- COST OF SERVICES FOR APPROVAL OF GAS WORKS

- ADVANTAGES OF WORKING WITH ENERGOGAZ Group of Companies

- Autonomous gasification

- Which houses can be connected to gas supply

- SCHEME OF WORK FOR THE DESIGN OF GAS CONNECTION

- REQUIREMENTS FOR GASIZED PREMISES

- Installation of a gas pipeline in a private house

- The price of the turnkey facility gasification service

- Design requirements

- Commissioning work

- Gasification of industrial facilities: goals and objectives

- Gasification of industrial facilities on a turnkey basis

- Terms of use and provision

- CONNECT GAS, GASIFICATION IN GREATER MOSCOW

- How to order the design of a gas supply section and not make a mistake

- COST OF SERVICES FOR APPROVAL OF GAS WORKS

- ADVANTAGES OF WORKING WITH ENERGOGAZ Group of Companies

- Features of gasification of residential buildings

- Types of gas supply

- Preparation of Specifications

- The application must include the following information:

- The following documents must be attached to the application for the issuance of technical specifications:

- Conclusions and useful video on the topic

COST OF SERVICES FOR APPROVAL OF GAS WORKS

Energogaz Group of Companies, performing gasification and gas supply on a turnkey basis, without fail coordinates projects in all necessary organizations and authorities.The principle of work based on the result opens up wide opportunities for cooperation.

In practice, the approval service is an indispensable part of the entire range of works, so our company, as part of a long-term partnership, provides it free of charge. In addition, we always strive to fulfill our obligations as soon as possible. The price of the service is a strong long-term mutually beneficial cooperation. At the moment, we have already agreed on more than 500 projects.

ADVANTAGES OF WORKING WITH ENERGOGAZ Group of Companies

The extensive capabilities of the ENERGOGAZ group of companies make it possible to implement any projects from a simple coordination of the installation of a boiler to a large-scale gas connection to a settlement.

The baggage of our experience includes the coordination of such complex projects as the laying of a gas pipeline through the lands of the forest fund with the intersection of water barriers and railway lines. We can offer a well-established scheme of interaction with all operating organizations in Moscow and the Moscow region.

Autonomous gasification

The concept of Gazprom's participation in the gasification of Russian regions implies a differentiated approach to gasification, taking into account the availability of natural gas reserves in the regions and the development of existing ones, as well as the possibility of using alternative energy sources, including liquefied and compressed natural gas (LNG and CNG), liquefied petroleum gas (LHG ).

Particular attention is paid to the gasification of small settlements remote from main gas pipelines, which is especially important for rural areas. In 2014, Gazprom implemented the first autonomous gasification project, building an LNG complex in the Perm Territory. The complex included a mini-plant for the production of LNG in the village ofKanyusyata (Karagai district), as well as three stations for receiving, storing and regasifying natural gas

The capacity of the complex is 19 million cubic meters. m of gas per year

The complex included a mini-plant for the production of LNG in the village of Kanyusyata (Karagai district), as well as three stations for receiving, storing and regasifying natural gas. The capacity of the complex is 19 million cubic meters. m of gas per year

In 2014, Gazprom implemented the first autonomous gasification project, building an LNG complex in the Perm Territory. The complex included a mini-plant for the production of LNG in the village of Kanyusyata (Karagai district), as well as three stations for receiving, storing and regasifying natural gas. The capacity of the complex is 19 million cubic meters. m of gas per year.

LNG complex in the Perm region

Enlarged photo (JPG, 405.4 KB)

In the Tomsk region, it is planned to build five facilities: a low-tonnage complex for natural gas liquefaction with a capacity of 7 tons per hour and four receiving, storage and regasification stations.

Which houses can be connected to gas supply

Centralized gas supply provides for the transportation and delivery of natural gas to the consumer. Connecting a capital structure to a gas main includes two stages - organizational and technical actions. The set of organizational measures includes the preparation and collection of the necessary technical documentation, the filing of an application for gasification and the conclusion of an agreement in the event of a positive decision by the gas service.

Technical actions: connecting the gas main to the land, connecting the house to the gas distribution network, installing a gas meter and starting gas.

Gasification of a residential building is clearly regulated by law.According to Government Decree No. 1314, gas connection is allowed to capital construction facilities. If residential, country or garden houses, as well as garages and utility buildings have a strong connection with the ground, that is, they are installed on the foundation and registered as real estate, then there will be no problems with their connection. In any other case, gasification will be denied. An attempt to connect gas supply to non-capital construction facilities is prohibited by law and, depending on the consequences, is punishable by a fine or criminal punishment. In an apartment building, gas is connected to the entire house. To connect capital buildings located on the territory of garage cooperatives, gardening or summer cottages, an application for technological connection is submitted by the owner of the territory.

SCHEME OF WORK FOR THE DESIGN OF GAS CONNECTION

1. Residential building gasification project (for individuals):

- selection of a place for laying an underground gas pipeline;

- selection of places for distributing internal gas pipelines;

- equipment selection;

- selection of equipment locations;

- implementation of a preliminary design, coordination with the Customer;

- drawing up a working draft;

- approval of the working draft.

For a gasification project for a residential building, it is necessary to provide a plan of the gasified house, technical specifications and engineering and geodetic surveys (if you did not order a comprehensive service).

2. Project of gasification of a settlement, an industrial facility:

- analysis of a possible place for laying a gas pipeline route, including preliminary coordination with executive authorities, local governments, operating services, determination of private land ownership;

- performance of engineering-geodetic and engineering-geological surveys, if necessary, passing the state examination, in accordance with the legislation on urban planning, additional engineering and environmental surveys are carried out;

- execution of design work;

- coordination of the project with executive authorities, local governments, operating services;

- passing the state examination, in accordance with the legislation on urban planning;

- obtaining permission to place an object in the Moscow region or an urban planning plan for a land plot in Moscow.

REQUIREMENTS FOR GASIZED PREMISES

Today it is difficult to say what specific requirements apply to the premises in which the installation of gas-consuming equipment is planned. There are at least four regulatory documents.

One of the regulatory documents (SNiP 41-01-2003 "Heating, ventilation and air conditioning") states that in the case of installing a gas boiler with a closed combustion chamber, a room volume of at least 7.5 m3 is required and does not regulate the need to install a ventilation duct in the room ( natural ventilation), while another regulatory document (SNiP 42-01-2002 "Gas supply") requires a room of at least 15 m3 and 6 m2, and according to fire safety rules (SNiP 21-01-97 * "Fire safety of buildings and structures ”), in all rooms where gas-using equipment is installed, a ventilation duct must be provided to ensure three air exchanges per hour.

Also, each manufacturer indicates its requirements for the installation of gas equipment, most often they are associated with the conditions for its further operation.

This is not a complete list of all requirements. It is impossible to develop one unified scheme for the gasification of any facility.

Therefore, the first step of ENERGOGAZ Group of Companies in gasification is a survey of the gasified object. There are no houses that cannot be gasified!

Installation of a gas pipeline in a private house

The connection fee obliges the contractor to bring the gas distribution network to the connection point and prepare the facility for gas launch no later than the terms established by the contract. Wiring of communications on the site and inside the applicant's house is paid separately. If these works are carried out by specialists of the gas distribution organization, then their cost will be calculated at tariff rates. To save time for work within the boundaries of the site and inside the capital structure, third-party companies can be involved. In this case, payment is charged at market prices.

Installation of the meter when entering gas into the house from the outside

If a gas distribution network is laid to the border of the site, installation work to conduct gas to a private house for citizens of the first category must begin no later than 9 months after payment for technological connection. The connection of the house to the gas pipeline must be completed within 10 days from the start of work.

The final stage of installation work is the installation of a meter, the connection of gas appliances, checking the system for possible leaks, checking ventilation and control start-up of gas.These works can only be carried out by GDO employees. After that, an act of readiness is signed, the owner of the house receives a technical supervision receipt, and the documents are again sent to the gas distribution organization. Within three weeks, Gorgas workers should come and seal the gas meter. Then a gas supply agreement is concluded with the consumer and the capital structure is included in the gas supply system. These relations are regulated by Government Decree No. 549.

Insertion into the central gas pipeline for connecting a residential building

The price of the turnkey facility gasification service

The cost of gas connection and work to create a gas supply system for a capital construction object depends on the specific project. Here are some examples from the practice of our company.

1. Gasification of the settlement (SNT, DNP, etc.).

The main factors are the distance from the gas distribution pipeline to the gasified facility, as well as the length of public networks

The number of facilities involved in gasification is also important, because the total cost of work is divided by all

members. If the complex gasification of SNT for 250 sites costs 18,000,000 rubles, then with the participation of all members of the SNT, the cost of creating common networks will be 72,000 rubles and about 220,000 rubles for work on a private site

As a result of gasification work

will cost 300,000 rubles for each site. With the participation of a limited group, for example, 50 people, the cost per site will increase (360,000 rubles for general networks and 220,000 rubles for the private sector). The total amount in this case will be

figure of 700,000 rubles.

In order for all gasification participants to get a clear idea of the upcoming work and prices, we send a responsible representative of the company to the general meeting of members, where he will be able to answer in detail all the questions of the interested

sides.

2. Industrial and commercial facilities.

In this matter, the cost of connection services (technological connection) plays an important role, which depends on the maximum hourly consumption planned for the installation of gas-using equipment. You can refer to the following

formula:

x 30,000 rubles.

If it is necessary to perform work in difficult conditions, the calculation is made according to increased indicators, after which a state examination of the estimated cost is carried out.

The cost of work on the applicant's site is always determined on an individual basis, taking into account the specifics of the project. For the most part, the price depends on the parameters of the network (length, diameter, pressure, etc.), as well as on the characteristics of the technological

equipment. It is worth noting that you can save on equipment if gas is used for domestic purposes. In the event of a failure, the repair takes no more than 8 hours, and during this time, even in a harsh winter, a warm room will not freeze through.

If gas is used at the enterprise in the technological process, then the savings are unacceptable!

3. Residential, country and other types of private houses.

The estimate for gasification services at home consists of the cost of the following works:

-

— Conclusion of an agreement for technological connection with a branch of Mosoblgaz JSC. Total cost: 50,000–65,000 rubles, including tie-in, gas launch into the system, as well as design and construction of a gas pipeline from a distribution

source gas pipeline to the site. -

– Engineering and geodetic surveys (topographic survey) and design work on the site. Total cost: 35,000–40,000 rubles, including the cost of approval in all instances.

-

— Construction and installation works. Estimated cost: 120,000–200,000 rubles, taking into account the cost of earthworks, as well as all materials and equipment (excluding the cost of a gas boiler and stove). In this case, on

the price is more influenced by the distance from the house to the gas pipeline, as well as the amount of work on laying the distributing gas pipeline around the house. An important factor is the pressure in the source gas pipeline: at low pressure, the cost can be reduced by 30,000

rubles.

Design requirements

The only essential condition that must be observed unquestioningly is the full compliance of the project with the requirements of regulatory documentation. Experienced professionals are well aware of these rules and have come across them in practice more than once.

The only essential condition that must be observed unquestioningly is the full compliance of the project with the requirements of regulatory documentation. Experienced professionals are well aware of these rules and have come across them in practice more than once.

For each project, you need to thoroughly study the points of the norms again and again. The requirements for gas networks may differ depending on the construction conditions, the method of laying the gas pipeline, the type of equipment installed, and many other things.

If the designer does not follow at least one essential rule, the project will not pass the test and will be returned for revision. Specialists of the technical department of gas services thoroughly check the documentation. Therefore, the approval of the project can sometimes take a whole month.

Watch the video, which discusses the negative consequences of violating the design scheme for gas supply to a residential building:

Commissioning work

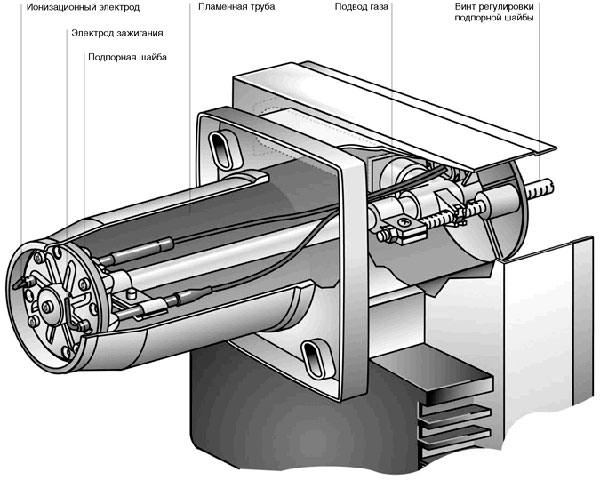

According to the agreement, the complex gasification of a country house includes commissioning for gas control points, heat generators with gas burners, all types of boilers and infrared gas emitters.

Gasification of the house at this stage includes:

- checking the correct installation of gas equipment;

- system tightness control;

- adjustment of units and units;

- switching on equipment and starting gas;

- checking and setting up a gas boiler in all modes of operation;

- taking indicators for drawing up an act of acceptance.

At the time of commissioning and acceptance by a representative of the gas service, the heating system must be ready for operation. The service company prepares and submits the executive documentation for the gasified area to the local gas service.

Gasification of industrial facilities: goals and objectives

For an emerging, modernized, scalable enterprise, thermal and energy supply is vital. It is impossible to do without the organization of a system of centralized or autonomous gasification. Gas is chosen just because it is the most economical way against the background of all possible options for generating energy.

- The company offers complex individual solutions.

- Turning to us, you get the whole range of services (separately and on a turnkey basis) - from the design of gasification facilities to installation and maintenance.

A well-built system allows a comprehensive solution to the problem of gas supply of any scale and complexity. Gas is traditionally used as the main coolant. If it is necessary to supply it uninterruptedly, we include the organization of backup gas supply in the project.

- As a rule, these are autonomous systems designed for force majeure situations, repair and other events of a temporary or periodic nature.

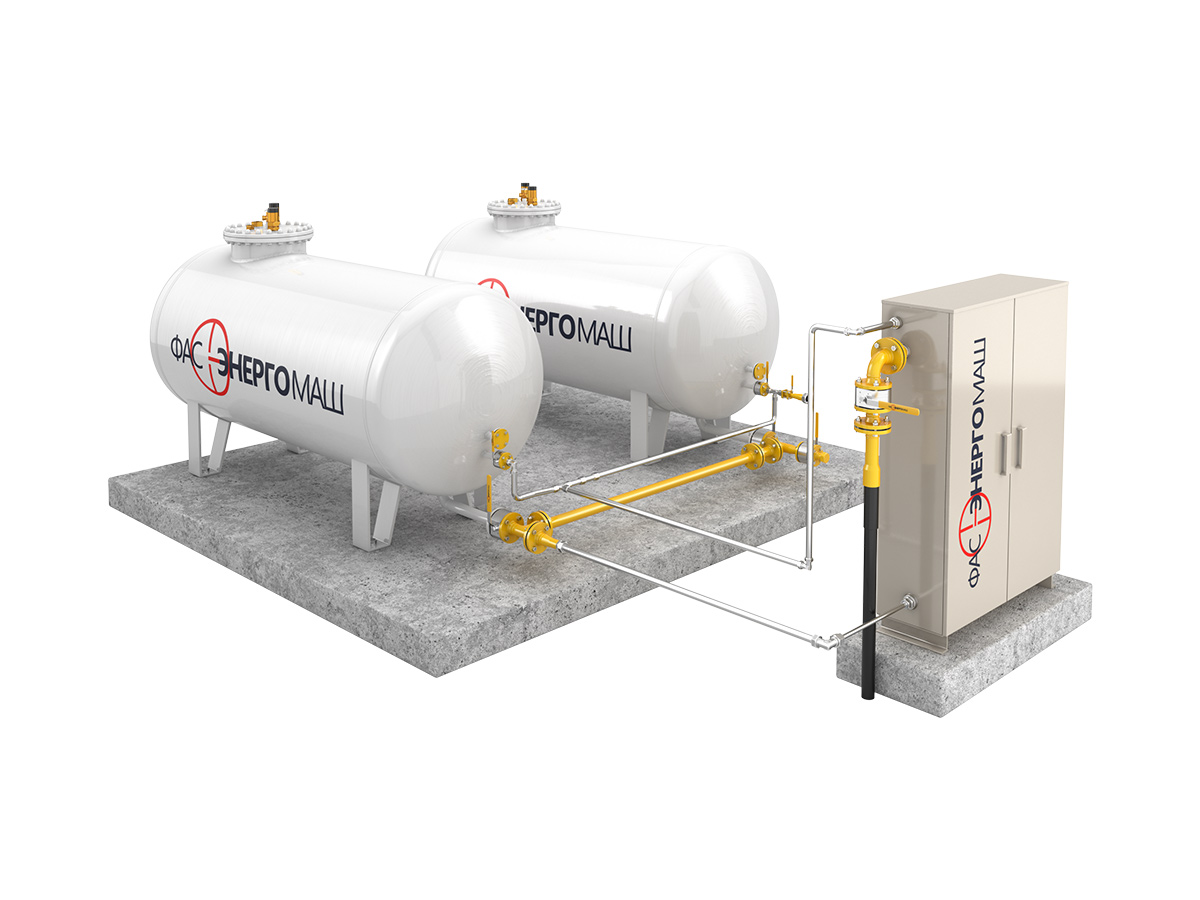

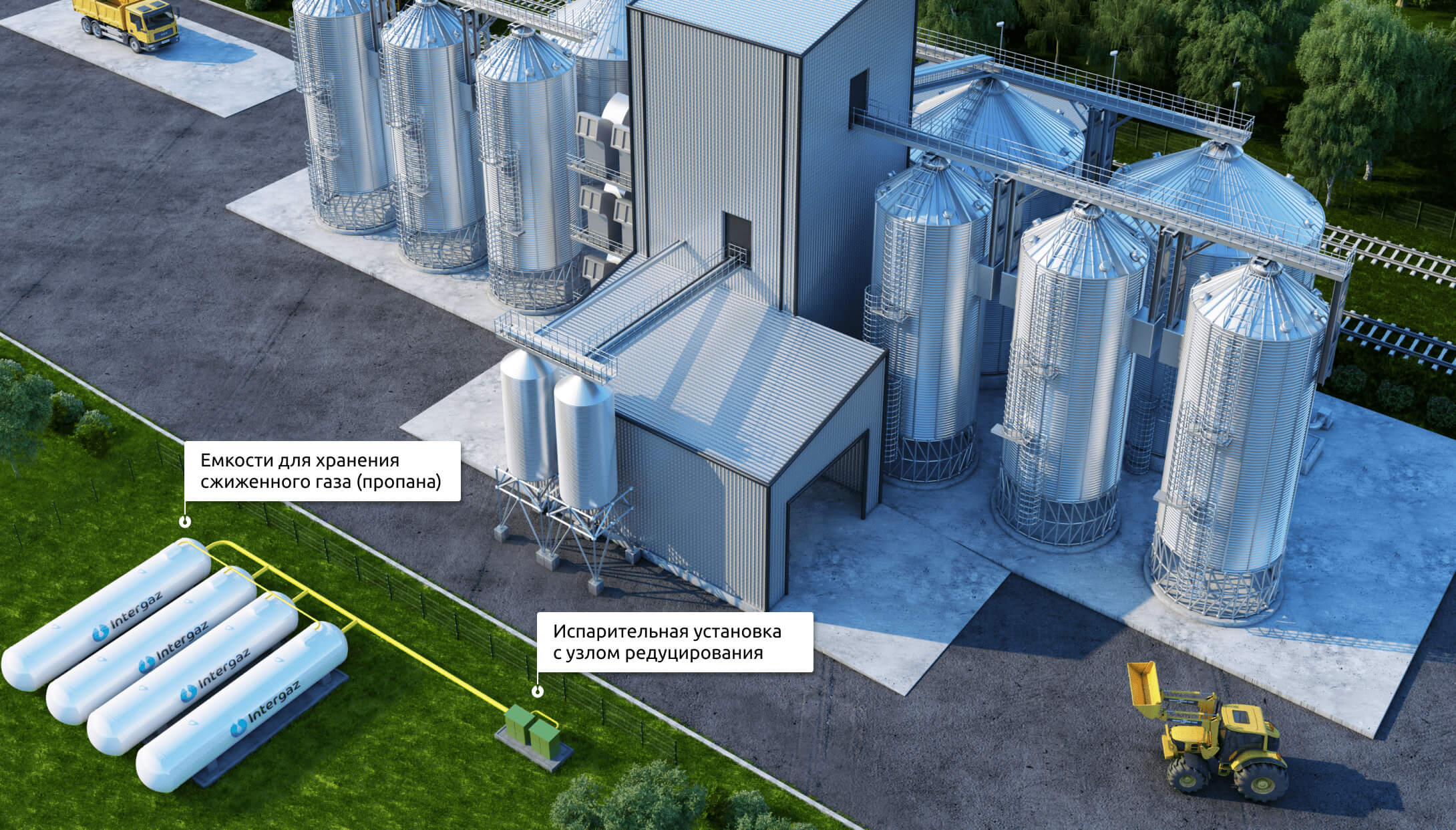

- Liquefied gas storage tanks are formed taking into account the tolerances, norms, rules, laws in force on the territory of the Russian Federation to ensure maximum safety of the facility and its environment.

- At the same time, clear calculations are required not only for equipment and automation of switching for the smooth operation of industrial facilities, but also for taking into account maximum loads.

Reserve gas supply is necessary for almost all enterprises. It involves the supply of coolant from gas tanks to prevent economic and production losses. They are possible not only in emergency situations, but also during regular, planned activities related to:

- repair or scaling of systems;

- connection of new equipment;

- transfer to other communications, etc.

The main losses occur in cases of unforeseen interruption of fuel supply through the centralized supply line, but even planned events, even well-prepared and carried out in the shortest possible time, can cause business losses. We all take this into account. For each object we find individual design solutions.

Gasification of industrial facilities on a turnkey basis

At present, in general, all companies prefer to order not individual services, but gasification of turnkey facilities. This is not only convenient, but also the most reliable, safe, and guarantees the longevity of the built-in gas supply systems of an industrial enterprise.

For our customers, we are ready to perform work of any complexity, to solve issues of gas supply to enterprises in a complex. The presence of our own qualified specialists (engineers, designers, installers and representatives of other specialties) allows our organization to independently:

- design and prepare project documentation;

- carry out the installation of technological equipment;

- carry out commissioning works;

- offer further maintenance of the created gasification systems for industrial facilities.

Consultations are carried out by masters free of charge. Please contact us regarding the gasification of your enterprise by phone or online.

Terms of use and provision

Organizations using gas equipment must:

- comply with the requirements of the law of the Russian Federation;

- keep the equipment in good condition;

- ensure its maintenance;

- keep records of consumed gas consumption;

- have reserve fuel systems ready, which, if necessary, are ready to work instead of gas equipment;

- have special regime cards and operate in accordance with them;

- comply with the instructions of regulatory authorities;

- comply with other legal requirements.

The heads of organizations are responsible for the fulfillment of all requirements stipulated by the Rules.

Control over the use of gas is assigned to the Ministry of Energy. Equipment must be in legally acceptable condition and have all necessary permits in order to provide appropriate services.

Gas supply projects are developed on the basis of the fuel regime and technical conditions for the use of gas and the connection of a pipe to the corresponding system. They are subject to mandatory registration within 24 months.

After carrying out the necessary work, the gas is launched on the basis of an act on the readiness of the equipment networks of the facility for connection. It is issued by the regulatory authority after the inspection of the equipment. The survey is carried out within 10 days from the date of notification by the organization of the controlling body of the completion of work.

CONNECT GAS, GASIFICATION IN GREATER MOSCOW

ENERGOGAZ group of companies offers the following services:

- Comprehensive work on gasification in New Moscow (Greater Moscow), Troitsky, Novomoskovsky districts.

- Conduct and connect gas to a private house, commercial facility or settlement (including villages, villages).

- Legal support, registration of all rights for settlements, SNT and DNP.

If necessary, you can order gas equipment from our company. Our specialists carry out:

- Assistance in the selection of a suitable gas boiler.

- Delivery of the selected gas boiler to the areas of New Moscow (Greater Moscow), the Trinity District.

- Installation of gas equipment in accordance with all manufacturer's requirements.

- Repair and maintenance of gas equipment.

How to order the design of a gas supply section and not make a mistake

When planning the repair or installation of a gas supply system, choose only experienced, reliable and qualified specialists. Study examples of previous work, clarify the specialization of the designer and organization before concluding a contract.Keep in mind that it is better to immediately correctly and accurately form the terms of reference, determine the types of work to be done and the requirements for equipment, than to spend time and money on reworking the project.

Smart Way is one of the leaders in the design of residential, industrial and other facilities. When ordering design from us, you will always receive a guarantee of the quality of documentation, support for approvals and permits.

Watch this video on YouTube

COST OF SERVICES FOR APPROVAL OF GAS WORKS

Energogaz Group of Companies, performing gasification and gas supply on a turnkey basis, without fail coordinates projects in all necessary organizations and authorities. The principle of work based on the result opens up wide opportunities for cooperation.

In practice, the approval service is an indispensable part of the entire range of works, so our company, as part of a long-term partnership, provides it free of charge. In addition, we always strive to fulfill our obligations as soon as possible. The price of the service is a strong long-term mutually beneficial cooperation. At the moment, we have already agreed on more than 500 projects.

ADVANTAGES OF WORKING WITH ENERGOGAZ Group of Companies

The extensive capabilities of the ENERGOGAZ group of companies make it possible to implement any projects from a simple coordination of the installation of a boiler to a large-scale gas connection to a settlement.

The baggage of our experience includes the coordination of such complex projects as the laying of a gas pipeline through the lands of the forest fund with the intersection of water barriers and railway lines. We can offer a well-established scheme of interaction with all operating organizations in Moscow and the Moscow region.

Features of gasification of residential buildings

With the help of gas in the house, you can successfully organize heating, hot water heating, and cooking. Gas equipment is reliable and diverse, and the cost of blue fuel is usually lower than the use of electricity, solid or liquid fuel for the same purposes.

In addition, gas lines fail extremely rarely, but power outages are common. Stocks of firewood, coal, diesel fuel and other similar energy carriers have to be constantly replenished.

The main problem with natural gas is its danger to human health and its ability to explode. Even a small leak can lead to poisoning or an explosion. That is why the requirements for the installation of gas communications are very high, you should not even think about doing all the work yourself.

In order to properly introduce gas into a private house, a special unit is used, which is called a reducer for reducing gas pressure.

To begin with, experts do not recommend saving on materials or system elements. Pipe laying of dubious quality and unprofessional installation are unacceptable.

Gas pipes almost always need to be laid in an open way (except for underground sections of the highway). They cannot be hidden under any decorative elements to improve the interior.

It is not recommended to introduce a gas pipe into the house through the thickness of the foundation; for this purpose, a hole is made in the outer wall and a sleeve is inserted into it for protection

It is recommended to avoid plug connections whenever possible. All places where pipes are connected must be located in such a way that at any time the point of contact can be examined and repaired if necessary.

Do not lay gas pipes inside the walls or in the thickness of the foundation. This rule also applies to other elements such as architraves, door frames, window frames, partitions, etc.

In some cases, it is allowed to lay a gas pipe in a wall niche, but this point must be clearly reflected and justified in the project. Special requirements are also imposed on the slope of the pipes. Horizontally, the position of the line is allowed to deviate by only 3 mm towards gas appliances.

Vertically, no deviations are allowed, but the riser may have a slight slope: no more than 2 mm per meter. It should not pass through living quarters, through a toilet or bathroom. The gas riser should be located in the stairwell, often through the kitchen.

You will also have to carefully monitor the installation of shut-off valves. So, the position of the central axis of the plug must be strictly parallel to the wall along which the pipe runs. When choosing the position of the valve, make sure that the position of the locking device is not blocked by the wall. From the ceiling and from the walls, the gas pipe should be located at a distance of 100 mm.

Gas pipes are fixed along the wall not close, but at a short distance so that communications remain available for routine inspection and repair

The gap between the wall and the pipe can vary from the size of the pipe radius to a limit value of 100 mm. This clearance is necessary so that the structure can be easily examined. A distance of 2.2 m should be maintained from the floor. Gas pipes are placed on special strong supports, sagging of the structure is unacceptable.

Therefore, it is necessary to make sure that there are no gaps between the bracket and the pipe. All these important points are taken into account in the design of the gas supply system, which must first be drawn up by specialist engineers.

Gas pipes should be laid at least 30 cm from the electrical panel, and at least 25 cm from open wiring. From the hidden cable should retreat at least five centimeters.

Types of gas supply

Centralized gas supply

When using a system of this type, gas is supplied to individual facilities through a single main (gas pipeline). The project for gasification of houses and other structures according to a centralized scheme does not provide for the creation of separate boiler houses for each point supplying a populated or industrial facility, therefore, users are connected to the main line in a shorter time.

Autonomous gas supply

With this type of gasification of objects, natural gas is supplied from tanks with a propane-butane mixture - gas holders. An autonomous gasification project for a house or other facility may provide for the use of the system as a backup source of heat in case of accidents on the central gas pipelines. Also, this system can be used as regular heating if it is impossible to gasify a building with a connection to a centralized network (if the gasified object is remote, the mains are overloaded, etc.).

Gasification design with this type of system has the following advantages:

- independence of a gasified facility - a gasification project for a private house of this type provides for the creation of such conditions under which the operation of the system does not depend on the level of gas pressure in a centralized main;

- the ability to regulate the volume of gas consumption - autonomous gasification of the cottage and other objects allows you to use the resources of the system in the required volumes, replenishing the gas reserves in the gas tank as necessary;

- durability - the average service life of autonomous gas heating systems for residential buildings and enterprises, subject to the rules of design and operation, is from 30 to 50 years.

Preparation of Specifications

In order to obtain confirmation of the technical feasibility of connection (technological connection) of the capital construction facility to the gas distribution network, it is necessary to send a request for technical conditions.

“In order to increase the openness of information as part of the process of confirming the technical feasibility of connection (technological connection) on the territory of the Samara Region, technical commissions have been established on the issues of connecting applicants to utility networks. To view the rules of procedure for the technical commissions, click here.

Use the map to determine if it is technically possible to connect (technological connection) to your facility.

An application for the issuance of technical conditions must be completed in accordance with the form.

The application must include the following information:

- Name of the Applicant;

- place of residence of the Applicant;

- postal address of the Applicant;

- telephone for communication;

- E-mail address;

- name and location of the capital construction facility that will be connected to the gas distribution network;

- the planned date of commissioning of the capital construction facility (if relevant information is available);

- the planned value of the maximum hourly gas consumption separately for various connection points (if there are several) with justification for the need to connect several points.

The following documents must be attached to the application for the issuance of technical specifications:

- copies of title documents for the land plot on which the capital construction object owned by the applicant (hereinafter referred to as the land plot) is located (will be located), and in the absence of title documents for the land plot during construction, reconstruction as part of the housing renovation program in the city of Moscow - a copy of the layout of the land plot or land plots on the cadastral plan of the territory approved by the authorized executive body of Moscow, except for the cases when technical conditions are provided for the connection of a gas distribution network facility to another gas distribution network;

- situational plan;

- calculation of the planned maximum hourly gas consumption (not required if the planned maximum hourly gas consumption is not more than 5 cubic meters);

- a power of attorney or other documents confirming the authority of the applicant's representative (if the request for the provision of technical conditions is submitted by the applicant's representative);

- a copy of the document confirming the right of ownership or other legal right to the capital construction object, if the construction of the said object is completed;

- the consent of the main subscriber for connection (technological connection) to the gas distribution and (or) gas consumption networks of the main subscriber, as well as the construction of a gas pipeline on the land plot of the main subscriber, if the connection is carried out on the land plot, the owner of which is the main subscriber, in the cases provided for in clause 34 of these Rules;

- documents provided for in paragraph 47 of these Rules, in the event that technical conditions are provided upon assignment of the right to use power;

- a document confirming the ownership or other legal basis for the gas distribution network (when reconstructing the gas distribution network), in the event that technical conditions are provided for connecting the gas distribution network facility to another gas distribution network.

Applications for the issuance of technical conditions and the documents attached to them are accepted at the Branches, Departments and Services for the operation of the gas facilities of SVGK LLC.

The reason for refusal to issue technical specifications is the lack of technical capability of connection (technological connection) of the capital construction object to the contractor’s gas distribution network, including in the absence of the capacity of gas distribution networks and the gas transmission system technologically connected with the contractor’s gas distribution network, except for cases when the elimination of these restrictions are taken into account in the contractor's investment programs or other investment programs in the current calendar year.

If there are no comments to the application and the package of documents, then the specialists of SVGK LLC develop and then issue the technical conditions to the Applicant.

Conclusions and useful video on the topic

How to choose and install a gas tank:

Laying a gas pipeline underground:

Laying a gas pipeline and adjacent gas systems to industrial facilities is a complex and multi-stage process. For its successful implementation, many nuances and features should be taken into account. It will also require serious cash investments for the purchase of equipment and payment for installation work.

However, the money spent will pay off in the near future. This is due to the low cost of natural gas, good price-to-quality ratio and high environmental friendliness. The company does not need to purchase expensive filtering equipment in order not to pollute the environment.

There are several possible problems that the company will have to face. It may be difficult to obtain agreements and licenses. It is also necessary to obtain the consent of the owners of the land on which the pipeline will be laid. All problems are easily solved by choosing the right approach.

Since working with gas is primarily a responsibility and qualification, it is important to choose a good contractor. It is recommended to cooperate with companies that have positive experience in laying gas communications

The company must know all the subtleties of the work and be aware of its responsibility.

In difficult situations, it is necessary to cooperate with state oversight bodies and comply with their requirements and recommendations. It is also possible to make adjustments during the laying and installation process.