility.

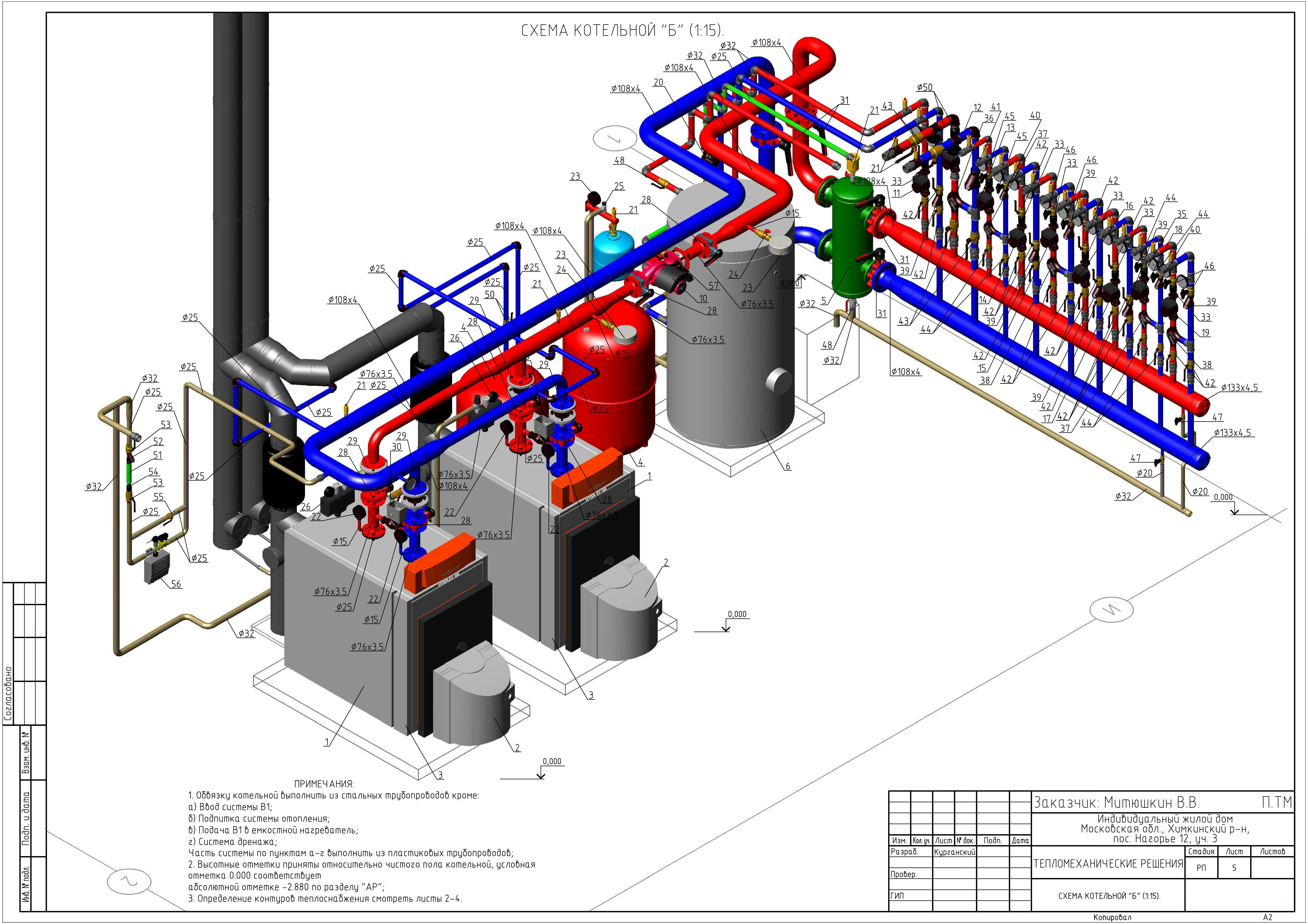

The scheme of piping of intra-house heating and ventilation networks is carried out according to a dependent scheme, through a mixing unit for the release of thermal energy, and the DHW system is carried out according to a closed scheme through a heat exchanger.

Heating systems are divided in front, with an individual unit for commercial accounting of thermal energy. A chemical water treatment system must be installed in the boiler room to supply soft water to the boiler and the heating circuit. These requirements are met to prevent scale formation on heating surfaces.

Which boilers to use

As sources of thermal energy in KKg, automated hot water boilers are used, capable of heating water with a heat carrier up to 95 C and pressure up to 1.0 MPa.

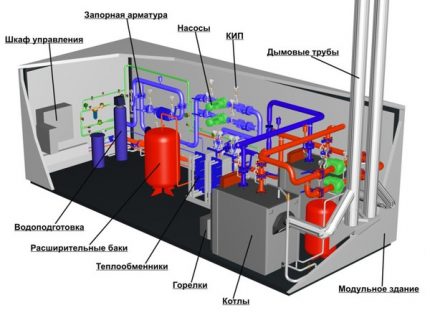

For example, a modular boiler house ARGUS TM-1000.00.PR.10 with a power of 1050 kW is equipped with:

- Gas boiler PROTHERM 120 SOO with a capacity of 105 kW and an efficiency of -90%, 10 units.

- Pump group with centrifugal pump WILO HWJ 202 EM 20L.

- Expansion membrane tank REFLEX N 200/6.

- Automation and regulation system.

- Group of instrumentation and primary sensors.

- Block of chemical water treatment.

- Smoke ventilation system.

How to supply gas

Gas pressure in the gas pipeline for KKg should not be more than 5 kPa.

External wiring of the gas pipeline to the boilers is carried out in places that are convenient for subsequent maintenance and exclude the possibility of its rupture. Connection to this gas pipeline of other consumers is not allowed.

The gas pipeline must not pass through ventilation systems, windows and doors. The internal gas pipeline in the boiler room is laid openly, while there should be free access for monitoring and technical inspection of safety and automation devices.

In addition, a safety shut-off valve (PZK) with an electromagnetic actuator is installed in the security system on the gas line, which cuts off the gas in an emergency.

Roof power supply

The electrical equipment of KKg must comply with the PUE, as an object of the second category of power supply reliability.

The power supply scheme should provide for the possibility of turning on backup electrical equipment when the main device, such as a pump, fan and smoke exhauster, exits.

Safety automation should ensure that the gas supply to the boiler is turned off in the event of an emergency: high gas pressure, separation of the flame from the burner, gas contamination in the boiler room, low draft in the furnace, high temperature and coolant pressure.

Fire safety

There are a number of important security fire requirements for KKg in a multi-storey building:

- The location of the boiler room directly above the apartments is prohibited.

- The boiler facility is assigned a categorization of class "G" for explosion and fire hazard.

- The height of the ceilings of the object must be higher than 2.65 m.

- Door width over 0.8m.

- Fire barriers must be installed in the building.

- The room must have a separate emergency exit.

- The facility is equipped with sound and light fire alarms and emergency fire extinguishing systems.

Compliance of the dimensions of the gasified building with the standards

When designing a gas-fired boiler room, the power of the heating unit is taken into account. According to this parameter, the volume of the furnace compartment is calculated.

The table shows the minimum volume and location of the furnace equipment, corresponding to a certain power of the heating device:

| Device power | Room volume | Location of the unit |

| Up to 30 kW | 7.5 cubic meters | built-in office or kitchen |

| 30-60 kW | 13.5 cubic meters | outbuilding, separate room in the house |

| 60-200 kW | 15 cubic meters | free-standing building, extension, basement or basement |

The table shows that it is allowed to install devices with a power of not more than 30 kW in the kitchen. At the same time, its area should be about 4 sq.m.

If the heating equipment is located in the basement or on the basement floor, the walls and ceilings adjacent to other rooms must be vapor and gas tight. In addition, when using heating appliances up to 300 kW it is necessary to provide for a separate exit to the street.

Rules and regulations for installing a gas boiler in a private house

The choice of installation location for a gas boiler depends on its power:

- with a power of up to 60 kW, installation is possible in the kitchen (subject to certain requirements);

- from 60 kW to 150 kW - in a separate room, regardless of the floor (subject to the use of natural gas, they can be installed in the basement and basement as well);

- from 150 kW to 350 kW - in a separate room on the first or basement floor, in an annex and a separate building.

This does not mean that a 20 kW boiler cannot be installed in a separate boiler room. You can, if you want to collect all life support systems in one place. That's just the volume of premises there are requirements. The minimum size of a boiler room in a private house should be:

- for boilers with a power of up to 30 kW, the minimum volume of the room (not the area, but the volume) must be 7.5 m3;

- from 30 to 60 kW - 13.5 m3;

- from 60 to 200 kW - 15 m3.

Only in the case of installing a gas boiler in the kitchen, other standards apply - the minimum volume is 15 cubic meters, and the ceiling height is at least 2.5 m.

Installation option for a wall-mounted gas boiler - up to the wall at least 10 cm

For each variant of the premises for a gas boiler room, certain requirements are imposed. Some of them are common:

Any boiler room in a private house should have natural light.Moreover, the area of windows is normalized - at least 0.03 m2 of glazing should fall on 1 m3 of volume

Please note that these are the dimensions of the glass. In addition, the window should be hinged, open outward.

The window should have a window or transom - for emergency ventilation in case of gas leakage.

Mandatory ventilation and removal of products combustion through the chimney

The exhaust of a low-power boiler (up to 30 kW) can be led through the wall.

Water must be connected to the boiler room of any type (feed the system if necessary) and sewerage (heat carrier drain).

Another general requirement that appeared in the latest version of SNiP. When installing gas equipment for hot water supply and heating with a capacity of more than 60 kW, a gas contamination control system is required, which, in the event of a trigger, will automatically stop the gas supply.

If there is a boiler and a heating boiler, when determining the size of the boiler room, their power is summed up

Further requirements differ depending on the type of boiler room.

Separate building for the boiler room

Equipment with a power of 200 kW or more must be installed in a building separate from the house.

Along with the general requirements, in this case, some additional conditions are imposed:

- Heat resistance of the building material from which walls and roofs are constructed (including internal finishing).

- A separate boiler room must have a room volume of at least 15 m3. To the result obtained, 0.2 m3 is added for each kW of power involved in heating the home.

- Ceilings. Height - from 250 cm.

- Glazing area.It is determined by the formula 0.03 m2 / 1 m3 of the building volume.

- Window. Be sure to have a window or transom.

- The presence of a separate foundation for the boiler. It should not be higher than 15 cm in relation to the general level. If the weight of the heating equipment does not exceed 200 kg, it can be mounted on a concrete floor.

- Existence of system of emergency shutdown of gas. It is installed on the pipe.

- Doors. It is allowed to use only non-reinforced structures on weak hinges.

- Ventilation. Its power should be enough to ensure that in one hour all the air in the room is replaced at least three times.

Acceptance and placement of the boiler in the boiler room is strict: representatives of the gas service usually do not go for concessions.

Requirements for boiler rooms for the installation of solid and liquid fuel boilers

The requirements for volume, dimensions and materials for the boiler room are the same. However, there are several specific ones that are associated with the need to organize a chimney and a place to store fuel. Here are the basic requirements (mostly they are written in the boiler passport):

- The cross section of the chimney must not be less than the diameter of the boiler outlet pipe. It is not allowed to reduce the diameter along the entire length of the chimney.

- It is necessary to design a chimney with the least number of elbows. Ideally, it should be straight.

- At the bottom of the wall there should be an inlet (window) for air to enter. Its area is calculated from the power of the boiler: 8 sq. see per kilowatt.

- The outlet of the chimney is possible through the roof or into the wall.

- Below the chimney inlet there should be a cleaning hole - for revision and maintenance.

- The chimney material and its connections must be gas-tight.

- The boiler is installed on a non-combustible base.If the floors in the boiler room are wooden, a sheet of asbestos or mineral wool cardboard is laid, on top - a sheet of metal. The second option is a brick podium, plastered or tiled.

- When using a coal-fired boiler, the wiring is only hidden; laying in metal pipes is possible. Sockets must be powered by a reduced voltage of 42 V, and switches must be sealed. All these requirements are a consequence of the explosiveness of coal dust.

Please note that the passage of the chimney through the roof or wall must be made through a special non-combustible passage unit. Oil fired boilers are usually noisy

Oil fired boilers are usually noisy

It is worth saying a few words about liquid fuel boilers. Their work is usually accompanied by a fairly high level of noise, as well as a characteristic smell. So the idea of putting such a unit in the kitchen is not the best idea. When allocating a separate room, you should make sure that the walls give good sound insulation, and the smell does not penetrate through the doors. Since the internal doors will still be metal, take care of the presence of a high-quality seal around the perimeter. Perhaps the noise and smells will not interfere. The same recommendations apply to attached boiler houses, although they are less critical.

Advantages and disadvantages of an autonomous boiler house

So, you are thinking about the possibility of installing your own boiler room, which would heat the entire apartment building and supply hot water to each of the apartments. What strengths and weaknesses do you need to be aware of in order to make the right decision that will not make you repent in the future?

Scheme of the heating system in an apartment building

To begin with, it is worth talking about the shortcomings, since there are much fewer of them.

- The high initial cost of the project is the purchase of the equipment itself, its installation and the connection of communications to each of the apartments. Yes, initially each of the owners of an apartment in the house will have to invest a considerable amount so that the team of tenants can make such an expensive purchase. Many of the owners can simply refuse such a significant expense, albeit a one-time one.

- The need to maintain the entire system in working order. If, when connecting to a heating plant, all the responsibilities for maintaining the equipment fall on the shoulders of the specialists of the company providing services, now, in case of any breakdown, you will have to solve the problem on your own. This means that it will be necessary to hire specialists who will conduct regular inspections of equipment, and if breakdowns are detected, they will be repaired. This can bring unnecessary hassle and financial costs.

On this, the main disadvantages of an autonomous boiler house are exhausted. Of course, they are very significant, which is why today not every house has a mini-boiler room installed. But still, the number of such mini-boilers is growing rapidly. Why? Due to the following advantages of independent heating.

- Full independence from city monopolists in housing and communal services. Everyone is well aware that in every city there is only one company that provides heating and hot water services to residential apartment buildings. And they can almost uncontrollably increase the cost of their services. If you install your own boiler house, then the monopolists will no longer have leverage over you.

- Minimizing heat loss.As practice shows, passing through many kilometers of heating mains, the coolant (hot water) loses up to 30% of the heat received (depending on the distance from the city boiler house).

An example of heat loss in an apartment building

And end users also have to pay for this heat. In autonomous heating systems, heat losses are measured in fractions of a percent. So already due to this, the payment is reduced by a third.

- A boiler room that heats one house, not thousands, is easy to set up. If the apartments get too hot, you can easily reduce fuel consumption, and on frosty days - increase it. Thanks to this, the temperature in the rooms will always be optimal, suiting each of the inhabitants. You do not have to ventilate the premises, lowering the temperature and at the same time releasing heat into the street, for which a lot of money has been paid. But at the same time, you do not have to use additional heat sources (electric heaters) to maintain a sufficiently high temperature in the apartment.

- In order for the boiler room of an apartment building to be kept in perfect order, it is enough to hire one dispatcher who monitors the readings of all devices, as well as one or two incoming servicemen who are involved only when breakdowns are detected. If your house is connected to the city heating main, you will have to pay for the services of not only dozens (or even hundreds) of ordinary installers, but also hundreds of accountants, directors, their deputies, secretaries, drivers and many others. This also saves a lot of money.

- In most cases, heating of houses connected to the city heating plant starts on October 15 and ends by April 15.And even if autumn and spring are unusually cold or warm for a given area, no one will change the start and end dates of the heating season.

Therefore, in the off-season, it is often too hot or too cold in apartments. The presence of an autonomous boiler room allows you to turn on and off the heating exactly when it is needed. Most often, such decisions are made by the council of the tenants of the house. Of course, this allows not only to reduce heating costs, but also to maintain the optimum temperature in the premises, regardless of the temperature outside the walls of the house.

What conclusion can be drawn from all of the above?

But it allows you to save a lot of money every month. Therefore, all initial costs will be compensated fairly quickly, and very soon you will notice that you have free money that used to go to pay utility bills.

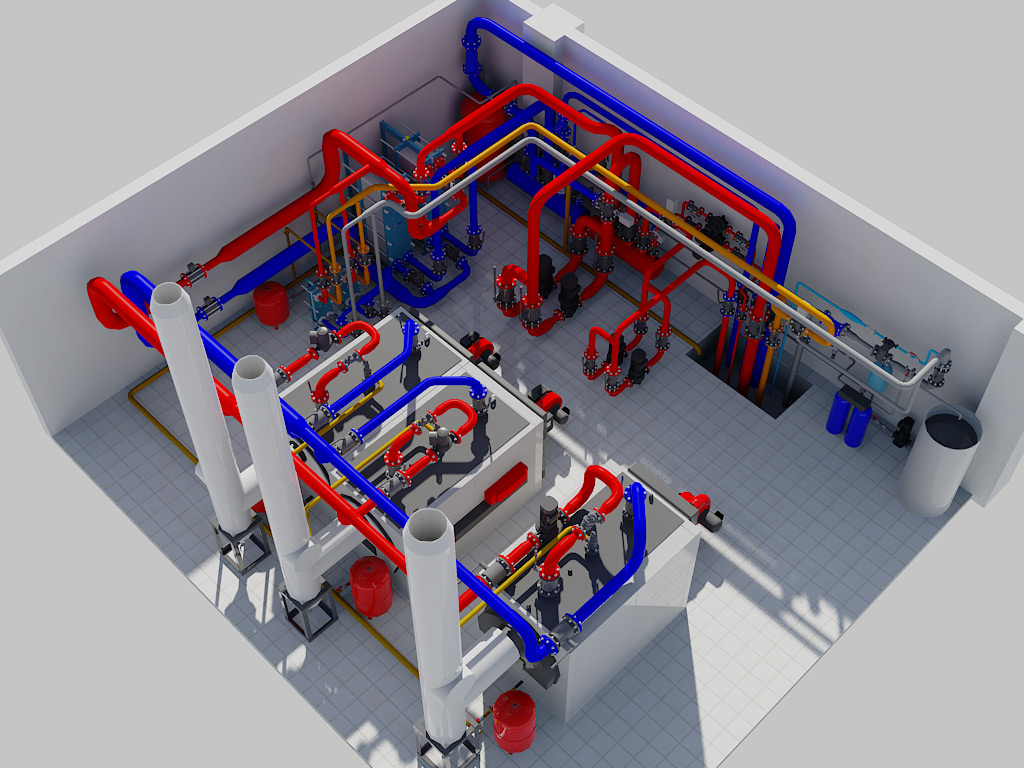

Some features of the device autonomous boiler rooms

To comply with safety requirements, no more than two boilers are placed inside the boiler rooms - one main, the other backup. Installation is carried out in the central part of the room, then the least problems arise with maintenance and repair.

For wall cladding, it is imperative to use materials that do not support combustion. An example of a great option is steel sheets. The floors are poured with a concrete screed, the non-combustible coating is laid from above. The main requirement is a non-slip coating.

Natural gas is the compositionprocessed during the operation of autonomous boiler houses. Installations with automatic operation contribute to uninterrupted supply.If a leak or breakdown is detected, special sensors simply block the operation of the system.

For developers, one of the most profitable options will be the purchase of block autonomous boiler houses. Delivery and installation of such installations takes a minimum amount of time. The equipment differs and an acceptable level of prices. In the future, such a purchase will protect against the shortcomings that centralized systems have.

Analysis of typical mistakes in the installation of boiler rooms can be found in this video:

Share this post

Discussion: there is 1 comment

- Ivan says: 12/21/2019 at 18:23

Such a boiler room certainly gives serious savings. Central heating is now very expensive. Do manufacturers of such autonomous boilers guarantee that the boiler will work without failures in a house with a large number of floors?

Reply

Room for the installation of a gas boiler

The volume of the room for a gas boiler depends on the type of unit and its power. All requirements for the boiler room or other place where the device is located are prescribed in SNiP 31-02-2001, DBN V.2.5-20-2001, SNiP II-35-76, SNiP 42-01-2002 and SP 41-104-2000 .

Gas boilers differ in the type of combustion chamber:

…

- units with an open combustion chamber (atmospheric);

- devices with a closed firebox (turbocharged).

To remove combustion products from atmospheric gas boilers, you will need to install a full-fledged chimney. Such models take air for the combustion process from the room in which they are located. Therefore, these features require a device for a gas boiler in a separate room - a boiler room.

Units equipped with a closed firebox can be placed not only in a private house, but also in an apartment in a multi-storey building.The removal of smoke and the influx of air masses is carried out by a coaxial pipe that exits through the wall. Turbocharged devices do not require a separate boiler room. They are usually installed in the kitchen, bathroom or hallway.

boiler room requirements

The minimum volume of the room for installing a gas boiler depends on its power.

| Gas boiler power, kW | Minimum volume of the boiler room, m³ |

| less than 30 | 7,5 |

| 30-60 | 13,5 |

| 60-200 | 15 |

Also, a boiler room for placing an atmospheric gas boiler must meet the following requirements:

- Ceiling height - 2-2.5 m.

- The width of the doors is not less than 0.8 m. They must open towards the street.

- The door to the boiler room must not be hermetically sealed. It is required to leave a gap between it and the floor 2.5 cm wide or make holes in the canvas.

- The room is provided with an opening window with an area of at least 0.3 × 0.3 m², equipped with a window. To ensure high-quality lighting, for every 1 m³ of the volume of the furnace, 0.03 m2 of the area of the window opening should be added.

- The presence of supply and exhaust ventilation.

- Finishing from non-combustible materials: plaster, brick, tile.

- Electric light switches installed outside the boiler room.

Note! Installing a fire alarm in the boiler room is not a mandatory, but recommended condition. It is strictly forbidden to store flammable liquids and objects in the boiler room. The boiler must be freely accessible from the front panel and from the side walls.

The boiler must be freely accessible from the front panel and from the side walls.

It is strictly forbidden to store flammable liquids and objects in the boiler room.The boiler must be freely accessible from the front panel and from the side walls.

…

Requirements for the room for the installation of a turbocharged unit

Gas boilers with a closed combustion chamber with a power of up to 60 kW do not require a separate furnace. It is enough that the room in which the turbocharged unit is installed meets the following requirements:

- Ceiling height over 2m.

- Volume - not less than 7.5 m³.

- Has natural ventilation.

- Closer than 30 cm next to the boiler there should not be other appliances and easily combustible elements: wooden furniture, curtains, etc.

- The walls are made of fire-resistant materials (brick, slabs).

Compact hinged gas boilers are even placed between cabinets in the kitchen, built into niches. It is more convenient to install double-circuit units near the water intake point so that the water does not have time to cool before it reaches the consumer.

In addition to generally accepted standards, each region also has its own requirements for a room for installing a gas unit

Therefore, it is important to find out not only how much space is needed to install a gas boiler, but also all the nuances of placement operating in a given city.