- Making a wood-burning electric generator with your own hands

- Types of gas installations

- Power plant diagram - for craftsmen

- Instructions for creating

- The device and manufacture of the gas generator

- Conclusion

- How to make a gas generator with your own hands?

- Gas generator device

- Types of gas installations

- Power plant diagram - for craftsmen

- Instructions for creating

- 6 DIY

- What is a wood burning gas generator

- Precautionary measures

- Classic variant

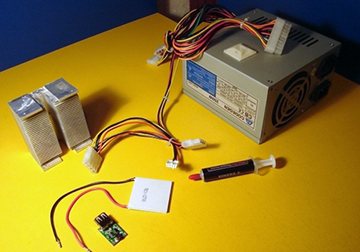

Making a wood-burning electric generator with your own hands

The basis of the device is the Peltier element. It can be specially bought or removed from the computer (it is located between the processor and the heatsink).

In addition to it, for the operation of the unit you will need:

- voltage stabilizer, it is also a module with a USB output;

- metal for the case (you can use the case from the old power supply);

- cooling radiator and cooler;

- thermal paste;

- tool - riveter, metal shears, drill;

- soldering iron;

- rivets.

To begin with, the body of the wood chipper is made (on which you can boil water in a saucepan with the help of small brushwood).

This is a square jar without a bottom, it has holes for air at the bottom, and a container stand on top (although this is not necessary, the generator will work without water).

A Peltier element is attached to the case on the side, and a cooling radiator is attached to its cold side, through thermal paste.

It is important that the contact between the parts is as tight as possible. It turns out the basis of the furnace-generator

The radiator must cool the system as well as possible, since the greatest efficiency is achieved with a large temperature difference. In winter, there will be no problems, since the device can be put in the snow. But in the warm season, the radiator will gradually heat up, so a cooler is installed to cool it.

Next is the electrical part. Well, if you managed to find a voltage regulator in the same case with a USB socket - it will be convenient.

The stabilizer is needed so that the output always has a given voltage, regardless of how much the generating element produces.

You can purchase ready-made with a diode indicator that lights up when the voltage reaches a predetermined value.

The stabilizer and Peltier are soldered, according to the poles. The stabilizer is carefully insulated so that no moisture gets in.

The design is ready, it is possible to carry out tests.

Types of gas installations

The modern market for power plants offers equipment that runs on gas of three main types:

- Direct generation method;

- Reverse;

- Horizontal.

The former are suitable for burning coal and semi-coke. In such units, oxygen enters from below, and gas is taken from above the unit. But since in these models moisture from the fuel does not enter the combustion zone, it has to be brought in specially. This allows you to increase the power of the device.

Reversed process units are ideal for wood waste incineration.In them, air is supplied directly to the combustion zone, and the gas is taken from below.

The transverse method devices are distinguished by high-speed air supply through tuyeres in the lower part of the body. And here, only from the opposite side, gas is also taken. These units are characterized by a minimum start-up time and good adaptability to changing modes.

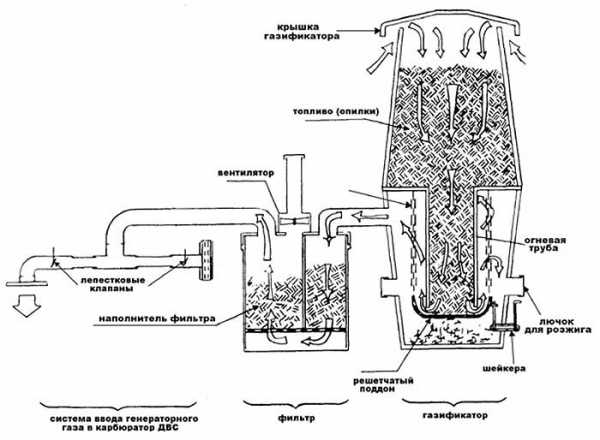

Power plant diagram - for craftsmen

Assembling such a unit with your own hands is not so difficult. However, before you start making a gas generator with your own hands, you need to familiarize yourself with the principle of operation of the unit, as well as choose the scheme that is most suitable for your conditions.

For the simplest device, items that are easy to find in every home will fit perfectly:

- Barrel;

- Pipes;

- Radiator;

- Filters;

- Fan.

This set can be supplemented with other elements. What and in what sequence to collect can be found on the Internet. Moreover, these are not necessarily drawings and photos, but most often a video that shows in detail and explains in detail how to assemble a gas generator on your own on manure, firewood and other fuels. If the scheme is selected, then you can proceed directly to the assembly.

Instructions for creating

Any unit consists of a body, inside of which the main components and mechanisms are located. This is not alien to a gas generator assembled by one's own hands. It also has a case in which are placed:

- Bunker;

- combustion compartment;

- air distribution part;

- Grate;

- Pipe branch;

- Filters.

The body of the unit is usually made of sheet metal. For ease of installation, legs are welded to the bottom. The shape of the structure can be both oval and rectangular.

We do it ourselves, the stages of work:

The hopper is made of mild steel and is fixed inside the unit. It is equipped with a lid with a seal made of asbestos or other material. The bottom of the device is occupied by the combustion chamber. For its manufacture, special steel grades are chosen that are most resistant to high temperatures. A neck is attached to the chamber, which is also separated from the body with an insulating material.

Specialists who have had to assemble gas generators with their own hands more than once offer to make a combustion chamber from a gas cylinder.

The air distribution chamber is usually located outside the instrument housing. And at the exit a check valve is installed from it, designed to prevent gas from escaping through this hole. There is a fan in front of the box.

The grate in a do-it-yourself gas generator is made of cast iron, while the middle part must be movable to simplify the maintenance process. But it is not enough just to assemble the generator, you also need to properly adjust the air supply to it, as well as the exhaust gases.

You can install such equipment both on the street and in the basement, providing it with good ventilation.

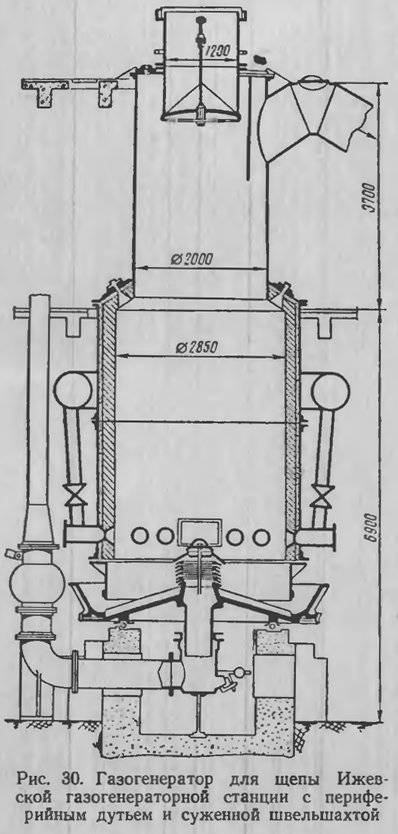

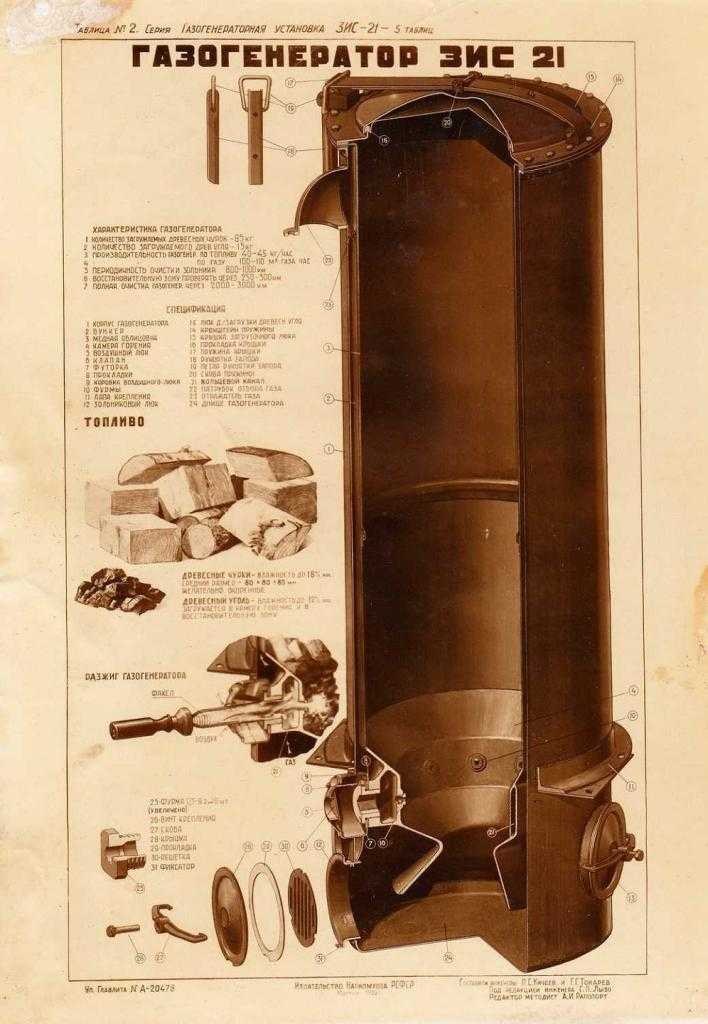

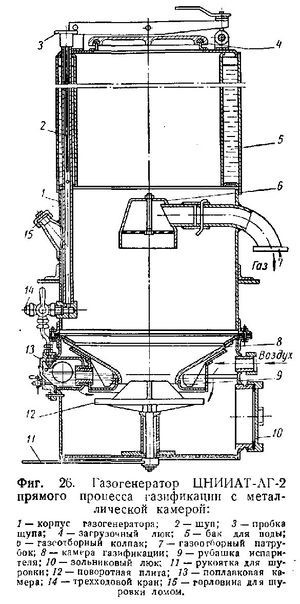

The device and manufacture of the gas generator

Let us consider in more detail the device of the gas generator. In addition to the case, inside which is located the main part of the elements, the design includes:

- bunker (chamber for loading fuel);

- combustion chamber (this is where the process of smoldering of wood takes place at high temperatures and with a minimum air supply);

- the neck of the combustion chamber (here cracking of resins occurs);

- air distribution box equipped with a check valve;

- lances (calibration holes, due to which the junction box communicates with the middle part of the combustion chamber);

- grate (serves as a support for smoldering fuel);

- loading hatches equipped with sealed covers (the hatches in the upper part are required for loading fuel, in the lower part - for cleaning the unit from accumulated ash);

- outlet pipe (flammable gas exits through it and enters the welded pipe of the gas pipeline);

- air cooler (in the form of a coil);

- filters for cleaning the mixture of gases from unnecessary impurities.

The gas generator circuit may include a fuel drying system. For pyrolysis to be effective, the firewood must be dry. If a part of the gas pipeline runs along the ring around the fuel loading chamber (between the walls of this chamber and the housing), damp firewood will have time to dry before it enters the combustion chamber. This will significantly increase the efficiency of the installation.

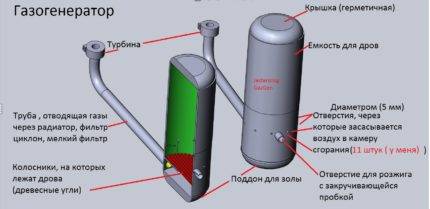

The body of the gas generator is made of a metal barrel, on top of which a pipe is attached to the seal with corners and bolts, and a propane cylinder is attached to the bolts from the inside

Before you make a gas generator, you need to find information about a suitable device model and detailed drawings indicating the dimensions of all elements.

Particular attention is paid to the choice of materials for each of the structural elements. The gas generator can have a rectangular or cylindrical shape - the body is usually welded from sheet metal or a metal barrel is used

The bottom and cover must be made of steel sheet with a thickness of 5 mm.

The hopper, which is bolted inside the hull, shall be made of mild steel.The combustion chamber is made of heat-resistant steel, you can use an empty bottle of liquefied propane.

The gas cylinder is installed inside the barrel and bolted to its top.

The lid of the bunker should be equipped with a reliable seal made of heat-resistant material (asbestos cord with graphite lubricant). A refractory insulator (asbestos cord or similar material) is laid between the neck of the combustion chamber and the body. It is more convenient to make the metal grate of the grates removable, from reinforcing bars, so that it is more convenient to clean the combustion chamber.

A pipe is attached to the bolts on top of the barrel

The air distribution box with a non-return valve at the outlet is installed outside the housing, in front of it you can mount a fan that blows air to increase the efficiency of the unit when working on freshly cut wood.

Blower fan to help improve efficiency

As an air cooling coil, some craftsmen fit a steel or bimetallic radiator. The mixer, passing through which the purified combustible gas is mixed with air, is equipped with a fan.

When choosing materials for a fixed installation designed to generate electricity for domestic use, the emphasis is on reliability and affordability. If you want to make a gas generator for a car, preference should be given to stainless steel - this will make the unit lighter and more compact. But the use of stainless steel significantly increases the cost of construction.

Conclusion

The compact wood-fired gas generator is suitable for installation on a truck or car.The unit for a local power plant can be installed in the basement of a house, in an outbuilding, or, if necessary, installed on the street or under a canopy (when it is necessary to provide electricity to any stationary electrical equipment).

The fundamental issue is the correct operation of the gas generator. In order for the unit to function with high efficiency, it is necessary to carefully adjust the level of air supply (taking into account the moisture content of the fuel), the intensity of the exhaust gases, etc. It is desirable to manufacture a gas generator according to professional drawings, in compliance with all sizes and proportions.

Related video:

How to make a gas generator with your own hands?

Is it possible to make a gas generator with your own hands? Yes, but you will need a set of tools and the materials themselves. The following will be used: sheet steel to create a body, a fuel tank (which will contain firewood), heat-resistant steel for a container where the combustion process will take place, various heat-resistant gaskets, ideally not asbestos, because it is considered dangerous for the body. All sorts of pipes that will connect all the nodes of the gas generator, filters to remove impurities (western colleagues are experimenting with the same wood mixtures), a special cast-iron grate that allows burnt elements to pass through, and such trifles as doors, covers and valves. Having obtained all the necessary elements and armed with a suitable drawing, you can proceed directly to the creation of such an apparatus as a home-made wood-burning gas generator with your own hands. The accuracy and individuality of gas generator design calculations in accordance with your car is desirable, but sometimes not required.Some, especially observant and handy "homemade" manage to copy the necessary unit, using standard drawings.

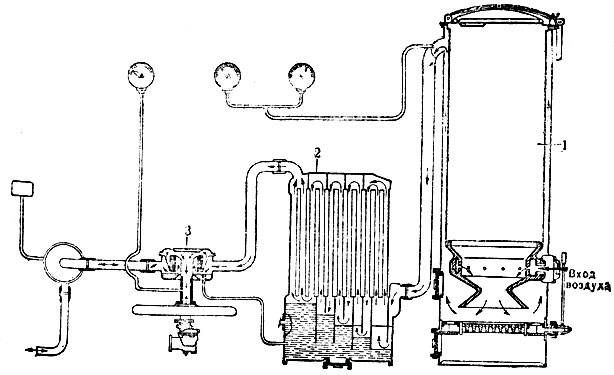

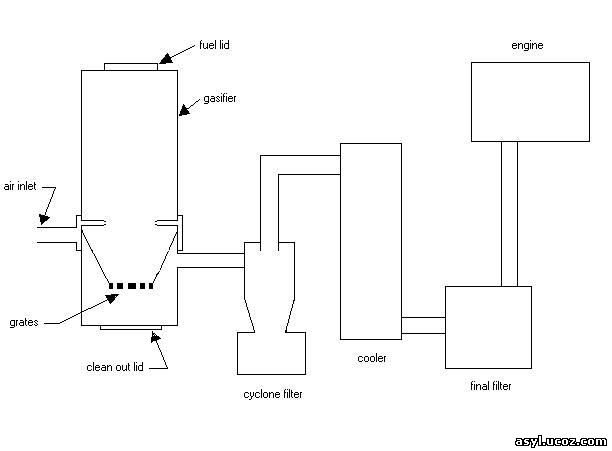

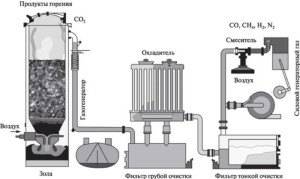

Gas generator device

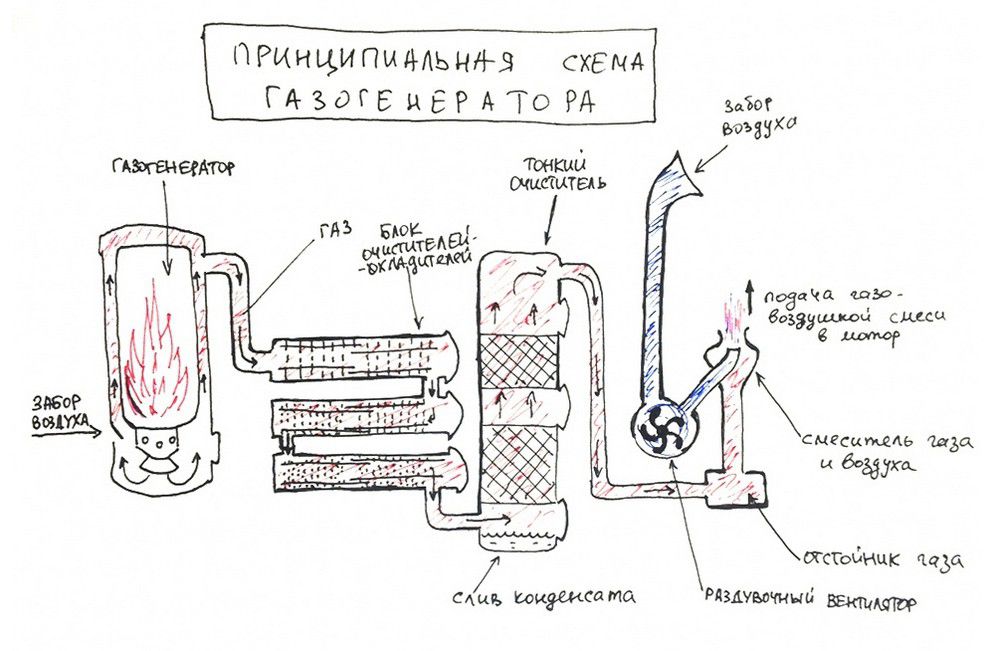

What is a wood burning gas generator for a car? The secret of the unit is quite simple. During the combustion of wood fuel, a gas is produced, which, freed from excess impurities, passes through the cooling stage, is mixed with air and injected into the internal combustion engine.

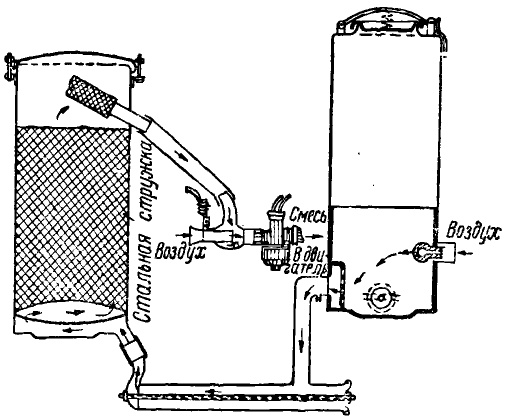

This means that you will need the gas generator itself, various types of filters, a mandatory cooling system, all kinds of pipelines and an electric fan - to speed up and improve the combustion itself. The system looks like this: the necessary fuel is loaded into a high cylindrical tank (a square is also possible), under which the combustion chamber itself is installed. The resulting gas passes through a purification system. Further, the fuel temperature drops to ideal, and then air enrichment - and the desired mixture is in the engine. Modern developments of craftsmen differ little from the attached old scheme, and therefore, if you do not equip a truck with a gas generator, but put it on a passenger car dear to your heart, you will either need to build a frightening structure in the trunk, or somehow attach the unit on an additional trailer to the car.

Types of gas installations

The modern market for power plants offers equipment that runs on gas of three main types:

- Direct generation method;

- Reverse;

- Horizontal.

The former are suitable for burning coal and semi-coke. In such units, oxygen enters from below, and gas is taken from above the unit.But since in these models moisture from the fuel does not enter the combustion zone, it has to be brought in specially. This allows you to increase the power of the device.

Reversed process units are ideal for wood waste incineration. In them, air is supplied directly to the combustion zone, and the gas is taken from below.

The transverse method devices are distinguished by high-speed air supply through tuyeres in the lower part of the body. And here, only from the opposite side, gas is also taken. These units are characterized by a minimum start-up time and good adaptability to changing modes.

Power plant diagram - for craftsmen

Assembling such a unit with your own hands is not so difficult. However, before you start making a gas generator with your own hands, you need to familiarize yourself with the principle of operation of the unit, as well as choose the scheme that is most suitable for your conditions.

Installation design and connection diagram

Installation design and connection diagram

For the simplest device, items that are easy to find in every home will fit perfectly:

- Barrel;

- Pipes;

- Radiator;

- Filters;

- Fan.

This set can be supplemented with other elements. What and in what sequence to collect can be found on the Internet. Moreover, these are not necessarily drawings and photos, but most often a video that shows in detail and explains in detail how to assemble a gas generator on your own on manure, firewood and other fuels. If the scheme is selected, then you can proceed directly to the assembly.

Instructions for creating

Any unit consists of a body, inside of which the main components and mechanisms are located.This is not alien to a gas generator assembled by one's own hands. It also has a case in which are placed:

- Bunker;

- combustion compartment;

- air distribution part;

- Grate;

- Pipe branch;

- Filters.

The body of the unit is usually made of sheet metal. For ease of installation, legs are welded to the bottom. The shape of the structure can be both oval and rectangular.

We do it ourselves, the stages of work:

The hopper is made of mild steel and is fixed inside the unit. It is equipped with a lid with a seal made of asbestos or other material. The bottom of the device is occupied by the combustion chamber. For its manufacture, special steel grades are chosen that are most resistant to high temperatures. A neck is attached to the chamber, which is also separated from the body with an insulating material.

Specialists who have had to assemble gas generators with their own hands more than once offer to make a combustion chamber from a gas cylinder.

The air distribution chamber is usually located outside the instrument housing. Moreover, a check valve is installed at the outlet of it, designed to prevent gas from escaping through this hole. There is a fan in front of the box.

The grate in a do-it-yourself gas generator is made of cast iron, while the middle part must be movable to simplify the maintenance process. But it is not enough just to assemble the generator, you also need to properly adjust the air supply to it, as well as the exhaust gases.

You can install such equipment both on the street and in the basement, providing it with good ventilation.

6 DIY

The production of any device begins with the production of a drawing.After studying the detailed information, a person has an idea of \u200b\u200bthe external design of the unit. Then it remains to bring your idea to life.

To make the device look aesthetically pleasing, you should choose the right details. For its manufacture you will need:

- barrel for 100 l;

- can made of steel with a tight lid on the latches;

- a pipe with thick walls with a diameter of 15-16 cm and a length of 30 cm;

- fire extinguisher;

- steel sheet 0.6-1 cm thick;

- part of a domestic heating radiator.

First you need to make 5-6 holes at the top of the pipe. It will become the top of the structure. An oxygen supply tube should be welded to one of the holes obtained. The rest will release gas. In the lower part it is necessary to weld a perforated stainless steel bottom. Get the grate part, which will accommodate the coals. Dust will come out through the holes.

From the inside of the resulting glass, a metal cone is welded to supply coal. Then a metal sheet should be welded with a hole the size of which matches the inner diameter of the pipe. The structure must be placed perpendicular to the top of the tube. The sheet will become the bottom of the bin. The functions of the latter will be performed by a can.

Making a car on wood with your own hands is not as easy as it might seem at first glance. The procedure requires a lot of effort and time. However, for a skilled craftsman who is ready to experiment and is not afraid of difficulties, this is a very real task.

It is very important to study in detail the device and the principle of operation of the product, as well as correctly draw up its drawing.

What is a wood burning gas generator

The gas generator has a fairly simple design, since all the processes taking place in it are based on the pyrolysis combustion of firewood. That is, the idea of gas generators is based on pyrolysis boilers, where wood burns out in a lack of air, while releasing a large amount of various gases. Further information about the structure of this device will be given.

- Frame. It is usually made from sheet steel. All elements are connected by welding. In general, the case can have both a cylindrical and a rectangular shape, although the cylinder shape is more common, and it looks aesthetically pleasing. In the lower part, the legs are welded on which the structure will stand.

- Bunker. It is also made from low carbon steel sheet. Like the body, the hopper can also be shaped like a cylinder or a rectangle. It is inserted into the housing and attached to the walls of the housing with bolts. There should also be a lid covering the opening at the top that leads into the hopper. Asbestos or some other material is used as a sealant.

- The combustion chamber. It is located at the bottom, and is usually made of steel with a high chromium content. Here, combustion of solid fuel occurs in conditions of insufficient air supply. There are asbestos cords between the inner walls of the housing and the combustion chamber. On the side walls of the combustion chamber there are several holes, or, as they are also called, air supply lances, through which air is supplied to the combustion chamber. These tuyeres are connected to an air distribution tank which communicates with the atmosphere. When air leaves this container, it overcomes the check valve.The function of this valve is to block the exit of the gas formed during the combustion of firewood to the outside.

- The grate is located at the bottom of the device. Its function is to maintain hot fuel. Also, through the numerous holes of this grate, the ash formed during the combustion of the fuel enters the ash pan.

- Loading hatches. There are three such hatches in the design of household gas generators. The first one is on top, its cover is folded horizontally. Asbestos cords are used as sealing when closing and sealing. In modern models, in the hatch attachment area, you can find a special shock absorber spring, which automatically comes into action if the pressure inside the device exceeds a certain norm. Under the action of this spring, the hatch overturns. On the side of the structure there are two more loading hatches. The first one is located at the recovery zone level. This hatch is used to load fuel into this area. The lower hatch is located at the lower end of the device, at the level of the ash pan. It is used to clean it. The gas formed during the combustion of solid fuel is removed from the upper part of the structure. To do this, there is a special pipe for the outlet of gas.

Next, we will consider the processes during which combustible gases are released from wood. In general, the entire structure can be divided into several zones:

- Drying zone. It is located at the top of the structure, immediately below the loading hatch. Here, the fuel dries quickly due to the fact that the temperature in this zone reaches about 190 degrees Celsius.

- Dry distillation zone. It is located below the drying zone. Dried fuel is charred here due to the fact that the temperature reaches up to 500 degrees. During these processes, resins and some organic acids are removed from the fuel.

- Burning zone. Located at the bottom. Fuel enters here and burns at a temperature of 1200 degrees. Air is supplied through special tuyeres. During combustion, carbon monoxide and carbon dioxide are released.

- Recovery zone. The gases released during the combustion of the fuel rise up and reach the reduction zone. Coal is loaded here through a special hatch, which is held on the grate. Carbon monoxide and carbon dioxide react with coal. When carbon dioxide and coal react, carbon monoxide is formed during the reaction. But there is water in coal, which is also active in relation to gases. As a result of all these reactions, carbon monoxide, carbon dioxide, hydrogen, methane, some volatile unsaturated hydrocarbon compounds, and nitrogen are formed. This mixture of gases is purified from all impurities, then mixed with air. This is the end result. The resulting mixture of gases can be used for domestic needs.

Precautionary measures

It is impossible to convert a conventional furnace into a gas-generating one. Such manipulations will only lead to smoke building. In order to fully use the gas generating device, it is necessary to take into account its shortcomings.

At the outlet of such equipment, cold gas is formed. If the chimney is not properly insulated, condensation will form. Moisture will drain back into the appliance. Therefore, experts recommend the use of insulated sandwich structures.They consist of 2 pipes nested in each other, between which there is a heater.

In order for the gas generator to work as efficiently as possible, it is necessary to install an economizer (optional equipment).

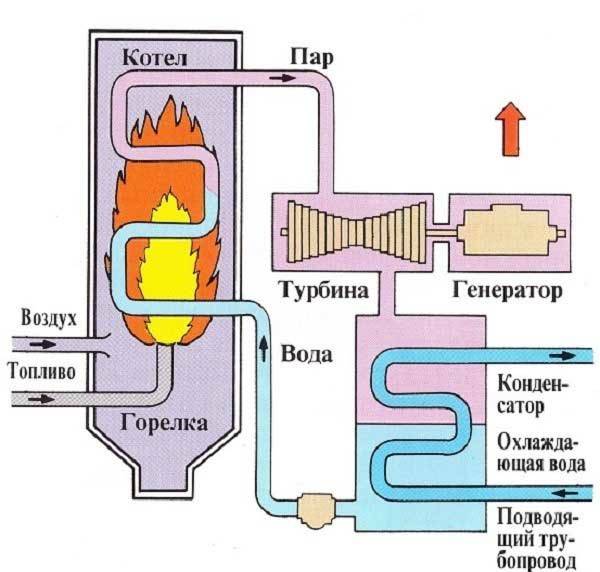

Classic variant

As already noted, several technologies are used in a wood-fired power plant to generate electricity. The classic among them is steam power, or simply the steam engine.

Everything is simple here - firewood or any other fuel, burning, heats up water, as a result of which it passes into a gaseous state - steam.

The resulting steam is fed to the turbine of the generator set, and due to rotation, the generator generates electricity.

Since the steam engine and generator set are connected in a single closed circuit, after passing through the turbine, the steam is cooled, fed back into the boiler, and the whole process is repeated.

Such a power plant scheme is one of the simplest, but it has a number of significant drawbacks, one of which is explosiveness.

After the transition of water into a gaseous state, the pressure in the circuit increases significantly, and if it is not regulated, then there is a high probability of rupture of pipelines.

And although modern systems use a whole set of valves that regulate pressure, the operation of a steam engine still requires constant monitoring.

In addition, ordinary water used in this engine can cause scale formation on the pipe walls, which reduces the efficiency of the station (scale impairs heat transfer and reduces pipe throughput).

But now this problem is solved by using distilled water, liquids, purified impurities that precipitate, or special gases.

But on the other hand, this power plant can perform another function - to heat the room.

Everything is simple here - after performing its function (rotation of the turbine), the steam must be cooled so that it again turns into a liquid state, which requires a cooling system or, simply, a radiator.

And if you place this radiator indoors, then as a result, from such a station we will receive not only electricity, but also heat.