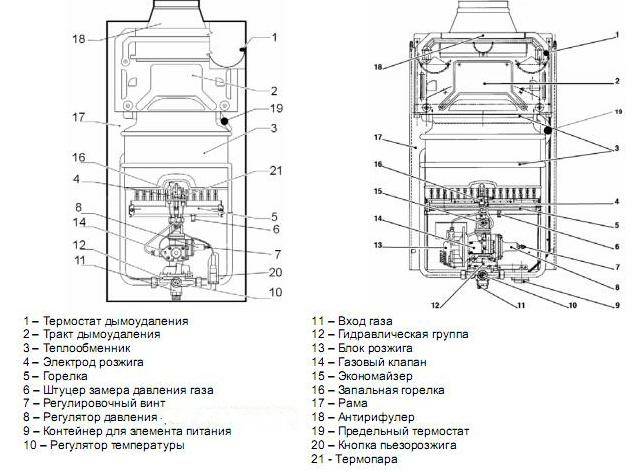

- Valve adjustment

- 3 Types of breakdowns of gas water heaters

- Problems with ignition

- Clap Questions

- Ignition and instant extinction of the gas column

- Troubleshooting new hardware

- Column microswitch failure

- Flow sensor malfunction

- Displacement of the working candle

- Incorrect operation of the ignition retarder

- Sources of the accident

- Features of repairing old models

- Why does the column turn off during operation?

- Traction is poor or completely absent

- Soot accumulation on the heat exchanger

- Clogged shower head and hose

- No draft in the chimney

- Column does not turn on

- Insufficient pressure

- Faulty ignition system

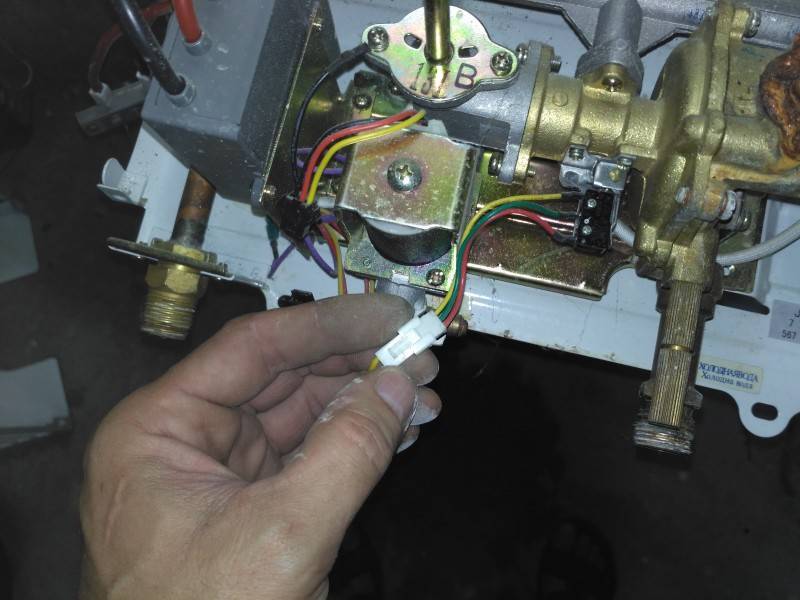

Valve adjustment

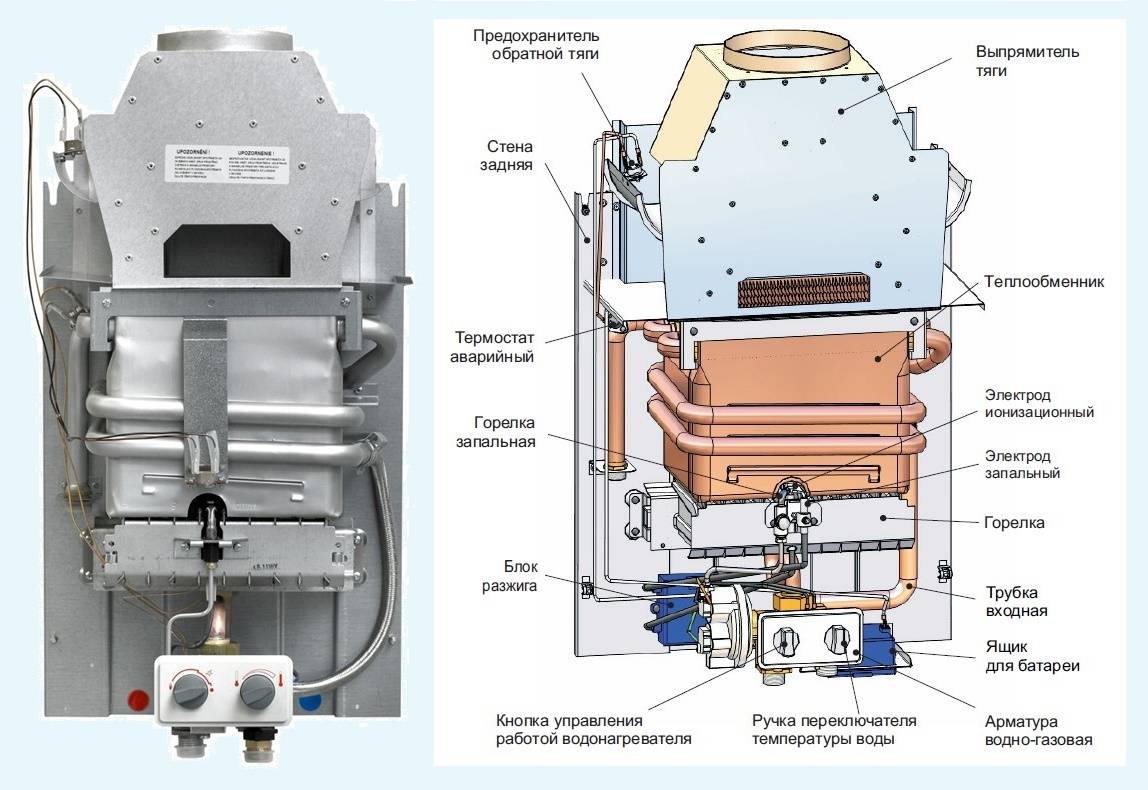

To do this, you need to remove the water-gas unit from the apparatus and separate it into a water and gas component.

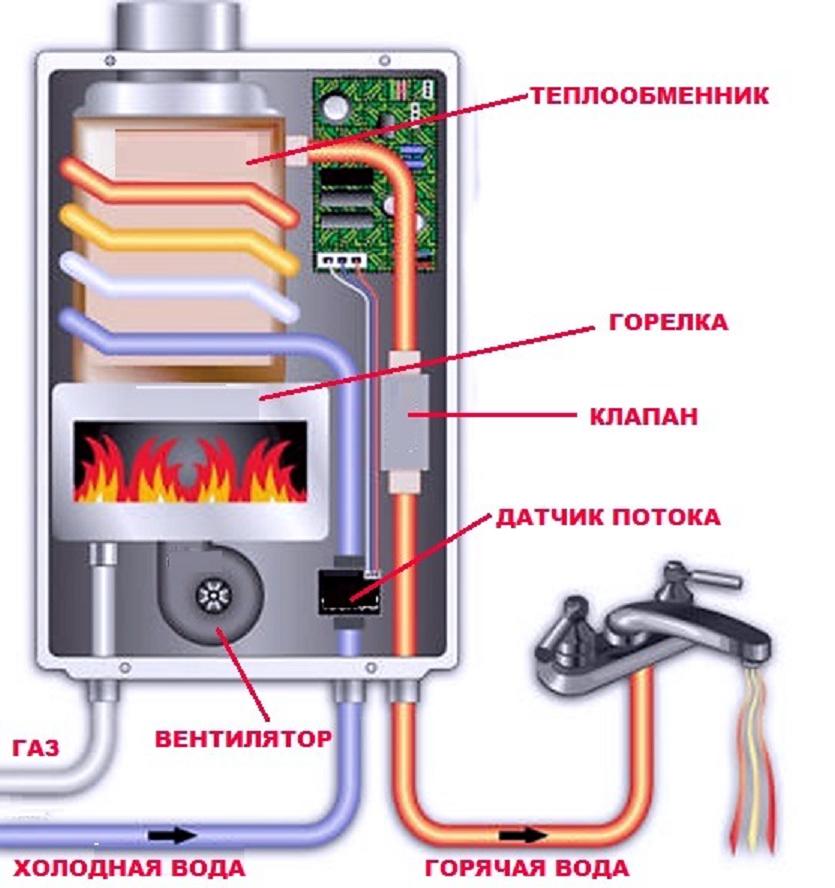

When the valve with hot water is opened, the membrane is deflected. And the stem of the first component is displaced and presses on the stem of the second component of this block.

The microswitch is activated. The control unit generates a spark and blocks the flow of gas to the burner using a solenoid valve (EMV).

When the hot water valve closes, the gas movement is stopped by the gas mechanism spring. The membrane goes to its initial position, and the microrelay opens.However, the stem of the gas block does not follow to the initial position - "closed". Then the control unit does not isolate the EMC, since the burner fire does not go out and heats the flame presence indicator.

To solve this dilemma on your own, you need to study the structure of the gas node:

Investigate which spring causes the stem to close. The device should automatically turn off. If his work continues, the stem is limited in movement.

It must be pressed with a screwdriver. If he begins to move more freely, then there was a modest problem. It is possible that dirt will get on this element.

3 Types of breakdowns of gas water heaters

Hot water equipment is far from being an innovative development; the first gas column was invented and put on sale at the end of the 19th century. For almost 120 years of operation of household appliances of this type, users have been able to identify the most common types of device breakdowns. During the operation of the unit, the following types of failures and malfunctions may occur:

- the inability to light the wick, which is also called the igniter;

- short burning of a lit wick and its abrupt shutdown a few minutes after ignition;

- a short time of operation of the device, followed by a lightning-fast shutdown or gradual attenuation;

- smoking kindled equipment;

- abnormal functioning of the heating element, which does not heat the water when the toggle switch is on.

Problems with ignition

Usually, batteries in gas water heaters are located in the lower right corner, and replacing them does not require much effort.

Often there are situations when gas is supplied, there is traction, the pressure is normal, and the gas column does not ignite.If you have a Neva or Oasis geyser with electric ignition installed, listen to see if there is a spark generation. The presence of a spark is indicated by a characteristic crackling sound heard when the tap is opened. If a crackling sound is heard, but the geyser does not ignite, try replacing the batteries - this is a very common reason for the lack of ignition (a weak spark makes normal ignition impossible). Owners of speakers with piezoelectric ignition need to make sure that the igniter is working. If it burns, then the column should light up immediately, without hesitation. If there is no flame, try to ignite it with the ignition button. If the gas in the igniter does not ignite, then the problem is in the fuse itself (in the jet) - it needs to be cleaned. To do this, we disassemble the geyser, get to the fuse and clean it with steel wire. Next, we try to light the column again.

When repairing your geyser, be careful and always turn off the gas supply before carrying out any operations. As for hydrodynamic ignition, it is a combination of a small generator and an electrical circuit that generates a spark and feeds some other electronic components.

If the generator or circuit is out of order, the geyser will not ignite. Self-repair here is possible only if you have the appropriate knowledge and experience in electronics repair

As for hydrodynamic ignition, it is a combination of a small generator and an electrical circuit that generates a spark and feeds some other electronic components. If the generator or circuit is out of order, the geyser will not ignite.Self-repair here is only possible if you have the appropriate knowledge and experience in electronics repair.

Clap Questions

If the geyser does not immediately ignite and slams hard, the reasons for this lie in weak traction or its absence, lack of fresh air in the room and a faulty ignition retarder.

If this dilemma exists in wick machines, then the pilot wick fire is not correctly positioned here.

If the unit has automatic ignition, then the causes of such problems are:

- Dead power supplies in the control unit.

- Microswitch malfunction in the water mechanism.

- Incorrect positions of the spark plug.

The biggest problem is the microswitch. It is checked with an ohmmeter. In an open format, the minimum resistance should be several megaohms. In a closed one - less than ten thousandths of OM or not calculated at all. If these values are not determined, this part should be replaced.

If the spark plug has shifted, then it is necessary to loosen its screw and arrange it so that a gap of 4-5 mm is obtained. The spark should ignite the fuel on the first try.

Ignition and instant extinction of the gas column

This situation most often occurs due to improper use of the device by users. When such a water heater is in working condition, it is strictly forbidden to open cold water to dilute hot water. This action is the most dangerous violation of the rules for its use. It can cause serious damage to the device. The temperature of the liquid is controlled solely by the supply of gas.

Depending on the models, there are three types of ignition: electric ignition (in modern versions), an igniter, which has a small constant flame, a hydraulic turbine - from pressure.

The electric ignition is powered by built-in batteries. According to the manufacturers, they are enough for about a year. But as practice shows, the service life of such batteries is less. For example, in the Bosch geyser models W 10 KB or WR 10-2 B, there is an LED on the front panel that indicates the state of the batteries. Also, this type of ignition is equipped with a range of gas water heaters Neva Lux. If necessary, old batteries are replaced with new ones.

If the wick is the cause of the problem, then it is best to seek help from qualified specialists. They will check the function of the thermocouple and the gas control system, clean and adjust the igniter. Often the problem, when the igniter of the gas column goes out, is solved by completely cleaning the water heater.

In the case of a hydroturbine type of ignition, for example, as in the Bosch WRD 13-2 G or WRD 10-2 G, a malfunction may occur due to the lack of water pressure on which it is based.

Microexplosions during ignition

These unpleasant processes are only a consequence of low thrust, batteries unsuitable for operation, contamination of the apparatus itself, or a very large volume of gas that is supplied to the column. To fix the problem on their own, the owner can only clean the exhaust duct or replace the batteries. If the problem is not solved, then only gas service employees can understand why the column goes out.

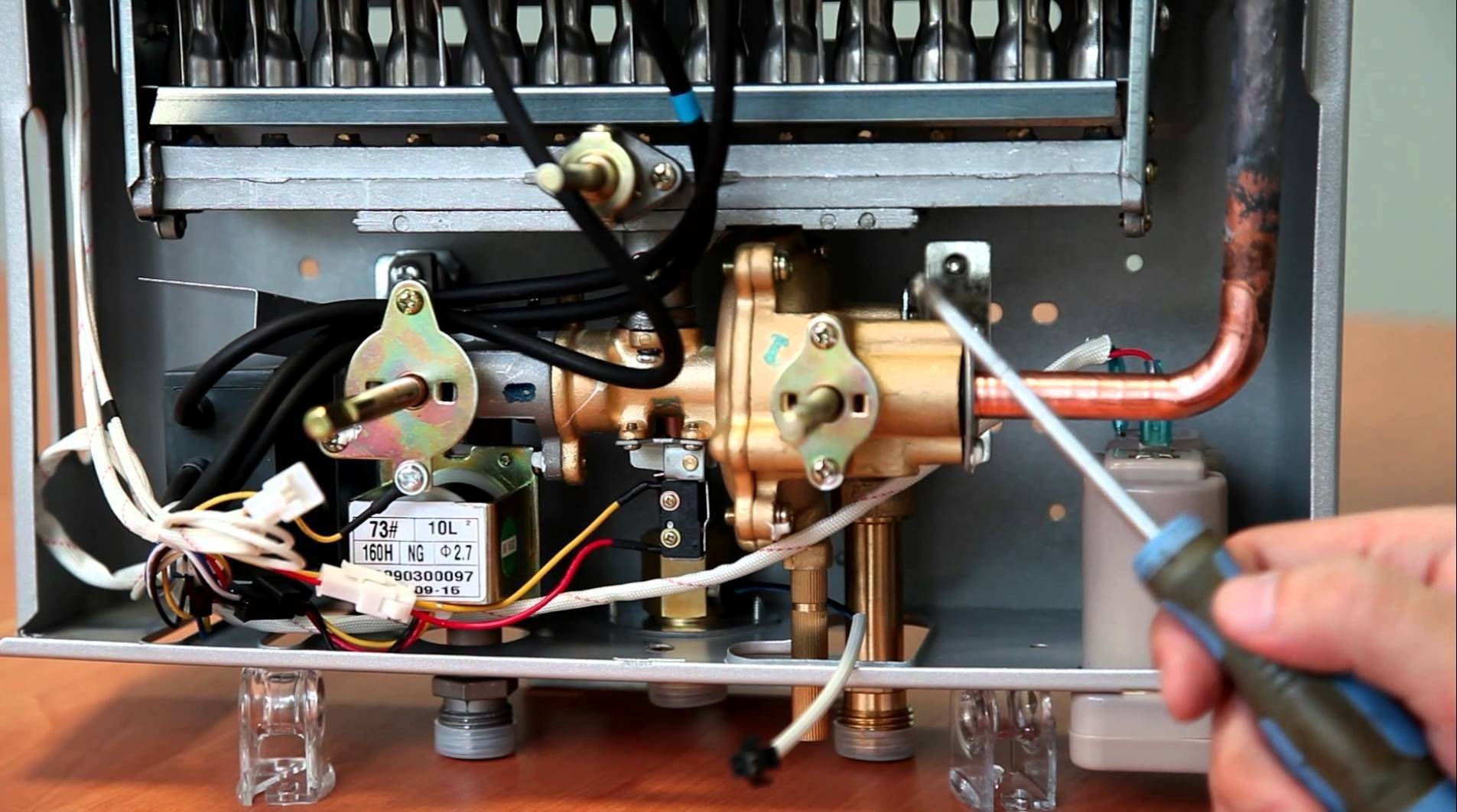

Troubleshooting new hardware

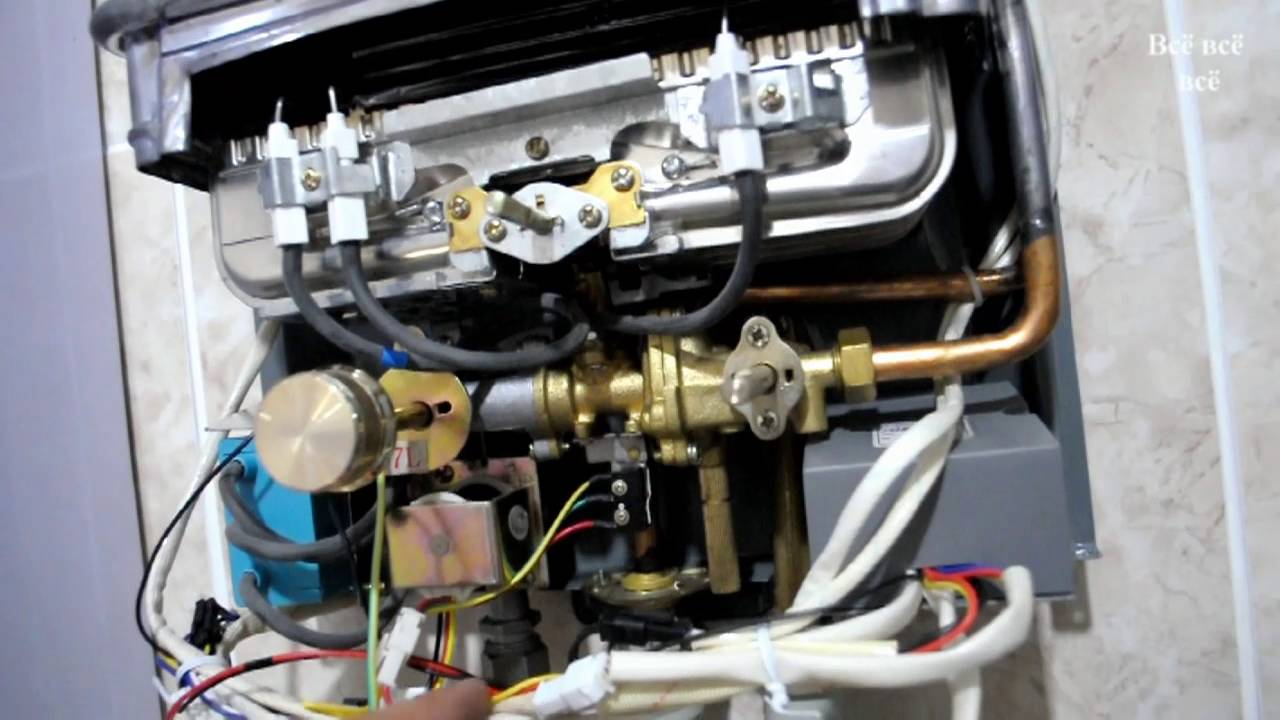

New equipment can also cause various problems.Most often, they manifest themselves in the operation of the flow sensor, in the operation of a candle, or in the power system. Let's take a closer look at these issues.

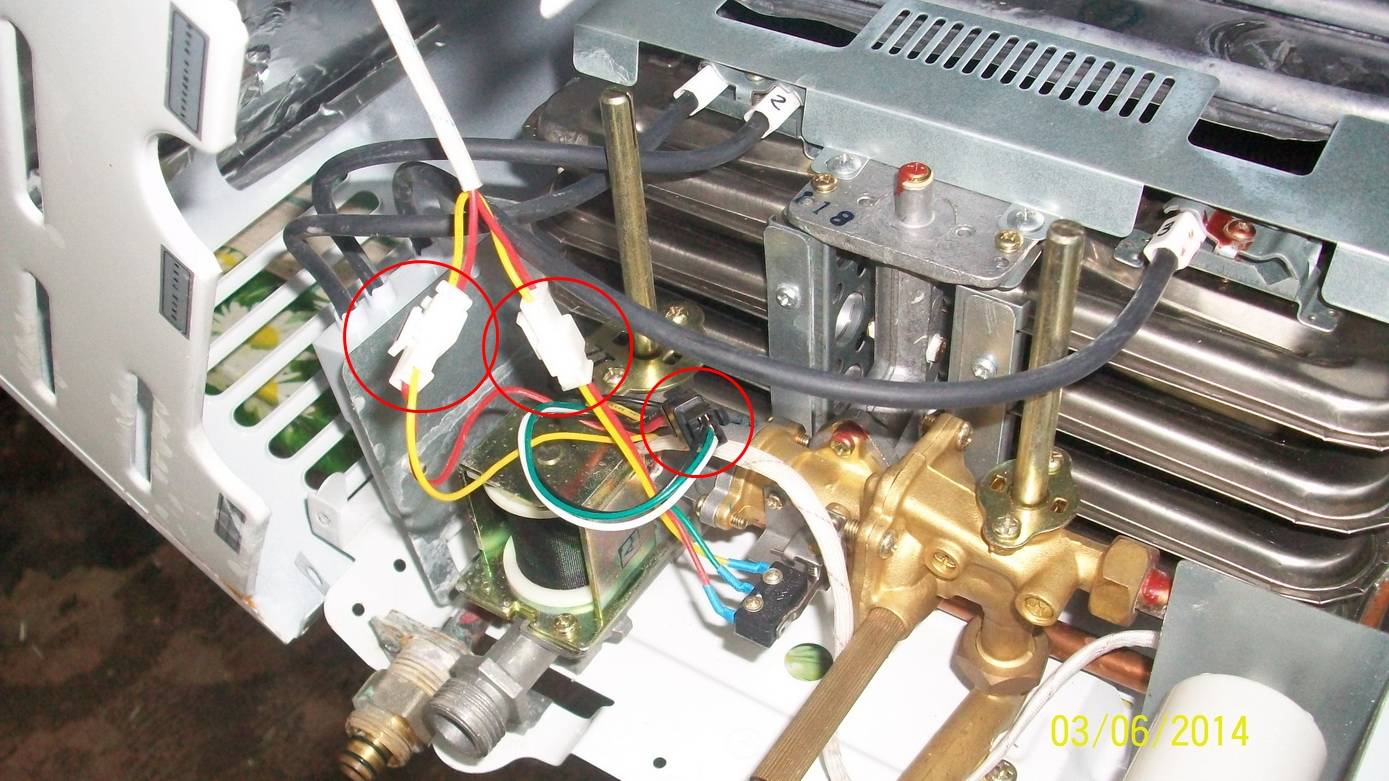

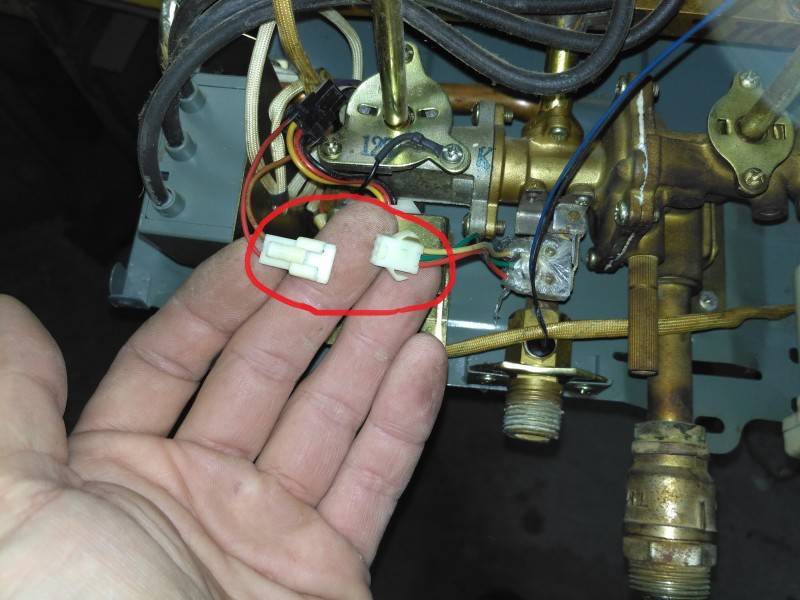

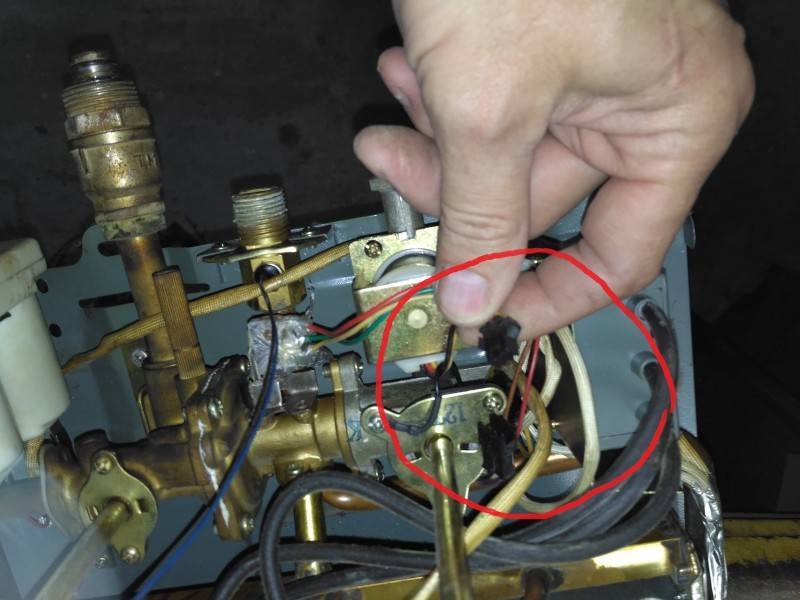

Column microswitch failure

Often, the problem of the occurrence of a loud pop during ignition becomes an insufficient discharge of the batteries, which provokes the inability to instantly ignite the gas-air mixture.

The power supply is connected to the control unit through special microswitches, which are responsible for the occurrence of a signal to activate the ignition when the DHW tap is opened. If the signal arrives out of time, this causes the problem. Such a malfunction occurs most often due to oxidized contacts. The microswitch cannot be repaired and will need to be replaced.

If the microswitch breaks down, repairs will not be possible, since this system will have to be completely replaced

If the microswitch breaks down, repairs will not be possible, since this system will have to be completely replaced

Flow sensor malfunction

Often the problem of cotton is in the duct sensor. It is located in the input circuit. A signal is sent to the controller of the control unit about the presence of liquid in the pipe. The data instantly activates the ignition system. Intensive use of this element forms an increased risk of breakdowns. For example, contact groups can be oxidized.

Such sensors are most often made in a non-separable design, therefore, in the event of a problem, they cannot be repaired, they must be replaced.

Displacement of the working candle

The problem may lie in the operation of the candle. After applying voltage, it provokes the formation of an electric spark. Modern candles are made in such a way that they are able to last for a long time.Element failures are rare, but do happen.

Most often there is a displacement of the ignition device relative to the nominal position. It can occur as a result of numerous heating and cooling. Such processes are associated with a change in the size of individual structural elements. As a result of adjusting the position of the candle, the spark parameters become normal, extraneous noises completely disappear.

Incorrect operation of the ignition retarder

A rare breakdown is the incorrect operation of the ignition retarder. When disassembling the column, you need to remove the water regulator. On its cover there is a bypass hole, in this hole the ball is located. The adjusting screw determines the position of the ball.

If, when you shake the lid, you hear the sound of a moving ball, then you should not further manipulate this part. If there is no knock, then you can stir the ball with a thin copper or aluminum wire through the through hole, which is located in the regulator cover.

Most often, the retarder is a ball of metal or plastic that covers part of the bypass in the water regulator. In most dispenser designs, this retarder is located in the boss of the water regulator cap.

Most often, the retarder is a ball of metal or plastic that covers part of the bypass in the water regulator. In most dispenser designs, this retarder is located in the boss of the water regulator cap.

In extreme cases, you will have to resort to the element parsing procedure. It must be said right away that the outer screw does not affect the position of the ball in any way.

The inner screw must be removed very carefully. You should first remember its original position, as well as clearly determine the number of revolutions by which this screw is screwed

This will allow you to save the required location of the element (ball) during subsequent assembly.

After repair work, be sure to check all connections to completely eliminate leakage of both water and gas. All connections must be treated with a sealant, ensuring tightness. After that, you can put the casing back in place and use the column in the usual way.

Sources of the accident

There are several reasons for the failure of the burner, the main ones are the following factors:

1. Lack of traction.

For any model, be it the Neva, Oasis or Vector, the flame goes out or does not light up due to the fact that the chimney is often clogged with dust, dirt and foreign objects. In modern equipment, in this case, a protective valve is activated, which automatically shuts off the fuel supply to the gas column. This is because the products of combustion are not discharged in full and in accordance with the technical requirements.

To verify the malfunction, you need to check the traction. To do this, open a window and bring a lighted match or a sheet of paper to the pipe. If the chimney is clogged, the wind will not be felt, so the geyser does not light up. The cleaning of the combustion waste disposal system is carried out by specialists

It is important not to miss this moment, as the exhaust gas enters the room, which can lead to serious consequences.

An ingenious way to almost NOT PAY for electricity! A clever meter that saves electricity Pays for itself in 2 months!

Sometimes the automation works when the hood is turned on, located nearby, the flame goes out or does not appear.If the device has a large power, it interferes with the removal of waste, so you should never install two units in one place, especially in small rooms.

2. Malfunction of sensors.

If the igniter flame goes out, it is necessary to inspect the device that controls the exhaust of gases. To do this, disconnect the wires and check the resistance using a special device. The indicator must be indicated in the passport, if it does not reach the optimal value, the sensor will have to be replaced. The burner goes out when the thermocouple breaks. In this case, the gas column does not ignite due to low voltage, the optimal parameter of which is 10 mV.

3. Discharged batteries.

The main function of the batteries is to keep the valve open during operation. The service life of the elements is no more than a year, therefore, manufacturers of such gas units as the Neva recommend changing batteries on time. In addition, the reason that the burner does not ignite may be a malfunction of the piezoelectric element or the power cable. It is necessary to disconnect the wires and check them for internal and external breaks. If there is still no spark, the column does not turn on, then the source of the problem is different.

4. Blockage of the inside.

If dirt and soot get into the gas supply tunnel from the fittings to the burner, the flame goes out or does not ignite. The injectors need to be cleaned. If the fuel pressure is not adjusted, a characteristic whistle will be heard, flame separation appears, then it disappears. Also, a burner of the wrong diameter can create such a malfunction. In this case, you need to correct the gas supply or replace the elements. When airing, the gas column ignites, but immediately goes out.To eliminate the defect, you need to unscrew the nut on the fitting and bleed the air, then return the mount to its place, fix it and check if the burner goes out.

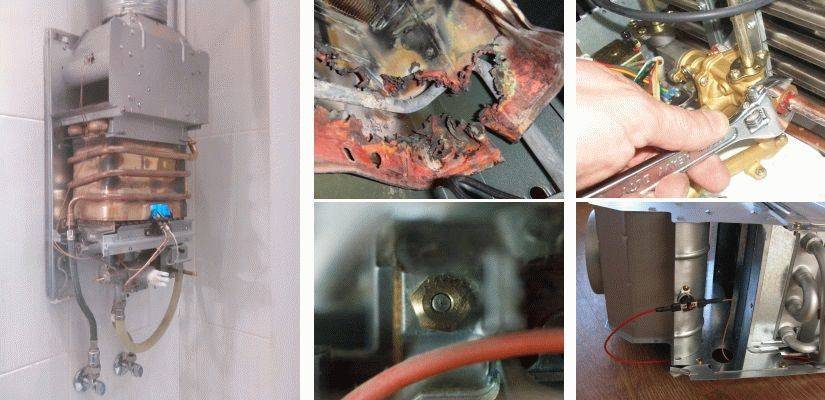

5. Deformation of elements.

If the water is too hard, scale appears in the pipes, which gradually clogs the filters, so the gas unit goes out or does not turn on. The grate is taken out, thoroughly cleaned. If it has been damaged by deposits, it is better to replace it.

The membrane of the water supply unit often breaks, so the column does not turn on. To determine its condition, remove the top cover of the case. The plate should not be in cracks and gaps, has the correct shape, smooth and even. In case of the slightest deformation, it will have to be replaced. It is better to choose a part made of a durable and elastic material that is resistant to temperature fluctuations and the influence of scale. Install the membrane carefully, crimping the fasteners around the perimeter.

6. Water pressure.

As in the draft situation, the automation blocks the gas supply; if the supply is poor, the burner immediately goes out. It is worth contacting the utilities to find out the reasons, turn off the unit until then. You can use the column only if the water pressure is normal. In private homes, the pressure is increased using a compact station and a regulator. If the column turns on and works normally, and the water is still cold, the device may not have enough power, the parameters are noted in the passport.

Here's the secret to saving water!Plumbers: You'll pay up to 50% LESS for water with this faucet attachment

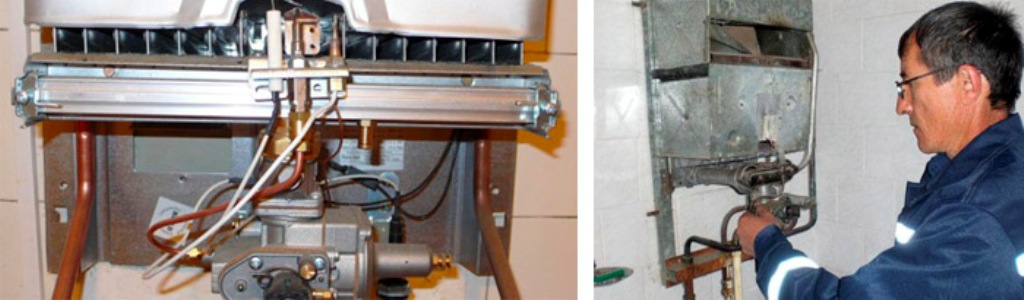

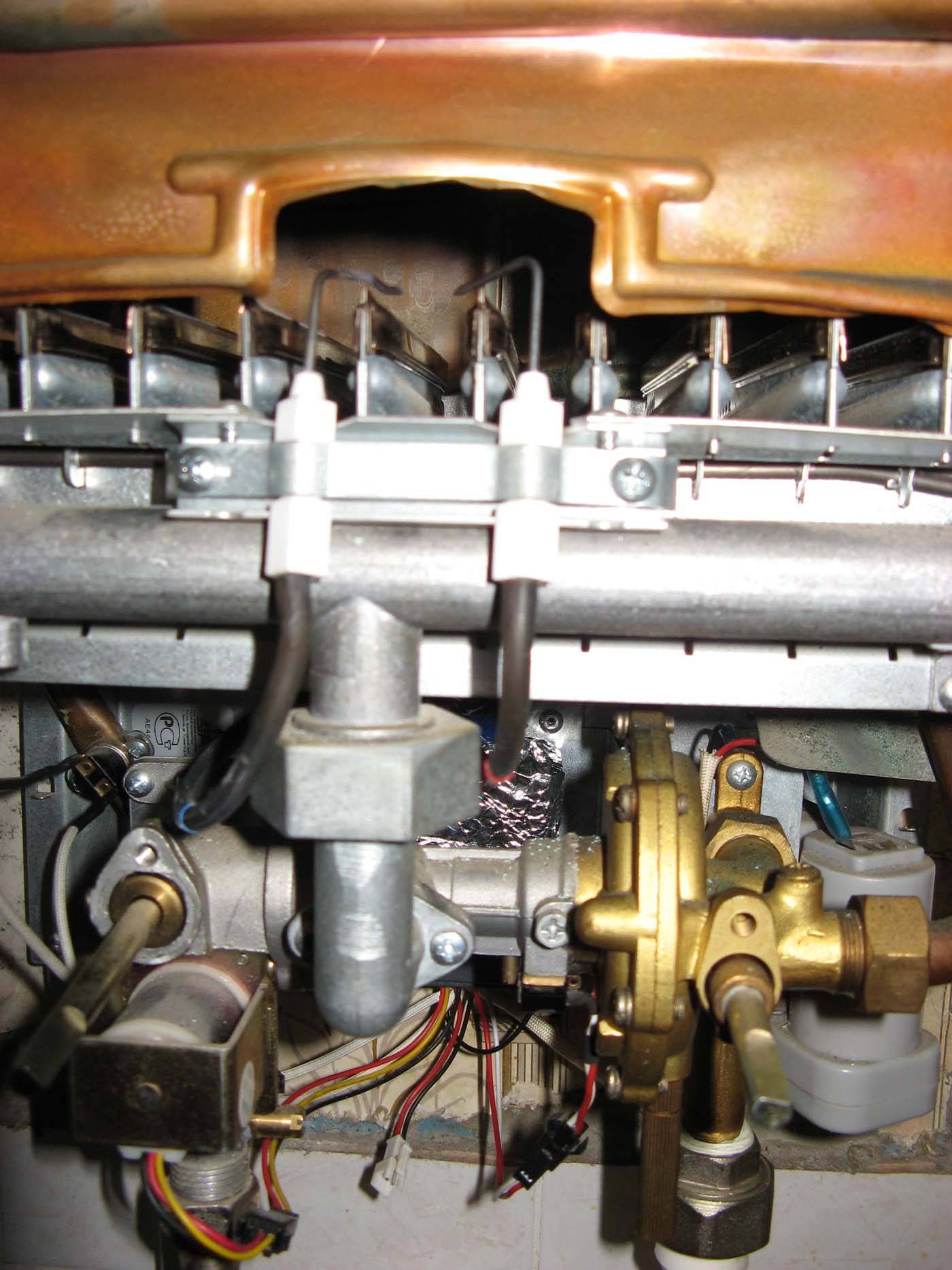

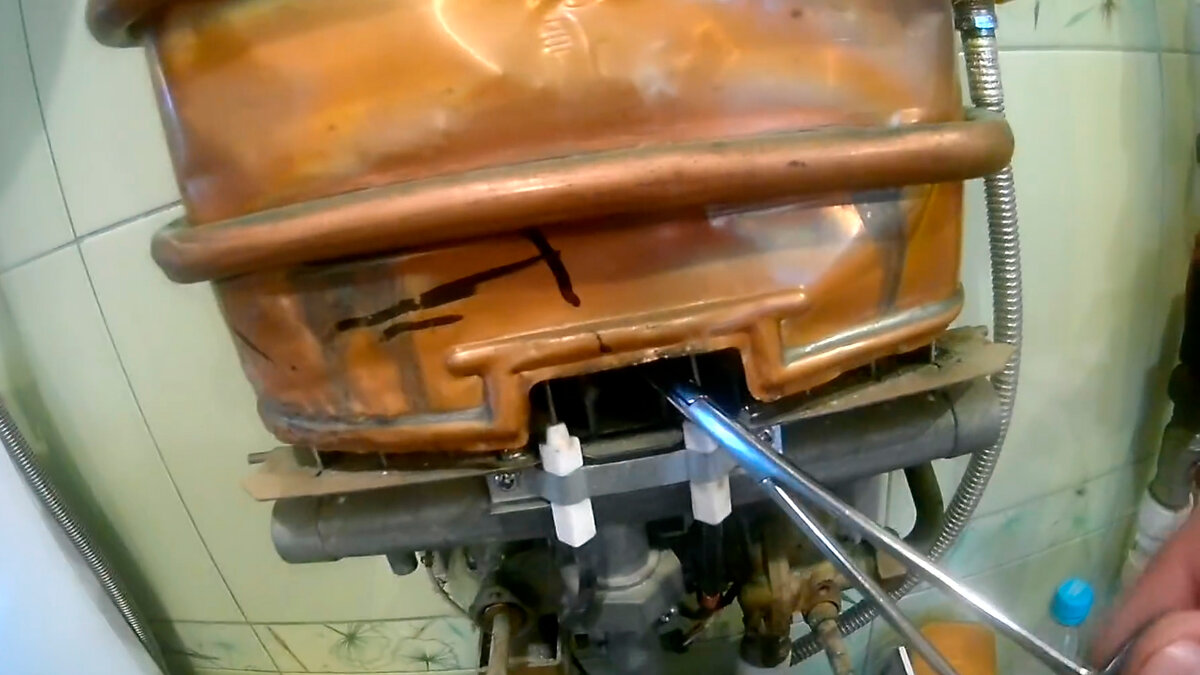

Features of repairing old models

First of all, you need to determine why the geyser pops and makes noise when the water is turned on, and if all of the above disadvantages have already been eliminated, and the cotton is still preserved, then you need to check the functional state of the product.

Let's start by looking at simple examples of equipment with wicks that are used to ignite a combustible mixture.

In such models, loud popping noise often occurs if the calculated parameters do not match the contours of the flame. Timely ignition of the burner does not occur if the dimensions of the fire are small or too large. The cause of such a problem is considered to be mechanical clogging of the nozzle holes. Through these holes, a metered gas supply is formed.

Old models of geysers break down. The cause of cotton when turned on is most often a clogged jet, burner, or lack of thrust.

Old models of geysers break down. The cause of cotton when turned on is most often a clogged jet, burner, or lack of thrust.

To fix the problem, you will have to perform the following actions:

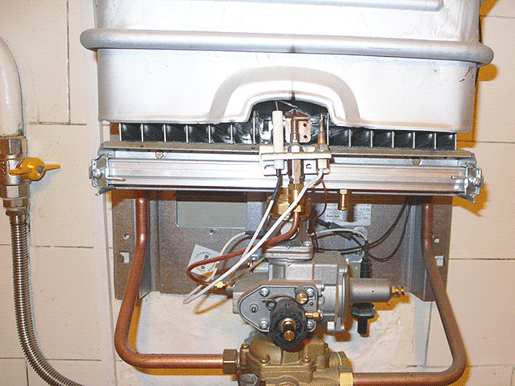

The main casing is dismantled in order to free full access to all internal components of the column.

The unit where gas and air is supplied (this structure is used by many manufacturers) must be disconnected from the pipe system.

The next step is to clean the jet. The most commonly used wire is made of soft metal. Could it be copper or aluminum?

The procedure is done carefully so that the calibrated hole is not damaged.

Assembly is carried out in reverse order, with particular attention paid to the integrity of the threaded connections and seals.

The jets can become clogged in the main burner. With such clogging, the inclusion is also carried out with cotton.When disassembling the device, it must be remembered that some components and elements, for example, gaskets, valves, a thermocouple, are not very durable, so they must be handled extremely delicately.

Why does the column turn off during operation?

If the geyser ignites normally, but for some reason goes out during operation, this may indicate the correct functionality of the device's security system.

The column design has a sensor that is triggered when the internal temperature rises. Inside the system, there are two plates that repel each other, stop the power supply, turn off the column. This happens when the internal temperature rises quickly and uncontrollably.

You can check the sensors by resistance. A serviceable part shows the sign of infinity. When another value is highlighted, we call the wizard.

If the device works long enough, and then turns off, check the settings. Sometimes users accidentally set automatic shutdown after a certain time.

What else leads to a shutdown:

- poor water or gas pressure;

- violation of contact between the thermocouple and the solenoid valve (you need to clean the contacts, tighten the connections);

- oxidation of the contacts of the power supply when the device clicks, but does not light up.

It is useful to check the batteries. Standard replacement of power supplies is carried out every six months. Batteries hold charge longer.

Traction is poor or completely absent

The accumulation of combustion products is most often associated with clogging of the chimney with soot, soot, and debris. When there is no traction or it is insufficient, working out is not displayed.

It is important to remember that the flame can go out due to external factors - gusts of wind, for example. The draft in the mine increases or decreases under the influence of a draft

You can clean the chimney through a “pocket” located 25 cm below it. If such manipulations did not help, call the utilities.

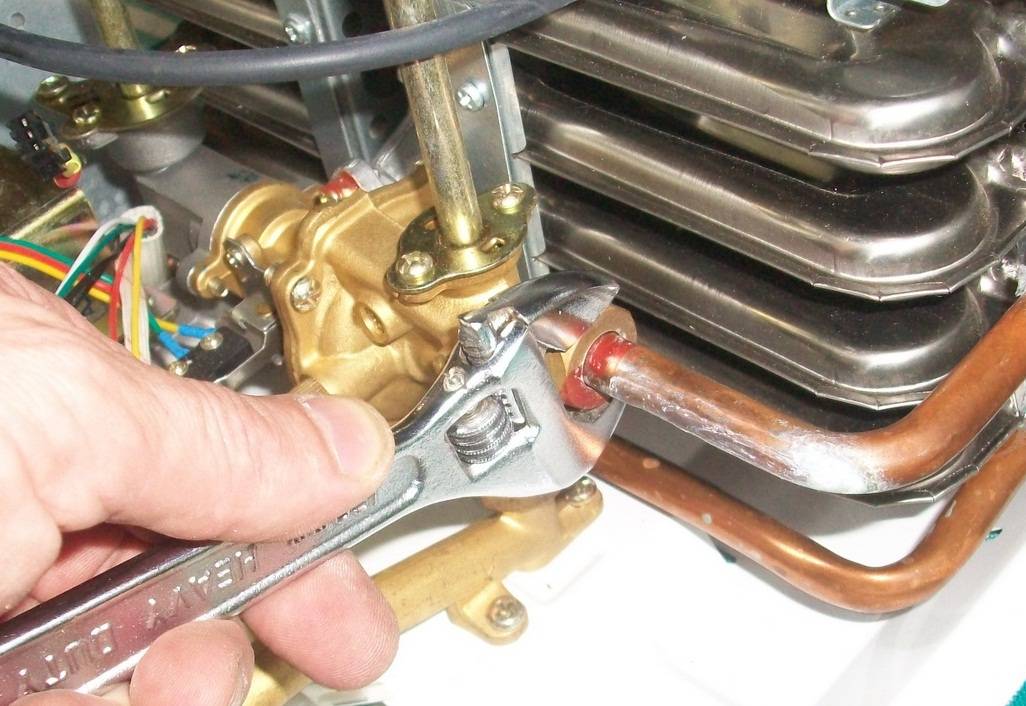

Soot accumulation on the heat exchanger

The heat exchanger accumulates soot, soot, and scale during operation. When it clogs, the color of the flame changes from yellow to blue.

How to clean the heat exchanger:

- We remove the cover.

- Unscrew the screws holding the cover.

- Shut off the water supply.

- Open the faucet to drain hot water.

- We disconnect the thread of the heat exchanger and the tap. You will need a stand - water can flow.

- We prepare a solution of hydrochloric acid (3-5%).

- Take a pipe with a diameter of 1/2 "or use a hose.

- We connect one end to the input, the other to the output.

- Pour the solution into the funnel. If foam appears during washing, this is normal.

- As soon as a strong pressure appears at the exit, we stop the procedure.

Be sure to wear gloves while working. After descaling, rinse the heat exchanger thoroughly to remove acid residues.

If during the cleaning process defects were noticed on the tubes, then the heat exchanger will have to be repaired.

Cleaning work is recommended to be carried out once a year. Regular maintenance will help the machine function properly.

Clogged shower head and hose

It happens that the geyser turns on and for some reason immediately goes out when you switch to the shower. This may be due to clogging of the openings of the watering can.

It is necessary to unscrew the watering can, clean and rinse the holes. Soaking metal elements in a solution of citric acid is also effective.

The next detail that can cause the wick to go out is the shower hose. If it gets tangled or clogged, the pressure power decreases and the column goes out.

The mixer can also break or become clogged. You need to disassemble it, check it, clean it if necessary.

At the entrance to the water supply unit there is a filter that traps small debris. It is also useful to clean it periodically. To do this, unscrew the screws, remove the element, rinse, brush with citric acid.

No draft in the chimney

Let us immediately draw the reader's attention to an important circumstance: the presence of draft depends not only on the state of the chimney, but also on whether there is air flow into the kitchen. Today, citizens massively clog their homes with sealed double-glazed windows, completely ignoring the need to install a supply valve in this case.

It is assumed that fresh air will enter the room due to periodic ventilation, but you need to understand that the rest of the time the chimney and ventilation system will actually be paralyzed.

It is assumed that fresh air will enter the room due to periodic ventilation, but you need to understand that the rest of the time the chimney and ventilation system will actually be paralyzed.

It is a completely different matter with the supply valve: the air flows constantly and evenly, and the speed of its supply can be adjusted.

Accordingly, the chimney works as it should.

The valve is usually installed in the room farthest from the kitchen and bathroom - so that the whole apartment is ventilated. Then you need to make sure that all interior doors, including the kitchen one, have a clearance at the bottom or a special vent with a decorative grille.

So, making sure that there is an inflow, we check the draft: for this, you should bring a piece of paper or a burning match to the viewing window of the water heater.If the flame or paper is deflected by the air flow, there is draft; if not, you need to repeat the experiment directly for the chimney, disconnecting the column from it. If there is a draft here, you need to clean the column heat exchanger from soot, if not, you should clean the chimney itself.

Column does not turn on

If the geyser does not turn on, it is not always necessary to call the masters. There are a number of malfunctions in the geyser that the user is able to repair on their own.

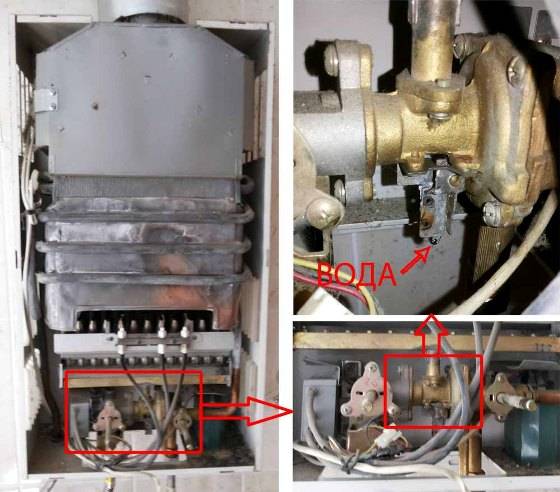

Insufficient pressure

The automation of the system blocks the gas supply in case of insufficient water pressure. You can estimate the pressure by simply opening the water taps. If it is small or completely absent, then the emergency shutdown in the geyser is not due to a breakdown of the device.

In the case of normal pressure in the tap, it is worth looking for reasons in the water heating system. As a rule, a decrease in pressure is a consequence of filter contamination or membrane failure.

Coarse filter

To correct the sources of breakdown, due to which the wick of the gas column goes out, the owner will have to:

- clean or change the filtration system;

- put a new membrane partition for the water unit;

- clean the pipeline.

Faulty ignition system

Depending on the models, there are three types of ignition: electric ignition (in modern versions), an igniter, which has a small constant flame, a hydraulic turbine - from pressure.

The electric ignition is powered by built-in batteries. According to the manufacturers, they are enough for about a year. But as practice shows, the service life of such batteries is less.For example, in the Bosch geyser models W 10 KB or WR 10-2 B, there is an LED on the front panel that indicates the state of the batteries. Also, this type of ignition is equipped with a range of gas water heaters Neva Lux. If necessary, old batteries are replaced with new ones.

In the case of a hydroturbine type of ignition, for example, as in the Bosch WRD 13-2 G or WRD 10-2 G, a malfunction may occur due to the lack of water pressure on which it is based.