- Method number 3 - Homemade stations

- Do-it-yourself gas from firewood

- The device and principle of operation of a wood-burning gas generator

- How to do it yourself?

- Training

- Manufacturing scheme

- The device and manufacture of the gas generator

- Conclusion

- What air heating equipment is the best

- Valuable information on gas generators

- The principle of operation of wood gas generators

- Advantages and disadvantages

- Cons: schematic

- Criteria for choosing a gas generator

- What wood is needed for the generator

Method number 3 - Homemade stations

Also, many craftsmen create home-made stations (usually based on a gas generator), which they then sell.

All this indicates that it is possible to independently make a power plant from improvised means and use it for your own purposes.

Next, consider how you can make the device yourself.

We recommend: Cooling towers of open and closed types: their design, operating modes, photo

Based on thermoelectric generator.

The first option is a power plant based on a Peltier plate. We note right away that a home-made device is only suitable to charge your phone, flashlight or for lighting using LED lamps.

For manufacturing you will need:

- A metal case that will play the role of a furnace;

- Peltier plate (sold separately);

- Voltage regulator with installed USB output;

- A heat exchanger or just a fan to provide cooling (you can take a computer cooler).

Making a power plant is very simple:

- We make an oven. We take a metal box (for example, a computer case), unfold it so that the oven does not have a bottom. We make holes in the walls below for air supply. At the top, you can install a grate on which you can place a kettle, etc.

- We mount the plate on the back wall;

- We mount the cooler on top of the plate;

- We connect a voltage regulator to the outputs from the plate, from which we power the cooler, and also draw conclusions for connecting consumers.

POPULAR WITH READERS: What are smart sockets, their types, device and principle of operation

Everything works simply: we kindle firewood, as the plate heats up, electricity will be generated at its terminals, which will be supplied to the voltage regulator. The cooler will also start to work from it, providing cooling of the plate.

It remains only to connect consumers and monitor the combustion process in the stove (toss firewood in a timely manner).

Based on a gas generator.

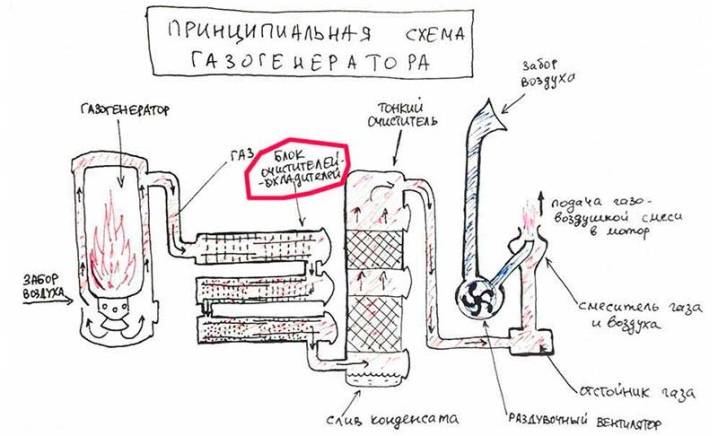

The second way to make a power plant is to make a gas generator. Such a device is much more difficult to manufacture, but the power output is much greater.

To make it you will need:

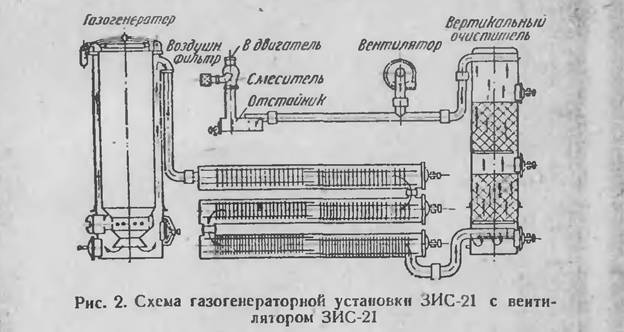

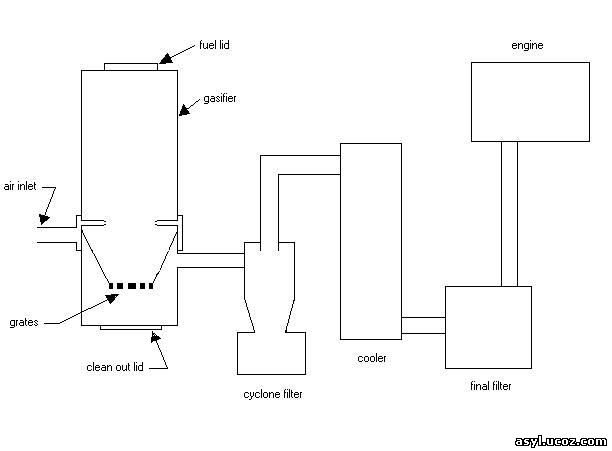

- Cylindrical container (for example, a disassembled gas cylinder). It will play the role of a stove, so hatches should be provided for loading fuel and cleaning solid combustion products, as well as an air supply (a fan will be required for forced supply to ensure a better combustion process) and a gas outlet;

- Cooling radiator (can be made in the form of a coil), in which the gas will be cooled;

- Capacity for creating a filter of the "Cyclone" type;

- Capacity for creating a fine gas filter;

- Gasoline generator set (but you can just take any gasoline engine, as well as a conventional 220 V asynchronous electric motor).

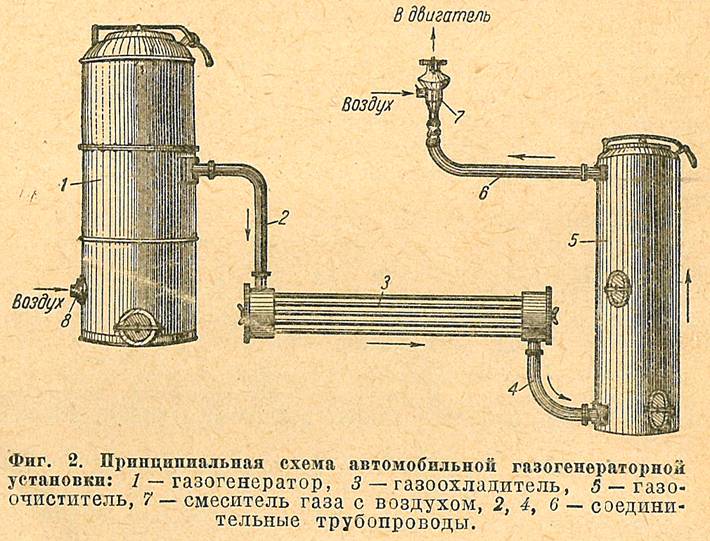

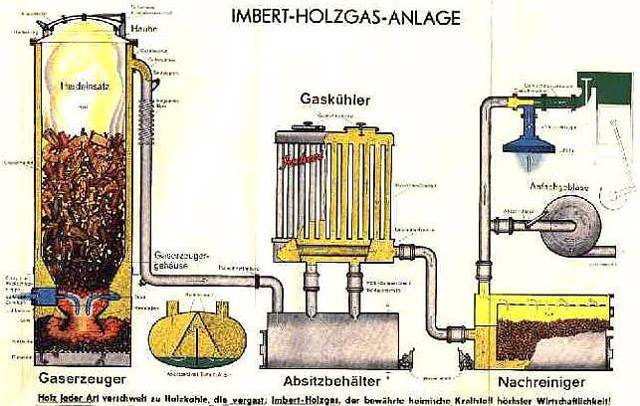

After that, everything must be connected into a single structure. From the boiler, gas must flow to the cooling radiator, and then to the "Cyclone" and fine filter. And only after that the resulting gas is supplied to the engine.

This is a schematic diagram of the manufacture of a gas generator. Execution can be very different.

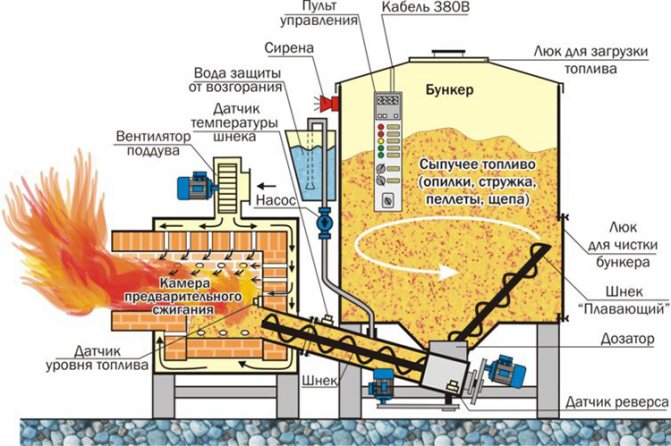

For example, it is possible to install a mechanism for the forced supply of solid fuel from a bunker, which, by the way, will also be powered by a generator, as well as various control devices.

Creating a power plant based on the Peltier effect, there will be no special problems, since the circuit is simple. The only thing is that some safety measures should be taken, since the fire in such a stove is practically open.

But when creating a gas generator, many nuances should be taken into account, among them is ensuring tightness at all connections of the system through which the gas passes.

In order for the internal combustion engine to work normally, you should take care of high-quality gas purification (the presence of impurities in it is unacceptable).

The gas generator is a bulky design, so it is necessary to choose the right place for it, as well as ensure normal ventilation if it is installed indoors.

Since such power plants are not new, and they have been manufactured by amateurs for a relatively long time, a lot of reviews have accumulated about them.

Basically, they are all positive. Even a home-made stove with a Peltier element is noted to fully cope with the task. As for gas generators, the installation of such devices even on modern cars can be a good example here, which indicates their effectiveness.

Do-it-yourself gas from firewood

Getting gas from firewood was widely used during the Second World War. Liquid fuel went to the front line, many destroyed oil refineries spurred the invention of gas obtained from firewood.

Getting gas from firewood was widely used during the Second World War. Liquid fuel went to the front line, many destroyed oil refineries spurred the invention of gas obtained from firewood.

At that time, firewood was more affordable than oil products. Therefore, Soviet and foreign equipment was equipped with gas generators. On wood gas worked: tanks, cars and motor vehicles.

In the 21st century, after the rise in the price of liquid fuel, people remembered the technology and began to produce gas from firewood with their own hands.

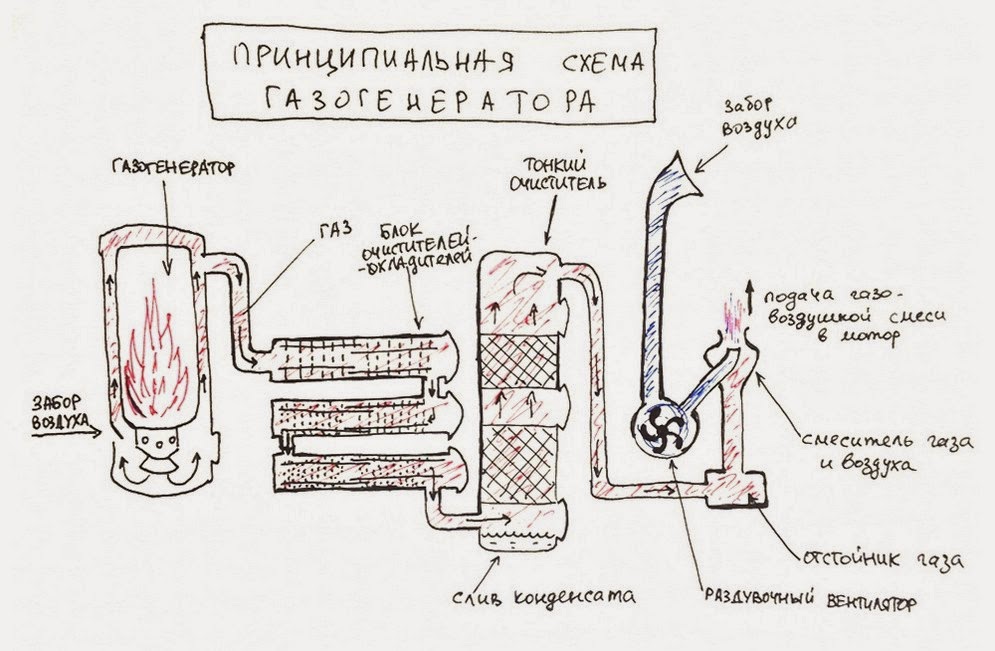

The gas production technology is simple. Firewood is loaded into the gas generator, set on fire. After the firewood is kindled, the oxygen supply decreases, the firewood begins to smolder, carbon monoxide is released, which rises hot, enters the cooling coil, is filtered through filters, the cooled and purified gas enters the gas combustion chamber. Combustible gas heats the room faster than solid fuel.

The device and principle of operation of a wood-burning gas generator

Combustible gas can be obtained by burning wood in a gas generator

Combustible gas can be obtained by burning wood in a gas generator

Under normal conditions, with free access to oxygen, the process of burning wood is accompanied by the release of a certain amount of heat.But when there is not enough oxygen for active combustion, firewood smolders with the formation of wood gas, which includes combustible gases CO (carbon monoxide), H2 (hydrogen), CH4 (methane) and unsaturated hydrocarbons without tar. Also, non-combustible substances are formed at the outlet: CO2, O2, N2, H2O, which are ballast, and ultimately the gas mixture must be cleaned of them.

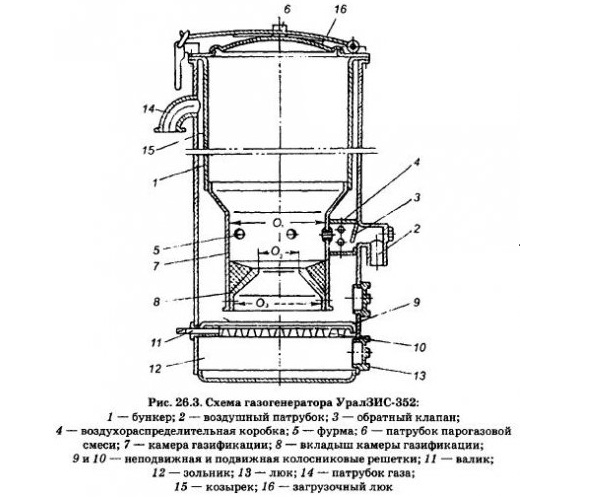

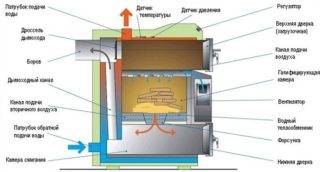

The gas generator is arranged as follows:

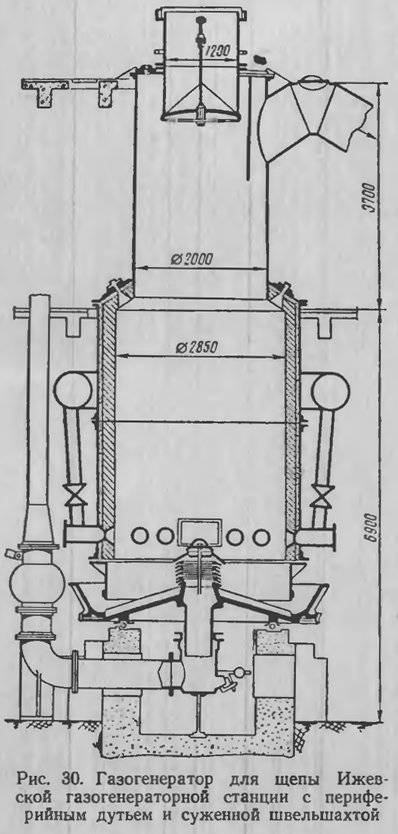

- The body is made of steel, most often cylindrical. There is a filling chamber into which fuel is loaded. The camera is installed inside the housing and secured with bolts. The hatch of the loading chamber is equipped with a seal.

- The combustion chamber is installed at the bottom, inside it is ceramic. It burns fuel. Resin cracking occurs in its lower part - there is a neck made of chromium steel with an asbestos cord, which plays the role of a sealing gasket between it and the body.

-

Air is supplied to the combustion chamber through openings connected to the air distribution box, the so-called tuyeres. A non-return valve is installed at the outlet of the chamber to prevent the release of combustible gas. A fan installed at the inlet allows you to increase engine power or burn fuel with a moisture content of more than 50% in a wood-burning gas generator.

- The grate is located at the bottom of the gas generator and is designed to hold hot coals. It has holes through which the ash falls into the ash pan. Its middle part is movable so that it can be cleaned.

- There are several loading hatches: the top one with a shock absorber that lifts the lid under excessive pressure, and two side ones: one above - for adding fuel to the recovery zone, and the other below - for removing ash.

- Behind the housing there is a filter of cyclone vortex type. This is where gas cleaning takes place. Then the gas mixture is cooled in the cooler and enters the fine filter. After the filter, it is sent to the mixer, where it is saturated with air. Then the gas-air mixture goes to the place of use.

Homemade gas generator device

Homemade gas generator device

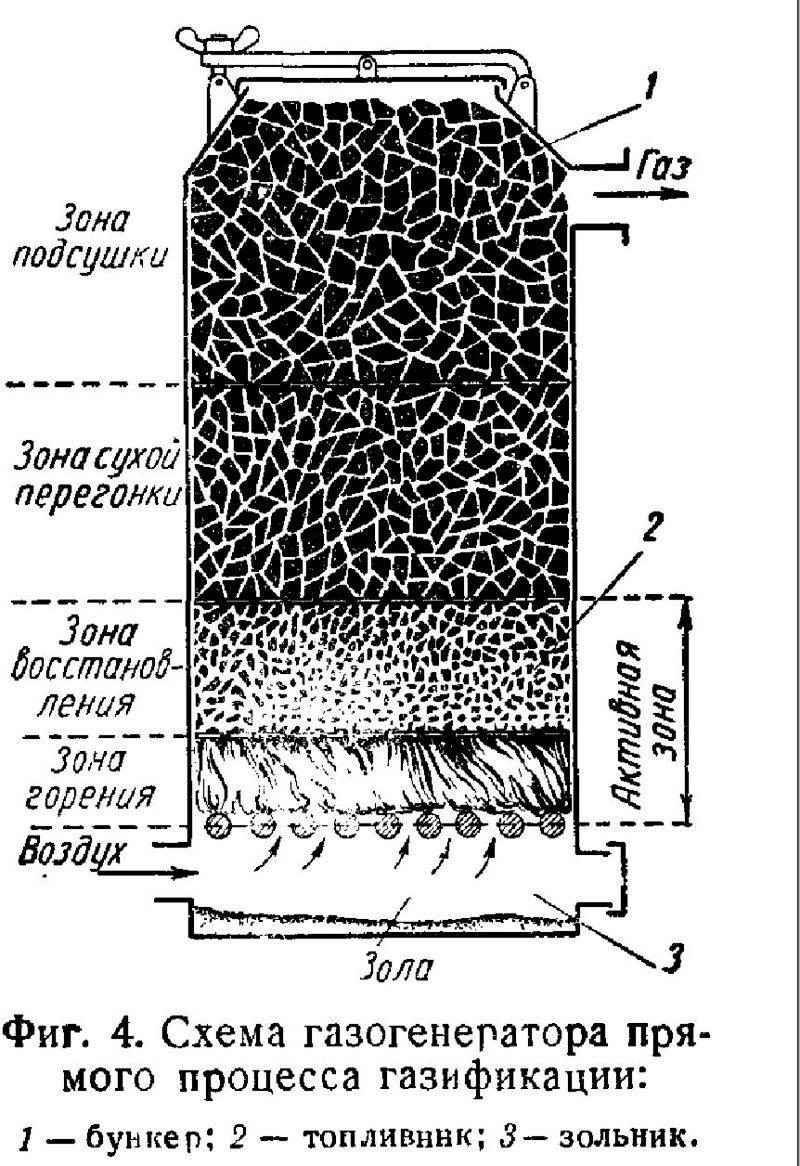

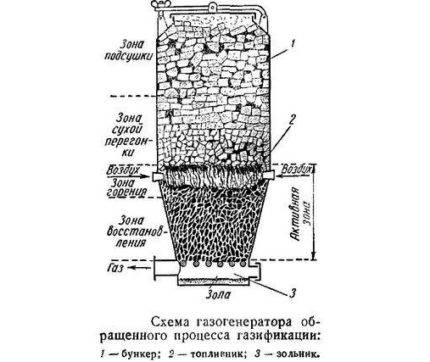

Combustible gas in the gas generator is obtained as follows:

- In the upper part of the loading chamber, the temperature is at the level of 150–200°C. Due to the fact that an annular pipeline is organized through which hot gas that has just exited the gas generator passes, the firewood is dried here.

- The middle part of the bunker is the dry distillation zone. At this level, the fuel is charred at a temperature of 300–500°C without air. Tar and acids are released from the fuel.

- In the combustion zone, which is located below the combustion chamber, the temperature is maintained at 1100–1300°C. The charred fuel, as well as the resins and acids released from it, are burned by the air supply to form CO and CO2 gases.

- The recovery zone is located above the combustion zone: between it and the grate. The CO2 gas that has formed in the combustion zone rises up, overcomes the hot coal and interacts with the carbon of the coal, thus being reduced to the formation of carbon monoxide. In addition to CO, CO2 and H2 are also formed.

At the exit from the reduction zone, the mixture of gases is cooled, then purified from acetic and formic acid, ash particles and mixed with air.

How to do it yourself?

Now let's try to figure out how to make such a wood-fired gas generator with our own hands. First, consider what we need, after which we will try to understand the manufacturing process of this device.

Training

So, to create a gas generator yourself, you will need to prepare:

- used gas cylinder;

- a barrel from which the gas generator body will be made;

- welding machine;

- several screws;

- valves and filters for gas cleaning, which can be purchased at specialized stores.

In addition, you will need to prepare drawings of the model that you are interested in. Their use should not be neglected, because they allow you to fit all the necessary components to each other as accurately as possible and save you from any mistakes and unnecessary blunders. Therefore, it is better to have them at hand and carefully read them before starting work.

To create the case, you will need to prepare the corners and sheet steel pre-cut and cut according to templates. For the bunker, sheet metal should be prepared. You will also need heat-resistant steel from which the combustion chamber is made. For the neck of the combustion chamber, asbestos gaskets are needed, with which it is separated from the body.

Manufacturing scheme

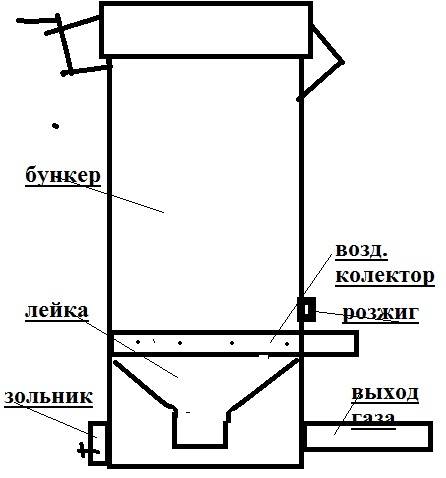

Let's try to figure out how the assembly is carried out do-it-yourself wood-fired gas generator. So, for starters, the body is assembled from pre-prepared steel sheets, which are interconnected by welding. After that, the legs should be welded from below.

At the second stage, the bunker is created. Its form can be anything. After it is done, it must be placed in the case and be sure to secure it inside with bolts. It should be supplemented with a lid.

In the next step, you will need to install a container in the lower area of \u200b\u200bthe bunker, which will be the combustion chamber. It just can be cut out of a used gas cylinder. Here you should be careful and fill the container with water before working with the cylinder so that the remaining gas does not accidentally explode. We cut off the upper part, and make the rest a combustion chamber.

The next step is to create a box for the distribution of oxygen. Its installation takes place behind the body. At the outlet of it, a check type valve is installed.

The grate is made of cast iron. The penultimate stage will be the creation of a device for supplying oxygen and a gas outlet. They must be installed at the top and bottom of the gas generator, respectively. And the last step will be the installation of the chimney.

The device and manufacture of the gas generator

Let us consider in more detail the device of the gas generator. In addition to the case, inside which is located the main part of the elements, the design includes:

- bunker (chamber for loading fuel);

- combustion chamber (this is where the process of smoldering of wood takes place at high temperatures and with a minimum air supply);

- the neck of the combustion chamber (here cracking of resins occurs);

- air distribution box equipped with a check valve;

- lances (calibration holes, due to which the junction box communicates with the middle part of the combustion chamber);

- grate (serves as a support for smoldering fuel);

- loading hatches equipped with sealed covers (the hatches in the upper part are required for loading fuel, in the lower part - for cleaning the unit from accumulated ash);

- outlet pipe (flammable gas exits through it and enters the welded pipe of the gas pipeline);

- air cooler (in the form of a coil);

- filters for cleaning the mixture of gases from unnecessary impurities.

The gas generator circuit may include a fuel drying system. For pyrolysis to be effective, the firewood must be dry. If a part of the gas pipeline runs along the ring around the fuel loading chamber (between the walls of this chamber and the housing), damp firewood will have time to dry before it enters the combustion chamber. This will significantly increase the efficiency of the installation.

The body of the gas generator is made of a metal barrel, on top of which a pipe is attached to the seal with corners and bolts, and a propane cylinder is attached to the bolts from the inside

The body of the gas generator is made of a metal barrel, on top of which a pipe is attached to the seal with corners and bolts, and a propane cylinder is attached to the bolts from the inside

Before you make a gas generator, you need to find information about a suitable device model and detailed drawings indicating the dimensions of all elements.

Particular attention is paid to the choice of materials for each of the structural elements. The gas generator can have a rectangular or cylindrical shape - the body is usually welded from sheet metal or a metal barrel is used

The bottom and cover must be made of steel sheet with a thickness of 5 mm.

The hopper, which is bolted inside the hull, shall be made of mild steel. The combustion chamber is made of heat-resistant steel, you can use an empty bottle of liquefied propane.

The gas cylinder is installed inside the barrel and bolted to its top.

The gas cylinder is installed inside the barrel and bolted to its top.

The lid of the bunker should be equipped with a reliable seal made of heat-resistant material (asbestos cord with graphite lubricant). A refractory insulator (asbestos cord or similar material) is laid between the neck of the combustion chamber and the body. It is more convenient to make the metal grate of the grates removable, from reinforcing bars, so that it is more convenient to clean the combustion chamber.

A pipe is attached to the bolts on top of the barrel

A pipe is attached to the bolts on top of the barrel

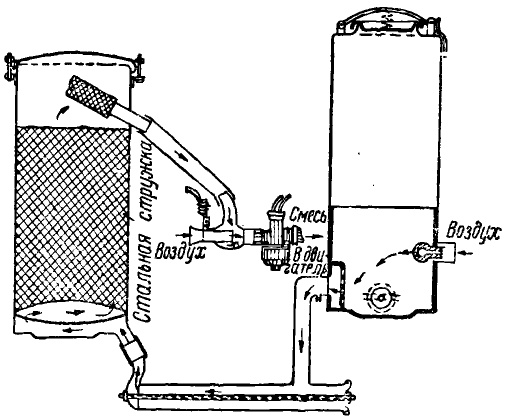

The air distribution box with a non-return valve at the outlet is installed outside the housing, in front of it you can mount a fan that blows air to increase the efficiency of the unit when working on freshly cut wood.

Blower fan to help improve efficiency

Blower fan to help improve efficiency

As an air cooling coil, some craftsmen fit a steel or bimetallic radiator. The mixer, passing through which the purified combustible gas is mixed with air, is equipped with a fan.

When choosing materials for a fixed installation designed to generate electricity for domestic use, the emphasis is on reliability and affordability. If you want to make a gas generator for a car, preference should be given to stainless steel - this will make the unit lighter and more compact. But the use of stainless steel significantly increases the cost of construction.

Conclusion

The compact wood-fired gas generator is suitable for installation on a truck or car. The unit for a local power plant can be installed in the basement of a house, in an outbuilding, or, if necessary, installed on the street or under a canopy (when it is necessary to provide electricity to any stationary electrical equipment).

The fundamental issue is the correct operation of the gas generator.In order for the unit to function with high efficiency, it is necessary to carefully adjust the level of air supply (taking into account the moisture content of the fuel), the intensity of the exhaust gases, etc. It is desirable to manufacture a gas generator according to professional drawings, in compliance with all sizes and proportions.

Related video:

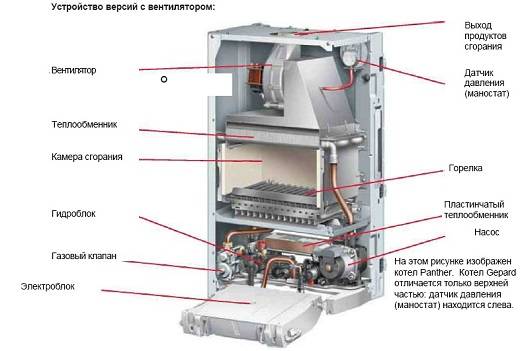

What air heating equipment is the best

Buyers have many questions regarding the long-burning stove: how choose the best model or development, where the catch can lurk? All models of this type of equipment have their own advantages and disadvantages. The choice must be made based on the requirements of a particular room.

Butakov oven, design.

Butakov's heating device. This is a long burning convection oven, which has the following structure:

- steel or cast iron body;

- combustion chamber;

- ash pan;

- convection pipes that run throughout the chamber;

- door with convector;

- chimney;

- adjusting gate.

Compared to the Canadian analogue, the furnace of the Butakov furnace is not divided into two chambers. However, this fact does not affect the performance of the instrument. Thus, the efficiency of Butakov's heating equipment reaches 80-85%. The principle of operation of the Butakov furnace, like all air heating devices, is based on two phenomena: pyrolysis and convection.

Pyrolysis takes place directly in the combustion chamber, where firewood is laid. Under the action of high temperature and in an environment of insufficient oxygen, organic matter decomposes into gas and water. The latter comes out with combustion products.Carbon monoxide and a mixture of other wood derivatives in the upper part of the chamber ignite, as secondary, heated air is supplied there. The temperature of the upper part of the Butakov furnace furnace is much higher compared to the lower part, and therefore is often used for cooking.

Air convection passes through the pipes. They are located in the upper part of the furnace at a certain distance from each other and at the right angle. Such a device device provides the fastest possible passage of cold air from the lower part of the room and its maximum heating. Air convection also occurs through the appliance door. There you can see the corresponding holes.

Butakov's long-burning metal furnace has a significant advantage over other models of similar devices. Its chimney is located in such a way that condensate does not accumulate in the tank, but flows down the walls of the pipe, falling into the combustion chamber, where it burns.

The principle of operation of the Buleryan long-burning furnace.

What is a Buleryan oven. If we compare Butakov's and Buleryan's long-burning furnaces, then the second one has two chambers in the furnace section, which improves its efficiency. Thus, the efficiency of Buleryan heating equipment reaches 85-90%. In addition, today there is a Buleryan-Aqua furnace for sale, which is suitable for servicing a water heating system.

The device has the following structure:

- oval body made of steel or cast iron;

- collectors;

- injectors;

- upper combustion chamber;

- lower combustion chamber;

- chimney with damper;

- door with gate;

- ash pan.

These are the most efficient long-burning stoves, since their original design allows you to blow air into the convector with injectors without the help of an electric fan. Natural air circulation occurs due to a noticeable temperature difference at the inlet and outlet of the tubes. It is about 120°C.

Tying the furnace Buleryan-Aqua with a water jacket.

Air ducts can be connected to the oven convectors. This makes it possible to heat adjacent rooms. In conditions of elevated air temperature, which circulates through the pipes, it is recommended to use aluminum ducts. However, no one has canceled heat loss, and therefore the consumer, wanting to increase the efficiency of heat transfer, is obliged to insulate the ventilation wiring.

Another feature that characterizes cast iron long-burning heating furnace Buleryan-Aqua is the ability to connect to it water heating circuit. The furnace is mounted in the heating system of both open and closed type. To do this, the pipes are connected to the convectors of the heating equipment. And now it is not air that circulates through the pipes inside the furnace, but the water of the heating circuit. Such wiring has one significant disadvantage - cold water cools the combustion chamber. As a result, the efficiency of the furnace also decreases, as a result of which the amount of energy carrier used increases.

The disadvantage of the device is the accumulation of condensate in a special container. Also, when using an energy carrier with a high percentage of moisture, oily deposits form on the inner surface of the chimney. They harden over time, making cleaning difficult.

In addition to the above options, experts advise to build long-burning stone stoves for a summer residence or a country house. How it works and how it works are described in the video:

Valuable information on gas generators

Sometimes the expectations of owners of private houses who are thinking about purchasing or making their own gas generator turn out to be too rosy compared to the real situation.

There is an opinion that the efficiency of a gas generator, which is about 95%, significantly exceeds the efficiency of a conventional floor-standing gas boiler, which reaches 60-70%. These figures are generally correct, but it is incorrect to compare them.

In the manufacture of a home-made gas generator, used gas cylinders, cans, kitchen utensils, etc. are used. A practically free device economically consumes not the most expensive fuel with a fairly high performance

The first indicator reflects the efficiency of combustible gas production, and the second - the amount of heat received during the operation of the boiler. In both cases, wood is burned, but the result of this process is qualitatively different. If in the future the combustible gas obtained by the pyrolysis combustion of wood is used to heat the dwelling, such a comparison can be made.

It is also worth remembering that homemade gas generators, although they can work with high efficiency, are rarely as effective as industrial models. This point should be taken into account at the stage of designing the unit and calculating the cost of the project and its expected efficiency.

If the need to create a gas generator is due only to the desire to improve the heating system at home, you should pay attention to a similar device - a pyrolysis boiler that works on very similar principles. Its main difference from the gas generator is that the resulting gas is immediately burned, and the energy obtained is used to heat the coolant in the home heating system.

In such a device, an additional combustion chamber is mounted, into which it is necessary to organize a separate air supply. If you need to heat the house with a gas generator, you will also need to choose a convector for heating. This will increase the cost of upgrading or arranging heating. It is necessary to calculate whether in this case the game is worth the candle?

An important point is the correct maintenance of the gas generator during its operation. Advertising claims that this is a universal device in which everything burns: from sawdust to freshly cut wood.

But the advertisement is silent about the fact that when loaded with wet raw materials, the amount of combustible gas produced can be reduced by 25% or more.

The best fuel for a household gas generator is charcoal. When it is burned, too much energy is not spent on the evaporation of excess moisture, which allows you to get the maximum amount of combustible gas

The optimal fuel for the gas generator, according to experts, is charcoal. When it is burned, the evaporation of moisture takes a minimum amount of energy, which makes it possible to accelerate the pyrolysis processes.

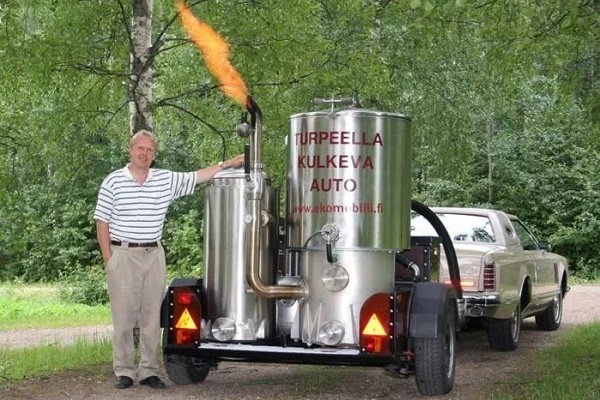

Vehicle owners can rely on a gas generator not only for heating, but also for the operation of their vehicle.indeed, in Europe, quite a few motorists have quite successfully adapted their vehicles to work on wood. But most often these are compact and durable devices made of thin and durable stainless steel.

The cost of such units, even made independently, is not at all small. In Russian realities, gas generators for cars are made from improvised means and installed on trucks.

The effect of their work is low, usually the presence of such a unit is accompanied by such phenomena as prolonged ignition, the need for constant engine operation at high or medium speeds, which contributes to its rapid wear.

For a car, it is best to use a high-quality gas generator made of durable stainless steel, which has a relatively small weight and compact dimensions.

An interesting option for using a gas generator in private households is the use of combustible gas for a home power plant. Such a project is implemented using a diesel internal combustion engine.

The principle of operation of wood gas generators

The rapid burning of firewood in the open provides mainly some useful heat. But wood behaves quite differently during the so-called pyrolysis combustion, i.e. burning in the presence of very little oxygen.

In such a situation, not so much burning is observed as smoldering of wood. And the useful product of this process is not heat, but combustible gas.

Gas generators were once actively used as a fuel supplier for cars.And now you can occasionally meet machines that run on the gas they produce:

Image gallery

Photo from

For the production of gaseous fuel, not only firewood, all types of coal, straw, pellets, but also practically free woodworking waste are used.

A small unit for generating gas and a gas mixture is freely placed in the trunk of a small passenger car

A generator that can fully cover the needs of a car is more suitable for trucks. To provide a small car, it is most often installed on a trailer

Gas generator use in vehicles

Advantages of installing gas generators on a car

The location of the generator in the trunk of a small car

Application of productive generating systems

With slow burning of wood, the output is a mixture containing the following products:

- methane (CH4);

- hydrogen (H2);

- carbon monoxide (aka CO or carbon monoxide);

- various limiting carbohydrates;

- carbon dioxide (CO2);

- oxygen (O2);

- nitrogen (N);

- water vapor.

Only a part of these ingredients are combustible gases, the rest is pollution or non-combustible ballast, which is better to get rid of. Therefore, it is necessary not only to burn the tree in a special installation, but also to clean the result, as well as to cool the resulting gas mixture. In industrial production, this process includes the following steps:

- Combustion of solid fuel in the presence of a small (about 35% of normal) amount of oxygen.

- Primary rough cleaning, i.e. separation of volatile particles in a cyclone vortex filter.

- Secondary rough cleaning, in which the gas is cleaned with a water filter, a so-called scrubber-cleaner is used.

Homemade devices for home use look simpler and take up less space, but the principle of their operation, as well as the design, are very similar. Before starting the manufacture of such a device, it is necessary to think over everything well, as well as draw up or find a project for the unit.

On the Internet, there are many recommendations on how to make a homemade wood gas generator. Some of them are equipped with drawings that are quite real for implementation.

Masters who have already managed to some extent to carry out this exciting process, note that it may take a lot of time and effort. It may be necessary to perform more than one alteration and carry out a number of experiments in order to obtain an aggregate with acceptable characteristics.

Advantages and disadvantages

To understand the full benefits of a long-burning unit, consider the advantages that the device will bring to its owner:

High efficiency - up to 95%. This means that the consumption of formed fuel is justified - the gas burns completely, without losing extra calories to the atmosphere.

- Long burning time. This feature frees owners from the constant loading of fuel, and with automatic settings, from constant monitoring. However, handicraft wood-fired boilers are no different and care is needed. In the case of a bright head of the owner, arranging security automation is not so difficult.

- Use of any kind of fuel. Only the material used in the construction of the unit will depend on it - home-made long-burning boilers on wood are made of thick iron, on coals alloyed steel or cast iron is already required.

- The amount of harmful substances entering the atmosphere of the house is minimized due to the tightness of the structure and the rare loading of fuel - the latter is put into the gas-generating boiler only after the previous portion has completely burned out.

The main criterion for choosing a unit for heating by owners of private houses is obvious efficiency. Benefit is derived from any garbage that has the ability to burn, firewood may not be needed. Infrequent loadings allow saving on wood fuel, which is required 3-4 times less than a standard stove. Thanks to stable operation, the heat of the house is kept at the same level - there is no need to heat the frozen rooms and, accordingly, spend a certain amount of raw materials on heating.

Cons: schematic

Unfortunately, gas generation is not possible without forced ventilation, therefore, a wood-burning boiler for heating is considered energy-dependent, since a fan is used. During power surges, it is impossible to leave the boiler unattended, so the problem is solved by connecting an uninterruptible power supply - a device that supplies the accumulated electricity.

It is important to maintain a working wood-burning gas generator in a given mode in a timely manner - a decrease in power leads to the formation of tar that settles on the walls of chambers, gas ducts and furnace doors. Therefore, when choosing a factory unit or assembling your own design, it is important to take into account the needs and not purchase an overly powerful boiler for use. DIY drawing

DIY drawing

According to the previous paragraph, the temperature of home heating should not be less than 60⁰С.If this becomes a problem for the owners - a small room, a summer house, intolerance to heat - you should purchase a different solid fuel boiler, and not a wood-burning generator.

Criteria for choosing a gas generator

Air-cooled generators can run 6-20 hours, which is the manufacturer's recommended time. Of course, at first, he will be able to work more, but you don’t need to overdo it, otherwise he may soon fail.

If you let the generator cool down, you can start it after a few hours. Therefore, when choosing a generator, one should not confuse them with power plants that are liquid-cooled and can work continuously.

In the event of an unexpected complete power outage, the gas generator should serve as a backup power source. Therefore, you need to calculate its power, depending on which devices should be connected to it, and then look for a suitable model for just such parameters.

Also, when choosing a gas generator, you should pay attention to what gas will be used there, what pressure, where you want to put it, whether an autostart system is needed

What wood is needed for the generator

Any standard options for conventional ovens are suitable here. It can be wood chips, branches, firewood and even wood waste. The main firewood must be the right size. To simplify the process of chopping firewood to the desired size, an unusual tool for chopping firewood will help - the standard kolundrov wood splitter. Such a wood splitter is safe, because it is simply impossible to get hurt by a wood splitter. The splitter is suitable for use by almost anyone who wants to practice chopping wood, including the elderly and women. The principle of operation is extremely simple.

It is enough to place the log in the ring of the cleaver and hit from above with a sledgehammer or something heavy. Unlike an ax, the impact force is concentrated in one place, which inevitably leads to a split even of damp and knotty logs. Heating the house is no longer a problem, as even a pensioner can handle chopping firewood with a good kolundrov wood splitter. Also, wood-burning generators have become common equipment for modern fishermen and hunters, summer residents and hikers. After all, it is not very convenient to completely abandon civilization in the forest. The selection and purchase of a wood splitter for any type of generator will greatly simplify the process of preparing the necessary fuel and will take much less time.