- Ways

- Soldering pipes under nitrogen

- Soldering pipes with a building dryer

- Capillary soldering

- Induction soldering

- Soldering Components

- Solder selection

- Flux selection

- Selection of fittings

- Applications

- Which gas burner to choose

- Assembling the pipeline with fittings

- Tools and materials

- Assembly instructions

- Can soldering torches

- 6th place - a metal burner for a can

- 7th place - a typical burner that is put on a can

- 8th place - a burner for a spray can with a wide nozzle

- Types of gas burners

- Flux

- Main types

- Threaded installation using ferrules

- Safety precautions when soldering copper pipes

- Learning to solder with a gas burner

- Which brand of gas burner is better to choose

- Technology nuances

Ways

There are two technologies for soldering copper pipes.

- Low-temperature (soft solder is used) is used in plumbing or heating systems. The environment where this technology is applied should have a temperature not higher than 110 degrees.

- High-temperature soldering (hard solder) is used in systems with high temperature and high pressure. Mainly used in industry.

Which of the two methods to choose is your own business.But for high-temperature soldering, you need a professional torch, which is not so easy to find in the store, and it costs a lot of money. At low temperature it is allowed to use a blowtorch or an inexpensive hand burner with a replaceable cylinder.

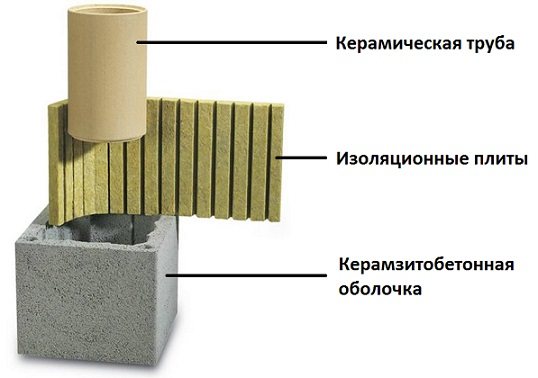

Soldering pipes under nitrogen

Nitrogen treatment is needed for installation, and brazing copper pipes without nitrogen gas is not allowed. Often, structures are soldered with hard solder, which allows you not to worry about whether the connection will withstand high temperatures during operation. In the process of hard soldering, copper is heated to a red color of the metal, this has a negative effect on the structure of the material itself. Scale is formed on the inner and outer surface of the pipe. Dross - the remains of burnt copper, which were formed when it was heated. The walls of the pipes become much thinner.

If you decide to use nitrogen, then follow these recommendations in your work:

- connect the line to the cylinder containing nitrogen;

- then install the gas regulator or rotameter;

- adjust the reducer of the nitrogen cylinder to the minimum nitrogen pressure, set the rotameter to a speed of 5 m/min;

- as soon as soldering is completed, nitrogen is let through the pipe, this is done until the pipe has completely cooled down.

Soldering pipes with a building dryer

It is possible to solder pipes with a building hair dryer if the pipe diameter is small. Manipulations with this method are similar to the use of a burner. With this connection, the seams are very strong and withstand high temperatures. For beginners, copper burns are inevitable when using this method. The metal is easy to overheat, it is because of this that the material breaks.

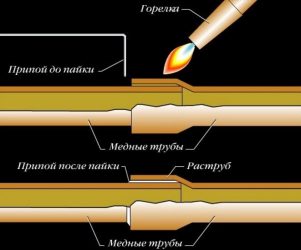

Capillary soldering

If the pipes have different diameters (the difference is not more than 0.5 mm), the capillary soldering method is used. The solder fills the resulting space between the pipes. It should be noted that as such a seam does not work, a seamless connection. Then hard solders are used, their protective functions are better.

Induction soldering

High frequency current can have a beneficial effect on the metal. Induction soldering has become widespread due to its uniqueness, work with this method is carried out quickly, while the material does not become thinner, but retains its qualities.

The following advantages have been identified:

- Heat is generated in the pipe without outside interference;

- All equipment is automated, devices help to get the desired result with specific parameters;

- Induction brazing is carried out in a vacuum, the metal in this environment is protected from corrosion;

- Saving production resources;

- Safety - when induction soldering does not need a flame or gas, only the seam is heated.

Soldering Components

To ensure a high-quality and strong pipe connection, it is necessary to select the right materials for soldering.

Solder selection

Solder for soldering can be soft and hard. Hard solder has the form of rods and melts at an operating temperature of 900 degrees. With its help, high strength of the pipe connection is achieved. This is an important indicator in the construction of water supply, air conditioning, refrigeration and gas supply systems.

Two types of solders are considered convenient and are most often used:

- with the addition of Cu 94;

- with the addition of Cu 94 P 6 Ag 2.

A six percent concentration of phosphorus in the additive allows you to reduce the temperature at which copper melts to 750 degrees.The strength of the connection is achieved due to the similarity of the thermal expansion coefficients of copper and solder.

Soft solder is a wire 2-3 mm in diameter. For its melting, a temperature of 300 degrees is sufficient, so it is usually used in household repairs. The composition of such solder includes: lead, tin and their alloys with an admixture of silver.

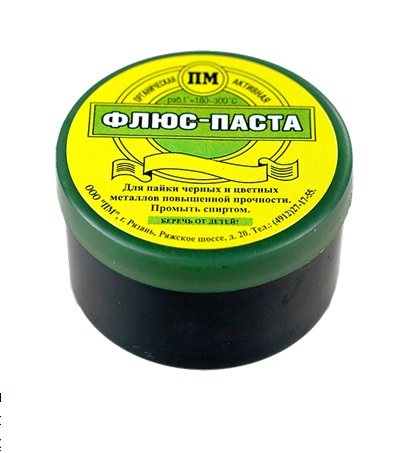

Flux selection

Fluxes are of two types:

- high-temperature, with a working temperature above 450 degrees;

- low-temperature, with a working temperature below 450 degrees.

Fluxes provide a tight connection of the solder to the metal, help prevent oxidation of the pipe, contribute to better cracking of the solder, and protect soldering areas from the influence of oxygen.

Before melting the solder, the surfaces to be joined are cleaned. Then a flux is applied evenly on them with a brush in a thin layer. After soldering the pipe parts, excess flux must be removed to prevent surface corrosion and leakage.

Selection of fittings

Fittings are parts for pipe outlets, bends and transitions to threads. The fitting sockets have certain diameter standards, taking into account the gaps, suitable for various types of pipes. Fittings are quite expensive and, if possible, a pipe expander is used instead.

Applications

The use of a gas burner is very extensive:

- The torch is used for soldering wiring or various cables, repairing large electronics. Soldering aluminum with a gas burner is carried out quite often, which is associated with a low melting point of this material.

- The device is used to repair various structural elements of the car. An example is the case when a heat sink made of fusible alloy is damaged. Leaks can be eliminated by exposure to high temperatures.

- Soldering copper tubes can take place using a gas burner. Repair work is being carried out. The device is also used during the installation of various structures, for example, for metal tempering.

- Some alloys have increased fusibility. The connection of metals, for example, copper, can be carried out using a burner. It is enough to heat the metals and connect them mechanically. After cooling the material, a high-quality connection can be obtained.

- The device can be used when you need to spend time outdoors in the winter. You can use it to warm up a fire or scorch game, heat up tools or do other work.

Soldering with an acetylene torch

Despite the rather large distribution of the burner, in most cases it is used for soldering various alloys. For example, brass soldering is carried out using a gas burner. It should be borne in mind that there are a fairly large number of varieties of the device, each with its own specific features.

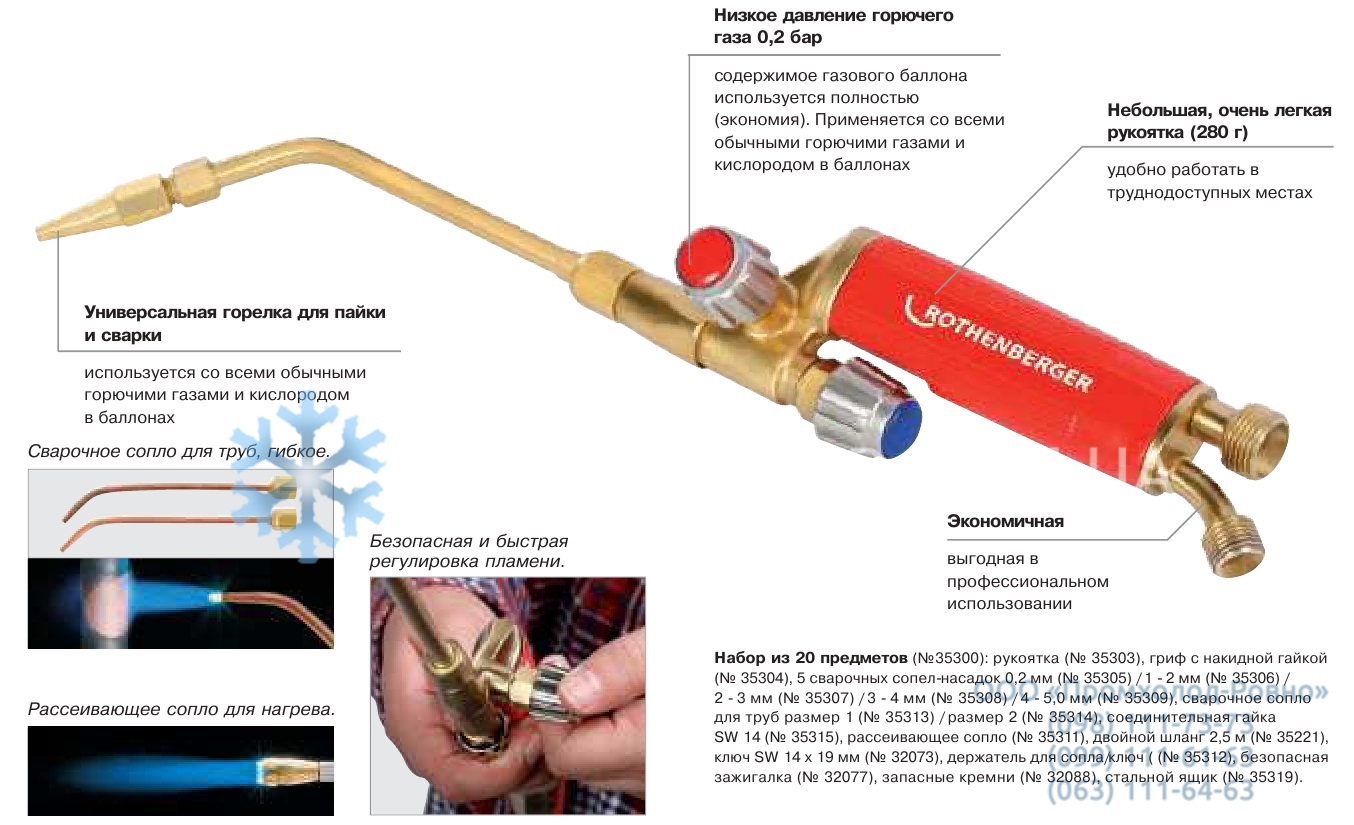

Which gas burner to choose

The copper soldering tool is sold in the market in large quantities. The latest models of devices are made exclusively using the latest technologies. Therefore, it is rather difficult for a non-professional to choose a gas heater.

Before buying, it is recommended to determine the operating conditions of the device. If this cannot be done, the choice should be made on the universal model.

It is also recommended to take into account the following criteria:

- The type of gaseous fuel used.

- The power of the device, selected depending on the wall thickness and diameter of the pipes.

- Scope of application, because the device for soldering copper elements can not always be used to cut metal.

- Materials that can be machined with the selected fixture.

When buying, you also need to consider weight. One of the best is a device weighing approximately 400 g. A non-professional is recommended a model that includes tips of a standard, cyclone and super cyclone type. These parts will allow you to solder various configurations.

Assembling the pipeline with fittings

Compound copper pipes with fittings produced exclusively in places accessible for inspection. This rule is due to the fact that the connection is not completely sealed and leaks may form over time.

The advantage of a threaded connection is that, if necessary, repairs can be made without additional effort, since the resulting connection is detachable.

Tools and materials

To assemble the pipeline, you will need the following materials and tools:

- copper pipes of suitable diameter;

- connecting crimp or press fittings;

Special Devices for Piping Assembly

The types and number of fittings are selected in accordance with the pipeline scheme.

- pipe cutter or hacksaw;

- pipe bender for copper pipes. The device is used to organize a pipeline with fewer connections, which increases the strength of the system;

- file for processing pipes after cutting (before joining).Additionally, you can use fine sandpaper;

- FUM-tape for sealing threads. In addition to the FUM tape, you can also use linen thread, Tangit Unilok thread or any other sealing material;

- wrench.

Assembly instructions

Do-it-yourself assembly of a copper pipeline using fittings is carried out in the following way:

- cutting pipes for the pipeline. The length of each pipe must fully comply with the scheme drawn up during the development of the system;

- removal of the insulating layer. If pipes with insulation are used for an equipped pipeline system for any purpose, then the insulation layer is removed for a strong connection. To do this, the desired section is cut with a knife and the pipe is cleaned;

- the cut edge is processed with a file, sandpaper until a smooth surface is obtained. If burrs, potholes or other irregularities remain at the end of the pipe, the connection will turn out to be less airtight;

Stripping the pipe before connecting to the fitting

- if necessary, pipes are bent;

- a union nut and a compression ring are put on the prepared pipe;

Installation of fitting elements for connection

- the pipe is connected to the fitting. Initially, the tightening is done by hand, and then with a wrench. During tightening, the ferrule completely seals the connection, eliminating the need for additional sealants. However, when connecting a copper pipe to a pipe or fitting made of a different material, additional sealing with FUM tape is required.

Fitting fixation

It is important not to overtighten the threads, as soft copper is easily deformed.

Can soldering torches

6th place - a metal burner for a can

A very simple and narrow burner that is worn on a gas cartridge. Reglitor and narrow nozzle allows you to get to the right parts in narrow places. There is no piezo ignition, but everything looks high quality - metal and a large gas supply regulator are all around. A cylinder of butane allows you to get a temperature of about 1300 degrees Celsius from this burner.

Advantages:

a lot of metal, a narrow nozzle.

Flaws:

no piezo ignition.

7th place - a typical burner that is put on a can

It is positioned as a burner for tourists and cooking: barbecue, cakes, sushi, etc. Of course, it can be used for soldering, cutting and welding metals. Piezo ignition and flame regulator included. The burner works classically with butane. The body is made of plastic, the nozzle casing is made of stainless steel.

Such a cost.

Advantages:

well suited for cooking, has a piezo ignition.

Flaws:

The case is made of plastic, so you need to be careful not to break it.

8th place - a burner for a spray can with a wide nozzle

The brass burner does not have a piezo ignition, but it is able to fry barbecue and massive metal parts well. The orange regulator makes it easy to change the length of the flame. Butane from a cylinder heats the flame to 1300 degrees.

Advantages:

good for cooking and massive parts.

Flaws:

no piezo ignition.

Types of gas burners

Gas-burners

- fastening of a cylinder with liquefied gas;

- inlet nozzles;

- instrument head;

- fuel supply regulator;

- reducer.

All gas burners according to the type of combustible mixture are divided into:

- propane burners;

- on MAR gas.

In everyday life, there are two types of burners:

- domestic with jet temperature up to 1500 degrees Celsius;

- industrial with temperatures up to 2000 degrees.

The most common type of burner is propane. Such devices are equipped with a piezoelectric ignition system and a gas mixture saving mode. The best option for soldering copper parts is to use a MAPP torch.

Torch for soldering copper.

A jet of fire from such a burner does not burn copper at all and ensures uniform heating of the part.

Torches with a disposable gas cylinder are the best choice for joining copper products.

Such devices have the following advantages:

- Ease of use.

There is no need to connect electrical power. - Multifunctionality.

- High mobility.

Thanks to a small fuel tank, the device can be moved from place to place without much physical effort. - Safety.

The presence of non-return valves guarantees the safe shutdown of gas in the event of an emergency. - Good drink.

A powerful and uniform flame warms up the solder well and makes it harden as evenly as possible.

Parts that require increased strength should be welded using stationary torches. These machines typically use a mixture of propane and oxygen to provide a much better weld.

Flux

For most types of solders, pre-treatment of pipes with a special composition, which is called a flux, is necessary.

Flux is produced:

in liquid form;

Soldering compounds in liquid form

in the form of a paste.

Soldering compound in the form of a paste

It is more preferable and more convenient to use a flux made in the form of a paste, since a more solid composition contributes to uniform application and does not spread over the surface of the pipe.

Flux allows:

- perform additional cleaning of pipes from oxides;

- more evenly distribute the solder during the soldering process;

- protect the joint from corrosion and the formation of oxides.

Main types

Manufacturers produce a large number of gas devices for soldering copper. They differ in operating temperature:

- household devices capable of creating temperatures up to 1500 ° C;

- professional appliances with a minimum heating setting of 1500°C and a maximum value exceeding 2000°C.

Gas burners for soldering copper pipes are available with different types of units that allow you to connect disposable or refillable fuel containers. These parts of the device can be threaded and collet. Devices are also produced to which cylinders are connected by piercing.

Threaded installation using ferrules

Such connections are called collapsible. In this case, in the event of a pipeline replacement, the ring will still have to be replaced. Installing copper pipes in this way makes it possible to identify shortcomings, leaks in time and timely repair connections - dismantling and replacement.

Connection of copper pipes on the thread is made according to the following scheme:

1. Cut a piece of pipe to a certain length. 2. In case of installation of pipes insulated in PVC, it is necessary to remove the insulation at its edges. To do this, cut the insulation layer with a sharp blade and remove its unnecessary part manually. 3. The burrs that appear after cutting the pipe section must be removed with a file. 4. Select appropriate fittings. 5. First of all, you need to put a union nut on the pipe, then a compression ring. 6. Nut and compression fitting must be attached.Next, tighten the screw connection. The nut should first be screwed in carefully, manually, if possible, after using a special wrench. As a result, the compression ring tightly fits the pipe, due to which there is a complete sealing of the connection of the system elements.

In the case of a fitting, a special fum-tape or traditional tow on paint must be used to transition from a steel pipe to a copper pipe. I wind the fitting onto the thread, having previously wound the tow soaked with paint or a special tape on it.

Safety precautions when soldering copper pipes

Safety precautions should never be ignored when a person is interested in how professionals solder copper products. First of all, it must be remembered that any copper structure heats up very much when it is exposed to a burner flame. Therefore, it is impossible to take the part with unprotected hands in any case. Pliers can be used to move short elements. It is recommended to wear gloves.

Flux should not be allowed to come into contact with the skin. If such a situation nevertheless arises, then the aggressive composition is washed off with soapy water.

Work must be done in tight clothing. It is recommended to wear cotton clothes. Clothing made of synthetic fabrics should not be used during soldering, because artificial fibers melt easily.

The process of connecting parts must be carried out with good ventilation, since the flux often lights up during soldering. Therefore, dangerous vapors appear in the air.

After completion of installation work, the system must be flushed with water.It must be hot and clean. This allows you to get rid of excess consumables inside the pipeline.

Learning to solder with a gas burner

For soldering work, a professional gas burner is best suited. For soldering small parts, it is desirable to use devices that operate on light gas or acetylene.

The results obtained when the burners operate on light gas are of better quality. Also, this type of fuel is cheaper.

When soldering parts in small quantities, it is desirable to preheat the parts. This will save time and ensure uniform heating of all elements of the assembly. As a result, warping and other defects will be avoided.

Before starting work, the parts must be fixed in such a way that they do not have to be moved during soldering. This can be done on a workbench or a special device.

Before soldering, a layer of flux is applied at the solder points. If it is necessary to add flux during operation, then the hot end of the solder rod is immersed in it.

When soldering parts from different materials, the flame must be directed to one of them that has a higher thermal conductivity. You need to be careful when working with elements of different sizes.

It is important that all components are heated to the same temperature. In this regard, thick parts need to be heated longer.

Do not melt solder in the flame of the tool. In this case, it may drip. Melting is carried out directly when the wire comes into contact with the parts to be soldered.

The solder will flow into the hotter solder spots. Based on this, the flame must be directed before soldering.If it does not flow into the seam, then this means that the part has not warmed up to the required temperature.

You should not warm up the solder joints for too long, as this can lead to a change in the composition of the solder, that is, to its burnout, and a decrease in the effectiveness of the flux.

Which brand of gas burner is better to choose

Devices are classified according to the type of fuel, the method of attaching the cartridge, and design features. These characteristics determine the scope of the burner, the convenience of its use and the ability to work in certain conditions. When choosing, it is recommended to take into account the reputation of the manufacturer, which affects the durability of the equipment. The ranking includes the best device companies:

- Flame is a dealer of Chinese gas burner manufacturers. The company's policy is based on the principle of doing business honestly. It guarantees the quality of the goods provided, fulfills all obligations to customers. The devices are characterized by original design.

- Qingdao Olympia Heat Energy Equipment Co., LTD is a Chinese company founded in 2003, with many years of experience in the fuel equipment industry. Products are manufactured taking into account the latest technologies, environmental standards, financial capabilities of customers.

- Nabia Co, LTD is a South Korean company, founded in 1997. It works on the principle of "We make efforts to provide you with convenient devices." The products are adapted for use in the Russian climate.

- Ecos - the company's activity is aimed at the implementation of high-quality devices that meet the needs of consumers. All supplied equipment has ISO certificates.The professionalism of the employees is confirmed by numerous positive customer reviews.

- Pathfinder is a domestic manufacturer of gas burners. All products are tested in real conditions, which allows them to improve and send only the best to store shelves. In terms of quality, the products are not inferior to analogues of famous brands, and the price is affordable for the Russian buyer.

- Kovea - a company founded in Korea in 1992, is considered the leader in the production of this type of fuel equipment in the country. The brand's products have quality certificates. Achievements in the field of the latest technologies have brought the firm recognition and love of consumers.

- Wolmex is a domestic company producing household and industrial gas burners for heating boilers, smokehouses and autoclaves. The advantages of buying appliances include a large burning area, the ability to smoothly adjust the flame.

- Elco - produces advanced gas burners for heating and process applications. Products have high performance and reliability in accordance with environmental standards. In the laboratories of the company, new technologies are constantly being developed to improve the quality of manufactured devices.

- Baltur is an Italian company whose staff is working on improving the created models of devices. This allows us to improve the quality of products, to take a leading position in the fuel equipment markets.

Technology nuances

Fluxes for soldering copper are not always used. They are not needed if the technology involves heating to a high temperature. They are usually needed when low temperature solder type soldering is planned.In addition, there are modifications on sale designed for high-temperature soldering.

Its components differ in purpose. The use of flux provides ease of soldering, improves the quality of its result. It is a measure to prevent foreign elements from entering the joints. This eliminates the possibility of pore formation during soldering.

Fluxes actively enter into chemical reactions with oxides. They are inactive to solder elements. When heated, they begin to melt before copper, but do not come into contact with it. As for the type of consumable material by type of production, in addition to the industrial format, soldering flux can be homemade. For example, for this you can dissolve rosin in palmitic, stearic and oleic acids.